- Finding and eliminating causes

- Reason number 1: an error in the connection of pipes

- Reason number 2: lack of draft in the chimney

- Reason number 3: high sensitivity of the protective relay

- Reason #4: Dead Ignition Batteries

- Reason number 5: not enough strong water flow or its complete absence

- Reason #6: Dirty Filters

- Reason #7: Membrane Deformation

- Specifics

- Model 8910-00.02

- Model 8910-08.02

- Model 8910-15

- Model 8910-16

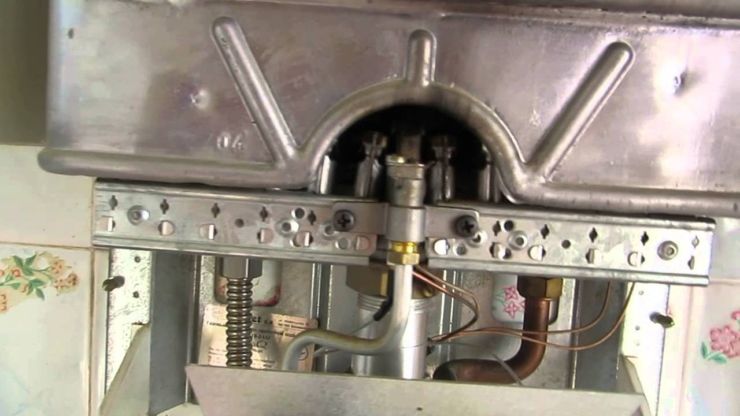

- The device and operation of the geyser

- Adjustment

- Causes of breakdowns and their elimination

- Problem # 1 - lack of traction in the column

- Problem #2 - Difficulties with water pressure

- Problem #3 - insufficient gas pressure

- Problem # 4 - no ignition when turned on

- Problem # 5 - the presence of blockages in the tubes

- The geyser goes out

- How is the heat exchanger

- Unstable or incorrect temperature operation

- How to solder a gas column heat exchanger

- Preparation for soldering

- Soldering methods

- Powerful soldering iron

- Burner with gas bottle

- cold welding

- How to check tightness

- Gas water heater does not ignite

Finding and eliminating causes

So, why does the gas column not turn on? A number of situations can be at fault:

- Error in connecting pipes;

- No draft in the chimney;

- High sensitivity protective relay;

- Discharged ignition batteries;

- Weak water pressure or its complete absence;

- Filter clogging;

- Membrane deformation.

Let's consider all the listed reasons in more detail and analyze effective methods for their elimination:

Reason number 1: an error in the connection of pipes

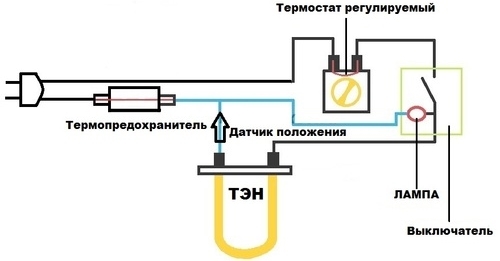

The water heater protection system itself shuts off the gas supply if errors are made in connecting pipes. To prevent this, simply follow a simple and understandable scheme:

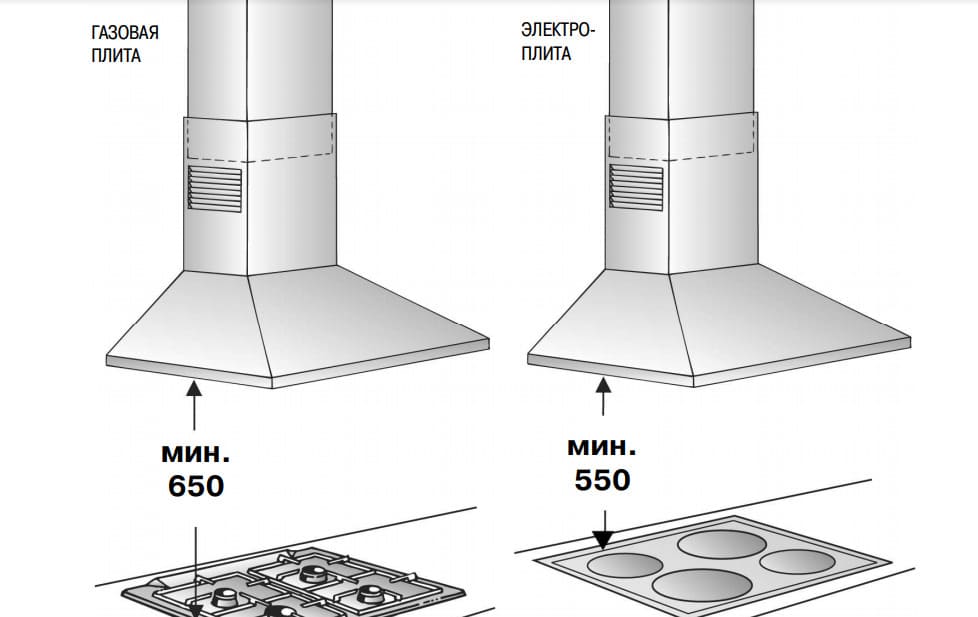

Reason number 2: lack of draft in the chimney

Due to the pollution of the chimney as a result of the accumulation of soot or the ingress of construction debris into it, the vector of movement of combustion products changes up to the opposite. This poses two dangers:

The returning mixture of carbon monoxide and air extinguishes the burner

. As a result, the protection system is activated, and the operation of the gas water heater is blocked;

The returning mixture of carbon monoxide with air penetrates into living quarters

. This option is even worse, as it poses a danger to the health and even the life of the household. It is possible in the case when the force of the "overturned" thrust is not enough to put out the fire.

Let's figure out what to do in the described situation:

| A photo | Description |

| First check, if someone installed a satellite dish above the exit of the ventilation shaft. This may be quite enough to create a reverse thrust effect. In this case, the problem can be solved by negotiating with neighbors without calling chimney cleaning specialists. | |

| Call specialists to clean the ventilation duct. If no external factors interfere with the release of combustion products, then the reason for the lack of draft is clearly a clogged chimney.You can try to clean it yourself, but there is a danger that you, without the appropriate experience, will damage the neighboring branches with your actions. |

Reason number 3: high sensitivity of the protective relay

The gas column lights up, after which it soon fades out? In this case, the problem is most likely a too sensitive relay, in which overheating protection is triggered. There are two options for solving the problem:

Temporary

. You should open the window to lower the temperature in the room;

Radical

. The only way to fix the problem is to replace the relay.

Reason #4: Dead Ignition Batteries

Another reason why the main burner does not light up may be dead batteries. This can be determined by the idle clicks of the piezo ignition element when hot water is turned on.

It is also worth noting that the problem described applies exclusively to water heaters equipped with an automatic switching system.

