- Gas boilers "Buderus"

- Troubleshooting Tips

- Overview of the Proterm brand series

- Brief information about the device of the heating system

- Why does the control board fail

- Causes of breakdowns

- poor water quality

- quality of power supply

- improper installation of equipment

- non-compliance with operating conditions

- Why does the coolant in the heat exchanger not heat up

- Error 6A

- Signs of a critical shortage of coolant

- Advantages and disadvantages

- What to do if the boiler smokes

- Mounting Features

- Tips and tricks for operation

Gas boilers "Buderus"

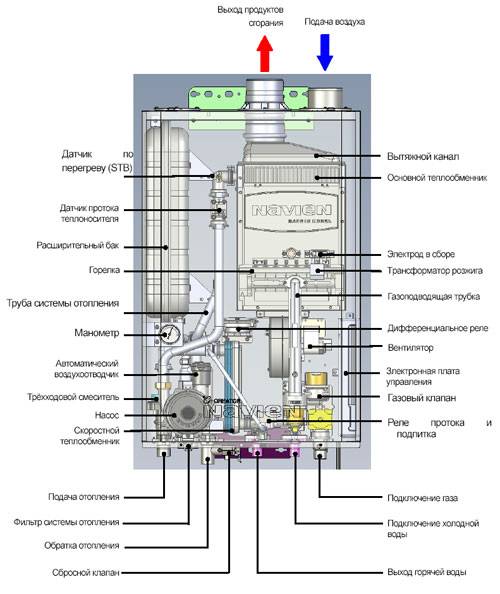

Natural gas remains the cheapest fuel, so the popularity of gas boilers is only growing. Single-circuit gas units are used in heating. Double-circuit floor or wall models easily cope with two functions necessary for comfortable living in a private house: heating and hot water heating.

The well-known company Bosch Thermotechnik GmbH is engaged in the production of gas household and industrial appliances of the Buderus brand. In addition to gas units, electric, solid fuel and diesel fuel boilers are manufactured.

Buderus gas models are the largest group of heating equipment.This is due to the popularity of equipment produced specifically for the climatic conditions of Russia.

Boilers are diverse in design and installation method, they are single- and double-circuit, with an open or closed combustion chamber.

Current gas-powered models can be divided into 4 groups:

- wall condensing;

- wall traditional;

- floor condensing;

- floor cast-iron atmospheric.

The choice of model according to the method of placement depends on the power of the unit. In the apartments of the old housing stock, up to five storeys, and in small country houses, wall-mounted units are used. Large private buildings, commercial enterprises, production shops are equipped by installing floor options.

Features in the design are not fundamental, but still there are, but the malfunctions are usually the same, as are the ways to eliminate them.

Everything is important for the good operation of a gas boiler: proper installation of the unit and chimney, regular maintenance, compliance with operating rules, timely cleaning and replacement of parts, high-quality fuel. If at least one item ceases to meet the requirements, breakdowns are possible.

The most frequent of them:

If at least one item ceases to meet the requirements, breakdowns are possible. The most frequent of them:

Image gallery

Photo from

Pollution of the heat exchanger with mineral inclusions

The burner does not ignite or goes out

Separation of contacts of wires of sensors

Breakdown of the electronic control board

Often, operational difficulties arise simply due to inattention, when the user forgets to turn on the gas valve or connect the electricity. Read more about breakdowns and how to fix them below.

Troubleshooting Tips

The following points can be applied as a troubleshooting guide for the Baksi gas boiler:

- The burner does not operate at full capacity. Such an error in the operation of gas equipment may appear in a situation where the pressure inside the system is not properly adjusted. A similar problem also appears if the gas modulator is damaged. Or the diode bridge may be faulty. You can deal with this problem by adjusting the system parameters according to the equipment operating instructions.

- The heater switches off immediately after switching on. This problem occurs in gas appliances due to low pressure in the gas pipeline. Possible solution: adjust the gas pressure down to 5 mbar.

- The coolant does not heat up when turned on. To correct it, it is worth rechecking the gas valve. It is possible that the minimum and maximum values have been reversed.

- The modulation mode is faulty. This problem can be solved by resetting the valve.

- Temperature sensors show incorrect data. In this case, you should also dismantle the sensor, replacing it with a new one.

- The hot water supplied to the taps is not heated enough. When restoring water heating, you need to make sure that the three-way valve is fully open. Sometimes this happens if this device is damaged. To be sure that the malfunction is caused by the valve, you need to wait a bit until the system cools down. After that, shut off valves should be closed. Then switch the appliance to hot water mode. If, as a result, the heating system heats up, then the problem was in the valve, and it needs to be replaced.

- A sharp jolt is heard when the burner is ignited.Uncharacteristic noises can occur due to various factors: one of them is too low pressure in the gas pipeline. Another, it happens, happens due to incorrect transportation of the boiler, when the igniter is displaced, and the distance from it to the gas supply becomes larger or smaller. The solution to this problem is to establish the correct distance. It should be approximately 4-5 mm.

