- Repair of geysers of popular brands at home

- Features repair of geysers "Bosch"

- The nuances of do-it-yourself repair of the gas column "Junkers"

- Brief instructions for repairing the geyser "Oasis"

- Features of the repair of the geyser "Vector"

- Why burners don't work?

- Preventive advice

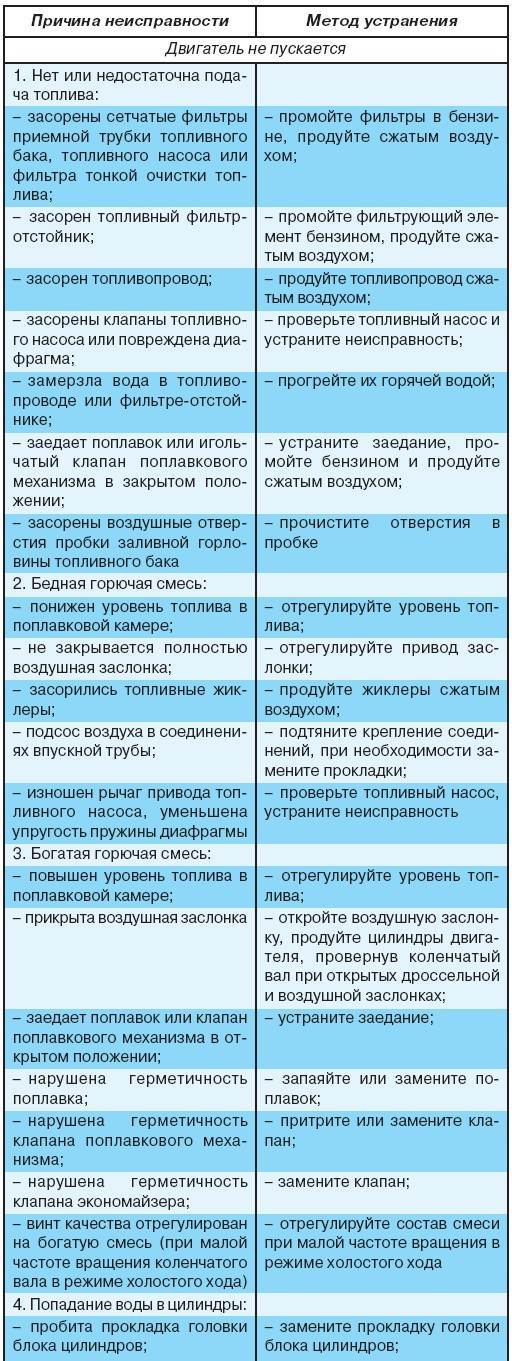

- Causes of breakdowns and their elimination

- Problem # 1 - lack of traction in the column

- Problem #2 - Difficulties with water pressure

- Problem #3 - insufficient gas pressure

- Problem # 4 - no ignition when turned on

- Problem # 5 - the presence of blockages in the tubes

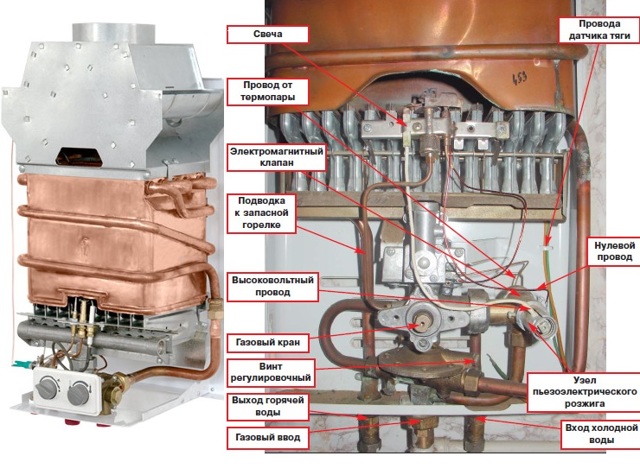

- Device and principle of operation

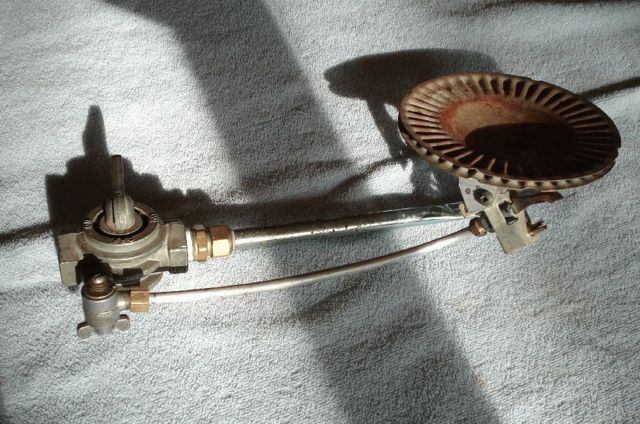

- Rules for dismantling and disassembling the gearbox

- Removing the reducer from the column

- Dismantling the frog of the water heater "Neva 3208"

- The procedure for removing the gearbox "Neva-transit"

- Water Regulator Disassembly

- Frog reassembly

- Testing the repaired node

- How to replace the piezo element?

- How to extend column life?

