- Most common water heater failures

- Reasons for leaks

- Features of connecting a floor water heater

- How does a boiler work

- Types of heaters according to the applied heating element

- Features of heating devices

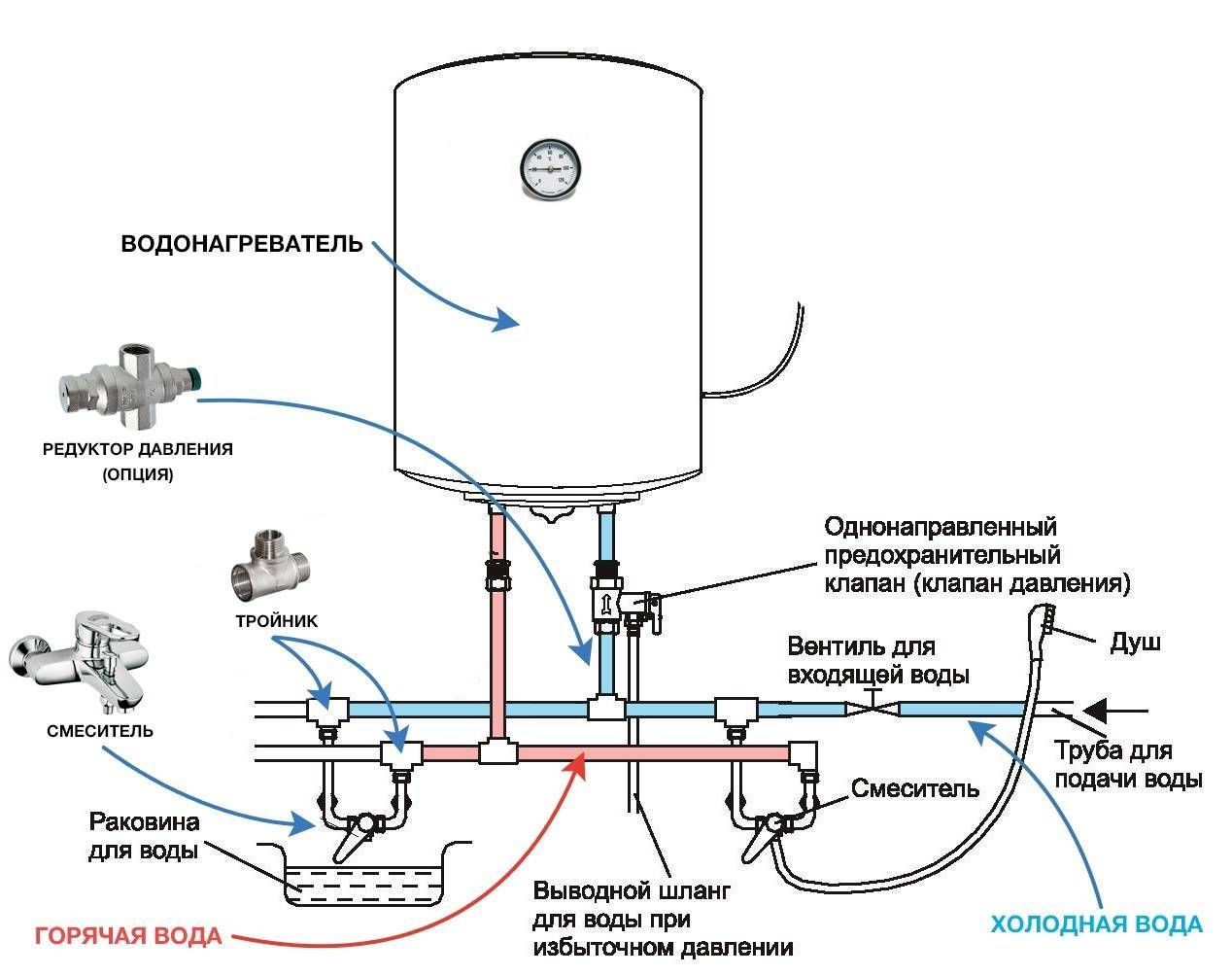

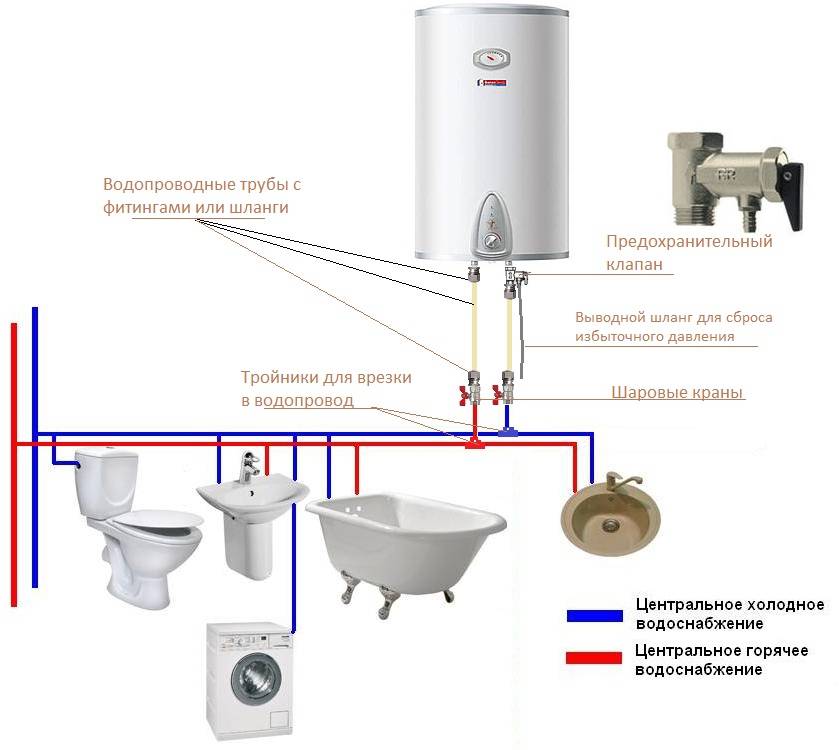

- Methods for connecting a water heater to a water supply

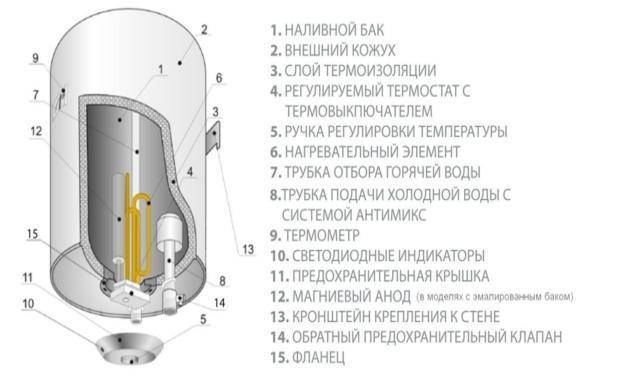

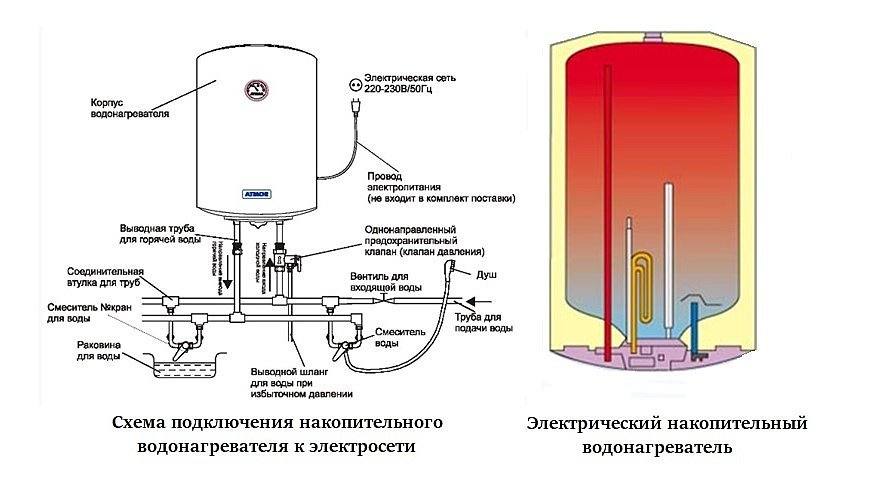

- The device of storage and instantaneous water heaters

- Causes of breakdowns

- Features of various designs

- Electric heaters

- Indirect heating systems

- Gas and flow structures

- How to use the water heater taps (closing and opening)

- Types of malfunctions and their causes

- Replacement of heating element or anode

- Elimination of leaks

- Device device

Most common water heater failures

In case of independent intervention in the design of the water heater, the warranty service of the boiler, which is provided by the manufacturer's support service, is canceled. That is why, if a problem occurs, you should carefully analyze the nature of the malfunction, as well as determine the best way to eliminate it.

Consider the most common problems that occur during the operation of the water heater

- Cold water outlet from the boiler. This problem often occurs due to a malfunction of the heating element. Also, insufficient water heating can be caused by poor electrical contact between the heating element and the thermostat.To restore the functionality of the equipment, it is necessary to clean or replace the heater according to the above instructions.

- The heating element does not turn on when there is voltage in the network. If the heating element does not respond to external influences or the second thermostat is activated, the equipment should be checked for proper operation.

