- Faucet contamination

- Trouble-shooting

- Scale clogging

- Failure of the pressure reducer

- Thermostat failure

- Clogged mixer

- When you need specialist help

- How to repair a boiler with your own hands

- Leak in the heater

- No water heating

- The water temperature is above normal

- The boiler does not turn on for a long time, often turns off

- Do-it-yourself troubleshooting

- How does a boiler work

- Types of heaters according to the applied heating element

- Types of leaks

- Do-it-yourself Termex boiler repair

- Replacing the heating element

- Faulty thermostat

- tank leak

- Other malfunctions

- We make dismantling

- Water removal

- Open access inside

- Features of various designs

- Electric heaters

- Indirect heating systems

- Gas and flow structures

Faucet contamination

Liquid will flow in a trickle if mixer spout congestion has occurred. The pressure will be equally bad for both cold and hot water. To fix the problem, you need to carry out a number of procedures.

- Close the riser to turn off the water.

- Remove the mixer carefully.

- Unscrew the spout from the common body.

- Remove the mesh and rinse it under running water. In case of formation of salt deposits or dense dirt, let it soak in a special cleaning solution.

- Rinse the mixer spout thoroughly and clean the insides of dirt with a brush.

- Reassemble the faucet in reverse order and reinstall it. Don't forget to open the riser.

This procedure may take some time, as an alternative, you can simply replace the clogged mixer with a new one. Experts recommend replacing worn parts every few years to avoid serious breakdowns in the future.

Trouble-shooting

Having found a problem node, you need to start restoring the boiler's performance. The procedure depends on the specific reason that prevents the device from working normally. Let's consider the most common situations.

Scale clogging

Clogged water heater

Scale is deposits of insoluble carbonate salts on the walls of appliances for heating water. It is found in kettles, washing machines, water heaters.

The amount of scale depends on the hardness of the water. In regions with hard water, even for a year of operation of the boiler, the amount of salts deposited on the walls may be enough to completely block the lumen of the heating element tubes or significantly narrow it.

If scale has caused the failure of the water heater, repairs must be carried out in the following order:

- Open and remove the protective cover from the water heater.

- Unscrew the nuts holding the heating element in place and remove it.

Dismantling the heating element

Wash the boiler walls and the heating element coil from carbonate deposits. Organic acid - lemon or oxalic - will help dissolve the hard crust. You can also use industrial products - antiscale. Soak the part in an acidic solution to free it from accumulated deposits.

Cleaning the heating element from scale

- Using a tester, make sure that the heating element coil has not burned out due to a violation of heat removal by scale.

- If the spiral is intact, assemble the device in the reverse order of dismantling.

If the heating element is out of order, you will have to look for a new one or buy a new boiler - you need to choose the most economical solution. If repairs require large financial costs, it is more profitable to immediately purchase new equipment.

Failure of the pressure reducer

The pressure drops of the incoming water in the system can be from 2.5 to 7 atm. To compensate for surges at the inlet to the boiler, a special unit is installed - a gearbox. Its task is to ensure equal pressure at the outlet of the boiler and from the tap. If it fell due to the failure of the gearbox, it is necessary to adjust its operation or replace the broken part.

Low pressure in the main water supply also leads to a drop in pressure at the outlet of the water heater or instantaneous water heater. Unscrew the hose and check the pressure level: if water comes from the main water supply in a thin stream or does not flow at all, it is worth waiting, as the problem may arise due to repair work. If the pressure has not recovered within a few hours, it is worth contacting Vodokanal.

Thermostat failure

If the water leaving the boiler does not heat up enough or does not heat up at all, the cause may be the failure of the thermostat - it is he who is responsible for maintaining a constantly high temperature. To diagnose, turn off the power to the boiler and remove the thermostat from the housing.

Next, you need to perform the following steps:

- Press the thermostat button.

- Heat up the copper tip of the thermostat. If the node is healthy, the button should be disabled.

- Ring the thermostat circuits with a tester.

Typically, a thermostat malfunction is caused by an overheat protection trip. As a result of the operations performed, the device should start working, and the problems will disappear after it is installed in place. If the tester shows an open circuit, you will have to replace the burned-out thermostat.

Clogged mixer

If water comes out of the boiler with sufficient pressure, and it runs slowly from the tap, the reason lies in the clogging of the mixer with scale or rust. You will need to turn off the water, disassemble the mixers and thoroughly clean the filter mesh. You also need to inspect all the sealing gum and make sure that the crane boxes are working properly.

