- How to identify the cause of a malfunctioning drain pump?

- What are the types of drainage pumps

- The device and principle of operation of drainage pumps

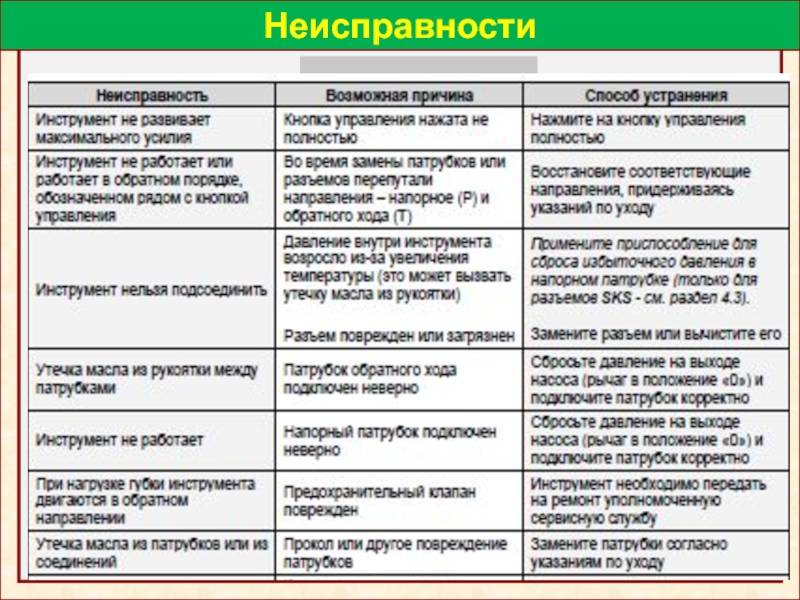

- Troubleshooting

- Preventive measures and regular maintenance of pumps

- Device and principle of operation

- How is the drainage pump

- Common problems

- How to clean parts

- Common causes of breakdowns of the pumping station

- Repair after a sudden shutdown

- Malfunctions of the pumping station, or How to repair a pumping station with your own hands

- Frequent breakdowns

- Differences between submersible and surface models

- The pump pumps jerkily, turns on and off very often

- Drain pump selection criteria

- How to disassemble the unit to diagnose a breakdown

- Symptoms of a malfunctioning vacuum brake booster

- Causes of breakdowns and ways to eliminate them

- Repair of drainage pumps

How to identify the cause of a malfunctioning drain pump?

Before looking for the cause of the breakdown, thoroughly flush the pump. After that, try to turn it on again: perhaps it did not break down and it does not need to be repaired, it could simply become clogged with particles of feces. If flushing does not help, then all other simple breakdown options that do not require disassembly of the drainage pump should be dismissed.

For example, these options might include:

- A sudden power outage in the house (oddly enough, but most often the cause of the “breakdown” is precisely this).

- Cable break (this option is also possible: check the entire cable for integrity, also check the plug and the socket itself or the extension cord to which the pump is connected).

If all this did not help to find the cause of the pump failure, then you will have to disassemble the pump. You can try to do the repair yourself.

What are the types of drainage pumps

According to their purpose, such pumps for pumping out dirty liquids are divided into:

surface pumps. This type of device is used for pumping liquid from small tanks. The unit is installed on the ground, at the edge of the drain pit. To pump out waste, a hose is lowered to the bottom of the tank. When the pump is operating in automatic mode, it is necessary to bring the float mechanism to the activation lever, it will monitor the water level in the tank or pit. When effluents rise above a certain level, the float rises with them and turns on the equipment.

Such a device should have two pipes:

- entrance, for sucking water from the waste pit;

- outlet, through which the liquid is discharged outside of it.

During operation, it is necessary to ensure that water does not get into the engine, which can lead to damage to the device. Therefore, the pumping of sewage must be carried out faster than their level in the pit can rise.

The main advantage of surface drainage devices is their mobility. The device can be easily moved to any place, and if necessary, it can be repaired quickly and easily.