- You can adjust the gap between the igniter and the burner on the Baksi gas boiler as follows: the front panel opens and is removed from the device. When this is done, the shutter is removed from the viewing hole. There is an igniter there. To give it the correct position, you need to unscrew the screw with which the electrode is attached to the boiler. The igniter must be removed, gently bent and then returned to where it was, and then close the damper.

- A strong decrease in the temperature of the coolant. Often this is due to dirty filters. The only way to eliminate them is to clean them. Sometimes in case of severe clogging, the filters should be replaced. It is also worth checking for damage to the pipeline. If, for example, the radiators are clogged or exposed to low temperatures, only repair will help. A damaged segment will need to be replaced or cleaned.

Overview of the Proterm brand series

If we consider equipment that runs on gas, then at the place of installation, all boilers can be divided into two large categories:

- wall-mounted - "condensation Lynx" ("Lynx Condence") and "Lynx" ("Lynx"), "Panther" ("Panther"), "Jaguar" ("Jaguar"), "Gepard" ("Gepard");

- floor - "Bear" (series KLOM, KLZ17, PLO, TLO), "Bison NL", "Grizzly KLO", "Wolf (Volk)".

Despite the Turkish and Belarusian assembly, the quality of equipment is high in European style.

Among wall models - 1- and 2-circuit, atmospheric and turbocharged, with a capacity of 11-35 kW.

Floor models are made of steel or cast iron, equipped with injection or fan burners, can operate on natural and liquefied gas. The power range is wide - 12-150 kW - so it is not difficult to choose a device for specific conditions.

The main purpose of the equipment is the organization of hot water supply and heating in private residential buildings, and some units are designed for industrial use.

Each of the series has distinctive features regarding design, dimensions, installation method, technical characteristics, additional functions:

- "Lynx" - condensing models work 12-14% more economically than non-condensing ones, therefore they are recognized as energy-efficient devices for heating country houses and cottages.

- "Panther" - the latest models are available with a convenient eBus communication bus and an updated security system

- "Jaguar" - the main advantages are the low price of the unit and the possibility of separate adjustment of two circuits - heating and hot water.

- "Cheetah" is a popular wall model that can be installed both outside the city, in a country house or cottage, and in a city apartment.

- "Bear" - among the representatives of various series - reliable units with a built-in boiler, a cast-iron heat exchanger and a power of up to 49 kW.

- "Bizon NL" - universal models for the fuel used: they work equally efficiently on gas, fuel oil or diesel fuel, power - up to 71 kW.

- "Grizzly KLO" - able to heat private homes and office space up to 1500 m², maximum power - 150 kW.

- "Volk" - an electrically independent boiler with a steel heat exchanger, steadily supplies heat to country houses and residential buildings even in the absence of electricity.

According to consumer reviews, Proterm units are reliable, efficient, easy to install and operate, and with regular maintenance they almost never fail.

However, durable materials, good fuel and excellent assembly do not guarantee flawless service, so boilers of all the listed series sooner or later require replacement of spare parts, cleaning or repair.