- Features of using batteries

- Column heat exchanger quality

- System water quality

- Overheating of the geyser

- Methods for self-diagnosis of faults

- Working principle of ceramic infrared gas heater

- What can be repaired in a geyser with your own hands

- Making an infrared heater

- What can be repaired without gasmen?

- Conclusions and useful video on the topic

Repair of geysers of popular brands at home

Repair of the main breakdowns of all gas water heaters is similar to each other, since the principle of operation for all devices is similar. However, different manufacturers have weaknesses in equipment that are most common.

Only minor damage can be repaired on your own

Only minor damage can be repaired on your own

Features repair of geysers "Bosch"

The weak point of the models of the Japanese manufacturer is a thermocouple, after a couple of years of operation, problems with ignition and combustion may arise, the gas column may not turn on when the water is turned on or go out spontaneously. You can clean the thermocouple yourself, but this only temporarily eliminates the cause. The part will need to be replaced soon. Another problem is that the igniter tube is not rigidly fixed, and therefore, it may be displaced. To fix this problem, you just need to return it to its place.

Thermocouple for geyser

Thermocouple for geyser

The nuances of do-it-yourself repair of the gas column "Junkers"

The weak point in the Junkers models is the ignition system. Over time, the burner or wick may go out, in connection with this there is a problem of heating water. To fix it, you need to check the operability of the node.

Ignition unit for water heater

Ignition unit for water heater

Brief instructions for repairing the geyser "Oasis"

The equipment of the German manufacturer is distinguished by the assembly of very high quality. No problems specific to this brand have been identified, and to eliminate ordinary breakdowns of the Oasis gas column, you should familiarize yourself with the installation diagram and our repair instructions using the above methods.

Geyser "Oasis"

Features of the repair of the geyser "Vector"

According to experts, all the malfunctions of the speakers of this manufacturer are in the use of poor quality spare parts and improper assembly. The main problem, why the Vector gas column does not light up, is that the contacts in the power supply are oxidized. In this case, even replacing the batteries will not bring the desired result, you must carefully clean the contacts. Another possible nuisance: the stem hangs on the water valve.

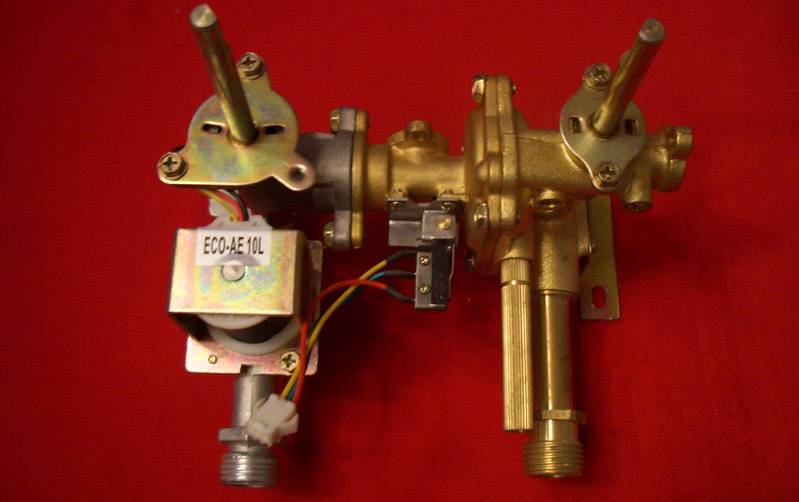

Gas water heater unit

Gas water heater unit

Related article:

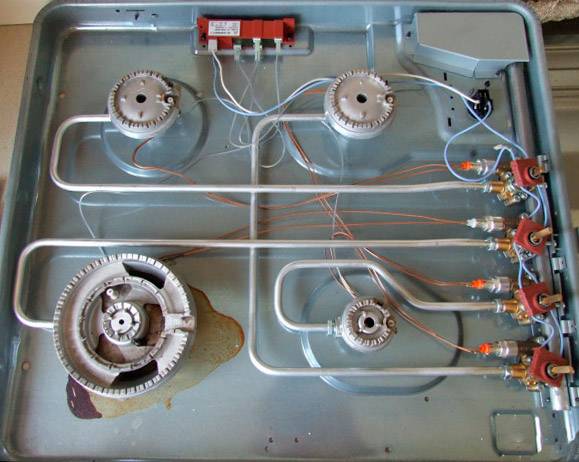

Why burners don't work?

The most common cause of problems with the performance of a gas stove is dirt clogged in the jet nozzle. These structural elements are located directly under the burners. Therefore, particles of food and detergents often get into the channel designed for dosing gas.

They burn out under the influence of high temperatures, but the residues still accumulate and over time interfere with the supply of gas to the burners. Which leads to a partial, and sometimes complete loss of their performance and poor combustion.

The described procedure occurs unevenly, so burning problems occur for each burner separately.

