- Types of refrigerator malfunctions

- Lack of lighting

- Malfunction of the cold generator

- water dripping from the bottom drawer of the refrigerator

- Noise in the refrigerator

- Ice layer in the freezer

- How to call a specialist?

- The following signs indicate that the unit is out of order:

- From simple malfunctions to serious problems

- More complex repairs

- Refrigerant change

- Burnt or faulty control board

- Evaporator defect

- Temperature sensor glitches

- Thermal fuse blown

- Malfunctions of NoFrost systems

- Ice maker not working

- Whole replacement

- Start Relay Problems

- Breakdown of the thermal protection relay

- Motor replacement steps

- Tips & Tricks

- What to do, where to run

- The main symptoms of a malfunction of Liebherr refrigeration equipment

- Refrigerator failure

- Refrigerator failure

- Freezer malfunction

- Wine cabinet malfunction

- Service cost

- There are signs of a malfunctioning refrigerator. What to do?

- Easy Repair

- Changing light bulbs

- Cleaning the drainage system

- Replacing the rubber seal

- Eliminate compressor noise

- Hanging and leveling doors

- Checking the correct installation

- If there is a lot of ice in the freezer

- Common malfunctions of Ariston units

- Turning off the refrigerator

- Excessive ice formation

- Small cooling

- The specifics of Liebherr refrigerators

Types of refrigerator malfunctions

In this section, we will look at the main problems that occur in all refrigerators, regardless of brand and model.

Lack of lighting

A fairly common failure. What can you do yourself to find out the reason? Check the light bulb, if it's all about it, then just replace it with a new one. If the bulb is intact, then you need to check the voltage in the network.

A common reason is the lack of voltage between the refrigerator plug and the outlet; it is enough to check the contact of the mechanism. If it's the reason, then after fixing the problem, the light in the refrigerator turns on.

The second reason may be a malfunction of the power button. You can fix it, but it's better to call an electronics specialist and replace it with a new one - it will not cost much.

Malfunction of the cold generator

This is the most important part of the refrigerator device. If you do not have the necessary knowledge about the operation and design of the mechanism. Then unplug the refrigerator and call the wizard. What can happen when the cold generator fails:

- Noise at work. Tapping, rattling, humming can be heard;

- Spontaneous shutdown of the refrigerator, less than a minute after starting;

- Too low temperature or insufficient cooling in the refrigerator compartment;

- Rapid formation of frost in the freezer;

- Water leakage and lack of cooling when the compressor is running.

Any of the above reasons requires a call to a repairman. Do not try to fix the problem yourself.

water dripping from the bottom drawer of the refrigerator

The reason is simple - this problem is caused by a clogged drain tube.You can fix this problem yourself. What do we have to do:

- Turn off the refrigerator and remove all food from it.

- Under the pipe in the place of blockage, place a container for draining debris and water and clean the pipe using hot water and a brush.

- It is necessary to repeat the procedure two or three times, so that clean water flows out of the tube when you spill it.

The use of cleaners and detergents is not allowed.

Noise in the refrigerator

The unit is turned on, unusually loud noise, something rattles and taps. The reasons for the malfunction of refrigerators of any brand, in this case, may be:

- Incorrect installation of the refrigerator;

- Damaged compressor suspension.

In the first case, eliminating the cause of noise is not difficult. It must be checked that the device does not come into contact with pipes and pieces of furniture. Be sure to make sure that the case is set correctly, for the refrigerator to work properly, it must be slightly tilted back. To do this, you need to adjust the slope by twisting the legs located under the doors. You can check this by opening the doors, they should close themselves. It may be necessary to place foam rubber between the casing and the frame.

The suspension should be inspected by the master and determine the cause of the noise. If replacement or repair of the motor-compressor is required, only a specialist can do this.

Ice layer in the freezer

The freezing of an ice “coat” on the walls of the freezer occurs for two reasons:

- The door is not hermetically sealed;

- Temperature controller malfunction.

We immediately check the door, set the angle of inclination of the case back and inspect the seal, perhaps the reason is in it. It cannot be repaired, you will need to call the master for replacement.This minor malfunction of the refrigerator is fixed at home.

The regulator is a serious and complex device that, if it fails, is rarely repairable, therefore, replacement will be required.

