- Manual gas burner with piezo ignition

- HEALTH REQUIREMENTS BEFORE STARTING WORK

- Manufacturing features

- Main steps

- Frame

- Nozzle

- Assembly

- How to choose the right gas burner for a stove or boiler

- How to ignite?

- How to replace the piezo element?

- Learning to solder with a gas burner

- Safety

- Gas burner diagnostics

- Fault definition

- Purpose

- soldering tool

- Some features of the operation of plates of various brands

- Features of a gas burner with piezo ignition

- General classification of gas burners by type of fuel

- Turbocharged types of gas burners and their design differences

- Methods for troubleshooting gas water heaters

Manual gas burner with piezo ignition

Such a model of a gas burner is a stove replacement for outdoor enthusiasts. This item is indispensable for fans of camping. Undoubtedly, one can try to challenge this fact by citing the classic example of making a fire. But in order to cook soup or porridge, it is necessary not only to collect firewood, but also to wait until they burn out a little. For trips over long distances, this is a significant waste of time; for rest at a halt, you can limit yourself to a short break.Another significant bonus is that in bad weather and in pouring rain you don’t have to dream of a fire, but nothing prevents you from hiding under the crown of a tree and warming yourself with hot tea or porridge cooked on a gas burner. Piezo ignition eliminates the need to look for matches or a lighter, gas is consumed economically and one cylinder is enough for a long time.

Advice! If you take a gas burner on a hike, make sure you store the cylinder, do not allow direct sunlight to fall on it, overheating in the sun leads to an explosion of the cylinder. When putting in a backpack, it is better to place the cylinder in the middle so that it is reliably protected from high temperature. Also, the gas is sensitive to low temperatures, the burners work properly at temperatures down to -20. For more severe temperatures, it is necessary to purchase a cylinder of a gas mixture that is not sensitive to cold.

For gas burners, odorless liquefied gas is used, this adds a certain specificity to the use of the tool. Firstly, when using the burner, do not turn it over and tilt it strongly, the flame can go astray and lose static, it becomes uneven

Secondly, you need to be careful when using balloons. In the event of a malfunction, a gas leak may occur, which cannot be felt due to the lack of smell

You can check the balloon for leaks using a soapy solution, and you can also lower the balloon into water for testing.

HEALTH REQUIREMENTS BEFORE STARTING WORK

2.1. Before starting work, you should put in order and put on overalls, safety shoes, if necessary, check the availability and prepare other personal protective equipment. Overalls must be of the appropriate size, clean and not restrict movement. 2.2.Before work, you need to select the tools and technological equipment necessary to perform the work, check their serviceability, tools and materials should be located in a convenient place, taking into account the technological sequence of their use. 2.3. When preparing a gas cylinder for operation, it is necessary to remove the steel cap and plug from the valve using a non-ferrous metal wrench, inspect the fittings, if necessary, remove dirt and purge the valve by quickly turning the handwheel (open-close). 2.4. If the cap is not removed, the cylinder is considered defective, it must be sent to the warehouse. 2.5. Before starting work, it is necessary to check the gas burner, since a clogged nozzle can cause intermittent flame, "back" blows, gas leakage at the junctions of the hoses with the burner and with the cylinder. 2.6. All tools and fixtures for the performance of work must be in good condition; defects found during the inspection should be eliminated, if it is impossible to eliminate the malfunctions on their own, work cannot be done. 2.7. Before starting work, it is necessary to carefully inspect the place of the forthcoming work, put it in order, remove all foreign objects and, if necessary, install protective fences. 2.8. You should not start work in case of the following violations of safety requirements: - in case of malfunctions of the tool used, technological equipment, protective equipment for workers; - with insufficient illumination of the workplace and approaches to it. 2.9. The employee must personally verify that all the measures necessary to ensure safety are implemented. 2.10.An employee should not start work if he has doubts about ensuring safety during the performance of the work ahead.

Manufacturing features

The design features are that it is very easy to operate, there are no traces of soot and repulsive odors during the use of a gas burner. This device is compact and can be used virtually anywhere. The main component of the burner is the industrial valve. You can buy a new part, however, and used, but in working condition are quite suitable. The process of making a burner with your own hands begins with a handle, then a body and a nozzle are made.

In order to get a safe and fuel-efficient burner, it is necessary to make it a rule to avoid scaling and adjusting the example circuits.

