- Self repair gas stove

- Troubleshooting step by step guide

- Symptoms

- How to disassemble the electric stove?

- The reasons

- Broken "gas control" burners

- Instructions: how to turn off the gas stove during the repair

- When should an injector be replaced?

- Results of the work done

- Common problems and solutions

- If the burner burns weakly

- The burner burns weakly or goes out

Self repair gas stove

It is impossible to imagine any kitchen without a hob, whether it is an electric or gas stove, since it is on these units that the cooking process takes place. But unfortunately, these devices fail over time for various reasons. Gas stoves should be repaired, repaired and serviced by a qualified gas service specialist. But there are minor malfunctions in which you can fix the gas stove on your own. So, you can repair a gas stove with your own hands with the following malfunctions:

- one or all burners do not light up;

- electric ignition does not ignite gas;

- after igniting the gas, the burner goes out;

- the oven lid does not close.

Troubleshooting step by step guide

Algorithm for identifying the most common equipment failures:

- Check the presence of voltage at the terminals of the supply cable using a voltmeter. After making sure that power is supplied to the control panel, press the "Sand" button. Sound and light indication is activated on the touch panel.

- On the introductory machine located in the power supply switchboard, the voltage on the upper contacts is checked. This process is carried out using a multimeter, a low voltage indicator (UNN) and a single-pole indicator.

- The voltage supply to the mechanical and electronic control mechanism is carried out using a special unit. To check the health of the cooking zones, it is necessary to alternately measure the electric current with an ammeter.

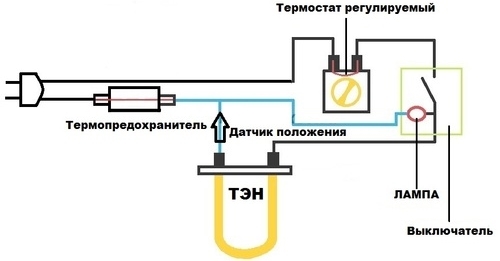

- Tubular electric heaters, temperature sensors, electrical switches, normally open and closed contacts, all kinds of regulators are checked for faults and to find the causes of device failure.

Symptoms

Are you trying to light a burner but the ignition does not work? This is a fairly common problem for gas equipment owners. If you notice malfunctions in the operation of electric ignition, you should call the master at home. You can carry out preliminary diagnostics and try to determine the problem, but it is not always worth it to repair the electric ignition of a gas stove on your own - this can only exacerbate the problem.

Signs by which you can determine that the electric ignition has stopped working are:

- continuous clicking of electric ignition;

- when the button is pressed, the electric ignition does not work;

- ignition continues after the button is released;

- the constant appearance of sparks when the button is off;

- the burner in the gas stove does not work or works with varying degrees of success;

- knocking out the machine in the shield.

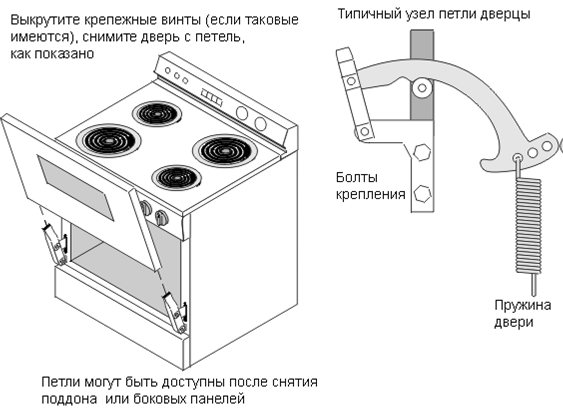

How to disassemble the electric stove?

Plates can differ not only externally, but also in design and dimensions. There is no specific algorithm that would be suitable for disassembling absolutely all models. But without exception, all devices have a thermal insulation layer, which should be handled very carefully.

The first step is to dismantle the hob, which is fastened with screws to the body. It is enough to unscrew them and it can be easily removed. It is under it that the burners, wires, mechanical temperature controllers located on the front panel are located. All these parts must be dismantled in order to get to the bottom of the appliance, where the oven heating elements are located.

It is easier to work with modern stoves - they are equipped with glass-ceramic hobs and in order to disassemble the body and get inside, it is enough just to remove the top panel.

The reasons

Gas is a source of extreme danger. When mixed with air, it becomes highly flammable and explosive, so there are only a few steps you can take when doing repairs yourself without calling a qualified technician. You can identify some possible reasons for what is happening. The main ones are as follows.

