- The refrigerator does not freeze or does not freeze well

- Malfunctions from the category of extremely serious

- Refrigerator non-stop operation

- Indecently short cycle time

- Atlanta thermostat failure

- Atlas, easily shocking

- Reasons for contacting the service center

- Reason #1. Refrigerator quick shutdown

- Reason #2. Damage to the external and internal thermostat

- Reason #3. Current breakdown on the refrigerator case

- Reason #4. Clogged capillary tube and freon leak

- How to define normal work?

- When you can't do without a master

- Shortened refrigeration cycle

- Malfunctions of the motor-compressor

- Rapid accumulation of snow "coat" on the back of the device

- The refrigerator body is shaking

- Fundamentals of diagnosis and simple repair

- Troubleshooting

- Elementary Causes

- footage

The refrigerator does not freeze or does not freeze well

The reason that fridge not working properly, an insufficiently closed door of one of the chambers may protrude. This situation may occur as a result of not very tight contact of the rubber with the body. The reasons for the deformation of the seal may be different, but basically it passes air due to its wear. In this case, it should be replaced.

Some users do not consider it necessary to defrost the device as indicated in the instruction manual. If, during defrosting, you try to break off pieces of ice from the walls, then such actions lead to the fact that the upper chamber of the refrigerator does not work. Freon leakage may occur due to damage to the inner casing of the case.

The penetration of air into the chambers, due to which the device stops working normally, is also facilitated by a skewed door. You can correct the situation by adjusting it. Diagonal rods are located directly under the door panel.

The lack of normal temperature inside the refrigeration unit can lead to spoilage of the products stored in it. Therefore, after repairing the device, it is recommended to wash it thoroughly with the help of special products that destroy unpleasant odors. After that, let it dry well, after opening the doors.

Malfunctions from the category of extremely serious

This is the category of problems that amateurs are better off not trying to “fix” on their own, usually they get the opposite result of what they expected - the failure of the refrigerator forever. The only thing that the owners can do is to determine the nature of the breakdown.

Refrigerator non-stop operation

Such consequences are caused by unidentified malfunctions in time - a refrigerant leak or a clogged capillary tube. Both problems are the reasons why the Atlant refrigerator compressor has become a perpetual motion machine.

The blame for the first trouble lies with the careless owners, damaging the channel with various piercing and cutting objects because of the desire to quickly defrost the freezer compartment. With a shortage of freon, the circuit is filled with refrigerant, leakage is prevented.

If a no lack of gas detected, diagnosing blockage. The reason for it is the “clogged” type of freon. It is characterized by “engagement” with engine oil, because of this misalliance, a blood clot appears in the system. It is eliminated by blowing through the capillary tube. The interference clot moves to the evaporator and enters the drying filter.

Indecently short cycle time

First of all, check the mains voltage. If interruptions are detected, a stabilizer is purchased. When the power supply is normal, the thermal relay is dismantled, and the electric motor is connected directly. If the unit starts to work normally, change the relay. Other diagnoses are motor jamming, compressor winding breakage. Their "treatment" will be expensive.

Atlanta thermostat failure

Most of the former Minsk models “sin” with this. Typical symptoms of a “disease” of a thermostat are a refrigerator that does not want to turn on or off, freezing of products stored in the refrigerator compartment.

More often this device in models is located outside the refrigerator, so there is serious work to be done:

- remove the door;

- on the cover remove the plugs, unscrew the screws;

- remove the panel, take out the thermostat by unscrewing the screws securing the brackets.

After replacing the device, the refrigerator is assembled. In those two-chamber models where the freezer compartment is located on top, the thermostat is located on the back wall of the refrigerator.

Atlas, easily shocking

Even a not very powerful discharge of current when touching the device is a sufficient reason for an emergency call to the master. If such a problem occurs, there are bare wires inside that are in direct contact with the walls.It is impossible to fix a malfunction on your own, only a refrigerator is able to quickly find a dangerous place and insulate the wires.

Reasons for contacting the service center

Diagnostics and repair of refrigeration equipment should definitely be entrusted to the refrigeration specialist if it is necessary to disassemble the circuit, check the compressor, thermal relay and the presence of freon. Condition assessment, repair of electrical wiring and electronic control unit is a task for professionals.

Reason #1. Refrigerator quick shutdown

To determine the possible cause of the shortened cycle of operation, it is necessary to analyze the sound when the unit is turned on / off.

