- How can I flush the heat exchanger if there is no special apparatus?

- Difficulties with models

- How is the heat exchanger

- Therm 4000 S WTD 12/15/18 AM E23/31.

- Possible malfunctions of the column and how they can be eliminated

- Specifications NEVA 4511

- Geyser Neva 5514 and Neva 4511

- Geyser Neva Neva Lux 5514 Characteristics:

- Geyser Neva 4511 Characteristics:

- Breakdown diagnostics

- Gas column device

- Neva Lux 6011

- Causes of breakdowns and their elimination

- Problem # 1 - lack of traction in the column

- Problem #2 - Difficulties with water pressure

- Problem #3 - insufficient gas pressure

- Problem # 4 - no ignition when turned on

- Problem # 5 - the presence of blockages in the tubes

- Column ignition

- Restoring the flanges of the gas column pipe by soldering

How can I flush the heat exchanger if there is no special apparatus?

A cheaper, safer, and no less effective way to clean is with citric acid. If the radiator of the Neva gas apparatus is clogged, you will need to dilute 80 grams of citric acid with 700-800 ml of hot water. For cleaning, take a large container (boiler), fill it with 30% water, put it on the stove.

Remove the radiator, place it in a container, pour in the prepared solution with a funnel, turn on the stove, hold for about an hour and a half. Then turn off the heat and leave to cool completely, about another hour. Then rinse under a stream of strong water, you may notice pieces of plaque flowing out, if the pressure of the outgoing water does not increase, repeat the procedure again. Then install it in its original place.

Difficulties with models

In many ways, leaks in geysers are caused by the same reasons. But in devices of different brands, specific breakdowns occur more often, leading to similar problems.

For example, the Neva gas column leaks most often for the following reasons:

- Membrane breakage.

- Stem seal leaks.

- Violations of the integrity of the stem plate

Automatic budget models of this brand, such as the Neva 4510, often leak due to heat exchanger breakdowns. It has an aluminum body and is not very durable.

Even in such units, gas often flows due to the thin-walled igniter tube and the drying of the stuffing box.

It is also extremely difficult to eliminate the leakage of the stem gland, since the connecting bolts of the gas and water compartments are very difficult to unscrew, as well as the microswitch. These fasteners often break during disassembly.

Water from the Junkers gas column drips for the following reasons:

- Radiator failure.

- Drying of o-rings (more inherent in older models).

- Cracks at the attachment point of the frog (flow regulator).

- Membrane wear.

You can solve these difficulties on your own. Point 1 can be corrected by soldering. P.2 - by replacing these rings. This is also one of the ways to fix item 3.

In general, high-quality and timely repair of the water unit is needed. gas column Junkers.

At home, you will need to disassemble the column, get this node. In most cases, the problem lies in the worn membrane and cover. These items need to be replaced.

Such problems most often occur with models of the Junkers W 275 1 line. And if the replacement of problematic parts does not work, you need to contact the masters.

Quite often, customers turn to the service - owners of Bosch speakers, the membranes of which wear out quite quickly. Experts recommend always having several of these products in stock.

Owners of Ariston speakers often complain about leaks from below. This is due to a worn flange gasket. She has to be replaced. To do this, the device is de-energized, all water is drained from it. The cover is removed, the flange is taken out, the gasket is changed.

The second common reason for models of this brand is a violation of the sealing of the connecting sections. The solution is to cover these areas with a strong sealant.

The same problem is relevant for Oasis speakers. They also often leak from under the flange and due to the accumulation of scale. The owners of this technique need to change the anode 2-3 times a year. Otherwise, the heating element will leak or completely collapse. Therefore, you should regularly clean the device from dirt and scale.

Owners geysers Astra often complain about leaks in the connecting sections and wear of TO. A temporary solution to the problem is soldering. Effective - the acquisition of a new TO.

In Electrolux columns, the most common causes of leaks lie in the radiator. The solution is fast and high-quality soldering.

Vaillant models often have problems with gaskets and maintenance. It is logical to replace these elements.

Whatever your gas water heater is, regularly remove dirt and scale from it. If problems are found, fix them urgently if you have the necessary experience. Most often, the most effective method of solving a problem is to replace a particular part or assembly.

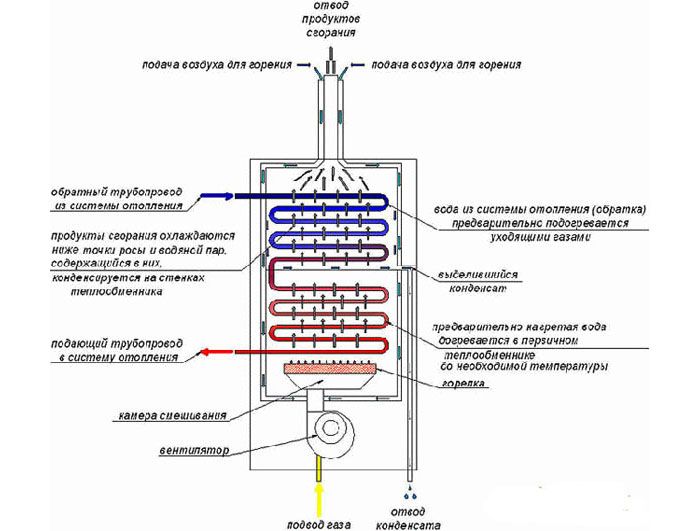

How is the heat exchanger

A heat exchanger, or radiator, is designed to heat water from a burner. The stream flows through the tubes of the coil, instantly warming up from the burning fuel. Most often, the block is steel or copper. How much does the device weigh? Copper device - from 3 to 3.5 kg. The steel apparatus is much heavier, for this reason it has a lower efficiency.

