- Faulty refrigerator compressor

- Causes of the malfunction

- Damaged air sensor or freezer thermostat

- Proper care will get rid of problems

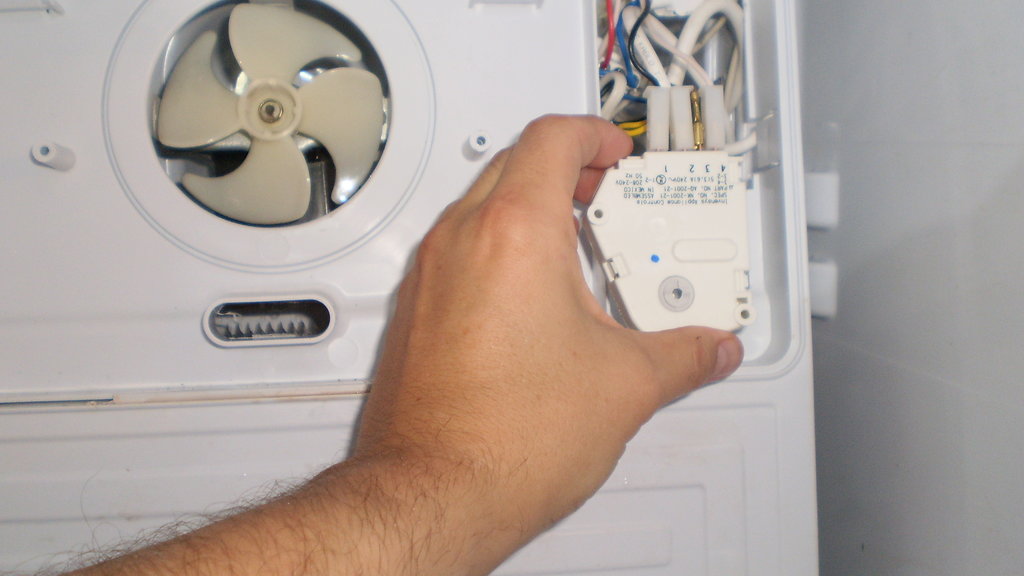

- Fan failure

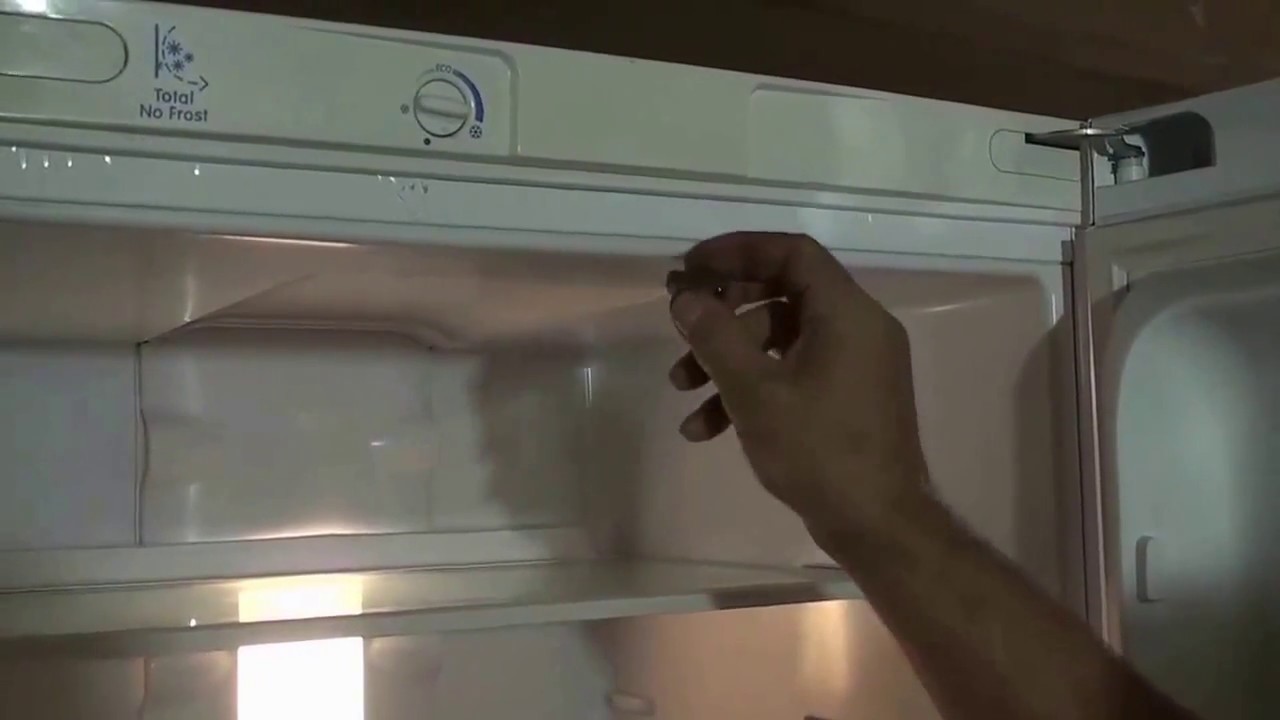

- Why the upper chamber does not freeze

- Possible problems

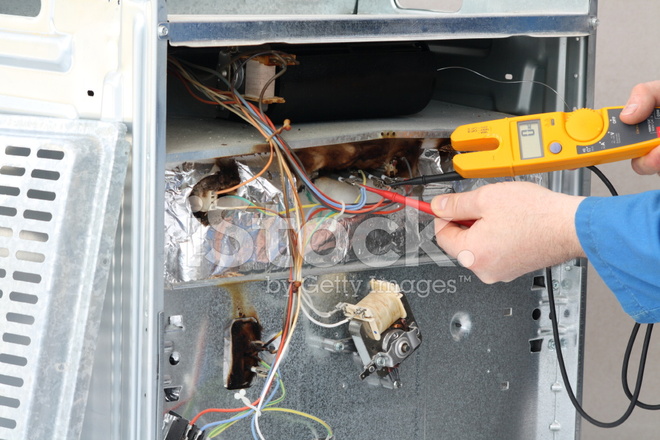

- Faulty start relay

- Freezer not freezing

- Unpleasant odors

- Refrigerator makes gurgling noises but is not cold

- Recommendations of experts to help avoid damage to the refrigerator during defrosting

- Compressor overheats

- Why the refrigerator stopped freezing and how to avoid it in the future

- What to do to find out the reason

- Other malfunctions

- Main sources of noise

- Start relay broken

- The refrigerator does not turn on - where to start?

