- How to choose

- Gilex Drainage

- GRUNDFOS

- Possible problems and solutions

- The pump hums and the impeller does not turn

- The pump does not work at all

- The pump turns on, but stops after a couple of minutes

- Pump makes noise when turned on

- Pump vibrates and makes noise

- Weak pressure

- Equipment does not turn on

- Brief repair scheme for centrifugal type devices

- Repair and prevention of breakdowns of centrifugal pumps

- Drainage device

- Causes of failure of the drainage pump

- Faults and repairs

- What are the types of drainage pumps

- The device and principle of operation of drainage pumps

- The pump does not start

- What is the phenomenon of cavitation

- Pump Failure Prevention

- How to repair a water pump

- Causes of failure of the drainage pump

- How to disassemble the unit

- Do-it-yourself float device repair

- How to disassemble a float

- Float switch repair

- The main malfunctions of submersible pumps

- Pump runs but no water comes out

- The main causes of failure and methods for their elimination:

- After turning on the pump, the circuit breakers are turned off

- The main causes of failure and methods for their elimination:

- Excessive heating of the product in a short period of time

- Pressure drop during device operation

How to choose

To choose the right model, you need to answer a few questions.

- How much liquid should be pumped out at a time?

- From what depth do you need to excavate?

- How often will it work?

- What is the level of water pollution and what is the maximum size of solid particles in it?

- Acceptable price.

On the video - how to choose a drainage pump for a well:

Below are the main models of drainage submersible and surface pumps that have gained popularity in the Russian market.

Gilex Drainage

Fecal submersible with a grinder dzhileks is used for cleaning septic tanks, country sewerage, drainage wells. Power - 400 W, productivity - 9 cubic meters. per hour, the maximum allowable size of solid particles is 35 mm. Price - 3,400 rubles.

Power - 900 W, productivity - 16 cubic meters. in hour. Price - 4,000 rubles.

GRUNDFOS

The company produces various models of submersible drainage and fecal pumps. Average price per model power 300-500 W and performance 5-10 cubic meters per hour starts from 10 thousand rubles. The pumps are equipped with a built-in float switch and dry running protection.

Possible problems and solutions

What breakdowns can occur and how to repair the circulation pump with your own hands? Let's figure it out.

The pump hums and the impeller does not turn

Possible reasons:

- Foreign object in the impeller chamber.

- A long downtime of the apparatus led to the oxidation of the rotor shaft.

- The power supply to the device terminals is interrupted.

In the first case, troubleshooting can be done by carefully removing the device and unrolling the housing in the impeller area. If there is a foreign object, remove it and turn the shaft by hand.In order to avoid re-entry of a foreign body, a filter should be installed on the nozzle.

The circulation pump buzzes even in the event of a power failure. First, check the voltage with a tester. If the cable is damaged or broken, it must be replaced. If the cable is in order, look at the voltage at the terminals. The infinity icon on the tester indicates a short circuit. Less voltage means winding break. In both cases, the terminals must be replaced.

The pump does not work at all

The pump does not work when there is no voltage in the network. The tester checks the voltage, as well as the correct connection of the device to the power supply.

Circulation pump shaft

If there is a fuse in the pump, there is a risk of it blowing from power surges. If this happens, replace the fuse. It is advisable to install a reliable stabilizer.

The pump turns on, but stops after a couple of minutes

The reasons may be:

- Lime scale between moving parts of the device.

- Incorrect connection of the pump in the terminal area.

The pump can turn on, but also immediately stop if there is scale. Remove limescale and lubricate the joints between the stator and the rotor.

In the second case, check the density of the fuse on the device. It is removed and all clamps are cleaned. All wires must be correctly connected in the terminal box.

Pump makes noise when turned on

If the pump is noisy, this may indicate the presence of air in the system. It is necessary to bleed the air from the pipes, mount a unit in the upper part of the circuit so that the air is released automatically.

The pump may also make noise due to wear of the impeller bearing. It is required to disassemble the body of the apparatus, and, if necessary, replace the bearing.

Pump vibrates and makes noise

If turning on the pump is accompanied by vibration and noise, then the reason is insufficient pressure in a closed circuit. You can solve it by adding water to the pipes or by increasing the pressure at the pump inlet.

Weak pressure

With a low pressure or when the pump almost does not pump the coolant, check the direction of rotation of the impeller in the body of the apparatus. If the impeller does not spin correctly, then a mistake was made when connecting the pump to the terminals by phases if a three-phase network is used.

The decrease in pressure may be due to the high viscosity of the coolant. At the same time, the impeller experiences increased resistance and does not work well, not at full strength. It is necessary to check the mesh filter and clean it. It is also advisable to check the cross section of the pipes of the holes. After that, you will need to adjust the correct parameters for the pump.