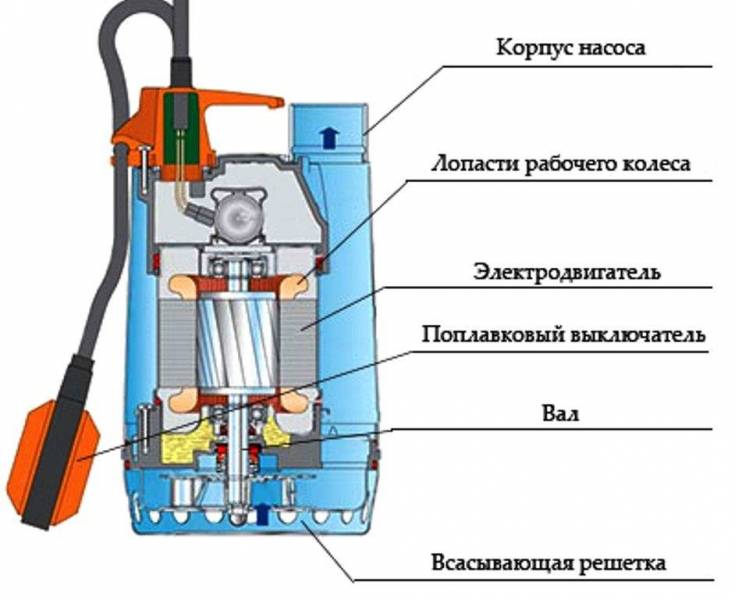

Submersible pumps.Such models are most often used to clean deep tanks and large-scale flooding, to eliminate excess water. In this case, the units are lowered into a container or pit, from where liquid must be pumped out, and water is sucked in through the holes located in their bottom, and not through the inlet hoses for drainage pumps. Mesh filters of the devices protect it from stones and other large particles entering the pump impeller.

The use of a float or a plastic bubble allows, with a certain amount of wastewater, to automatically turn on the submersible pump. To prevent a possible short circuit, when the device is immersed in a liquid, manufacturers have provided high-quality electrical insulation. The undeniable advantages of drainage pumping equipment for liquids are:

- Versatility.

- Long service life.

- No mandatory regular maintenance is required.

If you need to pump or pump a heavily contaminated liquid, it is better to prefer sewage or fecal pumps. They have a special cutting or chopping tool and can pump and process liquids containing large household waste.

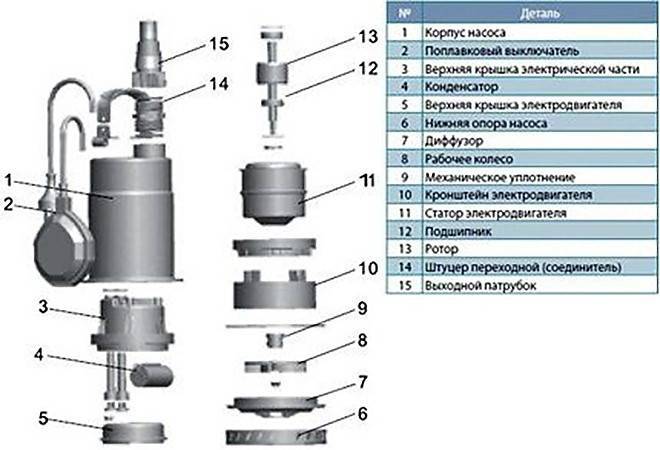

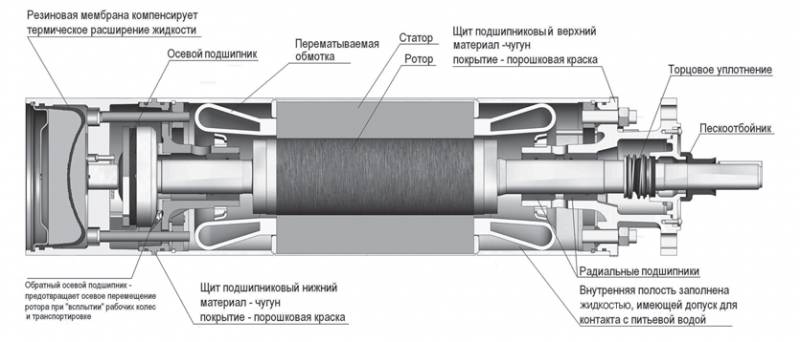

The device and principle of operation of drainage pumps

The main elements of the drainage pump are:

- Engine. If the price of the pump is small, the motor is located in an inner casing made of plastic.

- A capacitor motor with a thermal cut-out that prevents overload is available on more expensive retrofit units. Here:

- housings are made of high-strength polypropylene, reinforced with fiberglass; it is possible to manufacture the pump housing from stainless steel or plastic, and stainless steel is taken for the motor housing and shaft;

- the working shaft is made of stainless steel.

- Housing internal.

- The body is external.

- Shaft.

- The impeller, or impeller, is located on a shaft in the outer casing of the pump. The wheel configuration determines how large dirt particles can pass the pumps.

When the pump is running, the space between the housings is filled with water, forming a cooling “jacket”, which protects the unit from overheating.

For automatic shutdown and start-up, the pumps are equipped with float switches that control the water level in the tank, protect the device from dry running and flooding, and monitor the timely switching on of the pump.

Quality and long pump life performance can be obtained if the content of fibrous inclusions is kept to a minimum and the size of the solid particles does not exceed 5 mm. The smaller the installation depth, the better.