- Lack of oxygen. May cause fire problems. Try starting the device with the door open.

- Burners clogged. Perhaps this part is simply contaminated with combustion products, then the heat is uneven or it is simply not enough. The gas control system can shut off the gas supply, assuming that there is no flame, the fire will go out immediately after the handle is released. The problem is easily solved. Remove burner, clean and reinstall.When cleaning, use a liquid agent, powdered substances spoil the technique.

- A burner misalignment has occurred. If the burner is incorrectly placed or misaligned, this will result in uneven flames and heat build-up, resulting in soot. Check the location of the part and correct it if necessary.

- Decreased fuel pressure in the pipeline. Check: it is possible that there is no need to call the master, and the cause of the trouble lies in an almost empty cylinder or problems in supplying gas to the gas pipeline. Weak flame intensity may prevent the system from starting.

- Doesn't hold regulator. Are you turning the knob but not turning on? To check, try to ignite without it. Carefully dismantle the handle, keeping all the small components that are hard to find later. Arm yourself with pliers, lightly press down and turn the valve stem. When the gas comes out, try to light it.

- The auto-ignition function is broken. If the gas is flowing, but the flame does not ignite, do not keep the knob turned for a long time and gas the room. There is a hole in the front center of the oven for lighting matches.

- The temperature sensor has moved out of the flame zone. Then you need to return it to its previous position to resume work.

When the baked goods are poorly baked, the heat in the oven is weak, it may be time to change the rubber door seal.

Despite the fact that ovens are the “long-lived” among household appliances, and some of them work for more than 50 years, malfunctions still occur due to broken parts inside the device. Sometimes gas control components wear out. It is possible that the contacts in the system have oxidized and need to be cleaned.During operation, there is also a constant heating of the thermocouple, which leads to its destruction. Sometimes this part is beyond repair. It is simply replaced with the same new one.

The temperature is maintained by a mechanical thermostat. It is a liquid-filled container. The appliance is placed inside the oven. At high temperatures, the cylinder filler expands, pushes the valve, which closes the gas supply. If the oven is consistently low on heat, the thermostat may need to be replaced.

One of the reasons why the device cannot be turned on may be the wear of the ignition unit or a faulty solenoid valve. The longer the period of operation, the greater the likelihood of such troubles. The valve is usually just replaced. The function of the unit can be checked. Turn off the lights in the room at night. Turn on the electric ignition. Look at the result:

- there is no spark at all - the wiring is damaged;

- the spark goes to the side - a crack in the candle;

- a yellow or red spark - a block has worked.

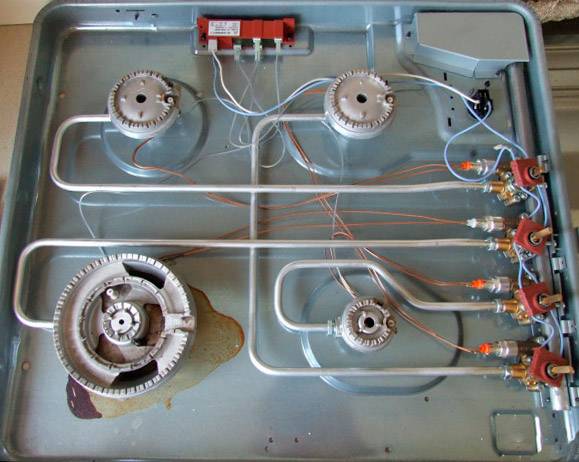

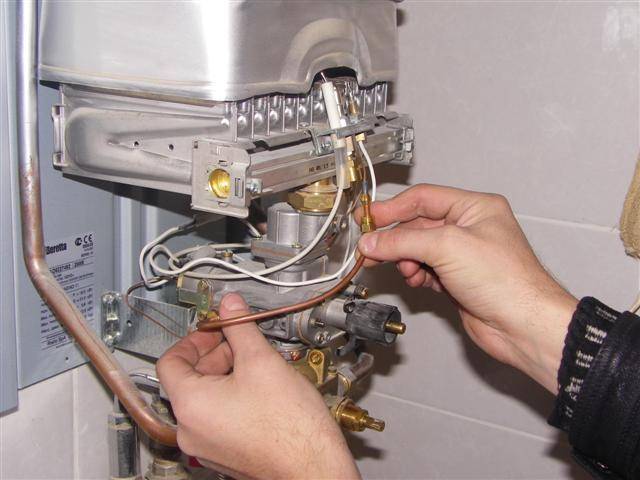

Broken "gas control" burners

If after cleaning the burner continues to go out, the fire burns, but is not fixed, the cause of the malfunction lies in the automation. It is possible to determine the state of automation using a multimeter. The thermocouple measures the voltage under heating. The solenoid valve is called for a broken winding.