When you need specialist help

Some types of malfunctions of the Termex boiler can only be eliminated by the master, and in such cases it is highly not recommended to make repairs on your own. Problems that only a specialist can solve:

- incorrect operation and emergency shutdowns of new equipment for which warranty service has not ended;

- the settings on the electronic thermostat are reset;

- RCD often turns off the unit;

- a tank leak, although the effectiveness of such a repair is doubtful - it will be cheaper to purchase a new device.

But before calling the service, make sure that there is pressure in the line through which cold water is supplied. There are models of units that turn off the boiler in the absence of pressure in the supply.

How to repair a boiler with your own hands

Consider the main malfunctions and ways to eliminate them.

Leak in the heater

The most common problem with electric boilers is considered to be a leak. Occurs due to corrosion of the tank, when individual elements fail. Most often it is:

- Lack of grounding, which leads to electrical corrosion.

- Natural wear.

- Breakage of the safety valve.

What to do if the tank is leaking? You can not weld a leak yourself: this can lead to irreparable consequences!

Why You Shouldn't Repair Your Tank:

- The outer and inner parts are inseparable.

- In modern technology, glass enamel is used, which is easily damaged and cannot be repaired.

It happens that a leak occurs from under the flange that secures the heater. Then you need to drain all the water, remove the gasket and assess its condition. If it is damaged or worn, replace it. In order not to miscalculate with a new gasket, take the old one to the store.

No water heating

If cold water flows instead of hot water, the heater is broken. In addition to the lack of hot water, the RCD can be knocked out when the boiler is connected to the network. Problems with heating elements arise due to corrosion and scale.

How to understand that the scale completely covered the heating element:

- Since it precipitates, a rumble can be heard during water intake.

- There is a smell of sulfur.

To make sure that the heater is broken and does not work, diagnostics will help:

- Drain the tank.

- Open the heater cover.

- Measure the voltage at the terminals of the heating element using a tester (220-250 V).

- If everything is in order, set the multimeter to resistance measurement mode.

- Disconnect the heater from the mains.

- Disconnect the heater contacts.

- Attach the multimeter probes to them.

- When broken, the indicators will tend to infinity.

- If the part is operational, 0.68-0.37 ohms will be displayed on the screen.

Additionally, make sure that there is no current leakage to the case:

- Attach one probe to the copper pipe, the other to the heating element contact.

- If there is no leak, the display will show 1.

- If there is, the tester will give values with a minus sign or, conversely, too large.

Heater cannot be repaired, needs to be replaced

It is important to choose the right part for your model, so it is better to write down the part number or take it to the store

The water temperature is above normal

If too hot water is supplied, the problem is in the thermostat or thermostat. An additional sign of a breakdown is the lack of heating when the thermostat does not turn on the heating element. To perform diagnostics and repairs, the thermostat must be dismantled.

Troubleshooting:

- Disconnect the boiler from the network.

- Drain all water.

- Remove the tank from the wall.

- Remove the lid (for vertical models, the lid is located at the bottom, for horizontal models it is on the left, for Termex models the panel screw is in the middle).

- The thermostat is marked in yellow in the picture. Disconnect its contacts and remove from the case.

Now you can check the part for serviceability. The easiest way:

Press the safety button as shown in the photo:

- Heat the copper tip with a lighter.

- If OK, the button will be disabled.

Diagnostics with a multimeter is carried out as follows:

- Set the tester knob to the maximum value.

- Measure the resistance across the contacts.

- If the multimeter does not respond, the part cannot be repaired, it is better to replace it immediately.

The boiler does not turn on for a long time, often turns off

This also indicates a problem with the heater. Due to the scale, the water can heat up for a very long time, the consumption of electricity increases, as the heat removal is disturbed. To avoid breakage, change the magnesium anode in time, which purifies water from impurities.

There are such problems:

- During operation of the appliance, the surrounding equipment also heats up. This happens when the plug is designed for more power consumption than the socket, or the contact between them is broken. It is best to call an electrician to check and replace.

- Weak water pressure. It is necessary to check whether cold water is pumped normally. Inspect the mixer, perhaps the reason is in it. If everything is in order, inspect the relief valve. Clean it from dirt and scale.

