- Original and compatible nodes

- All error codes and their interpretation

- Fault indication on different models

- Main malfunctions and ways to eliminate them

- Violation of the circulation of the coolant.

- The main malfunctions of Ferroli gas boilers

- Connection types

- No flame signal

- Enable and disable

- Ferroli wall mounted gas boilers

- The boiler does not start, the burner does not turn on

- Why does pressure drop

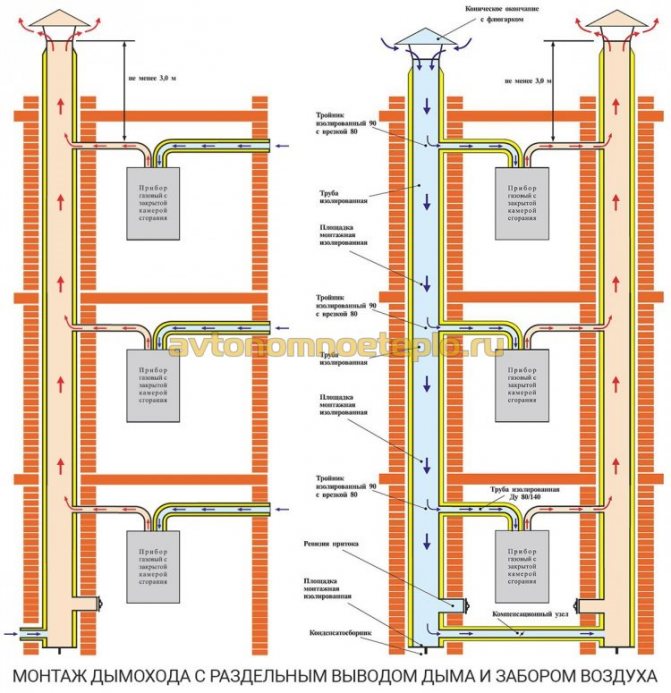

- Malfunction of the air intake/smoke exhaust system

- The boiler does not start (the burner does not turn on)

- The boiler does not start, the burner does not turn on

- User manual

- The boiler does not start (the burner does not turn on)

- The main malfunctions of Ferroli gas boilers

- Accessories

- Why does pressure drop

- Preventive advice

- Conclusion

- Conclusions and useful video on the topic

Original and compatible nodes

If any boiler unit breaks down, if it cannot be repaired, a replacement problem arises. Ferroli equipment is not so common that you can be sure that you can quickly find the original part. However, many probes and tubing are in a generic format, in which case third party products can be purchased.

For Ferroli boilers, original spare parts are as follows:

- control board;

- gas valve;

- ignition and combustion unit;

- node (faucet) make-up;

- fan for chimney;

- display and control knobs;

- heat exchanger (original mount);

- expansion tank.

When replacing a make-up tap, it is imperative to know the model of the boiler, since Ferroli has two very similar varieties of this part.

Circulation pump, safety valves, temperature and pressure sensors, pressure switch, flow switch, wiring, insulation elements, anodes can be purchased compatible

But it is important that their specifications are exactly the same.

All error codes and their interpretation

Consider standard error codes Immergas gas boilers:

| The code | Decryption |

| 01 | No ignition |

| 02 | The thermostat gave the command to block the ignition |

| 03 | Smoke sensor problems |

| 05 | RH temperature sensor failure |

| 06 | DHW temperature sensor failure |

| 08 | Unlock button not working |

| 09 | Setting function launched |

| 10 | Reduced coolant pressure |

| 11 | Internal blocking |

| 12 | Boiler overheating |

| 15 | Boiler electronics failure |

| 16 | Fan failure, poor contact |

| 20 | The system detects a flame when the burner is off |

| 27 | RH circulation failure |

| 31 | Control board problems |

| 37 | Critically low supply voltage |

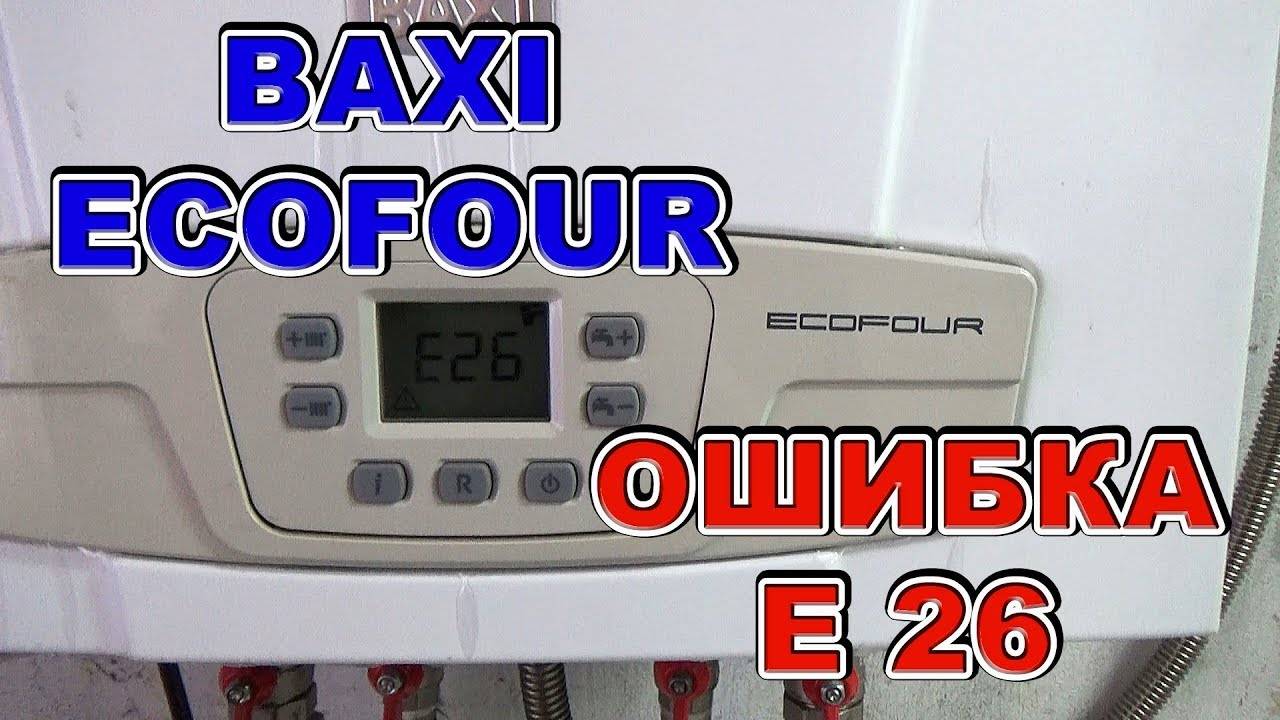

Fault indication on different models

Ferroli boilers are equipped with a self-diagnosis system and, in the event of an emergency, give the user an error code. Knowing the type of malfunction, you can quickly find the cause of its occurrence. Many breakdowns do not require special knowledge to fix them.

All the problems that arise during the operation of Ferroli boilers, the manufacturer conditionally divided into 2 categories:

- Critical errors causing a complete block. Designated by the letter “A” before the code.If such a malfunction occurs, it is necessary to eliminate the problem and restart the boiler by pressing the “reset” or “reset” key.

- Problems causing temporary shutdown of the boiler or one of its components. Designated by the letter “F” before the code. Automation is waiting for the normalization of the situation, after which it will restart the boiler itself.

The error code information can be displayed on the LCD or on the remote control. For older models, you can find out the type of breakdown by indicators.

Also, sometimes a code starting with the letter “D” appears on the screen. This is technical information that warns the user that the boiler is changing from one mode to another.

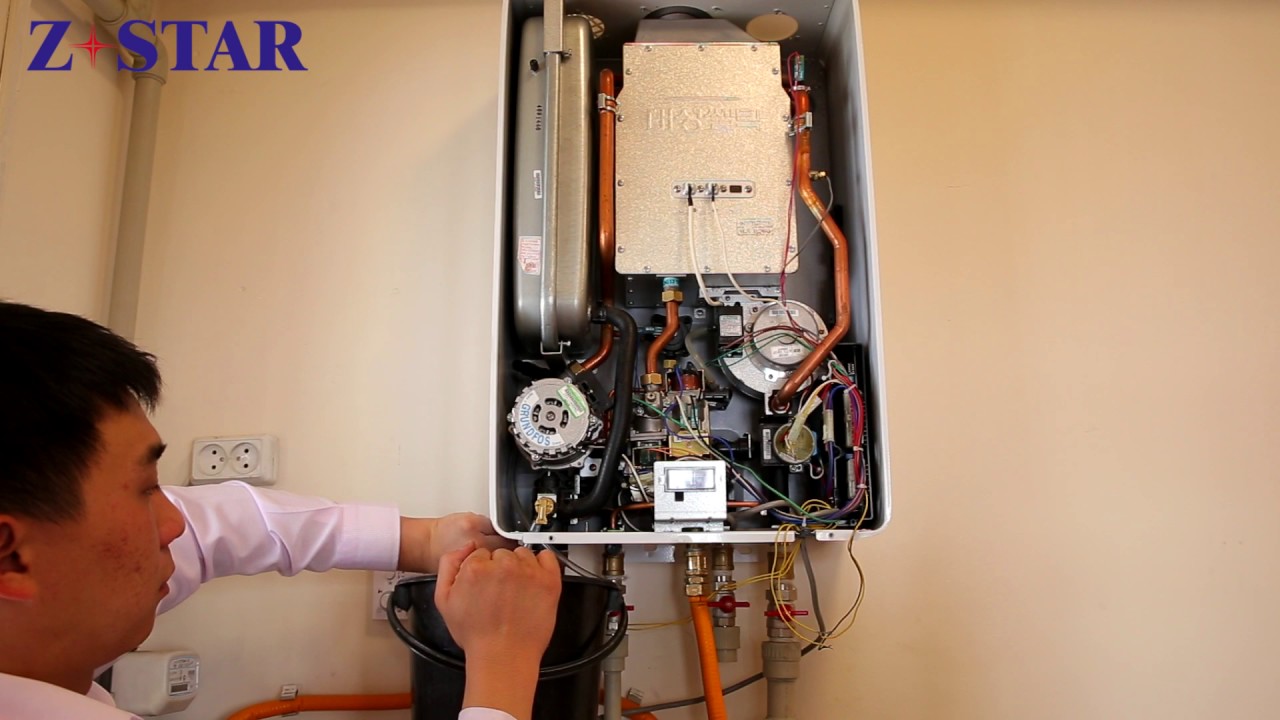

Main malfunctions and ways to eliminate them

The Ferroli gas boiler diagram will allow you to understand what design features the purchased equipment has. Some home masters are also able to figure out the causes of the malfunction, as well as fix the problems on their own. If the device does not turn on, then there may be no gas in the network, but when the water pressure drops in the boiler, the main reason may be a malfunction of the circulation pump. Similar problems sometimes occur when the ignition power is insufficient, in this case it must be increased. However, damage to the electronic control board of the boiler cannot be ruled out.

If you purchased a Ferroli gas boiler, malfunctions can also be expressed in extraneous noise inside the device. Only a master can deal with such a problem, and you need to contact support as soon as possible. If the water pressure drops, the water supply system may be clogged, so the plug should be disposed of immediately.