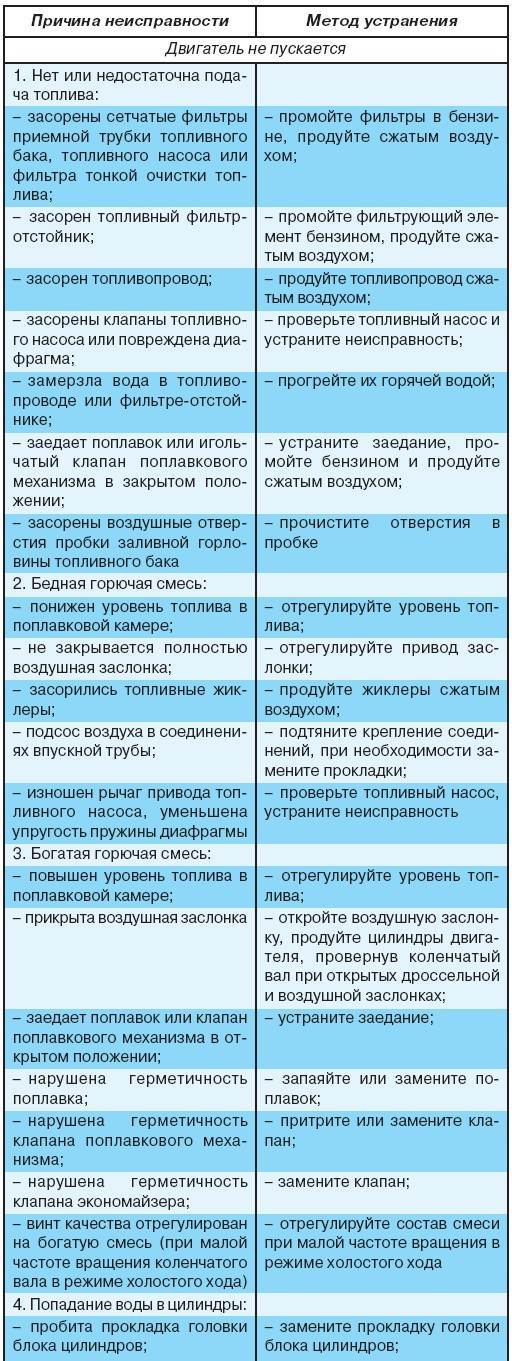

Troubleshooting

If the motor pump does not start, stalls under load, does not pump or pump water, does not start, you must carefully remove the impeller, disassemble and adjust it. For each type of breakdown there is an individual solution to the problem. If it is impossible to start the motor pump, the following measures must be taken:

If it is impossible to start the motor pump, the following measures must be taken:

- fill fuel in strict accordance with the manufacturer's instructions;

- checking the filling level with a dipstick and, if necessary, carrying out an additional filling of fuel;

- horizontal placement of the device;

- checking the operation of the motor shaft using a starter cord;

- cleaning the float chamber of the carburetor;

- removal of contaminants in the fuel supply filter;

- complete closing of the carburetor damper;

- removal of carbon deposits from the spark plug;

- installation of a new candle;

- opening the fuel supply valve;

- cleaning the filtering devices by unscrewing the bottom plug on the float chamber.

If there are interruptions in the operation of the device, the following manipulations must be carried out:

- cleaning the filter and all approaches to it;

- installation of new filter parts and snails;

- determination of the nominal value of the frequency of the rotor;

- pressure increase in the compressor.

In case of severe overheating of the engine, it is imperative to perform several actions:

- engine adjustment;

- compliance with the temperature regime of the environment during operation of the device.

Often, when performing work, the motor pump stops sucking up liquid and pumping water. In the event of this problem, there is an established algorithm of actions:

- adding water to the pumping part;

- tight closure of the filler plug;

- replacement of seals and stuffing box;

- replacement of the suction hose;

- sealing of places of penetration of air streams.

Many owners of motor pumps over time notice a decrease in the volume of pumped liquid and a sharp drop in device performance. The elimination of this breakdown consists of several manipulations:

- checking the connection of the intake hose to the pumping equipment;

- fixing the fastening clamps on the branch pipe;

- washing of filter parts;

- connecting a hose of the appropriate diameter and length;

- moving the installation to the water mirror.

To eliminate the breakdown of the time relay, it is enough to clean the internal equipment of contaminants, add the missing amount of oil and check the integrity of all parts. To resume the silent operation of the motor pump, it is necessary to check the absence of mechanical damage and various defects in the components. Only electricians of the service center can eliminate the breakdown associated with the disconnection of the device. Before calling a specialist, you can only check the junction box for the possibility of a voltage drop and remove visible soil particles inside the device.

Congratulations, you have become the owner of a motorized water pump!

And so, you assembled this unit, filled in the oil, what kind of gasoline to fill in the motor pump, you ask? 92 is the simplest without additives. In the 95th, the degree of combustion is higher, therefore, engine wear will be higher, and additives on the carburetor have a bad effect in this technique.

