- The main errors and malfunctions in Protherm gas boilers

- F0

- Advice

- Repair of domestic gas boilers: what you need to know about the device

- Causes of failure

- How to change a thermocouple?

- The device of electric boilers

- Reasons why the boiler does not turn on

- If it does not light up the first time

- Other malfunctions

- Do-it-yourself boiler repair

- What can be repaired

- Overview of the Proterm brand series

- What do the error codes F2, f5, f6, f8, f10, f15, f22, f23, f24, f25, f29, f33, f55, f62, f63, f72, f73, f83, f84, f85 mean

- Errors of outdoor units Proterm

- What is an electric boiler

- Device

- Electric heating elements

- induction

- Ionic

- Is it worth it to do the repair yourself?

- What can be repaired with your own hands

- Cleaning the valve of a single and double-circuit gas boiler

- Boiler repair services Proterm Panther in Moscow

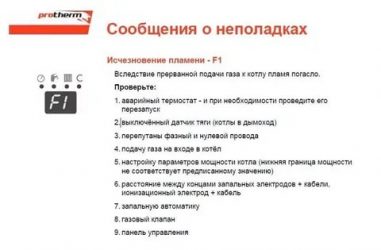

The main errors and malfunctions in Protherm gas boilers

All possible problems are constantly monitored by the sensors of the self-diagnosis system. This is a group of thermistors and other elements that are triggered when the specified operating mode changes.

The signal from the sensor passes to the electronic control board, which immediately gives an alert to the display. An alphanumeric code appears, for example F 01 or F 28.

Each combination denotes a particular error, i.e.failure or failure of the corresponding unit unit.

IMPORTANT!

A complete list of errors, which is quite long, is set out in the instructions, which it is recommended to keep on hand to quickly identify the problem node.

The operation of a gas boiler is entirely based on the use of a burner. This is the main and most critical unit of the apparatus, since it is the burner that performs the main task and is the source of maximum danger.

This determines the degree of control over its work from the boiler automation. In addition, the state of the heating circuit (presence and pressure of water), the smoke exhaust system are subject to increased attention.

The Protherm boiler self-monitoring system includes several dozen positions in its list, most of which determine the state of gas equipment and smoke exhaust systems as areas of increased danger. However, less important elements have not been neglected.

F0

The error informs about a critical pressure drop in the system (below 0.65 bar), leading to an emergency stop of Proterm. Make-up clears the fault code. But such a measure is a temporary solution to the problem. The heating circuit is a closed system, and the error cannot be caused by the evaporation of the coolant.

Top up the heating system with water

Protherm make-up tap

Advice

If the heating system needs to be recharged regularly, the leak is caused by a minor defect. It is difficult to find a microcrack due to the evaporation of the coolant from hot materials (plastic, metal). If the water treatment is organized correctly, then there are no traces of rust, stains with yellowness, characteristic raids on the damaged area. Solution: wait until surfaces cool.Drops will begin to flow down, and it is not difficult to determine the defective section of the circuit.

Water leak near the heating expansion tank

Boiler control board Protherm

Repair of domestic gas boilers: what you need to know about the device

Any part of the boiler can fail for any reason: poor-quality assembly units, improper operation, an object hit the expansion tank (and now there are puddles under it every day). Be that as it may, the repair of proterm gas boilers or any other must be carried out very carefully, especially when it comes to the security group responsible for proper operation.