In addition to the problems described above, the following problems may occur:

The compressor does not work and there is no cold, while the lighting works. In this case, a number of malfunctions can be observed: breakdown of the thermostat, motor, compressor, starting relay, electrical circuit. Only a specialist can determine the cause; this will require a diagnosis of the entire refrigerator, using special equipment.

After turning on, the refrigerator starts up, but after a while it turns off. The most common is a breakdown of the trigger mechanism. It is required to carry out a complete diagnosis of the equipment, which will help to establish the cause.

How to call a specialist?

You can leave a request by dialing our phone number +7 (495) 222-13-94. We have also provided an opportunity for you. The master will call back as soon as possible!

When submitting an application, please provide information about:

- Models of your refrigerator. Its marking (Liebherr TX 1021 Comfort, Liebherr ECN 6156) is located on the inner wall of the product or outside. The model name can also be found in the instruction manual or warranty card;

- Signs of a malfunction. Describe exactly what happened. For example, a loose fit of the door, the presence of leakage, excessive ice formation;

- Time and date convenient for the visit of the master;

- Your contact details (name, home address and telephone number).

After receiving the application, we will call you within a few minutes to clarify the information.Our employee will arrive at the exact time specified by you with the equipment necessary for carrying out diagnostic measures. As soon as they find the cause of the failure, you will be provided with information on the price and timing of the repair. Upon completion of the repair work, warranty obligations are issued.

Our service center is ready to repair Liebherr equipment of any complexity. Masters have the necessary qualifications and solid work experience. They do an excellent job with all the tasks assigned to them, because, despite the recognized quality of German products, they are not insured against breakage.

Where to order urgent refrigerator repair?

Often, if refrigeration equipment fails, it is recommended to call specialists immediately. This rule applies to both household units and those installed at industrial and commercial facilities.

The following signs indicate that the unit is out of order:

- F2 or F4 error. This combination of numbers lights up on the control panel display;

- Cracks coming from the refrigerator compartment. accompanied by an increase in temperature. Most often, this “symptom” is observed in models equipped with the BIO fresh function;

- The temperature in the "freezer" is too low, which does not correspond to the parameters set by the user. Often occurs in CBP modification;

- Warm air in the freezer. A beep is heard and the Alarm icon lights up. Breakage occurs mainly in variants with No Frost (for example, CNPes 4858);

- The growth of ice, which is located on the back wall, while maintaining the set temperature, which leads to freezing of products. Actual for models CN and CP (CN 3915, CN 4005).

From simple malfunctions to serious problems

All the problems that happen with any refrigerator can be "sorted" into two groups:

- obvious - a breakdown can be easily noticed and diagnosed by yourself, or an inscription on the electronic display of the device will report this;

- hidden (implicit) - that there is a malfunction, some details “say” that are not typical for the normal operation of the device. If you do not pay attention to such “symptoms” in time, the breakdown may require serious repairs.

Let's deal with the obvious problems first.

- Hardware broke.

According to ALM-repair employees, this is the most common breakdown among Liebherr refrigerators. 3-4 years after the purchase of the refrigerator, the handle may break off. But this does not mean that such a nuisance will definitely happen: you need to consider how often and with what force you pull the appliance door. Shelves also break, door fasteners loosen, but this happens after 5–6 years of active use of the refrigerator.

Such "troubles" are eliminated by a specialist at home and quite quickly. It is not worth delaying the repair of a skewed or loose-fitting door: the tightness of the refrigerator is broken, the compressor works more intensively and fails faster. Agree, it is cheaper to fix the door than to buy and install a new motor.

The inscription "Error" on the electronic scoreboard

Intelligent technology can itself diagnose problems and display an error message on the display, which is accompanied by the glow of the Alarm button. Deciphering these inscriptions:

- error "F0" - the biosensor of fresh air, which is responsible for the temperature in the "freshness zone" ("zero chamber"), has failed;

- error "F1" - the air sensor in the device chamber has failed;

- error "F2" - problems with the refrigerator evaporator sensor. The refrigerating chamber may not be sufficiently cooled or, conversely, it may be frozen;

- error "F3" - problems with the air sensor in the freezer;

- error "F4" - the evaporator sensor in the freezer compartment is broken;

- error "F5" - the matter is in the control module. You may need to flash or replace the microprocessor board.