- The boiler does not turn on at all. After the repair, the device did not work? You need to check the electronics and the main board. This work is best left to a specialist.

Now you are aware of the main problems of boilers. Carry out routine inspections, install water filters, clean the heater in a timely manner, then problems will not affect you.

This is interesting: Calculation of the current transformer according to the load power of 250 kW - we describe from all sides

Do-it-yourself troubleshooting

Heating of the cold water supply pipe can occur only for two reasons:

- Safety valve defective.

- The valve is not in place.

Repair comes down to the fact that it is necessary to replace the faulty valve or simply install it at the junction of the cold water pipe and the boiler pipe. The installation of a safety valve, if it is included in the kit, is mandatory at the request of the manufacturer. Failure to install it will result in a denial of warranty repair. The absence of a valve can lead to a rupture of the tank due to water hammer.

The leakage of the water heater tank occurs in the event of a leaky connection between the flange and the body or when the tank is worn. In case of damage to the internal tank, it is impossible to repair the water heater with your own hands and you will have to replace it if the boiler model allows.Or you have to buy a new water heater.

If it is determined that it is leaking from under the flange gasket, drain the water from the tank as above, remove the flange and visually inspect the condition of the gasket. Buy a new one, taking the defective one as a sample. Replace the gasket and continue using the boiler.

Heating of the plug can occur due to loosening of the contacts in the socket and insufficient contact between it and the plug. With prolonged use and constant overheating of the contacts, the case may melt, which will lead to a short circuit.

Heating of the plug can also occur with insufficient power sockets and electrical wiring in the apartment. 10A must be marked on the socket housing.

If the plug body melts, it is cut off and replaced with a new one.

The boiler is energized, the machine turns off or it does not heat the water - this indicates the failure of the heating element. If, when disassembling the boiler, it is found that the heater is black, it burst along - this will unmistakably indicate its failure.

If the heating element does not have obvious signs of breakdown, you can diagnose the malfunction using a multimeter.

- Step 1. Wet the heater tubes with water. Set the multimeter pointer on the ohmmeter scale to the maximum value and measure the resistance, touching the tube of the heating element with one probe of the instrument, and with the other any of its contacts. If numbers appear on the display, the heater is defective and must be replaced. "1" indicates no leakage "to the body"

- Step 2. Touch the probes with the contacts of the heating element. If the numbers appear, there is no break in the spiral, it is working. "1" on the display in this case indicates a break in the spiral and a malfunction of the element.

These are the main malfunctions of the boiler, when do-it-yourself repairs are possible.

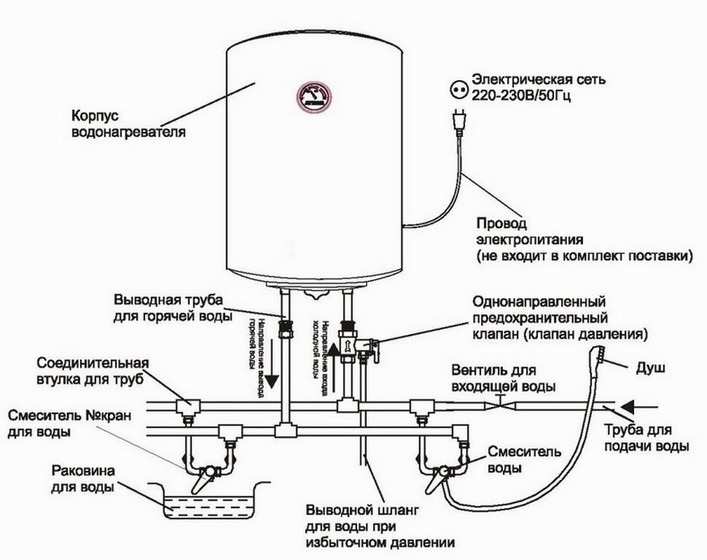

How does a boiler work

Distinguish between storage and flow type water heaters. The first consist of a large container in which a heating element is installed. Inside the device water enters, which is stored there at a certain temperature.

With the help of a temperature sensor connected to a thermostat, the temperature is maintained at the set level. To prevent the loss of thermal energy, the body of the storage tank is covered with a layer of insulation.