A high-quality flame is homogeneous, blue in color, does not smoke and its tongues do not try to break away from the burner. In this case, gas must be supplied from all openings of the burner. And if at least one of the items listed above is not observed, then this indicates a malfunction

A high-quality flame is homogeneous, blue in color, does not smoke and its tongues do not try to break away from the burner. In this case, gas must be supplied from all openings of the burner. And if at least one of the items listed above is not observed, then this indicates a malfunction

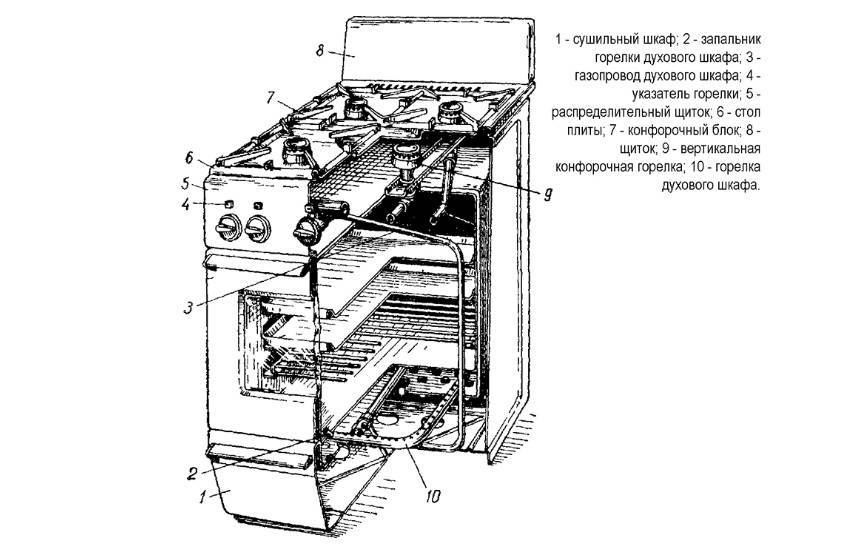

The situation with nozzle contamination is one of those that you can solve yourself. Since this does not require special knowledge and skills, as well as a rare tool. Before proceeding with repair work, we recommend that you first familiarize yourself with the device of the gas stove.

In addition, to troubleshoot the problem, you must perform a number of actions:

- Remove the lid from the burner.

- Dismantle the burner. This is easy to do - it is simply removed from the seat with one hand movement.

- Dismantle the gas stove table, which will allow access to the nozzle. For which it is sometimes necessary to unscrew a few screws.

- Clean the nozzle channel.

The last procedure is performed using a pre-prepared needle or a piece of thin wire. Which, for convenience, needs to be bent at an angle of 90 °, and this will also prevent the homemade device from dropping into the nozzle channel.

For cleaning, a needle or wire is inserted into the nozzle channel and reciprocated.

A dirty gas stove is shown in the photo not by chance - it is the burnt, melted remains of food and detergents that often cause burners to malfunction. Since they, getting under the table of the cooking device, clog the nozzles of the nozzles, cover the surfaces of candles, temperature sensors of the gas-control system, which leads to malfunction of the latter or even to breakage

A dirty gas stove is shown in the photo not by chance - it is the burnt, melted remains of food and detergents that often cause burners to malfunction. Since they, getting under the table of the cooking device, clog the nozzles of the nozzles, cover the surfaces of candles, temperature sensors of the gas-control system, which leads to malfunction of the latter or even to breakage

It will be possible to remove crumbling dirt by opening the gas valve for a few seconds. At the same time, it is not necessary to set fire to the "blue" fuel.

It is possible to check the quality of the work performed without mounting the gas stove table.

What is the burner for:

- installed in the workplace;

- cover with a lid.

And then the usual procedure for igniting the flame is performed. If its parameters are not inferior to those of other burners, then the troubleshooting procedure is considered successfully completed. After that, it remains only to mount the table and install the burners.

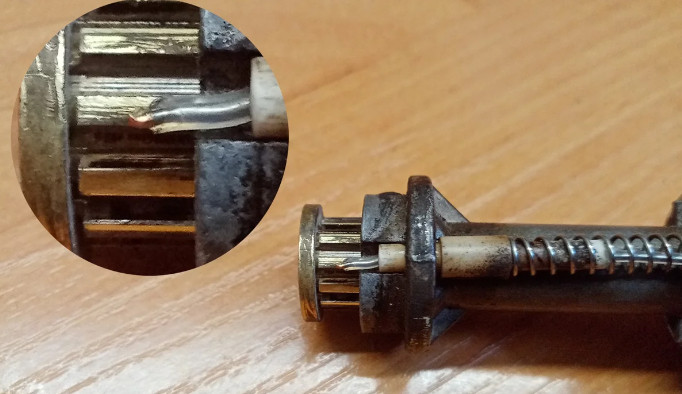

The photo shows jets, the nozzles of which are often dirty, and then become the cause of unstable operation of the burner and the stove as a whole. They are easy to clean, as such products look like an ordinary bolt with a longitudinal hole. Where you just need to insert a needle and use it as a brush. But with the replacement, not everything is so simple, this is evidenced by the mass of troubles that the jets caused. And therefore, it is worth changing these parts yourself only if there is an understanding that an incorrectly made hole will lead to gas leakage

The photo shows jets, the nozzles of which are often dirty, and then become the cause of unstable operation of the burner and the stove as a whole. They are easy to clean, as such products look like an ordinary bolt with a longitudinal hole. Where you just need to insert a needle and use it as a brush. But with the replacement, not everything is so simple, this is evidenced by the mass of troubles that the jets caused. And therefore, it is worth changing these parts yourself only if there is an understanding that an incorrectly made hole will lead to gas leakage

Rarely, but it happens that it will not work to clean the nozzle from contamination in the installed position. As a result, it will have to be dismantled. But there is no need to be afraid of this, since the whole procedure, if you have the right key, will take several minutes. After that, cleaning will be easier.