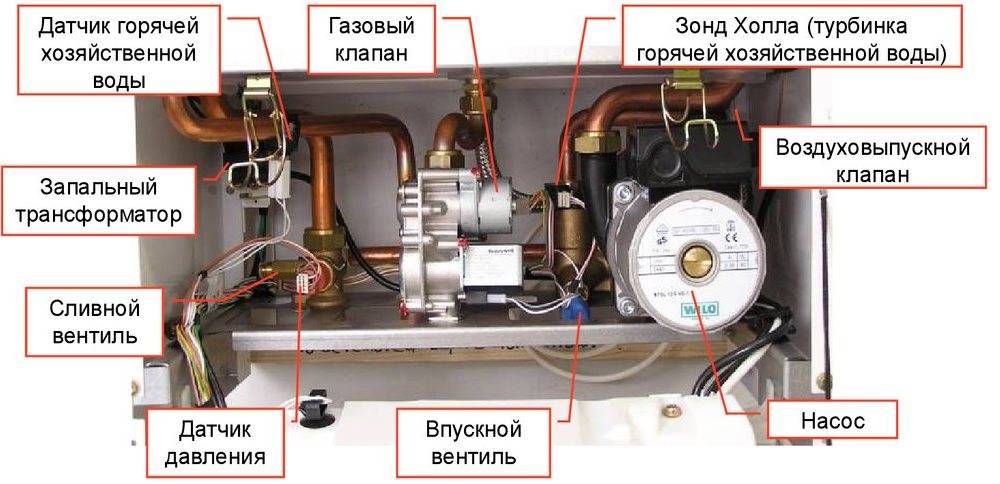

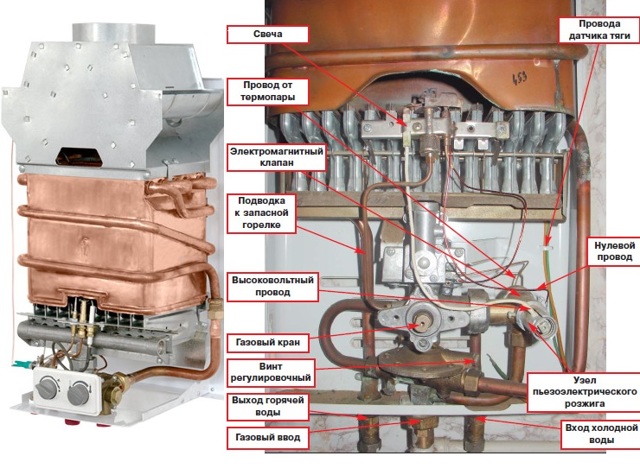

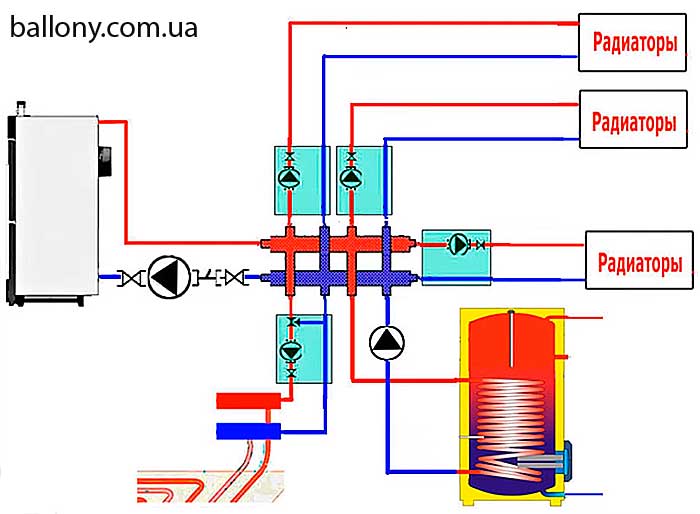

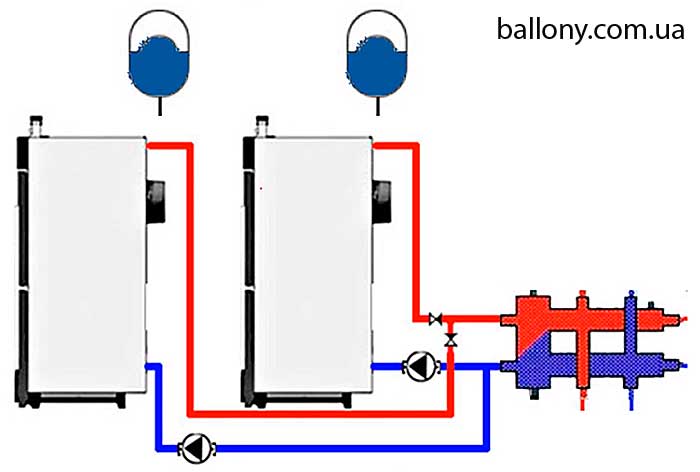

Brief information about the device of the heating system

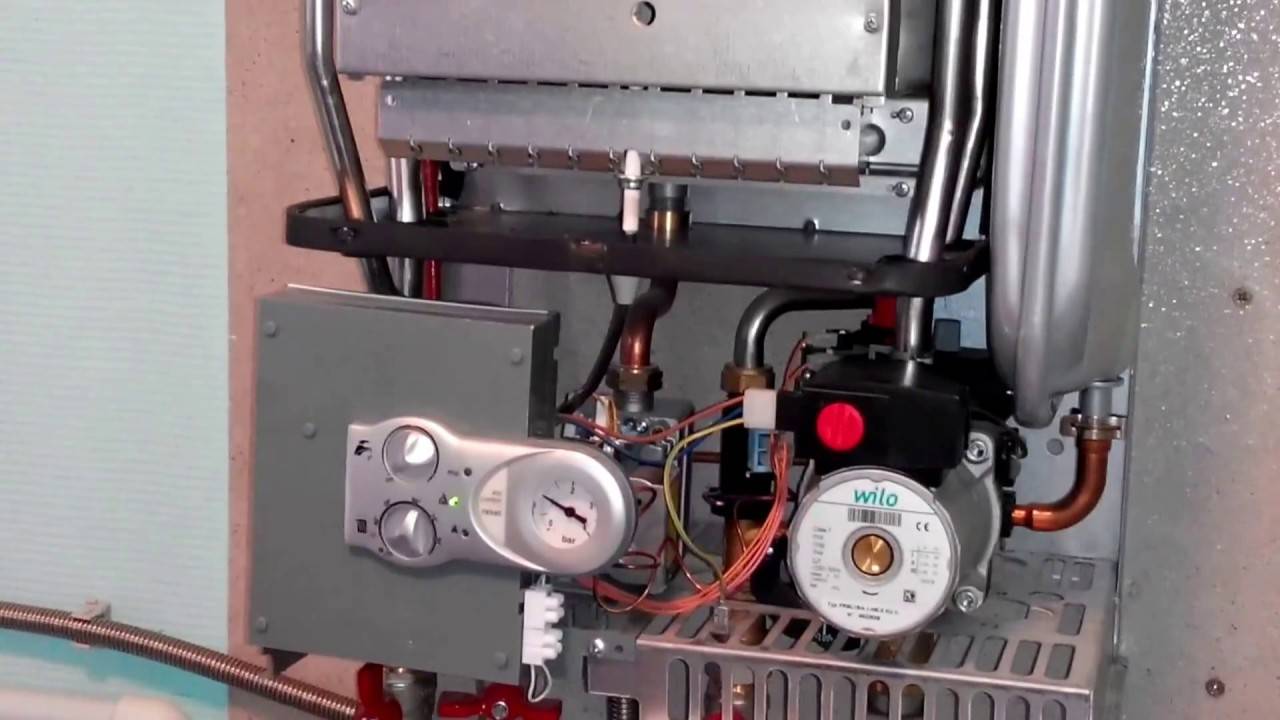

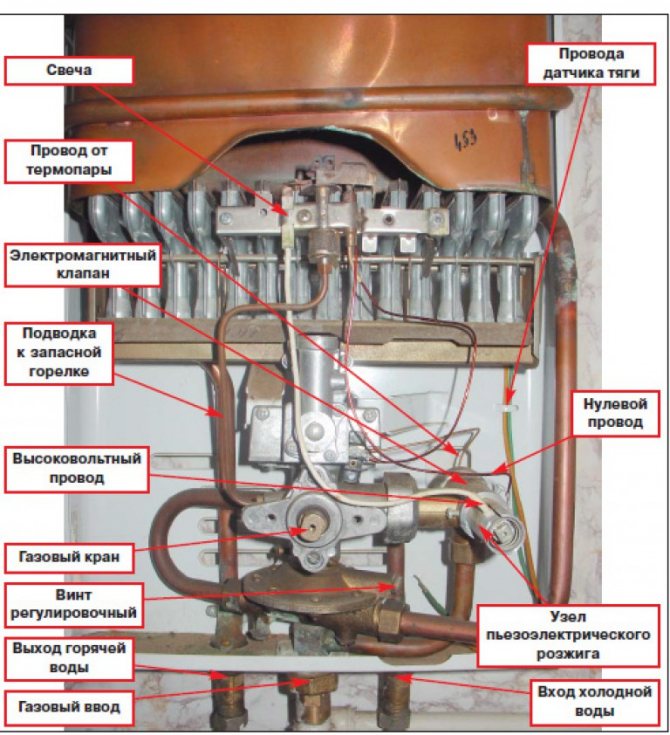

Modern gas heating installations are complex systems. Control of their work is carried out using a whole range of automatic devices, which you need to familiarize yourself with before starting an independent repair of gas boilers.

Basic elements of a security group:

- Traction sensors rated for 750C. This device makes it possible to monitor the condition of the chimney. If normal smoke extraction fails, the temperature rises and the sensor is triggered. Optimally, in addition to the thrust sensor, a gas alarm is purchased.

- The monostat provides protection for turbocharged gas units from impaired removal of combustion products due to a clogged chimney or heat exchanger.

- The limit thermostat is designed to control the temperature of the coolant in the heating installation. When the water boils, the overheating sensor turns off the device.

- The flame control electrode, when its absence is detected, turns off the operation of the heating unit.

- The blast valve serves to control the pressure.When the pressure rises above the critical value, portionwise discharge of excess coolant occurs.

This is interesting: How to connect the boiler correctly - we understand all the details