The refrigerator worked for several seconds, before turning off there was a click, and the motor began to work loudly, which means that the compressor or thermal relay is damaged. Violation of the usual work intervals is associated with a breakdown of the electronic board or power surges

To diagnose the problem yourself, you can do the following:

- Check mains voltage.

- If the indicator is within the normal range, then it is necessary to remove the thermal relay, and then connect the motor directly.

- If the unit is working properly, then the cause of the shortened cycle has been identified. The next step is to replace the thermal relay.

If the cycling is caused by fluctuations in the power supply of the network, then the installation of an AC voltage stabilizer is required. More serious breakdowns are a break in the compressor windings or a jamming of the motor. Troubleshooting or a complete replacement of a defective unit will be expensive.

To replace the start-up and thermal relays, which are a single unit in household refrigerators, it is better to contact the workshop. However, it is quite possible to do the work yourself, focusing on the information presented in the video:

Reason #2. Damage to the external and internal thermostat

In most Atlant models, the thermostat is located outside the refrigerator compartment - under the top cover. Replacement of the element should be entrusted to professionals.

For reference, here is a general workflow:

- Remove refrigerator door.

- Remove the plugs on the cover and unscrew the screws.

- Remove top panel.

- Unscrew the screws that secure the thermostat brackets, remove and replace the element.

- Reassemble in reverse order.

In two-chamber modifications with an upper freezer, the thermostat is located inside the refrigerator - the bellows tube is attached to the rear wall of the unit.

Failure of the thermostat - a minor breakdown. The master will fix the problem at home - you don’t have to deliver the equipment to the service center

Reason #3. Current breakdown on the refrigerator case

If even a light touch on the case is accompanied by at least a slight discharge of electricity, then find out the cause and troubleshoot yourself highly not recommended. It is likely that bare wires are in contact with metal walls. The refrigerator will identify the damaged area and isolate the problem area.

Reason #4. Clogged capillary tube and freon leak

Both malfunctions lead to similar consequences: an increase in temperature inside the refrigerator compartment and the continuous operation of the motor-compressor. To establish an accurate “diagnosis”, the wizard performs diagnostics - opens the system.

If the gas is in sufficient quantity, then a blockage of the capillary pipeline is determined.

Ways to fix the problem:

- punching with a press - oil under pressure acts on the blockage;

- flushing with a specialized solution of the type of "liquid desiccant";

- purge with compressed nitrogen;

- complete replacement of the capillary circuit.

If the Atlant refrigerator has stopped cooling and does not work due to a lack of refrigerant, the circuit will need to be charged with freon, the rules for which are described in detail in the article we recommend.