Then we connected all the hoses, poured water into the pumping unit. You didn't forget to do this, did you? Otherwise, the motor pump does not pump water, there is no pressure created by the impeller, in addition, you will have to take care of replacing the motor pump oil seal, and it is ceramic and creates more dry friction, it may crack. We start, fine, the pump starts up, but there is no result. You add speed, the water poured out, but somehow badly, we turn off. And so, if you have done all the above manipulations, but nothing works, the pump sucks poorly, then at some stage there is air leakage, what should I do? We disconnect the hoses and start the pump with the pumping unit filled with water, after which we put our palm to the inlet, closing it, if there is a draft, then everything is fine.We wrap all the threaded connections with your hoses with a fum tape, maybe you didn’t do this, after which we rejoice at the quality of the work done.

If the motor pump does not suck in water, the reasons are not clear, we are taking it to the supplier, perhaps just a defective stuffing box, or the absence of an o-ring at the junction of the bell of the pumping unit, it is definitely not your fault, all costs are borne by the seller. In addition, do not forget that the time of continuous operation of the motor pump should not exceed 6 hours, overheating is possible.

Preventive measures and regular maintenance of pumps

As you can see, the cause of wear of parts can be both inevitable wear and violation of the rules for operating the equipment. To make the device last longer, try to follow the manufacturer's recommendations. For example, position the housing so that the suction device is at a certain distance from the base of the tank and does not capture coarse particles.

At least once a year, check the integrity of the cable and internal parts by disassembling the case as much as possible. Perform preventive cleaning, which will increase the life of parts several times. Do not confuse a drainage device with a fecal one - it does not have a special grinder and cannot cope with the movement of large inclusions.

Device and principle of operation

The brook submersible pump consists of the following parts:

- housing connected by four screws;

- electric drive;

- vibrator.

The body of the device is made in the form of a casing. In the upper section of the casing there is a glass for water inflow through the holes and a branch pipe for the water outlet.A special valve opens and closes the inlets.

The electric drive of the device consists of a core with two coils and a power cord.

The vibrator is assembled with a shock absorber, a diaphragm, an emphasis, a coupling and a rod. At the top, the rod is connected to the piston, at the bottom - to the anchor.

The oscillations of the armature and the piston, which are created under the action of an elastic shock absorber, convert the electric power of the network into a translational mechanical vibration. The piston under the action of the rod creates pressure in the glass with holes, the valve closes simultaneously and water is squeezed out into the outlet pipe.

Assembly of the vibration pump Brook

Advantages of the upper water intake of the pump:

- self-cooling of the system occurs during operation;

- there is no suction of sludge from the bottom by the working body.

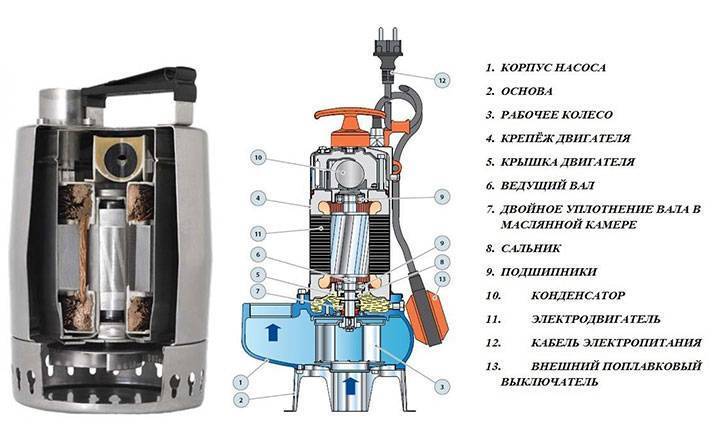

How is the drainage pump

This type of pumping equipment belongs to the category of "centrifugal". An impeller is mounted on the motor shaft, which pumps water. A large number of different models work according to this principle. But the drainage one differs from the rest in that its impeller is made of steel, while the walls of the blades are thicker than those of conventional devices. In addition, the passage between the body of the unit and the walls enclosing the feed chamber and the compartment where the electric motor is located is larger. This allows sand, small pebbles, organic inclusions and other large particles to move freely through the gap.

Manufacturers offer drainage pumps with a float switch. The latter reacts to the level of pumped water. And if it drops to a critical level, the pump immediately turns off. The float performs the functions of protection against dry running.

Common problems

The nature of the failure and the cause of its occurrence:

- Doesn't buzz and doesn't work. The drainer is lowered into the water, the float has risen and is on the surface, the cable is connected to the circuit, but the engine does not work, there is no vibration. The cause of the breakdown is a discrepancy between the declared power of the motor and the electrical network to which the device is connected. Carefully read the characteristics of the pump, its power and efficiency. The pump is not lowered into the water deep enough, and the float does not work. Remove the device and, lifting the pillow up, turn it on again.