Features of steel product:

- Lower cost compared to copper.

- Due to the plasticity of the material, heating does not harm the surface.

- Differs in resistance to corrosion.

Copper Appliance:

- Possesses high efficiency, fast heating.

- Products that contain additional impurities are cheaper.

- Corrosion resistance.

- Light weight if it is pure copper.

Trying to reduce the cost of production, manufacturers add impurities to copper. Because of this, the radiator heats up unevenly, which leads to burnout of individual parts. Some cover the surface with heat-resistant paint, but this brings little results. Service life does not exceed 2-3 years.

Copper is more resistant to corrosion than steel. Most manufacturers do not indicate how much copper goes into the production of the product, assuring that the heat exchanger is made of a thick layer.

How much does it cost to replace a gas boiler radiator? If you take into account the purchase of a new device, delivery and installation, it will be cheaper to repair the heat exchanger.

Therm 4000 S WTD 12/15/18 AM E23/31.

Before starting, you must make sure that, on the plate installed by the manufacturer on the device, the gas marking corresponds to the gas connected to the device. It is possible to connect a remote control to the device, which completely duplicates the operation of the display on the column.

Open the gas cock and water valves. Connect the machine to the mains.

The water temperature set by the manufacturer is 42 degrees, this is the optimum temperature.

To turn on the device, you just need to press the power button and open the hot water tap. To control the temperature, you must press the "+" or "-" button and select the temperature you need. Until the temperature you have selected is reached, the reading on the monitor will flash.

If it does not reach this value within thirty seconds, the water faucet icon is displayed on the monitor, which indicates the need to increase or decrease the water flow. If you press the P button, the programmed constant temperature of 42 degrees will appear. Setting the minimum temperature reduces energy consumption and makes it possible to reduce the formation of limescale in the heat exchanger.

But if you know how to turn on the column, but encounter malfunctions (the flame goes out, does not ignite), then where the causes and methods for their elimination are described.

It is far from always possible to fix malfunctions due to which the gas column does not light up when the water is turned on. Some breakdowns require the involvement of a specialist.On the other hand, the cause of problems in the operation of the water heater is not always associated with the failure of internal components and modules. You can fix minor damage with your own hands.

Possible malfunctions of the column and how they can be eliminated

If you have a minor breakdown, then you can fix it yourself. Here is some of them:

- After a short period of operation, the water heater switches off. The reason is low traction. To do this, it is enough to clean the chimney. It also does not hurt to check the connection of the exhaust pipe. In the event of a malfunction, the connection must be sealed;

- If the outlet is water with a temperature above 90 °. To eliminate such a problem, it is necessary to lower the gas flow, and, on the contrary, increase the water. Thus, it is possible to achieve the desired inlet temperature;

- If the column does not start when the tap is opened. To do this, you need to replace the batteries or check their installation;

- Carbon formation on the flame sensor. It needs to be cleaned up.

- If the water pressure in the system is weak, then you should contact the utility;

- If there is not enough water, the fluid flow must be adjusted;

- If scale has appeared in the heat exchanger or the filters are clogged, then it is necessary to clean it;

- It is necessary to fully open the taps at the inlet and outlet of the water, if they are partially open;

- If, after opening the tap, the column does not start, but there is a spark. In this case, it is necessary to open the gas supply valve;

- When you turn it on for the first time or after a long period of inactivity, air often appears in the communications. To solve this problem, you can open the tap for a few seconds, then close and open again. You can carry out this procedure several times;

- If a spark does not enter the gas stream. With such a problem, it is necessary to adjust the distance between the burner and the candle electrode.

Before using the gas column Neva-4511, you must carefully study the attached instructions. It describes in detail all possible problems and how to solve them. In more difficult situations, it is necessary to contact specialists.

The Neva-4511 column is an excellent inexpensive option that is produced in Russia. In addition, it has many positive aspects. For a small family, this column is perfect.

Specifications NEVA 4511

The water heater is similar to the 4510 model in terms of ignition type, color design, and the presence of an LCD display. But the power and performance are different: 21 kW and 11 l / min. In addition, the copper heat exchanger here is slightly larger than in the previous heater. It is made without tin and lead.

The manufacturer himself calls the model 4511 a bestseller. However, some buyers regret the purchase. People do not like the quick wear of parts, possible interruptions in the operation of the column. Among the advantages, users name compact dimensions, reliability, the ability to regulate the water temperature.

Geyser Neva 5514 and Neva 4511

Geyser Neva. Today it is perhaps one of the most popular brands of instantaneous water heaters on the Russian market. It is worth noting that this success is well deserved. Homeland of origin - Russia. The production of domestic gas instantaneous water heaters of the NEVA series is carried out by the Armavir Gas Equipment Plant.

The plant is part of the concern BaltGaz Group.The group specializes in the production of gas instantaneous water heaters, wall-mounted boilers, Unigar atmospheric burners, as well as the manufacture of 8-liter and 11-liter heat exchangers. Armavir Gas Equipment Plant is considered one of the largest gas equipment manufacturers not only in Russia, but also in the CIS countries

The Neva gas water heater is designed to ensure uninterrupted supply of hot water to both apartments and country houses. Neva water heaters are able to serve 2 points of water intake at the same time. All serial columns are equipped with a copper heat exchanger manufactured using oxygen-free soldering using innovative technology.