Reason number 5: not enough strong water flow or its complete absence

In order for the gas column to turn on, there must be a pressure of water of a certain strength. If it is too weak, then the unit will not turn on. In this case, you should first clarify the source of the problem by opening the cold water tap in the bathroom:

If the water supply level is weak there too

, means that the matter is in the city water supply system. There's nothing you can do here, you'll have to wait;

If the liquid runs normally

, most likely, the column itself is clogged.

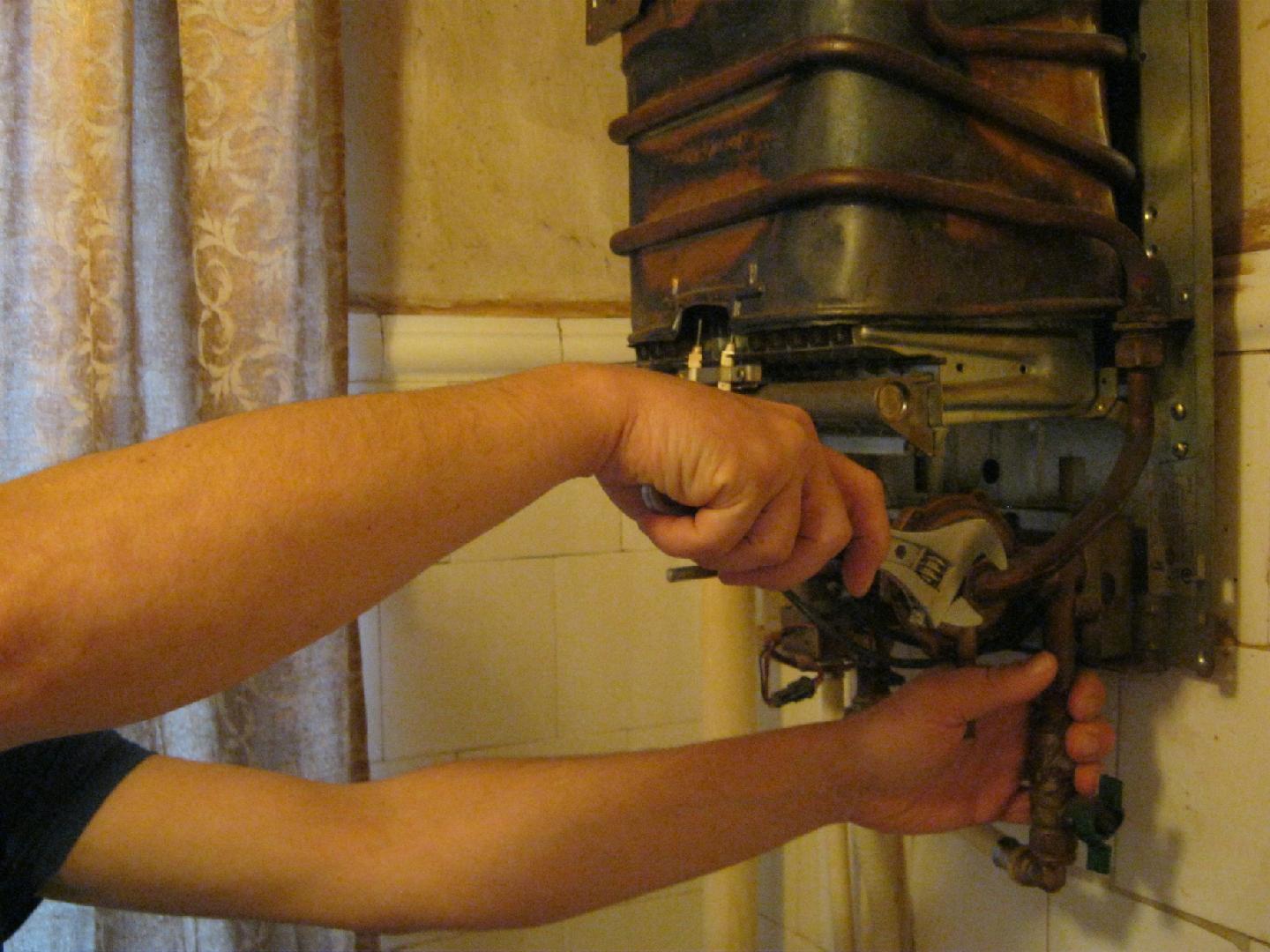

In the second case, you can call the wizard, or you can try to clean the device yourself. The instruction looks like this:

- Shutting off the gas supply;

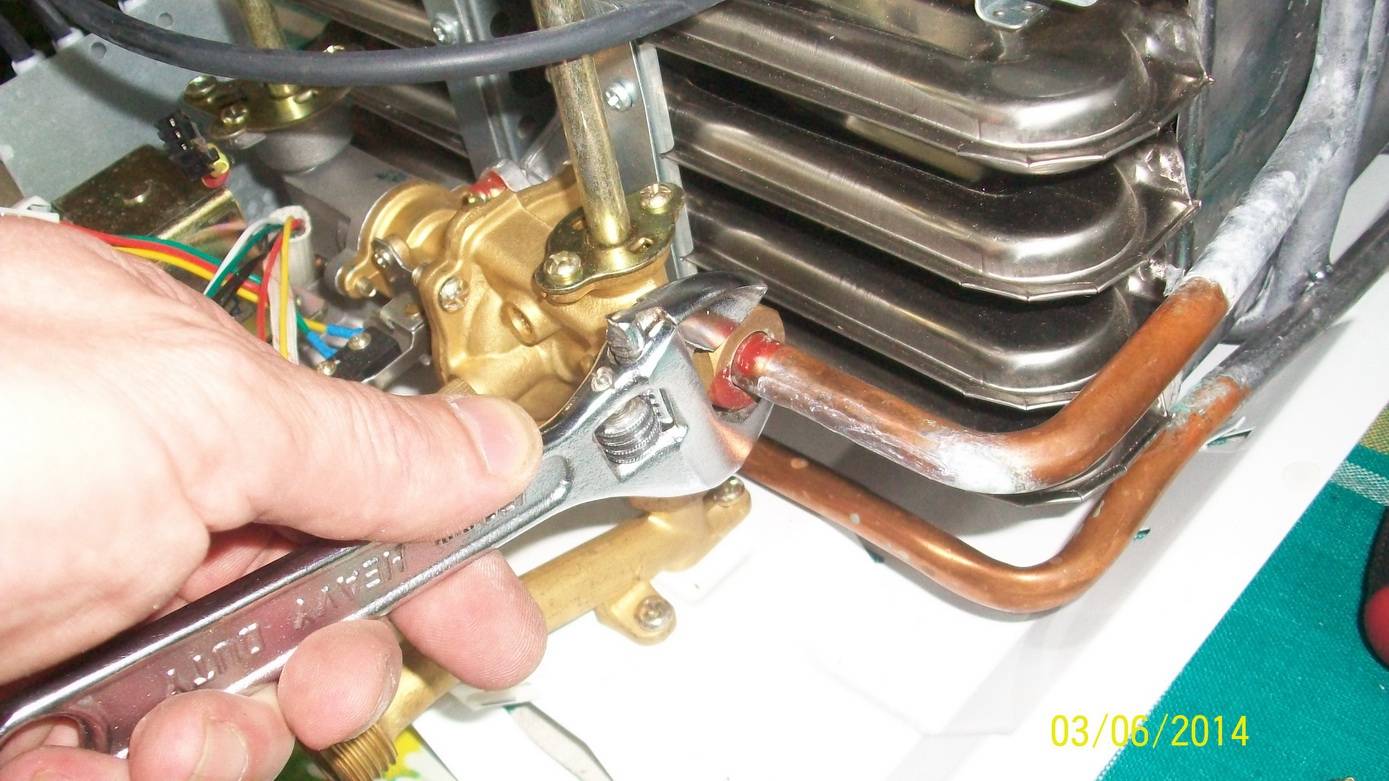

- We unscrew the pipes;