Equipment does not turn on

The pump does not turn on when there is a power problem. It is necessary to check the phases and fuses. If they are in order, then the drive winding burned out. In this case, you will have to seek help from specialists.

The internal surfaces of the pump must be free of rust.

When diagnosing equipment, you can use the indicator - a tester for the rotation of the shaft of the circulation pump. It allows you to verify that the pump is working without connecting to the mains.

Brief repair scheme for centrifugal type devices

The sequence of repair activities looks like this:

- the body of the device is washed from the outside;

- the device is disassembled;

- parts are inspected, washed and cleaned;

- parts are removed, repaired or replaced;

- spare parts are completed;

- the apparatus is assembled;

- run in and tested;

- body is painted.

Repair and prevention of breakdowns of centrifugal pumps

Any centrifugal pump requires care and thoroughness during repairs due to the complexity of the design. The basic rule of repair is to disconnect the device from the network before starting work. The stages of repair of centrifugal pumps consist of the following items:

Professional repair of industrial centrifugal pump

- before repairing the device, it must be disassembled. Disassembly is carried out by removing the device case. After disassembling the centrifugal pump with your own hands, it must be inspected;

- inspection and measurement of the gaps of the sealing parts and the rotor of the unit;

- replacement of bearings;

- the shaft is checked for roughness and cracks. When detected, it is changed;

- measurement of the body for the presence of a deviation from the norm;

Such activities are carried out to maintain the device in good condition, so the frequency of such repairs is once every 4500 hours.

For a global repair when operating 26,000 hours, it is necessary to perform the following manipulations:

- shaft change;

- change of sealing rings, bushings;

- replacement of sectional parts of the device;

- hydraulic test.

Repair of centrifugal pumps and their maintenance is a complex task, so problems arise during its implementation. These difficulties include:

- removing the clutch. To perform the procedure, you must resort to the help of a puller;

- removal of the pressure flange;

- removing liners;

- analysis of bearings;

- removal of impellers.

Grinding the impeller of a centrifugal pump

After repair work and replacement of necessary parts, it is necessary to assemble the apparatus. The build sequence is:

- Checking and preparing parts to be installed.

- Fitting parts to their locations.

- Grinding and lapping of replacement parts locations.

- When using a diametric key and observing the force, the screw fasteners are tightened.

- The impeller is assembled on the shaft, observing the axial clearance.

- At observance of perpendicularity to the front side, an unloading disk is installed.

After repair work, the mechanism is tested on a specialized stand. Tests consist of several points:

- short start and stop;

- warming up the device;

- operating mode test.

With a short start, lasting about three minutes, check the lubrication of the bearings, the correct readings of the instruments and the correct rotation of the rotor.

Warm up devices designed to work with hot liquids.

When testing the operating mode, the electric motor is turned on, the valve is opened when the entire speed is reached, the device is run in for two hours.

For a long service, your unit must be periodically given for scheduled repairs or you can do it yourself. This action will reduce the number of breakdowns. And by making timely repairs, the device will last a long time.