In fairness, it should be noted that not all gas appliances are calculated according to the laws of gas dynamics. But if the manufacturer changes the dimensions of the structural parts, then the Reynolds number of the fuel (or intake air) will go beyond the limits indicated in the original product. The burner with such an “improvisation”, if an optimistic forecast is given, will begin to smoke and will be “gluttonous”, or even completely dangerous in operation.

And one more important note regarding the features of the manufacture of burners: it is impossible to increase its power above 10 kW. And that's why. With a burner efficiency of 95% (which is an excellent indicator for an amateur invention), with a device power of 1 kW, it will take 50 W to self-heat

It is theoretically possible to get burned on the structure, but it is not fraught with an explosion. But if the burner is built for 20 kW, 1 kW will be superfluous. The threshold manifestation is expressed by the fact that the structure is hot or flashes.Therefore, those burner drawings that focus on 7-8 kW should not be considered

With a burner efficiency of 95% (which is an excellent indicator for an amateur invention), with a device power of 1 kW, it will take 50 watts to self-heat. It is theoretically possible to get burned on the structure, but it is not fraught with an explosion. But if the burner is built for 20 kW, 1 kW will be superfluous. The threshold manifestation is expressed by the fact that the structure is hot or flashes. Therefore, those burner drawings that focus on 7-8 kW should not be considered.

Main steps

It is not difficult to make a burner or a mini-burner according to the drawings, as already noted, without spontaneous changes in parameters.

Frame

The body is usually steel. A brass rod with a width of 2 cm is suitable for its manufacture. A divider can be made from the same rod. Then several holes are made to help form the circulation of oxygen in the apparatus. Fire, as you know, does not exist without oxygen. There should be 4 such holes: each about 1 mm in diameter. They are made in the core of the burner divider. The next step is to press the divider into the body of the device. The inner flange is installed with a gap of 0.5 cm. This gap will subsequently slow down that powerful gas flow that comes to the igniter.

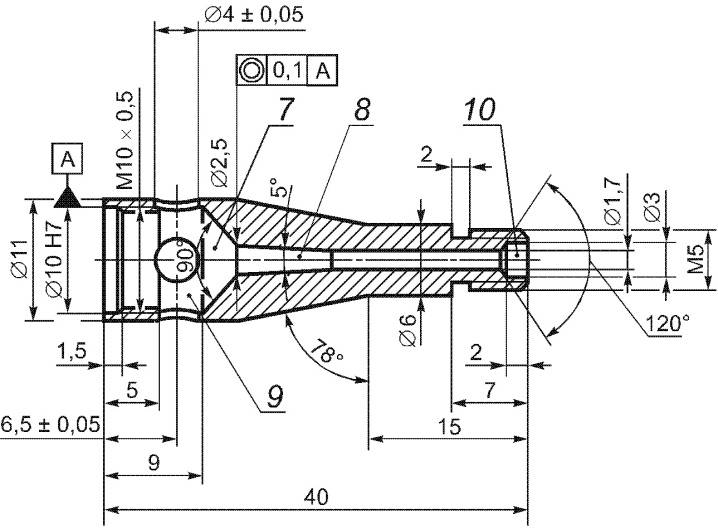

Nozzle

This part of the device provides fuel supply from the cylinder to the outside. It is made from a metal rod. At the moment, the master will need a two-millimeter drill to form a blind hole in the nozzle. And for the jumper you will need a four-millimeter drill.

Then a hose from the gearbox, made of special fabric or rubber material, is fitted to the end of the tube. Fastening is carried out with a clamp by using a conventional screwdriver.

Assembly

When the mechanism is accurately fixed correctly, you should set the desired pressure in the cylinder, supply gas from it. The air is then completely expelled from the hose. The length of the fire, if all the parts are located correctly, will be 40-50 mm. There is another manufacture and assembly of the burner, in this case - a miniature one. This device is convenient in that it is easier to make it yourself, and you can hold it in your hands without fear of getting burned. That is, for those who doubt their abilities regarding more complex manufacturing, this option is suitable.

What you need to make and assemble a mini-burner:

- old, broken gas burner;

- thin copper tube (10 mm);

- copper wire;

- syringe needle;

- bolt number 8.

And everything is done like this.

- First, a tube for the burner is prepared (a file is used).

- The nozzle is made from a medical syringe.

- The tube is connected to the wire.

- 2 pieces of copper tube are connected.

- The adjusting bolt is inserted.

- The adjustment of the device is being tested.

- A stand for the burner is being made.

- It remains to check the performance of the device.