To do this, it is dismantled and the current resistance is measured. Checking the mechanism should begin with setting the adjusting handle of the tester to the maximum position. Then measure the resistance at the thermostat terminals.

If there is no reaction during the testing of the device, the element has become unusable and cannot be repaired. In this case, it is necessary to perform its complete replacement.

When the control thermostat is triggered, the following actions should be performed:

- - set the thermostat control knob to the “Min” position;

- - fix the measuring probes of the device on the terminals of the mechanism;

- - heat the thermostat device (flask or rod) with a lighter.

If the thermostat is working, then in the process of carrying out these manipulations, a thermal relay is activated, which opens the circuit. In this case, the resistance on the contacts, as a rule, tends to infinity. The absence of this phenomenon is a sign of thermostat burnout.

- Supply of excessively hot water to the consumer. Incorrect operation of the boiler often indicates a breakdown of the thermostat. Checking or replacing the mechanism is performed in accordance with the instructions described above.

- Heating the plug from the boiler cord. As a rule, this phenomenon occurs when there is insufficient power in the electrical wiring, sockets in the apartment, or as a result of the presence of loose contacts.

Remember, prolonged use of faulty equipment will inevitably lead to melting of the socket housing, and may also cause a short circuit.

To prevent overheating of the plumbing structure, the installation of electrical fittings marked with at least 10 A will help.

- Heating of the cold water pipeline. This process often occurs due to the failure of the safety valve. At the same time, the shut-off valve begins to let hot water through. Replacing the faulty valve with a new mechanism will help fix the problem.

- Frequent cycles of switching on and off the boiler. As a rule, such a problem occurs when a significant amount of scale forms on the heating element. Thorough cleaning of the heating coil will help to eliminate the malfunction. However, if this problem arose immediately after the purchase of the product, the installed heating element does not correspond to the capacity of the tank.

Following the above recommendations, it is not difficult to repair the water heater with your own hands. To do this, you need to determine the nature of the malfunction, as well as study the sequence of work to eliminate it.

Reasons for leaks

The tank water heater is a fairly simple device. Its basis is a container made of steel, covered from the inside with a protective layer, which prevents premature corrosion of the container walls and, accordingly, prolongs the service life.

The coating of the inner surface can be made of enamel, glass enamel, glass ceramic, titanium protective layer, stainless steel layer, etc.

Usually this coating is the development of the manufacturer itself, and is kept in strict confidence.

At the bottom of the boiler there is a cover in which a heating element, a thermostat and a magnesium anode are mounted. There is also a thermometer in the tank. An inlet pipe from the water supply is connected to the boiler from below and a hot water pipe leading to the shower and kitchen sink faucets is output.

Outside, the water heater tank is covered with a layer of thermal insulation made of polyurethane foam and a decorative metal casing. The main reasons that contribute to the premature failure of the boiler capacity are the following:

- if the pressure in the plumbing system is more than 2 atmospheres, it is necessary to put a reduction gear in front of the boiler, since when heated, the pressure will rise even higher, and an unacceptable deformation of the walls will occur with a violation of the integrity of the protective coating;

- a safety valve is not installed directly in front of the boiler inlet, which relieves excess pressure when water is heated in the water heater;

- if the boiler is not prevented once a year, then scale forms on the walls and the heating element, which worsens the operation of the heating element and leads to premature wear of the boiler itself. It is also necessary to change the magnesium anode once a year, which prevents corrosion of the walls.;

- heating the boiler to a high temperature above 70 degrees Celsius. The best option would be to operate the water heater at temperatures up to 50 degrees;

- do not drain the water from the boiler for a long time - this leads to premature corrosion of the metal.

By putting into practice all the above warnings, you can significantly increase the service life of the storage water heater and thereby provide yourself with comfortable conditions for many years.