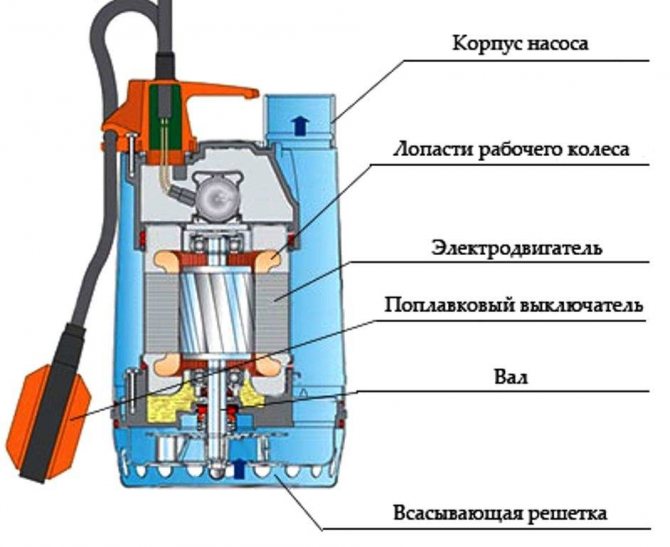

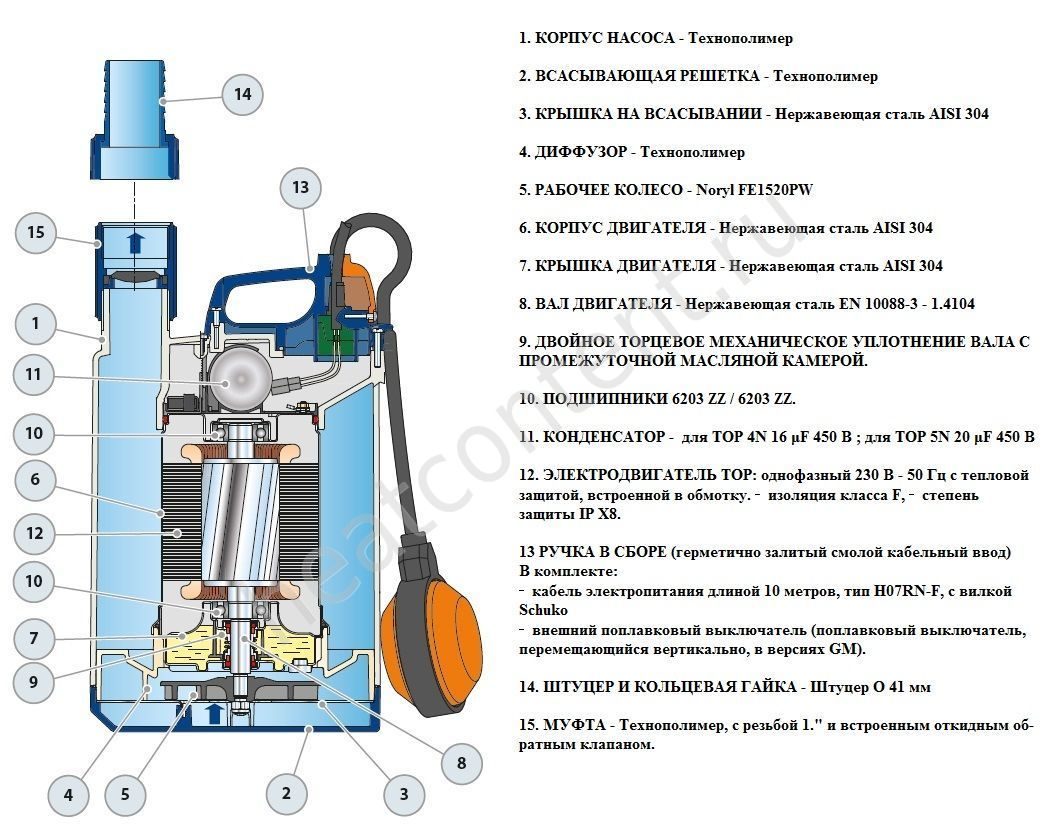

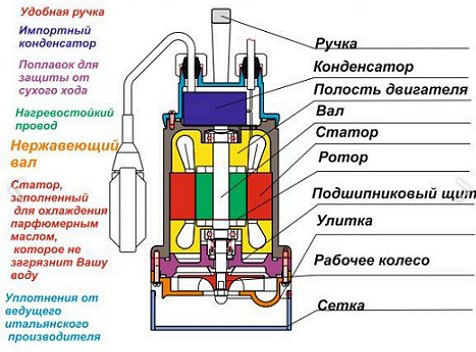

Drainage device

In the body of the device are installed:

- Protective mesh on the bottom of the device. Prevents debris and large parts from entering the impeller.

- Impeller (impeller). Rotating, it creates a rarefied environment around itself, due to which liquid is absorbed.

- Bearing shield. Protects the motor, rotor and shaft from moisture.

- The rotor sets the rotational energy for the impeller.

- The shaft is considered an element of the engine, passing through the entire cavity of the unit, it is attached to the rotor.

- The capacitor serves as a switch.

- Float. Located on the outside of the appliance, when lowered, prevents the engine from starting, preventing overheating from dry running.

- Cable. Designed to supply electricity.

The unit is hermetically sealed. In each compartment, including the engine, there are sealing rubber gaskets between the partitions.

Causes of failure of the drainage pump

There are a lot of reasons for the breakdown of drainage pumps, here are the most common of them:

- Violation of operational standards (the device constantly experiences overloads, it is not completely immersed);

- The pump is not regularly maintained;

- The pump has been incorrectly mounted;

- Perhaps this is a manufacturing defect.

Before starting repairs, it is necessary to exclude the last of the listed options. If you bought the pump recently, then check if the warranty period has not expired, if any. Because in the event that you try to repair the pump yourself, then it will no longer be accepted for warranty service.

To prevent damage to the pump, it is necessary to carry out its maintenance on time.

Preventive measures to avoid repairing the float pump, points to pay special attention to:

- Air entering the pump must be free to pass through and out. If the air does not flow freely, then somewhere in the pump there is an air lock.

- There should be no visible damage to the piston.

- The distance between the valves and the inlet opening must be observed.

Faults and repairs

Most pump products of different brands often face the same problems

Most pump products from different brands often face the same problems. We list the most common of them and indicate what needs to be done to troubleshoot:

- The hum of the motor is heard, but the unit does not pump water. This means that the device works “dry” (without water). If you are sure that the equipment is installed correctly and the problem is not related to the debit of the hydraulic structure, then the probable cause of the malfunction may be loosening of the nuts securing the shock absorber, wear of the rubber parts (valve) or stem breakage. To troubleshoot, do the following:

- Locate the shock absorber of the pumping equipment. There are two nuts on the stem that fix it. They must be tightened to the stop, and for greater reliability, it is better to lock the topmost nut.