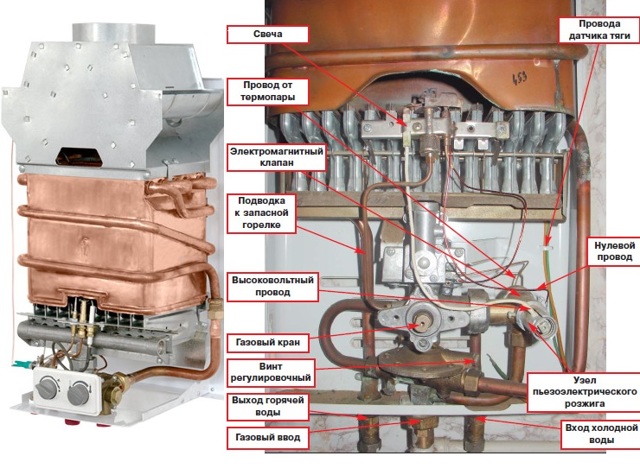

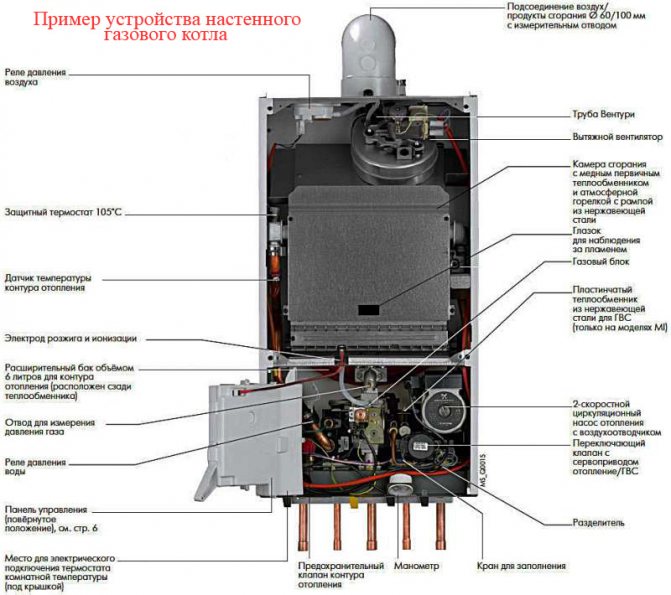

At the moment, any master in charge of repair Baksi gas boilers or another, knows that a security group consists of the following elements:

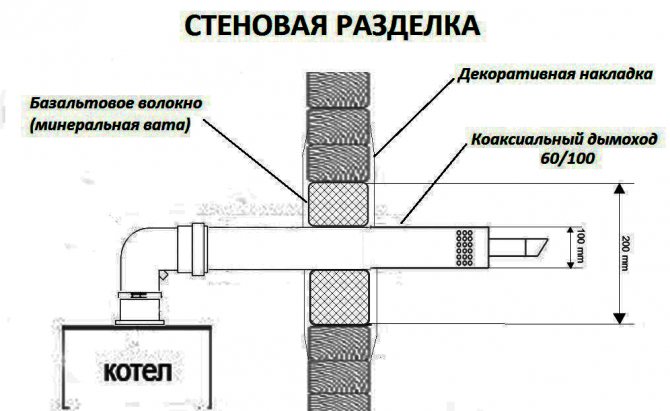

- thrust sensor with a plate rated at 75 degrees Celsius. This device monitors the state of the chimney for the boiler, responds to a failure in the removal of combustion products into the chimney, their exit to the smoke traps. As a result, it heats up, works, but it is best if a gas alarm is purchased in addition to it;

- monostat to protect turbo boilers from insufficient smoke removal due to a clogged heat exchanger or chimney;

- limit thermostat that controls the water in the boiler. If it boils, the overheating sensor turns off the boiler;

- ionization electrode to control the presence of a flame. Quite often, the repair of viessmann gas boilers begins precisely with checking the electrode, since the operation of a gas boiler without a flame can even provoke an explosion.

- blast valve for pressure control. At pressures above 3 bar, the system will force the boiler to dump dangerous excess.

Causes of failure

The smoke exhauster may be faulty for the following reasons:

- Damaged inductor. Under the influence of high temperatures arising from the removal of hot gases or motor overload, the wire insulation is melted, which leads to an inter-turn short circuit or to a break in the coil winding.

- Turbine out of balance. In the process of removing smoke, the fan blades are covered with soot, dust, etc., which leads to a change in the center of gravity of the wheel.

- Worn bearings. The armature shaft is equipped with sliding or rotation bearings. When the turbine is unbalanced, there is insufficient lubrication, the service life of these units is reduced.

- There is no power supply to the smoke exhauster. The impeller will not rotate if the control board module responsible for supplying power to the fan fails.

- Low mains voltage. When the electrical voltage supplied to the boiler is less than 195 volts, the pressure switch can turn off the fan, because due to a decrease in power, sufficient vacuum is not created. An underestimated supply voltage of the gas boiler does not lead to a breakdown of the fan, but creates a malfunction effect.