6 reasons why the gas stove burner does not work.

We repair automation. "Gas control" is a set of parts working in pairs (thermocouple and solenoid valve).When heated, the thermocouple generates electricity to magnetize the valve. Loss of contact, as well as mechanical wear, will lead to a rupture, and the combustion of the gas will stop. It is easy to repair: we dismantle the table tray and securely fasten it in an upright position. A thin copper-colored wire from the burner to the gas stove faucet is called a thermocouple. The junction of the tap and the thermocouple is a contact. Separate the parts and clean the contacts with sandpaper, connect and screw securely.

Tip: If the gas control stops working, replace the thermocouple or solenoid valve. Install original spare parts according to the hob model. Universal parts differ in the diameter of the seats. The fit and installation height of the thermocouple plays an important role.

Instructions: how to turn off the gas stove during the repair

Very often it is necessary to turn off the stove to replace the flooring or carry out repairs. When you turn off the electric stove, there are absolutely no problems, you just need to unplug the cord from the outlet

When turning off the gas stove, it is important to observe safety precautions and it is advisable to contact the master in the gas service

Regardless of the model of the gas stove, turning it off consists of such actions as:

- Shutting off gas access;

- Dismantling the locknut;

- Removing the clutch on the descent to the plate;

- Plug installation.

Regardless of how long the gas stove needs to be turned off, it is imperative to control the flow of gas into the burner, since an explosion can occur when fuel is mixed with air. If the stove needs to be turned off for a long time, then a plug must be installed on the pipe leading to the gas line.

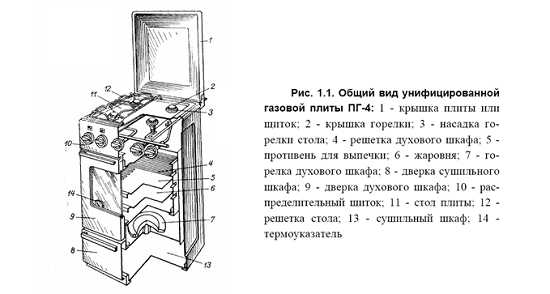

Regardless of whether the old gas furnaces, in particular, such as Darina, Wrozamet, Brest 1457, Elekta, or new, modern models, the principle of their design and operation is identical. Models in which the surface of the hob is separate from the oven are considered very convenient and functional. In particular, we can distinguish such Hephaestus, Ariston, Indesit, Ardo, Kaiser, Hansa. Multifunctional devices that are easy to maintain and repair are considered such as Hansa, Gorenje, Bosch, Zanussi.

When should an injector be replaced?