- If the valve is worn out, it must be replaced with a new product. Such a malfunction occurs if the unit pumps heavily polluted water. To prevent this from happening, use a coarse filter on the inlet pipe.

- If the stem breaks, it will not be possible to repair the device, so you will have to buy a new pump.

- During start-up, the device knocks out plugs. This may occur due to the burning of the winding or a malfunction of the electrical cable. You should start looking for a problem by testing the cable. If it fails, the cable must be replaced. If it is in order, then the problem lies in the burnt winding. You can try to replace the old coil with a new product or take the unit to a service center to rewind the winding.

- During operation, the pump gets very hot and vibrates. Both problems are related to the operation of the device "dry".The thing is that water cools the body of the device well, but if it works outside this environment, it quickly overheats, which causes the magnet to detach and the piston to stop. To repair the device, do the following:

- The unit is disassembled and, tapping on the body, find the place where the magnet is to be installed.

- Then all the parts are removed from the body, and on the inner surface with the help of a grinder a notch is made of vertical and horizontal stripes 2 mm deep.

- After that, the notched place is lubricated with a good moisture-resistant adhesive or sealant.

- The magnet must be well pressed into this glue.

- When the adhesive is dry, the device can be assembled.

- Low pressure may be due to the fact that too little clearance is left in the vibrator. To adjust it, do the following:

- First you need to check the tightness of the nuts on the stem, the integrity of the rubber valve, and also make sure that there is no break in the thrust.

- If everything is normal, then you need to increase the gap for water penetration. To do this, the required number of washers is screwed onto the vibrator. Their number can be different and depends on the required pressure and stroke of the pumping equipment.

Video instructions for repairing the Whirlwind borehole pump:

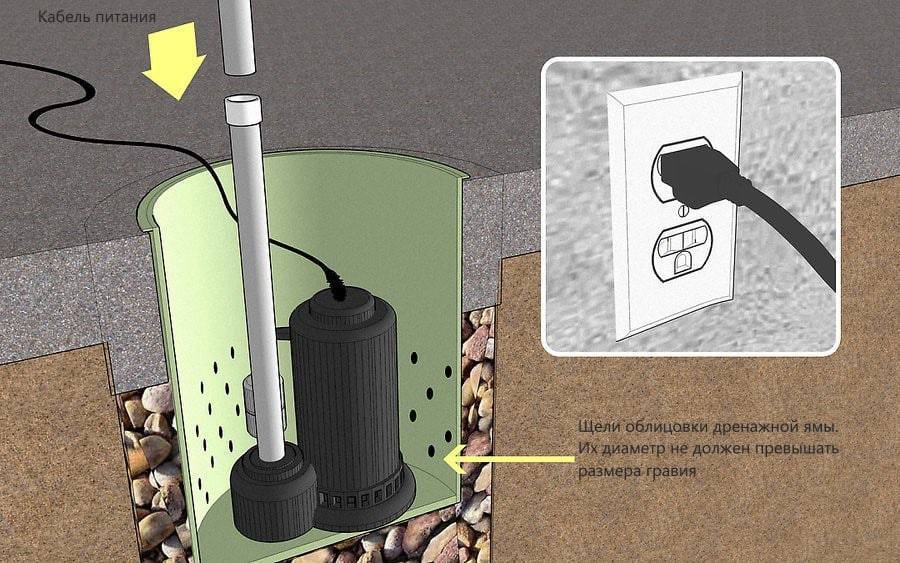

What are the types of drainage pumps

According to their purpose, such pumps for pumping out dirty liquids are divided into:

. This type of device is used for pumping liquid from small tanks.

The unit is installed on the ground, at the edge of the drain pit. To pump out waste, a hose is lowered to the bottom of the tank.

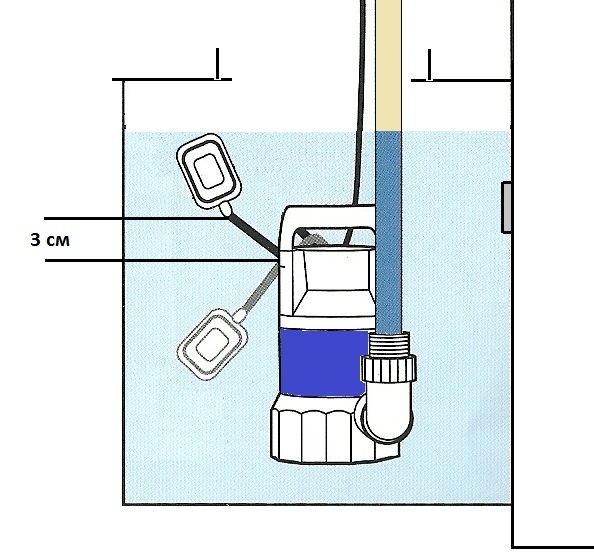

When the pump is operating in automatic mode, it is necessary to bring the float mechanism to the activation lever, it will monitor the water level in the tank or pit. When effluents rise above a certain level, the float rises with them and turns on the equipment.