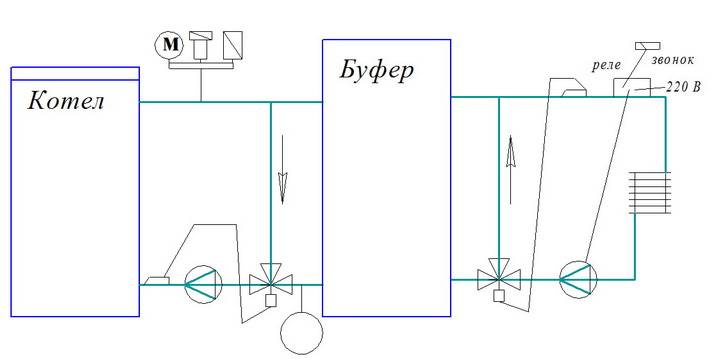

Violation of the circulation of the coolant.

A boiler error of this kind can be caused by a breakdown of the circulation pump, contamination of the heat exchanger, filter or radiator valves, poor-quality coolant or errors in the heating installation. A jammed pump rotor can be removed by turning the motor shaft with a screwdriver or a suitable tool through the air outlet plug. You should also check the power supply of the pump and the health of the boiler board. The contamination of the heat exchanger can be checked by reading the pressure gauges and characteristic noises during the operation of the burner. Errors in the installation of the heating system can cause hydraulic misalignment, which is especially common in systems with a large number of circulation pumps. It is possible to exclude the mutual influence of heating circuits in the case of using a thermo-hydraulic distributor (hydraulic arrow), flow and differential pressure regulators.

The main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by a well-thought-out and high-quality study of all components and details.

However, any system has weaknesses, and gas boilers are no exception.

The operating conditions of some parts of the units are very difficult, temperature loads contribute to the occurrence of the phenomenon of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on. There can be different causes and ways to fix them, one of the most common problems.

- Pressure drops or rises. This is a serious problem that results in either leakage of the heating medium, which causes overheating and blockage of the boiler, or overpressure and blockage.Especially dangerous is the increase in pressure, from which the parts of the unit can burst.

- Failure of the fan or circulation pump. The loss of both functions means the system is unable to function - the inability to remove smoke causes sudden overheating and blocking, and the lack of liquid movement has the same consequences, only detected by other sensors.

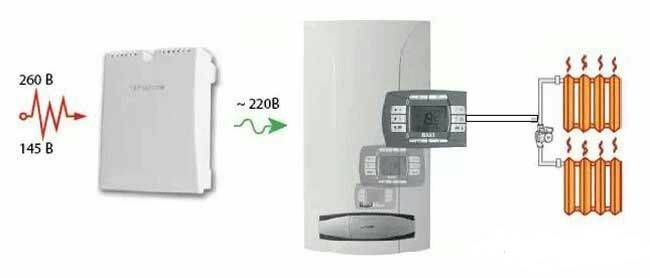

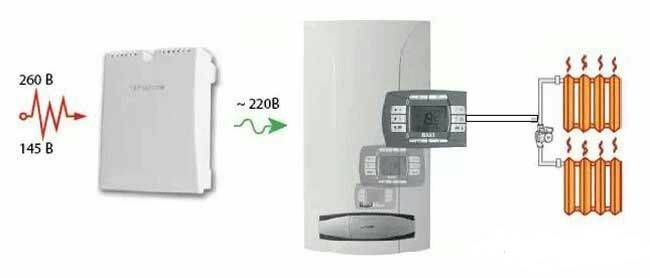

- Malfunctions of the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of high-quality grounding. The boiler electronics are very sensitive to any changes in the operating mode. When drops or jumps appear, it starts to issue a continuous series of errors that do not repeat when restarted. Often there is an accumulation of static charge on the case, which is transferred through the mass to the control board and ionization electrode, which causes the appearance of an A02 error (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for a while and restore (or create) high-quality grounding.

Connection types

In order to function perfectly and have a long service life, the hydraulic system of the boiler must be sized to meet the standards of the manual and ensure proper operation and uninterrupted flow of water.

To connect the gas connections, it is necessary to clean the gas pipes. Connection takes place strictly according to current regulations.

In addition, the boiler has an electrical connection, in which you need to properly connect to the ground loop.

The boiler must be put into operation by highly qualified specialists.

Today we will consider the types of gas heaters of the Italian manufacturer Ferroli.So, there are two types of Ferroli boilers: wall and floor. Units that are suspended are also divided into two groups - conventional and condensing. The latter are characterized by high efficiency.

No flame signal

Malfunctions in the electrical network of the boiler: often the cause of many errors.

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

Checking the polarity in the plug-socket connection: turn the plug 90 degrees and insert it back into the socket or stabilizer.

Check the potential on the metal part of the boiler: the error may be related to interference (stray currents). They appear for various reasons (power lines are nearby, a powerful source of radiation, the insulation of the power cable is damaged, or otherwise), but the result is the same: where there should be no potential, it is present. Do not forget also about installing a dielectric coupling on a gas pipe.

Check grounding: the main reason for the appearance of errors installed in apartments.

In the private sector, loop testing is carried out with a megohmmeter, when measuring resistance, it should show R no more than 4 ohms.

Check the potential on the metal part of the boiler: the error may be related to interference (stray currents). They appear for various reasons (power lines are nearby, a powerful source of radiation, the insulation of the power cable is damaged, or otherwise), but the result is the same: where there should be no potential, it is present. Do not forget also about installing a dielectric coupling on a gas pipe.

Check the potential on the metal part of the boiler: the error may be related to interference (stray currents). They appear for various reasons (power lines are nearby, a powerful source of radiation, the insulation of the power cable is damaged, or otherwise), but the result is the same: where there should be no potential, it is present. Do not forget also about installing a dielectric coupling on a gas pipe.

Failures in the gas supply to the house: often the gas supply pressure decreases on the main line and the boiler does not enter the operating mode. The check comes down to igniting all the burners on the stove at maximum mode. Flame tongues with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity, stability - the constancy of pressure and its normal value.