- Removing the gas column from the hinges;

- Set it upside down on the table;

- Pour inside a special cleaning liquid with a syringe. The price of such a mixture is not very high, and you can buy it at any specialized store;

- We leave the unit for a couple of hours.

Reason #6: Dirty Filters

Another reason for the column to malfunction may be filter contamination. Scale, rust and other insoluble impurities clog the grates over time, and they need to be cleaned. In this case, we are talking not about one object, but about several at once:

| A photo | Name and location of the filter |

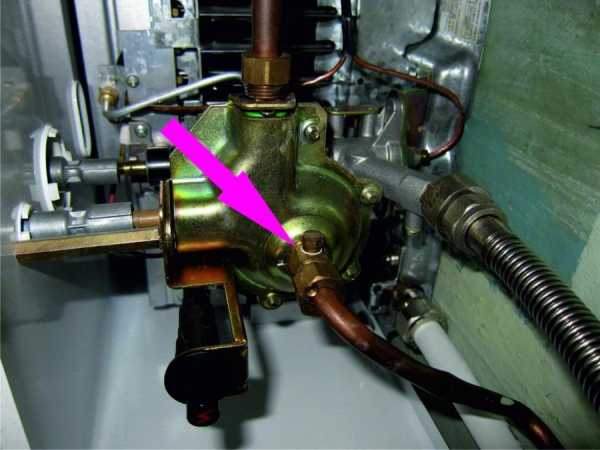

| Water node in the column itself. In some cases, it can be cleaned in the manner described above, in others it will be necessary to disassemble the device and clean the grate manually or completely change it. | |

| Coarse filter. It is located on the pipe supplying cold water to the water heater. | |

| Faucet filter. |

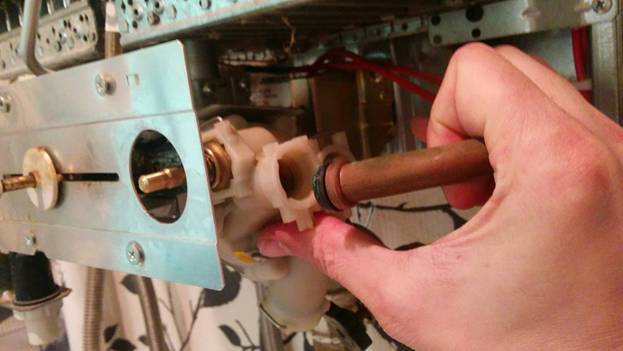

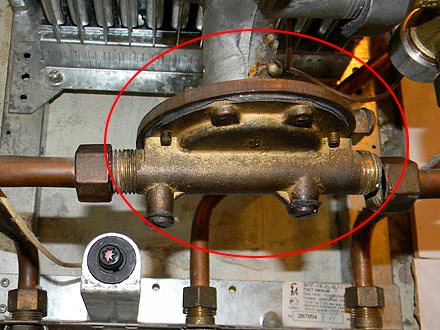

Reason #7: Membrane Deformation

The geyser also does not work in the event of cracks, ruptures or other deformations on the membrane. In this case, you need to replace it.

Specifics

JSC PKO "Trubny zmeevik", producing gas water heaters "Astra", has been around for more than fifty years. Perhaps even our grandparents used his products. True, then this company was called differently.

The Astra column is necessary for working with hot water supply. Only gas is used as fuel.