How to change a thermocouple?

Only a specialist should replace the device, as this is very dangerous. If the mount is leaking, then any breakdown of the device will give a spark, which will cause the gas stove to explode. To avoid a fire in your home, do not replace the thermocouple yourself, but ask a specialist to do it.

To replace the device, you will need to buy a new thermocouple from a specialized store. When choosing this device, choose only a quality device that will serve you for many years.Before buying a new appliance, consult with a specialist who will advise exactly the sensor that is right for your gas stove or water heater.

Replacing the thermocouple sensor on a gas boiler is a little more difficult. In a gas boiler, a chromium and aluminum thermocouple or a chromel and kopel thermocouple is most often used, less often an iron constant is used. All these metals are designed for high temperature conditions, such sensors are often used in the foundry industry.

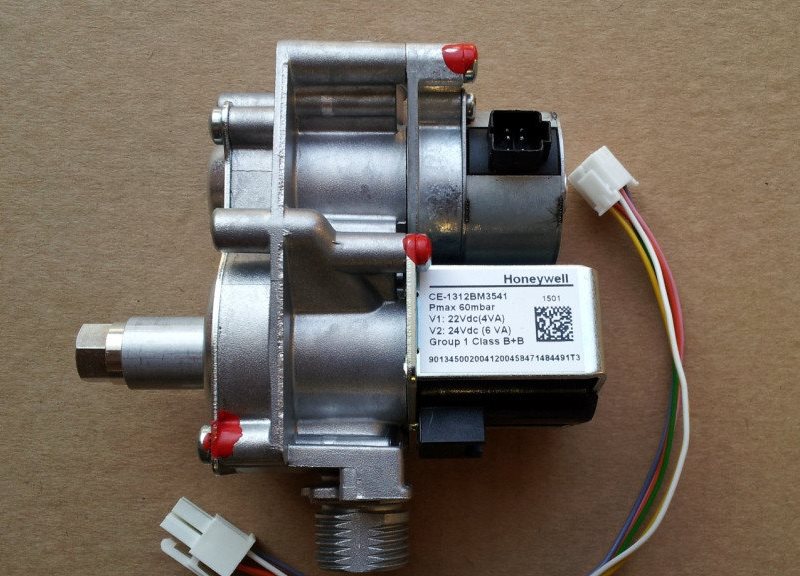

The gas boiler control system includes a solenoid valve and a thermocouple.

To replace the device, you need to follow a series of sequential steps.

- Using a wrench, unscrew the nuts that secure the thermocouple to the solenoid valve, then you need to get one of the ends of the thermocouple.

- Check connectors. If they contain various contaminants or oxidation, they must be cleaned. To do this, you need fine-grained sandpaper.

- Check the thermocouple sensor with a multimeter. To do this, attach one of the metal ends of the device to the multimeter, and heat the other with a lighter or burner. The multimeter should be within 50 mV.

- After that, if the indicator matches the data, you need to collect it in the same sequence. If not, it will most likely need to be replaced.

Replacing the thermocouple in the oven of a kitchen gas stove is carried out differently. First you need to remove the cover of the gas stove, it is located on the opposite side from the one where the oven faucet handle is located.

Remove the cap, but first clean it with sandpaper.If the terminal is removed, the cap rotates freely. When you see the center valve, check it. If it is faulty, it must be replaced. Remove the terminal by pulling downwards with your fingers. Remove the cap and close the valve on the gas riser, now you can connect the burner and check the operation of the device.

After that, use the wrench to unscrew the nut and carry out diagnostics. Check valve and thermocouple separately.

