- Socket, plug

- Malfunctions and malfunctions of the electric stove

- What can be repaired without gasmen?

- The cost of a specialist

- Types and arrangement of hobs

- How is the hob arranged?

- Types of heating elements of hobs

- What may be needed for repairs?

- The operation of the taps of the gas stove is disrupted

- Violations in the operation of the burner control system

- Tools for repair

- Price for repair and connection of gas equipment

- How to fix: step by step instructions

- electrical surface

- Finding out the causes of the problem

- Recommendations of the masters for the repair of hobs

- Hob Fault Groups

- Breakage of heating elements

- Failure of switching elements or conductors

- Electronic circuits

- Nozzle clogged with dirt

Socket, plug

The problem may not be in the stove itself, but in the socket or plug. The first can be checked by connecting another electrical appliance, for example, a kettle

When choosing an outlet, you should pay attention to the rated current. If it differs from that specified on the machine, then the wiring may melt or even catch fire

For a single-phase network, a classic 32 amp outlet is more than enough.

The chrome elements of the fork must be clean with no signs of burning.If there are any, then it must be cleaned, and in difficult cases, replaced. The same rule applies here: buy a plug with an eye on the rated current of the machine.

Malfunctions and malfunctions of the electric stove

The following are the most likely causes of breakdowns and malfunctions of the electric stove during operation:

- Faulty cord and plug - the main cause of this defect is a kink or fracture at the junction of the cord with the plug. Another most common mistake that cooker owners make during use is when they turn off the device, they pull on the connecting wire, and do not remove the plug from the block. As a result, there is a violation of the electrical connection between the contacts.

- Wiring fire or short circuit - most often occurs when the stove is connected incorrectly and the operating rules are not followed. When a pan with the wrong diameter or with an uneven bottom is used, the glass-ceramic surface that is also switched on is left without a pan.

- The electric stove has stopped turning on - it occurs when the contacts in the junction box of the device are broken, the heating element is completely or partially burned out, there is a disturbance in the power source.

- There is no light indication on the electronic control panel - occurs when the cable breaks on the LCD display and on the LEDs. Also, when the oven and burners are turned on at the same time, the control unit generates an error, resulting in a failure in the control program.

- The malfunction of the burner on the ceramic hob is the main factor of the disadvantage, it lies in the switches, with prolonged exposure to high temperatures, their elasticity is lost and the contacts break.

- The appliance's oven heats up unevenly. This problem may occur due to poor-quality coating of the heating element, which is made of fusible materials. They have low resistance to corrosion and high temperatures. If the outer coating of the heating element is damaged, the devices quickly fail.

- After turning on the oven, the electric stove is turned off - a breakdown can occur if the insulation of the supply wire is weak, the circuit resistance is low, the fuse is blown, or the introductory machine malfunctions.

- The cooking time on the hob has increased - a technical malfunction consists in the wear of the heat-carrying conductor (nichrome), as a result of this, a hole occurs between the burner and the grounded body of the stove.

What can be repaired without gasmen?

There are several main causes of failures. This is the improper operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or poor-quality components.

When repairing yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

During the repair of gas equipment, the main danger is a possible gas leak.

Therefore, it is necessary to carefully carry out all manipulations for the installation and dismantling of components and parts of the device.

Particular attention should be paid to the replacement of components associated with the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for their elimination allows you to independently make simple repairs. It is worth remembering that serious repairs can only be done by gas workers, but there are procedures available for independent home craftsmen.

Boiler manufacturers strongly recommend calling gas service employees to fix problems associated with breakdowns in the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently set up, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler, these are:

- Gas burner closed / open type;

- Specific security blocks;

- Heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, chimney, boiler control devices, multi-level security systems.

Most often, users have problems of the following nature: the boiler emits an unpleasant smell of gas, does not turn on, turns off during operation, does not heat pipes or smokes

Most of these items cannot be changed and repaired by yourself.In the event of intervention in the design of the boiler, its owner loses the right to restore working capacity at the expense of the manufacturer during the warranty period. But what and how the masters from the organization with which the contract for the maintenance of the unit and the supply of gas is repaired must be known.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is produced in cases of weakening of traction by mechanical manipulations or with the use of chemicals.