Refrigerator repair in these cases mainly consists in replacing the corresponding sensors.

The backlight in the main chamber or freezer has stopped working

Most often, the cause is a burnt out light bulb - you can buy it and change it yourself. Worse, when the electronics are “naughty” or the breaker is broken. In this case, qualified intervention is needed.

Among the most characteristic "implicit" signs of a refrigerator malfunction, we highlight the following:

Among the most characteristic "implicit" signs of a refrigerator malfunction, we highlight the following:

- Ice builds up inside the refrigerator compartment

An ice coat on the back wall of the refrigerator appears due to the fact that in a hurry they put a still warm pan in the refrigerator, or the door was not tightly closed. Too dense loading of the chamber also leads to the fact that the compressor works with all its might and, as a result, ice deposits.

The reason may also be a breakdown of the temperature sensor or depressurization of the refrigerator.

Water at the bottom of the main compartment

Have you noticed that liquid began to stagnate under the boxes for vegetables or meat? The reason is the blockage of the drainage system.If a special hole at the bottom of the refrigerating chamber is constantly filled with jars and products, then in a couple of years it becomes clogged with dirt, and water can no longer drain into the drainage. If you start the problem, the liquid will flood the freezer, it will flow out and drip onto the floor.

The drainage system needs to be cleaned. Moreover, it is better to do this periodically, without waiting for the “lake” in the refrigerator.

The motor-compressor runs without stopping

Dryer filter clogged. Another option is a refrigerant leak through cracks in the mechanism. In parallel with this problem, you can notice that the device has become worse to freeze.

By the way, do not be afraid of sudden clicks, murmurs or periodic buzz inside the refrigerator. Such sounds indicate the normal "peristalsis" of the refrigeration unit.

More complex repairs

When there is a serious breakdown of the refrigerator, you should immediately contact the master. A timely response will extend the operating life and help to avoid costly repairs, such as a compressor or refrigerant circulation system.