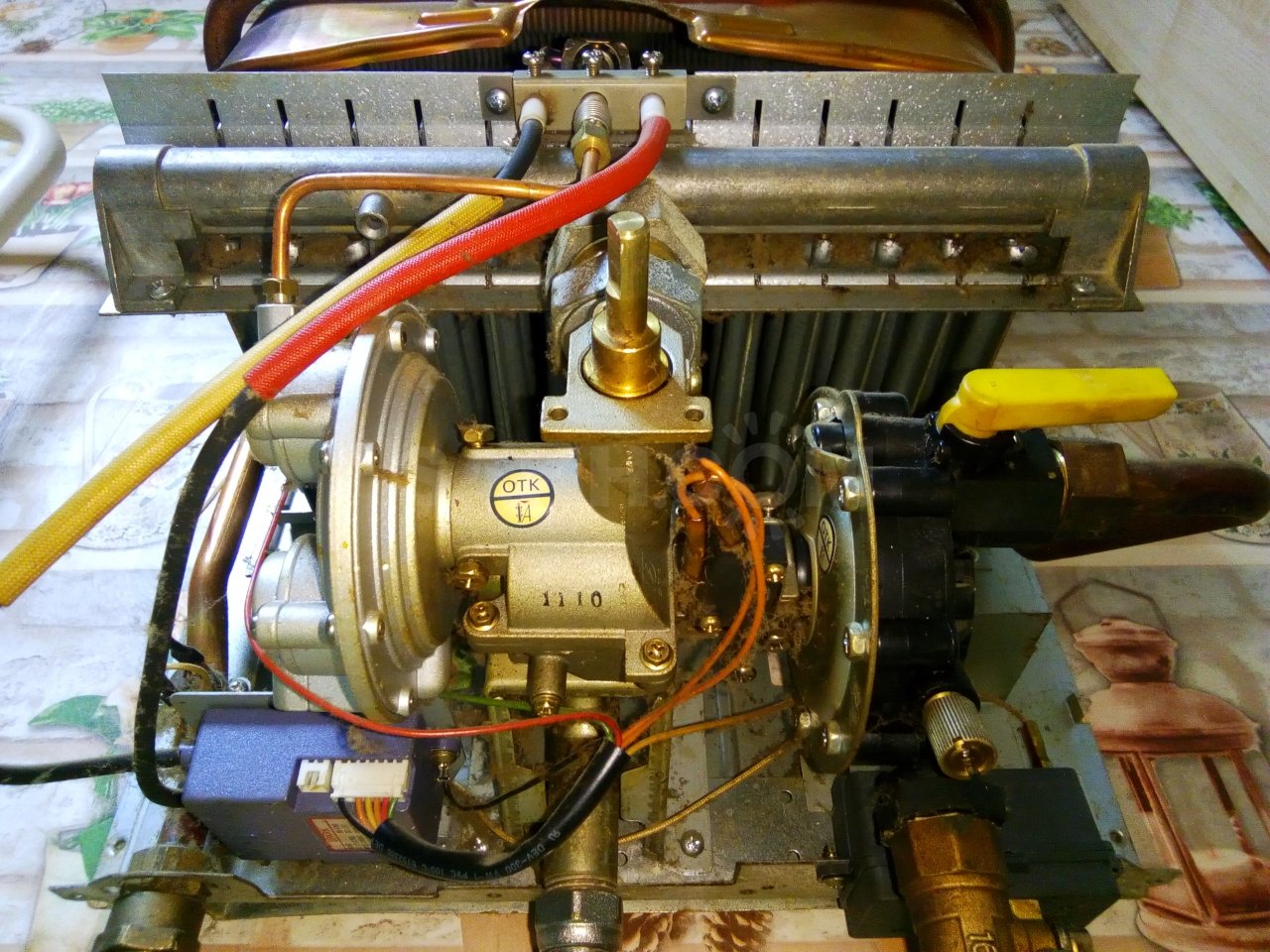

The device of such a column is very simple and includes several components. The main part - a rectangular case - is fixed on the wall. On the front panel there are windows for ignition and combustion control, a power button, and gas supply adjustment knobs.At the bottom there are threaded connecting elements from two sides of the gas supply, cold and hot water, and on top there is a section of the chimney pipe.

All key nodes are located in the middle of the case and are fixed on the panel at the back. It also has mounting holes. The firebox is made of good refractory material, containing a long service life. Ease of execution is considered an advantage in the model market and provides the manufacturer with a great demand for their own products.

The working principle is as follows: in order for gas to enter the gas block and the ignition wick, you need to turn the ignition burner handle to the left and turn on the device by pressing the button - the burner will turn on methodically. The temperature of the hot water at the outlet is set by the position of the control knobs. By turning from right to left, the gas supply increases, thus increasing the water temperature, and from left to right, vice versa, it decreases.

By functionality, the components of the column are figuratively divided into water and gas parts. On the market, you can choose repair kits and spare parts for any node separately, as well as the whole node completely.

The technical properties of Astra speakers make it very easy to compete with other manufacturers. The main plus is the power of the device: for certain models it equals and even exceeds 20 kW. A large firebox and relatively low gas consumption perfectly distinguish this brand.

Naturally, any model has its own small details in the characteristics, but you can derive general values.For example, the hot water supply is approximately 10-12 l / min, the outlet water temperature range is 35-60 degrees, the operating pressure range is 0.5-6 bar.

The manufacturer also thought about the safety of their own products. If the burner goes out, the water supply will end.

Each model comes with a data sheet and an operating manual, which details the operating rules and non-hazardous operation, as well as an important diagram of the device.

Now on the market there are a lot of gas-powered columns with an original color palette. Consumers sometimes make a mistake, preferring color to the detriment of technical specifications. The gas column "Astra" does not seek to distinguish itself due to its appearance, but relies on working capacity, has its own range of models.

Model 8910-00.02

has a high power - up to 21 kW and a working capacity of 12 l / min. Dimensions - 700x372x230 mm. The chimney has a diameter of 120 mm. Gas consumption per hour is 2.3 cubic meters. m. Ignition occurs manually.

Firebox of open type. It is not difficult to study thrust. The gas pipe for connection has a cross section of 3-4 inches, the water pipes - 1-2 inches. The weight of the device is 15 kg.

Model 8910-08.02

has a slightly small power (up to 18 kW) and productivity (10 l / min). However, fuel consumption is also lower - 2 cubic meters. m/h The weight of the unit is 14.7 kg. The rest of the device is very similar to the previous model. Ignition is also done manually

Model 8910-15

It has one significant difference - this system with electronic ignition of the burner, which is very comfortable. Now there is no need to worry about the presence of matches.

The power of the unit can reach 20 kW, productivity - 10 liters of hot water per minute. Gas consumption is 2 cubic meters. m/h The column weight is 13.9 kg. The diameter of the chimney is 135 mm.

Model 8910-16

It is also equipped with an electronic burner ignition automatic control system. This automatic device is a champion in power (up to 24 kW). The device heats water at a rate of 12 liters per minute. Gas consumption - 2.3 cubic meters. m/hour. The weight of the device is 14.7 kg.

It should be noted that spare parts for Astra columns can be easily found at inexpensive prices.