You also need to check:

- The position of the valves controls: perhaps the gas supply valve to the house was accidentally shut off or the shut-off valve worked during a power outage.

- Serviceability, condition of technical devices: meter, reducer (with autonomous gas supply), main filter, tank filling level (gas tank, cylinder group).

The gas valve of the boiler is faulty: we check the windings of the coils with a multimeter (we measure in kOhm).

The resistance of the coil of the modulating valve should be ~ 24 Ohm, shut-off 65 Ohm

In case of non-compliance, the gas valve is replaced (turn-to-turn short circuit). If R = ∞ is a break, R = 0 is a short circuit.

Ionization electrode: controls the burner flame, if the electronic board does not receive a signal from the measuring device, the boiler is blocked.

Common causes of electrode failure are:

Damage to the electrical circuit (break, unreliable contact, short circuit to the boiler body).

Defect of the sensor holder: it is located on the same assembly with the ignition electrodes (crack, chipped ceramics).

Wire contamination: dust, soot, oxides accumulate on it, and as a result, the sensor does not detect a flame after ignition. It is solved by cleaning the electrode with a fine-grained sandpaper.

Wire position: during maintenance, the electrode is knocked off by inaccurate actions, it ceases to detect the presence of a burner flame.

Adjust the ignition power in the service parameters menu (parameter P01).

Cleaning the burner: flame separation occurs when the nozzles are clogged with dust, there is enough oxygen, but no gas. We clean with a vacuum cleaner and a toothbrush.

Make sure there is a nominal (3.0+0.5 mm) gap between the burner and the ignition/ionisation electrode.

Condensation on the electrode: if the boiler is in an unheated room or leaks from the chimney without a reverse slope, dampness can affect all boiler appliances, it is necessary to dry the chamber.

Faulty ignition transformer: the cause is damage to the electrical circuit: open, no contact.

The electronic board is faulty: a fault in the EA circuit also initiates an error in the boiler.

Defects are detected by inspection for deformation, melting, breaks, and the like.

If the reason for the equipment failure is in the board, contact the service center indicating the alphanumeric marking of the unit.

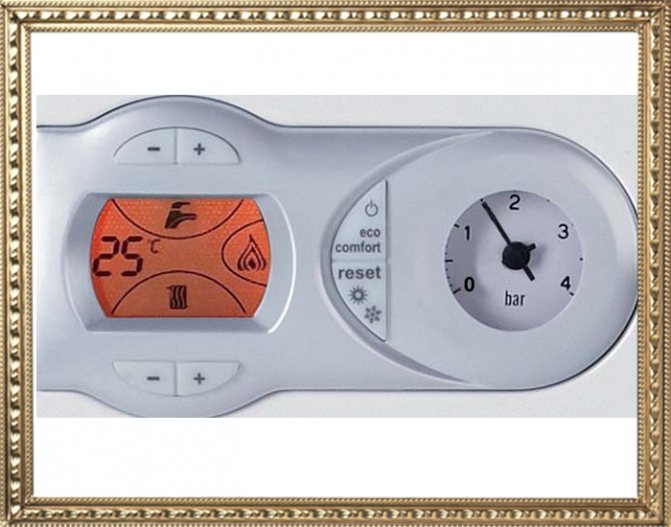

Enable and disable

Using the instructions, it is possible to familiarize yourself with how the gas unit starts and turns off. The gas cock located in front of the boiler must be opened. The air that is in the gas pipes must come out. After that, the ferroli is connected to the network, and the knobs of the regulators are set to a certain heating or hot water mode. After a certain request, ferroli will start its work. To turn off, turn the knobs to the minimum position. In this case, the electronic board is not disconnected from the voltage. The frost protection system is active.It ceases to function in the event of a power outage.

Using the remote control instruction, the temperature in the system will be at a certain level and controlled by the room thermostat.

The temperature of the heating system can be from 30°C to 85°C. But the operation of ferroli at temperatures below 45 ° C is not recommended.

The temperature of hot water supply can vary from 40°C to 55°C. By turning the knob, the desired temperature is set. When a remote control is connected, the hot water is adjusted from the remote control.