In addition, after its completion, it is recommended to wash the jet with any ordinary detergent. Next, the device must be wiped dry and you can proceed with the assembly.

Preventive advice

Each user's manual, attached to the heating boiler by the manufacturer, must contain a section describing the mandatory periodic maintenance of the device.

The owner can call the service center employees for this, or he can perform maintenance work on his own.

Before starting work, it is imperative to turn off the gas supply and power supply to the device

For maintenance you will need:

- wire brush;

- hard bristled toothbrush;

- skin with fine grain;

- air compressor or enema;

- thin awl or needle;

- a vacuum cleaner;

- soap solution;

- rag.

To perform maintenance, you will need to remove the case of the device. On some boilers, this will require unscrewing a few screws, other models are equipped with quick-release fasteners.

For maintenance, you will have to remove the gas boiler body

After removing the casing, you can begin to remove carbon deposits from various parts and assemblies. These include:

- heat exchanger radiators;

- gas-burners;

- igniter;

- security sensors.

Using the tools listed above and without applying excessive force, you need to carefully clean off the carbon deposits. After that, with compressed air, you need to blow out dust and residues of soot from the cavities and openings of the unit.

The next step is to clean the holes of the burner and igniter nozzles. For this, a needle or a thin awl is used. After cleaning, they must also be blown out with compressed air.

The electrodes of the sensors and the contacts of the electric ignition system are carefully cleaned with sandpaper and wiped with a rag.

At the end of the maintenance, the unit must be vacuumed, so, where possible, wiped with wet wipes or rags.

After installing the housing in place, check the chimney draft force and the absence of gas leaks in the connections.

Despite the fact that a gas boiler is a rather complicated device, in some cases it can be repaired with your own hands. It is enough to follow the above repair instructions, and in difficult cases, contact the workshop. Regular maintenance extends the useful life of a gas boiler and reduces the likelihood of unexpected failure by several times.

Causes of breakdowns and their elimination

Despite the simplicity of design, unpretentiousness in operation, the flow heater is not immune from breakdowns. If the geyser of the Vector brand does not turn on, do not panic. There can be several reasons for the problem, and most of them can be fixed on your own.

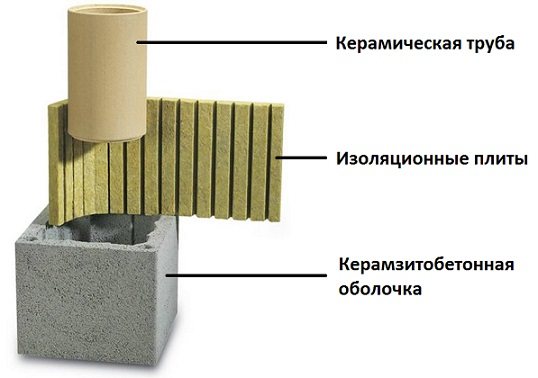

Problem # 1 - lack of traction in the column

The lack of draft indicates that the products of combustion cannot be quickly removed from the room. This poses a danger to users, so the sensor turns off the geyser.

Sometimes the burner ignites, but immediately goes out. This can happen when there is not enough air to burn the gas - the flame goes out due to a lack of oxygen to support combustion.

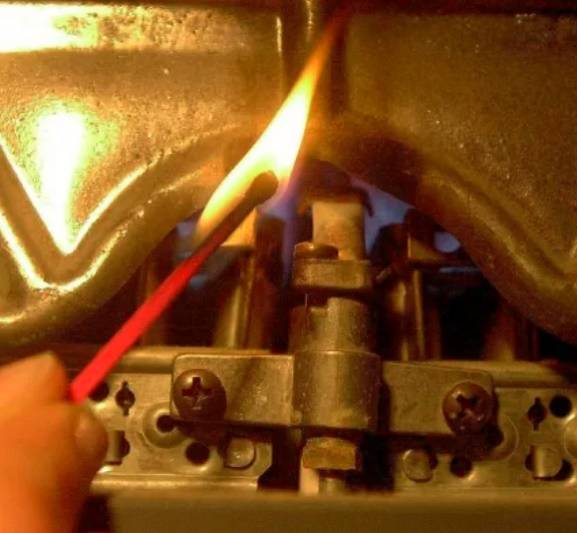

In any case, you first need to check the draft by bringing a burning match to a special hole on the column body. If the flame is directed inward, then the chimney is working normally, the combustion products will be quickly removed, and the cause of the malfunction is different. If the flame remains motionless, directed upwards or towards the user, then it is worth carefully inspecting the chimney, cleaning it.

Soot gets into the air along with the products of combustion. It gradually settles on the walls of the chimney, narrowing its opening. As a result, traction is lost. The problem is solved by thorough cleaning of the chimney

Problem #2 - Difficulties with water pressure

Another reason why the household geyser of the Vector brand does not ignite may be the low pressure of cold water or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption, evaluate its pressure.If there is insufficient water pressure in the system, the solution may be to install a pump or replace old, clogged pipes.

