- What do you need to know about your equipment?

- The device of the gas boiler AOGV - 17.3-3

- Consider the method for finding the above malfunction

- Causes of breakdown of gas equipment

- Possible malfunctions and do-it-yourself repair methods

- Smells like gas in the house

- Fan not working

- High temperatures

- Sensor failure

- Boiler chimney clogged

- Self shutdown

- The principle of operation of the smoke exhauster of a gas boiler

- Diagnostics

- Causes of breakdowns of gas boilers

- Why the boiler does not turn on

- Why does the pressure in the heating boiler rise?

- Air lock in the system

- Bimetal boiler plate

- Is it worth it to do the repair yourself?

- What can be repaired with your own hands

- Mounting Features

- Conclusion and useful video on the topic

What do you need to know about your equipment?

Many issues of operation and maintenance are covered in the instructions for the equipment. Serious manufacturers usually give recommendations for each model, pointing out its features. So often the instructions describe possible breakdowns or malfunctions that can be diagnosed (and sometimes eliminated) on their own. Therefore, if you have a question why the heating boiler does not work or how to clean it, refer to the instructions. Perhaps you will find the answer there.Moreover, almost all models are equipped with numerous sensors - combustion, temperature, water level, pressure and others. And even if they are not included, it makes sense to install them as an option. After all, it is the operational monitoring of the condition of the equipment and the system as a whole that helps prevent serious breakdowns that may lead to the need to replace the heating boiler.

The device of the gas boiler AOGV - 17.3-3

Its main elements are shown in rice. 2

. The numbers in the figure indicate: 1- traction chopper; 2- thrust sensor; 3- draft sensor wire; 4- start button; 5- door; 6- gas magnetic valve; 7- adjusting nut; 8-tap; 9-storage tank; 10-burner; 11-thermocouple; 12- igniter; 13- thermostat; 14-base; 15- water supply pipe; 16- heat exchanger; 17-turbulator; 18- knot-bellows; 19- water drainage pipe; 20- the door of the traction control; 21-thermometer; 22-filter; 23-cap.

The boiler is made in the form of a cylindrical tank. On the front side are the controls, which are covered with a protective cover. gas valve 6 (Fig. 2)

consists of an electromagnet and a valve. The valve is used to control the gas supply to the igniter and burner. In the event of an emergency, the valve automatically turns off the gas. Traction chopper 1 serves to automatically maintain the vacuum value in the boiler furnace when measuring the draft in the chimney. For normal operation, the door 20 should freely, without jamming, rotate on the axis. thermostat 13 designed to maintain a constant temperature of the water in the tank.

The automation device is shown in rice. 3

. Let us dwell in more detail on the meaning of its elements. Gas passing through the purification filter 2, 9 (Fig. 3)

goes to the solenoid gas valve 1. To the valve with union nuts 3, 5 draft temperature sensors are connected. The ignition of the igniter is carried out when the start button is pressed 4. There is a setting scale on the body of the thermostat 6 9. Its divisions are graduated in degrees Celsius.

The value of the desired water temperature in the boiler is set by the user using the adjusting nut 10. Rotation of the nut leads to linear movement of the bellows 11 and stem 7. The thermostat consists of a bellows-thermobalon assembly installed inside the tank, as well as a system of levers and a valve located in the thermostat housing. When the water is heated to the temperature indicated on the adjuster, the thermostat is activated, and the gas supply to the burner stops, while the igniter continues to work. When the water in the boiler cools down 10 … 15 degrees, the gas supply will resume. The burner is ignited by the flame of the igniter. During operation of the boiler, it is strictly forbidden to regulate (reduce) the temperature with a nut 10 - this can lead to breakage of the bellows. You can reduce the temperature on the adjuster only after the water in the tank has cooled down to 30 degrees. It is forbidden to set the temperature on the sensor above 90 degrees - this will trigger the automation device and turn off the gas supply. The appearance of the thermostat is shown in (Fig. 4)

Consider the method for finding the above malfunction

Check at

repair of a gas boiler begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6 ... 12 months of operation it “acquires” a thick layer of dust. Bimetal plate (see fig. 6)

oxidizes rapidly, resulting in poor contact.

The dust coat is removed with a soft brush.Then the plate is pulled away from contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special spray "Contact". It contains substances that actively destroy the oxide film. After cleaning, a thin layer of liquid lubricant is applied to the plate and contact.