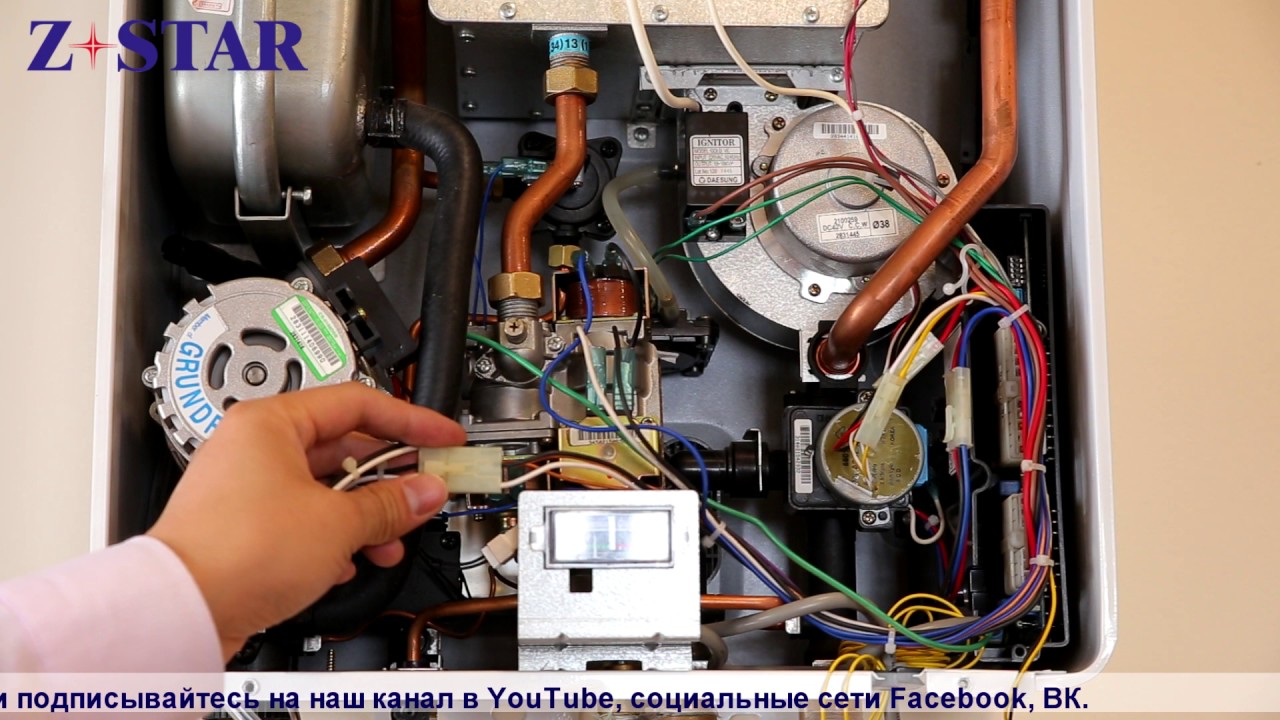

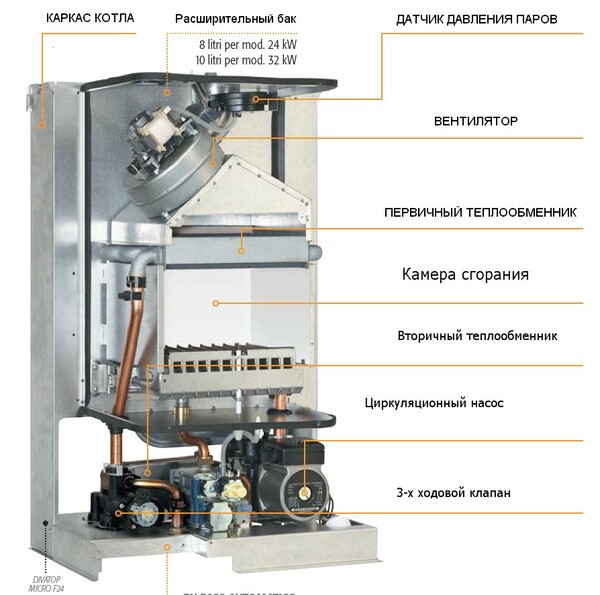

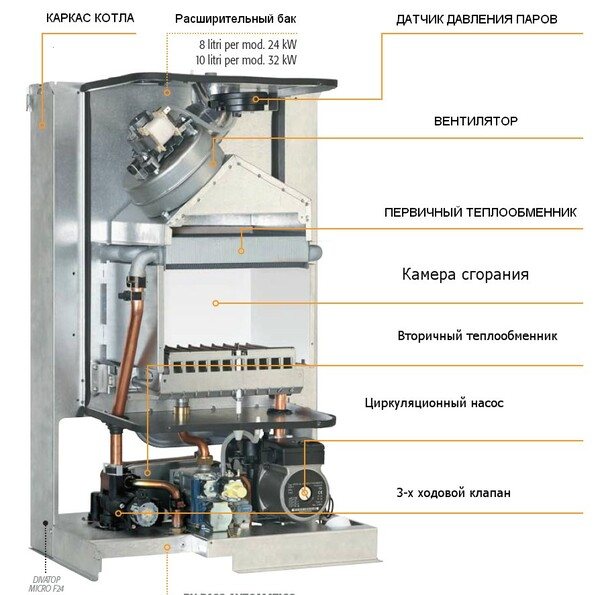

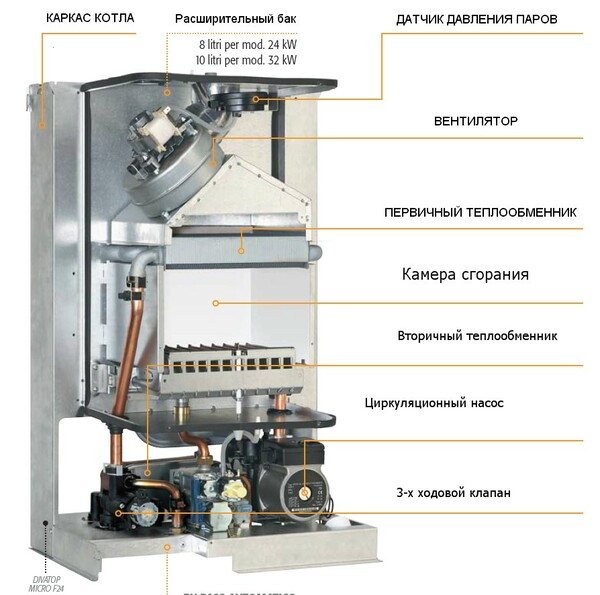

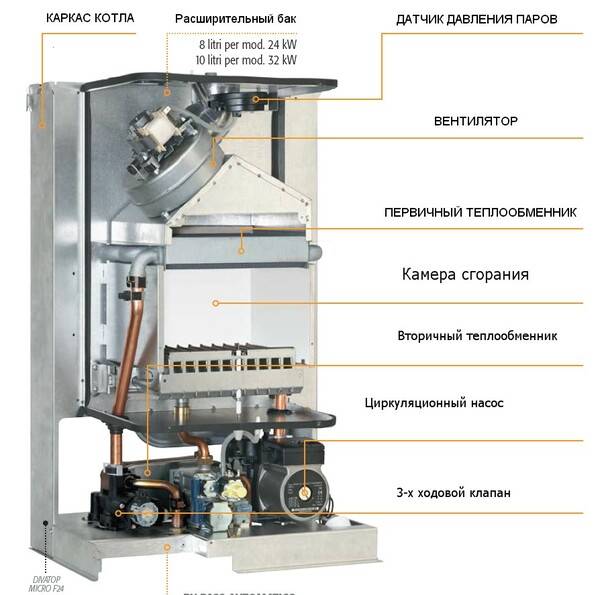

Ferroli wall mounted gas boilers

Wall heater Italian company Ferroli.