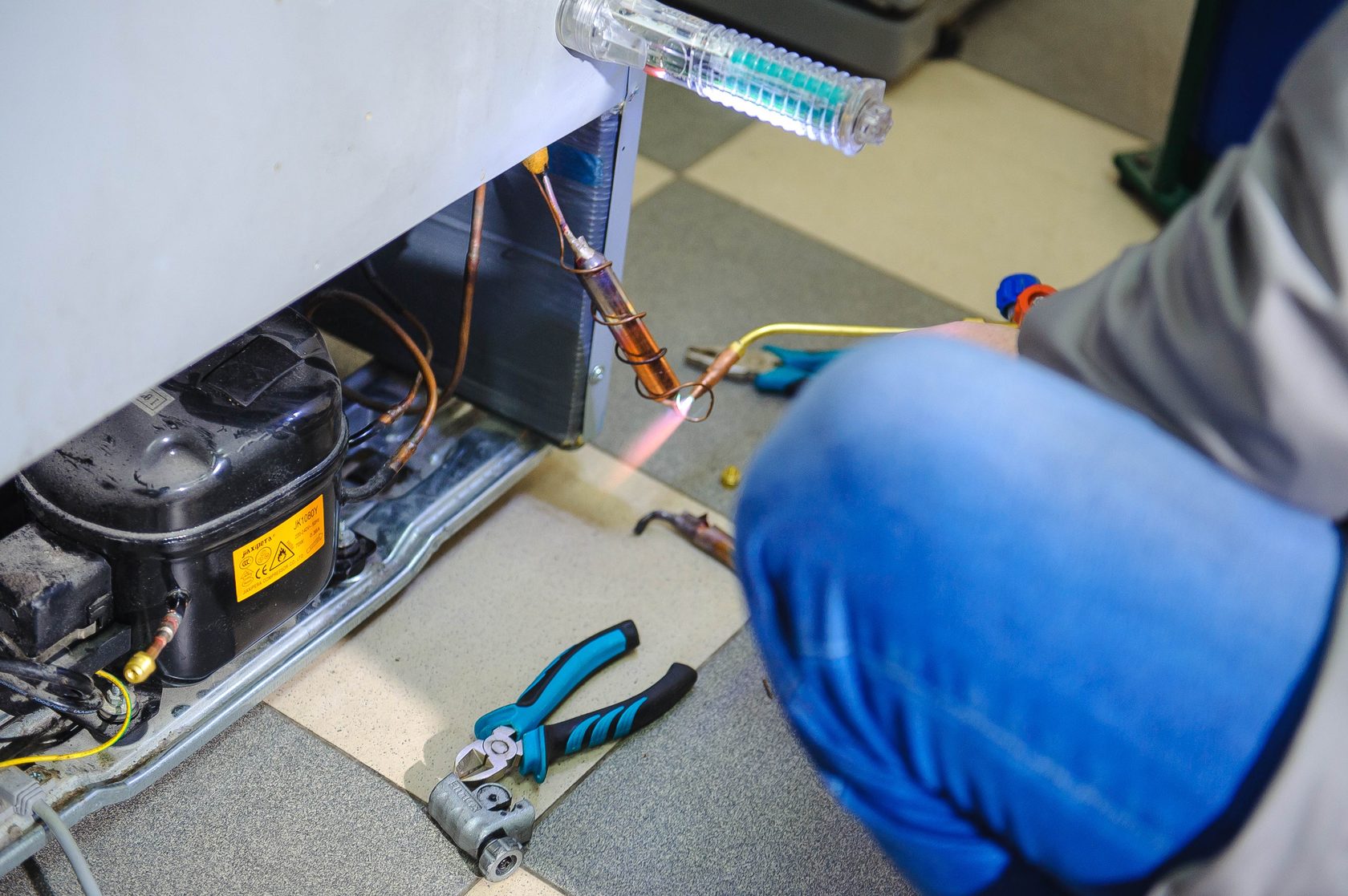

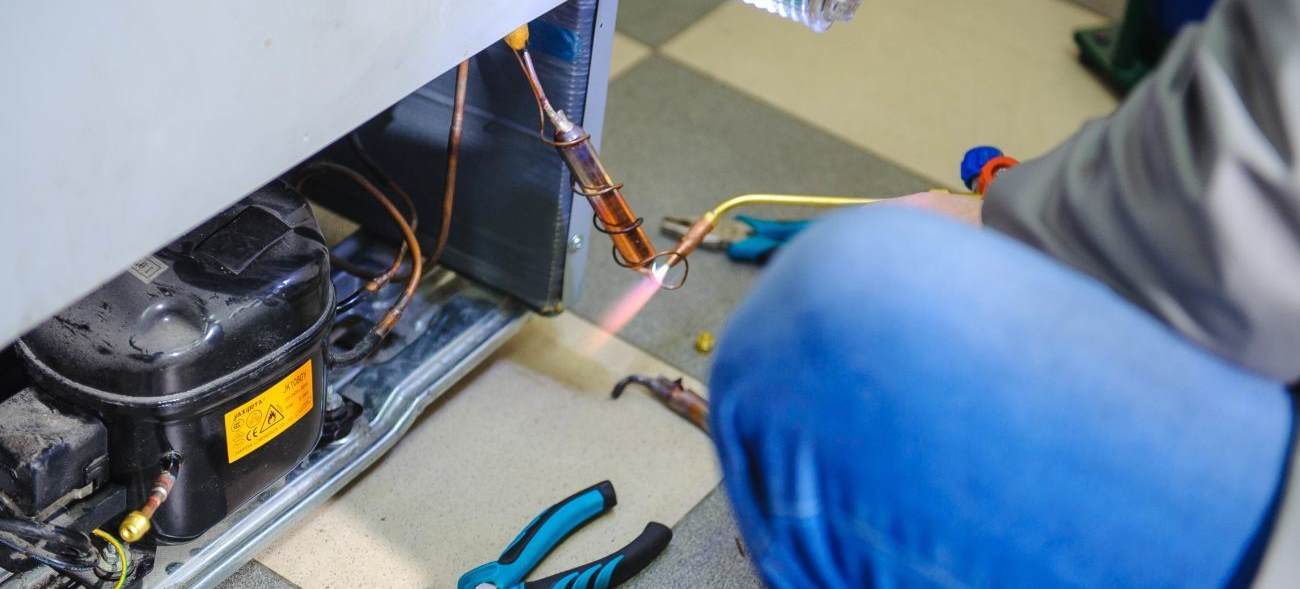

Refrigerant change

Freon leak is one of the most common breakdowns.