Natural gas appliances are made from a metal pipe, a handle from a blowtorch and a spray can. A home-made device is suitable for soldering copper, for repair roofing, for singeing the necessary structural parts.

How to choose the right gas burner for a stove or boiler

Gas equipment with improper operation is associated with a certain risk.It is necessary to correctly select a furnace gas burner (nodal parts), and for this you need to have a general idea of \u200b\u200bthe design differences between the devices

When buying, it is important to know what types the product is divided into according to the method of burning fuel in the boiler:

Gas burners can also be used in solid fuel furnaces.

Gas burners can also be used in solid fuel furnaces.

- atmospheric burner;

- inflatable.

Not every manufacturer should be trusted, it is better to purchase from authorized dealers who provide certificates and all technical documentation. In the event of the acquisition of low-quality components or assemblies, there will be someone to file a claim with.

Gas-fired heating equipment is distinguished by various features, including the method of ignition and flame adjustment

When buying, experts recommend paying attention to the following indicators:

- heat generator power;

- exactingness to the quality of the gas mixture;

- the possibility of automatic regulation;

- the authority of the company and the country of origin;

- price-quality ratio".

Burners for floor boilers are available in the following versions:

- atmospheric;

- supercharged,

- piezo;

- electronic.

For the correct adjustment of the gas burner, it is better to contact a specialist.

For the correct adjustment of the gas burner, it is better to contact a specialist.

According to the power adjustments, you can choose a burner:

- 1-speed;

- 2-speed;

- with a smooth transition

- with automatic adjustment.

The flow of the gas mixture in different boilers is:

- straight-through;

- twisted (more powerful).

The most popular are gas burners for German-made boilers (Buderus, Vaillant), Slovak (Protherm) and Italian (Lamborghini). Among the products manufactured by domestic companies, Lemarks, Vakula and Conord equipment have proven themselves well.Among industrial devices - burners of the "Impulse" series.

The duration and productivity of any unit depends on the right choice and proper operation. Gas equipment is purchased not according to the principle where it is “cheaper” or “more powerful”, but according to the existing type of boiler.

How to ignite?

In the specialized literature, a clear order of ignition of the device is usually indicated. First of all, open access to oxygen. Then the flammable gas is supplied. The resulting mixture must be ignited immediately. Extinguishing is carried out in the opposite order: initially the gas valve is closed, then the valve responsible for supplying oxygen.

The problem is that if you first turn on the oxygen and then the gas, the flame is likely to be blown off by the oxygen stream. Therefore, the feed should not be opened completely, but by ¼. Some solve the problem differently: they initially open the gas, ignite it and smoothly open the access of oxygen. This method helps to adjust the torch, and the only negative is a small amount of soot.

How to replace the piezo element?

Do-it-yourself gas burner repair is always necessary if there is no spark. This problem in most cases indicates a breakdown of the “device in the device”. Therefore, there is only one way out: this is the replacement of the failed element. This operation is not so complicated, and the purchase of a new piezo, most likely, will also not be required.

It must be said right away that the external differences in the models of gas burners do not affect the structures. All devices have the same equipment, the elements are standard, so finding a replacement for them is quite simple. As already noted, it is the piezoelectric element that most often fails.Failure provokes the ingress of water, other liquids, breakage is possible due to a strong impact, the device falling from a great height, etc.

To repair a gas burner with your own hands, the master will need the following tools and materials:

- soldering iron;

- screwdriver and bits for it;

- heat shrink tubes for wire insulation;

- electrical tape, if there is no heat shrink on the farm at the moment.

It is good if there is a new or empty lighter in the house, since the easiest way to get a piezoelectric element is from it.

First of all, the apparatus is checked to again make sure that there is no spark. After receiving evidence of a malfunction of the device, its case is disassembled. During this work, the condition of the remaining parts is carefully studied, such a check is more related to various contaminants. They should be disposed of immediately.

After they get to the piezoelectric element, they cut the wire connecting it to the burner. Then it is removed. In the same way, remove the element from the gas lighter. The supply of wire must be sufficient to connect it to the burner.

When replacing the device for conductors, heat shrink tubing is used, which is heated with a lighter. The repaired gas burner is reassembled in exactly the same sequence as it was dismantled.

After completion of the operation, the device is tested. If no errors were made, then the gas burner should function flawlessly.

Learning to solder with a gas burner

For soldering work, a professional gas burner is best suited. For soldering small parts, it is desirable to use devices that operate on light gas or acetylene.