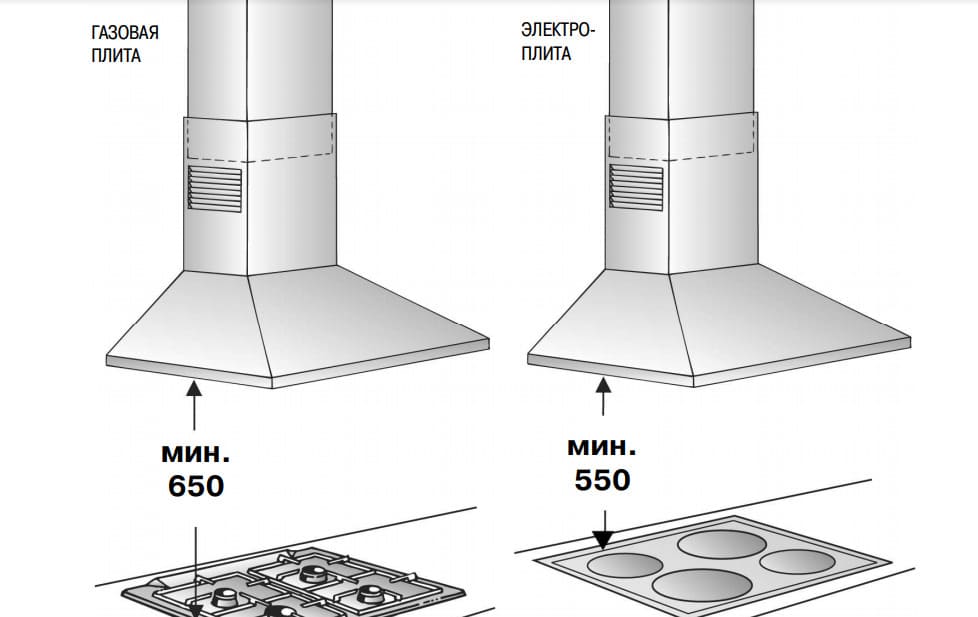

Modern gas stoves, for the most part, are designed for a centralized gas supply. Methane is used in central networks, the pressure in the system is different from the pressure in the cylinder, so a slightly larger nozzle hole is needed. When using bottled gas, propane is used for domestic needs, so a jet with a smaller opening is needed.

The basic configuration always uses nozzles designed to supply fuel through centralized lines. The package of modern models may include a spare jet designed for bottled gas. Also, for the use of cylinders, the gas reducer will additionally have to be replaced.

Trying to get rid of the cause of the appearance of soot on the burner of a household gas stove, it is important to purchase a jet that matches the brand of household appliance. Otherwise, the replacement of the part will not bring the expected result.

The correct selection of the jet, competent installation ensures the smooth operation of the gas stove. If there are installation errors, fuel will be supplied unevenly

The correct selection of the jet, competent installation ensures the smooth operation of the gas stove. If there are installation errors, fuel will be supplied unevenly

In older models of gas stoves, the nozzle is missing.However, they are equipped with a mechanism that allows you to regulate the intensity of fuel flow. It needs to be configured correctly. Adjustment is carried out by turning the tap, which is equipped with a gas cylinder. Without unscrewing the valve to the end, it is easy to reduce the gas pressure in the system, minimizing the likelihood of soot.

In some situations, soot appears when the oven is turned on. It is likely that the injector needs to be replaced here. In most gas stoves, the jet is located behind the left wall of the oven chamber, into which the burner is inserted, curved in an arc. To replace the nozzle, unscrew the screws, remove the burner, find and replace the part.

With prolonged use of a gas appliance, the jet could stick to the burner nozzle. In such a case, it is necessary to lubricate it with a special compound, wait a few minutes.

When the jet is deformed, the fuel flows to the burner unevenly, soot may appear, gas may accumulate in the device, which is dangerous. To replace the nozzle, you need to look at the brand of the gas stove, select the appropriate components.

It is important to remember that gas equipment is potentially dangerous, therefore, in case of any breakdowns, it is advisable to invite specialists from the gas company with which you have a service contract

Results of the work done

After gas supply and control soaping, no gas leaks were found! The tap is airtight and began to work much more pleasantly, without jamming!

Alexander Birzhin, rmtn.ru

Details Posted on 12/20/2016 04:38 PM

What should I do if I smell gas in the kitchen? It is highly likely that this is leaking the gas valve, which is located directly in front of the device.

As soon as you smell it, you should call the emergency service, because the gas is very explosive.

But it is also worth knowing how to deal with such situations yourself. If the valve is to blame for the leak, then it is better to replace it; for polypropylene pipes, a frialen 63 ball valve is suitable. But it may be enough just to lubricate the faucet. To do this, we will study in detail the instructions on how to scrupulously lubricate the tap.

Tools and materials that we need in the work:

Flat-blade screwdriver Rag Gag Graphite, solid oil or petroleum jelly Soap In order: 1

Examine the gas faucet, paying attention to how the main part of the faucet is made. It can be made in the form of a conical shape with a hole through, or pressed by a twisting spring using a special plug.

2. Turn off the gas supply to the house or apartment about the possibilities, this minimizes the possibility of an accident. If the gas could not be shut off, then you can work like that. Only you need to take into account important rules: Turn off all electrical appliances from the outlet; Ask all people not involved to leave the room, if possible, from the premises. Make sure there are no open flames in the room and never smoke while you work. 3. Next, unscrew and remove the valve from the tap and plug it with a gag to reduce the gas flow. Carefully remove all old grease with a dry cloth and apply new grease without sealing the holes. 4. After everything is done, you need to very quickly replace the gag in the gas valve with the shutter. Carefully twist the spring and clamp it with a stopper.We resume the gas supply if you blocked it earlier. 5. Ventilate the room well. Then prepare a soap solution and apply to the faucet. If there are no bubbles, then you have done the job. But still, when there are bubbles, try to reassemble the faucet again and check the leak in the same way. If the problem persists in this case, call the gas service immediately. Since even the smallest leak can lead to a destructive explosion.