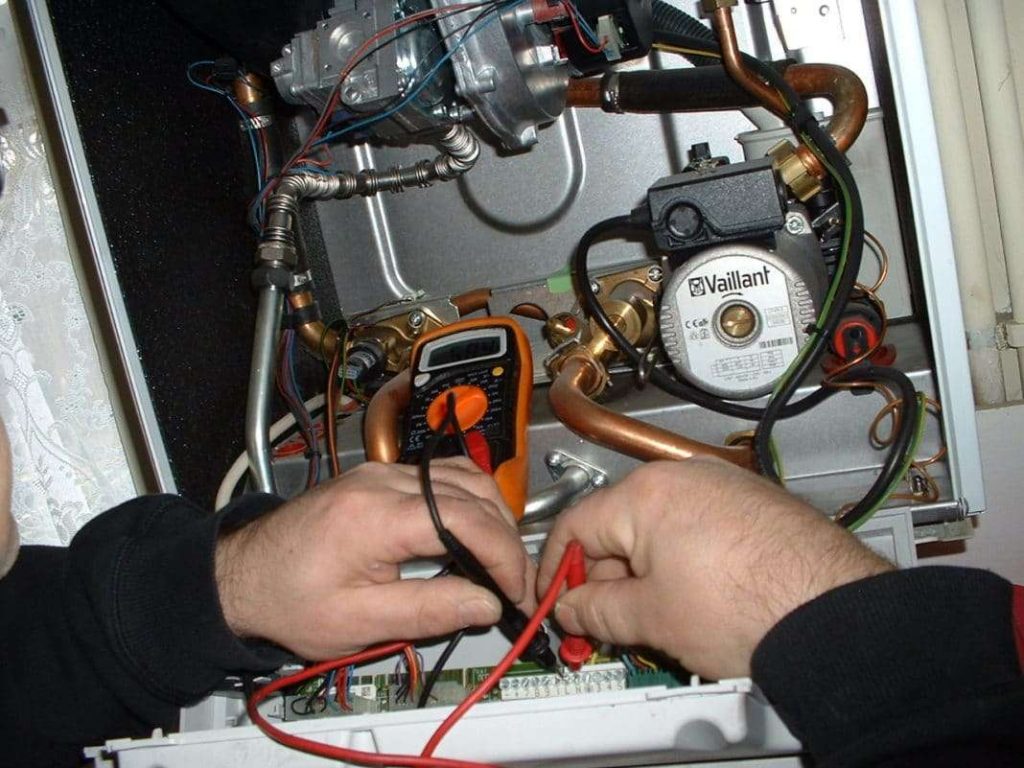

The next step is to check the health of the thermocouple. It works in heavy thermal conditions, as it is constantly in the igniter flame, naturally, its service life is much less than the rest of the boiler elements.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) sharply increases. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetal plate will be lower than the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the stem (Fig. 5)

.

Causes of breakdown of gas equipment

Despite the high quality of the products of the domestic manufacturer Conord, such gas boilers can fail over time.

The problem is not always the natural wear of parts, and, as a rule, this occurs only after at least 5 years after the start of operation.

One of the most common causes of gas boiler breakdowns is a sudden shutdown or a strong surge in electricity, as a result of which the device settings simply go astray.

One of the most common causes of gas boiler breakdowns is a sudden shutdown or a strong surge in electricity, as a result of which the device settings simply go astray.

If the equipment broke down almost immediately after installation, then this may occur as a result of an elementary failure in the settings or a voltage drop.

Often, malfunctions of gas boilers occur for the following reasons:

- Voltage fluctuations in the network. Sudden power surges can lead to a short circuit, and, accordingly, a blown fuse, which will need to be replaced with a serviceable part. In this case, it is recommended to purchase a high-quality stabilizer, which will no longer worry about voltage failures in the network.

- Poor quality water. In the operation of double-circuit boilers, which are also responsible for heating water, failures may occur. Heating low-quality water renders the flow heat exchanger unusable, so the only way out in such a situation is to install a full-fledged water purification system.

- Incorrect installation. The installation of gas heating equipment should be carried out by a qualified specialist, since even the slightest mistake can lead to serious consequences. For example, improperly executed piping of a cast-iron gas boiler can lead to the fact that at a low temperature its body will simply crack.

In addition, the correct operation of gas equipment can be disrupted by weather conditions, due to which the boiler may become unusable.