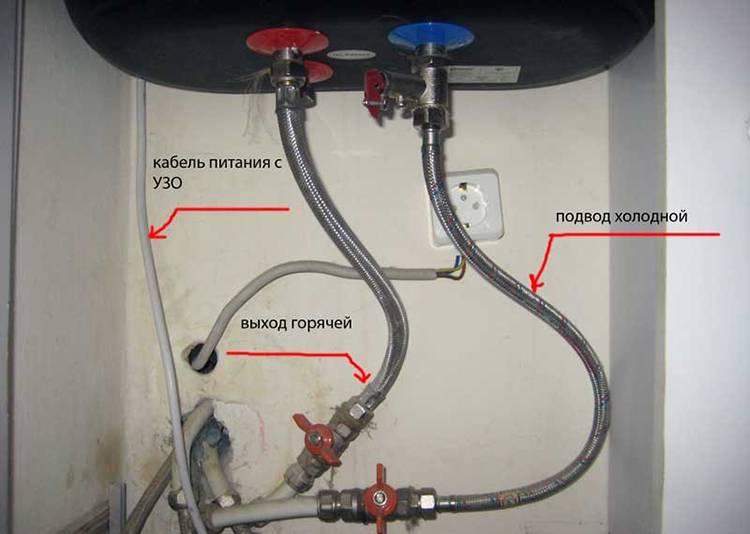

Features of connecting a floor water heater

Since such a heater is installed on the floor, all supplies to it are located not on the bottom panel, but at the bottom of the side or rear vertical wall. In everyday life, such storage boilers are rarely used, since the smallest of them have a tank volume of 100-150 liters. In addition, they take up a lot of space and have a large power, placing serious demands on electrical wiring and safety automation.

Connection to water for floor-standing heaters is carried out similarly to wall-mounted models. The connection to the mains, due to the relatively high power, must be carried out exclusively through a separate shield.

rmnt.ru

How does a boiler work

Distinguish between storage and flow type water heaters. The first consist of a large container in which a heating element is installed. Inside the device water enters, which is stored there at a certain temperature.

With the help of a temperature sensor connected to a thermostat, the temperature is maintained at the set level. To prevent the loss of thermal energy, the body of the storage tank is covered with a layer of insulation.

Flow models work differently. They also have a housing and a heating element, but no water is stored inside. The device turns on at the moment when a stream of water begins to pass through its body. The liquid quickly heats up to the desired temperature. These devices are more powerful than storage models, they consume more electricity. But their dimensions are compact and installation is a bit easier.

And yet, in everyday life, the accumulative version of the water heater is more often used.Breakdowns for different types of devices are similar, and they are eliminated by approximately the same means.

To automate the operation of the water heater, use a thermostat. This element receives data on the current state using a thermal sensor. It turns on and off the heating element based on the incoming information. This helps not only to maintain the optimal temperature inside the drive, but also makes it possible to save energy.

The device also prevents dangerous overheating of the water, which can cause a serious accident.

Hot water is gradually taken from the tank and replaced by cold streams from the plumbing. At this point, the heating element usually turns on. If the hot water in the boiler has not been used for a long time, it may cool down. Too low temperature also gives a signal to turn on the heating element.

Types of heaters according to the applied heating element

There are boilers with “dry” and “wet” heating elements. In the first version, the heating element is placed in a special flask, and in the second it is in direct contact with water. Both models have certain advantages. In terms of boiler repair, it is believed that it is much easier to replace a “dry” heating element than a “wet” one, since for this you just need to remove it from the flask and put a new element there.

In the case of a “wet” heating element, you will first have to completely drain the water from the tank, and only then make a replacement. Usually, “dry” heating elements are less productive than the “wet” version, therefore, not one, but two such heating elements are most often installed in the boiler.

Due to the peculiarities of operation, “dry” heating elements often burn out and need to be replaced, therefore models with “wet” heating elements are more popular.It is worth noting that you can also find modern boilers with very reliable “dry” heating elements of the latest generation, but the cost of such devices may be too high.

But the type of heating element does not affect the amount of scale formed during operation. But if a “wet” element has scale deposited directly on the surface, then with a “dry” heating element, deposits accumulate on a protective flask.

Features of heating devices

Each device has its own features of use and assembly nuances. Before carrying out any measures for the purpose of repairing equipment or preventive actions, it is worth reading the instructions that came with the equipment. This manual will give you a complete picture of what valve or lever means. Before figuring out how to drain the water from the boiler, it will not be superfluous to familiarize yourself with the nuances of the issue:

- First, inspect the room where this device is located. If the boiler room or utility room is constantly heated, then this process is not necessary, even if the homeowners are going to leave for a long time.

- If the boiler structure is made of stainless steel, then metal corrosion in a humid environment will be much faster, and periodic draining is not necessary.

Stainless steel boiler

- A copper container sometimes needs to be completely freed from water. Copper is very sensitive to hard water and if a person leaves for a long time, it is better to leave the tank empty.

- If the water supply comes from a central water supply, and not from a well, then a drain is not needed, because the bleach contained in the water will not allow bacteria to multiply and prevent the appearance of an unpleasant odor.Wells of this property are deprived.

- If the owners of the water heating system use a well, then periodic draining is necessary. This will prevent water stagnation and rotting.

If, nevertheless, stagnation has occurred, then the boiler device must be washed. To do this, turn on the tap and drain the water from the tank for a long time until cleaning occurs. After that, the new water in the tank must be heated several times.

After complete draining, new water needs to be heated several times.

