- Settings failure

- How is the heating system

- What is an electric boiler

- Device

- Electric heating elements

- induction

- Ionic

- Other faults and code meanings

- Fault #1 - noise during operation

- Fault # 2 - Batteries do not heat up

- Fault #3 - Board Errors

- Connecting a wall-mounted boiler Buderus

- Causes of breakdowns

- Typical malfunctions of gas boilers

- The smell of gas

- Flame sensor failure

- Boiler overheating

- Boost fan malfunctions

- Chimney problems

- Boiler turns off

- If the boiler makes noise or whistles

Settings failure

Settings are a "trouble" that can affect the owners of almost all volatile boiler plants, regardless of the manufacturer and brand of equipment. The problem may be in the voltage drop, which led to the failure of the settings. But, most often - the boiler starts to work inadequately after the intervention of the owner or "unfortunate repairmen" from the nearest workshop.

Tip: Self-repair of the control board of a gas boiler is a thankless task: any problem associated with electronics can lead to failure of the boiler installation or, worse, to an emergency. Entrust competent adjustment of the boiler to professionals.

How is the heating system

As already mentioned, modern heating systems are technologically complex systems. And the user, before undertaking repairs on his own, must have an idea about their device.

Usually, the entire process of monitoring the operation of an installation that heats a house is carried out using built-in automatic equipment. All boiler systems interact in a complex, and it is worth familiarizing yourself with them in some detail

In the group that is responsible for safety, the main elements include the following devices:

- a sensor that is responsible for adjusting traction. It can withstand up to 750 C. With the help of such an element, it is possible to monitor the general condition of the chimney. If failures occur during normal operation, the temperature immediately begins to rise, and the sensor gives a signal. If it is not included in the kit, then it is additionally worth purchasing another sensor that shows the gas content in the room;

- an element such as a monostat helps protect a turbocharged gas installation from such a nuisance as insufficient removal of products that remain after combustion. This happens if the heat exchanger grate is heavily clogged or there are problems in the chimney;

- the "limit" thermostat is mounted in order to be able to control the temperature fluctuations of the coolant itself;

- using the electrode, the operation of the flame is controlled; if the water begins to boil, then the entire installation stops its work;

- pressure control inside the system is carried out through a blast valve. If the pressure rises above the maximum mark, then the excess coolant liquid is discharged in parts.

What is an electric boiler

The electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules for its operation and to carry out timely technological maintenance.

Watch the video, which tells about the principle of operation and the device of the electric boiler P rotherm Skat.

Device

Despite the wide variety of boilers with different operating principles, the device of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler. If they fail, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have a different configuration.

- Electronic control unit. Regulates the temperature regime, turning the equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system, maintains a stable speed of the coolant in the circuit. Produces forced circulation of the liquid and creates the necessary pressure in the system, while ensuring the most efficient heat transfer and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if equipment is purchased without a tank, it will be necessary to purchase this part separately and install it by cutting into the heating pipe circuit.

- Filters. Purify and extract various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Carries out an emergency discharge of water when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids, gases inside the boiler and pipes of heating systems, it is necessary for monitoring.

- Thermal switch. It turns off the equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency air release from the tank in case of overpressure.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element - heating element. Water or other permitted liquids are used as a heat carrier, in accordance with the operating instructions.

induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside which passes a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant is heated.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when an alternating current passes through it.

A feature of the use of this type of boilers is the mandatory control of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomena of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in damage to the equipment.

The fluid used must not be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced craftsman.

Other faults and code meanings

Most of the error codes that we have not yet mentioned indicate a distress signal from a specific sensor, caused by its breakdown, a line break, or a malfunction of the equipment under control.

You can find out all the error options that the Junkers wall-mounted gas boiler gives out and repair it in the instructions for your model. Depending on the series, indication method and boiler configuration, the list of errors may differ, and sometimes the same code in different models does not have a completely identical meaning. Therefore, we will not give a complete list here so as not to confuse you.

Fault #1 - noise during operation

The boiler body is not airtight and dust often settles in it. Most of all, it accumulates on the fan impeller, because it sucks dirty air out of the boiler.

Dust often occurs with turbocharged boilers after repairs in the house, especially if walls are chiseled or ceramic tiles are cut.