Such a device should have two pipes:

- entrance, for sucking water from the waste pit;

- outlet, through which the liquid is discharged outside of it.

During operation, it is necessary to ensure that water does not get into the engine, which can lead to damage to the device. Therefore, the pumping of sewage must be carried out faster than their level in the pit can rise.

The main advantage of surface drainage devices is their mobility. The device can be easily moved to any place, and if necessary, it can be repaired quickly and easily.

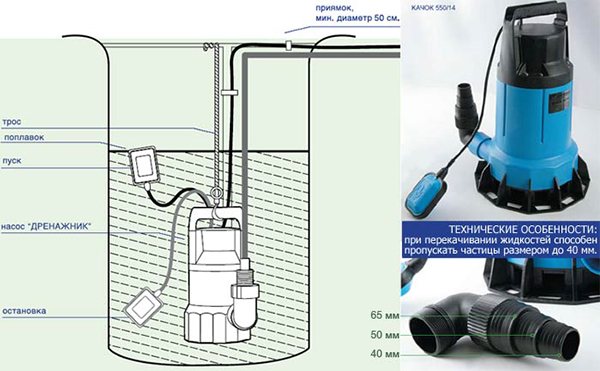

. Such models are most often used to clean deep tanks and large-scale flooding, to eliminate excess water. In this case, the units are lowered into a container or pit, from where liquid must be pumped out, and water is sucked in through the holes located in their bottom, and not through the inlet hoses for drainage pumps.

Mesh filters of the devices protect it from stones and other large particles entering the pump impeller.

The use of a float or a plastic bubble allows, with a certain amount of wastewater, to automatically turn on the submersible pump. To prevent a possible short circuit, when the device is immersed in a liquid, the manufacturers have provided high-quality electrical insulation. The undeniable advantages of drainage pumping equipment for liquids are:

- Versatility.

- Long service life.

- No mandatory regular maintenance is required.

If you need to pump or pump a heavily contaminated liquid, it is better to prefer sewage or fecal pumps. They have a special cutting or chopping tool and can pump and process liquids containing large household waste.

The device and principle of operation of drainage pumps

The main elements of the drainage pump are:

- Engine. If the price of the pump is small, the motor is located in an inner casing made of plastic.

- A capacitor motor with a thermal cut-out that prevents overload is available on more expensive retrofit units. Here:

- housings are made of high-strength polypropylene, reinforced with fiberglass; it is possible to manufacture the pump housing from stainless steel or plastic, and stainless steel is taken for the motor housing and shaft;

- the working shaft is made of stainless steel.

- Housing internal.

- The body is external.

- or impeller, are located on the shaft in the outer casing of the pump. The wheel configuration determines how large dirt particles can pass the pumps.

When the pump is running, the space between the housings is filled with water, forming a cooling “jacket”, which protects the unit from overheating.

For automatic shutdown and start-up, the pumps are equipped with float switches that control the water level in the tank, protect the device from dry running and flooding, and monitor the timely switching on of the pump.

Quality and long pump life performance can be obtained if the content of fibrous inclusions is kept to a minimum and the size of the solid particles does not exceed 5 mm. The smaller the installation depth, the better.

The pump does not start

If the device does not beep and does not function after turning on, the cause is probably the power supply. How to fix such malfunctions, you can watch the video of repairing the circulation pump. However, it should be understood that the reasons are different.

Repair does not always require disassembly of the pump. Use a multimeter to check the voltage at the connection points of the unit. Perhaps it does not meet the standards or is completely absent.

There is a fuse in the electronics of the device. If there were power failures, it may have burned out. You should disassemble the device and replace the fuse with a similar one.

What is the phenomenon of cavitation

Everyone knows that a certain amount of gases are dissolved in water. When a liquid moves at a certain speed, rarefaction zones sometimes form in it. In these zones of low pressure, gas bubbles begin to emerge from the water. After the bubbles enter the high pressure zone, they collapse. This process occurs with the release of a large amount of energy, from which the impellers and the pump snail are destroyed. The following photo shows the impeller of the unit, destroyed by cavitation.

The energy of the collapsing bubbles is capable of creating shock waves that cause vibration. It spreads throughout the unit and affects not only the impeller, but also the bearings, shaft and seals, from which these parts quickly become unusable.

The cavitation effect can most often be observed in pumping stations that operate on suction. In such systems, the impeller creates a vacuum, due to which water rises through the hose from the well. But if there is a lack of liquid at the inlet to the pump, then an excessive vacuum occurs in the impeller zone, provoking the occurrence of cavitation.