If there are no problems with the water supply, it is worth moving on to inspecting the column. The solution to the issue may be to adjust the water supply to the column. To do this, the corresponding valve must be fully opened.

Another cause of insufficient water pressure in the column is a clogged filter. To inspect it, it is necessary to shut off the water and gas supply with valves, unscrew the nuts, rinse the grid. If cleaning fails, the filter will have to be replaced.

It will take a few minutes to inspect the filter. However, in some cases, one flush is not enough, a complete replacement of the part is required.

Problem #3 - insufficient gas pressure

Sometimes the gas pressure is not enough to ignite the flow column, its normal operation. However, this problem cannot be solved on its own. You need to contact the gas service.

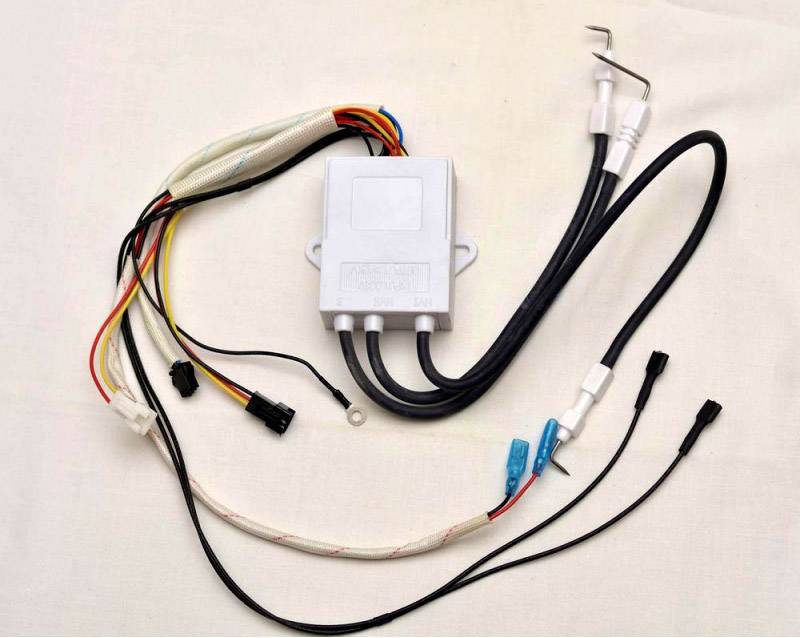

Problem # 4 - no ignition when turned on

The presence of an electric ignition system ensures the comfort of using the gas column, eliminates the use of a wick that is constantly on fire. However, it is this element that can cause a malfunction of the device.

When the tap is opened, automatic ignition should work. This action is accompanied by a characteristic crack. If the ignition does not work or the spark is too weak to ignite the gas, the column will not be able to connect. Replacing the batteries will solve this problem.

Batteries are required for the smooth operation of an instantaneous water heater. When the batteries are discharged, the electric ignition does not work, the column does not turn on

Problem # 5 - the presence of blockages in the tubes

Water and gas pass through the gas column Vector in the process of operation. The use of filters allows you to clean them from unnecessary impurities. However, the presence of blockages can cause the device to simply not turn on.

However, the filter is not always able to bring the water to an ideal state. Soluble salts get inside the heater together with the liquid, settle on the walls of the heat exchanger. As a result, the patency of thin tubes is impaired.

Specialists remove scale with the help of specialized reagents. A home master can deal with it using a solution of citric acid or vinegar. To clean the heat exchanger, you need to remove it, place it in a warm solution with the addition of vinegar. You can also use special purchased products - "chemistry" designed to clean heat exchangers.

It is better to entrust the elimination of blockage of the heat exchanger to qualified craftsmen, since the tubes are fragile and, in the absence of specialized skills, they are easy to damage

We discussed in detail about cleaning and repairing the heat exchanger in the next article.

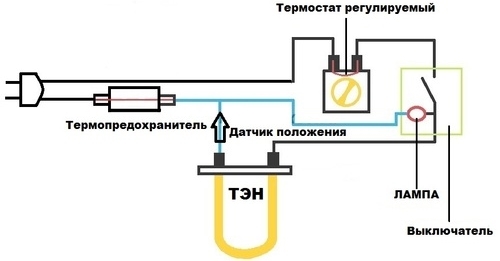

Device and principle of operation

Regardless of the manufacturer and model, the IR heater consists of the following main parts:

- metal case covered with a layer of heat-resistant enamel;

- heating element (heating element);

- radiating plate made of aluminum and covered with a layer of thermal insulation;

- mounts (if the selected model is designed for mounting to a wall or ceiling).

IR heater device

The principle of operation is as follows: electrical energy is converted into heat rays that heat all objects encountered in the path of infrared radiation.And the heated objects then share heat with the air space (for more details, see the article on the principle of operation of a heater with infrared radiation).

The principle of operation of the infrared heater

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the gas and cold water supply to the unit.

To drain the water from the system, open the hot water tap located below all water-folding devices powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will drain.

Removing the reducer from the column

Often the frog can be removed separately. But in some columns it is impossible to do this, so you have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of a frog, it is not at all necessary to dismantle it - just remove the cover.

Dismantling the frog of the water heater "Neva 3208"

In the column "Neva 3208" it is easy to dismantle the gearbox, as in other similar devices. To do this, unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit. When unscrewing the nuts and screws that fix the water regulator, hold the dismantled block with your hand so as not to accidentally deform the parts of the gas unit.