To fix the problem, the wizard needs to:

- using special equipment to find the place of the leak;

- repair the damage and check the tightness;

- refill the tank with freon.

You can learn more about this type of repair from this article.

Burnt or faulty control board

Modern refrigerators are equipped with a control board. She is responsible for the operation of the display, maintaining the optimal temperature, turning on the light when the chamber is opened, starting the compressor and fan.Recovery usually consists in flashing the module, because due to surges in electricity, non-volatile memory is buggy and sometimes overwrites data. If the board is burned out, a new part is installed, repair is not economically feasible.

Evaporator defect

An evaporator defect is manifested by an increase in temperature inside the refrigerator compartment, the appearance of an unpleasant odor and an ice coat. Masters search for freon leaks, restore the tightness of the tubes and refuel with refrigerant. If the evaporator is worn out, it must be replaced.

Temperature sensor glitches

There are several ways to eliminate the incorrect operation of temperature sensors.

- Repair an open in the control circuit contacts.

- Eliminate the effects of oxidation (we clean the rust).

- Restore the normal position of the sensors.

- Replacement assembly as the module is not repairable.

Thermal fuse blown

A blown thermal fuse may occur because the evaporator defrost heater has overheated. And to protect household appliances from fire, the fuse broke the circuit.

Ideally, check the resistance of the part with a multimeter, or at least ring. If an open circuit is detected, the heating element is replaced with a new assembly. You can try to “farm” by closing the circuit with a wire of a suitable section, but there is no answer for how long such a design will live and whether it is safe.

Malfunctions of NoFrost systems

The performance of the fan is checked manually - carefully turn the blades, if the impeller spins freely, check the electronic part. Ring the engine starter, if there is a break in the winding, change it entirely. The fuser may fail - this part is removed and checked with a tester.If the resistance approaches zero, then the part is considered serviceable. In the case when both technical units are working normally, it is necessary to replace the electric timer, it cannot be repaired.

Ice maker not working

It is impossible to determine the cause of the failure of the ice generator without diagnosing.

The most common factors:

- low water pressure;

- intake valve broken

- the generator block is faulty;

- the door switch does not work correctly;

- you need to change the filter.

Compressor resuscitation is one of the most expensive works.

Whole replacement

In most cases, the compressor cannot be repaired, so it must be replaced. To do this, order a suitable model and install it yourself or call the wizard.

Start Relay Problems

Contacts can jam in a start-up relay, the winding of electromagnets can burn out, and the spring plate loses its elasticity over time. Usually clicks are heard, but nothing happens. If the part is not completely out of order, the coil is repaired, the contacts are connected or cleaned. The easiest way is to throw out the old one and buy a new one for 500-1000 rubles, and not spend a lot of time looking for “phantom pains”.

Breakdown of the thermal protection relay

If the thermal protection relay fails, the cycle of switching on and off the equipment is disrupted, the electric motor overheats. Repair is allowed if the stem is jammed. In the event that there is damage to the winding, the part must be replaced.

