- Error f33 vaillant how to fix and what to do?

- VALIANT (Vailant) - Error F.62: malfunction of the combustion shutdown delay (the presence of a flame for more than 4 seconds after turning off the gas valve)

- Features of operation and diagnostics

- Setup and management

- What caused the malfunction

- Chimney

- Advice

- Fan

- Differential relay

- The reasons

- Possible malfunctions that do not happen so often

- Popular malfunctions of Vaillant gas boilers

- Causes of problems

- First steps

- Prevention

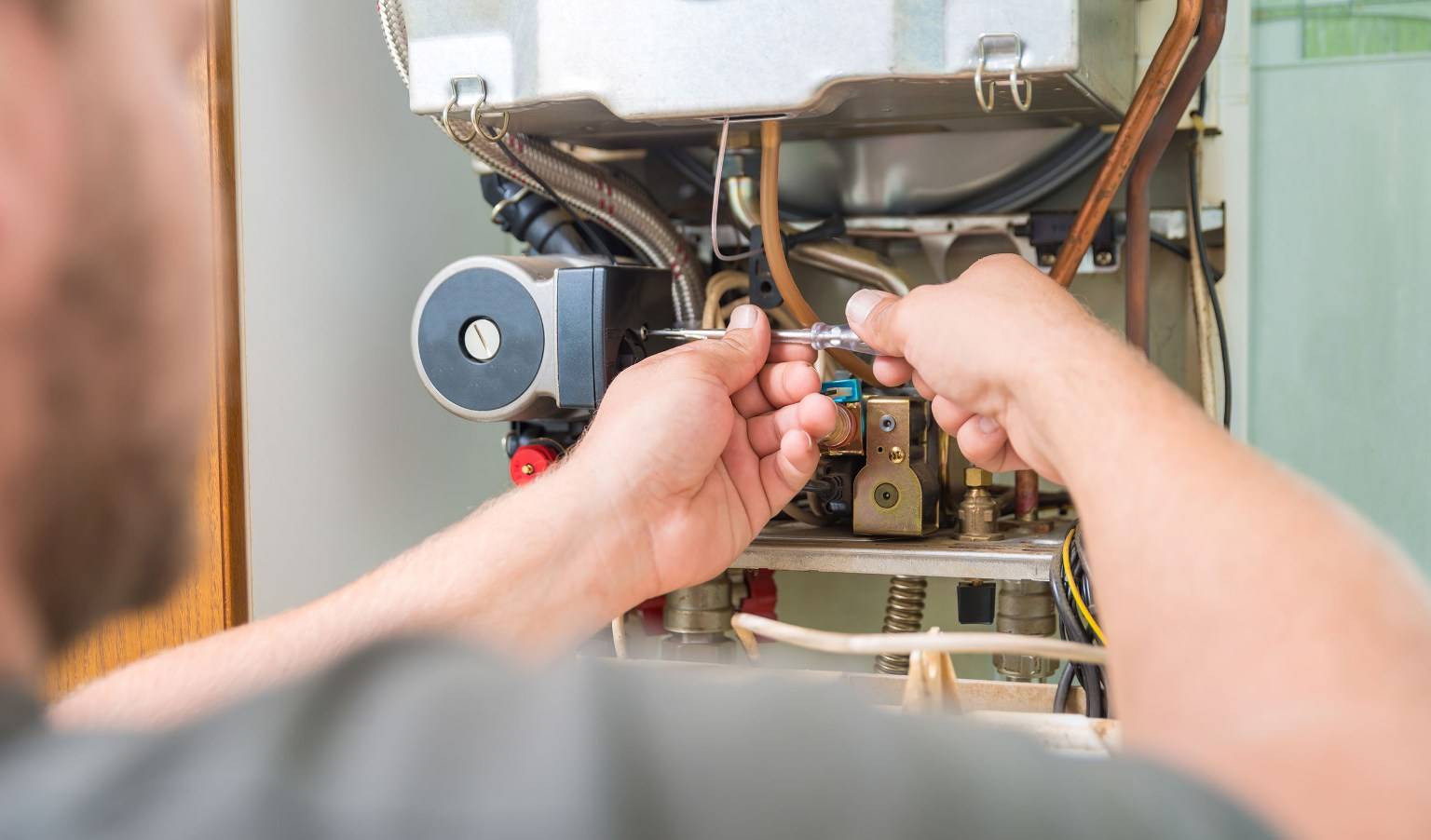

- Boiler cleaning

- Fight against deposits and scale

- Expansion tank service

- Burner and filters

- Connecting a room thermostat

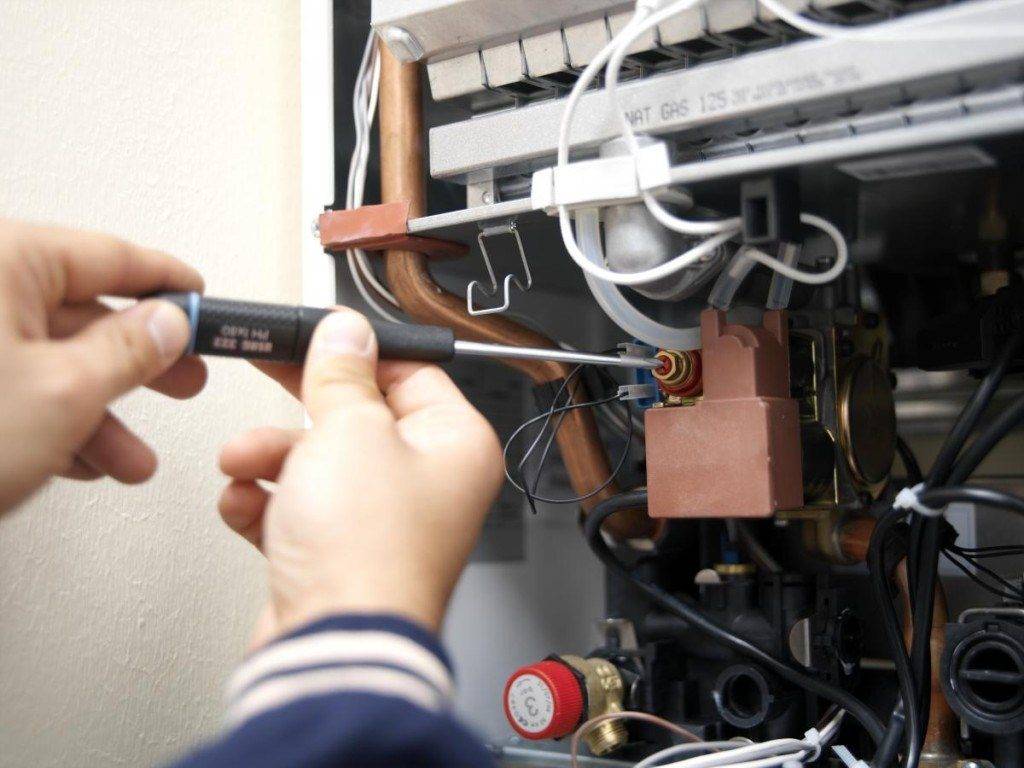

- Ignition transformer

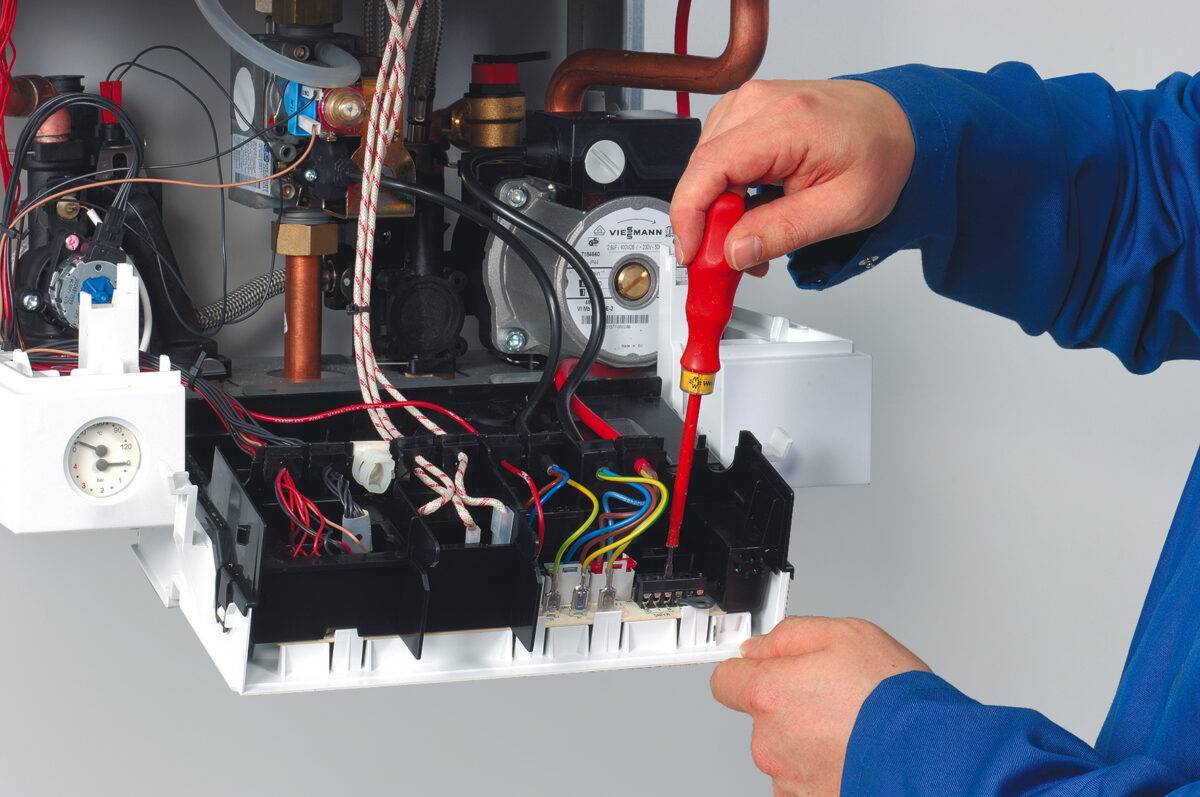

- Control board

- Helpful Hints

- Types of manufactured boilers

- single circuit

- wall

- floor standing

- Helpful Tips

- How to proceed

- EPU

- How to proceed

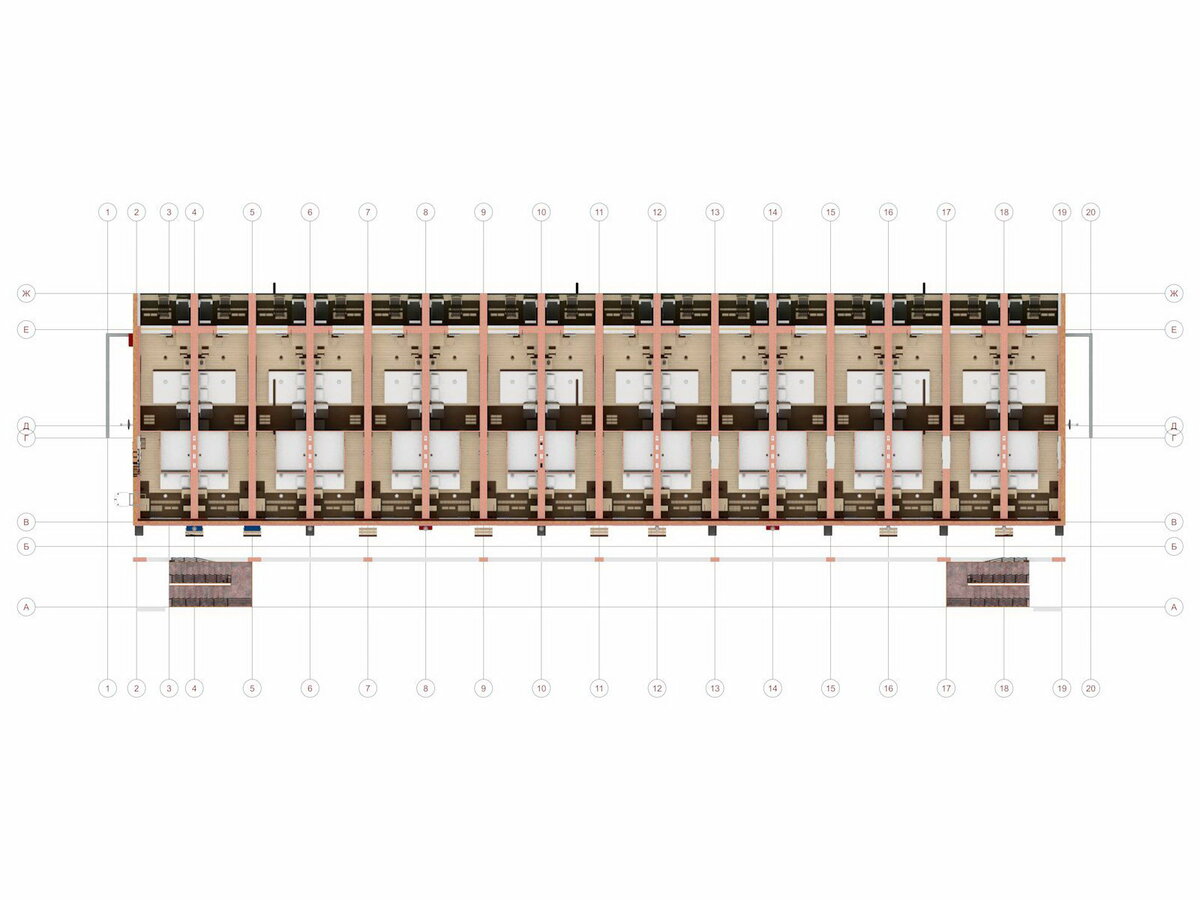

- Vaillant gas boiler installation

- Overview of Less Common Mistakes

- Features of Vailant boilers

- Conclusion

Error f33 vaillant how to fix and what to do?

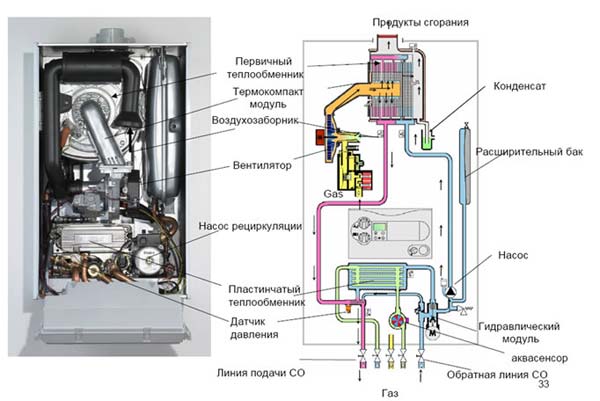

Occurs only in turbocharged boiler models. The source of the error is the pressure switch in the exhaust pipeline. The logic of operation of all modern gas boilers is approximately the same. When a request for ignition is received, the control board turns on the fan (exhaust fan), which creates a vacuum.When the required thrust is reached, the contacts of the differential relay close and thus a signal is transmitted to the board to open the gas valve and ignite the burner. Accordingly, if there is no signal from the relay or it is in a closed state after the fan is turned off, the vaillant automation generates an error f33.