Dust often occurs with turbocharged boilers after repairs in the house, especially if walls are chiseled or ceramic tiles are cut.

If you have an air compressor, the problem is easy to fix. Remove the front panel of the boiler and unscrew the turbine. Blow out the entire fan with compressed air, then the place of its landing, and then the entire boiler. Be careful when cleaning the board - a jet of air can knock off the contacts.

Allow the dust in the room to settle and repeat the blowdown of the boiler. Do a few of these cycles until completely clean.

The impeller and fan housing can be cleaned with soapy water - just do not wet the motor and electrical contacts. If there was a lot of dust, ask a Junkers gas boiler service and repair specialist to also remove and wash the gas burner. You should not do this yourself - incorrect installation threatens with gas leakage and explosion.

Fault # 2 - Batteries do not heat up

If the double-circuit boiler does not switch to heating mode, even when all hot water taps in the kitchen and bathroom are closed, the flow sensor or three-way valve is most likely faulty. In this case, as a rule, the error is not displayed - it seems to the boiler that there is a constant water intake, and it works in accordance with this situation.

If you really use hot water for a long time and the batteries have cooled down, the boiler is working normally, the DHW circuit is its priority.

In a system with a double-circuit boiler, the heated towel rail is connected to the heating circuit, and not, as in the apartment, to the hot water riser

In a system with a double-circuit boiler, the heated towel rail is connected to the heating circuit, and not, as in the apartment, to the hot water riser

When such a problem occurs already at the first start after installation, design errors are possible. For example, a heated towel rail can be connected to the DHW circuit, as in high-rise buildings with centralized hot water supply.

Water constantly circulates in it, and therefore the flow sensor does not close and does not allow the boiler to start heating.

Fault #3 - Board Errors

The electronic control board is the most capricious and expensive part of a modern boiler, its error F0, E0 or a flashing indicator of 75 degrees can seriously upset the owner who has looked into the instructions for decoding.

However, everything is not always so bad: perhaps the contacts just came off, and on the boilers of the Cerapur series, it also indicates the wrong ratio of gas and air supplied to the burner. Moisture on the printed circuit board can also be the cause of the malfunction. Everything will work after thorough drying.

It has been experimentally established that sometimes board errors resolve themselves if you set the 5th fan operation mode.

There is no specific explanation for some principles of the board's behavior, but the method's performance has been proven repeatedly, and experienced craftsmen know about it.

In addition, sometimes the board does not work correctly, the boiler behaves strangely, but does not give an error. The reason for this may be the low quality of electricity. Try disconnecting the boiler from the mains for half an hour so that all the capacitors are discharged, and then start it again. If it helps, that's the problem. Resetting the settings to default may also help.

The specialist can also solder or reflash the board, restoring its performance.

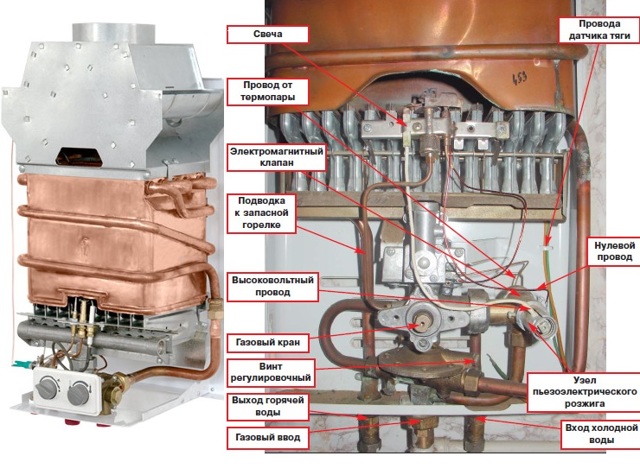

Connecting a wall-mounted boiler Buderus

The peculiarity of wall-mounted boilers is that it is, as they say, a boiler room in miniature.Inside one housing are enclosed both the boiler itself and the DHW circuit, sometimes together with a small storage tank, and the circulation pump and, of course, the control automation. Sometimes an expansion tank of a small volume is also placed inside. Naturally, all these nodes are combined and connected to each other already at the factory. But nevertheless, the boiler itself still needs to be correctly and reliably connected to the gas, chimney and pipes of the heating and hot water circuits. All connection operations are described in the installation instructions, and theoretically can be performed independently if you have the necessary skill. But do not forget that during the initial connection and commissioning, you will still need to have an agreement with a certified installation company in your hands.