Since in frosty weather, many users turn on the heating at full power, the pressure in the gas pipeline system decreases, which means that the boiler simply cannot produce the promised heat.

As an additional source of heating, you can install a solid fuel boiler on coal, which will allow you not to overload the gas boiler, and at the same time ensure a sufficient temperature inside the room

As an additional source of heating, you can install a solid fuel boiler on coal, which will allow you not to overload the gas boiler, and at the same time ensure a sufficient temperature inside the room

If you have a conventional Conord gas boiler (without heating hot water), it is recommended to install a good stabilizer, while it is better not to save on the purchase.So, you do not have to change the fuse after every power failure, and even more so, spend big money on purchasing a replacement for a burned-out pump.

Possible malfunctions and do-it-yourself repair methods

Any malfunction of the gas boiler must be dealt with by a specialist. However, the opportunity to use the services of a master is not always available, and breakdowns are trifling. Consider problems that are solved independently.

Smells like gas in the house

Usually the smell of gas appears when it leaks from the threaded connection of the supply hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then proceed according to the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply mortar to all threaded connections. If bubbles begin to inflate, a leak has been found.

- Close the gas valve.

- Expand the connection with the key. Wrap the FUM tape on the external thread and assemble everything back.

- Reapply the solution and restart the gas supply.

- If the leak is fixed and the smell of gas is gone, remove the remaining solution.

Fan not working

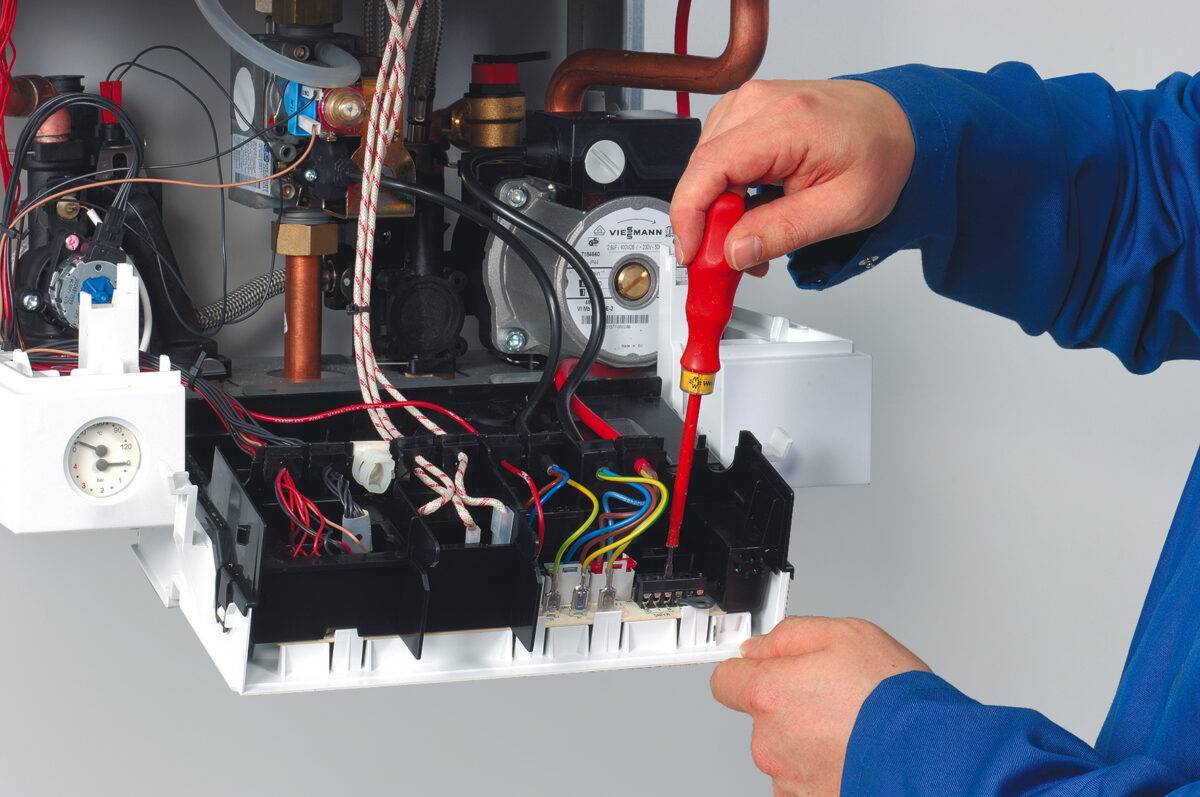

If during the operation of the boiler the sound emitted by the turbine disappears or decreases, this indicates a malfunction of the blowing fan. For repair you will need: a screwdriver, a new bearing, a rag, grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove turbine.