Vaillant boiler error f33 the reasons:

-

fan does not work (can be checked visually)

-

failure of the pressure switch (condensate may accumulate in the tubes, which drains into the sensor, renders it unusable;

-

error when installing the exhaust pipe (condensate can also accumulate and flood the relay)

-

clogging of coaxial pipelines, preventing normal air flow

-

blockage of the pitot tube (accumulated dirt or insects)

You can check the operation of the relay by creating a vacuum through the tube yourself (a characteristic click should occur). It happens that the relay “sticks”, i.e. in the normal state, it will be closed, which can be checked with a conventional multimeter. In this case, it will have to be replaced.

It happens that the tubes themselves or the Pitot tube are damaged, for example, from exposure to high temperatures.

The slightest change in shape can affect the readings and be the cause of the F33 error.

It is worth noting that this problem is almost all gas boilers. Some manufacturers solve it by installing a special widening (as BAXI did) to collect condensate, and some even make heated tubes to evaporate it.

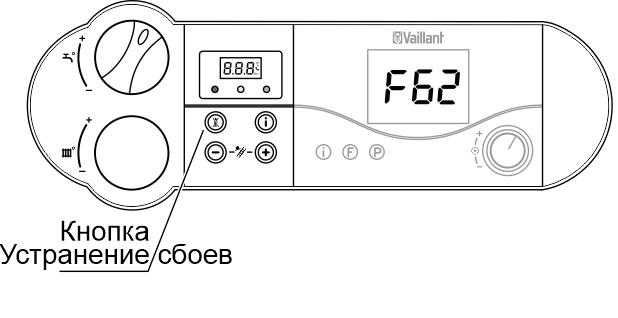

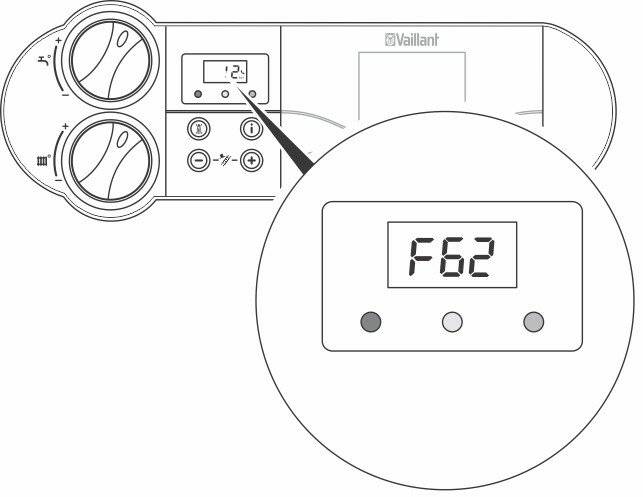

VALIANT (Vailant) - Error F.62: malfunction of the combustion shutdown delay (the presence of a flame for more than 4 seconds after turning off the gas valve)

Malfunctions in the electrical network of the boiler: we reboot the boiler - there is a corresponding button on the panel of Vaillant gas boilers (a crossed-out flame symbol or the RESET designation).