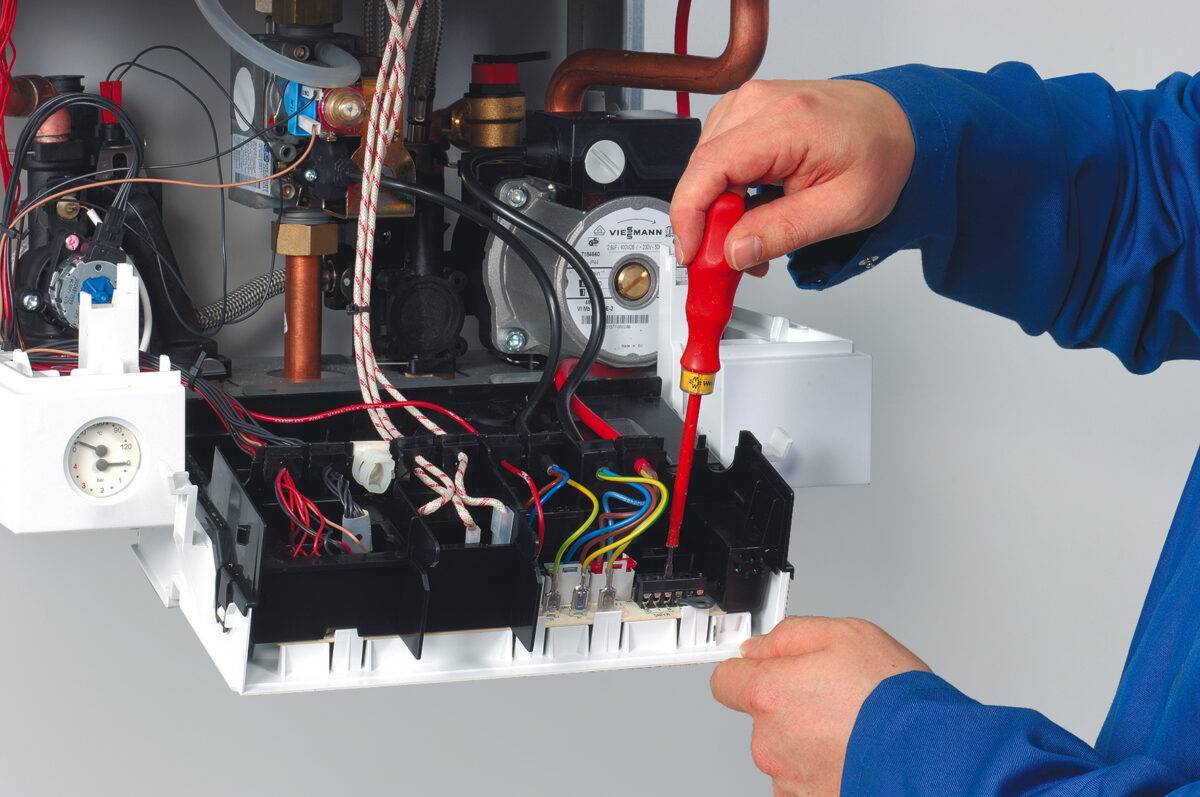

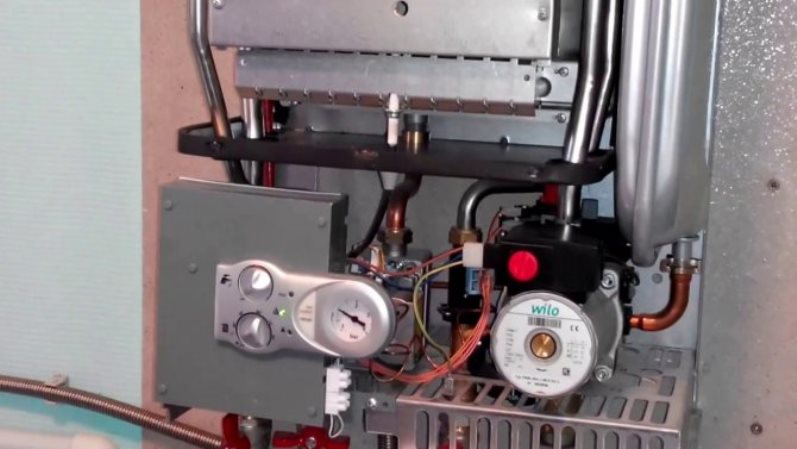

Why does the control board fail

The board works in very extreme conditions, it is forced to constantly monitor the operation of all sensors and actuators of the boiler. This ensures that the unit will operate within the allowable values for capacity, temperature and pressure of the medium.

As soon as it notices any deviations, such as fluctuations in air pressure due to a blocked chimney or a faulty fan, when adjustment is not possible, it blocks the gas supply to the burner and displays a fault code.

The error code helps the boiler repair service company to quickly fix the problem. This makes repairs faster than troubleshooting from scratch and helps reduce boiler repair costs.

Causes of failure of the boiler board:

- A leaking boiler, pump or cracked heat exchanger increases the humidity inside the structure and the condensation process on the board elements.

- Cracks and fractures on the printed circuit board.

- Weak or damaged solder joints.

- Degradation of the constituent elements of the circuit: a dried capacitor with an increased ESR in a switching power supply.

- Errors with EEPROM memory.

- Power surges in the mains, in the case when a voltage stabilizer or an uninterruptible voltage source is not turned on in front of the unit. In this case, any technical failure at the substation from poor-quality grounding, burning "0" or a lightning discharge can disable the board.

- A production defect, after which it will be impossible to adjust the operation of the boiler.

- Unprofessional repair.

- Boiler vibration, board components are extremely fragile. Excessive vibration can cause the unit's chip and PCB connections to break and damage the wiring. Before repairing it, you need to eliminate the vibration. The most obvious components to check are both the pump and the fan.

- Technical wear, after 14 years of operation.

Causes of breakdowns

Gas heaters are considered very reliable devices and rarely fail.

Service center specialists have formulated several main reasons why equipment may fail:

poor water quality

This reason is relevant for double-circuit boilers that supply hot water to the local water supply system. Mineral deposits and rust gradually accumulate in the tubes of the secondary circuit heat exchanger, reducing their cross section and causing corrosion, up to complete blocking. When the water circulation is reduced, the heat exchanger connections are subject to overheating and may break. To prevent such a situation, it is necessary to install a mechanical filter at the inlet of the circuit and periodically change the filter element in it.