- Use a cloth to clean dust and soot from the turbine blades.

- Inspect the electric fan coil for blackening. If everything is in order, move on or replace the fan.

- Disassemble the fan housing. A bearing is installed on the turbine shaft inside, it must be replaced.Some fans have a sleeve instead of a bearing. In this case, it must be lubricated.

The turbine may also not work due to low mains voltage or a malfunction of the control board. The first is eliminated with the help of a stabilizer, but the second is only by calling a specialist.

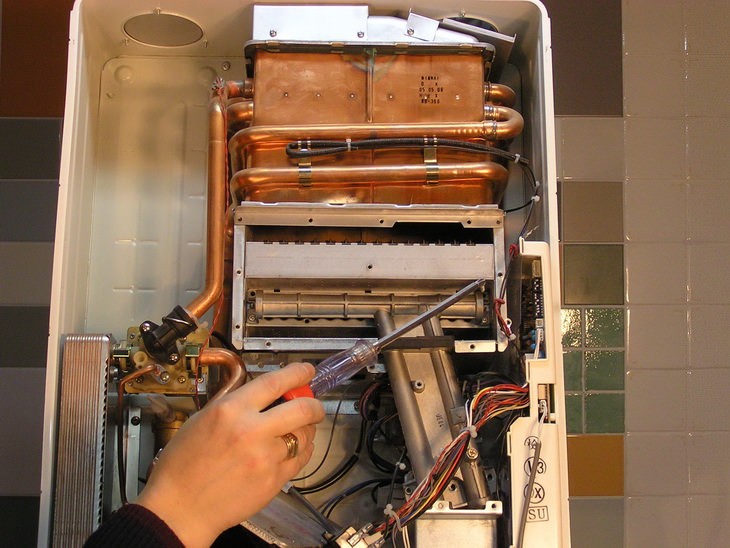

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger. To clean the device, you will need: a special solution of hydrochloric acid, an adjustable wrench, an FUM tape, a metal brush. Then proceed according to the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe. If foam appears, then there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Install back, after wrapping all threaded connections with FUM tape.

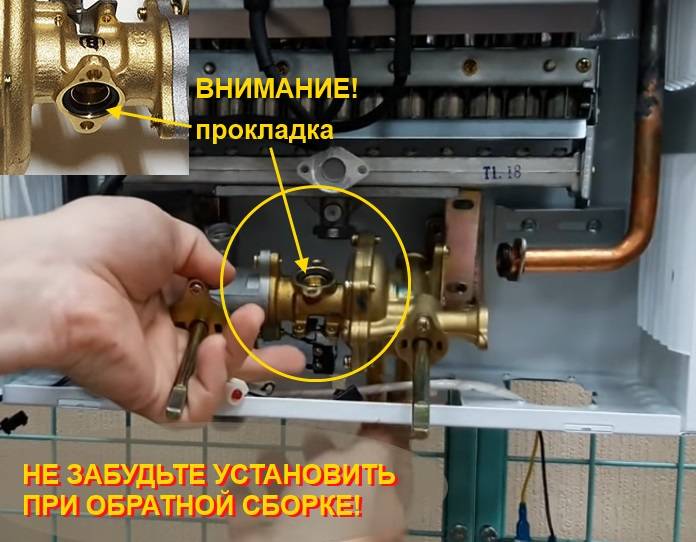

Sensor failure

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds, and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler, turn off the gas.

To repair the electrode, you will need sandpaper, with which the sensor probes are cleaned without removing it. If the failure remains, the sensor is replaced.

Boiler chimney clogged

Problems with the chimney occur only in floor-standing boilers. This is due to its size and vertical position. Mounted devices do not need to clean the chimney.

The chimney, consisting of metal parts, is cleaned with a metal brush. It must be disassembled and the accumulated soot removed mechanically. The whole chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the hardest to clean.