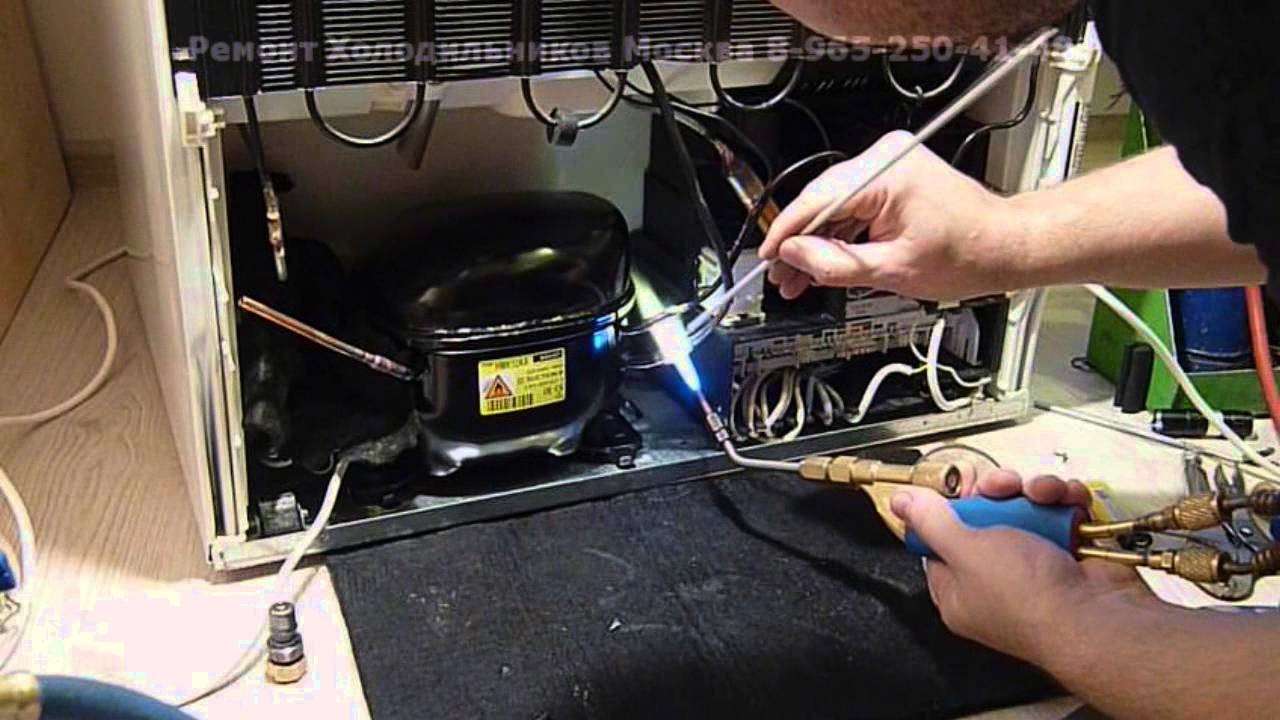

Doing the job requires care and special skills. Of the tools you will need: pressure gauges, a cylinder of freon, hoses

Refueling is carried out on an isolated site, away from heating elements, sources of fire

Freon leakage is often the fault of users. The most common cause is damage to the channel by sharp mechanical objects when defrosting the freezer or evaporator.

With one of the options for determining a breakdown, detecting a leak, with a method for its elimination and the process of pumping freon, the video will introduce:

h2 id="kak-opredelit-normalnuyu-rabotu">How to define normal work?

An ideally functioning refrigerator should work from 10 to 15 minutes, rest - 25-30. The duty cycle coefficient is calculated as follows: the time of work is divided by the time of "idleness". For example, 10/25 = 0.4. The gap between 0.37 and 0.5 is the norm. Any deviation (0.2 or 0.6) indicates problems. Correction requires the intervention of a master. Atlant refrigerator malfunctions are often easy to fix, so it usually serves people for more than a decade.

If you have any questions, you can kill two rodents at once - ask them to the author of this video and at the same time watch interesting material:

When you can't do without a master

One of the first signals that your refrigeration unit gives in the event of a malfunction is a burning red light. It is she who shows that a serious failure has occurred in the operation of the refrigerator, which requires the attention of an experienced craftsman. Below are the main problems that can occur when the red indicator lights up:

- shortened cycle of the refrigeration unit;

- malfunctions of the motor-compressor;

- rapid accumulation of snow "fur coat" on the back of the device;

- the refrigerator body is shocked.

Of course, if you have certain knowledge in the field of electrical engineering, you can try to eliminate these defects yourself. Let's consider each case separately.

Shortened refrigeration cycle

It is possible that due to a malfunction of the thermal relay or increased voltage in the engine circuit, the refrigerator starts to stop working immediately after being turned on. To find out the cause of the malfunction and carry out repairs, a series of actions should be performed.

- Measure the voltage in the electrical network.

- If the voltage does not exceed the norm, it is necessary to remove the thermal relay and connect the electric motor directly.

- If the refrigerator is functioning properly, you should change the broken relay to a working one.

Thermal relay

Malfunctions of the motor-compressor

If your refrigeration unit is running non-stop, pay attention to the room temperature and the position of the thermostat knob.If the latter is in the standard state and the temperature in the room does not exceed the norm, it is necessary to carry out the initial diagnostics of the unit

- If the thermostat knob is in the normal position, but the refrigerator is continuously running, it is possible that the cause of the breakdown was the failure of the thermostat.

- If a freon leak occurs, characteristic frost will not be present on the evaporator tubes. In this case, it is better to contact a repair shop, where they will determine the exact location of the refrigerant leak and make repairs.

Rapid accumulation of snow "coat" on the back of the device

There are many reasons for this error:

- insufficient fit of the door to the refrigerator body;

- increased temperature in the room;

- the situation when hot food is stored in the refrigerator;

- the refrigerator is operating in low productivity mode.

The first thing to do in the event of a malfunction is to check whether the seal fits snugly against the door and refrigerator body. If this is not the problem, your machine may not be operating at full capacity in a fairly warm room. Change the power to a higher level and the problem should be solved.