The results obtained when the burners operate on light gas are of better quality. Also, this type of fuel is cheaper.

When soldering parts in small quantities, it is desirable to preheat the parts. This will save time and ensure uniform heating of all elements of the assembly. As a result, warping and other defects will be avoided.

Before starting work, the parts must be fixed in such a way that they do not have to be moved during soldering. This can be done on a workbench or a special device.

Before soldering, a layer of flux is applied at the solder points. If it is necessary to add flux during operation, then the hot end of the solder rod is immersed in it.

When soldering parts from different materials, the flame must be directed to one of them that has a higher thermal conductivity. You need to be careful when working with elements of different sizes.

It is important that all components are heated to the same temperature. In this regard, thick parts need to be heated longer.

Do not melt solder in the flame of the tool. In this case, it may drip. Melting is carried out directly when the wire comes into contact with the parts to be soldered.

The solder will flow into the hotter solder spots. Based on this, the flame must be directed before soldering. If it does not flow into the seam, then this means that the part has not warmed up to the required temperature.

You should not warm up the solder joints for too long, as this can lead to a change in the composition of the solder, that is, to its burnout, and a decrease in the effectiveness of the flux.

Safety

Sufficiently safe work with a gas burner can only be performed by adults. They must be instructed in the field of labor protection and special training in order to work systematically and at large facilities.

Here are some more rules:

-

do not work in the dark and cramped;

-

check devices, hoses before work;

-

keep equipment and workplace clean and tidy;

-

use protective barriers;

-

firmly and directly put gas cylinders;

-

maintain optimal ventilation;

-

work without a gearbox;

-

do not place cylinders near open flames, in places of strong heat;

-

avoid heating gearboxes with an open flame;

-

do not walk up stairs with a lit burner.

For information on how to properly use a gas burner, see the following video.

Gas burner diagnostics

Rare owners in the event of a breakdown of such a small and relatively simple device will like the idea of causing a master. The specialist will have to pay a certain amount for "overwork", and it may well be comparable to the price of a new gas burner. For this reason, do-it-yourself gas burner repair remains the only logical option.

Fault definition

Correction is possible for almost any type of malfunction. However, before starting work, it is necessary to understand what exactly in the gas burner "ordered to live for a long time." For this, diagnostics are carried out.

- If, even before disassembling the burner, it was found that when the button was pressed, a spark did not ignite, then we can assume that the culprit was found. This is the piezo element itself. If there is a spark, but the device does not work, then usually the reason lies in the fact that individual parts of the gas burner are dirty.

- When a spark appears but the burner refuses to ignite, the atomizer is usually the first suspect. This is a hole for gas to enter. Most likely, it was clogged with dirt.

- For canister burners, some other malfunctions are also characteristic. For example, they are able to start letting gas through due to the fact that one of the rubber gaskets suddenly becomes unusable inside the case.

- Contamination of the grid, which is located on the other side of the atomizer, is another reason for the failure of the gas burner. In this case, the repair is as simple as possible: this filter must be washed with gasoline or alcohol.

- If a spark appears, but there is no gas supply, then the matter may be in the oxidation of the wire through which the spark is supplied. Melted insulation is removed with sandpaper or a file, then replaced with a new one.

There is another problem that owners of gas burners may encounter. This is one of the mysteries when gas is supplied and there is a spark, but the device does not ignite. One possible solution is to adjust the wire relative to the nozzle. Even a slight change in their relative position sometimes becomes a solution to the problem.

After troubleshooting, it is recommended not to assemble the device right there, but to carefully check all other elements for contamination, which can be difficult to determine at first glance. Having lost sight of something, the owners run the risk of soon again encountering a gas burner failure.

Purpose

Let's first decide what methods of heating furnaces are:

- wood;

- charcoal:

- oil;

- gas;

- electrical.

When using the oven in restaurants, cafes, etc. the question arises about the method of heating this furnace. And if it is convenient and environmentally friendly to use firewood in open areas and presumably in summer, then tandoors with gas burners will allow you to use them indoors and harmoniously fit into the conditions of a modern kitchen.

It is possible to use heat-electric heaters, but the cost for electricity cannot be compared with paying for gas. Therefore, if you intend to work indoors, then choosing a gas heating method is ideal.

The gas device is used for the primary heating of the tandoor and the accumulation of heat in the walls. It allows you to more smoothly regulate the heating, which will avoid cracks and burnout of the walls. In the future, the burners are used to maintain the required temperature in the tandoor, but not during the cooking period.