Gas is the main assistant of the cook and fireman, it will not be cold and hungry with him. Knowing the safety rules and behavior patterns during emergencies will save you from troubles and help strengthen your "friendship" with the gift sent to us by Mother Nature. Still do not know what to do when the gas valve in the kitchen is leaking and how to check if there is a leak? Well then, let's get down to business.

You probably know that natural gas comes to our kitchen directly from the bowels of the earth, naturally, bypassing kilometers of pipes. The main combustible component of the gas is methane. It is he who is a threat to human life if he leaves the pipeline. A 5% concentration of this substance in the air is enough, and if you do nothing, ignition or explosion is inevitable. “Why does everything have to end in fire?” - you ask. As a rule, due to ignorance of the rules of behavior in such situations, people do not stop using electrical devices (sometimes they even turn on the light to understand what kind of unpleasant smell comes from the kitchen), or even completely, when the gas tap in the kitchen sometimes poisons, they bring a lit match to the stove in order to understand which burner is broken.

According to the rules for handling gas, the population is prohibited from dismantling or repairing pipes on their own.But what if the gas faucet in the kitchen skips? First, open the doors, windows. Secondly, stop using electrical appliances. Third, call the appropriate service.

What to do if you suspect a gas leak, but you are not sure about it, do you exclude that everything seemed to you? There is a way to check the correctness of such an assumption. Make a soapy solution and apply it to the faucet or areas where you think gas might be leaking. If, however, there is a breakdown, then bubbles should appear, moreover, of a solid size. Doubt? Do the operation again, because calling the emergency service because of baseless suspicions is also bad, isn't it?

It looks like one of the models of the gas valve

Common problems and solutions

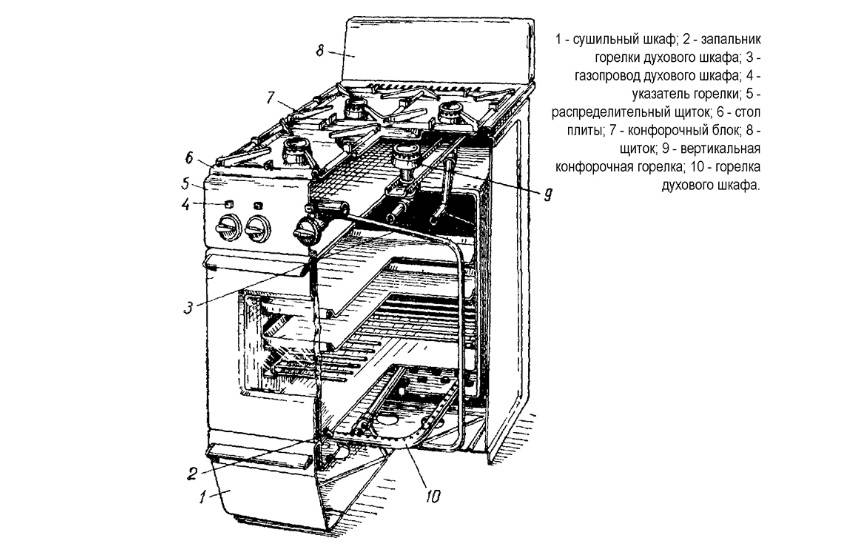

Before proceeding with the repair of equipment, it is necessary to study its design in detail, as well as to diagnose the device in order to identify the cause of the malfunction.

Frequent malfunctions and ways to eliminate them.

Poor oven heating. This problem is often caused by a broken switch. To fix the problem, it is enough to install a serviceable element.

Remember, if replacing the switch does not bring the desired effect, you need to check the heating coil.

To do this, you must first dismantle the back panel of the stove body, unfastening the clamping brackets of the device

In case of damage to the spiral, it is important to replace it. In this case, the new mechanism should be installed exclusively in the prepared grooves.Uneven length of flame in the burner or no fire in the burner

As a rule, this problem occurs due to clogging of the gas channels of the stove. To restore the functional properties of the unit, it is necessary to clean the through holes of the nozzle with a thin needle.