The gas column Neva is equipped with 6 security systems. The column automatically turns off under any unforeseen circumstances. Such as lack of water pressure or gas supply, poor draft or reaching water temperature of about 90°C. The manufacturer sets the service life of the column at least 12 years.

Currently, the Neva geyser is represented by a wide range of models: NEVA-4510 M, 4610, 4011, 4511, 5111, 5514, 5611, 6011, 6014. Today we will consider the two most popular models from the NEVA water heater family.

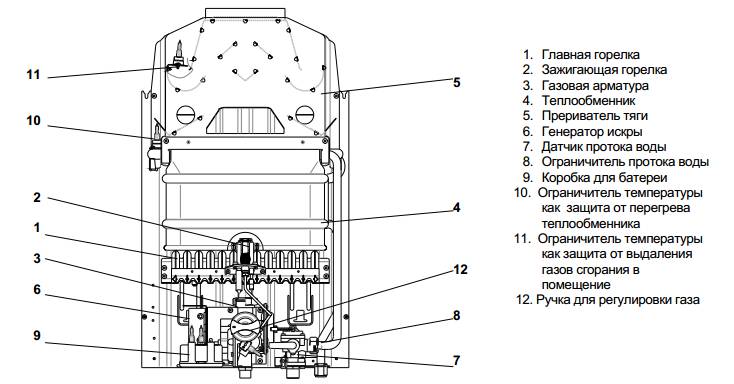

Geyser Neva Neva Lux 5514 Characteristics:

Advantages of the model:

- There is a flame sensor that monitors the operation of the pilot and main burners;

- electronic control provides ignition and gas supply

- There is a plug for draining water from the heat exchanger, preventing the column from freezing;

- The presence of a safety valve to protect the water heater from excessive water pressure;

- The first thermal switch ensures that the column is turned off in the absence of draft in the chimney;

- The second thermal switch turns off the device when the water in the heat exchanger overheats more than 90°C.

- Gas is supplied to the main burner only in the presence of a flame, which corresponds to the ionization sensor;

- The gas supply to the main burner is blocked when the water flow stops.

- Easy to operate with one handle

Geyser Neva 4511 Characteristics:

Advantages of the model:

- One of the compact in the range, fits perfectly into small spaces

- The presence of an ionization sensor ensures that the gas is blocked in the event of an unexpected flame break.

- No permanently burning pilot flame

- Gas automatically lights up as soon as you open a tap with water.

- Ignition automatic from batteries, display, water-cooled combustion chamber.

- Standard chimney diameter 120 mm - fits most air ducts.