- Checking the tightness of the water supply connections, gas supply lines, heating circuit branches.

- Installation of a voltage stabilizer.

Once again we warn that all actions for the implementation of which it is necessary to remove the casing from the boiler must be performed by a representative of the gas service.

However, if the warranty is not important for you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade aqueous solutions of citric acid (100g / 1l) or suitable household chemicals that can dissolve calcium deposits.

- Servicing the blower fan. Replace the fuse or the fan itself, check the electrical circuit connected to it, lubricate the bearings with technical fluid.

- Nozzle cleaning. Clogged nozzles cause a weak burner flame. They periodically need to be cleaned with a fine sandpaper and remove dirt with rags with household chemicals.

- System pressure regulation.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to make a visual inspection of it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the warranty from the manufacturer has already expired.

If you smell gas, you should immediately forget about your own intervention. It is necessary to shut off the gas supply, immediately produce salvo ventilation and call an emergency gang. The detailed rules for the operation of gas equipment are set out in the following article, the contents of which we strongly advise you to read.

The cost of a specialist

If you do not dare to do the repair yourself, you can involve a third-party specialist. The cost of calling a master electrician of household appliances will depend on the characteristics of the breakdown.

Consider the approximate prices that are relevant in the market for these services in 2019:

- Primary diagnostics and call of the master. From 500 to 1000 rubles. Some craftsmen do free diagnostics if they are paid for further repairs.

- Replacement of the central block. From 1800 rubles, excluding the cost of the part.

- Repair/replacement of heating switch or power regulator. From 1100 rubles excluding the cost of the part (in case of its replacement).

- Shadow replacement. From 850 rubles, excluding the cost of the part.

All prices are based on the average cost of services in Moscow and the Moscow region. When calling the wizard, you need to take into account the complexity of the breakdown.For example, if your central control unit is out of order, it may make sense to refuse to repair, since the cost of a new part can rise to 50-60% of the price of a new electric stove.

It is not so difficult to independently assess the condition of the oven. The main thing is to observe the order of disassembly. When removing the hob, you need to be especially careful with the wires. It is best to mark the order of their connection with paper stickers. If you doubt your own abilities, call a household appliance repairman.