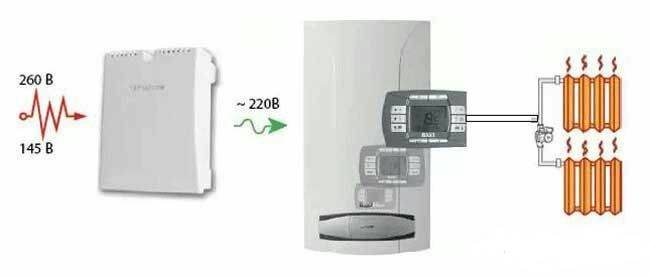

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

The ionization sensor and / or electrode are faulty: if the boiler ignites and a spark passes, the boiler ignites and goes out - this means that the flame control electrode (ionization sensor) “does not see” the flame.

Depending on the type of boiler, the ionization electrode is installed separately or already in conjunction with the ignition electrode.

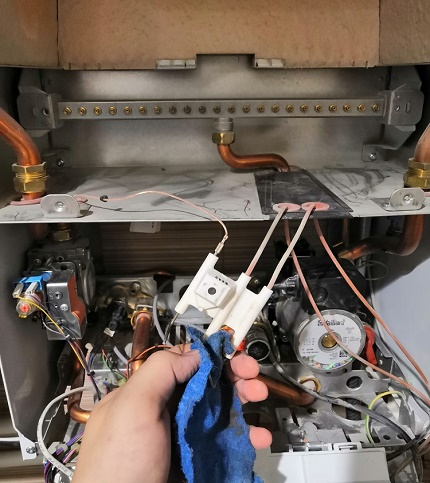

Often the electrodes become contaminated with soot and burnt dust, and it is often enough to wipe with your fingers, and the operation of the boiler is restored. If the electrode has not been serviced for a long time, you need to clean its tips with an abrasive sandpaper with a minimum grain.

Nozzle contamination: the holes are clogged with soot, soot, cleaning them quite often eliminates the error. It is done with a toothbrush and a vacuum cleaner. Not only the burner is processed, but the entire chamber (walls), heat exchanger.

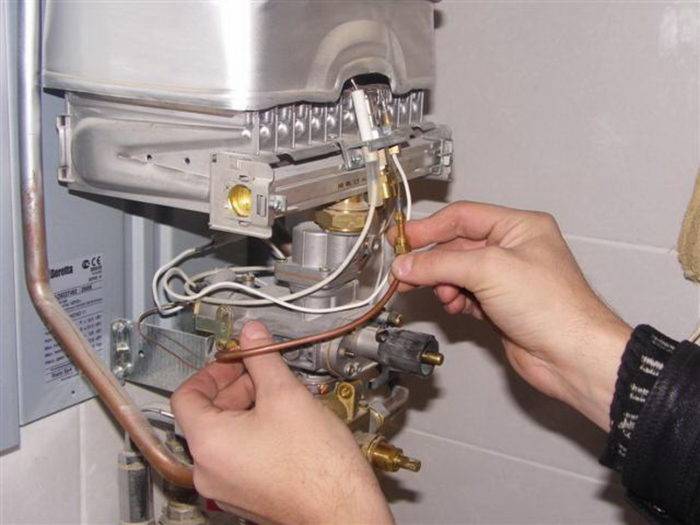

The gas valve is clogged / faulty: it is not difficult to disassemble it yourself, but it is highly undesirable because:

- Vaillant connectors have miniature latches. Users often break them when dismantling the valve from the boiler.

- A special lubricant is applied to the stem. Which one exactly is not an idle question.

- It is possible to reset the setting of the Vaillant fittings for the gas pressure at the inlet to the boiler burner.

But if you still decide, then after dismantling the stepper motor and removing the cap, you can see the rod, which is responsible for moving the membrane that regulates the gas supply to the burner of the Vaillant boiler. In the process of work, it becomes dirty, and layers interfere with its free movement.It is enough to rinse in any alcohol-based liquid, put in place and reassemble in reverse order.

Malfunction of the modulation coil / ignition transformer: its serviceability can be judged by the absence of a spark between the electrodes and the burner during ignition. If you have experience, you need to ring the winding with a multimeter to detect a break.

Thrust sensor: in a number of models of Vailant boilers, flame control is two-stage: by ionization current and exhaust gas temperature. A high value of t0 is evidence of burner operation. If the sensor characteristic “floated” during operation, error f62 appears. The device is inertial, the response time is from 1 to 2 minutes, but it is not worth excluding it from the number of "suspects". It cannot be restored, it changes.

Malfunction of the electronic board: go to the menu and look at the symbolism on the display: the letter S and numbers.

Inspect the board for damage (oxidation, dark areas, moisture, characteristic smell of burnt tracks and modules, remove excess dust), all operations with the board must be carried out with antistatic gloves.

Features of operation and diagnostics

During the connection, operation and maintenance of the Vaillant gas heating boiler, some malfunctions may occur. Models that have an electrical control system with a screen make it possible to understand what specifically does not work in a given situation.

To understand what to do in certain cases, consider the common error codes for the Vaillant gas boiler, and what needs to be done if they occur. If several errors occur at the same time, they are displayed alternately for approximately 2 seconds.

Icon designations can begin with the letter F (error) or S (status).Technical characteristics and codes that are inherent in each specific model are prescribed in the instruction manual.

Setup and management

Handling Vaillant boilers means competently transferring them from one mode to another. The question often arises of how to properly turn off the heating system for the summer so as not to pay extra money for gas and not overheat the house. The solution to the problem is to close the heating circuit for a short stroke, while using a crane and jumpers.

If the equipment is made according to the scheme with artificial circulation, everything will be even simpler: the circulation pump should be disconnected from the scheme and the boiler inlet should be sealed. Trying to solve the problem by installing additional speakers is impractical and not very economical.

It is important to remember that it will be necessary to ensure a stable temperature by normalizing the flow of hot liquid. It is required to pump up the expansion tank if the pressure level is constantly decreasing and increasing, changing unpredictably

A steady drop in pressure in the system is not so easily eliminated; it is imperative to find a place where the coolant is leaking and eliminate the cause of the problem. The search for defects should be carried out on radiator plugs, connecting lines and where fittings and pipes are soldered.

If pumping the tank does not give results or they persist for too short a time, the tank should be examined. Often its outer shell depressurizes and lets air through. But even more often, the efficiency of the spools is disrupted, which also begin to etch.

The pumping of the tank itself is carried out in the following stages:

- wrap boiler, supply and return valves;

- open the drain fitting until it is completely drained;

- connect the pump unit through the spool, in no case blocking the fitting.

Any type of pump is useful for work; you can take a car and a pressure gauge also from the car. The pumping of air is carried out until the outflow of water from the pouring fitting stops. Further, air is released and its introduction is repeated, continuously monitoring the readings of the pressure gauge. It should show 1.1–1.3 bar, more accurate information is given in the technical documentation. Now you can close the pouring fitting, open all the taps that were previously turned on, feed the boiler in the standard way up to 1.2–1.5 bar, and then start warming up.

It is especially important to control internal pressure if the house or other structure is visited only periodically. It is no secret that the stability of power supply is now far from ideal.

And if the power stops, the boiler stops working, so the pressure inside the tank may drop due to cooling below what is needed for the boiler to work. Even after the power supply is restored, the boiler cannot heat the house, because soon the uncontrolled house presents a sad sight - pipes and radiators torn from ice everywhere. Therefore, pressure control in the expansion tank must be constantly monitored. No less bad is the situation in which the level of pressure is constantly increasing. Of course, a well-chosen and correctly installed safety valve corrects the matter to some extent, but it is better not to rely on it, since this is still more of an emergency measure. It is always worth remembering that pressure control deserves increased attention.

What caused the malfunction

Chimney

Error f33 is often encountered by object owners who do not adhere to manufacturer's recommendations for arrangement exhaust tract. Violations of the requirements of the instructions negatively affect traction.

The reasons

-

Illiterate project: discrepancy between the values of the length, cross-section of the pipeline, the slope angle of the route, the number of turns.

-

Violation of the tightness of the channel is the cause of the error f33 of the Vaillant boiler. Check the connections, fix the flaws, and the code will be gone.

-

Wrong choice of installation location for the condensate trap or its absence.

-

The wind rose has not been taken into account. With such a miscalculation, the error f33 of the Vaillant boiler appears regularly when changing direction, gusts. The draft capsizes, the unit “blows out”.

-

Connection of Vaillant to the chimney available in the house. If the channel ensured the stable operation of another boiler, this does not guarantee that it will be the same with Vaillant. The calculations must take into account the type of heating installation, power.