When replacing a wall-mounted boiler, which at first glance is quite simple, it is also worth remembering that the boiler is high-risk equipment, and its poor-quality connection can lead not only to failure, but also to much more unfortunate consequences.

Any questions on connecting gas boilers are best left to professionals. There is an unimaginable number of subtleties, which, by the way, are well known to our specialists both in theoretical and practical terms, and if you do not want to face unforeseen heating accidents, we recommend that you contact the Thermal Company for solving connection problems.

The efficiency and safety of the operation of a gas boiler largely depends on its proper connection to the heating system. This process, also called strapping, consists of several stages.Due to the fact that gas is a very dangerous fuel, some work must be carried out by certified gas service employees, but much can be done by yourself.

Connecting a wall-mounted gas boiler is a set of works that includes: piping in the heating system, connection to the gas and electrical networks, installation of the chimney. In this article we will try to talk about each of the stages.

Causes of breakdowns

The causes of breakdowns can be laid even before the start of operation of the boiler. These are: errors in the design and calculations for the choice of additional devices (not included in the boiler configuration), switching elements, determining the type and section of the necessary installation wires.

The causes of breakdowns in the future may be:

- Poor quality, incorrect installation and connection of the device with deviations from the installation requirements.

- Violation of the basic rules for using the equipment specified in the instructions.

- Failure to comply with the requirements for carrying out routine, as well as preventive and periodic work and inspections.

- The presence of a factory defect, which is detected both during the warranty period and after its completion.

- All components and assemblies have a certain service life, and the reason for their failure is natural wear and tear.

- In heating elements boilers, failure of the heating elements themselves is possible due to the poor quality of water and the formation of salts and scale on their surface.

- Failure of most components and assemblies due to large voltage surges that exceed all permissible limits. These tolerances are specified in the operational documentation.

For ion boilers, water compliance with the required standards is of great importance.

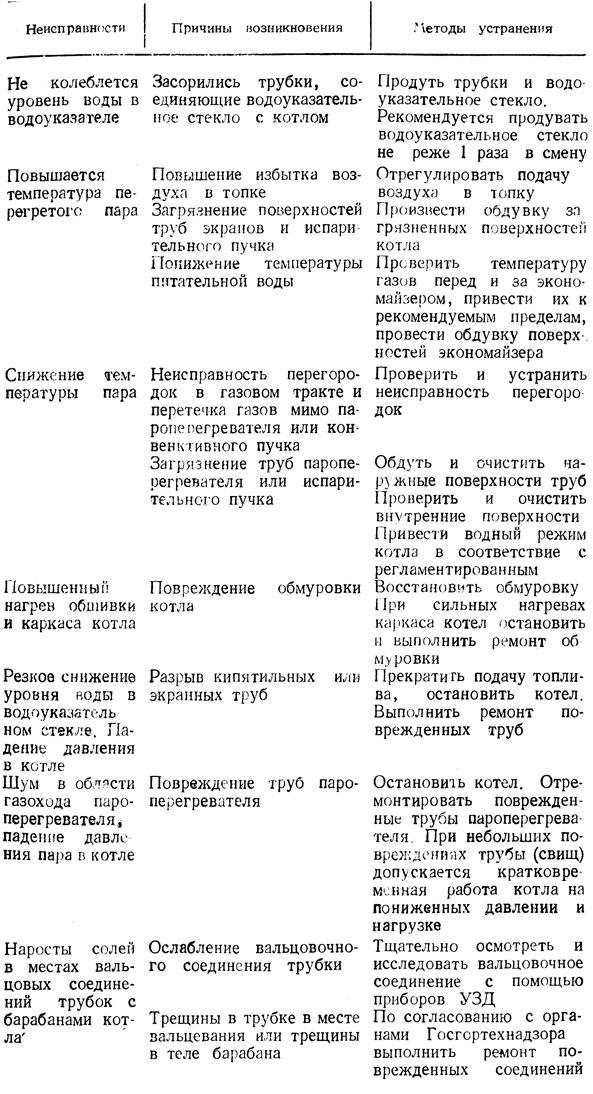

Typical malfunctions of gas boilers

Typical malfunctions of gas boilers

There are a number of typical problems, which in most cases can be dealt with on your own. Problems will also be listed, in the event of which you can only protect yourself before the arrival of a specialist.