To prevent cavitation in the pumps, the rule should be followed: there should be more water at the inlet than at the outlet. This can be achieved in several ways:

- move the device a little closer to the source;

- you can increase the diameter of the suction pipe (hose);

- to reduce the resistance in the suction section, the suction pipe can be replaced with a pipe made of a smoother material;

- if there are many turns on the suction pipe, then, if possible, their number should be reduced;

- it is desirable that all bends have large turning radii.

Advice! The suction hose of the station should not be lowered into the well to a depth of more than 8 meters. Typically, the maximum immersion depth of the hose (pipe) is indicated in the equipment manual.

Pump Failure Prevention

It is much easier to prevent any breakdown than to carry it out later. repair of water pumps.

The procedure for prevention is as follows:

- The pump comes from the well. This process is not always easy, especially if the depth of the well is large enough, and the weight of the equipment reaches 50 kilograms. The work must be done with an assistant.

- After removing the pump from the source, all the constituent elements of the equipment are carefully considered.

- The absence of damage on the body, the presence of contamination, and whether there are no centers of corrosion are checked.

- The pump briefly starts and its operation is heard, any side sound may indicate a problem.

- The likelihood of breakdowns can be significantly reduced by periodically monitoring the operation of the unit and cleaning it from dirt.

- Sand and silt on the pump indicate the need to build up the well, otherwise further silting may cause the pump to break down, which is unlikely to be eliminated.

How to repair a water pump

Water pump connection diagram for supplying water to the house

Possible causes of breakdowns and methods for their elimination are indicated in the table:

| Cause of failure | How to repair |

| Power is supplied to the electric motor, but the impeller is in place | |

| Impeller blocked, shaft oxidized | If the impeller is blocked by a foreign object, it must be removed. Oxidation that occurs during long periods of inactivity can cause the shaft to block. The shaft must be turned by hand, before that the protective cover is removed, or the impeller |

| The parameters of the electrical network do not correspond to the passport data | At the input, the mains parameters and the connection on the terminal block are checked |

| The pump does not turn on and there is no sound | |

| There is no supply voltage or there are disturbances in the electrical circuit | Voltage parameters are checked at the input, the absence of damage to electrical networks and the pump connection diagram |

| The fuse is damaged due to the operation of the electric motor with an overload | A damaged fuse is replaced, and negative results indicate damage to the motor winding |

| The pump makes unusual noise during operation | |

| Air got into the flow part, which is possibly caused by an overload of the electric motor | The accumulated air is released. Install an automatic air vent at the top of the pump piping |

| Cavitation has occurred in the pump, accompanied by vibration | In the suction pipe, the pressure must be higher than the NPSH of the pump by at least 0.5 m.a.c. |

| Formed "dry run" | Lack of water in the suction pipe |

| Below Suction Lift Liquid Level Mark | Lower the pump or raise the water level. Water from the lower tank can be raised by the pump to a height of no more than five meters due to the rarefaction that usually occurs in the impeller |

| The pump started to vibrate | |

| Bearing damaged | Bearings are changed and lubricated. |

| Pump body not fixed | Mount the pump securely on the frame or foundation. At the same time, the installation instructions must be strictly followed and the requirements of the project must be observed. |

| Below passport pressure or water supply | |

| AT reverse side rotates Working wheel | This can happen with pumps that have a three-phase power supply. |

| The external motor protection trips during start-up | |

| An electrical problem has occurred |

|

| Motor protection trips very often | |

| The room temperature is high | Room temperature should not exceed 40°C |

| Bearings damaged | Replace and lubricate elements |

How to correctly draw up a water pump repair flow chart is well suggested by the video in this article. Proper care, which requires a water pump, timely and high-quality repair of the device, will extend its operation for many years.

Causes of failure of the drainage pump

There are a lot of reasons for the breakdown of drainage pumps, here are the most common of them:

- Violation of operational standards (the device constantly experiences overloads, it is not completely immersed);

- The pump is not regularly maintained;

- The pump has been incorrectly mounted;

- Perhaps this is a manufacturing defect.

Before starting repairs, it is necessary to exclude the last of the listed options. If you bought the pump recently, then check if the warranty period has not expired, if any. Because in the event that you try to repair the pump yourself, then it will no longer be accepted for warranty service.

To prevent damage to the pump, it is necessary to carry out its maintenance on time.

Preventive measures to avoid repairing the float pump, points to pay special attention to:

- Air entering the pump must be free to pass through and out. If the air does not flow freely, then somewhere in the pump there is an air lock.

- There should be no visible damage to the piston.

- The distance between the valves and the inlet opening must be observed.