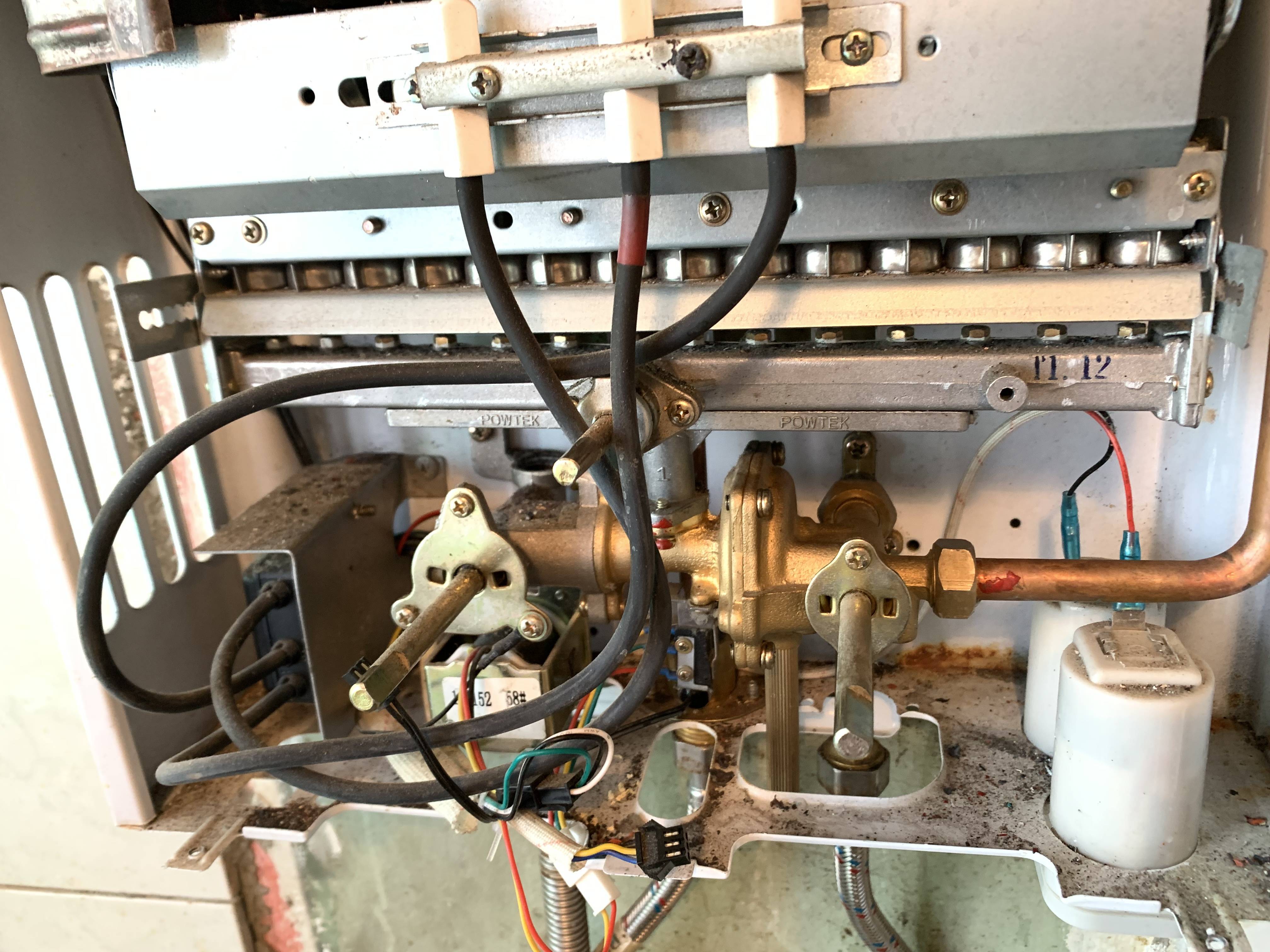

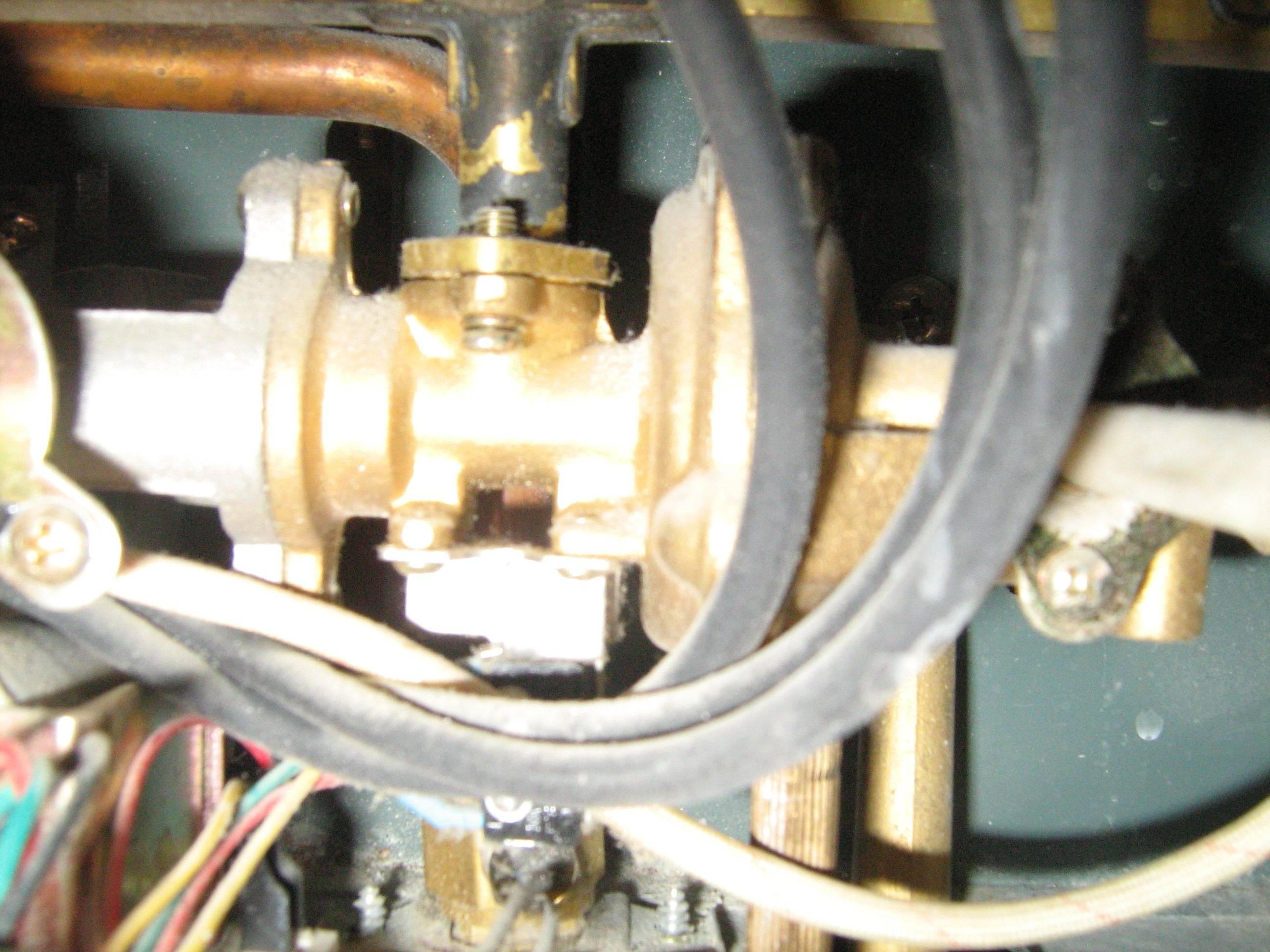

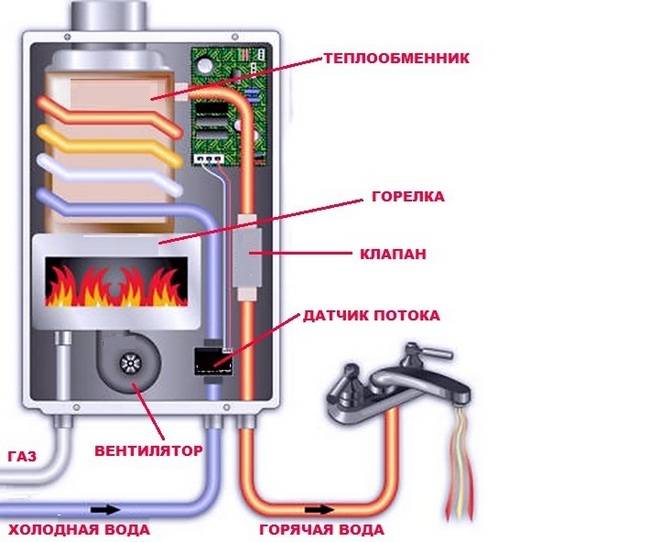

The device and operation of the geyser

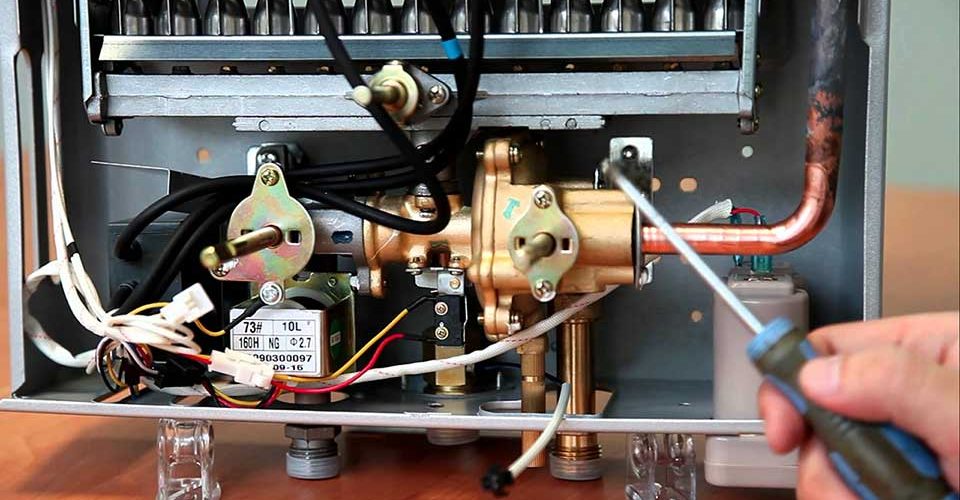

The geyser is similar to an ordinary kitchen cabinet. Two burners, a heat exchanger, temperature sensors, regulators and three small pipelines are mounted in this “cabinet”, which are responsible for supplying water, gas and removing heated water from the column. Geysers Beretta, Oasis, Electrolux, neckar, amina, bosch, termet have similar schemes for constructing internal components, so the repair process of this equipment does not have any special differences.

The process of heating water begins as the water tap is opened, after which the valve automatically opens to supply gas to the burner, which is ignited through the installed candle. The combustion process generates heat, which is controlled by a sensor. The accumulated heat is transferred through the heat carriers to the open faucet. The generated gas vapors are removed through the ventilation system. The temperature regime is controlled by a switch, which is located on the outer side of the column body.

Adjustment

After purchasing and installing a gas column, you should set up a comfortable temperature regime. This requires:

- set the water and gas supply to the minimum

- open the water and gas supply to the column

- open the hot water supply at the tap, then adjust the water pressure on the gas equipment

- wait a few minutes, then measure the water temperature

- increase the gas supply, thereby increasing the temperature of the water to the indicators you need

- leave all settings and use water at a comfortable temperature

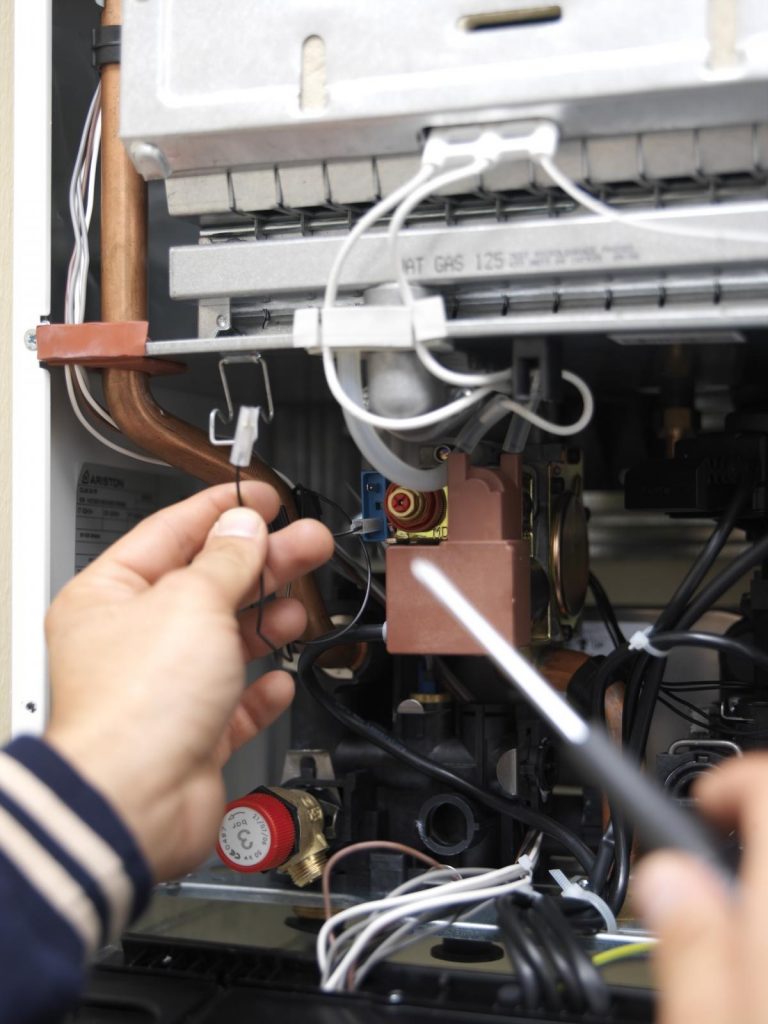

Causes of breakdowns and their elimination

Despite the simplicity of design, unpretentiousness in operation, the flow heater is not immune from breakdowns. If the geyser of the Vector brand does not turn on, do not panic. There can be several reasons for the problem, and most of them can be fixed on your own.