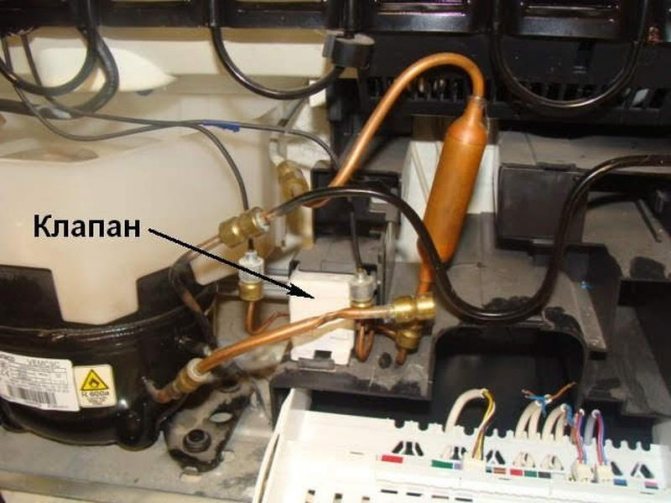

- How to troubleshoot the unit

- The main causes and solutions for refrigerator crackling

- Clicks while working

- Cracks but doesn't work

- Frost forms in the refrigerator (snow coat)

- Refrigerator won't turn on due to thermostat

- Compressor overheats

- Conclusions and useful video on the topic

Faulty refrigerator compressor

The compressor is one of the most important parts of a refrigerator. If the motor does not turn on, then the refrigerator will not work.However, if you have certain knowledge and skills, you can independently determine the cause of the malfunction of the refrigerator compressor.

To determine why the refrigerator compressor is heating up, you need to know its device. For most modern household refrigeration appliances, the motor design has no fundamental differences. This unit is a reciprocating electric motor and winding placed in a sealed housing and powered by alternating current. To understand the principle of its action, it is enough to recall a school course in physics.

From the hermetic housing in which the motor is located, three conclusions are made:

- general;

- launcher;

- worker.

These three contacts, in turn, are connected to a relay, which starts the motor. The most modern models of refrigerators have more complex electronic-digital start systems.

Causes of the malfunction

The most likely reason why the refrigerator compressor is heating up can be:

- burnt or “sticky” start-up relay;

- uninterrupted operation in fast freezing mode;

- violation of the tightness of the refrigerator or freezer;

- freon leak;

- clogging of capillary channels;

- software failures in the control module.

A damaged rubber seal causes the door to loosen, warm air enters the working chamber, and the motor has to pump the refrigerant hard.

Freon leakage can occur due to mechanical damage to the circulation channels. Usually this happens due to attempts to scrape frost from the walls of the freezer or unsuccessful transportation. In this case, sealing of damaged channels and refilling of freon is required.

Sudden power surges in the mains lead to malfunctions of the control module, its configuration and settings. In some cases, overvoltage provokes burnout of electronic components. The problem is solved by reprogramming the module or completely replacing the board. Frequent power outages and power surges are a fairly common situation in our time. Therefore, in order to avoid such troubles, you need to take care of high-quality stabilizers and network filters in advance.

If you notice that the refrigerator motor has become too hot, disconnect it from the power supply and call a repair specialist. Only the master will be able to determine the exact cause of the breakdown that led to the compressor overheating.

Damaged air sensor or freezer thermostat

The air sensor (in electronic models) or the thermostat (in electromechanical devices) stops sending signals to the “brain” of the unit that the temperature in the upper chamber has reached a critical level, but there is no signal, so the compressor does not start (in twin-engine units) or does not switch to mode cooling of the upper chamber (in single-engine units). A sign of failure is long breaks between compressor starts.

Service masters are ready to perform an urgent replacement of any sensors. In our warehouse of spare parts, original components for devices of all existing brands are always available.

Proper care will get rid of problems

Malfunctions often occur through the fault of the owners of household appliances themselves. The following errors are considered the most common:

neglecting the regular defrosting of the unit;

too frequent defrosting;

placing the device in heat;

overloading the chamber with products;

installation of heavy objects on the top panel of the unit;

careless handling, which led to depressurization;

attempts to remove ice with sharp objects.

It is important to follow the instructions for defrosting the refrigerator. It is necessary to turn off the power, open the doors and allow the frost to melt naturally. With proper care, the device will work properly for many years.

With proper care, the device will work properly for many years.

If the cycle of switching on and off the compressor is violated, repair should not be postponed. It is necessary to call a master who will figure out why the refrigerators do not turn off and take action. Delay will cause the motor to burn out and the cost of returning the refrigerator to working condition will increase markedly.