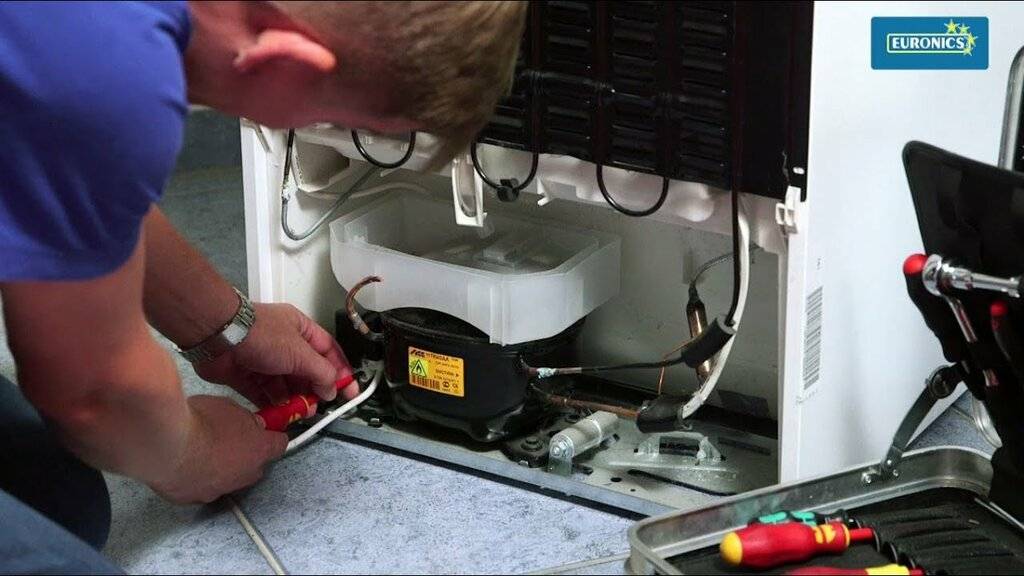

Motor replacement steps

If during operation extraneous sounds are heard coming from the compressor (rattling, knocking, clicks, vibrations), then the master will first check the correct installation of the motor casing suspension.In most cases, the cause of extraneous noise lies in its incorrect adjustment. Our mechanic will adjust the suspension bolts and tighten them thoroughly, and also check the stability of the relay location.

The compressor replacement process consists of:

- Dismantling the old electric motor. To do this, the specialist makes a small incision on the capillary expander with a burner, after which he breaks the tube and unsolders the filter-drier. Then the pipes are soldered from the motor, and the block itself is carefully removed;

- Installing a spare motor. After fixing the motor in the housing, procedures are carried out for docking the existing tubes (for filling, suction and suction) with the necessary nozzles by soldering;

- Replacement filter drier. To eliminate the possibility of dust and other small particles entering the capillary pipeline, a special filter is used. It is carefully cut out and then installed every time the cooling system is opened;

- Vacuum process. The master checks the tightness of the cooling system, creates a vacuum in it, after which the refrigerant of the brand recommended by the manufacturer is introduced into the system.

Trust refrigerator compressor replacement Liebherr specialists of the Holod Group service center - and be sure of the impeccable quality of the work performed!

Tips & Tricks

In order for household appliances to work without failures, it is worth following the recommendations:

- Drip refrigerators need to be defrosted regularly.

- The appliance must be placed on a level and solid surface.

- The upper and lower compartments should not be overloaded with products.

- It is forbidden to install household appliances of this type near heat sources.

- The evaporator (radiator on the rear wall) must be protected from the possibility of mechanical damage.

- The device must be transported carefully.

If household appliances are not equipped with the No Frost system and you need to defrost, you need to wait until the ice melts on its own. Do not pick it with sharp objects - there is a risk of damaging the refrigerant pipes.

It is forbidden to put hot food - violation of the temperature regime and the formation of a large amount of moisture will lead to serious damage. In the event of a malfunction, you should immediately contact a specialist: self-repair can only aggravate the situation.

What to do, where to run

German quality speaks for itself, so problems with Liebherr refrigerators happen very infrequently. However, any technique can fail. You need to be ready for this and be able to determine that “something is not right” with the device. Repairing Liebherr refrigerators is serious business. Even a seemingly trifling malfunction requires competent elimination.

If the refrigerator is still under warranty, immediately contact the nearest authorized service center. In the case when the warranty period has already expired, you need to find experienced craftsmen who specialize in repairing Liebherr equipment. For example, residents of Kyiv and the suburbs can call them via the Internet by contacting

Your job is to notice the "distress signal" from the device in time, and then connect professionals to the case. About what breakdowns most often happen with refrigerators of this company, we will tell further.

The main symptoms of a malfunction of Liebherr refrigeration equipment

Refrigerator failure

- accumulation of water at the bottom of the refrigerator compartment,

- poorly cools products on the bottom shelf,

- freeze products located in the balconies of the door,

- flashing indication and lighting in the refrigerator compartment,

- the compressor does not start and you can hear ticks and crackles,

- long operation of the motor - compressor and extraneous sounds.

Refrigerator failure

the temperature regime set in the refrigerator is lost,

the Alarm indicator (attention) flashes or lights up,

two dashes "-" or one "-" light up on the display,

does not cool products on the lower shelves,

the formation of a snow coat on the inner surface,

the compressor is constantly running.