Problem # 1 - lack of traction in the column

The lack of draft indicates that the products of combustion cannot be quickly removed from the room. This poses a danger to users, so the sensor turns off the geyser.

Sometimes the burner ignites, but immediately goes out. This can happen when there is not enough air to burn the gas - the flame goes out due to a lack of oxygen to support combustion.

In any case, you first need to check the draft by bringing a burning match to a special hole on the column body. If the flame is directed inward, then the chimney is working normally, the combustion products will be quickly removed, and the cause of the malfunction is different. If the flame remains motionless, directed upwards or towards the user, then it is worth carefully inspecting the chimney, cleaning it.

Soot gets into the air along with the products of combustion.It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction is lost. The problem is solved by thorough cleaning of the chimney

Problem #2 - Difficulties with water pressure

Another reason why the household geyser of the Vector brand does not ignite may be the low pressure of cold water or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption, evaluate its pressure. If there is insufficient water pressure in the system, the solution may be to install a pump or replace old, clogged pipes.

If there are no problems with the water supply, it is worth moving on to inspecting the column. The solution to the issue may be to adjust the water supply to the column. To do this, the corresponding valve must be fully opened.

Another cause of insufficient water pressure in the column is a clogged filter. To inspect it, it is necessary to shut off the water and gas supply with valves, unscrew the nuts, rinse the grid. If cleaning fails, the filter will have to be replaced.

It will take a few minutes to inspect the filter. However, in some cases, one flush is not enough, a complete replacement of the part is required.