Top 10 reliable refrigerators under 30,000 rubles

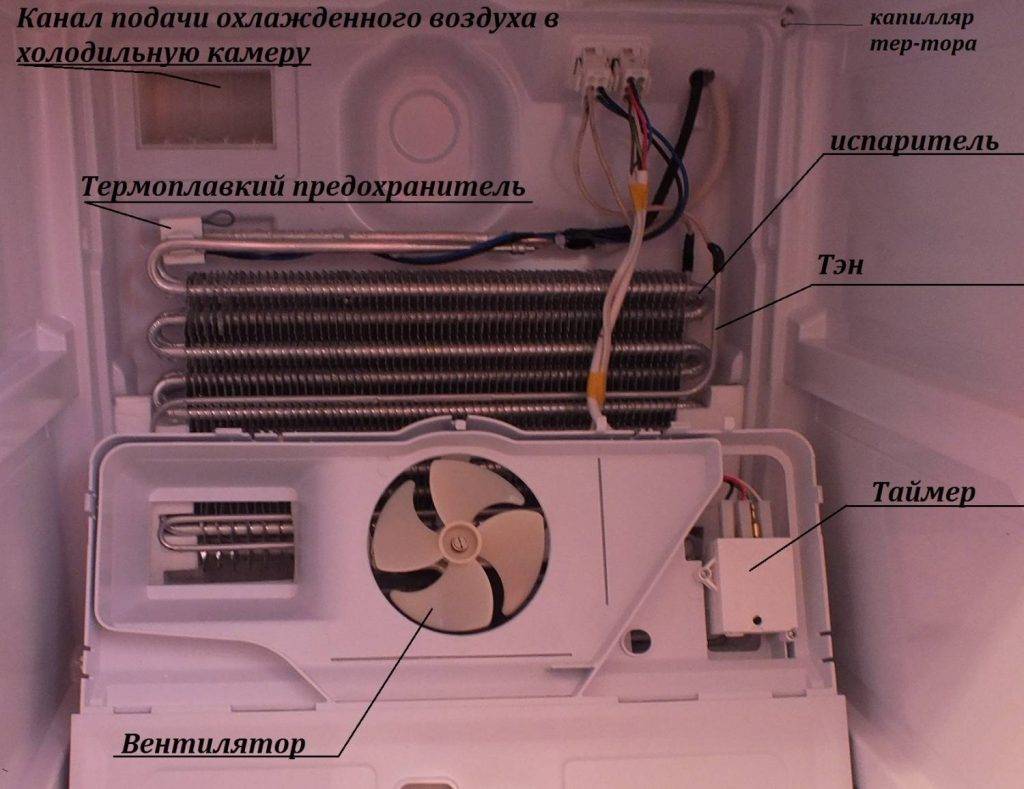

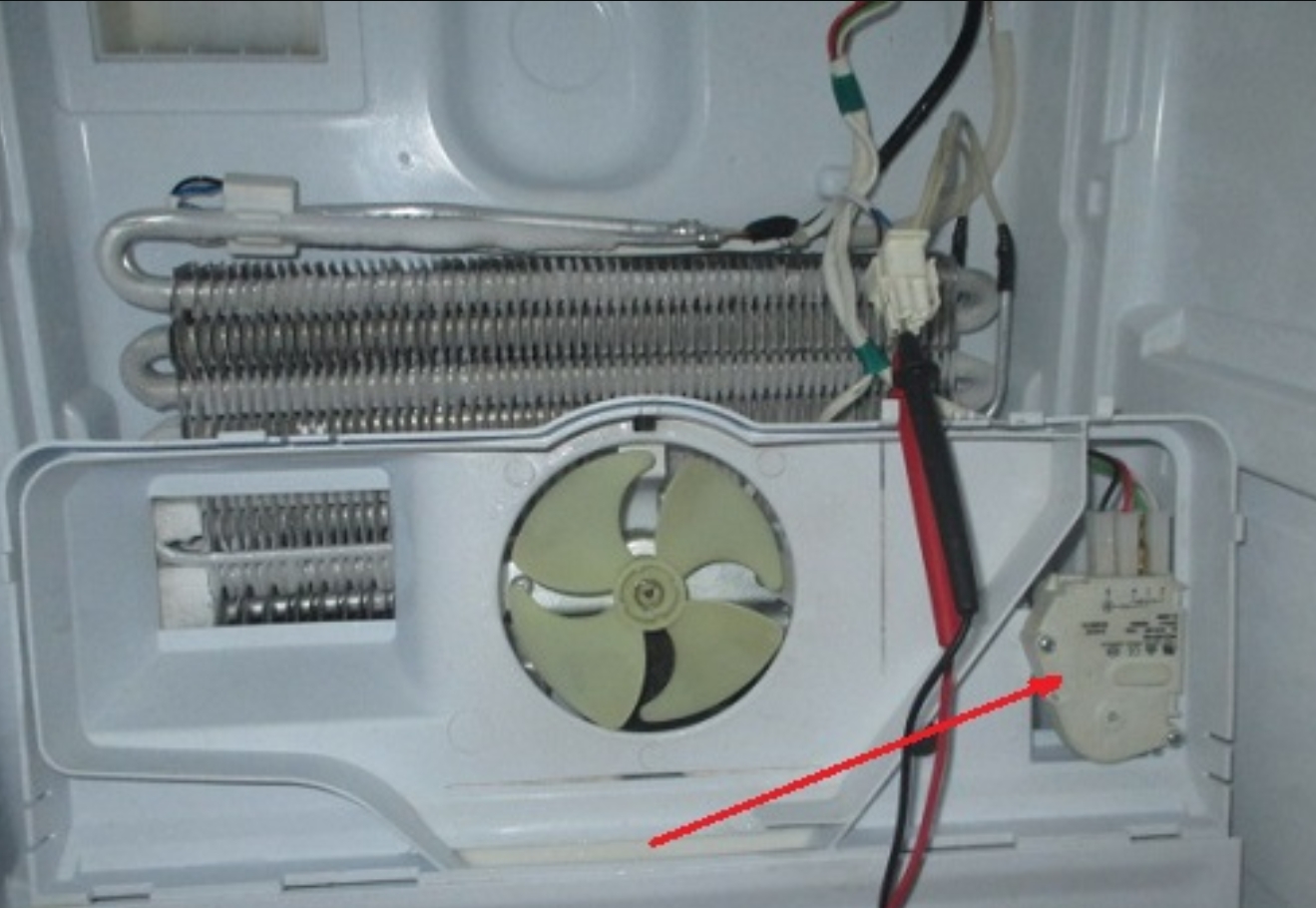

Fan failure

This malfunction is characteristic of refrigerators with the No Frost system and can be caused by:

- natural wear of the fan or its motor

- fan icing

The function of the freezer fan is to create air flows circulating through the channels of the refrigerator and preventing the formation of frost on the walls of its chambers. But even devices with an automatic defrosting system must be defrosted at least once every 2-3 years.

Moisture, which gradually accumulates in the freezer, provokes icing on the fan and the inner panel that closes the evaporator. There is a blockage of the channels through which air passes, as a result of which the rotation of the fan blades is difficult. The problem is solved by defrosting the refrigerator or replacing the fan (if the winding of its motor burned out due to overloads).

Why the upper chamber does not freeze

Beko's refrigeration equipment has its own freezing system with a special freon circuit. Therefore, if the main compartment has stopped cooling, the freezer works without disturbance. This occurs with problems with the seal, clogged drain tube and air sensor malfunctions.

When figuring out why the equipment is malfunctioning, you should make sure that the board is working. She often burns out. Therefore, experts recommend connecting devices with an electronic control unit only using a stabilizer. A similar requirement applies to models with linear inverter compressors.

Possible problems

The main components of the unit:

- motor-compressor;

- evaporator;

- fan;

- heating element;

- thermostat;

- start-protective relay;

- lines with refrigerant;

- air channels between the walls of the refrigerator.

Each of these structural elements can fail, as a result, the refrigerator or freezer stops working or, conversely, functions at the limit of its capabilities, but does not turn off. The nature of the breakdown of any equipment (and Indesit units) allows you to determine the probable malfunction. In this case, specific signs often appear, but if they are uncharacteristic (inherent in other problems in the operation of the refrigerator), you need to invite a specialist.