When dismantling the water regulator with a wrench, unscrew 2 union nuts of the pipes in the indicated order, then unscrew 3 screws with a screwdriver

The procedure for removing the gearbox "Neva-transit"

To repair the water reducer, it must be removed from the column housing.We will analyze how to do this using the example of dismantling the Neva-Transit column, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are just dressed in stocks.

After that, unscrewing the screws, remove the front panel

Please note that the digital display on the front panel is connected with detachable terminals to the electronic devices of the speaker. Therefore, by pulling the panel towards ourselves, we disconnect the terminals and only after that we remove the panel completely

Do you have a Neva gas water heater? We recommend that you read more about typical malfunctions and how to fix them.

Water Regulator Disassembly

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To facilitate the work and in order not to disrupt the slots, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace the parts that have become unusable, clean and wash the insides (surfaces, channels, if necessary, clean the body from the outside), install the parts in place and assemble the frog in the reverse order.

Frog reassembly

It is especially important to set the aperture correctly. The bypass hole must exactly match the holes of the same name in the cover and base.

If the channel connecting the cavities of the base and the cover is blocked, the column will not work.

After installing the cover on the base, tighten the screws.We install the assembled gearbox in place (also in the reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the platform of the gas burner leg.

Screws should be baited and finally tightened without misalignment. To do this, they are installed and baited in pairs-crosswise and similarly screwed up to the stop.

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the geyser is ensured by the tightness of this unit

Testing the repaired node

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

Watching:

- whether drops have appeared on the connections;

- whether the flow rate is the same when hot and cold water are turned on separately;

- whether the burner igniter clicks;

- whether the stem moves normally when opening and closing the valve.

If not everything goes as it should, it is worth double-checking your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the column. And if you smell gas, you should immediately shut off its supply, arrange ventilation and call the gas workers.

How to replace the piezo element?

Gas burner repair do it yourself always, if there is no spark. This problem in most cases indicates a breakdown of the “device in the device”. Therefore, there is only one way out: this is the replacement of the failed element. This operation is not so complicated, and the purchase of a new piezo, most likely, will also not be required.

It must be said right away that the external differences in the models of gas burners do not affect the structures. All devices have the same equipment, the elements are standard, so finding a replacement for them is quite simple. As already noted, it is the piezoelectric element that most often fails. Failure provokes the ingress of water, other liquids, breakage is possible due to a strong impact, the device falling from a great height, etc.

To repair a gas burner with your own hands, the master will need the following tools and materials:

- soldering iron;

- screwdriver and bits for it;

- heat shrink tubes for wire insulation;

- electrical tape, if there is no heat shrink on the farm at the moment.

It is good if there is a new or empty lighter in the house, since the easiest way to get a piezoelectric element is from it.

First of all, the apparatus is checked to again make sure that there is no spark. After receiving evidence of a malfunction of the device, its case is disassembled. During this work, the condition of the remaining parts is carefully studied, such a check is more related to various contaminants. They should be disposed of immediately.

After they get to the piezoelectric element, they cut the wire connecting it to the burner. Then it is removed. In the same way, remove the element from the gas lighter. The supply of wire must be sufficient to connect it to the burner.

When replacing the device for conductors, heat shrink tubing is used, which is heated with a lighter. The repaired gas burner is reassembled in exactly the same sequence as it was dismantled.

After completion of the operation, the device is tested. If no errors were made, then the gas burner should function flawlessly.

How to extend column life?

The durability of the column depends on many factors. Most of them are laid at the factory, the rest are determined by the operating conditions.

By following some rules and recommendations, you can significantly reduce the number of breakdowns and extend the life of the column.

Features of using batteries

Of all the parts, batteries require the most frequent replacement. For geysers, you should choose only alkaline batteries made using Alkalin power technology, size “D” and the first letter “L” in the designation - LR20. Their capacity and service life are five times greater than those of salt ones: from 1 to 1.5 years.

It is better not to buy too cheap items, they may be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

It is better not to buy too cheap items, they may be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

High-quality batteries cost from $1.2. There is a radical way to reduce the cost of replacing batteries - converting the speaker to mains power.

To do this, you can buy a special power supply, 3 V, or use a charger for a mobile phone, 5 V, with an additional stabilizer. The main requirement is that its power is enough for ignition, which occurs at a supply voltage of 3 V and a current of 350 mA.

For power outages, you can always keep batteries in stock, fortunately, alkaline batteries have a shelf life of 5 years or more.

Column heat exchanger quality

When choosing a column, special attention should be paid to the quality of the heat exchanger. The type of metal and its quality have a great influence on the life of the radiator

They are made of galvanized steel, stainless steel, copper.

The most durable of stainless steel, but inferior in thermal conductivity to copper.Accordingly, they are less economical, have lower efficiency. Copper - the most efficient in heat transfer, but also the most expensive.