Self shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

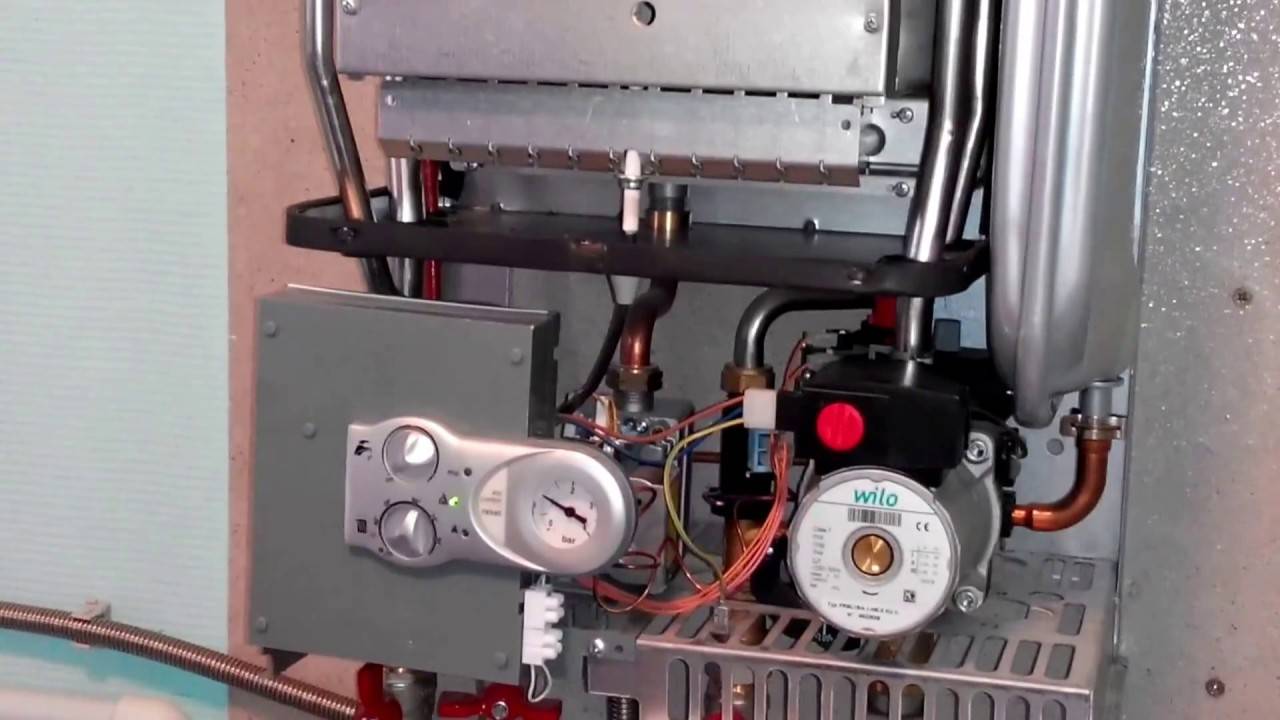

The principle of operation of the smoke exhauster of a gas boiler

The fan consists of nodes:

- An engine that rotates the impeller.

- Turbine that creates a vacuum in the combustion chamber.

- Blades for mixing supply air.

- Venturi tubes, which create a pressure drop for the efficient operation of the pressure switch.

Gas boiler fan device.

The turbine of the smoke exhauster is housed in a housing made of galvanized sheet or aluminium. The motor is attached to the body with mounting bolts, through vibration pads.

When 220 volts appears on the stator inductor, the armature begins to rotate the turbine and blades. The supply air is mixed and flue gases are removed through a coaxial pipe or a separate air duct and chimney.

The electrical power of the fan depends on the thermal power of the boiler, for domestic models, 35 - 80 watts.