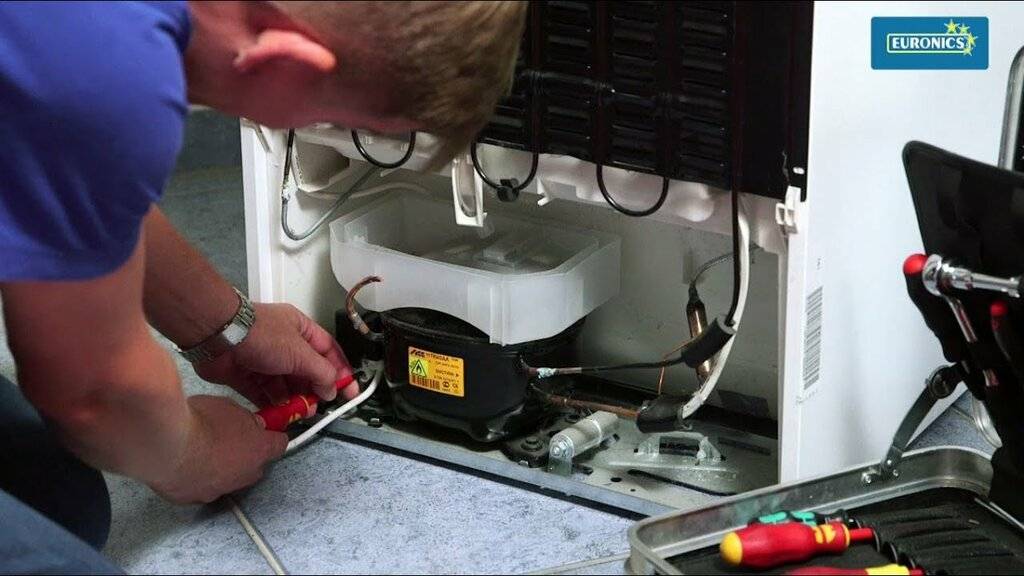

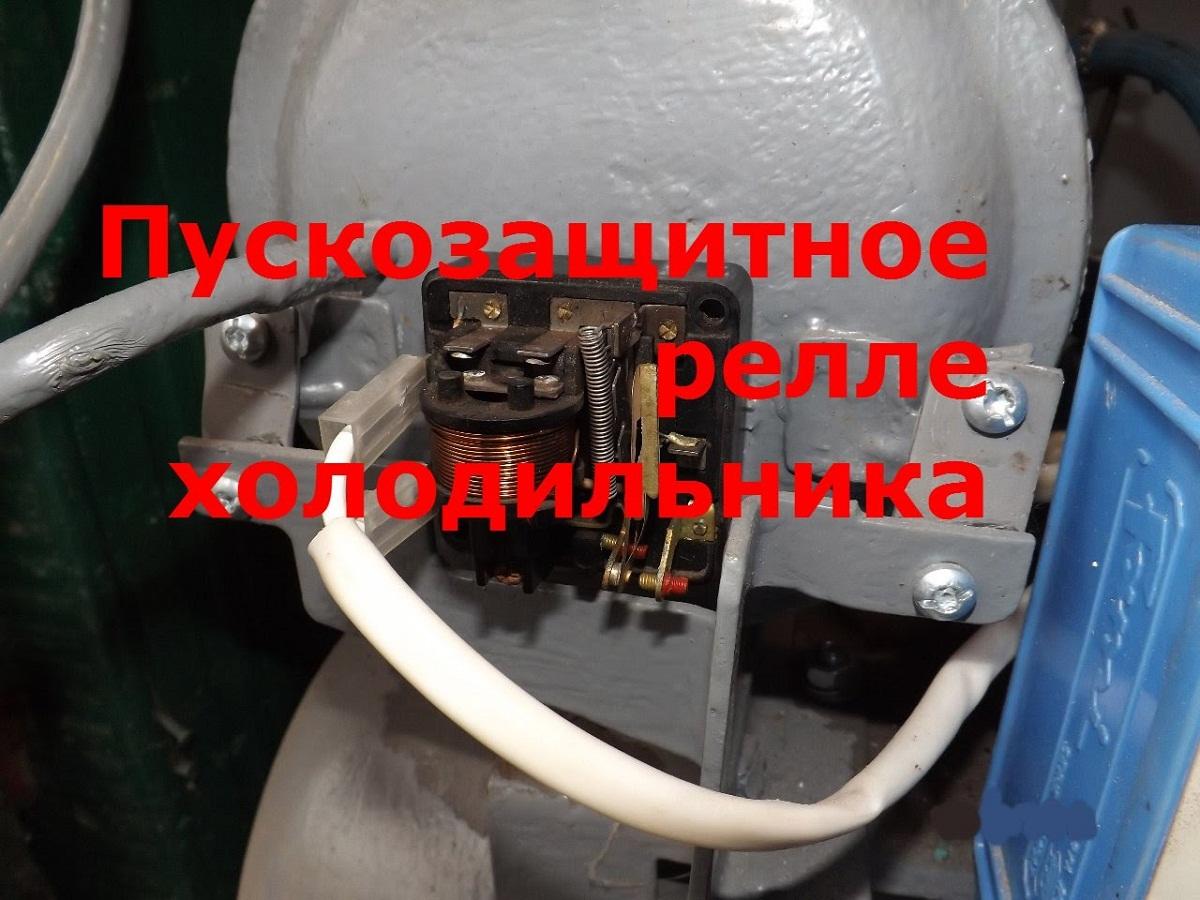

Faulty start relay

This node is located on the side of the case. Its main task is to manage operation of the compressor motor. The principle is as follows: the relay is responsible for the distribution of energy to the motor windings, this node operates in tandem with a temperature sensor. When the chamber becomes warm/cold, the relay starts or stops the motor-compressor.

In the event of a breakdown, 2 modes of operation are possible: the No Frost unit does not cool or operates without shutting down. One of the reasons for turning off the relay is the appearance of soot on the engine contacts. You need to understand how to check the relay. For this, a test instrument is used. It is necessary to determine the resistance of the circuit, also check the condition of the electromagnetic switch.

Freezer not freezing

If it was noticed that the performance of the refrigerator has decreased, and the lower chamber does not freeze, 2 reasons are suggested: a malfunction of the thermostat, a violation of the integrity of the routes through which freon passes. In the first case, the motor-compressor does not start when the temperature in the freezer changes to the limit value and becomes warmer.