- Affordable price in economy class

- gas control system

- thrust sensor

- Ability to work at low water pressure

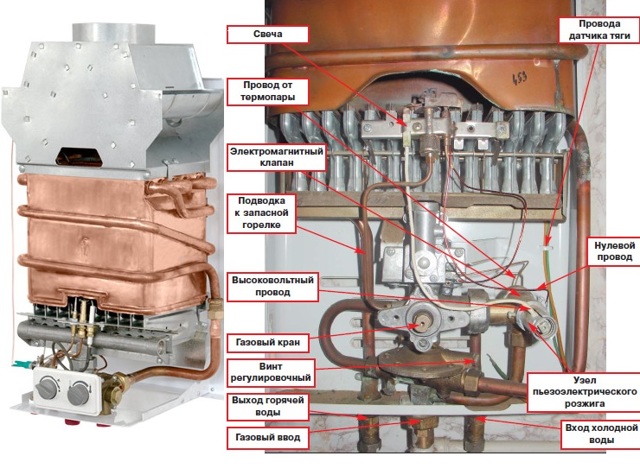

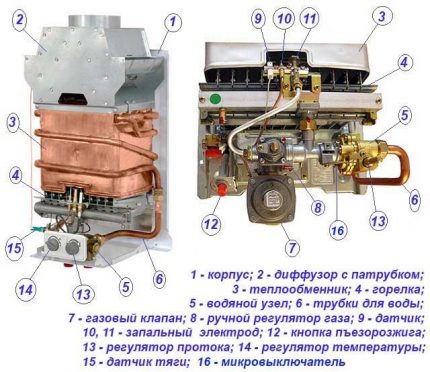

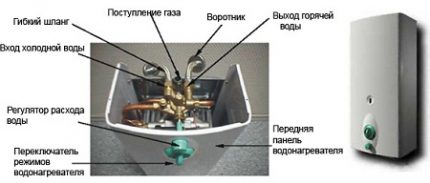

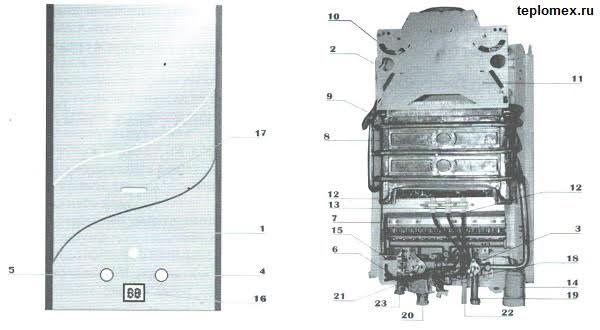

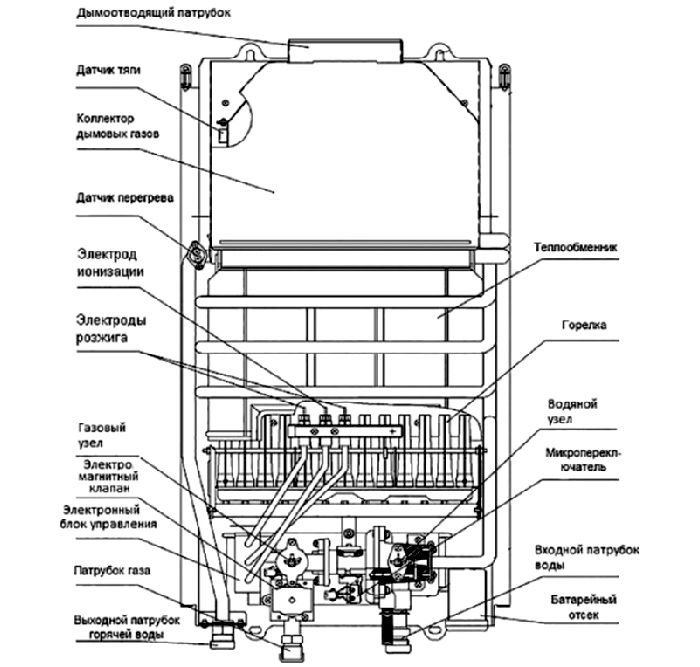

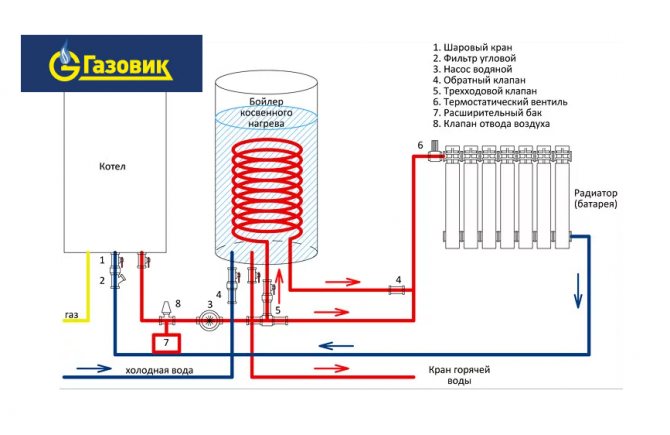

Geyser Neva - Scheme:

Sales of NEVA water heaters are accompanied by a wide network of service centers throughout the country, which characterizes the manufacturer as responsible for its products. Geyser Neva has no problems with the supply of spare parts.

A distinctive feature of all models is affordability in the price category, ease of operation, laconic design. Modern methods of production of BaltGaz Group put products on a par with famous brands.

Dear ladies and gentlemen, if you have experience in owning Neva water heaters, positive or negative, please leave a short review. Perhaps your review will help in choosing a future owner.

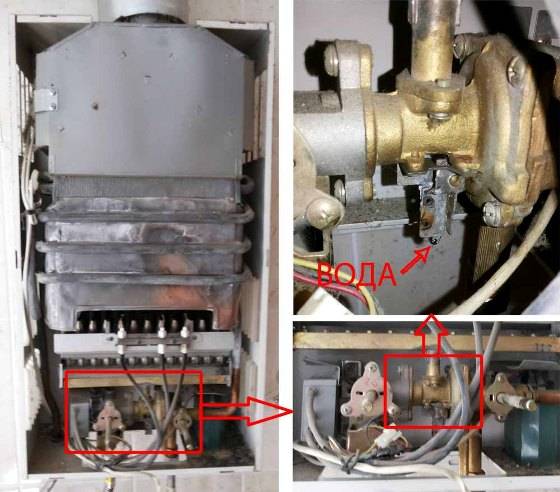

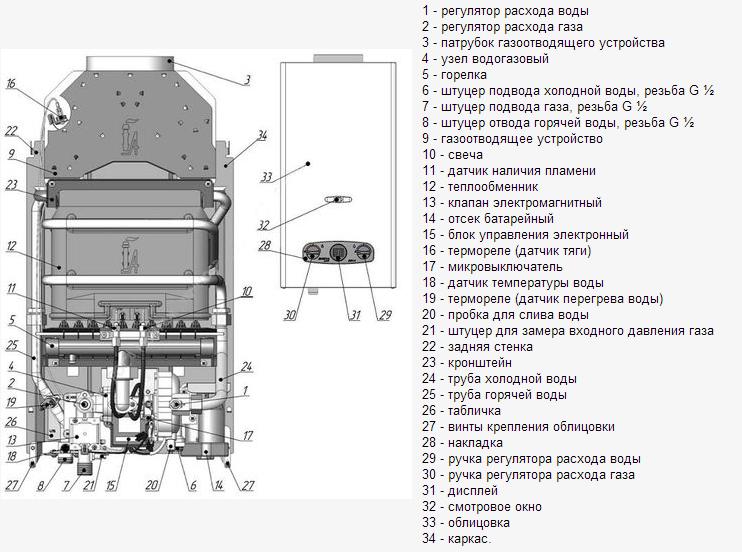

Breakdown diagnostics

Whatever problem occurs during the operation of the NEVA 3208 dispenser, to eliminate it, you first need to shut off the gas and water supply to the system, and only then proceed with the repair. After that, you need to dismantle the column casing. To do this, remove the round flame control handle, which is fixed on the stem with a special spring. The handle is removed with a simple pull. When it's removed, you can get to the two mounting screws that hold the shroud in place. Locking pins are also located at the rear of the structure. When the casing is finally removed, we can begin to identify the malfunction.