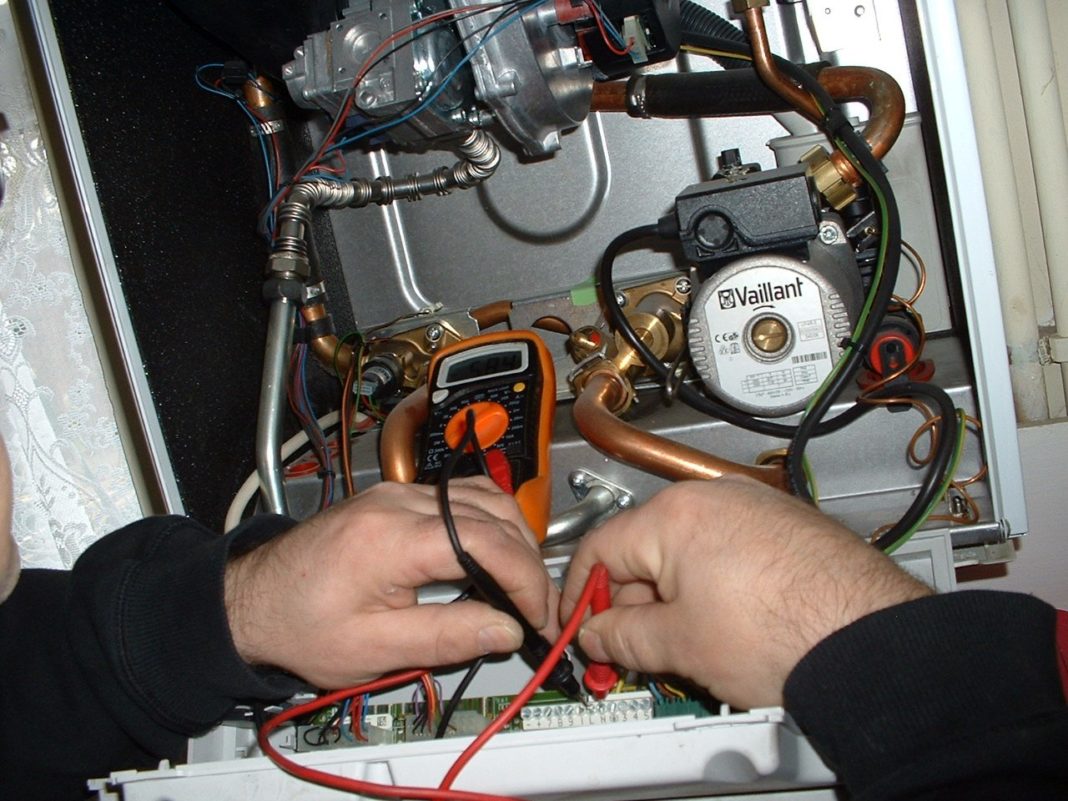

Problem #3 - insufficient gas pressure

Sometimes the gas pressure is not enough to ignite the flow column, its normal operation. However, this problem cannot be solved on its own. You need to contact the gas service.

Problem # 4 - no ignition when turned on

The presence of an electric ignition system ensures the comfort of using the gas column, eliminates the use of a wick that is constantly on fire. However, it is this element that can cause a malfunction of the device.

When the tap is opened, automatic ignition should work. This action is accompanied by a characteristic crack. If the ignition does not work or the spark is too weak to ignite the gas, the column will not be able to connect. Replacing the batteries will solve this problem.

Batteries are required for the smooth operation of an instantaneous water heater. When the batteries are discharged, the electric ignition does not work, the column does not turn on

Problem # 5 - the presence of blockages in the tubes

Water and gas pass through the gas column Vector in the process of operation. The use of filters allows you to clean them from unnecessary impurities. However, the presence of blockages can cause the device to simply not turn on.

However, the filter is not always able to bring the water to an ideal state. Soluble salts get inside the heater together with the liquid, settle on the walls of the heat exchanger. As a result, the patency of thin tubes is impaired.

Specialists remove scale with the help of specialized reagents. A home master can deal with it using a solution of citric acid or vinegar. To clean the heat exchanger, you need to remove it, place it in a warm solution with the addition of vinegar. You can also use special purchased products - "chemistry" designed to clean heat exchangers.

It is better to entrust the elimination of blockage of the heat exchanger to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, they are easy to damage

We discussed in detail about cleaning and repairing the heat exchanger in the next article.

The geyser goes out

The geyser goes out

If the heater turns on but goes out, the problem in most situations is the bimetal temperature sensor, which is necessary to protect the equipment from overheating. Also, due to malfunctions of this element, the heater may not turn on at all.

This problem has 2 main development scenarios.

- According to the first scenario, the burner lights up properly, the equipment functions for some time without any complaints, and then it goes out and does not show any signs of life for some time - attempts to ignite the heater do not lead to anything. Usually after 20-30 minutes the equipment turns on again and history repeats itself. This is due to the excessive sensitivity of the sensor. As a rule, it is "innate", i.e. This is a factory marriage. Doing something on your own is extremely difficult. It is better to immediately contact the manufacturer's service for warranty repairs.

- In accordance with the second scenario, the column may turn off randomly, and sometimes not turn on at all. The reason, as a rule, is the wear of the insulating material of the conductor of the bimetallic sensor. There is a banal short circuit to the case, as a result of which the safety valve is activated, and the column begins to behave abnormally.

How is the heat exchanger

A heat exchanger, or radiator, is designed to heat water from a burner. The stream flows through the tubes of the coil, instantly warming up from the burning fuel. Most often, the block is steel or copper. How much does the device weigh? Copper device - from 3 to 3.5 kg. The steel apparatus is much heavier, for this reason it has a lower efficiency.

Features of steel product:

- Lower cost compared to copper.

- Due to the plasticity of the material, heating does not harm the surface.

- Differs in resistance to corrosion.

Copper Appliance:

- Possesses high efficiency, fast heating.

- Products that contain additional impurities are cheaper.

- Corrosion resistance.

- Light weight if it is pure copper.

Trying to reduce the cost of production, manufacturers add impurities to copper. Because of this, the radiator heats up unevenly, which leads to burnout of individual parts. Some cover the surface with heat-resistant paint, but this brings little results. Service life does not exceed 2-3 years.

Copper is more resistant to corrosion than steel. Most manufacturers do not indicate how much copper goes into the production of the product, assuring that the heat exchanger is made of a thick layer.

How much does it cost to replace a gas boiler radiator? If you take into account the purchase of a new device, delivery and installation, it will be cheaper to repair the heat exchanger.

Unstable or incorrect temperature operation

To avoid unstable or incorrect operation of the speaker, you should familiarize yourself with the characteristics of the device when buying, as many speakers have different power levels, which may not be suitable for your house or apartment.

The next cause of problems with the operation of the temperature regime is the formation of blockages in the column. This can be determined by the uncharacteristic color of the flame and the presence of soot. In this case, the ventilation ducts should be cleaned.

If the heating temperature is insufficient or the water is overheated, a simple operation should be performed to regulate the gas supply to the column. If the water temperature is low, increase the flow, if overheating, reduce the flow accordingly.