Poor water quality - a possible cause of a gas boiler breakdown

Poor water quality - a possible cause of a gas boiler breakdown

quality of power supply

Voltage fluctuations, phase surges, periodic power outages and other manifestations of poor quality of power supply lead to the operation of the heater's electrical equipment with overloads, while its components are subject to accelerated wear. Particularly strong power surges can lead to their complete failure.To combat the low quality of power supply, the following methods are used:

- installing a stabilizer will eliminate voltage surges;

- connecting an uninterruptible power supply unit on a battery will allow you to survive short-term power outages;

- an electric generator with an internal combustion engine will provide power in case of long interruptions.

You should evaluate the quality of the network in advance, purchase and connect the necessary devices in advance

improper installation of equipment

If the unit was mounted by an amateur master, then not all installation instructions requirements:

- lack of grounding (or incorrect grounding) of the apparatus leads to the accumulation of static charges on the body and chassis and can damage the electronic control system;

- air plugs remain in the heating system, this leads to overheating and damage to heat exchangers and pipelines, the circulation pump may also fail;

- improper connection of the inlet and outlet pipes, neglect of emergency valves or blocking them with valves can lead to overheating of the coolant and failure of the pipeline system

There are also errors in installation of a coaxial chimney, as a result, it begins to freeze and the draft sensor turns off the boiler.

non-compliance with operating conditions

often occurs among those owners who incorrectly calculated the power of the boiler and did not provide for a 20% margin for extreme weather conditions. In such houses, during severe frosts or wind, the device operates at maximum power for a long time. Automation will periodically turn off the gas.In addition, such operation leads to its accelerated wear and failure in the midst of cold weather.

Why does the coolant in the heat exchanger not heat up

If the coolant is not heated either for heating or for supplying hot water, the reasons are as follows:

- The settings are set incorrectly. They need to be adjusted.

- The pump is blocked. You should try to reconfigure its indicators and put it into operation.

- A lot of scale has accumulated in the heat exchanger. It is recommended to descale the element using special tools or home methods.

- Thermal breaks. You need to change them for new ones.

In the event that the water is not heated only for hot water supply, the problem lies in the three-way valve, which just switches between heating and hot water.

Also, the causes of this breakdown are clogging in the coolant, leaks in the heat exchanger or connections.