Flow models work differently. They also have a housing and a heating element, but no water is stored inside. The device turns on at the moment when a stream of water begins to pass through its body. The liquid quickly heats up to the desired temperature. These devices are more powerful than storage models, they consume more electricity. But their dimensions are compact and installation is a bit easier.

And yet, in everyday life, the accumulative version of the water heater is more often used. Breakdowns for different types of devices are similar, and they are eliminated by approximately the same means.

To automate the operation of the water heater, use a thermostat. This element receives data on the current state using a thermal sensor. It turns on and off the heating element based on the incoming information. This helps not only to maintain the optimal temperature inside the drive, but also makes it possible to save energy.

The device also prevents dangerous overheating of the water, which can cause a serious accident.

Hot water is gradually taken from the tank and replaced by cold streams from the plumbing. At this point, the heating element usually turns on. If the hot water in the boiler has not been used for a long time, it may cool down.Too low temperature also gives a signal to turn on the heating element.

Types of heaters according to the applied heating element

There are boilers with “dry” and “wet” heating elements. In the first version, the heating element is placed in a special flask, and in the second it is in direct contact with water. Both models have certain advantages. In terms of boiler repair, it is believed that it is much easier to replace a “dry” heating element than a “wet” one, since for this you just need to remove it from the flask and put a new element there.

In the case of a “wet” heating element, you will first have to completely drain the water from the tank, and only then make a replacement. Usually, “dry” heating elements are less productive than the “wet” version, therefore, not one, but two such heating elements are most often installed in the boiler.

Due to the peculiarities of operation, “dry” heating elements often burn out and need to be replaced, therefore models with “wet” heating elements are more popular. It is worth noting that you can also find modern boilers with very reliable “dry” heating elements of the latest generation, but the cost of such devices may be too high.

But the type of heating element does not affect the amount of scale formed during operation. But if a “wet” element has scale deposited directly on the surface, then with a “dry” heating element, deposits accumulate on a protective flask.

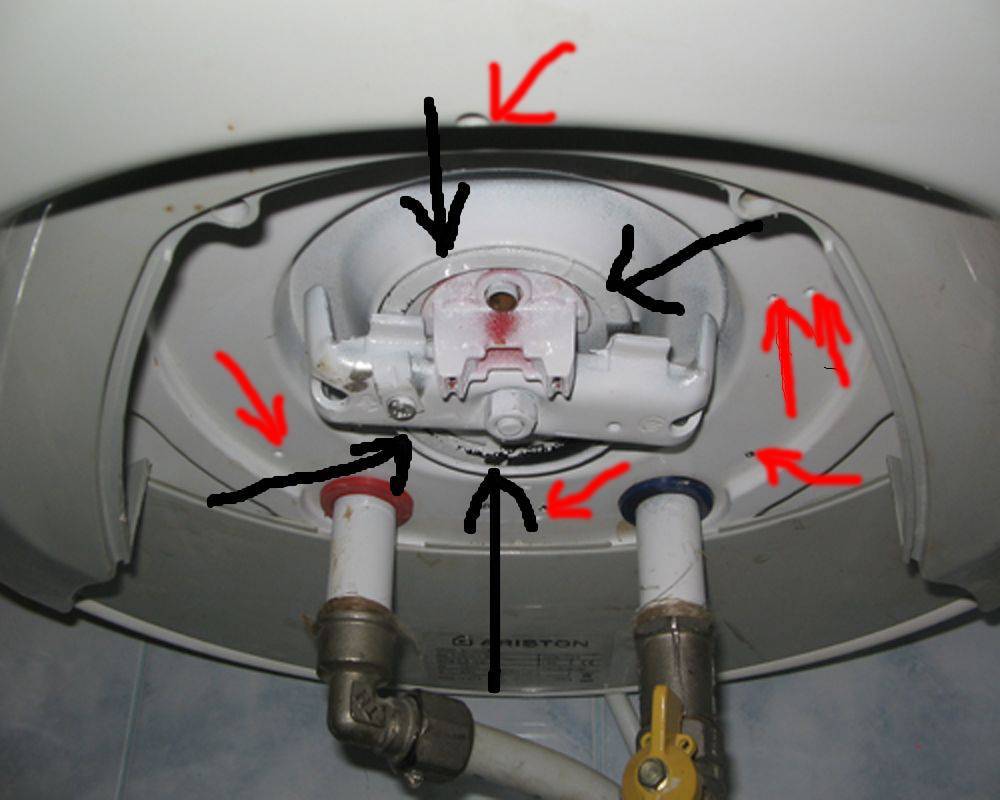

Types of leaks

If the boiler is leaking from above or below

It is necessary to disconnect it from the mains, substitute a basin and make a thorough visual inspection. Water leaks can be different: water can simply drip, or it can flow under pressure. In most cases, water flows from the bottom of the water heater.Use a flashlight to find the source of the leak.