Freezer malfunction

The breakdown of the freezer can be local, but it can also be part of the malfunction of the entire refrigerator. It depends on the technical device of the refrigerator. Common signs of a broken freezer are:

- does not reach the set temperature "-18",

- two dashes “—“ light up on the display,

- formation of water at the bottom of the freezer,

- continuous operation of the compressor.

Wine cabinet malfunction

A malfunctioning wine cabinet brings a lot of inconvenience. The safety of wine depends on the serviceability of the camera for its storage. The main signs of a broken wine cabinet are:

- flashing indication and interior lighting,

- lack of a set temperature in the chamber,

- formation of a snow coat in the corner,

- constantly running the motor.

Service cost

In our service center, we provide customers with really high-quality and at the same time inexpensive repair of Liebherr equipment. You can always consult with us over the phone regarding the nature of the problem with your household appliances. We work in the evening and at night, which will allow you to receive the masters on a convenient day, even after work.We will diagnose problems with the refrigerator on the spot, choose the most optimal repair option, if necessary, replace faulty components and be sure to issue a written guarantee for the work performed!

There are signs of a malfunctioning refrigerator. What to do?

Liebherr refrigerator malfunctions are very diverse. Signs are temporarily hidden, and are visible to the naked eye. It all starts with how you noticed... What? Something that was not there before and what should not happen in a working refrigerator. What to do? Most importantly, do no harm.

Liebherr refrigerator malfunctions are very diverse. Signs are temporarily hidden, and are visible to the naked eye. It all starts with how you noticed... What? Something that was not there before and what should not happen in a working refrigerator. What to do? Most importantly, do no harm.

The specialists of the workshop have carried out repair work many times already. Based on their knowledge, we have compiled for you a rough list of the most common malfunctions of household refrigerators:

- Refrigerator not working.

- The freezer is not working.

- The door handle broke.

- The drain hole is clogged.

- The motor-compressor burned out (it makes a loud noise or does not turn on).

- Faulty evaporator sensor.

Do not try to repair the damage yourself! Liebherr is an expensive and complex technique, repair of Liebherr refrigerators is possible only by a service master. At the first sign of a refrigerator malfunction, call a specialist.

Easy Repair

In some cases, it is possible to return household appliances to working condition after carrying out a simple repair with your own hands.

Changing light bulbs

Replacing a burned out light bulb with a similar new one is a simple job for a professional. You can read the instructions in the article, it describes in detail the procedure for removing the ceiling, how to properly unscrew the remnants of the base and other nuances.

Cleaning the drainage system

During operation, contaminants appear in the drainage system of the refrigerator - small pieces of food, grease, dust. So that there is no moisture under the vegetable compartment or under the bottom, it is worth regularly cleaning the drain tube.

Replacing the rubber seal

Wear of the seal appears as a result of inaccurate operation, leads to a change in the temperature regime inside the compartments. You can learn about the replacement of this component from the article.

Eliminate compressor noise

The noise that occurs during operation of the refrigerator may be due to improper operation of the compressor. The master needs to inspect the equipment and determine if the engine is in contact with pipes and other mechanisms.

Hanging and leveling doors

For ease of use, modern kitchen appliances are equipped with the possibility of hanging the door. Professionals will help to carry out such repairs, details can be found in this article.

Checking the correct installation

The refrigerator must be placed on a solid and level surface. To make sure that the requirement is met, you can use the building level. The technique should not stagger and be skewed to one side. In modern models, the legs are distinguished by the possibility of height adjustment, so unevenness can be eliminated. Read more here.

If there is a lot of ice in the freezer

Ice in the freezer may indicate that it is necessary to temporarily turn off the equipment, defrost, and then thoroughly wash the unit. You can find out how such a simple repair is performed in this article.

Common malfunctions of Ariston units

Refrigerated cabinets Hotpoint Ariston is a successful combination of verified design, price and quality. But, just like in refrigerators from other manufacturers, during operation, household appliances may fail due to malfunctions of some component or assembly. The most common violations that occur in Ariston refrigeration equipment are as follows:

- makes a lot of noise, buzzes, clicks, hisses and makes other uncharacteristic sounds;

- after starting, the unit immediately turns off;

- ice builds up on the walls;

- one of the chambers does not cool or freeze;

- lighting does not turn off;

- the red indicator is on;

- there are leaks in the refrigerator.