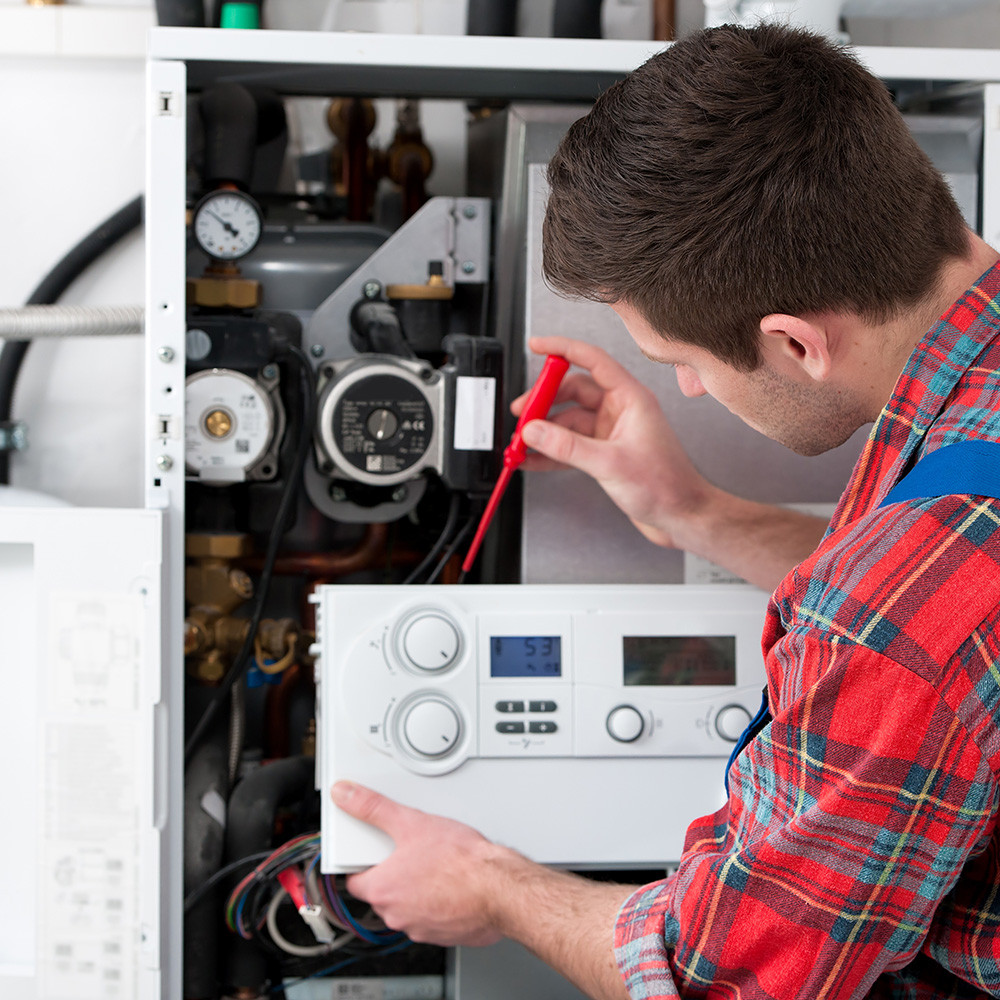

Diagnostics

Competent implementation of repair involves compliance with a certain sequence of actions:

- Troubleshooting. There are obvious and implicit breakdowns. With a boiler that has ceased to function, everything is clear, but there may be defects that are difficult to notice immediately or do not greatly affect the operation of the boiler room.

- Diagnostics: search for the causes that led to the breakdown.This may be a clogged filter, a violation of the integrity of the wires, the failure of individual nodes.

- Elimination of causes. First you need to determine whether it will be possible to repair the boiler on your own, in some cases you can save a lot by performing simple manipulations, and sometimes there is a risk of exacerbating the situation if the wrong actions are taken.

Reference! Do not disassemble and repair the boiler when the warranty period of its operation has not yet expired. If the equipment cannot be repaired on its own, the repairmen will refuse to fix the defects free of charge.

Unstable operation of the burner, which often fades. To maintain the combustion process, the presence of oxygen is necessary, its deficiency (during the operation of the boiler) can be easily detected if, for example, the windows in the boiler room are opened. Stabilization of combustion indicates the need to improve ventilation in the working room.

You may need to install air inlets or a door with a vent.

Insufficient gas flow in the line is determined when the hose is disconnected from the boiler. When the valve is open, hissing should be heard and the smell of additives in the gas mixture should be felt.

The pressure may drop as a result of the clogging of the filter, to clean it, the mesh inside must be removed and rinsed. If a blockage occurs in the gas meter, you will have to call the gas service workers.

Overheating of the coolant can cause an emergency shutdown of the equipment. This often happens due to a malfunction of the pump that accelerates the working fluid around the house.

If air has entered the working chamber of the pump, then to remove it, you need to add coolant there.

Sometimes the rotor - an element of the pump - sticks and stops rotating, you can fix the problem by disassembling the housing, the rotor is scrolled by hand, removing debris in the chamber if possible.