Consider the main reasons why the NEVA 3208 geyser does not light up, as well as methods for eliminating such problems.

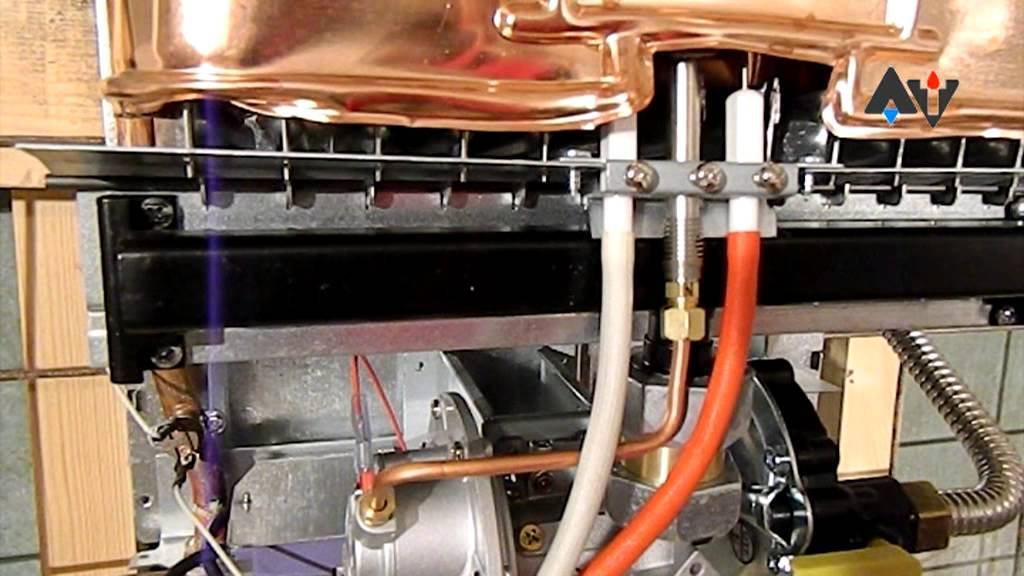

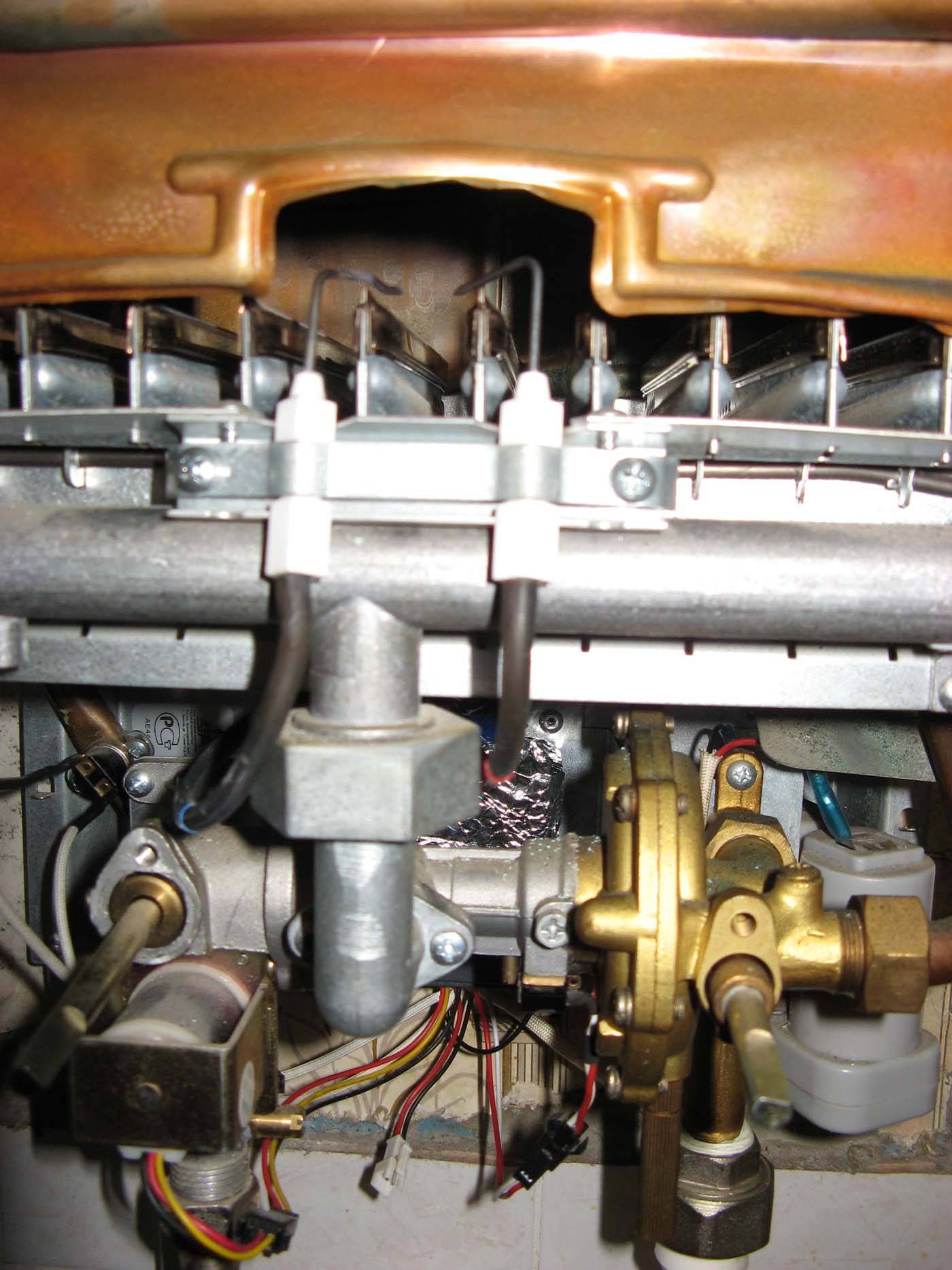

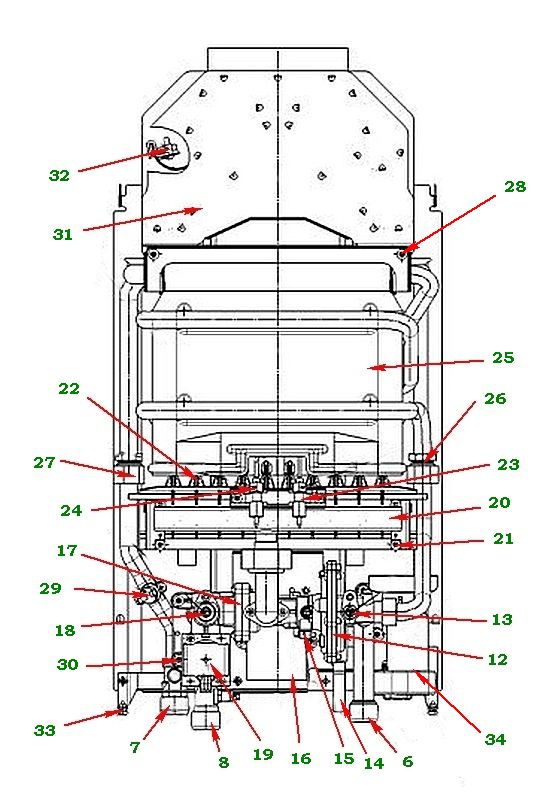

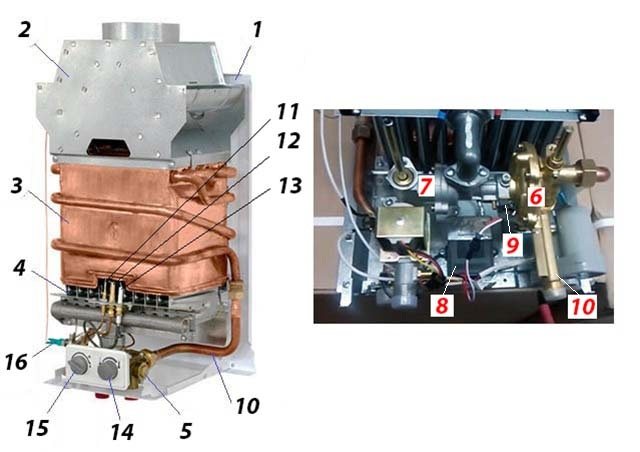

Gas column device

Regardless of the model of the gas column, its design includes the following elements.

- Heat exchanger.

- Main burner.

- Pilot burner.

The gas column works according to the following principle.

- When the water tap is opened, the pressure in the system drops and the pilot burner fires in the column.

- After that, the pilot burner sets fire to the main one. That, in turn, begins to intensively heat the heat exchanger, which is made in the form of a coil. In the process of passing water through the heat exchanger, it heats up and hot water is already flowing at the outlet from the tap.

- The products of the exhaust gas exit into a specially designated pipe.