-

Fluid in a pipe. It is often the case that the chimney exits the building in close proximity to the roof drainage system. Moisture floods the channel, it blocks, the boiler stops with fault code 33.

-

Icicles on the pipe, icing. There is no traction or it drops sharply, hence the error f33.

-

Hoarfrost, dust on the filter grid of the coaxial chimney.

-

Rubbish in the pipe. Cobwebs, fallen leaves, a small bird - anything can get into the channel in the absence of a grate. Cleaning fixes error f33.

-

Low temperature reduces the flow rate of combustion products. Chimney insulation solves the problem.

Advice

Checking the hood with a flame of a match, lighter, candle is pointless. If there is a “wick” deviation, this does not mean that the draft for the Vaillant boiler is sufficient. The sensor is characterized by a response threshold.Such recommendations of "experts" lead to erroneous conclusions, increase the time to search for the cause of the appearance of the 33rd code. Having removed the first knee, it is easy to assess the condition of the pipe through the light.

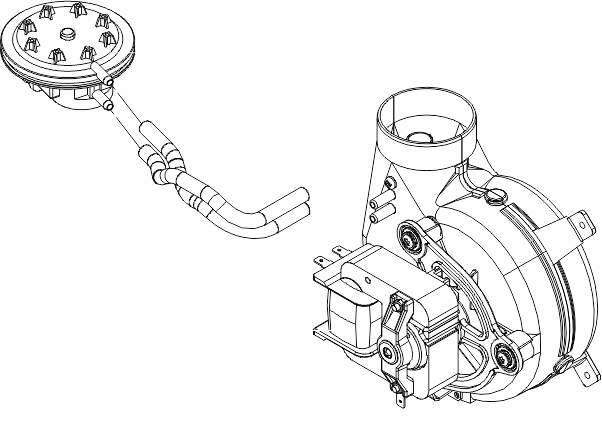

Fan

Its inclusion is evidenced by the characteristic noise and rotation of the impeller. Error f33 appears even when the smoke exhauster is running, if it does not enter the mode. With visual diagnostics, you need to make sure that the speed is normal. The slow rotation of the shaft is reflected in the thrust - it falls, the 33rd fault code is displayed.

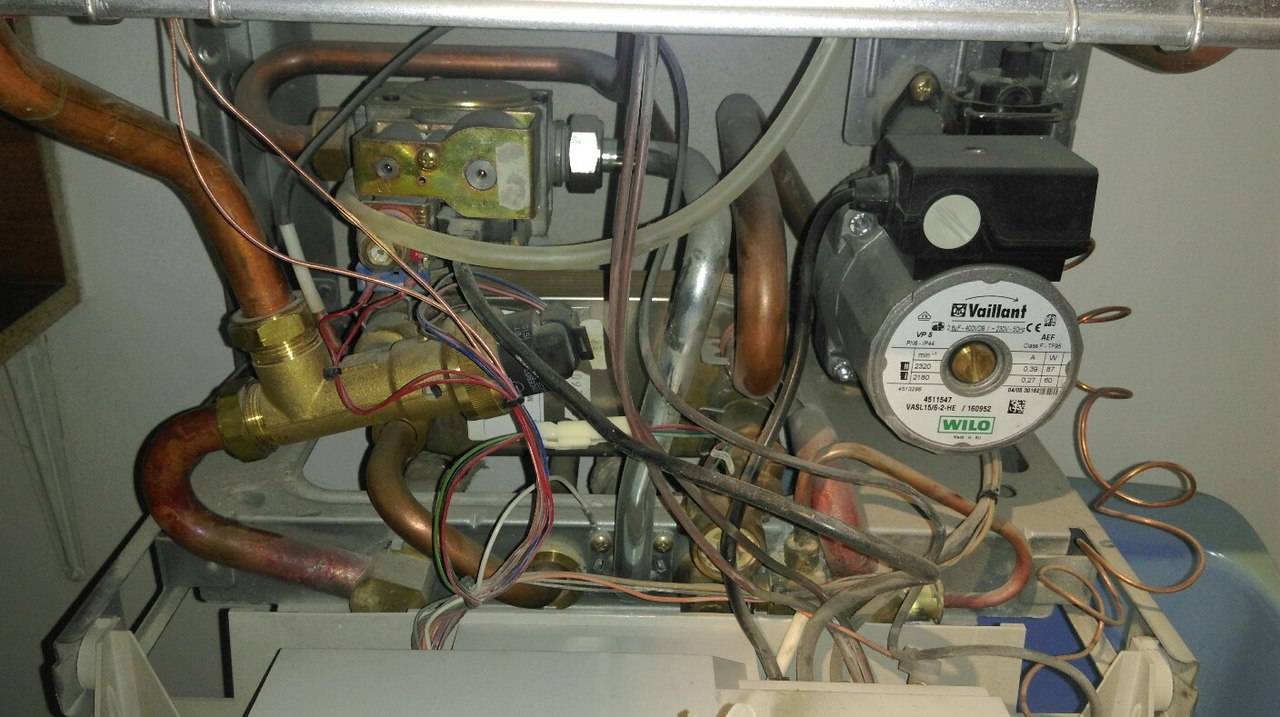

Boiler fan vaillant

Differential relay

The device is triggered by the presence of thrust, which is determined in the Vailant boiler using the Pico device. Here you need to look for a defect that leads to error f33.

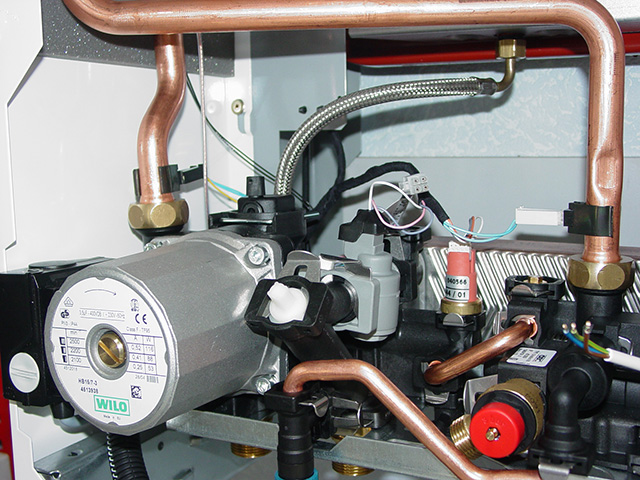

Pressure switch, impulse tube, Viessman boiler fan

The reasons

Clean the tubes of the Protherm boiler

-

Wrong connection. In the process of regulation, the master or user, removing the tubes for cleaning the cavity, inadvertently confuses them in places. A common cause of error f33.

-

polymer deformation. Differential relay, Pico device located in the high temperature area. Constant heating of the material leads to the melting of plastic, bending, and destruction. Check and replace damaged part.

Venturi tube

Advice

In some cases, it will be possible to restore performance. But this measure is temporary until a new device is purchased. If the failure of the sensor is associated with the loss of rubber rubber elasticity due to adhering to the membrane of the smallest particles, knock the housing against a hard surface. The mud will fall off and the problem with the f33 error will be resolved.

Possible malfunctions that do not happen so often

If the required error code is not in this list, it means that only the wizard can handle it.

- F0, F A fault has occurred in the NTC temperature sensor on the flow (F0) or return (F1). It is necessary to check not only the sensor, but also its cable;

- F2, F3, F An NTC sensor malfunction has occurred. Perhaps the plug is not inserted correctly or the sensor itself or the cable is broken;

- F5, F6 (Villant Atmo). The problem with the operation of the sensor, which ensures the safe removal of combustion products. You need to check whether it is connected correctly, or the failure occurred due to a broken cable or the sensor itself;

- F10, F A short circuit has occurred in the flow temperature sensor (F10) or return temperature sensor (F11). Check everything described above;

- F13, F The temperature in the unit has exceeded 130 degrees, and a short circuit has occurred in the hot start sensor. Check everything described above;

- F15, F16 (Villant Atmo). A short circuit has occurred in the sensor responsible for the output of combustion products. Check everything described above;

- F The boiler has overheated;

- F There is not enough water in the device, and the temperature between the flow and return lines is very different. It is worth checking the connection of sensors on both lines, the performance of the pump and cable or board;

- F The problem is similar to the previous one - not enough coolant. Check everything the same as in paragraph 8;

- F The machine has tripped due to an excessively high flue gas temperature. It is necessary to check the NTC sensor, cables and plugs;

- F The boiler reports a flame although the valve is closed. The reason may be a malfunction with the flame sensor or with solenoid valves;

- F32 (condensing boilers). Fan speed malfunctions. Most likely, the problem is in itself, but you also need to check the board, cable and sensor;