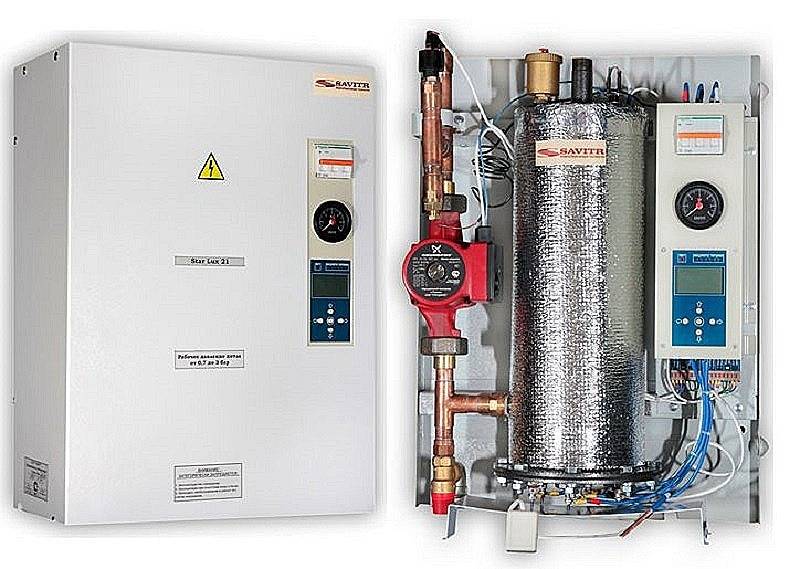

The device of electric boilers

The design of the heating electric boiler includes:

- Heating unit (heater, electrodes, induction coil). The heater or electrodes are always in the middle of the tank. The induction coil can be in and around it. In the first case, it is always in a sealed enclosure.

- Circulation pump.

- Thermal switch. It protects the boiler from overheating. Always connected to the temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank. In case of overpressure, it releases air from the tank.

- Safety valve. Connected to the return pipe. It drains water into the sewer if the pressure exceeds the established norms.

- Pressure gauge.

- The node that controls the power. Usually it is a coil that changes the voltage depending on the specified settings.

- Control Panel.

- Expansion tank.

Reasons why the boiler does not turn on

If the heating equipment does not light up at all, the reasons are such factors:

- the ignition system is out of order;

- the gas supply is stopped or the valve on the pipe supplying it is closed;

- too low or high gas pressure inside the pipe;

- burner nozzle clogged.

If it does not light up the first time

Breakdowns of a gas heating unit, in which case they do not light up immediately, are caused by various factors. External:

- too low gas pressure in the main pipeline;

- problem with the functioning of the chimney;

- voltage fluctuations;

- draft or low temperature inside the building where the boiler is located.

The internal ones include the failure of the electronics, pump, heat exchanger.

If the unit goes out, and then does not immediately light up, the cause of this phenomenon may be a violation of the ventilation in the room. This often happens with heating devices "Proterm", "Navien", etc., in which the combustion chamber is open. They take combustion air from the room.

Other malfunctions

When the pressure drops in the line, the AOGV or Vaillant double-circuit devices, for example, are turned off. This also happens with fluctuations in the fuel supply. If the igniter is incorrectly adjusted, the protection is triggered, the boiler stops working.

To determine other faults, knowledge of the device device that requires repair is required. Each model has its own distinctive features. But more often than not, nodes, sensors or circulation pumps break down for all brands. If such a pump fails, the burner will not turn on, and the boiler will not be able to supply hot water and heating. It happens that the pump is buzzing, but there is no work. It's possible he's stuck.

Sometimes throughout the house you can hear how loud and strained the boiler is working. This is more often caused by a large amount of scale in the heat exchanger. This factor often leads to overheating of the heat exchanger.

Whistling can also be emitted by nozzles. This happens when the boiler is ignited. The whistle signals the presence of air in the gas pipeline. To eliminate the whistle, it is enough to release the air.

If water or condensation gets on the main board, irreparable damage occurs inside it. If the cause is moisture, the board shows stains.

Attention! For a long service life of gas equipment, the board must be protected from water leaks and steam ingress

Do-it-yourself boiler repair

Many users with experience in operating domestic gas boilers are accustomed to repairing them on their own, but in the case of Western-made analogues stuffed with modern electronics, this cannot be done.

Firstly, the warranty will be violated, and secondly, it can lead to breakage of other important components. The boiler belongs to an object with increased danger, and the gas unit is doubly so, so you should not experiment with your own safety and the safety of loved ones. Therefore, experts advise to repair Protherm boilers only by specialized organizations.