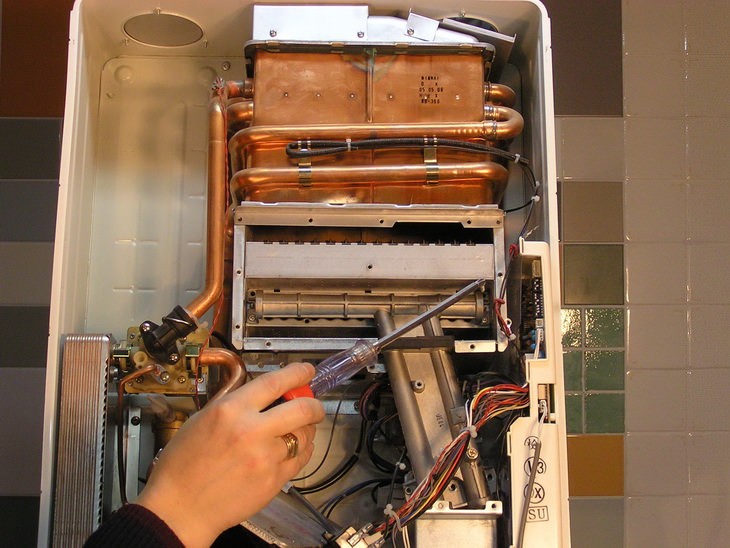

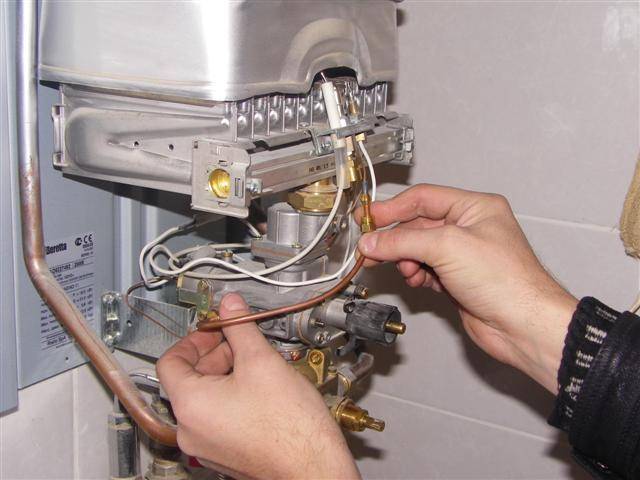

How to solder a gas column heat exchanger

Preparation for soldering

First of all, you need to remove the casing from the column. This must be done carefully, first disconnecting the wires from the display. In some models of water heaters, for example Neva 4510, the gas and pressure regulators must be removed before this.

Next, the water is turned on and the place of the leak is located. Often it is located on the bend of the heat exchanger pipes near the crate. If it is easily accessible, it will be possible to seal the fistula without removing the column.

If there is no direct access, and the fistula is located inside the radiator, it will be necessary to disassemble the column and remove the heat exchanger.

In modern columns there is a special plug for draining water, by opening which the liquid is poured into a substituted container. Remaining moisture is blown out with a compressor or vacuum cleaner.

This is important because during soldering, the liquid will boil and evaporate, creating pressure and blowing the solder through the fistula. The last stage of preparation is cleaning and degreasing the leak

This is done with fine-grained sandpaper. Cleaning must be done carefully so as not to make a through hole, since the pipes in the heat exchanger can be very thin. After that, the cleaned tube is wiped with any solvent or white spirit to remove any remaining dirt and grease.

The last stage of preparation is cleaning and degreasing the leak. This is done with fine-grained sandpaper. Cleaning must be done carefully so as not to make a through hole, since the pipes in the heat exchanger can be very thin. After that, the cleaned tube is wiped with any solvent or white spirit to remove any remaining dirt and grease.

Soldering methods

There are three ways to solder the gas column heat exchanger:

Powerful soldering iron

To solder the fistula site with your own hands, you will need a soldering iron with a power of about 110 W, flux and solder.

The first stage of soldering is the application of flux. This is a substance that cleans the surface of the material from oxides and allows the solder to spread more evenly. Flux paste with copper content is best. If it is not available, you can use ordinary rosin or an aspirin tablet.

Burner with gas bottle

You will need a burner, a small gas bottle, flux, solder. The burner is connected to the cylinder and ignited. It is necessary to choose a flame that is not very strong so as not to damage the radiator of the column.

First, the leak site warms up well. This is done so that the remaining moisture in the pipes evaporates. After that, the pipe is heated and solder is supplied to it.

After soldering, it is imperative to remove the flux residues, because it contains acid and can later corrode the walls of the heat exchanger pipes.

cold welding

It is important to choose a cold weld that will not melt from hot water. All operations must be carried out with protective gloves.

A small amount of cold welding comes out of the package. You need to knead it in your hands for about three minutes. As soon as the material begins to harden, you need to attach it to the site of the fistula and hold it firmly until completely solidified.

If there are several fistulas nearby on the heat exchanger tube or the hole in the tube is large, you need to solder a copper patch. You can also solder from a piece of copper pipe.

How to check tightness

After soldering the geysers, you need to check the tightness of all pipes.To do this, they are carefully examined to see even the smallest fistulas - small green spots indicate their presence. In order to avoid re-parsing the column in the near future, these defects are also cleaned and soldered.

After that, you need to connect water to the gas column with a brazed heat exchanger and open the tap.

At the very end, a boiler with a geyser is turned on to check its performance when in contact with hot water. At the same time, soldering areas can be wiped with a dry cloth to detect the slightest sign of moisture.

Gas water heater does not ignite

To repair a malfunction with your own hands, you need to check the draft in the exhaust pipe. To do this, a lit match is brought to the exhaust well and, if the chimney is in good condition, the flame is deflected to the side. If the flame does not stir, you need to check the well and remove dirt or foreign objects and everything will work without recourse to specialists.

Another problem in which there is no ignition of the column is the banal lack of power, of course, if we are talking about units with an automatic ignition system powered by batteries, such as Electrolux products. At the same time, despite all the manufacturers' assurances that the batteries should last for a year, they should be replaced much more often. To repair, do the following:

- check the correct operation of the button, turn on the gas appliance;

- banal replacement of the power source (batteries).

Also, problems with ignition in the gas column may be due to the lack of sufficient water pressure. Checking the water pressure with your own hands is also no problem. You just need to open the tap and visually assess the water pressure.And if a problem is found, then the pipeline needs to be repaired.

If it is found that cold water is supplied under high pressure, then the problem must be sought in the water unit of the gas water heater. Common causes of reduced hot water pressure are clogged filters or a deformed membrane. To fix the breakdown, you need to do the following:

- first you need to ask about the lack of pressure of cold water from utilities;

- check and, if necessary, flush or replace filters with your own hands;

- clean the gas appliance from scale, but it is better to entrust such preventive measures to specialists;

- replace the deformed membrane.

Often you can encounter a problem when a gas water heater lights up and immediately goes out. This is often due to improper adjustment of the water supply. To repair the breakdown, the water supply is reduced, which can be done by hand.