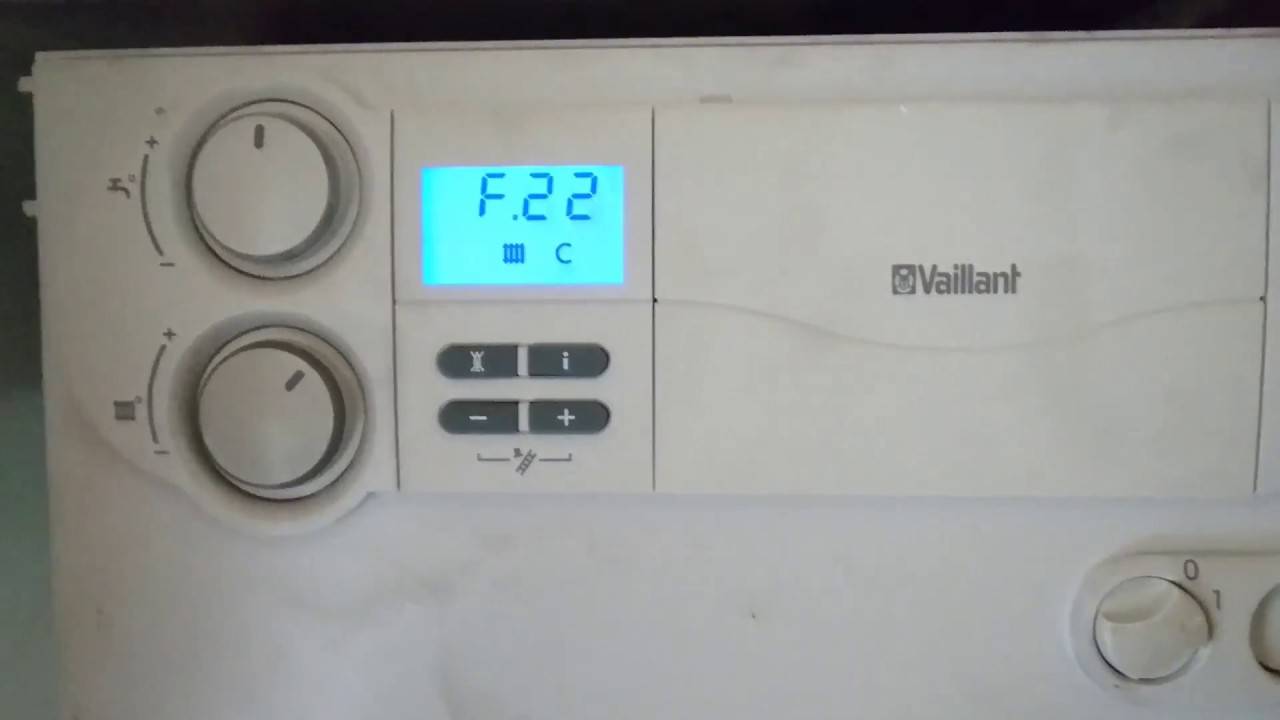

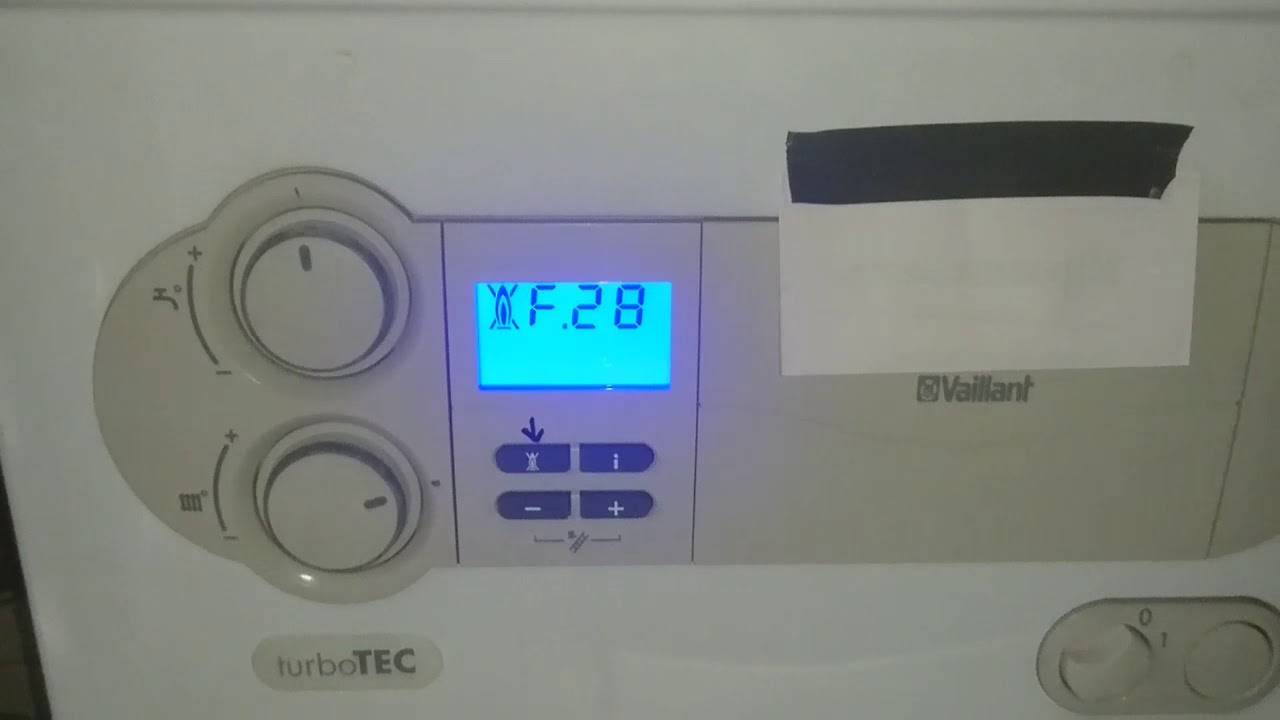

- F33 (Vaillant turboTEC).The pressure switch does not close the contact half an hour after the request for heat;

- F The eBus voltage has dropped. Perhaps it has a short circuit or it is heavily overloaded;

- F No control signal is sent to the valves. It is necessary to check the valves, cable and board;

- F Fault in valve off delay. Check if it passes gas and if the nozzles are clogged;

- F The electronics unit has overheated. The reason is either from the outside, or in a malfunction of the unit;

- F Low water pressure. Either the problem is in the sensor itself, or there is a short circuit in it;

- F High water pressure. The reason is stated above.