What can be repaired

Nevertheless, the owner can perform part of the work on the repair of Protherm heating boilers on his own, without prejudice to the guarantee and performance of the boiler. Such works include types of preventive operations and cleaning of the elements of the unit, without disassembling the main components.

The list of repairs that you can do on your own on the Proterm boiler:

- In case of error F0, reporting a low pressure of the coolant in the circuit, you need to disconnect it from the fuel and check the water supply line and the operation of the circulation pump, perhaps the error will be eliminated after the air lock is released and the line is replenished to 1-2 atm.

- F3 / F20, indicates a high temperature of the coolant, check the filter in front of the device on the circulation line, it may be clogged with sludge or the fittings are faulty and it will be necessary to re-install the shut-off valve.

- F23, low temperature difference between direct and return, check the contacts of the primary sensors, they may be oxidized and need to be cleaned.

- F25, danger of gas pollution in the room due to low vacuum in the furnace, check the blockage in the direction of the flue gases and the air supply to the furnace.

- F27 / F28 / F29, errors associated with the burner and the presence of a torch in the furnace, the communication line between the sensor and the shut-off valve may be broken, and the ignition electrodes are damaged by corrosion. An external inspection is performed and the contacts and electrodes are cleaned.

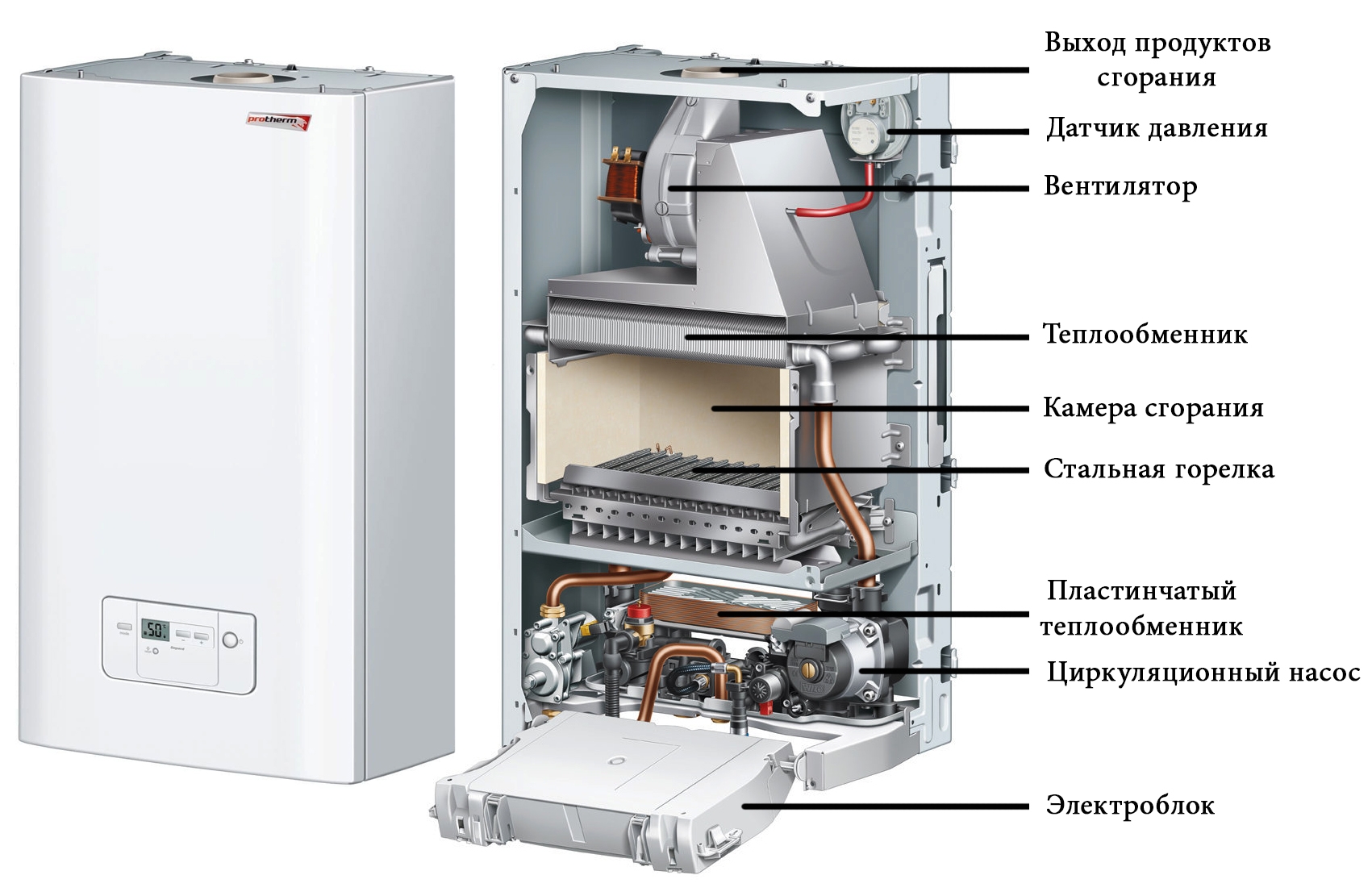

Overview of the Proterm brand series

If we consider equipment that runs on gas, then at the place of installation, all boilers can be divided into two large categories:

- wall-mounted - "condensation Lynx" ("Lynx Condence") and "Lynx" ("Lynx"), "Panther" ("Panther"), "Jaguar" ("Jaguar"), "Gepard" ("Gepard");

- floor - "Bear" (series KLOM, KLZ17, PLO, TLO), "Bison NL", "Grizzly KLO", "Wolf (Volk)".

Despite the Turkish and Belarusian assembly, the quality of equipment is high in European style.

Among wall models - 1- and 2-circuit, atmospheric and turbocharged, with a capacity of 11-35 kW.

Floor models are made of steel or cast iron, equipped with injection or fan burners, can operate on natural and liquefied gas. The power range is wide - 12-150 kW - so it is not difficult to choose a device for specific conditions.

The main purpose of the equipment is the organization of hot water supply and heating in private residential buildings, and some units are designed for industrial use.