In this case, the motor-compressor turns on more often or works constantly, because it compensates for the lack of freon in this way, which gradually evaporates through imperceptible cracks. A more obvious reason that the Indesit refrigerator does not freeze well is the incorrect installation of the sealing circuit during replacement.

Unpleasant odors

The unit can turn on and work normally at the same time. The smell in the Indesit two-chamber refrigerator is not always the result of a malfunction, it happens that improper operation makes itself felt. It is necessary to defrost the unit, while it is disconnected from the mains. They take out food, wash the chambers with citric acid or soda.

If the smell soon reappears, and at the same time the products quickly deteriorate, the Nou Frost unit's refrigerating chamber does not work.Moreover, the compressor can start, but does not perform its function due to a malfunction of related components: a relay, a temperature sensor.

Refrigerator makes gurgling noises but is not cold

In some older models, including those in Saratov, Daewoo or Orsk, gurgling sounds are heard during the operation of the refrigerator. This is normal, as freon passes through the cooling system. But if at the same time the unit stops cooling, there is warm air inside the chamber with the compressor constantly running, then there is a problem.

The cooling system may be malfunctioning if the oil filter is clogged. In addition, the capillaries through which the refrigerant is distributed may become clogged. It will not work to diagnose and fix the breakdown on your own, here a professional will come to the rescue. The master will immediately determine the cause and purge the system using special equipment.

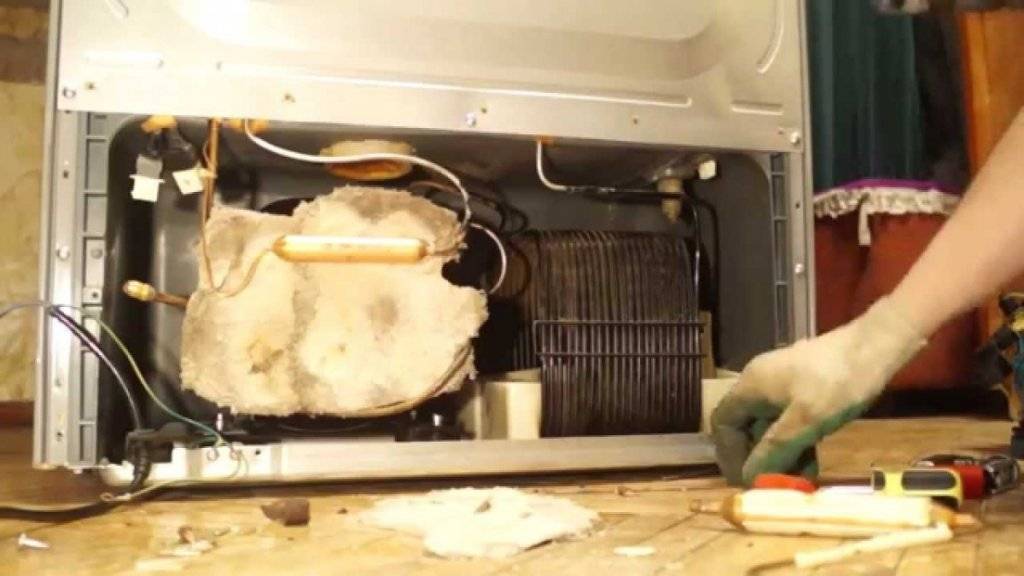

Recommendations of experts to help avoid damage to the refrigerator during defrosting

Required:

Remove all contents from freezers.

After opening the doors, give time for the temperature to equal the room temperature, do not try to speed up the defrosting process with the help of mechanical influences (chipping ice with a knife and other sharp objects)

It is important to properly defrost the refrigerator.

After complete thawing, carry out wet cleaning and allow the entire interior space to dry completely.

Turn on the refrigerator without loading, let it work in this form for several hours until it reaches the desired temperature .. Subject to all recommendations, the operation of the device will be uninterrupted

Both the refrigerator compressor and other elements will not require repair or replacement

Subject to all recommendations, the operation of the device will be uninterrupted.Both the refrigerator compressor and other elements will not require repair or replacement.

Compressor overheats

Modern models are quite reliable equipment, but still it sometimes needs maintenance and repair. Many owners are wondering why the refrigerator compressor is getting hot? It is especially relevant in the hot summer, when the motor simply does not play its role. However, most often overheating of the motor occurs due to violation of the operating rules.

Some models are equipped with an accelerated freezing function, which is used to quickly freeze a large amount of semi-finished products, meat, berries or vegetables. This mode provides for continuous operation of the compressor, but not all models have its automatic shutdown. Continuous operation in the mode of accelerated freezing leads to its overheating and premature failure. Therefore, it is necessary to be more attentive to technology and do not forget to switch the device to normal temperature conditions.

Why the refrigerator stopped freezing and how to avoid it in the future

Regardless of whether your refrigerator is old or new, you need to take care of it and follow certain operating rules.

Tips on how to protect the refrigerator from damage:

- You can not put uncooled dishes with hot dishes in the refrigerator;

- It is better to make the socket of the unit individual so that you do not have to constantly pull the plug to turn on another device, thereby loosening the socket itself;

- When turning off the device for defrosting, you should first turn the thermostat to "0", and only then remove the plug;

- There is no need to “help” the refrigerator when it is defrosting, scraping off snow and breaking off ice in the freezer - this can lead to the appearance of microcracks in the details of the device;

- A couple of times a year, you need to wipe the back of the refrigerator from dust with a slightly damp sponge, being careful not to touch or damage the wires and tubes.

What to do to find out the reason

To eliminate the "mechanical" influence on the operation of the device, it is necessary to check the installation method of the unit for compliance with the basic requirements:

- The device must be level, reliable, stable and without distortion.

- The minimum distance from the side wall of the apparatus to surrounding objects (all) must be 6 cm.

- The gap on the side of the rear wall should be more than 7 cm.

- The transport bolts that tighten the springs must be removed, the shock-absorbing fasteners must be in good order.

Consider if the refrigerator is very buzzing, what you can do and what you should not do:

- First, you can examine the inside of the chambers for rattling dishes, look under the freezer in search of excess frost on the walls, check if a foreign object has fallen behind the refrigerator. Move away from the wall a couple of centimeters.

- Then you can defrost the device to avoid touching the moving parts (fan) for frozen ice. No Frost systems in most LG devices require a long shutdown (5-6 hours). Thoroughly rinse the apparatus, transfer the products from glass containers to plastic.

- Do not try to examine the compressor of a working refrigerator, change its position, disassemble the unit connected to the network.

- You should not leave the device turned on when it is established that it has stopped freezing, the motor-compressor does not start, especially if there is a smell of burnt insulation.

Various squeaks, gurgles, clicks and some other sounds are characteristic of freezing units. Their origin is explained by the operation of the relay or thermal expansion / contraction of the materials of the apparatus body. A serious increase in noise coming from the circulation unit is the reason for the immediate call of the master to avoid leakage of poisonous refrigerant.

It is not recommended to try to fix internal breakdowns of the refrigeration unit on your own. For its correct maintenance, theoretical and practical skills in handling special diagnostic and filling equipment are required. The refrigerant circulating inside the apparatus, if leaked, can provoke severe poisoning: it is dangerous for human and animal health, the environment.

Careful operation is the key to your equipment, but no one is immune from unexpected problems. Is the compressor in the refrigerator heating up or not working? Further operation of such a faulty device will result in a more serious breakdown and subsequent costly repairs. The price of a new compressor can be a third of the total cost of a refrigerator. That is why at the first "symptoms" of a breakdown, it is better to immediately contact a qualified service center.

Other malfunctions

Most modern refrigerators operate with minimal noise. Therefore, if you hear a suspicious noise, then the legs of your Indesit refrigerator may not be properly adjusted.To eliminate this drawback, it is enough, taking a level, to adjust the height of the legs, unscrewing or twisting the legs. It is also worth checking the fasteners of the compressor to the casing. Maybe the mounting bolts are loose. Use a wrench to adjust the compressor fasteners.

If you have an unpleasant smell in the refrigerator, it is not necessarily that your food has gone bad. It could be that the condensate drain is clogged. To fix this, you need to clean the drain either mechanically or by air pressure. Always try to keep it clean and do not forget to defrost it in time. How defrost refrigerator quickly and safely read the dedicated article.

Of course, not all malfunctions can be repaired with your own hands. Yes, and diagnostics and repair of Indesit refrigerators in specialized centers for the repair of household appliances will extend the life of the refrigerator. But you yourself need to monitor the correct operating conditions for your Indesit two-chamber refrigerator, and knowing how your refrigerator works and how your refrigerator works, it will be much easier and easier for you to do this. After all, the service life of your assistant in the kitchen directly depends on this.

Indesit Refrigerator Repair

Main sources of noise

Most of the sounds accompanying the operation of freezing units are produced by the circulation system that pumps the refrigerant through the cooling channels: motor-compressor, control relays, evaporator. The more intensively it is involved (hot weather, warm food, frequent door openings), the more noise will be.

The body of the instrument may begin to resonate with these parts and amplify the sound of their operation.If a poorly balanced motor vibrates, the noise can be amplified by the contents of the freezer or glass and metal containers on the shelves.

Start relay broken

The breakdown of this element in any class and brand of refrigerator leads to an increase in temperature in the refrigerator chambers, because it is the relay that controls the operation of the compressor, which ensures the normal circulation of freon. A typical reason may be the appearance of soot on the terminals of the motor contacts - you must immediately check the connectors for the presence of moisture, check the correct connection, if you have already carried out an independent repair.

Due to incorrect connection, a short circuit may occur, the start-up relay will have to be changed due to its burnout. The operation of this device, and how a possible problem is eliminated, can be studied in detail using this video:

The refrigerator does not turn on - where to start?

Quite often, the failure of the refrigerator is not a consequence of some kind of internal breakdown, but of a third-party factor.

Finding out the causes of the malfunction, experts always first of all pay attention to the operation of internal lighting - whether the light in the refrigerator is on. We start with the same

If the bulb does not work, it can be assumed that the refrigerator is de-energized. We need to check the connection of the household appliance to the mains, we do it in the following order:

- check the socket

- check the cord

- check the plug.

If you have a connection problem, consider yourself lucky. There are no problems with the refrigerator itself, and the repair will not take much time. In the event that surface diagnostics did not give a result, and the lighting still does not work, then the problem is more serious.The same can be understood if the refrigerator does not turn on, and the light is on.

A characteristic feature of modern imported refrigerators is that they can be designed for a voltage different from the Russian one in the mains, therefore, with strong surges or large deviations from the norm, they can work intermittently.

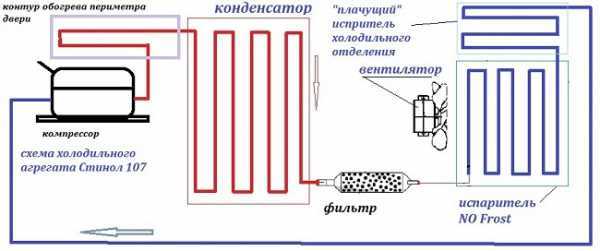

How to troubleshoot the unit

In cases where the lighting bulb is on and the refrigerator does not turn on, the freon circulation circuit may be to blame. It is a chemically inert substance that easily changes from liquid to gaseous state and vice versa.

The phase transition is accompanied by the release or absorption of a large amount of heat. The action of any freezing or climatic equipment is based on this. Knowing how a refrigerator works will never hurt its owner.

In general terms, the freon circulation scheme looks like this:

- the compressor compresses the refrigerant entering it to a pressure of 8-10 atmospheres, which at the same time becomes very hot;

- hot freon passes through a coil mounted on the back wall of the refrigerator, giving off a large amount of energy obtained during compression and at the same time turning into a liquid state;

- before entering the cooling chamber, the refrigerant is throttled, evaporating when the pressure decreases;

- the evaporation process is accompanied by a sharp drop in temperature, which leads to cooling of the food compartments of the refrigerator;

-

freon returns to the compressor and the cycle repeats many times.