And you should also check the expansion tank, which in modern models of boilers is built into the unit itself. The pressure in it is checked with a standard automobile pressure gauge, its value should be 0.2 atm less than the working pressure in the pipeline.

If necessary, air is pumped by a manual or electric pump.

Causes of breakdowns of gas boilers

Autonomous gas heating provides people with comfort and warmth. The “heart” of the entire system can be safely called the boiler, malfunctions in which can adversely affect the operation of the equipment or suspend its operation completely.

Gas boilers can fail for several reasons:

- settings failure;

- damage to shutoff valves;

- the pump does not work;

- poor performance of the hood;

- clogging of the chimney, resulting in the operation of a special draft sensor;

- violation of the rules of operation and safety;

- low quality components;

- power failure due to a drop in gas pressure;

- mechanical damage, etc.

Also, repair of gas boilers is required in case of defects in the controls and protective systems of the unit.

Why the boiler does not turn on

With a voltage drop, the board in the boiler may burn out and it will not turn on

With a voltage drop, the board in the boiler may burn out and it will not turn on

After proper installation, in the absence of violations, a wall-mounted boiler usually does not cause problems to its owners. The average service life of the unit is from 4 to 9 years, but breakdowns can occur at any stage of operation.When the wall-mounted boiler does not turn on, error information appears on its display indicating a personal code or number, depending on the specific model of the device.

You need to write it down and see the exact value in the instructions, which provide descriptions of the most common malfunctions. The most common problem is the lack of ignition of the gas-air mixture. The flame may light up and go out after a while or be completely absent if the boiler closes the gas supply valve. This happens for a number of reasons:

- connection polarity problems or phasing error;

- oxidation or contamination of the ignition electrode, the presence of a gap in the burner;

- cracks or breakdowns in the insulating part of high-voltage wires;

- difficulties with connecting electricity;

- lack of gas supply due to a faulty meter or dirty filters;

- broken control board.

Another common problem is lack of traction. In such a situation, the combustion products are not completely eliminated, the heating boiler does not turn on and does not ignite. In addition, there are often difficulties with water pressure, which should normally be at a minimum level and controlled by a personal sensor. Users can monitor the pressure level using the built-in mechanical or electronic type pressure gauge.

When the pressure in the boiler drops below the allowable level, the automation blocks the operation

All gas boilers operate in a closed heating system, the pressure in which periodically drops. If it drops to a critical level of 0.5-0.7 bar, the device will not start, because the sensor fixes the problem as a breakdown and suspends all operation of the device.

The boiler may not work in only one mode, for example, hot water or heating. In such a situation, the unit requires a full diagnostics from a specialist who will be able to accurately determine the cause of the breakdown.

Why does the pressure in the heating boiler rise?

Filling the heating circuit is carried out subject to the exact sequence of actions, deviation from the rules leads to malfunctions of the system. During the seasonal start-up of the system, it is necessary to adjust the adjustable auxiliary elements and fix the position of the valves in the correct position.

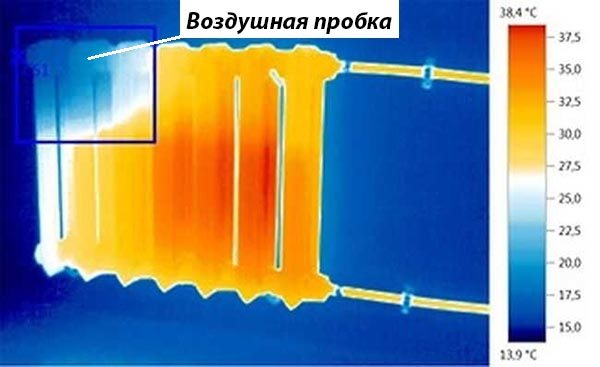

Air lock in the system

In the event of malfunctions in the heating system, expressed in an arbitrary increase in pressure, the temperature of the coolant sometimes drops and the boiler is blocked. As a result, in such situations, there is an imbalance in the functioning of the system, leading to the failure of expensive elements.

Airing the circuit can lead to similar consequences, and the resulting plugs are recognized as a common reason why the pressure in the boiler increases.

Air pockets can occur for a number of reasons:

- equipment malfunction;

- the system was launched with violations;

- failure of automation;

- formation of cracks in the heat exchanger housing.

The above consequences are the result of neglecting the established rules for operating the heating system.