When replacing a heat exchanger with a new one, pay attention to the thickness of the metal and the weight of the radiator. Quality should not be too light. The high cost factor of copper leads to the fact that manufacturers save as much as possible on the wall thickness of the heat exchanger, bringing it up to 0.5 mm, which significantly reduces the service life

For the same reason, other metals are added to copper. The resulting alloy can have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

The high cost factor of copper leads to the fact that manufacturers save as much as possible on the wall thickness of the heat exchanger, bringing it up to 0.5 mm, which significantly reduces the service life. For the same reason, other metals are added to copper. The resulting alloy can have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

System water quality

If the water in the system is subjected to frequent chlorination, this adversely affects the condition of the copper heat exchanger. Together with the thinner pipeline walls, this can quickly lead to corrosion and venting.

No less problems are caused by increased hardness of water in combination with heating. Scale buildup requires periodic rinsing.

You can improve the quality of water with the help of aqua filters and magnetic softeners. Detailed information and rules for choosing a filter for purifying water from a water supply system are given in the following publication.

Overheating of the geyser

The most important factor leading to malfunctions and a decrease in the life of the column is its overheating.

It is important not to bring the temperature to 65 degrees and above

To reduce the risk of overheating the water, do not use the faucet to cool it. Change the temperature only with the flame and water flow adjustment knobs intended for this purpose.

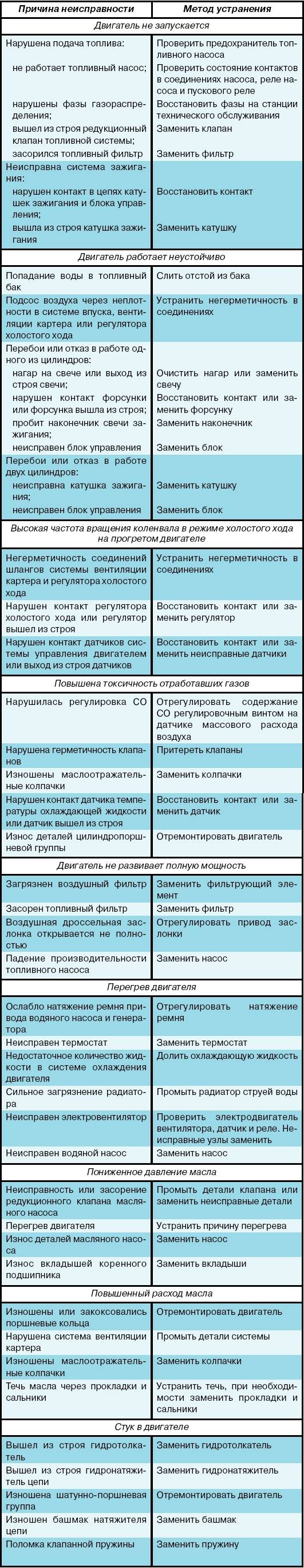

Methods for self-diagnosis of faults

Often the user is in a situation where he is not sure what exactly has broken in the gas boiler. In such cases, there is no need to rush to remove and repair something. This is risky and dangerous. Before work, it is necessary to diagnose the equipment and identify the exact causes of malfunctions.

If the boiler smokes, then usually the cause of this phenomenon is the consumption of low-quality gas or lack of air. You can check the cause of the malfunction yourself

Modern gas boilers are equipped with various sensors that reflect a number of important functional indicators of the unit. They track changes in temperature, pressure and other parameters. In the event of a malfunction, modern models of boilers provide for automatic shutdown of the device.

The source of the breakdown is identified by the consequences caused by it. For example, visually you can see burning, smudges, sparks. By smell, you can feel a gas leak or a short circuit. By the changed sound of the gas boiler, it becomes clear that the unit has failed.

The instructions that came with the purchase of the device describe the most common malfunctions in the boiler model being purchased and how to detect, diagnose, and eliminate them.It also indicates what a specific error code means and flashing lights on the dashboard.

So the light can flash in different modes: fast or slow. Or burn all the time. The color of the light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot.

Do not throw away the instructions from the device, as it may be useful to the gasman called by you to fix the breakdown. It indicates the characteristic features of the gas boiler model, the dimensions and location of components and parts.

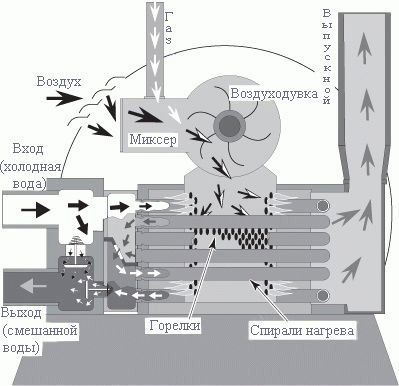

Working principle of ceramic infrared gas heater

This type of heating device works as follows:

- Gas from the cylinder enters the mixing chamber, where the gas, mixing with air, forms a gas-air mixture.

- The resulting mixture, passing through the holes in the ceramic plates, burns out, heating them up to 900 °.

- When heated, ceramic plates begin to radiate infrared heat.

The peculiarity of infrared radiation is that it does not heat the air, but objects located in the radiation zone.

Objects, when heated, give off the heat they receive to the surrounding space. This allows you to get much more heat from the infrared device than from a conventional heater using the same amount of fuel.

What can be repaired in a geyser with your own hands

Of course, not always a gas water heater wears out or breaks so thoroughly and irrevocably that it is impossible to do without the help of a specialist. According to the reviews of the same mechanics of the gas maintenance service, in 70% of cases, the repair of gas water heaters comes down to routine maintenance and the elimination of minor defects, usually associated with poor quality parts or improper adjustment.