Each of the series has distinctive features regarding design, dimensions, installation method, technical characteristics, additional functions:

- "Lynx" - condensing models work 12-14% more economically than non-condensing ones, therefore they are recognized as energy-efficient devices for heating country houses and cottages.

- "Panther" - the latest models are available with a convenient eBus communication bus and an updated security system

- "Jaguar" - the main advantages are the low price of the unit and the possibility of separate adjustment of two circuits - heating and hot water.

- "Cheetah" is a popular wall model that can be installed both outside the city, in a country house or cottage, and in a city apartment.

- "Bear" - among the representatives of various series - reliable units with a built-in boiler, a cast-iron heat exchanger and a power of up to 49 kW.

- "Bizon NL" - universal models for the fuel used: they work equally efficiently on gas, fuel oil or diesel fuel, power - up to 71 kW.

- "Grizzly KLO" - able to heat private homes and office space up to 1500 m², maximum power - 150 kW.

- "Volk" - an electrically independent boiler with a steel heat exchanger, steadily supplies heat to country houses and residential buildings even in the absence of electricity.

According to consumer reviews, Proterm units are reliable, efficient, easy to install and operate, and with regular maintenance they almost never fail.

However, durable materials, good fuel and excellent assembly do not guarantee flawless service, so boilers of all the listed series sooner or later require replacement of spare parts, cleaning or repair.

What do the error codes F2, f5, f6, f8, f10, f15, f22, f23, f24, f25, f29, f33, f55, f62, f63, f72, f73, f83, f84, f85 mean

Do-it-yourself repair of a Proterm gas boiler begins with determining the cause of the malfunction. For the convenience of diagnosing a breakdown, special codes are provided. There are a lot of them and they are described in detail in the instructions for heating equipment.

Brief description of other errors of the Proterm boiler:

- F2 - water sensor failure or antifreeze temperature is below 3 degrees. Due to the risk of ice formation, the system is blocked.

- F5 - malfunction of the external temperature sensor.

- F6 - breakage of the exhaust gas sensor or breakdown of the electrical board. The source of the problem lies in the malfunction of the ignition transformer.

- F8 - opening the circuit of the temperature sensor, grounding the boiler of the gas double-circuit wall-mounted boiler Proterm Gepard and similar models.