These failures can be caused by the following actions:

- filling the DHW circuit is carried out from the top point;

- at start-up, the system is rapidly filled with water;

- before launch, a check was not carried out, which air vents need, as well as each Mayevsky crane;

- air was not released from the radiators after repair;

- the vibrating impeller, which is equipped with the circulation pump, slowly pumps air, causing a circulation problem.

Such problems are eliminated by relieving pressure from the heating circuit. Next, the circuit is filled with water, carried out from the bottom point

It is important to bear in mind that during the filling of the system, it is necessary to keep the valves that release air open. Filling is carried out gradually without undue haste, and the signal for the end of the process is the appearance of water at the top of the system

Bimetal boiler plate

Heating systems on natural gas are devices of increased danger, therefore they include various sensors for monitoring the condition. So, the main safety element is a thrust sensor. It determines the correct direction of the exit of combustion products, that is, from the combustion chamber towards the chimney. This prevents carbon monoxide from entering the room and poisoning people.

The main component of the draft sensor is a bimetallic plate for a gas boiler. Its principle of operation is similar to that of any bimetal, and the dimensions and parameters of the material are calculated in such a way that exceeding the temperature of 75 degrees in the channel leads to deformation of the plate and actuation of the gas valve.

Is it worth it to do the repair yourself?

In a typical gas boiler, all structural elements are conditionally combined into three groups:

- burner;

- blocks that are responsible for security;

- a heat exchange unit equipped with a fan, a circulation pump, and many other elements.

During repairs, the main safety risk arises from a possible gas leak.The reason for this may be improper repair, dismantling or installation of equipment with fuel supply functions.

Because of this, it is better to have these structural parts repaired by a specialist. In addition, self-troubleshooting in the electronic equipment of the gas boiler is not allowed. The automatic system is quite specific, and if you do not have the appropriate qualifications, it is impossible to correctly restore this type of equipment in practice.

And yet, if you do not have enough experience, it is better to entrust the maintenance of heating boilers and the repair of gas water heaters to professionals.

What can be repaired with your own hands

All other elements can be repaired independently, for example:

- The heat exchanger is flushed manually (for this, the unit is dismantled, after which it must be correctly put in place). You can perform these works without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is performed).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, it is possible to repair a gas boiler on your own only in cases where we are talking about mechanical damage or blockages that are easy to identify visually (or by smell).

The remaining breakdowns are considered more serious, so they are eliminated with the help of a specialist, and not with their own hands.

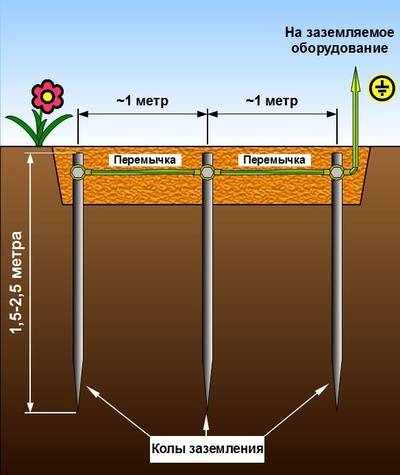

Mounting Features

The direction of the water must match the direction of the arrow on the body of the device

The valve is placed on the pipe so that the direction of the liquid coincides with the course of the arrow.The filter plug points down and the adjustment screw must be accessible for use. The manometer dial rotates to make it easy to read the values.

The winding material is used rationally so that the excess does not fall into the clearance of the gearbox. Boiler make-up in the form of a valve should not depend on main loads (compression, torsion, bending, vibration). For this, additional supports or compensators are placed.

The mismatch between the axes of the pipelines should not be more than 3 mm with a length of 1 m. With a longer length, 1 mm is added for each linear meter. The make-up circuit is connected to the pipeline near the expansion tank.

Conclusion and useful video on the topic

The video tells about what clocking is, how such a negative phenomenon occurs, and also outlines ways to deal with it:

The following video describes the situation with the attenuation of the boiler in strong winds:

The frequent repetition of off / on cycles of any modern gas boiler directly indicates its unstable operation. And therefore for the presence of a malfunction or incorrect setting, which is the cause of accelerated wear of the equipment. Therefore, once you identify a problem, you should immediately start fixing it.

Have you had to deal with interruptions in the operation of a gas boiler? What kind of problem did you have to face and how did you manage to get out of their situation? Please share your experience with our readers in the comments section.