- Works, but does not download. The engine is on but no water is coming to the surface. There are several reasons for this. The protective mesh blocking debris and stones at the bottom of the hull clogged. Raise the machine and clean the filter. The thick fraction got into the discharge hose, and a blockage occurred. With such a breakdown, it can be knocked out of the base of the pump, if this does not happen, you need to disconnect it yourself and rinse it. Impeller broken. Her screws may break or the bearing may collapse, you can find out by disassembling the pump.

- Vibrates and overheats. The braid of the electric motor was broken, water got into the engine compartment, the shaft bearing collapsed. The unit vibrates and heats up, while the water comes in jerks or stops altogether. We urgently de-energize the equipment and pull it out to the surface. The cause of the breakdown is hidden inside. For diagnostics, you will have to disassemble the case without fail. Several impeller blades are broken. Rotation occurs by an eccentric and hits the body from one side.

- Weak pressure with a properly running engine is a consequence of a breakdown of the mechanical part of the pump. Impeller or bearing, clogged discharge hose or suction filter.Eliminated by simple rinsing in clean water or by replacing mechanical parts.

- When the unit is connected to the network, the machine works. The fuse disconnects the network if a short circuit occurs. Check all electronic parts of the pump. Pass the cable with a tester and find out where the short circuit occurred - replace it. The motor's copper braid is also at risk if the unit has been running dry. Replace the braid or install a new motor only in a repair shop.

- The device works, but turns itself off. Connected to the network and works, regularly pumping water. Suddenly it turns itself off. The reason is the mismatch between the power of the motor and the mains. Power surges can also affect the smooth operation of the unit. The solution is simple - to study in detail the instructions and characteristics of the pump, install a voltage stabilizer.

How to clean parts

Pump blockage is formed due to accumulated lime deposits. Excessive pollution can lead to a complete failure of the heating unit. Small deposits on the shaft can be eliminated on their own with the help of ordinary vinegar essence.

To clean the inside of the pump from dirt, dilute it with water 1: 1. Pour the resulting solution into the pump through one of the fasteners.

After a day, lime deposits will partially dissolve, and to remove residues, disassemble the unit and clean it thoroughly.

Clean the insides of the pump carefully, removing residue deposits from all surfaces, using a wooden spatula. Finish off with sanding, which can be done with a piece of cloth or special paste.

Common causes of breakdowns of the pumping station

In the world, as the classics justifiably assert, nothing lasts forever, this also applies to equipment. Unexpected malfunctions in the operation of pumping equipment, its stop or incorrect functioning can be caused by a number of reasons, such as:

- lack of electricity;

- lack of water in the system;

- pump breakdown;

- breakage of the membrane tank;

- damage to the automatic unit, etc.

The device of household pumping units is not particularly difficult, and this allows you to do repairs yourself. In some cases, you need to disassemble the pump and replace the damaged part. Sometimes it is required to seal a crack in the tank, and sometimes it is enough just to check the availability of electricity. In each case, you need to determine why the pump does not pump water, and find a "recipe" for solving the problem. If you can not find an acceptable solution to the problem, you need to contact the experts.

Repair after a sudden shutdown

Instrument operation stops abruptly after a few minutes or hours. If this happens 1-2 times a day, then you should not worry. As soon as the frequency exceeds 3-4 times, you need to understand the reasons. Opens a list of those defense mechanism that suddenly works. Its task is to prevent "dry running" and overheating, but under certain circumstances it can work.

First you should pay attention to the float and the heating cable

Sometimes special electronic devices should be used to determine the breakdown of the pump.

If you feel excessive heat, then you need to delve into the characteristics of the household electrical network.

The procedure is as follows:

- Check if the pump is connected to the household network correctly;

- Make sure that the voltage in the house "does not sag" and does not go beyond the upper limits recommended by the pump manufacturer;

- If this is the case, then the float pump is equipped with a stabilizer;

- Everything can be done by hand in 1 hour.

There are several types of causes leading to pump failure. They are divided into mechanical, electronic and random. In the first case, we are talking about the physical wear of parts or the ingress of foreign objects into them. The second category includes power surges and errors during operation. Complete the list of human actions. Irregular maintenance and replacement of failed elements lead to significant damage.

Malfunctions of the pumping station, or How to repair a pumping station with your own hands

No device, no matter how reliable, lasts forever. Alas! This also applies to pumps for water supply systems. Therefore, at the end of the topic on pumping equipment, we will figure out what malfunctions of the pumping station occur and how to do the repair of the pumping station with your own hands. If you were looking for: malfunctions of the water supply pumping station, malfunctions of pumping stations for the home, malfunctions of the water pumping station, malfunctions of the pressure switch of the pumping station. then this article is for you. Further I will simply list possible malfunctions and “fix” them.