Snow coat

The refrigerator body is shaking

If, upon contact with the refrigerator case, you feel even a slight discharge of electric current, it means that the bare wires in your device are in contact with the case. A qualified craftsman, by measuring the insulation resistance of wires, will identify and insulate the place of the problem.

Fundamentals of diagnosis and simple repair

Let's analyze the simplest operations that need to be carried out to test the refrigerator. It’s worth starting with determining the quality of the mains voltage.It must strictly correspond to 220 V. Smaller values \u200b\u200bmay cause the unit to fail.

You should also inspect the mains plug with a cord. Bends, creases, damage should not be. If the elements are heated or sparkle, this is a clear sign of trouble.

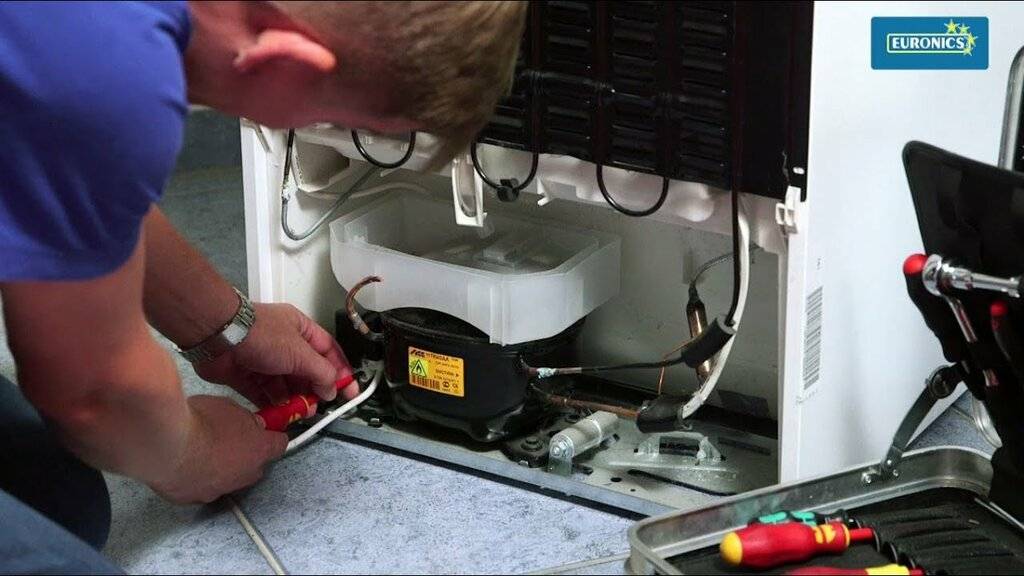

Refrigerator repair should begin with a visual inspection and diagnostics. so you can identify problems that the owner did not even suspect

The compressor terminals are checked and must be in working condition. After that, you need to use a tester to check whether the device receives sufficient voltage from the network.

After making sure that it is of good quality, the device must be disconnected from the power supply. Now you need to carefully inspect the compressor located at the bottom of the unit. There should be no visible damage here.

If visual inspection does not give results, proceed to testing the motor windings. First, disconnect the wires, guided by the designations on the terminals

To check the winding, the tester switches to ohmmeter mode. One end of the wire is fixed on the tester, after which the conclusions are checked one by one. Pair diagnostics are also carried out. A short circuit or damage to the winding will be indicated by the absence of movements of the tester arrow.

Next, check the control circuits. To do this, disconnect the wires from the relay and close them, and then check for contact between them and the power plug. The presence of such a contact indicates that the relay, cord and temperature sensor are working.

If a problem is found, each block will have to be checked individually. To test the temperature sensor, remove it and disconnect the wires.

From an ordinary nail, you can make a rod for moving relay contacts.Usually this part is made of plastic and often breaks. The diagram shows how this can be done.

Next, each of the wires is to be checked, if there is a short circuit, a conclusion is made about the malfunction of the detector. It should be replaced. If the control circuit is working normally, there are no breaks, the protection and start relays are checked.

You have to remove the cover to gain access. For older models, it is fastened with latches, with new ones - with rivets. They need to be carefully drilled, and after inspection, fix the cover on the screws.

The most common breakdowns of this assembly are jamming of the spring or core in the coil, burning of the contacts, or breakage of the stem. All this can be corrected. To begin with, the coil is removed from the latches, the core and the stem with contacts are removed from it.

