- Video instruction

- Replace the belt in the following sequence:

- How to change the belt on the washing machine Indesit

- Description

- Belt

- How to choose?

- Signs and causes of malfunction with the drive element in the AGR

- The main symptoms of a problem

- Why does the belt on the washing machine fly off

- Where to buy a drive belt?

- Why does the drive belt fly off (jump off)?

- Installing the belt on the machine

- Troubleshooting

- How to determine that it is time to change the belt in the washing machine?

- Self-replacing the drive belt of the washing machine

- The role of the belt

- Types of belts

- How to fix a broken washing machine belt

Video instruction

In order to visually understand the repair, you can watch the video - instructions.

The following factors may serve:

- Appeared incomprehensible noise during operation;

- