- Do-it-yourself troubleshooting of popular problems

- Burner out of order

- Heating switch problems

- Electronic control unit

- The design and device of the plate

- Setting the gas stove to a different type of gas

- Product cleaning and maintenance

- The control unit of the plate, the automatic ignition unit, flew out of order

- Gas stove maintenance

- The smell of gas

- The smell of gas occurs when the stove is turned off

- The smell of gas occurs during the operation of the stove

- Thermocouple malfunction

- How to eliminate?

- The main causes of failure

- Ignition gives a spark, but the burner does not ignite

- What to do if the oven stops working

- The oven does not work - the main reasons

- Diagnostics and restoration of indirect heating panels

- Typical malfunctions of induction heating systems

- Why does the oven go out?

Do-it-yourself troubleshooting of popular problems

Below we provide a list of the most common breakdowns of electric stoves. Many of them can be eliminated on their own, while others require professional diagnostics. Do-it-yourself electric stove repair can be done in the simplest cases. Let's take a closer look at them.

Burner out of order

Follow these steps to change the burners on your stove:

Unscrew the nut and remove the ground.

Under it, you will find a bracket or ring that presses the part to the body.

Burners are fastened with threaded connections or inserted into a special hole

In the first case, it is necessary to pry off the thread with a screwdriver and remove it, in the second case, lubricate it with oil and try to carefully unscrew it from the housing.

Heating switch problems

Follow these instructions to repair or replace a failed switch:

- If there is no click when turning the knob, then this indicates a malfunction. To check its condition, it is necessary to set the regulator in the middle position, apply voltage to the stove, as a result of which the automatic protection should work and turn off after 30 seconds.

- Then remove the adjusting knobs from the outside, unscrew the front panel.

- You'll find a bar underneath that needs to be removed to get to the faulty regulator and replace it.

Electronic control unit

If you do not hear a click when the relay is turned on, then check for a signal. In its absence, we can safely say that the problem lies in the output cascade or the microprocessor.

To repair the electronic unit, you need to find a circuit and understand the complexities of radio engineering. If you do not have such skills and knowledge, then contact a specialist.

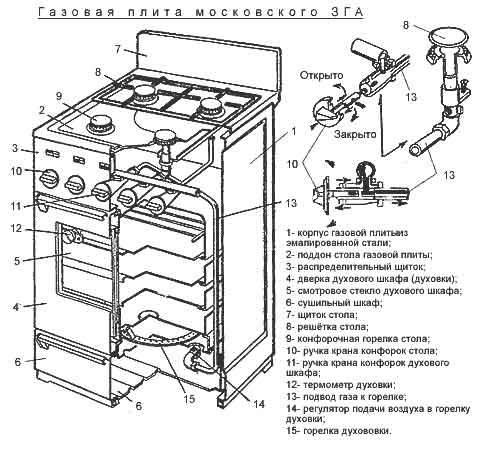

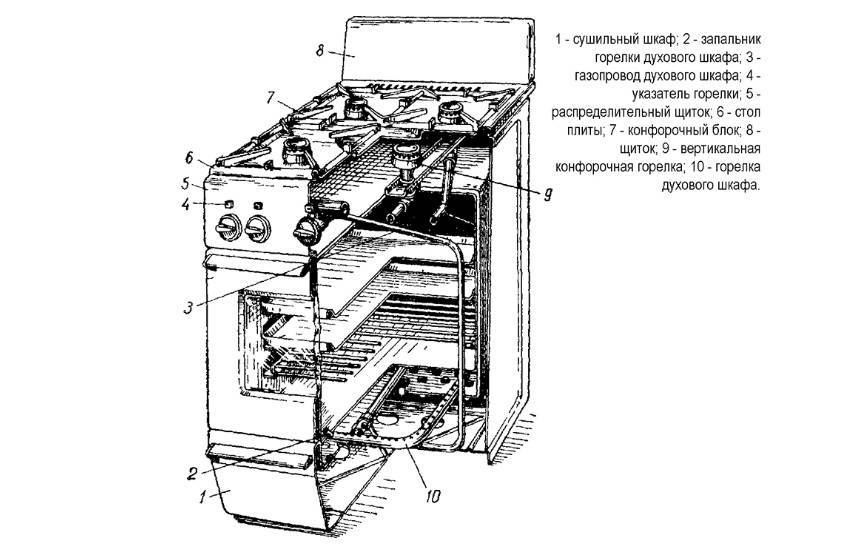

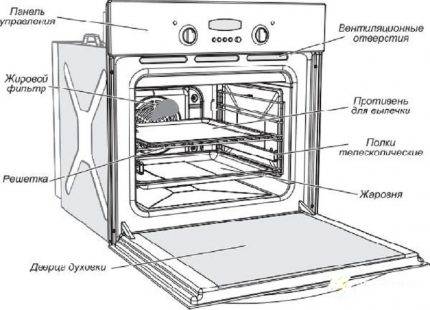

The design and device of the plate

All gas stoves are arranged in approximately the same way. Below the plate top you can see the following structural elements:

- Burners. They are attached to the plate with strong bolts. In this case, each burner is decomposed into its component parts - a divider, an injector and covers. To have access to them, it is necessary to disconnect the copper or steel pipe attached to the base of the burners.This will require a key for 13.

- Candles. Located around the perimeter of each burner. One is for ignition, and the other is used as a thermocouple. They are different from each other, so you can easily find the right candle. High-voltage candles are covered with a ceramic caftan.

- Collector. This is a thick tube from which wiring is supplied to each burner. When the flame of one of them is extinguished, the rest will continue to work.

- Distribution armature. Each ignition electrode is connected to single high voltage wires.

- Capacitor, thyristor, diode and fuses. These details are located inside the plate. They work when the charge needs to be formed due to a surge of energy from a candle.

Setting the gas stove to a different type of gas

The gas is endowed with two significant characteristics:

- The calorific value is determined by the composition. Higher content of methane, lower parameter. For natural gas, the calorific value is predetermined by the field of extraction of the natural resource.

- The pressure is determined by the type of gas. Liquid requires higher. For the main line, the typical value is 13 mbar. The parameter ensures the correct operation of solenoid valves, injectors, burners.

If the pressure is too high, the gas burns incompletely, soot, orange flames will appear. The system may not work correctly. I have come across instructions recommending the use of a reducer in order to obtain balloon 13 mbar. There are probably limitations. It is not for nothing that it is recommended to put two cylinders in parallel

Please note that the main gas is actually liquid, supplied through a reducer. It is pumped from tanks into tanks from which houses are supplied

Find out the connection diagram of the house at the place of residence.There is natural gas distributed centrally, having lower cost, pressure, calorific value. The pressure is assumed to be 13 mbar. It is necessary to take into account the aspect when installing and repairing a gas stove.

The reason to call professionals for installation and configuration is that the wizards know the parameters. Of course, the person with the certificate is also aware of local conditions. Now imagine what happens if you unknowingly connect the equipment incorrectly! It's gas, stop joking. Especially for the outback, where neighboring houses may have different connections. It is recommended to buy a set of replacement injectors for a different gas pressure. They described the process of self-boring jets, mentioned: the law prohibits reworking. Work is unsafe. Before buying, ask the gas service for the parameters, ask the store if the equipment is suitable. It's not too late to start making inquiries at the next cleaning. Not the fact that everything is done correctly.

How to adjust jets. Change the size of the center hole. Less pressure, the hole is taken more. Verticality and alignment must be maintained, otherwise the gas will bleed to the side, which will lead to an accident. It is appropriate to recall that in the old Soviet gas stoves, the jets are hidden in depth. The design of the burners is unusual. Between the nozzle and the divider is a tube with a pair of ears attached to the frame. There is one ram for every two burners. In pairs, the pipes are fastened with ears inside the body. A bowl with a nozzle is placed at the lower end, a divider is inserted into the upper end. The gas stove works due to the jet stream. Propane-butane is heavier than air.

Electric stoves today and for summer residents look like a more appropriate option.

Product cleaning and maintenance

To prolong the operation of the gas oven and prevent its breakdowns, regular preventive maintenance should be carried out.

Do not neglect the instruction manual for the product, it is important to follow it clearly. Meals should be cooked according to the recommended temperatures for them.

It is important to know the design of the gas oven components, follow the instructions for washing and lubricating the connecting elements.

After cooking, clean the walls and bottom of the oven from burning

All dirt and food debris must be removed immediately.

Observe safety precautions when using a gas oven. Do not leave the stove unattended, do not make the ignition modes so large that are not described in the instructions.

In order for the internal parts of the oven to remain intact, not to oxidize, after washing the oven, you need to dry them well or wipe them dry.

For washing, use only high-quality household chemicals, as cheap products will spoil the inner coating: they can harden the seal, destroy the enamel, or scratch the glass of the door (read about glass damage and repair here, and how to repair the doors is described here).

Ovens are considered reliable appliances. If the device is broken, the help of the master is not always required. Some faults can be fixed by yourself.

The control unit of the plate, the automatic ignition unit, flew out of order

If everything is in order with the electrode candle and wire, the malfunction lies in the unit itself. Probably one of the channels is damaged.A breakdown of the electric ignition unit is indicated by a too weak, intermittent yellowish spark or the complete absence of a spark on all electrodes. You can check this fault yourself by turning on the ignition in the dark.

If the spark, as I said, is orange-yellow, then the block is 99% worn out. The assembly is located inside the slab and repairs require disassembly. It is unlikely that you will be able to resolve this issue on your own. After replacement, the spark will become correct, bright blue

Please note that the unit cannot be repaired, it must always be replaced

Gas stove maintenance

In order to maintain the kitchen equipment in good condition, it is necessary to regularly inspect the product.

After using the appliance, daily clean the burners and the hob of the unit from dirt.

Cast iron burners can be cleaned with a fine-bristled metal brush. At the same time, for effective removal of contaminants, a teaspoon of baking soda can be added to the detergent. Special products should be used to clean metal plates.

After carrying out preventive maintenance, the device should be wiped dry.

If during the operation of the plate, the adjusting knobs began to sink or turn hard, it is necessary to lubricate the plugs of the levers, as well as clean the rods from contamination. To do this, it is necessary to dismantle the plastic elements of the taps and the front panel of the gas appliance. Then, unscrewing the mounting studs that fix the stem, one by one, remove the valves. After that, pull out the spring and cork mechanisms, carefully cleaning them from dirt.

In order to avoid damage to the element and, as a result, gas leakage, it is strictly forbidden to remove dirt from the plug with sharp objects.

Cork mechanism, after cleaning, can be treated with graphite grease

However, in the process of performing this procedure, extreme care must be taken not to close up the passage holes of the element. After the restoration of the cork, it is necessary to clean the stem from contamination. The assembly of the control valve should be done in reverse order.

Namely: insert a plug into the tap, then a spring, securing the stem with a pin

The assembly of the control valve should be done in the reverse order. Namely: insert a plug into the tap, then a spring, securing the stem with a pin.

After carrying out the maintenance of the plate, the plastic levers and the front panel of the device should be installed in their original place.

Thus, the above recommendations will help to identify and eliminate problems that often occur during the operation of gas equipment. At the same time, many malfunctions can be eliminated with your own hands. However, if it was not possible to fix the breakdown on your own, you should contact the service center for help.

The smell of gas

The appearance of the smell of gas is one of the most dangerous troubles that can lead to an explosion, fire, and poisoning. It indicates a depressurization of the fuel supply system and can occur both when the equipment is turned off, and when it is turned on or during operation.

The first thing to do in such a situation is to turn off the gas supply and ventilate the room! Only then can you start examining your stove.You may not be able to fix the breakdown on your own, but you can identify the source of the leak.

The smell of gas occurs when the stove is turned off

Soapy water will help to determine the place of depressurization. Apply it to all joints of pipes and hoses, both outside the stove and inside it. Where there is leakage, bubbles will appear.

To understand how to fix this type of failure, you need to determine the type of connection. If the threaded connection is depressurized:

- disassemble the damaged assembly, check the integrity of all parts by cleaning them from winding or old sealant;

- apply fresh sealant or make a new winding;

- collect all parts and recheck.

If the connection with the gasket is depressurized:

- disassemble the leaking assembly;

- install a new gasket;

- collect the parts and retest.

The smell of gas occurs during the operation of the stove

The most common cause of this type of malfunction is incorrect flame adjustment. Less commonly, the problem is a breakdown of the connections that connect when the stove is turned on:

- nozzle installation points;

- places of connection of tubes from taps to nozzles;

- joints between tubes and nozzle bodies.

In order to determine the leak in this case, it is necessary to remove the burners, remove the cover, reinstall the burners in their places (without the cover), apply soapy water to the joints and carefully light the burners in turn. Be careful: bubbles will appear at the leak point, indicating a depressurization

The reason for such a malfunction may be the destruction of the sealing washers on the nozzles, too loose tightening of the connections, a defect in the sealing ring at the points of attachment of the tubes.

If you inspect the stove and do not find a leak, the cause of the smell may be improper connection of the equipment to the gas source. In this case, do not try to fix the situation yourself. You need to call a specialist!

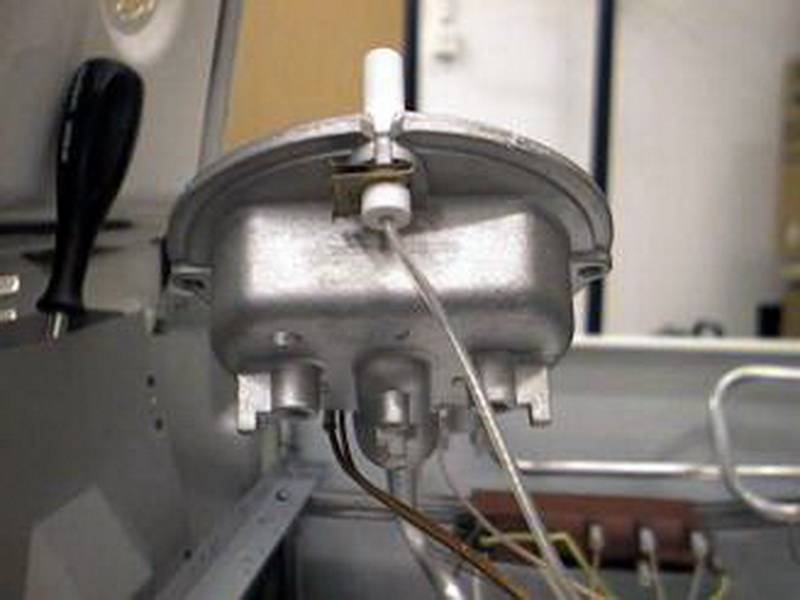

Thermocouple malfunction

The gas control function is a good contribution to the safe operation of the oven. If the burner goes out after releasing the knob, this system is probably broken. The fact is that the device is turned on by pressing and turning the knob. Automatic ignition ignites the burner, where there are special sensors - a thermocouple.

In turn, when the thermocouple is heated, millivolts are generated. This charge is directed along the entire actuator to the solenoid valve, which is magnetized and held open. This happens as long as millivolts are generated. If the burner does not heat the thermocouple, the valve will almost instantly shut off the gas supply, so the extinction of the flame after releasing the knob indicates a breakdown of the gas control.

Gas stoves with oven gas control

What can happen:

- The tip of the device has moved (up or down) causing insufficient heating. You can fix the problem by setting the tip exactly in the flame;

- thermocouple tip is dirty. There may be a complete failure of work or poor heating. This issue is resolved through cleaning;

- breakage of the thermocouple tip - the rod overheats due to high temperatures and a break is obtained;

- safety valve malfunction - the valve cannot open due to voltage problems.It requires the replacement of the gas valve with the entire mechanism. Only the gasman changes this thing.

A new thermocouple can be purchased at a specialty gas supply store. All devices differ in length and connection nut.

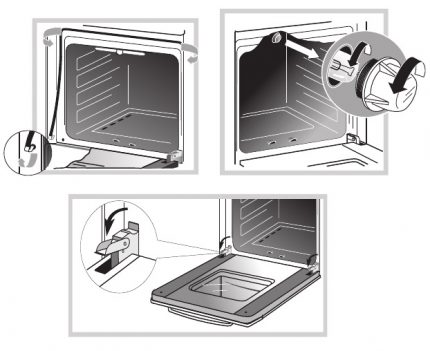

How to eliminate?

Most often, in case of violations in the operation of gas ovens, the owners are in no hurry to contact specialists, hoping to carry out repairs on their own. What breakdowns can and safely be repaired with your own hands? More on this below in our article.

- Cleaning the regulator knob. Shut off the gas supply before starting repairs. Troubleshooting starts with cleaning the faucets. After removing soot, dirt and grease from them, the spring is cleaned. The cork is wiped carefully, so as not to damage it. Violation of the surface will cause gas leakage. Use only a soft sponge. Next, the cork is treated with graphite grease, without touching the holes. The greasy coating is removed from the rod with a knife. After assembling the handle in reverse order.

- How to fix oven doors. Over time, the fasteners of the oven door become loose, then it does not fit snugly or does not close. To fix the problem, unscrew the fastening screws connecting to the plate. Having loosened them well, move the door in different directions until you find the position in which it has sat firmly on the hinges. To control, place a sheet of paper between the seal and the edge of the oven. If it does not clamp well, do the procedure again. After installation on the hinges, the bolts are tightened into place.

If it is noticed that the loss of heat is associated with damage to the seal located around the perimeter of the door, it will not be difficult to replace it.

- Remove the old seal.In some oven models, it can be attached with screws, to get to them, pull off the protruding edge of the rubber, in the rest it is glued.

- Wash the channel and door with liquid detergent. Clean off the remnants of old sealant or glue. Degrease.

- Install a new seal, starting to mount it from above, then down and to the sides. Finish the process by joining the edges at the bottom center. If the elastic needs to be glued, choose a food-grade heat-resistant adhesive up to 300º.

Among other breakdown options.

Checking and cleaning the thermocouple. The oven burns as long as you hold the handle - then you need to check the fastening of the thermocouple. In the lowest position, it should touch the tongue. In case of incorrect placement in most models it is allowed to adjust with screws. It is possible that the thermocouple contacts are dirty and this interferes with the maintenance of the flame. Try sanding the part with sandpaper.

The main causes of failure

Malfunctions and their causes:

-

The smell of burning appears during the inclusion in the mains. In this case, you must first check the plate visually. To do this, turn it off from the mains, inspect the burners. If the reason is in the accumulated and burning food residues, they are removed, the surface is washed well.

If the plates are clean, but the smell of burning is still emitted from the equipment, then the problem may be a wiring fault. You need to call the master or try to repair it yourself.

- The heating element stops heating up. The cause was the connecting wires or the burner. First, they check the control details, in which the contact often flies. If this does not help, you need to completely replace the heating element with a serviceable one.

- Due to a broken switch, it is not possible to set the required temperature for heating the burner. The reason is the displacement of the contacts, their disconnection.

- Problems with the spiral are detected with poor heating of the burner or its absence. The coil can be damaged due to overheating, rupture, or moisture ingress.

- The oven may heat unevenly or not reach the desired temperature. In this case, the matter is in the heating elements. Repair or replacement is necessary.

Important

You can repair glass-ceramic stoves on your own if you study the instruction manual well and know the structure of the electric stove. Otherwise, you need to call a specialist at home

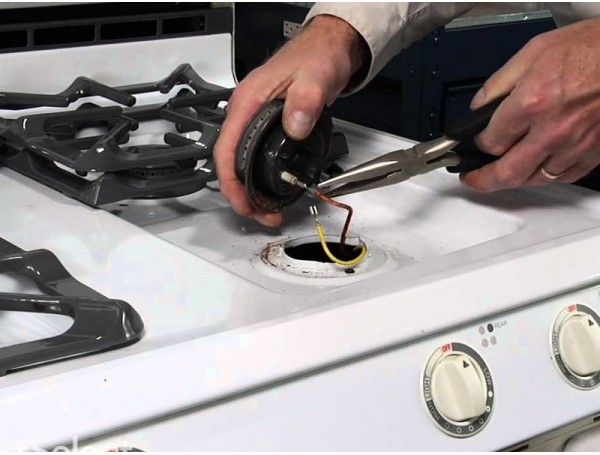

Ignition gives a spark, but the burner does not ignite

In cases where the electric ignition gives a spark, but the burner does not ignite, it is necessary to try to replace the thermocouple. Sometimes the problem is related to the solenoid valve, and after updating it, the equipment works as normal. You should check the ignition unit, because if everything is fine with it, but ignition does not occur, you need to look for a problem in the power wire or burner candle.

If a spark is applied, the flame ignites, but immediately dies out, try holding the gas button for a longer time. It is likely that the sensors responsible for the formation of a flame simply do not have time to warm up.

What to do if the oven stops working

Electric oven device

If the owner is guilty of a breakdown or the warranty period has expired, there are 3 options:

- fix the problem yourself;

- find a private master;

- contact a post-warranty repair company.

The choice is made after self-examination. It happens that failures in the work of repair do not require.The equipment may stop working due to a door not tightly closed, the cord being accidentally pulled out of the socket, power outages.

If the model has an electronic display, the cause of failures may be a stuck button or a long press on it. The error is determined by the codes, they can be eliminated independently after a detailed study of the instructions.

If the heating element is faulty, the food is cooked for a long time, the element is pale on one side and not hot (it is checked after turning it off by touching the hand in the oven mitt). It is impossible to determine the breakdown of the thermostat on your own. A malfunction is indicated by an increase in the cooking time at the set temperature.

If the timer fails, the electrical module burns out, the contacts are damaged, you cannot do without a master. Replacing these parts is not expensive. Another thing is the block. Its cost is quite high, so replacing it is slightly cheaper than buying a new oven.

If the equipment is gas, then only two reasons for poor performance can be eliminated on your own: burner contamination and replacement of the door seal. If the burner is at fault, the fire is not evenly distributed. You need to remove the baking sheet and clean all the holes. If the door is to blame, then the hand substituted for it feels hot. The seal is inexpensive, anyone can change it.

In case of problems with gas equipment, it must be remembered that the gas is explosive, therefore, in case of any serious malfunction, it is better to contact specialists. The rules for the operation of this type of device do not provide for their independent installation and repair.

The oven does not work - the main reasons

Before calling the master to repair the oven, you should check if there is a gas supply in the pipe. To do this, try to light the burner on the hob. If gas enters the burner, then the oven is really faulty.

The second point that you should pay attention to is the presence of electric current in the network. Without it, the electric ignition will not work.

If everything is normal, then the oven is really faulty. Do not attempt to repair it yourself. Without the necessary spare parts and experience, this will be very problematic and even dangerous.

The main malfunctions of gas ovens for Gefest, Hansa, Mora and others include:

- When the ignition button is pressed for a long time, a hiss of gas is heard, but the flame does not ignite.

- The flame caught fire, but after releasing the button, it immediately fades.

- The flame burns for 5-10 minutes and goes out on its own for no apparent reason.

- The flame is very weak. The food cannot be cooked.

- The flame is very strong and it is impossible to regulate it. The food is on fire.

- The gas supply valve cannot be turned on.

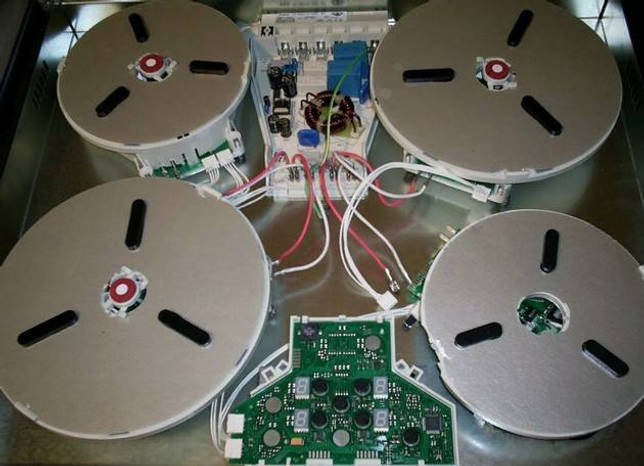

Diagnostics and restoration of indirect heating panels

Repair of induction hobs is only possible for experienced electricians. Without knowledge of the material, with a simple multimeter and pliers, the operation is doomed to failure. At the same time, many problems are not malfunctions at all: a common violation of the operating mode.

Typical malfunctions of induction heating systems

- The induction hob either does not turn on at all, or the power disappears immediately after the start of work. This may be a protective function: if you remove the dishes from the heating surface, or the size does not match the diameter of the burner, the automation blocks the work.The same applies to aluminum or copper cookware.

- The same problem (wrong cookware) can cause the induction hob to not work at full capacity.

- Independent turning on of the heater may be due to contamination of the stove, or the presence of a massive steel (cast iron) object next to it.

Real faults that are not associated with a violation of the operating mode appear in the circuit of the inductive field generator. As we have already noted, the winding fails extremely rarely.

Typical diagram in the illustration:

In fact, there are no space technologies here. The transformer converts the supply voltage, and the generator creates an increased frequency of oscillations of the electromagnetic field. After a visual inspection (for clearly “burned out” radio elements), the generator is checked using a home oscilloscope. If you have such a device, it makes no sense to explain the principle of checking the inductance generator, your level is sufficient for repair.

If you do not have enough experience, you will have to contact the masters. In any case, repairing a single unit is not as expensive as buying a new panel.

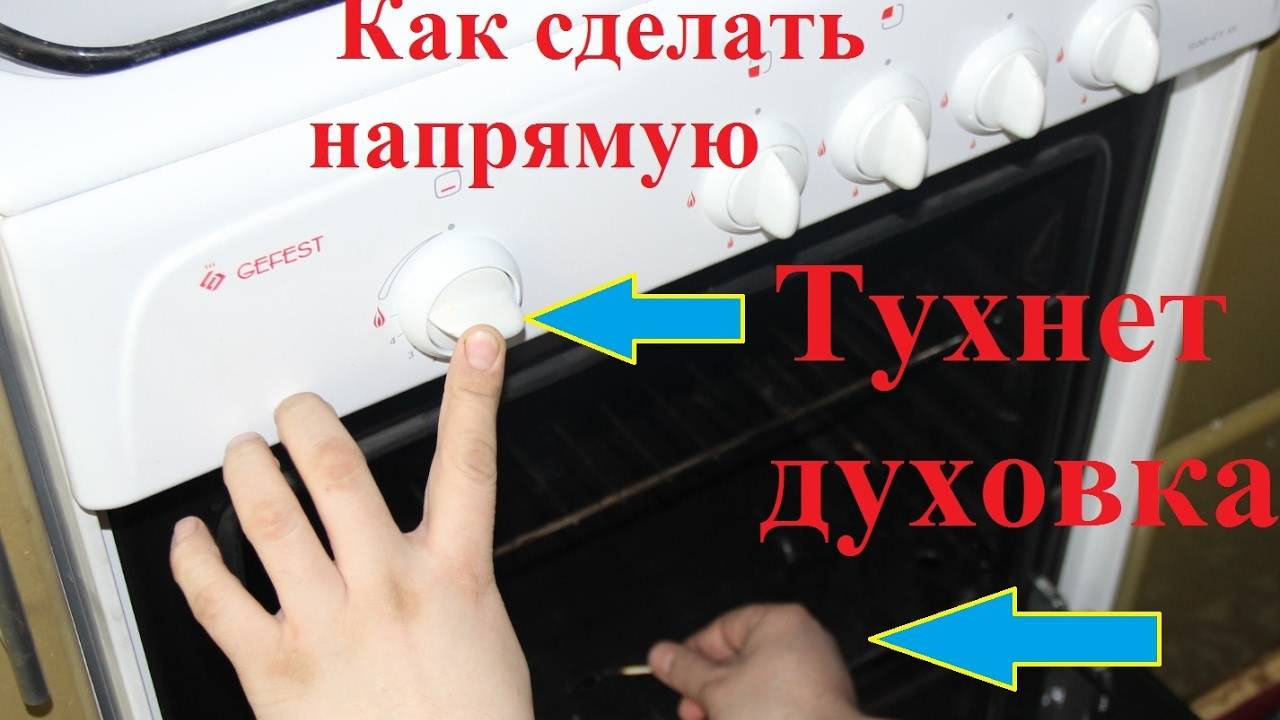

Why does the oven go out?

When operating gas ovens, there are often problems with gas control. To ignite the oven, it is enough to bring the flame to the cabinet opening through which fuel enters or use auto ignition, most modern models have this option.

A thermocouple is located next to the burner. If the flame goes out or does not light up at all, this means that the gas supply is blocked. The valve or thermocouple may need to be replaced. How to check their serviceability, we considered in the previous section.

Problems with the operation of a gas oven can occur due to too tight fitting of the doors, resulting in a lack of oxygen

Problems with the operation of a gas oven can occur due to too tight fitting of the doors, resulting in a lack of oxygen

First of all, you need to make sure that there is no blockage in the nozzle hole through which gas is supplied. Food particles often get into the plate part during cooking.

For cleaning you will need a soft thin wire. Insert it into the nozzle opening with a twisting motion. It is undesirable to use rigid steel wire, as a result, you can get a "roaring" burner. Not suitable for this purpose and a thin needle that breaks easily.

The design of the gas stove oven. The location of the grate, baking tray and other baking or grilling accessories can be adjusted

The design of the gas stove oven. The location of the grate, baking tray and other baking or grilling accessories can be adjusted

The flame in the oven can also go out due to low gas pressure. This can be determined by the insufficient height of the crown of the flame, the fire may go out after a while. Weak combustion and poor gas supply may be due to the hose supply to the stove, which is pinched or kinked. The hollow pipe is behind the stove.

Gas oven goes out also when you release the button due to the tight fit of the oven door. You can get rid of the problem by simply increasing the access of oxygen to the oven.

Flame problems also arise for other reasons that are not breakdowns.

Why the oven in the gas stove often goes out:

- Modern stoves have a gas control system. The sensor stops the gas supply if there is no temperature increase. The regulator does not work immediately, so try holding the gas on knob for about 15 seconds, to speed up the heating of the sensor and ignite the oven, unscrew the knob to the maximum.

- Problems with ignition of the oven may occur after washing the oven. Burner misalignment can be identified by an uneven orange flame. If the part is installed incorrectly, the oven starts to smoke.

- The gas control system responds to a decrease in the intensity of the flame with a drop in gas pressure in the pipeline, which shuts off the fuel supply. This situation is common when using bottled gas. It is necessary to fill the container or replace it with a new one.

Weak burner flame in the oven can also be due to difficult turning of the handle. This can happen as a result of a stuck gas valve.

When checking the gas valve, you should pay attention to the remnants of the factory grease, sometimes this is the cause of the stove malfunction. If necessary, the part can be treated with grease: LG-GAZ-41, Germeton, Klad-M, LS-II are suitable for old-style plates; in modern models it is better to use Molykote 1102 and Germetil. It must be disassembled, cleaned of clogs and lubricated

If the faucet is damaged, replace it with a new one.

It must be disassembled, cleaned of clogs and lubricated. If the valve is damaged, replace it with a new one.