Popular malfunctions of Vaillant gas boilers

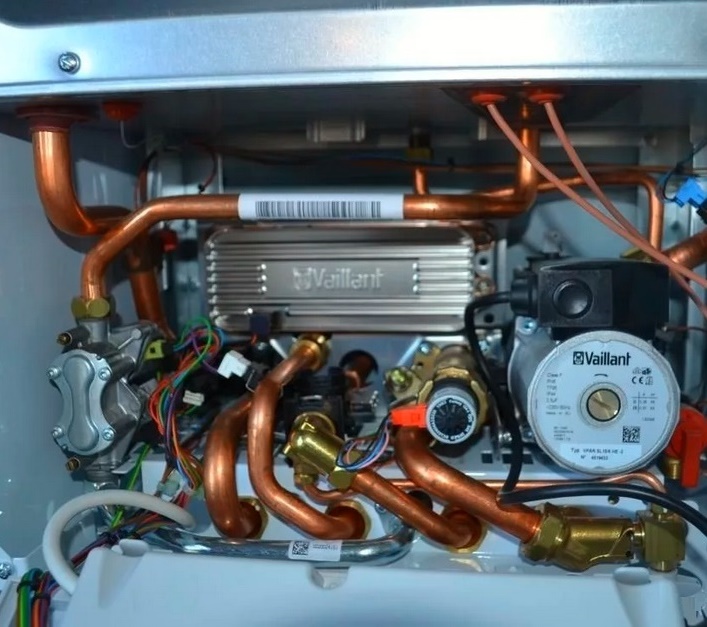

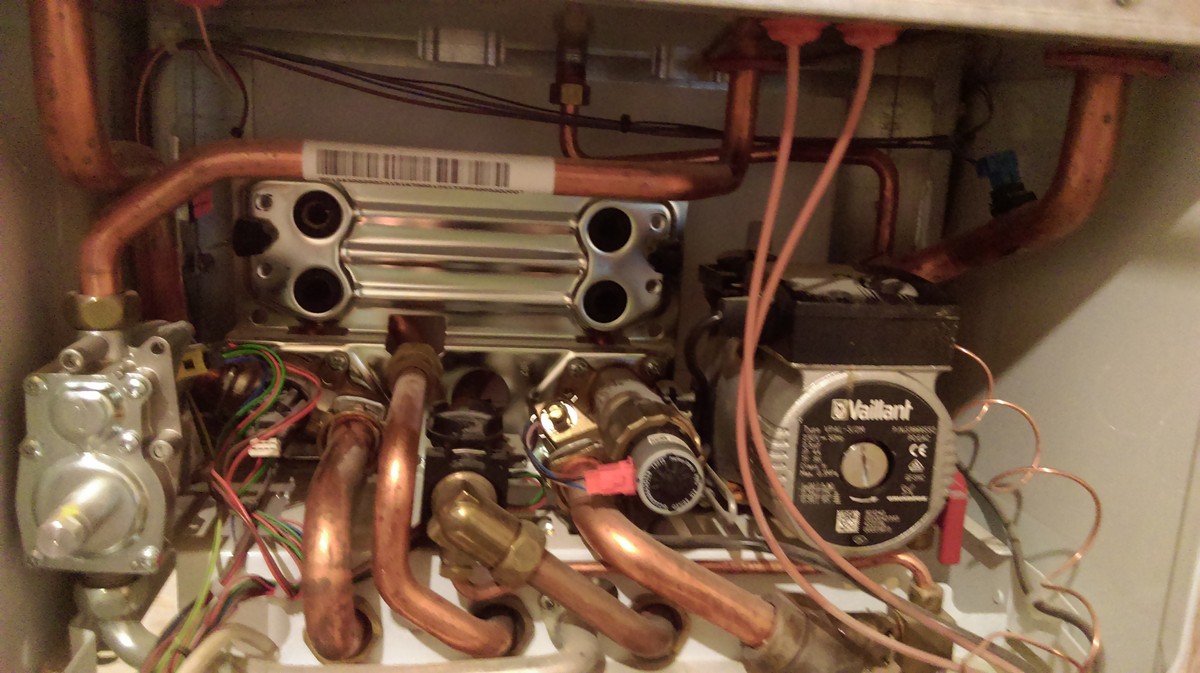

During the operation of the equipment, situations constantly arise when one or another node is under increased load and may fail.

Situations may arise in a variety of ways, but most of them can be systematized and classified as the most typical. The manufacturer cares about the reliability of their units.

The design of each installation contains a set of special sensors that monitor the condition of certain parts and notify the user when there are mode failures or failures of one or another element. These sensors constitute the self-diagnostic system, which provides signals to the electronic control board.

The presence of such a system greatly facilitates the process of localization of a malfunction that has arisen, and makes it possible to detect it at an early stage. The error code has priority over other system messages and is displayed in any situation.

This facilitates repairs and ensures the safety of expensive equipment.

Causes of problems

In order for the possible reviews about the boilers of this brand to be favorable, it is necessary to pay great attention to the prevention of malfunctions and their elimination. It is worth noting that not all problems are indicated by codes, some occur without warning.

The situation when the boiler does not turn on at all may appear due to incorrect connection of "zero" and "phase".

The problem may also be related to the following:

- air richly mixed with gas;

- low pressure in the gas pipeline;

- grounding errors;

- broken cables;

- illiterate connection to the gas pipeline.

When there is no hot water at all or the boiler does not heat it well, it is necessary to evaluate the condition of the flow sensor. Sometimes it gets dirty, the liquid moves, but the automation does not give the fan a command to blow through the furnace and fan the fire. Having released water from the hot water circuit, the pipes are saturated with air. Following this, it is necessary to sharply unlock and tighten the water taps in front of the boiler itself in order to remove dirt from the fan or sensor due to pressure drops. If the pressure rises or falls unpredictably, with hot water dripping from a cold faucet, damage to the secondary heat exchanger can be assumed.

Sometimes the boiler buzzes when turned on - no need to be afraid to open it. It is required to see that no tubes or other parts are in contact with the body. Then there will definitely be no problems with extraneous noise.

You should also check the following reasons:

- saturation of pipes with air;

- oxygen content in water;

- the appearance of scale;

- fan problems.

First steps

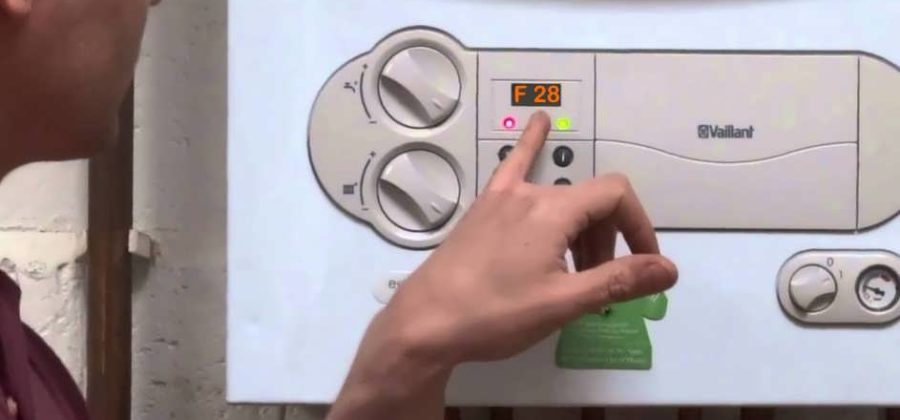

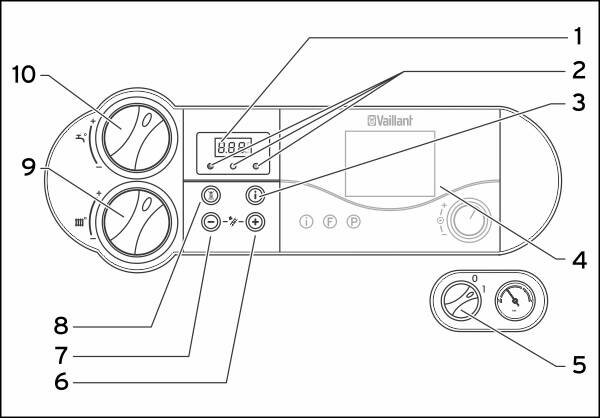

Press the button at number 8 on the Vailant boiler control panel

- Grounding check. Incorrect connection, unreliable contact, damage to the house circuit: it will not affect the functioning of other household appliances, but the Vailant electronics will react.

- Shut-off valve inspection. This protection element is installed on the gas pipe and blocks it in the event of a short-term power failure. In everyday life, devices of the “normally closed” type are used: when the valve is triggered, cock it manually. "Blue fuel" will begin to flow to the Vaillant boiler, error f29 will disappear.

This algorithm of actions saves time on troubleshooting problems with heating equipment. A negative result is a reason to look for the reason for stopping the Vaillant boiler.

On a note! In the instructions for gas equipment, information on malfunctions is scarce. The manufacturer, taking into account the complexity of the devices, their danger in terms of ignition (explosion), does not count on repairs by the user - only a certified master. A number of Vaillant boiler errors are caused by identical factors.

Prevention

Like any other equipment, the boiler requires timely preventive maintenance.

Boiler cleaning

Soot removal from the boiler is carried out with a soft brush from the outside. The use of hard cleaning is unacceptable, since the boiler plates are made of copper, with an anti-corrosion coating that cannot be removed. The disadvantage of the heat exchanger design is that it is not amenable to internal flushing, and the use of antifreeze or hard water supply to the circuit reduces the life of the unit.

Fight against deposits and scale

The problem of deposits is even more important in the operation of secondary DHW boilers, due to the constant circulation of hard water through its circuit. This means that it is even more clogged with deposits and scale.The manufacturer took care of this situation and created the conditions for periodic flushing of the heating surfaces of the DHW circuit. It can be performed using a booster with the addition of special equipment to the circulating coolant.

Next, the solution is driven away for several hours, dissolving and washing out the scale.

Note! In addition, it is recommended to maintain a low temperature regime for the supply of hot water, which does not require dilution with cold water. In this case, the intensity of scale formation, which starts from 60 ° C, will be practically reduced to zero.

Expansion tank service

Expansion tanks are subject to annual maintenance. To do this, the boiler is filled with water to a working level in the system of 1–1.2 bar. If at the same time water appears from the control outlet of the expander, then the tightness of the tank membrane is broken and it will need to be replaced.

Burner and filters

The filters on the gas line are made in the form of a mesh, for maintenance they are removed and washed with water. The gas burner also becomes clogged with combustion products over time, it is cleaned with a brush with soft bristles and a vacuum cleaner.

Connecting a room thermostat

A room thermostat is a device that controls the temperature in a room and regulates the operation of the heating system in accordance with it.

Using this device allows you to save on heating about 20%. This effect is achieved due to more rapid adjustment of the system temperature. The boiler's own sensor is guided by the temperature of the coolant.

When it warms up outside, it becomes too hot in the house, but no changes occur for the boiler system as long as the temperature of the coolant is within the specified limits.

The room thermostat is guided by the air temperature, so it immediately gives a command to change the heating mode.

To connect the device, the corresponding contacts on the control board are used, normally connected by a special jumper.

Ignition transformer

The unsuccessful start-up of the Vailant boiler is due to the absence of a spark or its insufficient power. If there are no defects in the wires, the Tr winding is checked with a multimeter: open - R = ∞, short circuit - R = 0. With an interturn device, the device will show resistance, but if the value does not match the passport data, the spark is weak, insufficient to ignite the burner. Error f29 is eliminated by replacing the transformer.

Burnt ignition electrode of the Vaillant boiler

Control board

Self-repair is within the power of a user with a specialized education, but this will take time. Error f29 is eliminated by replacing the Vaillant boiler assembly.