- F10 - short circuit of the temperature sensor or device plug, reducing the voltage level in the network.

- F15 - Short circuit of the reverse thrust signaling device. The sensor is located at the top of the boiler and is in contact with the ventilation pipes.

- F22 - water pressure drop in the heating circuit. The causes of the failure lie in the breakdown of the sensor or the blocking of the pump. The problem is manifested by the fact that the gas boiler Proterm Lynx lynx hk24 is flowing.

- F23 - excess of the temperature difference due to the pump or incorrect sensor readings.

- F24 - insufficient amount of liquid and its rapid heating.The problem occurs when air locks occur in the Proterm 24 kW system, the pump is blocked, and the fuel supply pipe is blocked.

- F25 - the protective mechanism has worked to prevent carbon monoxide from entering the room, so the Proterm gas boiler does not start. The source of the malfunction is the depressurization of the joints of the chimney pipe, poor draft, breakage of the temperature sensor, fan, control board.

- F29 - loss of fire during the operation of heating equipment. The cause of the failure is the blocking of the line, clogging of the burner, and grounding failure.

- F33 - operation of the protective mechanism of the fan of the boiler Proterm Panther or another model. The error occurs when the pressure switch breaks down and the integrity of the ventilation system is violated.

- F55 - failure of the carbon monoxide alarm. The reason for the failure of the Proterm boiler lies in the failure of the control board or the contamination of the relay contacts.

- F62 - problems with gas fittings and connections.

- F63 - failure of the memory board.

- F72 - the difference in the parameters of the flow meters and the return line. The source of the problem lies in the control board, pumping unit, sensors, heat exchanger, filter system, valve.

- F73 - shutdown or short circuit of the pressure sensor.

- F83 - no antifreeze, so the system does not heat up when the burner starts.

- F84 - long-term retention of the thermistor temperature difference.

- F85 - failure of feed and processing meters.

Errors of outdoor units Proterm

In case of malfunctions of the floor gas boiler proterm bear error codes appear:

- F2 - temperature sensor problems. This error reports a breakdown of the temperature sensor or a decrease in the temperature of the coolant to 3ºC.The operation of the unit is blocked, since the manufacturer does not allow switching on at temperatures below 3ºC.

- F3 signals an increase in the coolant temperature of 95ºC. In this case, the unit is blocked. It will resume work after the liquid has cooled down.

- F4 - failure of the boiler sensor. In this case, the unit does not heat the liquid in the boiler.

- F5 - the external temperature sensor is broken. The unit remains operational, but the temperature of the coolant will be controlled by the boiler sensor.

The error code that appears on the screen for the first time can be reset by pressing the "RESET" key. If this does not help, and you cannot determine the cause of the failure, call a Proterm service center specialist.

What is an electric boiler

The electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules for its operation and to carry out timely technological maintenance.

Watch the video, which tells about the principle of operation and the device of the electric boiler P rotherm Skat.

Device

Despite the wide variety of boilers with different operating principles, the device of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler. If they fail, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have a different configuration.

- Electronic control unit. Regulates the temperature regime, turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system, maintains a stable speed of the coolant in the circuit. Produces forced circulation of the liquid and creates the necessary pressure in the system, while ensuring the most efficient heat transfer and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if equipment is purchased without a tank, it will be necessary to purchase this part separately and install it by cutting into the heating pipe circuit.

- Filters. Purify and extract various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Carries out an emergency discharge of water when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids, gases inside the boiler and pipes of heating systems, it is necessary for monitoring.

- Thermal switch. It turns off the equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency air release from the tank in case of overpressure.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element - heating element. Water or other permitted liquids are used as a heat carrier, in accordance with the operating instructions.

induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside which passes a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant is heated.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when an alternating current passes through it.

A feature of the use of this type of boilers is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in damage to the equipment.

The fluid used must not be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced craftsman.

Is it worth it to do the repair yourself?

In a typical gas boiler, all structural elements are conditionally combined into three groups:

- burner;

- blocks that are responsible for security;

- a heat exchange unit equipped with a fan, a circulation pump, and many other elements.

During repairs, the main safety risk arises from a possible gas leak.The reason for this may be improper repair, dismantling or installation of equipment with fuel supply functions.