The simplest case is when the leakage comes from the safety valve. It is adjusted at the factory so that excess pressure during water heating is released through a small fitting.

A simple solution to this issue is to divert this water to the sewer using a plastic flexible pipe with a diameter of approximately 8 mm. In this case, you need to think about where to connect the second end of the tube. If the boiler is hanging in the toilet, you can bring this tube into the flush tank;

Leakage from connections

The source of the leak may be from loose connections in the inlet and outlet pipes in the boiler itself. This is easily eliminated - all threaded connections are repackaged;

Leakage from under the cover

Next, with the help of a flashlight, the place where the water flows from is determined. If leaks are found from under the cap, this is one of the best options. Since the cover is pressed against the boiler body through the gasket, you can try to eliminate the leak by tightening the nuts of the bolts on the cover.

If this does not work, it is necessary to drain the water from the boiler, remove the cover and change the gasket. And before that, you must disconnect all electrical wires.

Advice: in order not to be confused in the future, you can first take a picture of all connections on a digital camera or smartphone and display it on the laptop screen.

These are, perhaps, all the options in which boiler leaks can be eliminated without replacing it. However, in most cases, about 80 percent, the leak comes from the top or bottom of the boiler body.

It's important to know:

often it is almost impossible to determine the location of the fistula in the body, since it is covered with heat-insulating material and an outer casing.Water can flow down under the thermal insulation or flow out in the area of the thermometer. In the lower part of the boiler there are special holes, in case of water leakage from which it is possible to determine exactly that it is the water heating tank that is flowing.

In the lower part of the boiler there are special holes, in case of water leakage from which it is possible to accurately determine that it is the water heating tank that is flowing.

These are the most difficult and unprofitable options. All of the listed leak options refer to the most common brands on the market, such as Ariston and Termex.

Do-it-yourself Termex boiler repair

Before proceeding with the repair, first collect the necessary tools: a set of keys, an adjustable wrench, electrical tape, various screwdrivers, pliers. After that, turn off the water by shutting off the inlet and outlet taps to the water heater. Then drain the water from the boiler tank, disconnect it from the mains.

The next step is to remove the protective cover. If you have a vertically located boiler, then the cover is located below, and in the case of a horizontally located boiler, it is on the left or in front.

When dismantling the cover, pay attention to the stickers. Often the screws for its fastening are located under these stickers.

If you've removed all the screws and the cover still won't come off easily, check the stickers again.

Replacing the heating element

First, perform all of the above steps, remove the tank cap.

To make it more convenient to work, you can even remove the tank from the wall.

It is worth noting that most Termex models have not one, but two heating elements. Therefore, it is imperative to remember how and in what sequence the parts must be connected. And it is better to photograph the whole process.

To remove the heating elements from the Termex water heater, remove the top cover by unscrewing the bolt; disconnect all plugs and unscrew the heating element mounting bolts.

The heating element itself is turned off as follows:

- after removing the cover, find the protective thermostat, remove the tips from it;

- also remove the tips (3 pieces) from the heating element;

- cut the plastic clamp;

- unscrew the screws, while removing the sensor;

- now disconnect the cable and unscrew the four screws;

- then it is necessary to dismantle the nut on the clamping bar and pull out the heating element.

After dismantling the heating element, it is imperative to clean the surface of the tank from dirt and scale. Only after that you can install a new heating element and collect everything back.

Do not forget that the heating element does not always need to be changed. If the water in the tank is still heated, but it happens slowly, then, most likely, scale has formed on the heating element. Then dismantle it and descale it. Then install. The problem should be gone. Also, do not forget that it is desirable to clean the heater with chemicals, and not scrape off the dirt. In the latter case, there is a possibility of damage to the part.

To clean the heating element, you can use a solution of citric acid or vinegar (its percentage in the solution should be about 5%). The part must be immersed in liquid and wait until the scale falls off. Then you need to rinse the heating element.