Helpful Hints

- With autonomous gas supply, before the start of the cold season, it is advisable to update the thermal insulation of the outdoor cabinet with cylinders, the head of the gas tank. Hoping that the insulation is eternal is naive.

- Connect the Vailant boiler to the network via a UPS. Some errors are caused by voltage problems. The stabilizer helps out, but as long as there is no break in the line. The power supply unit is able to provide autonomous operation of Vailant for several hours: enough to eliminate a power line accident, problems with a backup power source. The UPS includes a stabilization circuit, a group of batteries, a charger.

- Periodically clean the heat exchanger housing. Dust accumulation is the cause of error f29. A layer is formed through which the combustion products do not completely pass through the fins of the appliance into the chimney. Partially, the flow of thermal energy is redirected inside Vaillant.In addition to reducing the efficiency of the unit, the temperature under the casing increases. The result is the melting of the insulation, the deformation of the electronic board, the periodic appearance of errors with an emergency stop of the boiler.

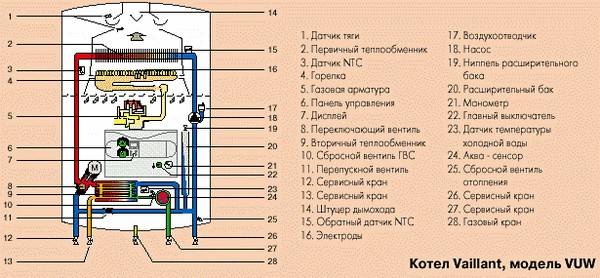

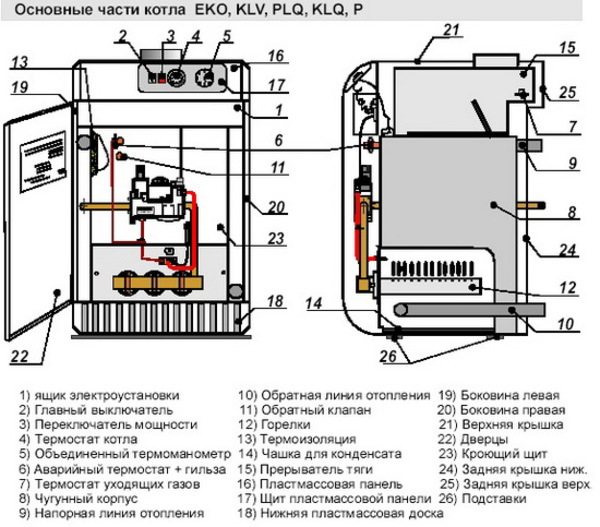

Types of manufactured boilers

Vailant produces gas and electrical equipment. Electric boilers are limited to one EloBLOCK model in several power options.

Gas appliances are represented by a more diverse assortment.

Among them:

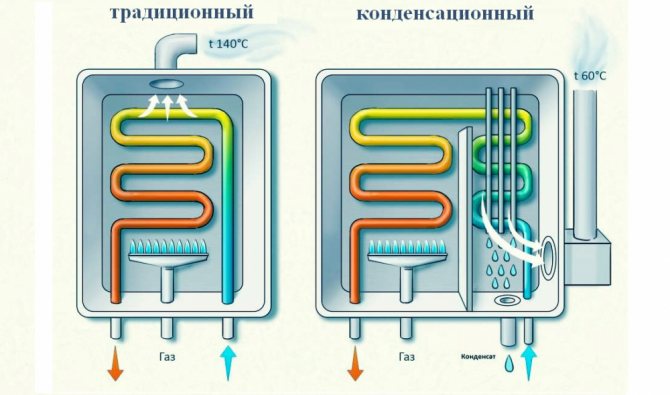

- traditional (throw away part of the useful heat along with smoke);

- condensing (use additional energy of exhaust gases);

- single circuit VU;

- double-circuit VUW;

- atmospheric Atmo (uses air from the room for combustion, standard chimney for exhaust);

- turbocharged Turbo (allows you to arrange an underwater and outlet path through the wall);

- hinged;

- floor.

single circuit

Boilers with one circuit are designed to heat only the heat carrier of the heating system. For water treatment, you can connect an external boiler.

In double-circuit models, water is prepared separately for heating and for household needs.

wall

Mounted boilers are mounted with fasteners on the wall. Save space due to small dimensions. In the wall-mounted design, domestic installations of low and medium power are manufactured.

floor standing

Powerful domestic and industrial boilers are permanently installed on the floor. They have significant weight and dimensions. In some cases, they require a separate room - a boiler room.

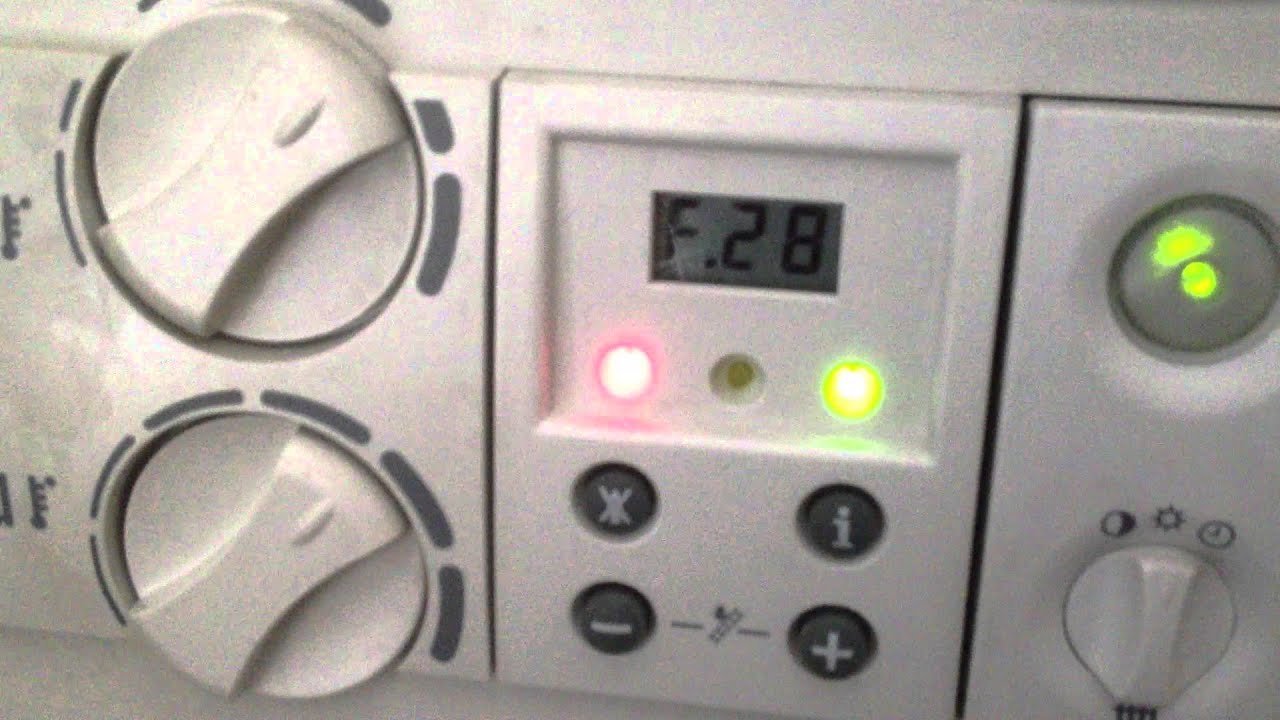

Helpful Tips

In order not to rack your brains over how to fix the F28 error in the Vaillant gas boiler, you must carefully study the instructions before using the device.It is quite simple and intuitive even for a novice user. Additionally, the device is equipped with a special display, which displays all codes with the name of certain problems.

If any error occurs, you need to clarify its number and read the annotation in the instructions. Some of the problems can be corrected on your own, but in most cases only specialized assistance may be required. To avoid trouble, before each heating season, it is recommended to call a master who can check the boiler for leaks, as well as for high-quality performance.

Incorrect pressure in the unit is the most common cause of error F28 in the Vaillant gas boiler. What to do in this situation? First of all, experts recommend maintaining the pressure level on the middle gray strip of the sensor. If the arrow goes into the red zone, then this indicates that the indicator is dropping very much. This can seriously affect the operation of the system.