Methods for connecting a water heater to a water supply

There are several ways to connect water heating equipment in an apartment, and the features of the work performed directly depend on the availability of water pipes of a centralized water supply system:

- The use of water storage tanks, which are usually installed at roof level in the absence of a water main. The main rule for connecting a water heater to a water tank is strict adherence to the optimal distance, which cannot be less than two meters. If the water tank is installed at a shorter distance, then the connection diagram should be represented by a standard tee, a ball drain valve, and a safety type valve.

- Connecting water heating equipment to a centralized plumbing system is a simple undertaking that is easy to do on your own. For this purpose, the standard installation of the device on the wall with the help of special fasteners is carried out, followed by connection to the water supply.

How to connect a storage water heater in an apartment

When connecting a water heater to storage tanks, it is very important to consider that the pressure inside the system should not exceed 6 bar. If the pressure is higher than the standard parameters, then it is mandatory to install a gearbox in front of the water-heating equipment that protects the water heater from failure. Special connection conditions are necessary if the water used for supply is of poor quality.

In this case, a special filter must be installed in front of the water-heating equipment.

Special connection conditions are necessary if the water used for supply is of poor quality. In this case, a special filter must be installed in front of the water-heating equipment.

The device of storage and instantaneous water heaters

Deciding to independently identify and eliminate the malfunction of the water heater, it is necessary to have a clear idea of \u200b\u200bits design and components. The internal tank of storage water heaters is made of stainless steel, which can be used in the food industry and medicine, with a thickness of not more than 1-2 millimeters. A sufficiently thin layer, subject to corrosion, often causes a leak. To avoid this, it is necessary to systematically replace the magnesium anode once a year.

The heating element is a heating element of various power. The higher the power, the faster the water heater heats the water. The magnesium anode is located in close proximity to the heating element, its main task is to protect the water tank and heating element from corrosion.

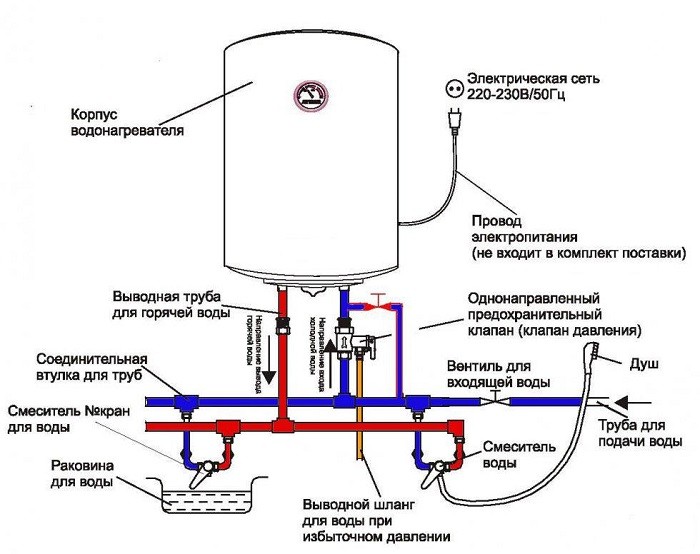

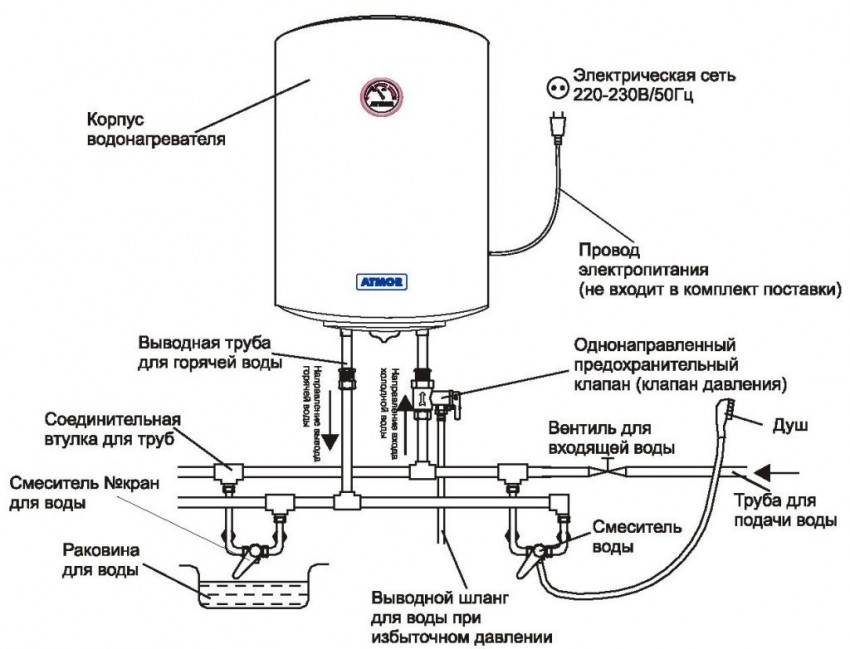

Water heater connection diagram.