The following activities can be included in the list of works available for repairing gas water heaters at home:

- Minor repairs and repacking of coupling and nut joints of pipelines;

- Replacement of the elastic membrane in the water-gas column regulator;

- Cleaning and adjusting the operation of the thrust sensor;

- Cleaning and flushing of the heat exchanger;

- Ignition board repair.

In a separate category, one can single out such an operation as the repair and soldering of heat exchangers.

It is clear that there is a certain category of expensive water heaters, saturated with automation and electronics, which simply does not make sense to even try to repair at home. For example, repairing Electrolux or Vaillant gas water heaters will cost less at a service center due to the high cost of spare parts. The exceptions are particularly critical components, such as a three-way valve or an ignition board, it is better to buy them from an authorized dealer, even if the price is higher. This is the only chance to repair and not kill an expensive Italian or German column with a substandard spare part.

Making an infrared heater

At home, you can make a lot of heaters. However, it is most advisable to focus on the manufacture of an infrared heater. This is because with it you can control the heating in different areas of the room.At the same time, some areas (the space under the ceiling or the corners in which furniture is placed) can be left without heat and, thus, save on heating a room and even the whole house. This advantage has long been appreciated by people who have learned how to make their own infrared device and know how to connect an infrared heater, as well as how to repair it.

What can be repaired without gasmen?

There are several main causes of failures. This is the improper operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or poor-quality components.

When repairing yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

During the repair of gas equipment of the main the danger is a possible gas leak

Therefore, it is necessary to carefully carry out all manipulations for the installation and dismantling of components and parts of the device.

Particular attention should be paid to the replacement of components associated with the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for their elimination allows you to independently make simple repairs. It is worth remembering that serious repairs can only be done by gas workers, but there are procedures available for independent home craftsmen.

Boiler manufacturers strongly recommend calling gas service employees to fix problems associated with breakdowns in the gas supply system and built-in electronic devices.An inexperienced person will not be able to independently set up, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler, these are:

- Gas burner closed / open type;

- Specific security blocks;

- Heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, chimney, boiler control devices, multi-level security systems.

Most often, users have problems of the following nature: the boiler emits an unpleasant smell of gas, does not turn on, turns off during operation, does not heat pipes or smokes

Most of these items cannot be changed and repaired by yourself. In the event of intervention in the design of the boiler, its owner loses the right to restore working capacity at the expense of the manufacturer during the warranty period. But what and how the masters from the organization with which the contract for the maintenance of the unit and the supply of gas is repaired must be known.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is produced in cases of weakening of traction by mechanical manipulations or with the use of chemicals.

- Checking the tightness of the water supply connections, gas supply lines, heating circuit branches.

- Installation of a voltage stabilizer.

Once again we warn that all actions for the implementation of which it is necessary to remove the casing from the boiler must be performed by a representative of the gas service.

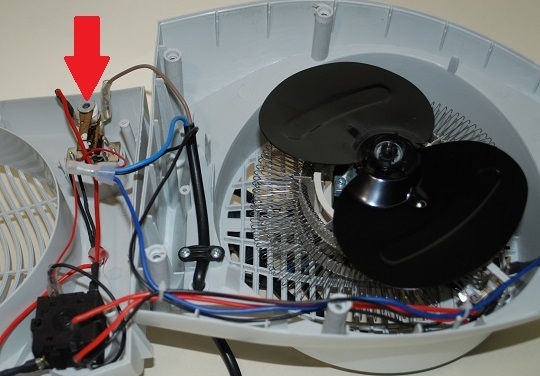

However, if the warranty is not important for you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade aqueous solutions of citric acid (100g / 1l) or suitable household chemicals that can dissolve calcium deposits.

- Servicing the blower fan. Replace the fuse or the fan itself, check the electrical circuit connected to it, lubricate the bearings with technical fluid.

- Nozzle cleaning. Clogged nozzles cause a weak burner flame. They periodically need to be cleaned with a fine sandpaper and remove dirt with rags with household chemicals.

- System pressure regulation.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to make a visual inspection of it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the warranty from the manufacturer has already expired.

If you smell gas, you should immediately forget about your own intervention. It is necessary to shut off the gas supply, immediately produce salvo ventilation and call an emergency gang. The detailed rules for the operation of gas equipment are set out in the following article, the contents of which we strongly advise you to read.

Conclusions and useful video on the topic

How to flush the gas boiler heat exchanger:

Detecting and correcting gas boiler faults:

Gas boilers are high-tech and safe devices. Like all equipment, they have their own expiration date. With timely preventive maintenance, the boiler will last a long time. If the boiler starts to malfunction or work poorly, it is necessary to immediately inspect and diagnose it, to identify the cause of the malfunction.

There are a number of common boiler malfunctions. Sometimes the unit simply refuses to turn on or its operation deteriorates due to a coarse filter that is too dirty. Also, users are faced with the problem of contamination of the heat exchanger and chimney. When carrying out repair work, safety precautions must always be observed.

Do you want to share your own experience in restoring the performance of a gas boiler? Do you have useful information on a topic that is worth sharing with site visitors? Please leave comments in the block form below, post photos, ask questions.