This principle of operation applies to automatic columns. In semi-mechanical or mechanical - the principle of operation is slightly different, but generally identical to an automatic burner.

Also, depending on the model, after the water heating cycle, the flame in the pilot burner remains burning, thereby maintaining a high temperature in the heat exchanger. When the water tap is opened, the whole process starts again.

This is interesting: Overhaul of apartment buildings: we tell in detail

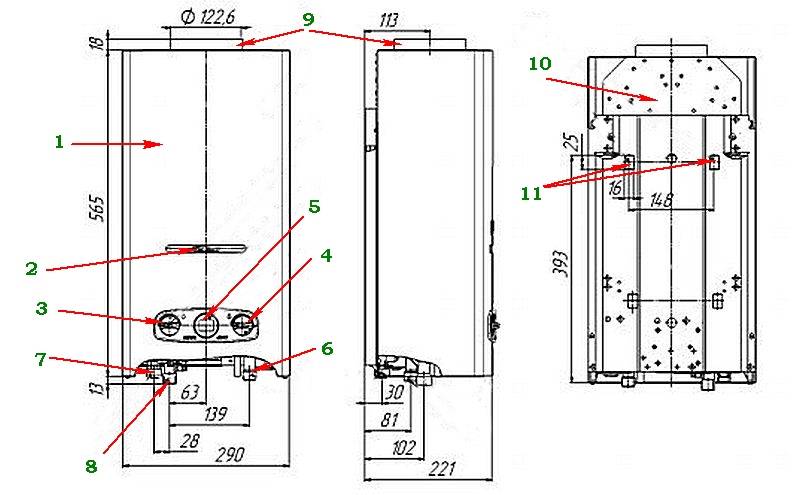

Neva Lux 6011

Specifications are similar to the "5611" model. At the same time, "Neva Lux 6011", as indicated above, is equipped with a push-button system with an electronic display instead of mechanical control.

This gas water heater is quite easy to operate. It has an automatic flame ignition system. Available in two colors (white and steel). The power of the gas heater is 21 kW. At a water temperature of +25 degrees. C. has a capacity of 11 liters / min.