Because of this, it is better to have these structural parts repaired by a specialist. In addition, self-troubleshooting in the electronic equipment of the gas boiler is not allowed. The automatic system is quite specific, and if you do not have the appropriate qualifications, it is impossible to correctly restore this type of equipment in practice.

And yet, if you do not have enough experience, it is better to entrust the maintenance of heating boilers and the repair of gas water heaters to professionals.

What can be repaired with your own hands

All other elements can be repaired independently, for example:

- The heat exchanger is flushed manually (for this, the unit is dismantled, after which it must be correctly put in place). You can perform these works without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is performed).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, it is possible to repair a gas boiler on your own only in cases where we are talking about mechanical damage or blockages that are easy to identify visually (or by smell).

The remaining breakdowns are considered more serious, so they are eliminated with the help of a specialist, and not with their own hands.

Cleaning the valve of a single and double-circuit gas boiler

It is best to clean every two years, otherwise it will be problematic to remove soot and scale deposits later.

Having closed the gas supply valve in advance, you should begin disassembling the boiler by removing the burner:

- remove all wiring from the gas valve;

- remove the thermocouple from the combustion chamber connected to the gas valve by a capillary tube;

- disconnect the gas supply pipe;

- unscrew the 4 nuts (or bolts) that hold the stove and burner;

- pull the whole knot out;

- clean the burner with a regular brush.

Gas boiler cleaning process:

- After removing the top cover of the boiler, disconnecting the draft sensor and removing the chimney pipe, you can access the heat exchanger. It is covered with a heater and a casing, they should be removed.

- Remove the tubulizers (swirlers) from the heat exchanger; they are cleaned with a metal brush.

- The heat exchanger itself is cleaned using homemade blades and scrapers of a suitable size and shape.

- A mixture of citric acid and vinegar is used as washing solutions.

- And there are also several types of factory products, for example, Antinakipin.

- The use of home-made flushing units allows you to clean the heat exchangers without disassembling or removing them. It is best to use reversible pumps for assembly, which allow you to change the direction of flow in one direction or the other.

Boiler repair services Proterm Panther in Moscow

It is not difficult to choose a service for the maintenance and repair of boilers in Russia, since the manufacturer has made sure that there are enough such service companies. He equipped them with modern equipment and trained the staff in repair technology.

The main Protherm repair centers in Moscow and the Moscow region that can perform urgent repairs or maintenance of Protherm boilers:

- LLC Modern technologies, Shabolovka 18;

- Ajax Thermo LLC, Serebryakova passage 14;

- Incomplex LLC, Parkovaya 10th 18;

- STI Service LLC, Ivan Franko 48;

- Energobyt Service LLC, Zhulebino, Privolnaya 75;

- LLC "TermoStream", Dorozhnaya 3 building 6;

- Energobyt Service LLC, Khimki, Babakina 5a;

- Comfort-Eco LLC, Dmitrovskoe sh. 100;

- Energopilot LLC, Rodionovskaya 12 building 1;

- OOO "Levada", Marshal Krylov Boulevard 13;

- AVG Engineering Service, Odintsovo, Transportnaya 2B;

- LLC "Atmosfera komforta" Aprelevka, September 2/1;

- ADL LLC, Istra, Nikulino village, st. Cherry, 2A/1.

The repair of such a boiler is not a cheap undertaking, which can reach from 20 to 200 euros, so the owner must minimize the possibility of an emergency in the heating device. The most productive thing is to follow all the recommendations of the plant for maintenance and its operating conditions.

Timely maintenance allows you to maintain the operability of the main and auxiliary equipment throughout the entire period established by the plant. During its production, the operation of the main components is tested, malfunctions are found and eliminated.

In addition, the specialist will be able to detect problems in the operation of the equipment and point out to the owner the wrong modes that should not be allowed. Usually, after such maintenance, the boiler returns to its original state and can be guaranteed to pass the coldest period of the heating season.

Repair of Proterm boilers allows you to restore the unit's performance and should be carried out only by service representatives.

In this case, the funds invested by the owner in the maintenance system of the unit will fully pay off, and it will be cozy and warm in houses and residential premises.