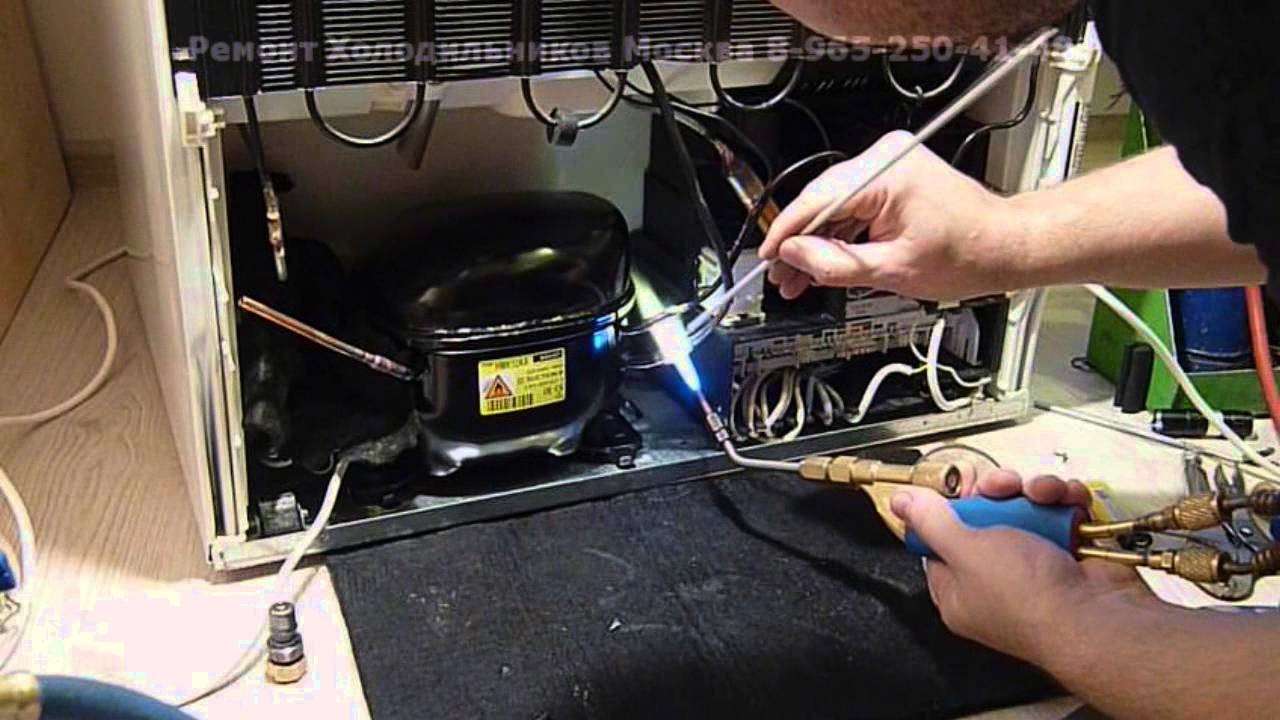

The circulation scheme is quite complex. It is in it that the reason why the household refrigerator does not work, and the light is on, may be hidden. In addition to compressor failure, there are two possible common problems:

- Freon leak.It occurs due to mechanical damage caused by careless handling, or dilapidation of old equipment. It is necessary to handle the tubes located on the back of the refrigerator with extreme care and not use sharp objects, trying to separate a frozen piece of ice or food from the wall of the freezer;

- Blockage in the refrigerant circuit. It is possible due to mechanical inclusions that appear during long-term operation or moisture left in the system at the time of refueling. The filter and narrow sections of tubes are usually blocked.

In these cases, the repair is accompanied by depressurization of the equipment, search and elimination of the cause of the failure, evacuation of the restored system to remove impurities and water residues with a simultaneous check of tightness, injection of the estimated amount of fresh freon.

Conclusion! These operations require special equipment and professional knowledge. In this case, you can not do without the help of a specialist.

During the repair of the circulation system, it may be necessary to replace:

- compressor;

- condenser;

- capillary tube;

- drying filter.

Usually rejected components and parts are replaced with similar ones.

The main causes and solutions for refrigerator crackling

Why there is a crack in the refrigerator, only people who understand the device will answer with accuracy. Not always extraneous sounds during the operation of the refrigerator indicate its breakdown. In some cases, you can fix them yourself. The main thing is to deal with the factors that provoke the appearance of cod and clicks.

With a strong, prolonged sound that is unbearable, in the case when the refrigerator is new, contact the seller, if not, contact the service center.

Clicks while working

There are several reasons for the appearance of clicks during the operation of the equipment.

- Compressor operation (the device is designed to maintain the required temperature, while the noise level is indicated in the device passport).

- Cracking of plastic casing due to temperature changes (when set to the optimal mode, the sound stops).

- Friction of the elements.

- Circulation through the refrigerant pipes.

- At the moment the motor is turned on and off, the thermostat clicks (the volume depends on the model and brand of freezing equipment).

- Uneven surface (clicks occur due to subsidence or malfunction of the adjusting feet).

- Thermostat malfunction (the equipment does not freeze during operation, the refrigerator must be turned off before the specialist arrives so that the engine is not damaged).

- Failure of the motor-compressor (when the equipment is turned on in the back, it creaks, cracks, the engine makes a hum and an unpleasant smell is felt. In this case, it is also worth unplugging the unit from the outlet and waiting for the master to arrive).

- Loose compressor mount (there is a loud clicking sound before disconnecting from power. You can fix the problem by adjusting the springs supporting the compressor).

- Burnout of the heating element of the evaporator (the resulting frost creates a load on the operation of the compressor).

- Contact of parts with motor tubes.

- Deterioration of compressor shock absorbers.

If this has not been observed in the refrigerator before, then in this case it is likely that the thermostat will need to be changed soon. Call a specialist to confirm or deny this point.

If, despite extraneous noises, the refrigerator and freezer continue to freeze, and the light inside is on, then there is no serious damage.

Cracks but doesn't work

The main reasons include the following factors.

- Breakdown of the thermostat (when the refrigerator is turned on, this unit gives a command to the control module that drives the motor. The start of the thermostat is always accompanied by a crash, but if the equipment does not start working, then the problem is 90% in the thermostatic relay).

- Failure of the start-up relay (the equipment does not turn on, there is no light and a click is heard).

- Breakdown of the motor-compressor (when connected to the power supply, a click occurs, the motor starts for a few seconds, hums loudly and stalls).

- Low voltage in the network (after turning off the engine does not start for a long time, and the refrigerator itself cracks).

If you find any damage, the best option would be to contact the service center. The cost of repairs varies depending on the severity of the damage and your region of residence.

Finding it difficult to determine why the refrigerator is cracking during operation, consult a specialist. It is better to call the master at home so that he can perform diagnostics to determine the exact cause.

The lack of necessary knowledge and tools for diagnostics makes it much more difficult to identify the true cause of extraneous noise.