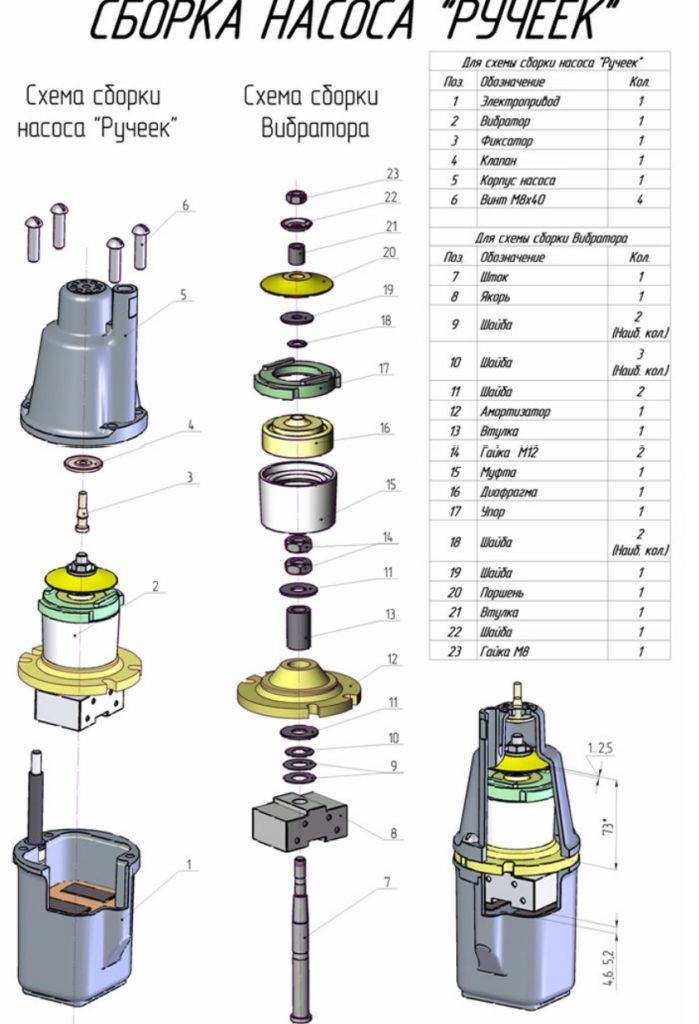

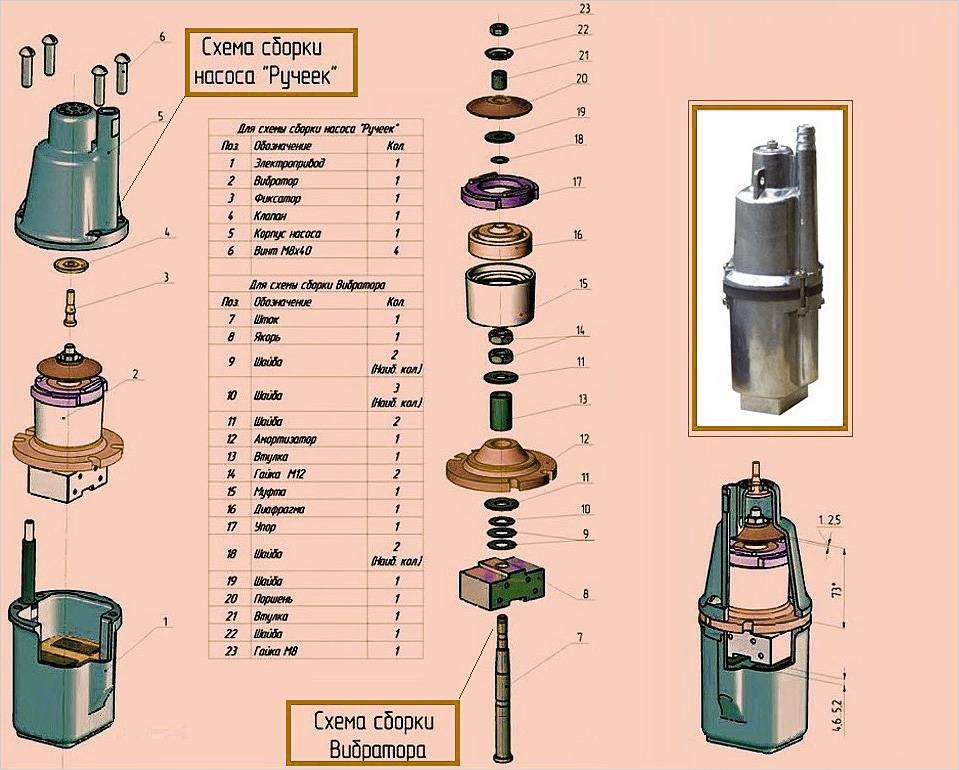

How to disassemble the unit

Do-it-yourself float device repair

First stage. We turn the device over with the impeller up and remove the protective grid. Almost all models have it. We unscrew the two nuts at the edges of the casing, freeing the impeller. For some units, the protective box is attached with clips or threaded.