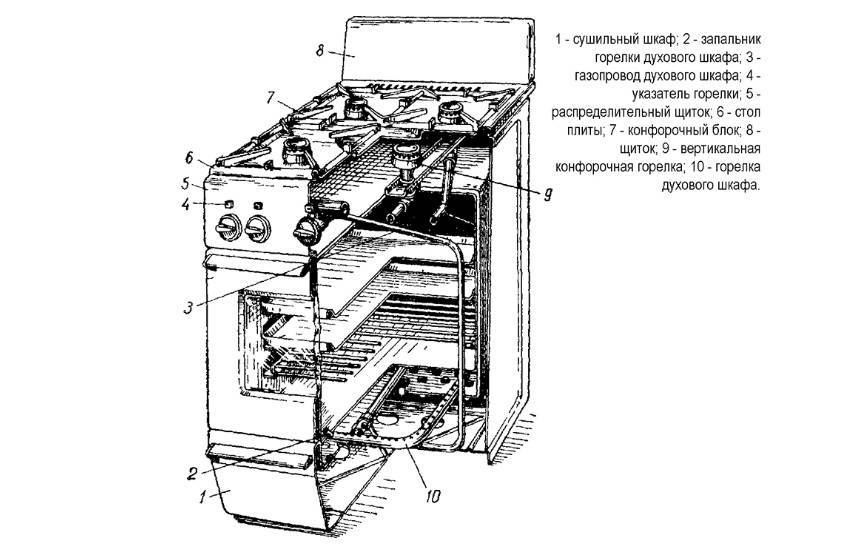

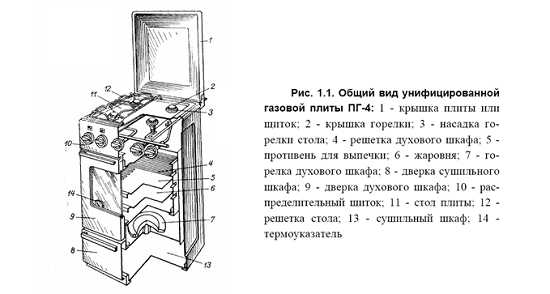

Types and arrangement of hobs

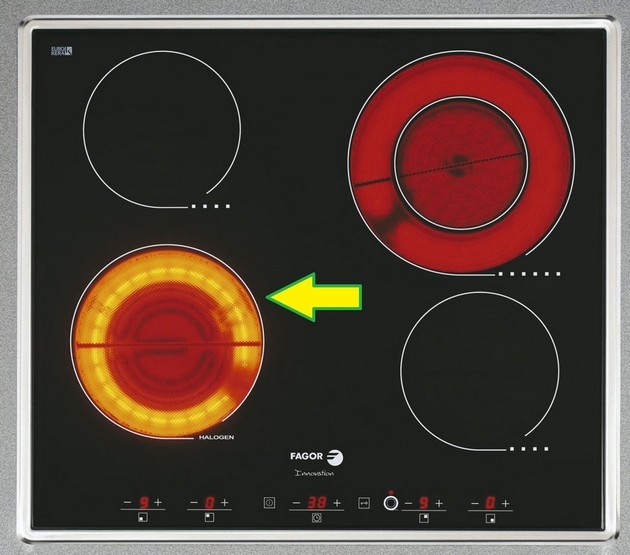

The hob is an electric or induction hob covered with ceramic or glass ceramic. To date, the following surfaces are produced:

- induction. They work on the principle of electromagnetic induction. Cookware made of special materials and a burner create a circuit with an electrical oscillation;

- spiral. The current passes through the spiral element, then heat is released, from which the dishes are heated;

- corrugated tape. The working process is similar to spiral devices. The only difference is the accordion heater;

- halogen. A plate with a tubular heater filled with halogen vapor heats up in 2 seconds. After warming up, the heating element is turned on.

To quickly identify problems during the repair process, it is important to know the design of the equipment

How is the hob arranged?

The main components of the device are burners with contacts for connection and a thermal relay. By means of wire contacts, the burners are connected to the control panel. With the help of a thermal relay, heating control and power off are performed. The control unit is responsible for the execution of the main programs.To turn on, use a button, a gas valve or a cord with a plug.

The main elements of the hob - burners and control panel

The main elements of the hob - burners and control panel

Types of heating elements of hobs

AT cooking surfaces used several types burners:

- induction - they heat only the dishes, and the working area itself is almost cold. Temperature and power can be adjusted from minimum to maximum;

- rapid - spirals that heat up and cool down in 10 seconds;

- halogen - a spiral with red illumination, which heats up in 2 seconds and releases a large amount of heat;

- Hi-Light - very thin spiral tapes that heat up instantly. High-resistance alloy provides minimal power consumption - up to 2 kW per hour;

- gas burners - automatically supply fuel, smoothly adjustable and heat up gradually;

- electric - cast-iron pancakes, the heating of which is indicated by a red circle in the center.

Interesting to know! Depending on the diameter of the heating element, the flame of gas models can burn in 2-3 rows (“crowns”).

What may be needed for repairs?

Any home master who decides to fix his electric stove on his own must clearly understand electrical engineering, know how it works and the safety rules that must be observed when performing work of this nature. In addition, a person must be sure that he will be able to carry out such a complex repair, independently determine the cause of the breakdown and eliminate it.

You will also need a certain set of special tools:

- To disassemble the plate, you should have at hand screwdrivers for a slot or a cross, with different thicknesses of the tip.

- You will definitely need box and open-end wrenches, wire cutters, pliers.

- For interior work, you will need a soldering iron, special side cutters, electrical tape, a device for measuring resistance and voltage.

The operation of the taps of the gas stove is disrupted

- Old-style gas stove taps can become clogged with excess grease. They can be taken apart and cleaned. In modern stoves, this malfunction does not occur.

- If the taps turn with difficulty, grease and dust are most likely stuck to the swivel mechanisms. Remove the faucets, wash the adjustment knobs and all parts of the faucets with soapy water, dry and reinstall.