How to proceed

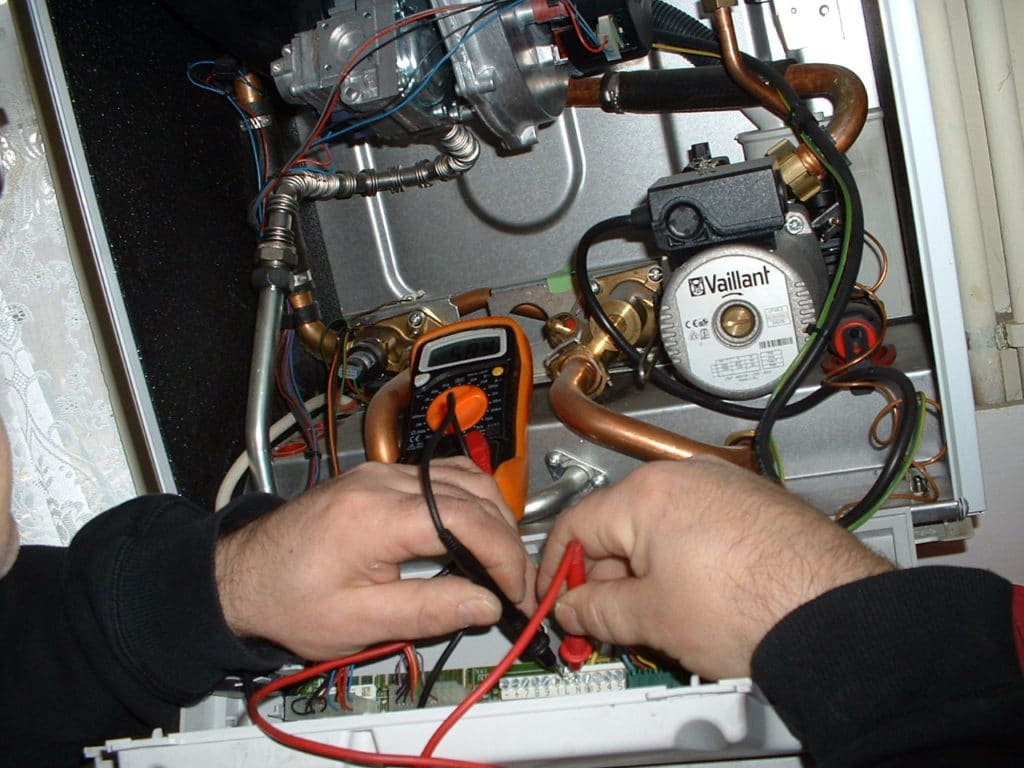

Checking the signal lines in the Vaillant boiler

By inspection, evaluate the integrity of the wires, the absence of short circuits, insulation melting, breaks, condensate. Any defect (shortcoming) is the cause of error f36.

Checking the Vaillant boiler with a multimeter

EPU

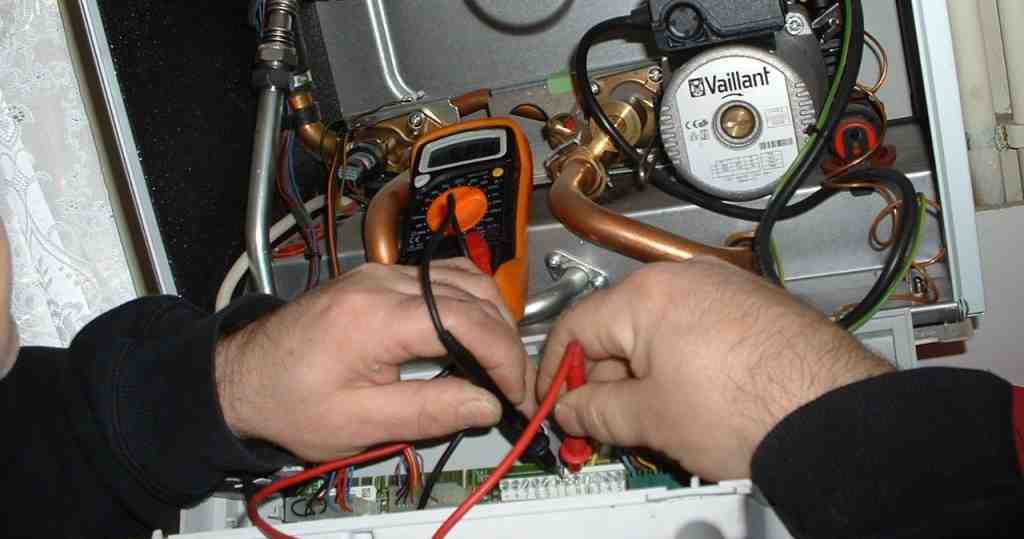

The electronic board is Vaillant's "brain", which controls its functioning. Diagnostics is carried out on the stand by imitation of different modes. The artificial creation of emergency situations determines the performance, the reaction of the boiler protection circuits. The user will not be able to do much on their own: the possibilities are limited.

Vaillant boiler control board

How to proceed

Inspect the board to identify the cause of error f36.

-

Condensate.If the Vailant boiler is installed in an unheated, damp room, microscopic droplets of moisture penetrate into it along with the air. Gradually accumulating on the surface, in the connectors, they cause short circuits and fault codes.

-

Breaks, short circuits of signal lines, unreliable contacts.

-

Damage to tracks, parts, dark spots on the panel (traces of thermal effects) are the causes of error f36.

-

Dust. Gathering on the surface, the layer absorbs moisture and becomes a current conductor. Neglecting the recommendations of the manufacturer of the Vailant boiler on the frequency of maintenance, careless performance of technological operations leads to error f36. For Atmo series units, dust is a “sore” issue. Such models need regular cleaning. Often code 36 is removed after removing dirt from the electronic board.

If the f36 error is not removed by the measures taken, contact an authorized service organization, indicating the year of manufacture, the type of boiler Vaillant.

Advice

It is advisable to conclude an annual service contract. A master is assigned to the boiler, and personal contact will make it possible to contact him at any time. If there is a problem with the unit, professional advice is enough to fix the error yourself.

Vaillant gas boiler installation

The main condition for ensuring the correct and stable operation of the boiler is the correct choice of premises. If the installation is not in a kitchen or other living room, frost protection must be provided.

In parallel, it is necessary to organize high-quality ventilation and install grounding, without which the unit will not be able to work. During installation, it is necessary to observe the established gaps and distances from the nearest walls or window openings.

The connection of pipelines must be carried out carefully so as not to confuse them with each other. All gas connections are checked for tightness with a soap solution.

Overview of Less Common Mistakes

We have listed the error codes that bother users more often than others. But there are other signs that indicate violations in the work. gas boilers Navien and potential renovation.

11 - failure in the operating parameters of the water level or pressure. This error appears on the displays of boilers with automatic make-up. The corrective action is to turn off the system, check the operation of the water filling valve, remove any remaining water in the pump drain, reconnect the pump and restart the system. If it doesn't help, call the technical service.

12 - no flame. There are many reasons, and we recommend acting as with errors 03-04. First, check if the gas valves are closed, if there is power supply and if everything is in order with grounding.

15 - problems with the control board. If it does not respond to the power supply, then it requires repair or replacement.

16 - overheating of the system, and any of the nodes can overheat: fan motor, heat exchanger, pump motor. What you can do yourself: clean the filters and heat exchanger, change the thermostat. After a half-hour "rest", the unit can be restarted - most likely, it will work.

17 - errors related to the DIP switch. It is necessary to correct the settings of the control board and restart the boiler.

27 - failure of the pressure sensor. If there is no blockage, you need to check the health of the sensor and fan, and then replace the failed part.

30 - smoke thermostat overheating.It is necessary to turn off the boiler, let it cool down for 30 minutes, then restart. If it does not work, check the fan and air pressure sensor, clean the chimney.

93 - the "on / off" button is broken. She should replace on your own or call a specialist.

Many problems are solved on their own, so the manufacturer gives brief instructions for resolving emergency situations.

But if it comes to complex repairs or replacements, it is better to repair the unit at a service center, followed by a guarantee for new parts.

But if it comes to complex repairs or replacements, it is better to repair the unit at a service center, followed by a guarantee for new parts.

If an unknown error code appears on the display of a gas column or a Navien floor model, it is also necessary to contact the specialists.

Features of Vailant boilers

Gas models of the ECO series have a gas condenser in their design. They fully comply with Class A requirements for energy efficiency. Therefore, their operation contributes to a significant reduction in the consumption of electricity (up to 20 percent), gas (up to 30 percent) and water (up to 55 percent).

Note! The high cost is not a reason for not buying a Vaillant boiler. Due to the increased energy efficiency, the products easily pay for themselves in 2-3 heating seasons

The operation of equipment from the German brand contributes to a reduction in carbon dioxide emissions by 97 percent. The reason for this is a fundamentally new heat generator that provides high-quality filtration of combustion products.

A huge number of floor-standing and wall-mounted gas appliances are presented to the choice of a potential buyer. Both types are particularly in demand on the market, as they are characterized by a wide range of applications.

Another important feature is compactness.This makes it easy to integrate the device even in rooms with a small area.

Conclusion

Malfunctions or failure of any components of the heating boiler are quite common, even on the most advanced installations.

Vaillant gas boilers are reliably protected from them by the presence of a self-diagnosis system, which significantly speeds up the search for a problem that has arisen and protects the user from irreparable consequences.

The appearance of an alphanumeric code on the display is a signal that it is necessary to call a technician from the warranty workshop, capable of competently repairing or reconfiguring the unit.

Trying to fix the boiler yourself is not recommended, as you can ruin it completely and find yourself in a difficult situation in the midst of winter frosts.