The body of an electric boiler can be made of plastic or metal.Faults associated with the housing are the result of mechanical damage. Parts in which boiler malfunctions rarely occur are pipes for the outlet of hot and cold water.

The thermostat is a sensor that indicates the temperature of the water in the tank. Malfunctions that occur due to its failure are not capable of seriously impeding the operation of the water heater and only create some inconvenience during use. Thanks to the thermostat, the water heating system is controlled and the water heater is protected from overheating.

The instantaneous water heater has a similar structure, except for the absence of a storage tank for water and the use of heating elements with greater power.

Causes of breakdowns

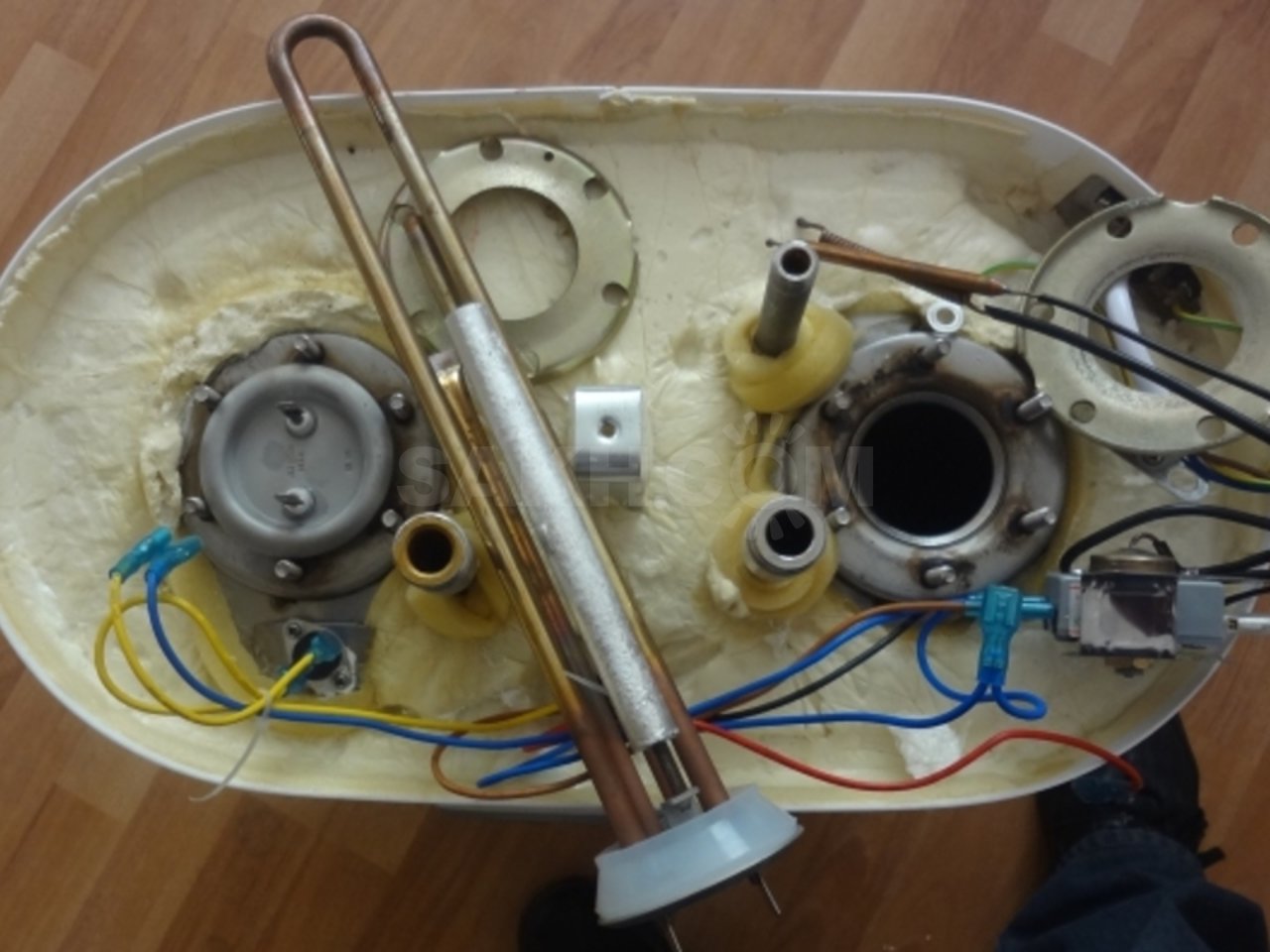

The beginning of the dismantling of the water heater Ariston

Despite the fact that the Italian company has been the world leader in the production of water heating equipment for more than a quarter of a century, given the quality of our water and the parameters of the power grid, breakdowns are also characteristic of such reliable equipment.