Ferroli wall-mounted boilers are available in different configurations and capacities, so you can choose a unit according to your requirements and budget. The first characteristic is the number of circuits. So, heaters can work not only to heat water in the heating system, but also simultaneously supply the house with hot water. Accordingly, single-circuit and double-circuit boilers are distinguished.

The second aspect is the type of combustion chamber and its configuration. The combustion chamber may be open or sealed. Open combustion chambers, like a conventional stove burner, burn the air out of the room (there is no fire without oxygen). Sealed chambers draw air from the street through a special chimney pipe called a coaxial chimney.

A heat exchanger (one or two) is installed in the combustion chamber. One heat exchanger (bithermic) is a pipe in a pipe, into which pipes are cut for separate smoke removal. The heat exchanger is made of copper. If there are two heat exchangers, then they are separated from each other. The primary is made of copper and the secondary is made of stainless steel.

Complete set of Ferroli gas boilers according to the instructions:

- heat exchanger (one or two);

- gas valve - Siemens or HoneyWell;

- three-speed circulation pump Wilo;

- branch pipes for smoke removal - separate smoke exhaust system;

- bypass;

- Control block.

There are models with and without LCD display. The display shows information about the parameters of the heater and errors that occur during operation. The display lights up blue. The DivaTop 60 model is available with a built-in 60 liter boiler.

The efficiency of the Ferroli wall-mounted heating boiler of any model is approximately 93%. The minimum power is 7.2 kW, the maximum is 40 kW. The unit heats the coolant for high-temperature heating systems up to 85 degrees, and the water for hot water supply - up to 55 degrees. Boilers operate on natural and liquefied gas. The nominal energy consumption is indicated in the passport for each model. The inlet gas pressure must be at least 20 mbar for natural gas and 37 mbar for liquefied gas.

How effective is vermiculite for ceiling insulation, read here.

The boiler does not start, the burner does not turn on

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board failed.

- The boiler is blocked due to a malfunction of any node.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure that you are ready for work.In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections are made, the wires are mixed up.

Why does pressure drop

The pressure drop in the boiler can be the result of three reasons:

- The appearance of a leak in the heating circuit (including in the boiler itself). A feature of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is fed. In this case, you need to find the place of the leak. First of all, you need to check the condition of the drain cock or valve, whether it is open or out of order. If no malfunctions are found in this node, the entire heating circuit is sequentially checked. Sometimes they forget to close the discharge valve on the radiators, fistulas appear on the pipelines, connections fail. It is most difficult to detect a leak if the faucet feeds a water-heated floor system poured into a concrete screed. You can detect a problem by a wet spot on the floor or on the ceiling of the lower floor, and for this you often have to remove the floor covering or stretch ceiling.

- Failure of the circulation pump. This problem is immediately detected by the self-diagnosis system, and it is easy to check the operation of the pump. It is enough to make a visual inspection of the element, and take appropriate measures.

- Expansion tank diaphragm rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intensive with an increase in the temperature of the RH. If it turns out that the problematic element is precisely the expansion tank, urgent measures must be taken to repair or replace the assembly.Otherwise, with the thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repair and restoration of the boiler.

Malfunction of the air intake/smoke exhaust system

Malfunctions in the electrical network of the boiler: often the cause of many errors.

It is strongly recommended to connect heating boilers through a stabilizer (for a boiler) or a UPS, this will save you from unnecessary costs for replacing the control board.

Checking the polarity in the plug-socket connection: turn the plug 90 degrees and insert it back into the socket or stabilizer.

Check the chimney: blockage that reduces the flue gas duct, icing on the tip. With regard to boilers with an open combustion chamber (air is taken from the room), it is necessary to ensure a good air flow into the room.

We install a temporary jumper (thereby simulating the closure of the contact) and restart the boiler.

Checking the integrity of the manostat and the tubes suitable for it: we blow into the hole of the manostat and fix the switching clicks, if there are no clicks, the manostat needs to be replaced. It will not be superfluous to check the resistance with a multimeter for closing and opening the contact.

Check the operation of the fan: make sure that the fan is working; when turned on, the impeller should spin and pressure should be created in the system. The error also appears when the turbine is running, when the fan does not reach the required speed and the thrust is lower than the calculated one.

- Performance is evaluated in dynamics (~220 per terminal). Remove the casing of the Ariston boiler, fold back the wires, turn on the power from the outlet.If the impeller rotates, there are no complaints about the device.

- The presence of U coming from the ED is checked. With error 607 of the Ariston EGIS PLUS model, the multimeter will show zero - no fan control.

Venturi device: if the boiler model does not provide a condensate trap, the tube cavity is gradually filled with liquid drops: it is easy to remove, blow through and install in place.

The gas valve of the boiler is faulty: we check the windings of the coils with a multimeter (we measure in kOhm).

The resistance of the coil of the modulating valve should be ~ 24 Ohm, shut-off 65 Ohm

In case of non-compliance, the gas valve is replaced (turn-to-turn short circuit). If R = ∞ is a break, R = 0 is a short circuit.

Ionization electrode: controls the burner flame, if the electronic board does not receive a signal from the measuring device, the boiler is blocked.

Common causes of electrode failure are:

Damage to the electrical circuit (break, unreliable contact, short circuit to the boiler body).

Defect of the sensor holder: it is located on the same assembly with the ignition electrodes (crack, chipped ceramics).

Wire contamination: dust, soot, oxides accumulate on it, and as a result, the sensor does not detect a flame after ignition. It is solved by cleaning the electrode with a fine-grained sandpaper.