The column is adapted to work with low water pressure in pipes (up to 0.15 bar). The device weighs 9.5 kg. It has small dimensions 565x290x221 mm.

Causes of breakdowns and their elimination

Despite the simplicity of design, unpretentiousness in operation, the flow heater is not immune from breakdowns. If the geyser of the Vector brand does not turn on, do not panic. There can be several reasons for the problem, and most of them can be fixed on your own.

Problem # 1 - lack of traction in the column

The lack of draft indicates that the products of combustion cannot be quickly removed from the room. This poses a danger to users, so the sensor turns off the geyser.

Sometimes the burner ignites, but immediately goes out. This can happen when there is not enough air to burn the gas - the flame goes out due to a lack of oxygen to support combustion.

In any case, you first need to check the draft by bringing a burning match to a special hole on the column body. If the flame is directed inward, then the chimney is working normally, the combustion products will be quickly removed, and the cause of the malfunction is different. If the flame remains motionless, directed upwards or towards the user, then it is worth carefully inspecting the chimney, cleaning it.

Soot gets into the air along with the products of combustion. It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction is lost. The problem is solved by thorough cleaning of the chimney

Soot gets into the air along with the products of combustion. It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction is lost. The problem is solved by thorough cleaning of the chimney

Problem #2 - Difficulties with water pressure

Another reason why the household geyser of the Vector brand does not ignite may be the low pressure of cold water or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption, evaluate its pressure. If there is insufficient water pressure in the system, the solution may be to install a pump or replace old, clogged pipes.

If there are no problems with the water supply, it is worth moving on to inspecting the column. The solution to the issue may be to adjust the water supply to the column. To do this, the corresponding valve must be fully opened.

Another cause of insufficient water pressure in the column is a clogged filter. To inspect it, it is necessary to shut off the water and gas supply with valves, unscrew the nuts, rinse the grid. If cleaning fails, the filter will have to be replaced.

It will take a few minutes to inspect the filter. However, in some cases, one flush is not enough, a complete replacement of the part is required.

It will take a few minutes to inspect the filter. However, in some cases, one flush is not enough, a complete replacement of the part is required.

Problem #3 - insufficient gas pressure

Sometimes gas pressure not enough to ignite the flow column, its normal operation. However, this problem cannot be solved on its own. You need to contact the gas service.

Problem # 4 - no ignition when turned on

The presence of an electric ignition system ensures the comfort of using the gas column, eliminates the use of a wick that is constantly on fire. However, it is this element that can cause a malfunction of the device.

When the tap is opened, automatic ignition should work. This action is accompanied by a characteristic crack. If the ignition does not work or the spark is too weak to ignite the gas, the column will not be able to connect. Replacing the batteries will solve this problem.

Batteries are required for the smooth operation of an instantaneous water heater. When the batteries are discharged, the electric ignition does not work, the column does not turn on

Batteries are required for the smooth operation of an instantaneous water heater. When the batteries are discharged, the electric ignition does not work, the column does not turn on

Problem # 5 - the presence of blockages in the tubes

Water and gas pass through the gas column Vector in the process of operation. The use of filters allows you to clean them from unnecessary impurities. However, the presence of blockages can cause the device to simply not turn on.

However, the filter is not always able to bring the water to an ideal state. Soluble salts get inside the heater together with the liquid, settle on the walls of the heat exchanger. As a result, the patency of thin tubes is impaired.

Specialists remove scale with the help of specialized reagents. A home master can deal with it using a solution of citric acid or vinegar. To clean the heat exchanger, you need to remove it, place it in a warm solution with the addition of vinegar.You can also use special purchased products - "chemistry" designed to clean heat exchangers.

It is better to entrust the elimination of blockage of the heat exchanger to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, they are easy to damage

It is better to entrust the elimination of blockage of the heat exchanger to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, they are easy to damage

We discussed in detail about cleaning and repairing the heat exchanger in the next article.

Column ignition

- ignition manually;

- piezo ignition;

- electronic;

- microturbine.

Manual ignition is a rarity for modern speakers. In older models, matches were needed to set fire to the gas. These models are rare today.

Piezo ignition. By analogy with piezo electric stoves, to set fire to the gas, you need to press the button on the column panel. This method is still used in modern models.

Electronic. The most convenient and popular way. Reliability and efficiency in gas consumption make such models a little more expensive. By analogy with a car, a spark is created by a small battery, batteries are more often used. The column NEVA 4511 belongs to this model range.

As for microturbines, the current in them is generated by a hydrodynamic generator controlled by a water flow. The cost of such copies is much higher.

Columns with electric ignition are easy to operate. The gas is ignited automatically when the water tap is opened, thus you can save gas consumption.