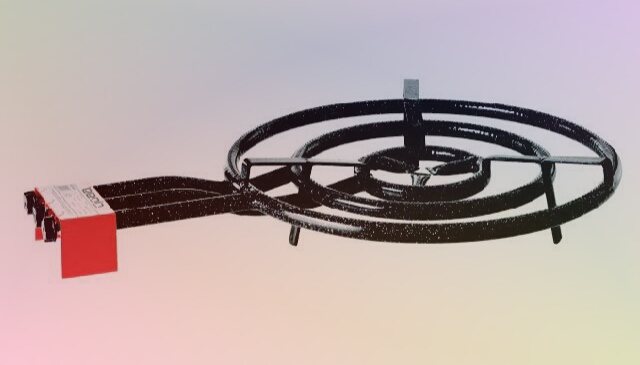

This is how the burners look in the photo:

Photo 1

Photo 2

soldering tool

The piezo ignition gas heater is a compact and mobile alternative to a hot air gun. For operation, it does not require a connection to the wires, the gas cylinder acts as a fuel source, in this the piezo ignition burner significantly bypasses the building hair dryer, which is less convenient to use due to the need to connect wires, which are not always convenient to pull.

Gas burner application:

- heating and melting metal or plastic elements;

- pipe melting;

- hardening of small metal parts;

- quick kindling of a fire, stove;

- soldering small parts;

- other small jobs that require a mobile heat source.

The gas temperature during combustion reaches 1300–1800°C. The tool is easy to use with one hand.

Some features of the operation of plates of various brands

Before buying a gas stove with the Hephaestus logo, you should find out how its oven works, what functions and protective systems the equipment is equipped with. It is necessary to check whether its technical parameters and settings correspond to the type and pressure of the gaseous fuel in the network.

Warranty maintenance of gas stoves and household ovens of the Gefest brand is carried out by the service master. Subsequent repairs or adjustments can be carried out by specialists who have the appropriate approval for the repair of gas equipment

The use of a gas stove in an apartment or a country house requires the owner to strictly comply with safety rules.

We invite you to familiarize yourself with Which is better: stove or hob and oven?

The operation of a gas oven is allowed if:

- the stove is installed in a fireproof place, grounding is carried out;

- the gas stove and, in particular, the oven, are in good condition, all structural elements are undamaged;

- the baking sheet and the grate are not overloaded - the permissible weight is up to 6 kg;

- the oven door is closed.

The device should be used only for its intended purpose - space heating, drying of flammable objects are unacceptable. If there is a smell of gas, first of all, the general valve of the fuel supply pipe must be closed, and then all the valves of the burners. Emergency services are called to fix the leak.

There are three main slab control systems:

- mechanical;

- electronic;

- combined.

The principle of mechanical and combined control is described above.

How to turn on the oven in a stove with an electronic programmer using the Gorenje brand as an example:

- The time is set by simultaneously pressing buttons 2 and 3, then and -.

- The choice of functions on the clock on the programmer with an analog display is carried out by pressing the "A" button.

- Pressing twice confirms the selection.

Press and hold the thermocouple button for several seconds and at the same time press the electric ignition button with the other hand (a spark, a light is shown near). If piezo ignition is not provided, matches are used.

To use the ARDO electric oven:

- Select the desired mode with the button or the adjusting knob.

- Ignite with a match or electric ignition.

- Do not close the door for a couple of minutes.

- Warm up the cabinet for 15 minutes.

The Bosch cooker is equipped with a timer, temperature, top and bottom heat knob. There are models with and without electric ignition. Set the temperature, select the heating, put the dish in the preheated oven and set the timer.

To turn on the Greta oven, turn and press the knob, hold it in this position for 15 seconds, then release. If necessary, not earlier than after 1 minute, repeat the procedure with the oven door open.

Be sure to read:

How to connect a gas stove with your own hands: step by step instructions, installation rules

In Indesit models with piezo ignition, it is enough to turn the regulator towards the maximum temperature and press. In models with manual ignition, it is necessary to keep the knob pressed for 15 seconds, otherwise the oven will not light up.

Be sure to read the instructions, study the safety rules.

The most important:

- Do not store cleaners, detergents or any other chemicals inside the equipment due to the risk of fire.

- Do not allow children to play with the appliance.

- For cooking, use special utensils.

- Use oven mitts as the equipment gets very hot.

- If the smell of gas is heard, smoke is emitted - turn off the oven.