- Sometimes turning valves is difficult due to lack of lubrication. Disassemble the tap, clean it of dirt and the old layer of grease, apply a new one in a thin layer.

- The handles of the cranes turn when turned on if the rotary mechanism is damaged. After removing the faucet handle, inspect the condition of the seat. On the side where the tap stem enters, there should be a small metal plate. If it fell out, the diameter of the hole increased - the crane turns. You can make a new part from a tin can. In some cases, it may be necessary to replace handles or taps.

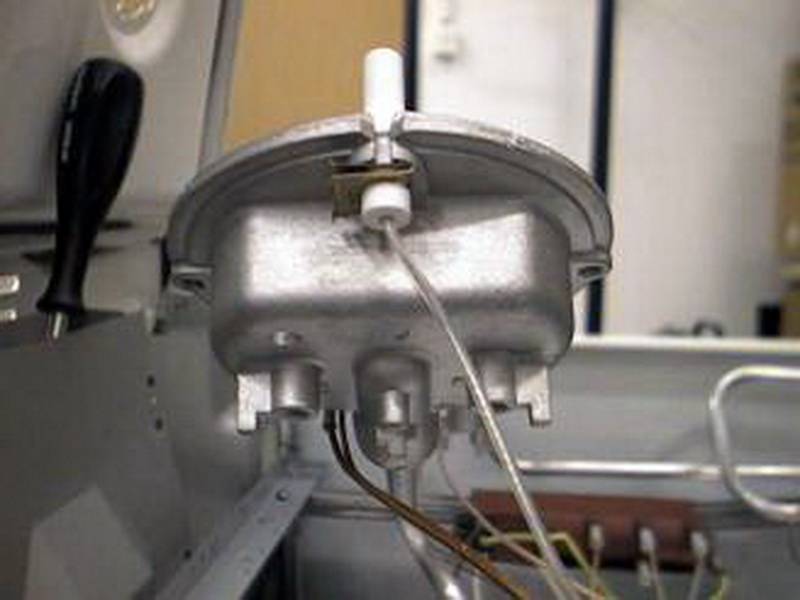

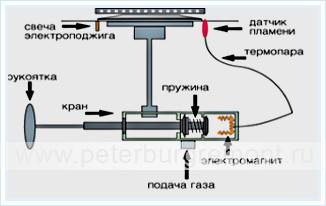

Violations in the operation of the burner control system

Modern gas stoves are necessarily equipped with flame front control systems. A thermocouple tongue is installed on the burner, which perceives heat from the flame. The heated thermocouple produces a small voltage across the contacts.

At the moment the burner is turned on, the handle is recessed by 3-5 mm, which leads to the fixation of the opening tap on the electromagnet built into the body.As long as the magnet receives voltage from the thermocouple, the gas valve remains open.

Repair of the control system is completely similar to the procedure for restoring the ignition system. Most often, a thermocouple is covered with a thick layer of deposits that interfere with the heating of the sensor. All repairs are reduced to a thorough cleaning of the thermocouple and its installation in the socket.

Experts also recommend cleaning the contacts on the connecting wiring, the voltage is low, so even a thin layer of fat deposits on the connectors can disable the system.

Tools for repair

To carry out repairs of any kind, you need to prepare a set of tools:

- To dismantle the plate and its elements, a screwdriver with interchangeable tips is useful.

- To determine the presence of voltage - a multimeter.

- To perform electrical work, shorten and strip the cable - assembly knife.

- For installation work - pliers, wire cutters, which cut the wires.

Attention

Socket wrenches may be needed for repairs, circuit diagram, therefore, owners who decide to repair the hob on their own need to take care of such details in advance.

Price for repair and connection of gas equipment

Gas burners turn off by themselves. This malfunction of the gas stove is caused by a breakdown in the gas leakage control system. Both the temperature sensor and the solenoid valve that shuts off the gas can be directly faulty.

Faulty electric ignition of the gas stove. If the electricity to the stove is supplied properly, and the electric ignition does not work, then it is out of order.The ignition unit needs to be replaced.