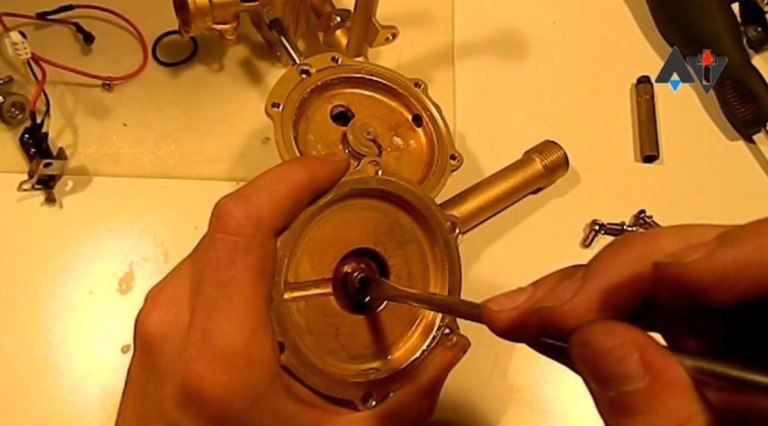

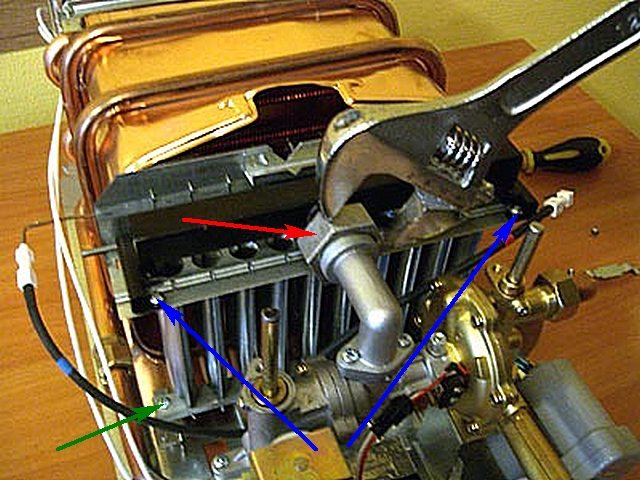

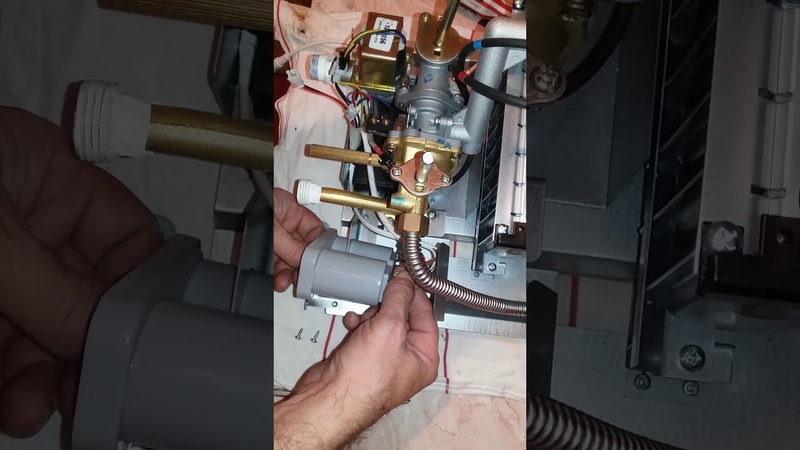

Restoring the flanges of the gas column pipe by soldering

Somehow, two pieces of copper tubes with flanges caught my eye, on which American union nuts were put on. These parts are designed for the installation of water pipes from copper pipes.

When soldering the gas column heat exchanger, I remembered them, and the idea arose to restore the previously cracked copper pipe connecting the heat exchanger outlet pipe to the hot water supply, soldering new flanges to them, which were idly gathering dust on the shelf. The task was somewhat more complicated, since the available parts had a copper tube bent at a right angle. I had to take up a hacksaw for metal.

First, a part of the tube with a flange was sawn off in the place where the bend begins. Further, an expanded part of the tube was sawn off from the opposite end for further use as a connecting ring. If the tube were straight, then there would be no need to cut. The result was two pieces of tube about a centimeter long.

The next step is sawing off the cracked flange from the pipe. The sawn off piece of pipe should be equal in length to the piece of pipe with the flange prepared for repair in the previous step.

As you can see in the photo, the sawn-off piece of the gas column pipe at the place where the flange was formed had many cracks.

The photo shows parts prepared for soldering. On the left - the end of the gas column pipe, on the right - a new flange with a union nut, in the middle - a connecting ring.

Before soldering, you need to check how the prepared parts fit together. The tubes of the branch pipe should enter the ring easily, with a small gap.

The mating surfaces of the tubes and the ring before soldering must first be cleaned with fine sandpaper to remove the oxide layer. It is convenient to clean the ring inside by wrapping a round rod with sandpaper, for example, the handle of a small screwdriver.Next, the cleaned surfaces must be tinned with a thin layer of POS-61 tin-lead solder using a soldering iron with a power of 60-100 watts. As a flux, it is best to use acidic zinc chloride flux, in other words, hydrochloric acid slaked with zinc. Since copper parts are soldered, rosin or aspirin is also suitable.

When soldering, it must be ensured that the pipe joint is inside the ring approximately in the middle. If, after tinning, the tubes do not want to enter the ring, then you need to heat them up with a soldering iron, the solder will melt and the tubes will enter. Do not forget to put a cap nut on the tube before soldering the pipe.

After the tubes are articulated, all that remains is to fill the gap with molten solder. As you can see in the photo, it turned out to be a completely hermetic and mechanically strong connection. The branch pipe is repaired, and you can install it in place in the gas water heater, it will serve no worse than a new one.

The check showed the tightness of the pipe at the place of soldering, but a leak occurred at its other end, for the same reason a microcrack appeared. I had to repair the other end of the pipe in the same way. The geyser has been working with a repaired pipe for more than a year. No water leaks were observed.

Using this technology, it is possible to restore the tightness of not only copper and brass tubes, but also stainless steel and iron tubes. The technology is applicable not only for the repair of gas water heaters, but also for the repair of other devices and machines, including cars.