Turning off the refrigerator

When, when starting the unit, it immediately turns off, the problem can lie in the starting or protective relay. A more serious problem is the failure and failure of the compressor motor. When the cause lies in the burnt winding, the compressor will be constantly hot, and the machine on the meter in the house or apartment will regularly “knock out”.

If the compressor does not work at startup, the root cause is most likely hidden in the temperature sensor. The thermostat is able to break down due to a break in the electrical circuit with the engine, when the electric motor does not receive a start command.

Excessive ice formation

If the refrigerator freezes too much - before ice forms, the problem can lie in the thermostat. This can happen in cases where defrosting is performed less frequently than once every six months. In Free Frost units, a snow formation unusual for these models can occur, which is an indicator of freezing of the evaporator of the freezer due to a malfunction of the timer that does not start defrosting.In such a situation, the temperature indicators of the freezer increase, which leads to the continuous operation of the electric motor, resulting in the formation of ice. Also, the continuous operation of the electric motor accelerates its wear.

Small cooling

When the unit does not cool enough, and there is a blinking of the indicator or an audible signal, there is a possibility of clogging of the capillary tube. This malfunction prevents the normal circulation of the refrigerant through the pipeline due to clots that can occur during the heating of engine oil, which is also present in the cooling circuit.

The main cause of most of the malfunctions is the incorrect functioning of the compressor. When there is a critical increase in temperature in the refrigerator, the equipment gives an error a1 and the unit sets the temperature to 0 ̊С - this happens so that the owner has time to use the food for the next day.

When the problem is not solved and the temperature still remains critically high, and for some reason the compressor cannot cope with cooling, the following error code is displayed on the display - a2. It is constantly present on the screen until the problem is fixed. At the same time, the refrigerator consumes more electricity, but the production of cold is reduced. A malfunction in the functioning of the electric motor and maintaining insufficiently low temperatures in the refrigerator compartment and freezer are often provoked by the following factors:

- failure of the defrost sensor;

- malfunction of the evaporator heater;

- refrigerant leak;

- control module failure.

Regardless of the specific defect in the functioning of the refrigerator, a master is called who will diagnose and fix the problem. When the temperature is insufficient and the unit does not cool well, it is impossible to correct the situation at home without the use of a specialized tool.

The specifics of Liebherr refrigerators

Refrigerators and freezers of this German holding are positioned as premium equipment. They are produced at factories in Germany, Austria and Bulgaria.

The high cost of devices is due to the price of components and customs duties for finished products. However, this does not deter customers who are willing to pay for a quality product.

Liebherr brand refrigerators are equipped with intelligent controls, a display that allows you to control the temperature and read errors in operation. However, the presence of complex technical components significantly complicates the repair

In total, Liebherr presented the following product lines for sale in Russia:

- refrigerators without freezers;

- freezers and lari;

- refrigerators with freezers, made according to the “European type” customary in Russia;

- made according to the "American type" two-door devices, when the refrigerator is located on the right, and the freezer is on the left;

- wine cabinets.

The manufacturer selects components and assemblies based on the principles of reliability, without compromising quality and cost. Therefore, the price of original spare parts is quite high.

The original fan for the CBN 3956 model costs 7400 rubles, and the compatible fan costs 2300 rubles. Official dealers have only branded components in stock (+)

Installing components from other manufacturers during repairs, even if they are suitable in terms of parameters, means reducing the reliability of the device. But, it should be noted that this often has to be done, since Liebherr-certified service centers do not exist in all cities.

Therefore, before buying a refrigerator from Liebherr, it is necessary to check whether a certified repair company is available in the immediate vicinity and therefore has a sufficient stock of spare parts in stock.

The procedure for performing operations when defrosting equipment of a certain type must be observed, since if there are facts that indicate incorrect operation, the manufacturer will refuse warranty service

When contacting the service, you must name the brand, serial number of the model and describe the problem. If the refrigerator is equipped with an electronic control and display unit, then you also need to name the error code that will be shown on the screen.

The error code indicates a malfunction of the refrigerator. However, self-diagnosis does not always correctly determine the type of problem: the cause of the breakdown may be different.