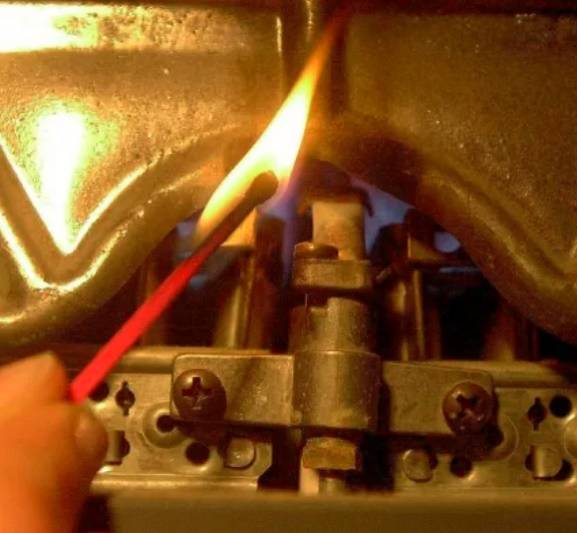

The smell of gas

The smell of gas

If there is a distinct smell of gas or smoke in the room, immediately turn off the boiler and leave the room, opening it for ventilation.

Scheme of functionality of a gas boiler

Flame sensor failure

If the combustion sensor or the gas supply pipe is broken, turn off the boiler, close all gas valves and allow the unit to cool completely.

After some time, return to the room to check it for the smell of gas. If everything is in order with the draft, try turning the boiler on again. If there is no traction, call a repairman immediately.

Boiler overheating

Overheating is one of the most common problems in modern gas boilers. The reason for this may be a malfunction of the automation equipment or a clogged heat exchanger.

You can clean the heat exchanger with your own hands. The most common materials for the manufacture of heat exchangers are copper and stainless steel. There are usually no problems with cleaning them, but still be extremely careful.

Primary heat exchanger for Beretta wall-mounted gas boiler

According to manufacturers' recommendations, heat exchangers should be cleaned of soot every few years (each manufacturer specifies a specific interval in the instructions for their equipment).

Primary heat exchanger (heating circuit) of the Rinnai SMF gas boiler

To clean the heat exchanger, simply remove it and clean it thoroughly with a wire brush. In the case of a copper heat exchanger, it is better to replace the brush with a metal sponge used for washing dishes.

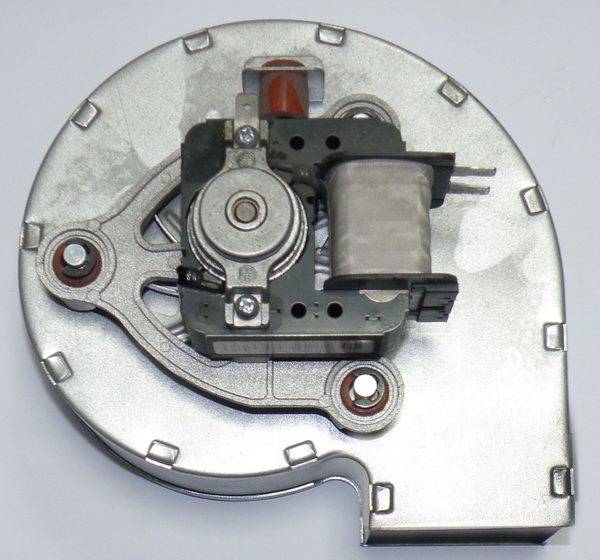

Boost fan malfunctions

The problematic place of fans are their bearings. If the fan of your boiler has stopped developing the set number of revolutions, try to eliminate the malfunction as soon as possible.

Fan (3311806000) for Daewoo gas boiler

To do this, remove the back of the fan, remove the stator and grease the bearings. Machine oil is fine for lubrication, but if possible, it is better to use a higher quality carbon compound with heat-resistant properties for this.

Fan RLA97 (Aa10020004) for Electrolux gas boiler

Also, an interturn short circuit can lead to problems with the fan. Only a specialist can cope with the elimination of this malfunction. Hand over the stator for repair to replace the winding, or immediately replace the faulty unit with a new device.