Second phase. We take off the hood. A clamping nut is located on the mounting rod. It has a left-hand thread, so you need to unscrew it clockwise.The stem has a recess for a screwdriver. Pre-lubricate the thread with oil or aerosol. Having unscrewed the lock nut, we are faced with a problem - the impeller has boiled or rusted. Sometimes it is mounted on special teeth or a hexagon on the stem. Tap the rod gently several times to release the disc.

Third stage. No damage was found, we continue to disassemble. In the upper part of the case there are clamping bolts, by unscrewing which, we will divide the device into two parts. The cover and the condenser with the float will remain on one side, and the motor and the stem with the shaft will remain on the other. In this case, a bridge of wires connected together will remain between the parts. Cables vary in color. Their location is best written on paper to facilitate reassembly. The engine compartment remains closed. It's just not possible to separate the engine from the body. In some cases, you will even have to knock it out with a hammer by hitting the stem from the back.

Fourth stage. Having completely disassembled the unit, it will become clear which part is faulty. Most often it is the engine or bearings.

How to disassemble a float

Fifth stage. Having disassembled the main parts, the malfunction is not fixed. It's time to look at the float and capacitor. The first is responsible for the uninterrupted switching on and off of the pump at the right time, and also prevents dry operation. You can disassemble it by unscrewing the four bolts on the case with a screwdriver and prying the edge with a screwdriver. Inside is a ball, the roll of which turns on the motor. The valve may sink or stick.

Float switch repair

Replacing the broken part, the assembly takes place in the reverse order. Before disassembling the device, make sure it is faulty again.

The main malfunctions of submersible pumps

Due to its simple design, the main breakdowns of submersible pumps and methods for their elimination have long been known. To repair the device, you must follow the correct sequence of basic steps, as well as the most necessary tool, which you can get at any hardware store.

Pump runs but no water comes out

The operation of the pump can be determined by the characteristic hum that appears after the passage of an electric current through an electromagnet. With this malfunction, not only a complete absence of water can be observed, but a decrease in pressure is also possible.

The main causes of failure and methods for their elimination:

At the junction of the steel rod and shock absorber, the nuts have loosened. The problem is not significant, but requires almost complete disassembly of the pump. The main problem during disassembly is the screws, which rust after long-term operation in water and it is very problematic to get them out. To save time, you need to use a grinder or a hacksaw for metal and simply cut them off, and then replace them with new ones.

After disassembly, tighten the nuts well enough, and fix the top one securely. To prevent this from happening again, you can replace the nuts with self-tightening ones.

- Damaged rubber valve. To eliminate this malfunction, the valve must be replaced. It has no special connections and replacement takes a minimum amount of time.

- Deformation of the stem or its breakage. Such a breakdown is very serious, since a damaged stem cannot be replaced.

After turning on the pump, the circuit breakers are turned off

If the amperage of the machines is large enough, then the cable may burn, through which the pump is connected to the network.

The main causes of failure and methods for their elimination:

- Short circuit in the armature winding. This can be seen either externally or by ringing the winding with a multimeter. Rewinding the anchor is possible only with the appropriate tool. Also, this procedure requires certain knowledge, it is better to contact a specialist.

- Short circuit of the wires of the network cable. You can determine the short circuit using a multimeter by setting it to the continuity mode. Not all models of submersible pumps provide for the replacement of the input cable; in some, the cable is filled with a compound. To fix the problem on such a model, the cable can be extended using twists.

The electrical component of the device is very important, since through its use the main work of the product takes place.

Excessive heating of the product in a short period of time

This failure is accompanied by excessive vibration of the entire device. There is only one reason, but to eliminate it, certain efforts must be made. You should not rush, as all actions must be accurate and correctly calculated.

Detachment of the electromagnet. Such a malfunction occurs due to the cessation of the water supply inside the product. It is necessary to completely disassemble the device and disconnect its electrical component. To determine the state of the magnet, just knock a little on its body. When peeling, play will occur.

To eliminate the malfunction, it is necessary to completely disconnect the magnet from the body of the device.By using a grinder or a hacksaw, you need to cut small (up to 2 mm) grooves on the inside of the case and on the magnet itself. To attach the magnet to the body of the device, you can use epoxy glue or sealant. After applying the material, the magnet is attached to the body and left for a while until it dries completely. After completing all the steps, the pump is assembled in the reverse order.

Pressure drop during device operation

The cause of the malfunction is simple, but requires a complete disassembly of the product. This failure occurs after a long period of operation of the device.

Increasing the gap in the vibrator. It is also possible to loosen the nuts, which should be properly tightened. Do not overdo it when tightening, the application of excessive force can lead to the breakdown of the nut.

If the reason is in the gap, then several copper washers should be used to reduce it. The number of washers should be determined experimentally. It is best to use exclusively copper washers, this material is durable, responds well to temperature changes.