Faulty thermostat

The thermostat in Termex water heaters is located under the cover, next to one of the heating elements, and its sensor is located inside the tank.

Sometimes the thermostat fails. This element cannot be repaired and must be replaced.To replace, you need to make all the preparatory steps, remove the cover, then remove the thermostat. But before dismantling, we recommend checking this part. To do this, use a lighter to heat the tip of the sensor (copper). If the thermostat is working, then you will hear a characteristic click, which means that the protection mechanism has worked and the circuit has opened. Otherwise, you will have to replace the part.

tank leak

No matter how trite it may sound, but first you need to find where the water flows from. A lot depends on this, because if the tank is rotten, you will have to buy a new water heater. So:

- if water oozes from the side seam, then the container is rusted, and repairs cannot be made;

- if water comes out from under the cover at the bottom, then you need to disassemble the tank.

If traces of leakage are located in the places where the heating elements are attached, then your water heater is not hopeless and can be saved by replacing the gasket.

In the case of the second option, complete all the preparatory steps, then remove the plastic cover. Next, take a close look at where the water is leaking. If it comes out near the flange, then the rubber gasket has deteriorated (less often this is a problem with the heating element). Otherwise, the tank has rusted, the boiler can be thrown away. To replace the gaskets, you need to remove the heating element. But at the same time, it is necessary to carefully consider the heating element itself. If it cracked, then it is also better to replace it.

Other malfunctions

If you checked and replaced all the parts, but the boiler still does not work, then it is quite possible that the electronics have failed. The control board cannot be repaired, and it will be extremely difficult to find a similar one in a store.Therefore, in this case, we recommend contacting specialists.

We make dismantling

Each owner of Ariston water heaters should know that when replacing the thermostat, relay and safety valve, the tank does not need to be dismantled. Drainage of water and complete disassembly of the boiler is carried out only during maintenance work and when replacing a burned-out heating element.

Disassembly of the product is divided into standard stages:

- Disconnect the water heater from the household power supply.

- Drain the water from the tank.

- Dismantle the flanges, gain access to the inside of the water heater.

Before disassembling the product, you need to make sure that it is disconnected from the mains: if the heater is powered by a separate line, then you need to turn off the circuit breaker, if just through the cord, then just unplug it.

Some readers may wonder: why emphasize these points so often? But statistics say that during home repairs or when burnt parts are replaced, very often craftsmen who neglect safety precautions receive electrical injuries of varying severity.

Only after a blackout can you start dismantling the Ariston boiler with your own hands:

unscrew the cover, which is fastened with screws;

before dismantling, take a picture of the location so as not to confuse anything during assembly;

disconnect the three-core cable, the first two wires - phase and zero were connected to the thermostat, so you can carefully remove it.

All work on the electrical part has been successfully completed, you can start draining the water from the tank.

Water removal

If the initial installation of the water heater was carried out by a service master, then he had to install a special tee with a drain tap and screw the fitting into it.Quite a convenient device - the user easily connects the hose, as shown in the photo, and drains it into the bathroom water. In the absence of a special device, water is removed by connecting a hose directly to the product nozzle.

Draining water can take several minutes if the heater capacity is up to 50 liters, and when you have Ariston 80 liters, the wait will take up to 30 minutes or more.

Hose with fitting

Open access inside

All modifications of products under the Ariston brand have an oval flange on which tenes, an anode made of magnesium and a tube with a thermostat inside are installed. A gasket made of elastic rubber is put on the bottom of the flange body to ensure tightness. The flange is fixed with a U-shaped bar, which is fixed with a nut.

We unscrew the nut, carefully push the flange inward, turn and remove it outward. Next, the replacement of failed parts and the cleaning of surfaces from salt and lime deposits are carried out.

Remove excess debris at the bottom of the tank, visually inspect the rubber seal, if everything is in order, then do not change it - it is very expensive, and it is very difficult to get a new one. Dismantling and subsequent assembly can be done independently by any user without special training. Attached is this video to help:

The statistics of the operation of similar heaters allows us to conclude: regular inspections of the wear of the magnesium anode, cleaning of the heating element, prevention of the internal coating of the tank must be done regularly and regularly, this will significantly extend the life of the product.

Features of various designs

Before you start repairing the water heater with your own hands, you need to figure out what type the device belongs to. There are several varieties:

- electric boilers;

- flowing;

- indirect heating systems;

- gas columns.