Here, the weak points were: a tubular heating element, a check valve and an anode made of magnesium.

However, these are fairly simple breakdowns and they can be easily fixed by hand at home with a minimum set of “garage” tools.

The Ariston storage tanks themselves have a fairly simple internal layout for repair or maintenance.

The causes of water heater failure are:

- the formation of scale (corrosion) on the heating element, hard water speeds up this process several times;

- unstable mains voltage leads to failure of the electronic control unit;

- decrease in water flow due to debris in the filter and non-return valve on the water supply pipe.

To return the boiler to normal operation, you will need some spare parts and cleaning it, washing the internal walls from plaque of solid salts.

This is important: when electrical appliance is on guarantee, do not interfere with its operation during this period, otherwise the free warranty service will be denied.

The main signs of malfunction:

- the operation of the machine after turning on the boiler indicates a malfunction of the electric heating element, it may burn out due to the formation of scale on it or an elementary lack of water;

- overheating of water indicates the failure of the thermostat, the cause of its failure may be increased humidity;

- heating of switching electrical equipment indicates an underestimated power of the socket supplying the electrical wiring;

- the formation of streaks on the walls of the tank and in its lower part.

During the operation of the electrical appliance, the display designed for the convenience of the user may fail (the electronic display reflects the current parameters, mode of operation). Here you may need to turn to specialists, although this breakdown does not significantly affect the operation of the water heater.

Features of various designs

Before you start repairing the water heater with your own hands, you need to figure out what type the device belongs to. There are several varieties:

- electric boilers;

- flowing;

- indirect heating systems;

- gas columns.

Electric heaters

This type of boilers is considered the most popular.The design consists of a tank, a heat-insulating layer (polyurethane foam is often used), as well as an upper casing.

The heating element is located at the bottom of the device. Water is heated to a certain temperature, which is pre-set on the thermostat, the maximum value is +75°C.

If there is no water intake, the device maintains temperature indicators, turning the heating element on and off. It is equipped with protection against overheating, so when the maximum performance is reached, the device turns off.

The optimum temperature value is + 55 ° C, it is in this operating mode that the structure will last longer and save electricity.

This device is the most common

The intake of hot water is carried out through a tube, which is located at the top of the device. The cold fluid inlet is located at the bottom of the device. The metal tank is protected from corrosion by a special magnesium anode, which has a certain working life. The element must be replaced once or twice a year, depending on the hardness of the water.

Indirect heating systems

Such products do not independently generate thermal energy, water is heated using a coil in which the coolant is located.

Cold water enters from the bottom of the device, hot water exits from above. Indirect heating devices can provide a large amount of hot water, which is why they are often installed in large houses. The principle of operation is the exchange of heat of liquids with different temperatures. In order for the output to be + 55 ° С, heating is carried out up to + 80 ° С.

The process takes a lot of time, this feature must be taken into account when choosing a suitable device.Like electrical counterparts, indirect ones are equipped with a magnesium anode. The structures are wall or floor, in addition, they can be connected to a double-circuit gas boiler. More expensive models are equipped with additional electric heating elements, which reduce the heating time as needed.

Gas and flow structures

Gas appliances are only wall-mounted. Inside the structure there is a heat-insulating layer. The chimney pipe is located on top, and the gas burner is located below. The latter is a source of heating, in addition, it is assisted by the heat exchange of combustion products. An automatic electronic system monitors and extinguishes the gas as needed. The column is equipped with a protective anode.

Gas water heaters produce a large amount of hot water in a short period of time.

Electrical systems carry out heating with the help of heating elements of increased productivity. Despite their small dimensions, the products are high-power, so their scope is limited. Hot water is supplied regularly without interruption for heating.

Gas water heaters are more efficient

How to use the water heater taps (closing and opening)

Cranes indicated in the diagram by numbers "1" and "2" will be needed to turn off the water when the electric heater is not in use. For example, if we needed to remove the last one.

Cranes indicated in the diagram by numbers "3" and "4" available in any apartment connected to the central water supply, located after the risers, because we sometimes have to turn off the water for various reasons.

Let's pay attention to the tap "4" - it blocks the circulation of hot water between the apartment and the riser during the operation of the device. If the tap is not closed, then all residents of the entrance can use hot water from our water heater - the water will go to the riser. The main rule of use - if hot water is supplied by the city boiler house, the water heater is in off mode - "1" and "2" taps are closed, and "3" and "4" are respectively open

If the boiler room "gets up" for prevention and hot water is turned off, we connect our device to the 220V network, open the taps "1" and "2", and close the tap "4"

Main rule of use - if hot water is supplied by the city boiler house, the water heater is in the off mode - "1" and "2" taps are closed, and "3" and "4" are respectively open. If the boiler room “gets up” for prevention and the hot water is turned off, we connect our device to the 220V network, open the taps “1” and “2”, and close the tap “4”.