Uneven length of flame in the burner or no fire in the burner. As a rule, this problem occurs due to clogging of the gas channels of the stove. To restore the functional properties of the unit, it is necessary to clean the through holes of the nozzle with a thin needle.

However, if the problem persists after following this procedure, it is necessary to check the tightness of the insulation on the spark plug, as well as the integrity of the solenoid valve. In the event of a malfunction, the worn element should be replaced.

-

The appearance of extraneous sounds during the combustion of gas. This problem often occurs when the balance of the air-gas mixture is disturbed. Correcting the problem when using old cookers will help adjust the air damper of the appliance. To eliminate noise, when operating devices of a new type, all flame dividers are replaced.

-

Spontaneous extinction of the gas burner. When the stove is working properly, the flame from the burner “washes” the thermocouple. However, if the fire does not reach the element, the burner may go out spontaneously. To eliminate the malfunction, clean the stove nozzle from dirt or adjust the gas supply.

-

Extinction of the flame in the oven. Modern gas stoves are often equipped with a gas control system.Due to the presence of this function, when the flame in the oven goes out, the fuel supply is automatically blocked. At the same time, the sensor, cooling down, transmits a signal to the valve of the device, which closes the furnace passage channels. However, if a malfunction occurs in the design of the gas control, the flame in the oven burns only when the ignition button is pressed. As a rule, after the cessation of exposure to the key, the burner spontaneously goes out.

This problem often occurs when the thermocouple is not cooled fast enough. As a rule, in the process of heating this element, an electric current is generated. At the same time, the flow, while holding the magnetic valve in the pressed position, does not allow the resource to close the orifice of the jet.

To restore the full operation of the unit, it is necessary to clean the thermocouple from dirt. This procedure is performed with sandpaper.

If cleaning the thermocouple from dirt did not bring the desired result, it is necessary to replace the faulty mechanism.

Poor gas burner flame supply. This problem often occurs when the holes in the jets spraying fuel are clogged.

Regular cleaning of the injector gaps will help prevent excessive accumulation of dirt.

The second reason for poor flame pressure is the wrong ratio of the air-gas mixture that enters the burner. If it is necessary to increase the intensity of the burning of the fire, the air damper of the stove should be adjusted.

Remember, improperly repaired kitchen appliances can lead to gas leakage and explosion.

If the burner burns weakly

Well, now let's figure it out.The most common malfunction of gas stoves is that the burner flame disappears completely or partially due to clogging of nozzles or gas burner dividers. This happens due to careless cooking - small holes are filled with boiled-away soup, milk, etc., clogged with crumbs, and also in the process of cleaning the gas appliance with powders. Therefore, I recommend not to bring the burners to the point that the “blue fuel” stops flowing to the burner, and wash the stove with cleaning gels. If the gas still stops flowing, or the flame has noticeably decreased in size, you should simply remove the burner and clean the nozzle or divider with a thin knitting needle or needle.

For many gas stoves, the faucet handles are plastic and put on the stem with a metal plate that is inserted into a special groove. With use, the handles become loose, and this metal plate tends to fly out and get lost. Do not rush to grieve ahead of time, everything is much simpler. Take an ordinary metal can lid or canning lid, cut out exactly the same plate with scissors and insert it into the groove on the handle. Problem solved!

The burner burns weakly or goes out

The burner of the table or oven burns weakly when the tap is open at full tap and the oven is cold. If there are problems with only one burner (the rest are working normally), then the reason is that the jet of the corresponding burner is clogged. Repair is easy. It is necessary to clean the nozzle (jet, nozzle). This is done with a thin wire or needle. At first, you can try to clean the nozzle without removing it. The burner nozzles of the table are installed under the burners (fig. 1. A). The oven burner nozzle is installed on the side of the stove (fig. 2. A).Getting to the oven nozzle is not always easy. Then you need to remove the bottom wall of the oven, unscrew and remove the burner (it is attached there with one or two screws). The nozzle can be accessed from the oven.

If it is not possible to clean the nozzle without removing it, then it can be easily unscrewed with a suitable key.

If all burners burn poorly, then the reason is low gas pressure. The combustion of the burner of an oven with a thermostat must be checked when the oven is cold. Otherwise, the thermostat may reduce the gas supply when a certain temperature is reached. This is, in fact, its regular function.