Frequent breakdowns

Even if you use high-quality pumping equipment from a well-known brand, the possibility of its breakdown is not ruled out. In this case, most often the cause of the breakdown is not one.Since the standard operating medium for domestic submersible pumps is water, the equipment is constantly exposed to negative factors. Since the cost of such products is rather big, it is quite expensive to buy a new unit. Much easier and cheaper to fix the old one. That is why it is not superfluous for any owner of a submersible pump to learn how to repair it on their own, as well as to properly operate and prevent possible breakdowns. Possible causes of breakdowns of pumping equipment:

- pumping heavily polluted water with a solids content of more than 50%;

- work "dry" (there may be several reasons from improper installation to complete pumping of water from a hydraulic structure);

- the level of the working fluid at the start of the unit exceeds 40%;

- power surges;

- poor-quality docking of cable connections;

- the cable on which the unit is suspended is incorrectly fixed on the head;

- improper fixation of the submarine cable.

Sometimes problems with the operation of the pump can occur due to violations of the installation and use of other elements of the water supply system, for example:

- in case of improper operation of the hydraulic tank;

- if the system does not use a coarse filter;

- the pressure switch is unstable;

- there is no grounding, which can lead to corrosion;

- system freezing;

- failure of the magnet (in this case, only the workshop will help you).

In addition, all breakdowns can be divided into mechanical and electrical. As a rule, if immediately after starting the pumping equipment you hear extraneous sounds, then this indicates a mechanical malfunction. In this case, you can try to repair the equipment with your own hands.Common causes of mechanical failures:

- the working environment contains too much solid impurities;

- lack of oil, etc. .

Differences between submersible and surface models

The submersible apparatus is useful for cleaning deep reservoirs, for example, a well that has just been put into operation. The first liquid accumulated in it cannot be called drinking, since there are many large inclusions of sand and clay. During the day, it is necessary to pump out the contaminated liquid so that clean, usable water comes in its place.

Unlike a submersible, a surface pump is not used for deep tanks; it is more suitable for pumping water from a pool or basement when it is flooded. A hose is placed at the bottom of the tank to receive dirty water, the second hose is used to drain wastewater.

If the pump is used in an emergency, it is appropriate to use a float device that will control the critical level of water rise. The advantage is that the design of the mechanism allows you to pump liquid with large pieces of dirt - up to 5 cm (less often - 10 cm).

It is clear that the surface-type aggregate differs in its structure. A working shaft and a wheel are fixed inside the metal case, and the engine can be different: for centrifugal products - single-phase with external ventilation, for self-priming - asynchronous bipolar.

Despite the contamination of the pumping medium, do not allow the pump to operate with a liquid in which gasoline, kerosene or other petroleum products and chemicals are dissolved.

The pump pumps jerkily, turns on and off very often

To fix this problem, you need to do the following:

Pay attention to the pressure gauge, which is located on the automation unit. If the pressure gauge arrow rises to the pressure that the station was set to (at the same time the pump turns off), then drops sharply until it is turned on, then there may be the following reasons: there is no air pressure in the hydraulic tank. At the factory, nitrogen is pumped into the tank to a pressure of 1.5 atm.

Sometimes, due to corrosion, cracks appear in the tank body, and the pressure does not hold for a long time. It is necessary to find a leak and repair the crack (for example, with “cold welding”). You can check the air pressure in the hydraulic tank by connecting a pressure gauge (at least a car one) to the nipple. The pressure in the tank may not necessarily be due to the appearance of a crack, but simply for some unknown reason, the air has left. Then you don’t need to bring yourself to a brain twist in search of non-existent cracks, but simply pump the air with a pump (in fact, you should start with this); rupture of the diaphragm separating air and water in the tank. You can check this through the nipple: if water flows from the nipple, then the diaphragm is damaged; pressure switch not working. which controls the activation of the pump

At the factory, nitrogen is pumped into the tank to a pressure of 1.5 atm. Sometimes, due to corrosion, cracks appear in the tank body, and the pressure does not hold for a long time. It is necessary to find a leak and repair the crack (for example, with “cold welding”). You can check the air pressure in the hydraulic tank by connecting a pressure gauge (at least a car one) to the nipple. The pressure in the tank may not necessarily be due to the appearance of a crack, but simply for some unknown reason, the air has left.Then you don’t need to bring yourself to a brain twist in search of non-existent cracks, but simply pump the air with a pump (in fact, you should start with this); rupture of the diaphragm separating air and water in the tank. You can check this through the nipple: if water flows from the nipple, then the diaphragm is damaged; pressure switch not working. which controls the activation of the pump.

Drain pump selection criteria

Let's summarize how to choose a drainage pump. When purchasing the necessary unit, be guided by the following points:

- Operating conditions of the equipment. Although drainage pumps can easily handle wastewater pumping, the technical characteristics are limited by the degree of their pollution (it should not exceed the permissible parameters). In other words, large stones, a high percentage of sand in the liquid, silt and dirt can adversely affect the operation of the unit. That is, to eliminate the flooding of basements, you can use a conventional drainage pump. But if you need to drain the reservoir, a solid platform with a flat surface is placed under the bottom of the pump. And if the front of the work is a construction site, then it is optimal to resort to the help of a powerful fecal pump with a grinder.

Drainage pump can drain even a pond

- Arithmetic calculations. When calculating the required capacity of the equipment, please note that 1 meter of vertical length is equal to 10 horizontal meters. This means that if you have a sewage pit depth of 5 m, then the length of the hose should not exceed 50 m. In this case, the sewage discharge rate will be low, although the drainage pumps operate in conditions of constantly arriving water.In order for the pump to cope with its task flawlessly, add to the height of the drains the length by which the discharge pipe will be laid on the surface of the earth in a horizontal direction. If even then the pressure is not optimal, you should add a "allowance" of length - about 3 m.

The lower the height of the effluent, the more efficient the pump works.

Pro tip:

When choosing a drainage pump, mainly pay attention to its power. Only this parameter determines the optimal use of a particular equipment.

- The selection of the drainage pump model is made depending on the condition of the surface where the drainage pump will be mounted. It is best to install a drainage pump in a pit, the depth of which is from 40 to 60 cm. This will protect against water from entering the basement floor. Then the pump can be equipped with a vertical float mechanism, which will turn on the equipment as the recess fills, leaving the floor dry. If it is possible to organize a pit with a width and length of 50 cm or more, any type of float will do.

Float pump will not allow maximum dehumidification

When it is required to drain the tank as much as possible, a special drainage pump is needed, which is mounted on a hard surface. In this case, the float is not needed, since it will only start working at a sewage level of at least a few cm. In all other cases, conventional models will also cope with the task.

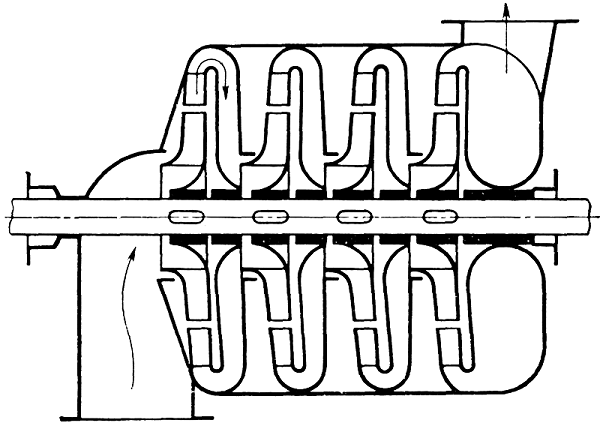

How to disassemble the unit to diagnose a breakdown

In case of pump breakdowns requiring replacement of parts located inside its housing, disassembly of the unit will be required.A submersible pump consists of a motor compartment and a compartment with one or more impellers, the purpose of which is to capture water. Below is a diagram of the device of that part of the centrifugal pump where the impellers are installed.

As can be seen from the figure, the impellers are mounted on the shaft of the unit. The more of them, the higher the pressure created by the pump. The rotary engine is located in the second compartment of the hydraulic machine. It is in a sealed case, and to open it, you need to know some of the nuances.

So, in order to move from theory to practice and disassemble the pump, follow these steps (depending on the manufacturer, the design of the unit may differ).

- Unscrew the 2 screws holding the mesh of the device.

- Remove the mesh and turn the motor shaft by hand. If it does not spin, then the problem may be either in the engine compartment or in the pumping part of the apparatus.

- First you need to disassemble the pumping part of the device. Unscrew the 4 screws holding the power cable channel and disconnect it from the machine body.

- Next, unscrew the 4 nuts holding the pump flange.

- After unscrewing the fasteners, separate the pumping part of the apparatus from the engine. At this stage, it is possible to determine in which section the jamming occurred. If the shaft of the pump compartment does not rotate, then this assembly must be disassembled.

- Unscrew all fasteners holding the lower flange of the pump part of the unit.

- An adapter must be screwed into the fitting located at the top of the block, which will help keep the threads from damage.

- Secure the pump in a vise.

-

Having picked up a suitable tool, unscrew the bottom flange.

- The impeller assembly can now be pulled out and inspected for faults.

- Next, you should check the support shaft for wear or play.

- To replace (if necessary) the impellers, it is necessary to fix the shaft in a vice and unscrew the top nut.

-

At the next stage, the blocks are removed, washed and, if necessary, replaced with new ones.

- The assembly of the pumping part of the apparatus is carried out in the reverse order.

- To disassemble the electric motor, it must also be fixed in a vise.

- Next, remove the plastic flange protection by unscrewing the fasteners.