Frost forms in the refrigerator (snow coat)

In old refrigerators, the formation of frost was taken for granted, defrosting (not the most pleasant activity) was put on the schedule of household chores, since the time for the growth of a fur coat was predictable.Newer models defrost themselves (water drains into a special pan, where it evaporates safely), the appearance of frost is out of the ordinary for them. In refrigerators with the No Frost system, frost can be regarded as a distress signal, but not immediately. It must be understood that a snow coat is only a consequence due to the incorrect operation of one of the nodes or incorrect settings. Having found ice, first of all you need to read the instructions to make sure that the equipment is working / malfunctioning (perhaps you just need to set the correct settings). If everything is correct, but there is frost, then something is broken.

Typical causes of frost formation:

- A refrigerator with two thermostats turns off less often than expected on the walls of the freezer or refrigerator (the back wall is mainly) an even layer of ice: the freezer / refrigerator compartment temperature sensor is faulty, it sends an erroneous signal about insufficient temperature, which causes the engine to work harder and longer in mode cooling, creating conditions for the formation of a fur coat. Repair - replacement of the temperature sensor.

- A refrigerator with one thermostat rarely turns off, frost forms in both chambers: the thermostat located in the evaporator is out of order and does not send a signal at the right time to complete the cooling, the compressor continues to work, the fur coat grows. Repair - replacement of the thermostat.

- In a refrigerator with a drip defrosting system, water accumulates at the bottom of the refrigerator compartment (correct for Free Frost), and a layer of ice forms at the bottom of the freezer compartment (correct for No Frost): drain pipe blockage - the water formed as a result of defrosting should drain into a special tray, but this it has no opportunity, therefore it accumulates / freezes. Repair - elimination of blockage (you can clean it with your own hands if access to the drainage hole is not complicated).

- In a refrigerator with No Frost, there is a layer of ice on the walls of the freezer, the unit works almost constantly, but the temperature is insufficient (in refrigerators with Full No Frost, the temperature is insufficient in the refrigerator compartment): a malfunction in the defrost system (one of the elements has failed: the defrost timer, defroster, evaporator heater, pallet heater, fuse, etc.) prevents the refrigerator from working in the desired mode, the evaporator (for Full No Frost - the cold air supply channel) freezes up, performance decreases, the compressor tries to compensate for the lack of cold, works in emergency mode, freezes the evaporator even more, which leads to an increase in the snow coat. The refrigerator, as a rule, gives signals: depending on the model and brand, it beeps, flashes with emergency sensors, and displays error messages. Repair is the replacement of a defective element of the defrost system.

- The freezer of a single-compressor refrigerator is overgrown with frost, the temperature in it is insufficient: the solenoid valve that switches cooling modes is faulty (there are two of them: cooling only the freezer or both chambers) - switching to the freezer does not occur, it does not have enough cold, but in the refrigerator, on the contrary, it overabundance. Repair - valve replacement.

- Ice has formed on the back wall of the refrigerating chamber, the motor turns off much less often than expected (modern models give signals: they beep, flash the temperature indicator): the capillary tube is clogged, which makes it difficult for the refrigerant to circulate. Repair - removal of blockage, refilling with freon. Often, a blockage forms when engine oil burns (soot forms into a blood clot), so you need to check its condition and replace it if necessary.

- On the walls of the freezer, a snow coat concentrates in areas near the door or frost forms on the back wall of the refrigerator compartment, the device complains (beeps, flashes, etc.) about insufficient temperature: the door seal of the problem chamber has become unusable, warm air enters the refrigerator, forcing motor to wear out. Repair - replacement of the seal.

- A thick layer of ice has formed at the location of the evaporator, the compressor does not turn off, but the temperature is still insufficient; there is an uneven fur coat in the refrigerator compartment - after defrosting, the refrigerator refuses to work: freon leakage, most often occurring in the perimeter heating circuit, locking connections, the evaporator of the refrigerator compartment. Repair - troubleshooting, charging refrigerant. If the leak was in the evaporator, it will also have to be replaced.

Refrigerator won't turn on due to thermostat

One of the common causes of breakdowns is the failure of the temperature control system inside the chambers. At the same time, symptoms such as “clicking” - attempts by the motor-compressor to start - are almost never observed.

Correction of malfunctions associated with thermostats is solved by replacing the broken part; buying a new one will cost from 1500 rubles.

The temperature control system in modern models of refrigerators is of two types - a thermostat device (also called a thermostat) in mechanical models and an air sensor in fully digital ones. In simple terms, when the temperature in the chambers rises, a signal is sent from the sensors to the motor-compressor, it starts up and the cooling cycle begins anew.

Checking the thermostat is easy - it is connected with a pair of wires fastened with a terminal. Find where the temperature sensor is fixed in your refrigerator (usually in the same block with a light bulb), release the wires, try to short them together. If the motor-compressor starts after that, the problem is in the thermal control system - the thermostat will have to be replaced with a new one.

Often the refrigerator does not turn on after defrosting, but not because of a breakdown, but because of the negligence of the owners; do not forget to move the temperature sensor from the “defrost” position to the “frost” position.

Compressor overheats

Modern models are quite reliable equipment, but still it sometimes needs maintenance and repair. Many owners are wondering why the refrigerator compressor is getting hot? It is especially relevant in the hot summer, when the motor simply does not play its role. However, most often overheating of the motor occurs due to violation of the operating rules.

Some models are equipped with an accelerated freezing function, which is used to quickly freeze a large amount of semi-finished products, meat, berries or vegetables. This mode provides for continuous operation of the compressor, but not all models have its automatic shutdown.Continuous operation in the mode of accelerated freezing leads to its overheating and premature failure. Therefore, it is necessary to be more attentive to technology and do not forget to switch the device to normal temperature conditions.

Conclusions and useful video on the topic

A selection of stories on the definition of diverse problems with refrigerators of different brands and the process of troubleshooting.

Video tips on how to properly troubleshoot: before disassembling the components, the unit must be completely defrosted without the use of force. The video demonstrates how it should look like properly working no frost system evaporator:

Search for the reason for the lack of cold in the refrigeration compartment of the Atlant unit with the freezer in operation. An example of diagnosing a short circuit in a compressor.

Video instruction on replacing the compressor with a serviceable one using special tools:

Refrigerator Indesit: search and elimination of leaks in the heating circuit in the video:

It must be remembered that proper operation and timely quality maintenance of the refrigeration unit will keep its performance for many years.

If cold has nevertheless stopped flowing into one of the compartments of the refrigerator, then it is necessary to find out the background of the problem that led to this breakdown. Knowing it, you can independently try to fix everything on your own.

Want to talk about how you restored the refrigerator with your own hands? Do you have useful information on the topic of the article that is worth sharing with site visitors? Please write comments in the block form below, ask questions and post photos on the topic of the article.