Types of malfunctions and their causes

There are many reasons why boilers fail. Most of them can be fixed on your own. Main problems:

- The device does not heat water. The reason may be the failure of the heating element or the electrical system. If the heating procedure takes longer than usual, this indicates multiple scale that needs to be removed. In addition, due to deposits, the boiler may turn on / off more often.

- Overheating of water is a consequence of a broken thermostat.

- A leak from under the flange indicates damage to the container due to mechanical actions or metal corrosion.

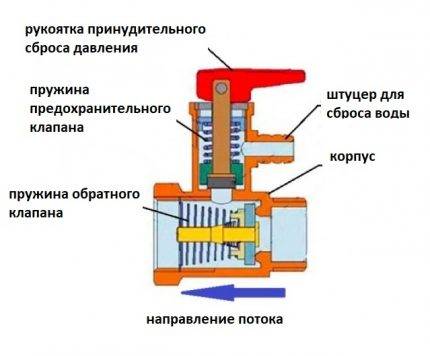

- If the machine is constantly making noise, there may be a lot of scale on the heating element, or the check valve is broken.

- The display shows an error.Some devices are equipped with an electronic system, a failure in which may occur due to power surges or module failure.

- Lack of hot water supply indicates a breakdown of the heating element or thermostat.

- Hot water that is dark in color indicates the presence of corrosion, the appearance of which can be provoked by hard water. If the tank is damaged, most likely you need to purchase a new device.

- The heater is energizing. This situation can happen due to damage to the cable or rupture of the heating element.

- The device does not turn on or off - the reason is the burnout of the contacts or the melting of the buttons.

- Constant burnout of heating elements is facilitated by a large amount of scale or improper installation of the device.

- If air has appeared in the water heater, it means that the gaskets have worn out or the non-return valve has broken.

Replacement of heating element or anode

If the temperature sensor or heating element burned out, the magnesium anode replacement time has come. First you need to disconnect the device from the mains, then:

Remove the plastic cover, disconnect the wires.

Shut off the cold water supply, disconnect the pipes.

Unscrew the fixing screws, remove the protective cover.

Remove temperature sensor and flange.

Remove the heating element carefully so as not to damage the rubber gasket.

Remove the appliance from the wall, place it in the bathtub, and then direct the water hose inside to remove the remaining scale. To clean the heating element, mix 50 g of citric acid in 2 liters of water. Keep in the resulting solution of heating elements until the deposits dissolve (10-12 hours).

Unscrew the magnesium anode and assess its condition. If one pin remains, replace the part.

After cleaning, return the parts to their place. Install a new temperature sensor as needed.

Assemble the structure in reverse order

Particular attention should be paid to the condition of the rubber gaskets. If they have become unusable, it is recommended to change them to new ones in order to avoid leakage of the product after assembly.

It is necessary to connect the product to the electrical network after it is completely filled with water.

Elimination of leaks

If water drips from the appliance, the cause may be worn seals or damage to the container. In the latter case, the repair of heating tanks does not make sense, the purchase of a new device is required. If the problem is in the rubber seals, you need to replace them with new ones.

During the installation of the water heater, specialists carry out the installation of locking elements. A non-return valve is installed at the cold water inlet, which is regulated during operation of the system.

The safety valve is located on the cold water supply pipe, following certain recommendations:

- Do not install shut-off valves between the valve and the boiler.

- For a flexible hose, you need to make a special hole in the sewer pipe.

- To quickly drain water from the device, it is permissible to install a ball valve with a tee.

- A valve leak may indicate valve failure. A complete replacement of components will help to correct the situation.

- Another reason for a leak can be excessive water pressure. To prevent this, it is optimal to install a regulator that lowers the performance to normal.

Device device

Before proceeding with the self-repair of the Termex water heater at home, you need to understand its design. When studying it, it turns out that its device is not too complicated, since it consists of a small number of components, presented below:

- load-bearing body made on the basis of steel sheet with a stainless protective coating;

- internal working tank, for welding of which alloyed steels are used.

- a metal base on which the main elements of the device are installed (magnesium anode, heating element and thermostat);

- the anode itself is a metal rod with a surface treated with a magnesium alloy. Due to this element, it is possible to reduce the corrosive properties of water, that is, to protect the tank from rapid destruction;

- heating electric device or heating element.

In addition to the above, the design of the unit includes a set of stainless steel pipes for supplying and discharging cold and hot water, a thermostat that controls the operating modes of the boiler.