- Remove the retaining ring holding the cover with a pair of pliers.

- Remove the cover using a slotted screwdriver.

- Remove the rubber membrane from the housing.

- Remove the capacitor.

- At this stage, you can check the oil level, its quality, identify the cause of jamming, etc. The engine block is assembled in the reverse order.

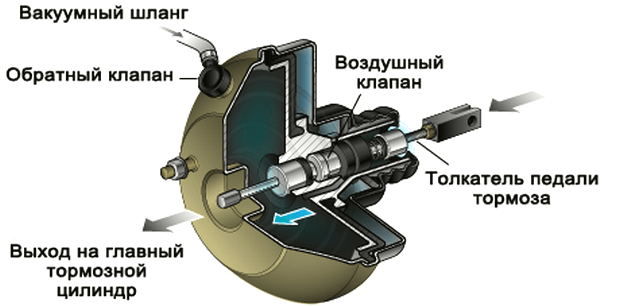

Symptoms of a malfunctioning vacuum brake booster

Due to the prolonged operation of the vacuum brake booster without replacement, defects may appear in it. Most often, the problem manifests itself in mechanical damage to the hose connection connecting the amplifier and the engine intake manifold. Mechanical damage or the formation of cracks in the rubber will lead to the fact that a vacuum will not be created in the working chamber of the mechanism, and this is necessary for its proper operation.

Internal parts can also fail in the vacuum brake booster, for example, the valve will lose elasticity or the working surface of the diaphragm will be damaged.

You can determine the malfunction of the vacuum brake booster by the following signs:

- The car began to slow down worse with the same pedal pressure;

- While pressing the brake pedal, hissing sounds are heard, at this moment the engine speed may increase;

- The car starts to "troit";

- Fuel consumption increases when the machine is running in the same mode.

In some situations, there may be other problems in the operation of the car due to problems with the vacuum brake booster. For example, spark plugs may stop working.

Causes of breakdowns and ways to eliminate them

There is a list of breakdowns when repair of the drainage pump is necessary. They include the following:

- short circuit of electricity as a result of overvoltage or voltage drops in the mains - in this case, the winding may burn out;

- the float itself can jam below the trigger level, it can be held back by the walls of the well itself or by hoses;

- mechanical fractions jammed the impeller after entering the structure body;

- the capacitor may be damaged.

Also, the equipment may not only not work, but also produce various strange sounds, for example, buzz. This may be due to a short circuit in the network, failure of the valve, loosening of the shock absorber on the stem, so that the stem could break, or due to the fact that the power source has broken.

Before looking for information on how to disassemble the drain pump, we recommend that you first check the power supply to make sure that the cause is not electrical overvoltage.

What damage can you fix yourself? Do-it-yourself repair of a drainage pump with a float can be done if the float has dropped, the impeller has jammed and the water supply has stopped, electricity is knocked out, if the cable (power cord) is needed to be repaired or the shock absorber needs to be reattached.

In order to repair the cable, for example, at the Whirlwind drainage pump, the following work must be done. Understand exactly where the cable is malfunctioning. This, first of all, can be a place of connection to the device or a segment at the plug. You can use the palpation method, namely pinching the cords with your fingers to connect them. Repair of a drainage pump with a wwq nsf600 float in the event of a cable break near the structure itself is possible only after disassembling the cable. Disassemble the tank with a regular screwdriver, remove the tensioner, unscrew a few bolts, remove the cord, cut off the breakage, insert the wire back.

If, for example, the Gnome drainage pump turns on and off on its own, then this is most likely due to a power failure. In this case, you need to solve the cause of the short circuit or check for blockage in the flow area. In order to eliminate the blockage, you need to remove the filter, then the diaphragm and simply clean the blockage area.

If the quality of water pumping has deteriorated, then this is due to the automation for the drainage pump. You need to change the impeller.

Repair of drainage pumps

The use of drainage pumps is due to the need to pump clean or dirty water. The most important element of such units is the engine, the design features of which directly affect the conditions of use, productivity and uninterrupted operation of the device itself. There are a lot of models and varieties of drainage pumps, but regardless of the manufacturer, price and quality, they all need repair work at some point.

Repair of the drainage pump requires a qualified approach, which is a guarantee of its normal functioning in the future and the absence of problems associated with further operation.

Our specialists will be able to repair a pumping station for drainage of any degree of complexity in the shortest possible time, without forcing the customer to waste precious time waiting for the necessary spare parts or blocks to be replaced.

Thorough diagnostics will help to identify the exact cause of equipment failure, for which it is not necessary to transport the unit to us. All necessary work can be carried out at the client's premises, which will save not only time, but also transportation costs.

The Hydroves company will help not only to eliminate problems with the operation of pumping systems, but to provide them with high-quality preventive maintenance, which will eliminate the occurrence of problems in the future.