Loud noise during gas burner operation. Noise arises from uneven supply of gas and oxygen to the burner. The burner may have been moved or not level after cleaning. Try installing a new burner. If these measures do not solve the problem, it is likely that the divider needs to be replaced.

The burners of the gas stove burn weakly. Weak burning of gas stove burners can be due to two reasons. First, problems with pressure in the gas pipeline. Second, the gas supply hose is pinched. Check the hose for creases and pinches, if such a problem is not found, contact a specialist.

The gas stove burner does not ignite immediately or does not ignite at all. Possible malfunctions in this breakdown are as follows:

- clogged burner nozzle,

- faulty spark plug

- burner moved,

- the gas leakage control system is faulty.

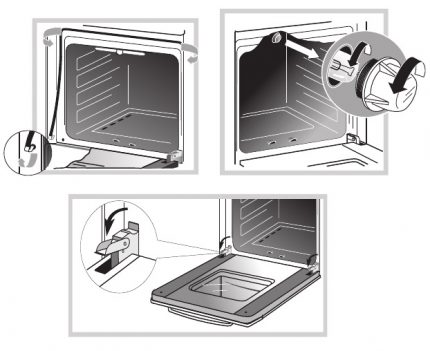

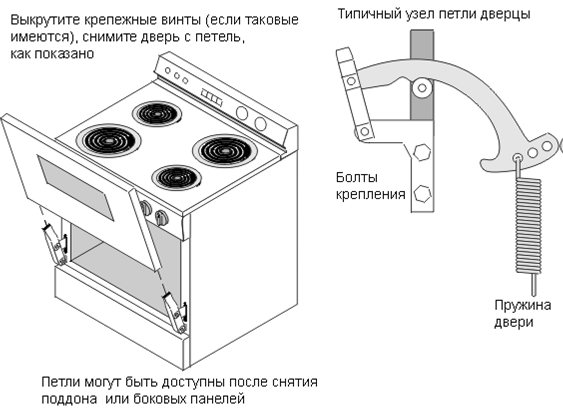

How to fix: step by step instructions

Depending on the problem that has arisen, one or another instruction is used:

Do-it-yourself regulator repair begins with shutting off the gas supply. Then they clean the taps (remove carbon deposits, grease and dirt from them, clean the spring). Gently wipe the cork with a soft sponge. Then it is treated with graphite grease, but the holes in it are not touched. A knife is used to remove greasy deposits from the stem. The handle is assembled in the same sequence, but in the opposite direction.

A gas oven cannot function properly without a tight-fitting door. To fix it, you need to unscrew the fastening screws that are attached to the plate. After they are well loosened, the doors are carried out several times in different directions until it finally sits on the hinges

Important

As a control, after completion of work, an ordinary sheet is placed between the seal and the edge of the oven. It should be tightly clamped when the door is closed.

If this does not happen, then the whole procedure should be repeated again.

In the event of a gas leak and a strong smell of burning, it is necessary to shut off the fuel supply. The leak is covered with soap suds, as are all gas pipe connections inside and outside the oven. In the place where the fuel will come out, bubbles appear. All knobs, faucets and regulators are tested. After removing the side panel, prevent leakage in the same way.

If the burner nozzle becomes clogged, it must be replaced or cleaned. Incorrect operation of the thermostat leads to a decrease in the heating level. The decrease is fixed by a temperature sensor, which is installed in each stove system. The emergency shutdown of the gas supply is due to a malfunction of the nozzle valves.

With the available voltage, it may not be enough to turn on the system. In this case, the thermocouple may be in working condition, but be far from the power source. In this case, you need to remove this part and screw it at a closer distance.