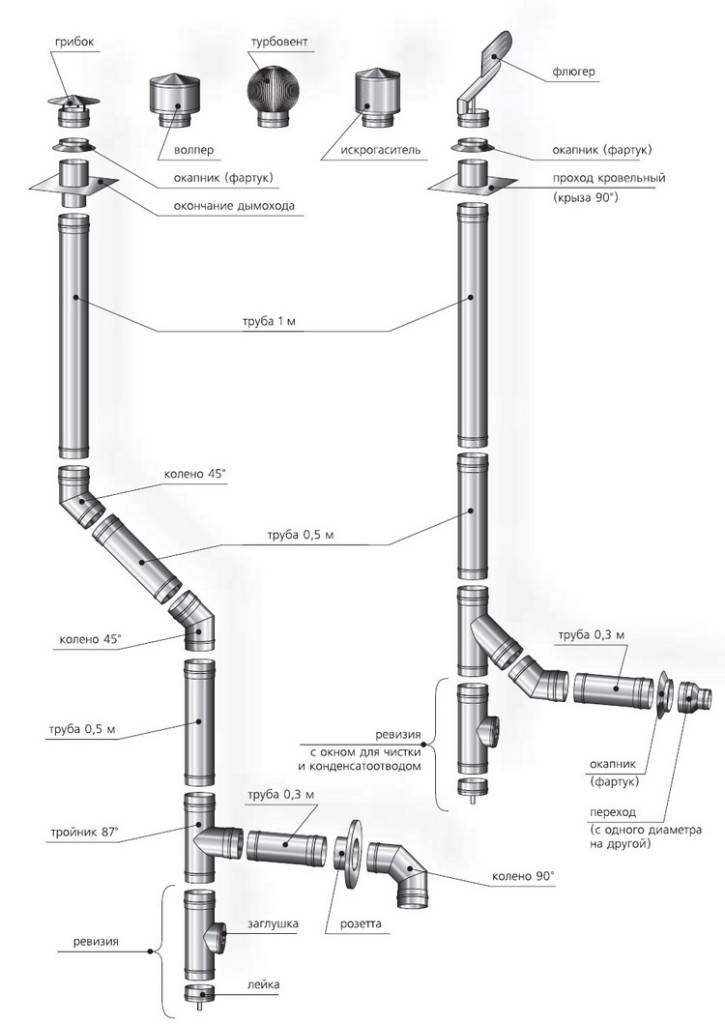

Chimney problems

Gas boiler chimney diagram

Often, excessive clogging of the coaxial chimney leads to the appearance of various malfunctions in the operation of a gas heating boiler.

Chimney

Remove the chimney and carefully clean all of its components from soot. So you will not only return the previous level of efficiency of the unit, but also significantly increase the efficiency of the boiler.

Boiler turns off

The boiler can spontaneously turn off for several reasons. This is usually due to a malfunction of the combustion sensor.This problem, in turn, most often leads to contamination of the gas pipe.

Draft sensor 87°C for Thermona boiler

Remove the nozzle, rinse it thoroughly with water, clean it with a cotton swab and blow out any remaining moisture. Return the pipe to its place and try to turn on the boiler. If it doesn't work, call the wizard.

If the boiler makes noise or whistles

When the boiler is noisy inside the house, this may mean that the inner walls of the heat exchanger are covered with a thick layer of scale. Under such conditions, antifreeze overheats and boils. Such sounds can be heard when water boils in an electric kettle.

When the boiler is noisy inside the house, this may mean that the inner walls of the heat exchanger are covered with a thick layer of scale. Under such conditions, antifreeze overheats and boils. Such sounds can be heard when water boils in an electric kettle.

Sometimes some layers of scale are left behind. Therefore, you can hear the device whistle.

To check whether the noise is really caused by scale, the return line is closed to a minimum, and the boiler is set to maximum operation. This will raise the temperature of the coolant to 80 °C. With it, the rumble of the boiler increases greatly. To eliminate excessive noise, you need to fill the heat exchanger with a special solution and rinse.

Scale also leads to overheating of the heat exchanger. At the latter, a fistula appears, through which the coolant begins to flow.

Injectors can also whistle. They do this at the moment when the boiler is lit. Whistling indicates the presence of air in the gas pipeline. An unpleasant sound is eliminated by dropping air. This procedure depends on the characteristics of the device, the diagnosis and maintenance of which can be quite simple.