Next, a thorough cleaning of all these elements is carried out. In the simplest cases, a soft cloth impregnated with alcohol will be enough. In more complex ones, to ensure free movement with the core, you will have to work with sandpaper or even a file. All contacts are also cleaned.

If it turns out that the stem is broken, and this happens often, since it is a plastic rod, it can be replaced with a piece of an ordinary nail. After repair, the assembly is assembled in the reverse order, put in place and connected.

Troubleshooting

Before proceeding with the repair, you need to determine what exactly is not working. To do this, examine the device and its components:

- For example, a compressor that should not make excessive noise, in addition, the compressor should turn on and off periodically.

- If it makes noise or works continuously, then this is a sign of a breakdown.

- You should also check the temperature in the refrigerator. Inside there should be no frost and water.

- It is also necessary to check the metal elements of the refrigerator. Over time, they can corrode, leading to refrigerant leakage and compressor failure.

- Make sure that everything is in order with the power sources, the presence of electricity in the house, the integrity of the power cord, the serviceability of the electrical plug.

- Check the rubber seal on the refrigerator doors to see if they are tight.

The most common breakdowns of Stinol refrigerators

The causes of breakdowns are usually improper installation and use of the refrigerator, mechanical damage, high temperature, power surges.

Common breakdowns:

Why the refrigerator does not turn on:

- Compressor winding failure.

- Thermostat malfunction.

- Damaged cable or plug.

Why does it freeze badly:

- Broken temperature controller.

- Seal defect.

- Filter clogged.

- Compressor failure.

One of the refrigerator chambers works, and the other does not (freezer or refrigerator compartment), which can cause this to happen:

- Coolant leak.

- Depressurization.

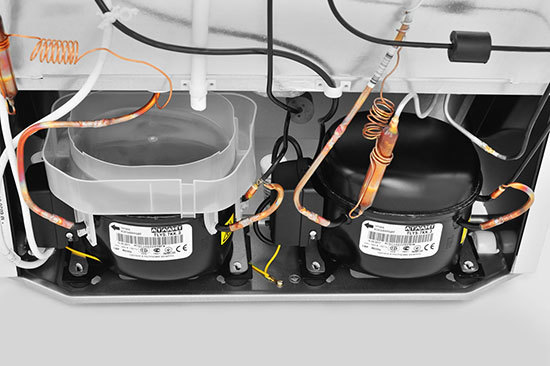

- One of the compressors broke.

Breakage of the refrigerator, refrigerator doors or the structure itself:

- Structural deformation.

- The gap between the seal and the surface of the refrigerator.

The lighting and light indication in the refrigerator does not work:

- Breakdown of the alarm for opening the refrigerator.

- Lack of food.

- The lighting fixtures were broken.

Frozen frost or frozen food:

- Too much cooling.

- Poor door fit.

- The thermostat has failed.

Elementary Causes

If the refrigerator does not work, before making repairs, you should check the correct installation and connection of the device. The temperature in the main chamber may rise due to the following factors:

- Leaky closing of the refrigerator compartment door. In this case, warm air from the room constantly enters the chamber.

- Incorrect maintenance of the device. The absence of defrosting adversely affects the condition of the compressor. Turning off the refrigerator and restarting it after 24 hours helps to cope with the problem. For proper defrosting, the doors must be kept open and wait for the ice to thaw. Do not use sharp objects to remove the snow coat.

- Incorrect loading of products. If the shelves in the refrigerator compartment are full, the air stops circulating, causing the temperature in the compartment to rise.

- Incorrect installation of the refrigerator. If the device is placed close to a wall or heating radiators, the temperature sensors start to work incorrectly. Sensors send a signal to the compressor to increase power, but the refrigerant heats up along the way.

footage

In the event of problems with the operation of the Atlant two-chamber refrigerator for 2 compressors, the troubleshooting instructions should be consulted first. The information that is necessarily included with the device describes in detail all possible breakdowns, their causes and troubleshooting options. If you are well versed in the structure and principle of operation of the refrigeration appliance, then it will not be difficult for you to eliminate simple malfunctions.But if you do not understand this issue or the problems that have arisen are quite serious, then it is better not to engage in amateur activities and call a master who will provide your home assistant with the necessary assistance. It is better to pay money to a specialist for such services than to buy a new refrigerator through the wrong repair.