- Do not leave the operating oven unattended.

- At the end of the cooking process, turn off the stove and remove the dish using oven mitts.

Features of a gas burner with piezo ignition

The device is portable, the mechanism includes a handle for the gas opening valve. In most models, the flame flow control and piezo ignition are taken out separately, which makes it easier to use, since by drowning out or increasing the flame, you cannot accidentally turn it off completely. The body of the burner is made of plastic or metal. The time of continuous operation of the temperature flow of the burner on the cylinder is at least 2 hours.

Different models of burners may differ in the power of the gas flow and the ability to adjust it; for some simplified mechanisms, the force of the gas flow is practically unchanged.

Since the gas is liquefied, when the cylinder is tilted, the flame may go astray. This happens as a result of the ingress of gas in the liquid fraction into the mechanism of the device. But in this regard, it all depends on the warming up of the device, when it warms up enough (the first few minutes pass), you can not be afraid of such failures.

General classification of gas burners by type of fuel

Country houses can not always be provided with natural gas supplied from a common highway.Therefore, the variability of the burners in terms of the use of different types of fuel is provided. If the fuel comes from a gas main, propane-butane gas burners are most likely used for heating boilers.

Main gas-methane is the most affordable natural fuel for boilers. However, now there is no big benefit in the price of liquefied blue fuel (propane-butane mixture). General heating provided by the main pipeline is also expensive.

Gas boilers operating on different types of fuel mixtures have approximately the same design. There is a slight difference in cost, but it is also insignificant (equipment for liquefied fuel will cost more). The burners themselves are slightly different, having different nozzles for liquid fuel and blue gas.

If natural gas is not supplied to the house, propane-butane gas burners are used.

Propane burners require adjustment to this type of fuel with the installation of a jet. When burning, the flames give off a yellowish color, soot accumulates more in the chimney. The jet is responsible for normalizing the pressure.

Modern burners operate in a wide temperature range - from -50 to +50 °C. Part of the equipment can be adapted for other types of energy carriers:

- waste oil;

- diesel fuel;

- fuel oil;

- kerosene;

- propanobutane base;

- arctic diesel fuel.

Modern fixtures often come with both types of nozzles or universal equipment for fuel varieties, which makes them easy to reconfigure.

Homemade gas burners are most often used in solid fuel boilers.

It is safer to purchase simple gas equipment adapted for gas in cylinders.Homemade equipment, although more affordable, but unsafe! Usually carry out "alterations" on the basis of old units.

Turbocharged types of gas burners and their design differences

Among modern gas equipment, many experts prefer closed-type burners for turbocharged boilers. They are self-sufficient in terms of design, suggest the presence of a compact chimney, which can even be diverted into general ventilation with autonomous heating.

The heating unit with a special closed-type combustion chamber receives oxygen from the outside - through a special supply pipe (coaxial chimney). In approximately the same way, combustion products are removed to the outside. Heating equipment is controlled by a sufficiently powerful fan on automatic control.

Fan gas burners also have a drawback - this is the price due to the complex design of the product

Such a device is much more expensive than atmospheric heating equipment. However, for an additional fee, the buyer receives a number of benefits, including autonomous operation in a residential area. This device, thanks to automatic control, has a high level of security.

Turbocharged equipment has the highest efficiency and flexible temperature scheme

Fuel burns almost completely, which is important for environmental performance. There are also disadvantages, including structural complexity, causing difficulties during installation and repair.

Gas burners for combined equipment are most often used in solid fuel boilers. This is a rather complex unit, so all nodes must meet certain requirements for efficiency and safety.The automatic device is able to switch from one type of fuel to another for uninterrupted heat supply. According to this principle, pellet and pyrolysis boilers are arranged, equipped with gas for burners, which drives the ignition process.

Methods for troubleshooting gas water heaters

Geysers "Vector" are one of the most popular in Russia. This is evidenced by sales statistics.

When, in the gas column "Vector" the piezoelectric element did not work, the spark does not appear and the burner does not ignite. The reasons for the failures are:

- No draft in the chimney. It could just be clogged and needs to be cleaned. There is a special sensor in the column that monitors the presence of traction. If it doesn't exist, it won't work. If you cannot do it yourself, payday loans gallatin tn is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. A very low pressure may indicate problems with the membrane or that the filter is clogged.

- The nutrient is not working. Kindling is done using batteries, without which there will be no current, for a spark to appear. It is necessary to remove the panel, then remove the battery pack, pull them out and insert new ones.