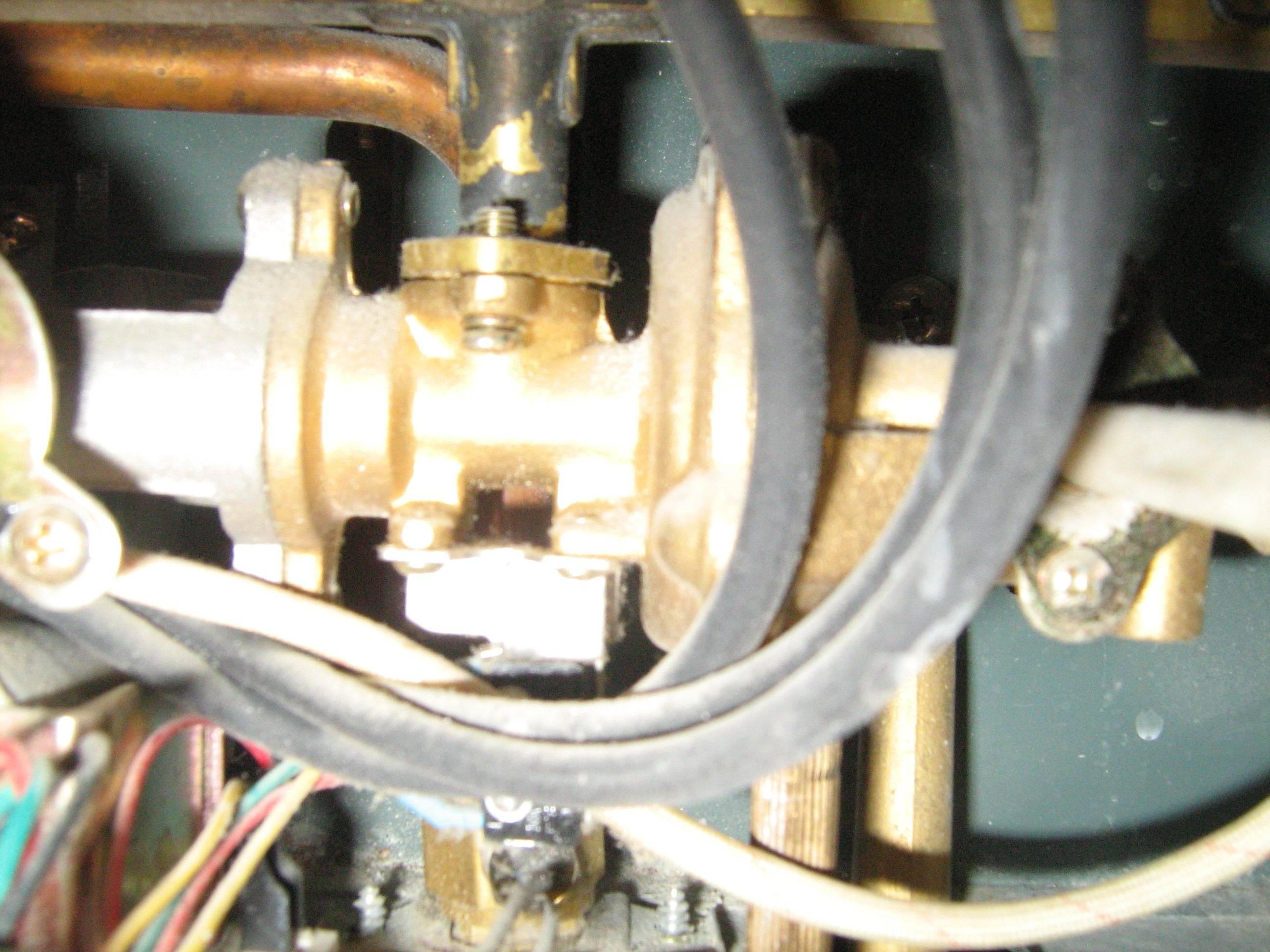

Error 6A

Error 6A, displayed on the display of wall-mounted gas boilers Buderus Logamax U 072 on absolutely all models with a capacity of 12, 18, 24, 28 and 35 kW, indicates the absence of a flame on the burner. To control the flame in the combustion chamber, an ionization electrode is installed on the burner, through which a small current flows during gas combustion, that is, a certain amount of free electrons and negative ions, which are transmitted to the control board by wire. If for some reason the ionization intensity drops below a certain level, the control board, after three attempts to ignite the burner, displays an error code on the display and the boiler goes into an accident!

This malfunction is extensive in nature and a large number of elements will have to be checked.

You need to start with the most elementary, this is to make sure that the gas valve is open, suddenly someone blocked it, so there is no gas!

Secondly, you need to make sure that there is sufficient inlet gas pressure. To do this, connect a pressure gauge to the gas valve fitting and check that the pressure is between 17 and 25 mbar.

Third, while the pressure gauge is connected to the gas valve, check that the adjustment is correct. operating gas pressure in minimum and maximum mode. But this is only in the case when the boiler, after resetting the error, can work for a short time. If the boiler does not start, then you cannot do this.

Fourthly, you need to check the gas fitting itself for the presence of power and serviceability of the coil and solenoid valve.

If anything is defective, the gas valve must be replaced.

Then we proceed to inspect the electrode and wires. Here you need to check the wire for a break and its reliable connection with the electrode and the control board. There should be no cracks or chips on the ceramic part of the electrode, and the metal rod itself should be clean and located at a distance of about 8 mm from the burner.

Then, fifthly, be sure to check the flue gas system for correct assembly and, no matter how trite it may sound, for the absence of foreign objects and debris in it. And if the malfunction appeared in winter, then there is a possibility of ice formation on the chimney head.

Sixth, the heat exchanger and burner in the combustion chamber must be clean and free of dust and soot.Otherwise, the lack of proper combustion due to lack of oxygen and soot can lead to incorrect readings of the ignition electrode, and to be honest, you don’t want to suffocate from carbon monoxide at all! I recommend servicing at least once a year!

And the last, seventh, is a board malfunction, which can be checked with a multimeter by measuring the voltage on the coil and electromagnet. If there is no voltage, then you need to change the board to a new one!

This error 6A is critical and after the malfunction is eliminated, the boiler will not start by itself, so you need to manually press the RESET button and reset the error.

Using the troubleshooting sequence, you can eliminate any non-working component and start the boiler so as not to freeze in winter. If I helped you solve the problem, then I did everything right! Support me with your thumbs up and subscribe to the channel! Until we meet again, see you!

Signs of a critical shortage of coolant

Not all owners of private houses monitor the technical condition of water heating, it works - and all right. When a latent leak forms, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is tracked by the following signs:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipe overheats, turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way, in addition, the gurgling of water in the riser is heard.

- On the gas heater (open circuit), there are frequent starts / burner starts - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall models of gas boilers automatically stop when they fall below the threshold of 0.8 bar.

- Floor-standing non-volatile units and solid fuel boilers continue to properly heat the remaining water in a closed system until the volume released by the coolant is filled with air. The circulation will stop, overheating will occur, the safety valve will work.

We won’t explain why we need to recharge the system - this is an obvious measure to keep the heating working. It remains to choose a method of replenishing the heating system.

Advantages and disadvantages

The advantages of the Beretta CIAO 24 CSI model include:

- Efficiency, reliability, stability in work.

- Resistance to external influences, maintaining the specified mode of operation.

- The ability to provide the house with thermal energy in conjunction with the supply of hot water.

- Automatic mode of operation that does not require constant human attention.