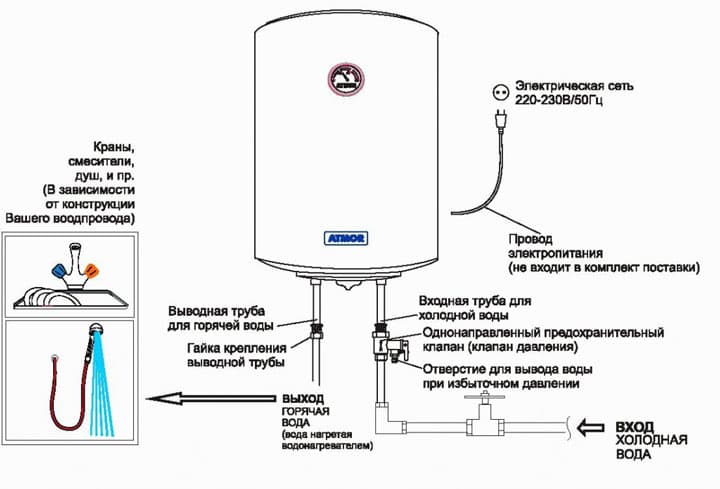

Electric heaters

This type of boilers is considered the most popular. The design consists of a tank, a heat-insulating layer (polyurethane foam is often used), as well as an upper casing.

The heating element is located at the bottom of the device. Water is heated to a certain temperature, which is pre-set on the thermostat, the maximum value is +75°C.

If there is no water intake, the device maintains temperature indicators, turning the heating element on and off. It is equipped with protection against overheating, so when the maximum performance is reached, the device turns off.

The optimum temperature value is + 55 ° C, it is in this operating mode that the structure will last longer and save electricity.

This device is the most common

The intake of hot water is carried out through a tube, which is located at the top of the device. The cold fluid inlet is located at the bottom of the device. The metal tank is protected from corrosion by a special magnesium anode, which has a certain working life. The element must be replaced once or twice a year, depending on the hardness of the water.

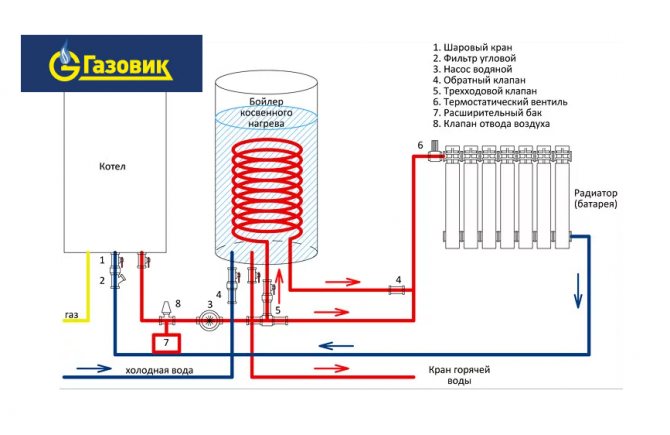

Indirect heating systems

Such products do not independently generate thermal energy, water is heated using a coil in which the coolant is located.

Cold water enters from the bottom of the device, hot water exits from above. Indirect heating devices can provide a large amount of hot water, which is why they are often installed in large houses. The principle of operation is the exchange of heat of liquids with different temperatures.In order for the output to be + 55 ° С, heating is carried out up to + 80 ° С.

The process takes a lot of time, this feature must be taken into account when choosing a suitable device. Like electrical counterparts, indirect ones are equipped with a magnesium anode. The structures are wall or floor, in addition, they can be connected to a double-circuit gas boiler. More expensive models are equipped with additional electric heating elements, which reduce the heating time as needed.

Gas and flow structures

Gas appliances are only wall-mounted. Inside the structure there is a heat-insulating layer. The chimney pipe is located on top, and the gas burner is located below. The latter is a source of heating, in addition, it is assisted by the heat exchange of combustion products. An automatic electronic system monitors and extinguishes the gas as needed. The column is equipped with a protective anode.

Gas water heaters produce a large amount of hot water in a short period of time.

Electrical systems carry out heating with the help of heating elements of increased productivity. Despite their small dimensions, the products are high-power, so their scope is limited. Hot water is supplied regularly without interruption for heating.

Gas water heaters are more efficient