Wire position: during maintenance, the electrode is knocked off by inaccurate actions, it ceases to detect the presence of a burner flame.

Cleaning the burner: flame separation occurs when the nozzles are clogged with dust, there is enough oxygen, but no gas. We clean with a vacuum cleaner and a toothbrush.

Make sure there is a nominal (3.0+0.5 mm) gap between the burner and the ignition/ionisation electrode.

Condensation on the electrode: if the boiler is in an unheated room or leaks from the chimney without a reverse slope, dampness can affect all boiler appliances, it is necessary to dry the chamber.

Defects are detected by inspection for deformation, melting, breaks, and the like.

If the reason for the equipment failure is in the board, contact the service center indicating the alphanumeric marking of the unit.

The boiler does not start (the burner does not turn on)

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board failed.

- The boiler is blocked due to a malfunction of any node.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure that you are ready for work. In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections are made, the wires are mixed up.

IMPORTANT!

If the phase is connected to the wrong electrode, the boiler will not start. It is also highly undesirable to have an electric potential between the working zero and the ground, which causes the appearance of an A02 error.

The boiler does not start, the burner does not turn on

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board failed.

- The boiler is blocked due to a malfunction of any node.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure that you are ready for work. In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections are made, the wires are mixed up.

User manual

The operation of Immergas gas boilers consists in creating appropriate conditions for the unit and non-interference in its operation.

Procedures that the user can perform:

- Adjustment of the temperature of the RH and DHW, performed in the operating mode according to one's own feelings.

- Switching the boiler to summer or winter mode (DHW supply without heating or both functions at the same time).

- Draining and filling the system.

- Cleaning the boiler body from dirt.

All other actions - annual maintenance, repair, cleaning of the chimney or heat exchanger - must be carried out by the specialists of the service center.

A particularly responsible procedure is the repair or replacement of individual components, parts. This is where a skilled craftsman is needed.

All adjustments are made on the control panel, which has a detailed device that allows you to simultaneously see several parameters of the boiler. This is much more convenient than on units from other manufacturers, but requires prior familiarization with the user manual.

All the most critical nodes are directly connected to the panel and have their own light indication.

If a problem occurs, the light will start flashing, signaling the need to take appropriate action.

The boiler does not start (the burner does not turn on)

Problems with starting the boiler are most common, since there are a lot of reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board failed.

- The boiler is blocked due to a malfunction of any node.

Most of the possible causes are detected by the self-diagnosis system, and the corresponding code is displayed on the display.

However, some possible reasons - a failure of the gas supply system, a closed valve and other mechanical obstacles, the system may not notice, so you should make sure that you are ready for work. In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes on the shield after the connections are made, the wires are mixed up.

IMPORTANT!

If the phase is connected to the wrong electrode, the boiler will not start. It is also highly undesirable to have an electric potential between the working zero and the ground, which causes the appearance of an A02 error.

The main malfunctions of Ferroli gas boilers

The design of Ferroli boilers is distinguished by a well-thought-out and high-quality study of all components and details.

However, any system has weaknesses, and gas boilers are no exception.

The operating conditions of some parts of the units are very difficult, temperature loads contribute to the occurrence of the phenomenon of fatigue of metals and other materials.

According to experts, the most common malfunctions include:

- The boiler does not turn on.There can be different causes and ways to fix them, one of the most common problems.

- Pressure drops or rises. This is a serious problem that results in either leakage of the heating medium, which causes overheating and blockage of the boiler, or overpressure and blockage. Especially dangerous is the increase in pressure, from which the parts of the unit can burst.

- Failure of the fan or circulation pump. The loss of both functions means the system is unable to function - the inability to remove smoke causes sudden overheating and blocking, and the lack of liquid movement has the same consequences, only detected by other sensors.

- Malfunctions of the electronic control board. The cause of these problems is most often an unstable supply voltage or lack of high-quality grounding. The boiler electronics are very sensitive to any changes in the operating mode. When drops or jumps appear, it starts to issue a continuous series of errors that do not repeat when restarted. Often there is an accumulation of static charge on the case, which is transferred through the mass to the control board and ionization electrode, which causes the appearance of an A02 error (the system sees a flame when there is none). The solution to the problem is to completely disconnect the boiler from the power system for a while and restore (or create) high-quality grounding.

In addition to the above, there are a lot of problems with the combustion mode:

- Too little flame.

- Spontaneous start of combustion.

- No DHW heating.

- A sharp flash of flame with a pop.

All these problems are associated with a deterioration in the gas supply due to clogging of the nozzles, failure of the thermocouple or fuel valve coil.