- The presence of a self-diagnosis system that notifies the owner of the appearance of problems.

- Compact, attractive appearance.

The disadvantages of the unit are considered to be:

- Excessive sensitivity of electronics, the need to connect external protection devices (stabilizer).

- Requirements for water quality. The bithermic heat exchanger is extremely difficult to wash, and replacement is expensive, so softening water filters must be installed.

- The need for service, the quality of which is not always at the proper level.

IMPORTANT!

The disadvantages of the Beretta CIAO 24 CSI boiler can be attributed to design features, since they are common to all such units. This does not reduce their negative effect, but allows you to more correctly treat their presence.

What to do if the boiler smokes

In many models, a problem may arise that when the ignition unit is turned on, soot comes out of it. The reason for this problem is the low concentration of air in the fuel, so the gas does not burn immediately. Eliminate this by adjusting the air on the burner:

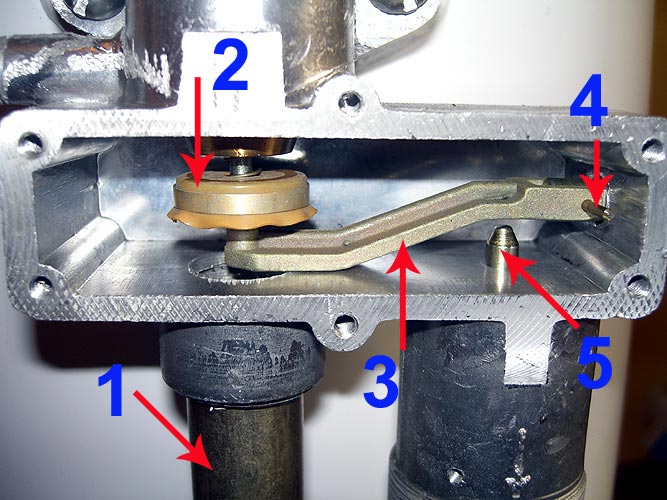

- find the adjusting washer and equalize the air supply with the burner lit;

- you should focus on the operation of the burner: if there is a lot of air, noise will be heard and the fire will vibrate; if it is small, then a red flame with yellow dots will appear; with good air concentration, the fire burns evenly and has a grayish color.

Clogging of the gas burner with dust also leads to the appearance of soot. In this case, the element should be cleaned of all kinds of contaminants.

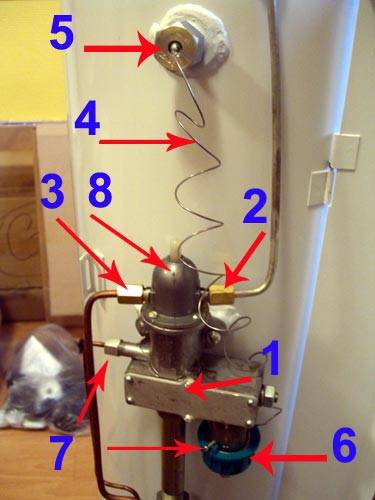

Mounting Features

The direction of the water must match the direction of the arrow on the body of the device

The valve is placed on the pipe so that the direction of the liquid coincides with the course of the arrow. The filter plug points down and the adjustment screw must be accessible for use. The manometer dial rotates to make it easy to read the values.

The winding material is used rationally so that the excess does not fall into the clearance of the gearbox. Boiler make-up in the form of a valve should not depend on main loads (compression, torsion, bending, vibration).For this, additional supports or compensators are placed.

The mismatch between the axes of the pipelines should not be more than 3 mm with a length of 1 m. With a longer length, 1 mm is added for each linear meter. The make-up circuit is connected to the pipeline near the expansion tank.

Tips and tricks for operation

In the instructions gas boiler Beretta from the manufacturer there are recommendations for users that will make the service of the purchased device long:

- Do not open the gas valve yourself. Call a specialist to avoid accidents. You can check the filter at the inlet of the gas pipeline if there are malfunctions in its operation. However, this requires basic knowledge of the operation of gas boilers.

- If during the operation of the boiler the phase was reset due to incorrect connection of the plug to the socket, you should first try to put it in the correct position. If it doesn’t work and the coolant gives an error, you need to contact the master.

- When using the boiler for the first time, it is necessary to scroll the rotor on the circulation pump by unscrewing the washer, the backing of a piece of cloth and scrolling the rotor to the left.

- It is necessary to check how the pressure and temperature sensors work in the off state of the device.

- To check the connected contacts, you need to disconnect the wire from the sensor, and then insert it back.

- Adjust the power in strict accordance with the instructions.

Additional Information! It is recommended to periodically clean the outer surface of the boiler, install the coolant 5 centimeters from the walls for ventilation and install a temperature thermostat to ensure the rational use of energy resources.

In general, the instruction of the Beretta gas boiler involves step-by-step installation with special equipment by professional gas workers, as well as careful use of the device, followed by annual maintenance.

Watch this video on YouTube

Watch this video on YouTube