If the gas cock is jammed, check the lubrication. Lack of it will lead to failure of the entire system. A rotating mechanism without proper impregnation will constantly become clogged with small particles. To clean the parts, you need to wipe them well and put them back in place, having previously treated them with grease.

here

electrical surface

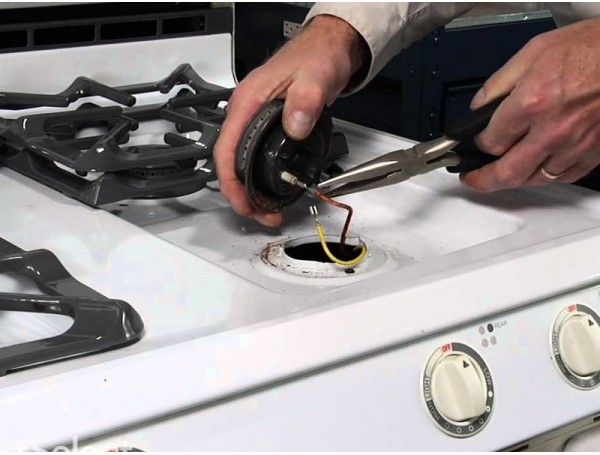

First, let's talk about how to repair an electric hob and what kind of malfunctions this stove option can have.Most often, owners are faced with a situation where the hob does not work or one of the burners does not heat up when the power is connected.

In this case, the repair comes down to the fact that you need to perform the following steps:

- Check the voltage in the outlet, because. it is possible that this particular electrical point has failed, as a result of which there is no power.

- Carefully inspect the cord and plug for mechanical damage. Sometimes this is where the repair ends - you just need to replace the electrical plug or cord.

-

Dismantle the hob from the countertop by disconnecting all wires and unscrewing the mounting strips.

-

Using a multimeter, check the thermal fuse (pictured below) and the transformer. If there is no resistance or it differs from the nominal, it is necessary to replace the circuit elements with new ones.

-

Check all wire connections (on the control unit, switches, thermostat, burners) and make sure that there is no banal open circuit. First, try to visually find the fault, and then ring all sections of the circuit according to the diagram with a multimeter.

Often, finding a broken electric hob with your own hands is not difficult if you know how to handle a multimeter. In the absence of this device, you can use an indicator screwdriver, which will show the presence of voltage in a certain section of the circuit.

In addition, I would like to tell you why the hob may stop working so that you know the cause of the malfunctions and how to repair each. So, among the main breakdowns, the most common are the following:

- The fuse blows as a result of a power surge. Replacement is not difficult, besides the cost of the fuse is negligible.To protect the equipment from such a malfunction, it is recommended to install a network surge protection device.

-

The burner does not work (one or several at once). Most likely there was an open circuit on the heating element. If this wiring is unsoldered, do-it-yourself repairs will not be difficult if you have a soldering iron. If the heating element is burned out, it must be replaced with a new one. They called the heating element, but is it whole? Check the control unit, sometimes an open contact occurs on the switch, which needs to be either repaired or replaced.

-

The sensor is not working. Here things are already more serious, because. the touch hob will be difficult to repair for a novice electrician. First, as in previous cases, ring the sensor. If you can’t find the banal cause of the malfunction, you will either have to replace the touch panel or send it in for repair. Usually, the failure of this circuit element is extremely rare and is caused by improper operation of the equipment. If you find that the sensor does not turn on after washing, then the control unit simply burned out from the saline solution, which is recommended by some would-be advisers on the forums to wash the surface.

- Doesn't get hot or doesn't get hot enough. Again, ring the heating element, thermostat, temperature controller. The opposite situation may occur when the electric hob gets very hot and does not turn off. In this case, with a probability of 95%, we can say that the cause of overheating is the failure of the thermostat, which does not turn off the power when the burners are sufficiently heated. The thermostat cannot be repaired, so it must be replaced.

- Cracked surface.The rarest of cases that can happen with a glass ceramic hob. If you see that a web of cracks has formed on the surface, and at the same time you are 100% sure that none of the family has dropped heavy dishes on it, there may be two reasons.

Finding out the causes of the problem

If the burner on the gas stove does not burn well or does not ignite, then you must first disconnect the equipment from gas and electricity. The hob may only be inspected and repaired after the gas supply has been shut off.

It is impossible to neglect elementary security measures here.

Whether or not there is a smell of gas in the kitchen after the burner is attenuated - it does not matter, any manipulations with the maintenance of gas equipment should be performed only with open windows and good natural ventilation of the room

Many modern gas stoves are equipped with electronics and automatic ignition systems that require power. Often, inexperienced home craftsmen, when working with a gas hob, forget about this feature of this appliance. As a result - ignition of methane vapor from sparks. Therefore, before starting repairs, it is recommended to disconnect from the network not only the stove itself, but in general all electrical appliances in the kitchen.