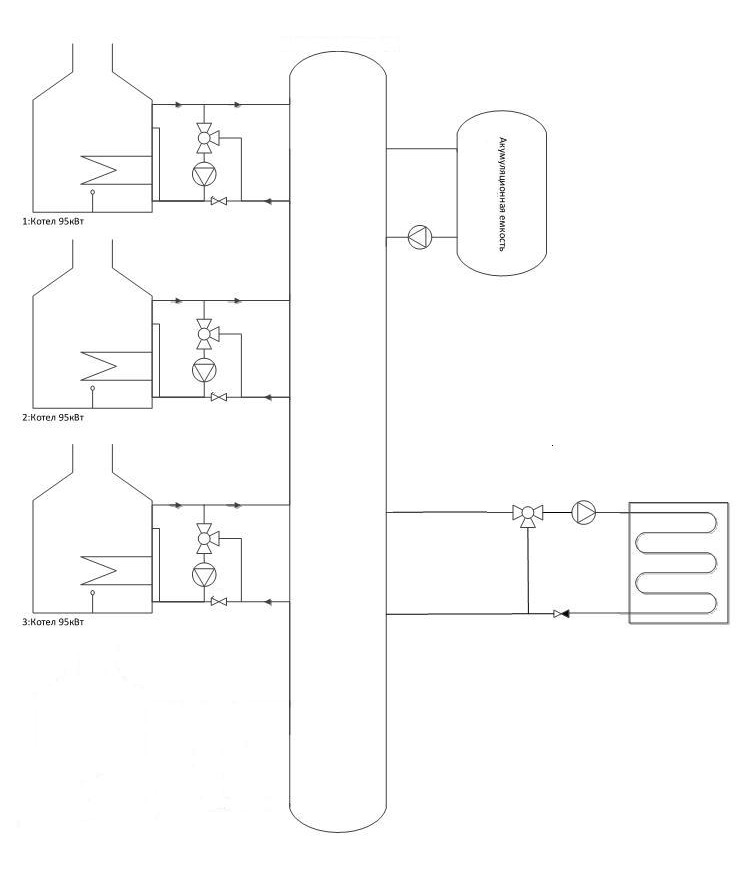

Accessories

For each category of boilers, the manufacturer also provides additional accessories. In particular, wall-mounted double-circuit models can be supplemented with a kit for smoke exhaust systems and devicesallowing the equipment to operate on liquefied gas. In turn, the Ferroli floor standing gas boiler can be equipped with boilers, hot water priority systems, turbo nozzles and devices for cascade control. Condensing units have the largest range of additional options. They can be provided with outdoor temperature sensors, control boards for multi-circuit systems, hydraulic switches, a mounting manifold frame, as well as special sets of fittings for connecting boilers.

Why does pressure drop

The pressure drop in the boiler can be the result of three reasons:

- The appearance of a leak in the heating circuit (including in the boiler itself). A feature of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is fed. In this case, you need to find the place of the leak. First of all, you need to check the condition of the drain cock or valve, whether it is open or out of order. If no malfunctions are found in this node, the entire heating circuit is sequentially checked. Sometimes they forget to close the discharge valve on the radiators, fistulas appear on the pipelines, connections fail. It is most difficult to detect a leak if the faucet feeds a water-heated floor system poured into a concrete screed. You can detect a problem by a wet spot on the floor or on the ceiling of the lower floor, and for this you often have to remove the floor covering or stretch ceiling.

- Failure of the circulation pump.This problem is immediately detected by the self-diagnosis system, and it is easy to check the operation of the pump. It is enough to make a visual inspection of the element, and take appropriate measures.

- Expansion tank diaphragm rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intensive with an increase in the temperature of the RH. If it turns out that the problematic element is precisely the expansion tank, urgent measures must be taken to repair or replace the assembly. Otherwise, with the thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repair and restoration of the boiler.

Preventive advice

Modern gas boilers are very practical and thoughtful units, they have absorbed the best experience of the past decades, combined with the latest developments in the field of boiler materials, control and protection automation. They are made block, with the possibility of replacing worn parts and assemblies.

The units, which are operated according to the manufacturer's regime maps, are able to operate for decades without emergency shutdowns and replacement of components.

The weakest components of the Proterm boilers and the Buderus boiler:

- Heat exchanger - serves to transfer the heat of the exhaust gases through the developed pipe surface to the water of the heating circuit: heating and hot water. The duration of its operation largely depends on the quality of tap water and the presence of hardness salts and suspended impurities in it, as well as on the temperature regime in the network. At a temperature of more than 70 C, hardness salts are intensively deposited on the walls of pipes from the water side, gradually clogging the flow area.Low circulation causes overheating of water and pipe walls, on the surface of which fistulas form from excessive overheating. At the slightest suspicion of the presence of scale in the pipes, chemical cleaning of the inner surface of the heater is carried out according to the technology and reagents specified by the boiler manufacturer. In order to prevent scale formation, water purification filters are installed at the inlet to the boiler.

- circulation pumps. According to the new operating rules, the gas boiler unit operates on a closed heating system, which increases the efficiency of space heating and the possibility of automatic control of thermal conditions. Repair of pumps is usually caused by the presence of damage in the mechanical and electrical parts of the structure.

- The heating circuit temperature sensor outputs a parameter that is the main one in the automatic mode control system, in connection with which the boiler is turned on / off, its malfunction may be in the contact group or caused by a break in the communication line.

- Gas burner - the main device of the boiler, which burns fuel to produce thermal energy. The repair of this device consists in cleaning the nozzles.

- An expansion tank is a unit that compensates for the excess pressure of the medium that occurs during the heating process. The repair is carried out by replacing the elastic membranes.

Most of the parts and assemblies for repairing the boiler are in the distribution network, they are also easy to find on the Internet, but if the boiler is under warranty, it is recommended to purchase them through service centers, which will guarantee not only high-quality repairs, but also its durability.

Conclusion

Italian gas boilers are distinguished by high build quality, reliability, and thoughtful design.

Immergas products are not inferior to other well-known manufacturers, representing gas boilers that meet all strict European requirements and standards. Any malfunctions, from which no unit is insured, are automatically detected and immediately displayed on the boiler display.

This significantly reduces the time for finding and localizing a malfunction, allows you to more accurately and efficiently perform repairs and increases the life of the boiler.

The main task is to create the necessary operating conditions, and the equipment will last a long time, without failures and malfunctions.

Conclusions and useful video on the topic

An example of solving an elementary problem in the event of a boiler breakdown associated with an error in the readings of the air pressure switch. Quick do-it-yourself repair:

Cleaning the flue system with a vacuum cleaner:

You can fix the Ferroli gas boiler yourself if you know the type of error and how to fix it. However, it should be remembered that gas equipment is an element of increased danger. Therefore, it is better to entrust all maintenance and repair work to representatives of the gas service with which the contract has been concluded.

In the block below, you can share your own experience in cleaning and restoring gas boilers from an Italian manufacturer. It is possible that you have useful information that is worth sharing with site visitors. Share information and photos on the topic of the article, please ask questions.