Problems with gas stove burners arise due to:

- incorrect operation of the solenoid valve and/or thermocouple;

- nozzles clogged with grease and soot;

- faulty spark plugs;

- a long break in the service of gas equipment.

Owners of private houses and apartments where there is a gas stove are required to conclude an agreement for regular inspection of the equipment in question with a specialized organization. Without such an agreement, gas will not be supplied to the consumer.

And gas workers should come at least once a year, checking the efficiency of the hob and, if necessary, immediately repairing it. All other calls are charged separately.

If problems with the stove arose during the period between routine checks, you will either have to call the master again, or make repairs yourself

If problems with the stove arose during the period between routine checks, you will either have to call the master again, or make repairs yourself

At the same time, if during self-repair of burners and other devices of the hob they are damaged, then it is forbidden to turn on the faulty appliance without gas workers. Even if the stove is more or less operational, then during the annual check, a gas company specialist will identify a breakdown and immediately turn off the gas until the defects are eliminated. And this is an inevitable additional cost. Plus, they can also impose a fine.

Do-it-yourself repair of a gas stove is recommended only if you are sure that you will do everything right

There are no special difficulties in these works, but you can break something by negligence or ignorance

The problems are as follows:

- The flame is not supposed to be blue - there is not enough oxygen or the gas is supplied to the nozzle in too much volume.

- The burner does not ignite - the spray holes are clogged with soot or the thermocouple or candle is faulty.

- The fire goes out - the gas supply is cut off due to a faulty gas control or problems with the gas pipe.

You can clean or replace the burners on the gas stove yourself.But if the problem is the meter, directly the gas pipe (cylinder) or an external gas sensor, then it is better to refuse arbitrariness.

In such a situation, you should seek help from the gas workers responsible for the health of the VKGO and VDGO.

Recommendations of the masters for the repair of hobs

- Screw terminals and coiled rivets are used as temporary measures.

- The main cause of breakage of hobs is non-compliance with the manufacturer's instructions.

- Induction hob should only be repaired by a specialist.

- In the absence of a multimeter for individual sections of the circuit, you can use an induction screwdriver.

- The dismantling of the hob is carried out after disconnecting the wires and unscrewing the fasteners.

- Thermocouples are soldered to the chip or connected through a cord.

Watch a video about the device of the hob and its repair

Hob Fault Groups

Regardless of the type of heaters, the main failures of the panels are similar. Repair of your hob is needed when typical faults are found.

Faulty hob requires immediate repair

Faulty hob requires immediate repair

Breakage of heating elements

Mechanically damaged parts are repairable. For halogen models, the heater needs to be replaced, and the induction winding is almost not prone to failure.

Failure of switching elements or conductors

You can troubleshoot contacts, thyristor keys, relays in 1 day. Repair work with knowledge of the design of the plate and the availability of relevant skills will not present any difficulty for you.

Electronic circuits

If the user does not know how power supplies, controllers, generators and transformers work, it is better to entrust the repair to the master.The burnt element must be dismantled and replaced with a new one.

Important! Before starting work, it is worth checking the power supply from the outlet, the presence of moisture on the panel or dirt on the sensor unit. They can interfere with button sensitivity

Nozzle clogged with dirt

Another popular reason why one or all burners do not light up is a nozzle clogged with dirt. It is a small nozzle through which gas is supplied. To clean it, you should follow strict recommendations so as not to worsen the situation and not endanger yourself:

- remove the burner, clean it if necessary;

- find a small hole - a nozzle;

- with a needle, an unbent paper clip, a wire, carefully clean it, turn the tool in one direction and the other. The object used must pass freely through the channel! If there is an obstacle, be sure to contact the appropriate service, do not break through it yourself;

- assemble the burner and check the work.

You can not run gas directly through the nozzle, not covered with a disk - burner!

Systematically clean the stove with high quality, make sure that dirt does not collect on the surface. Proper care is the best preventive measure in such a situation.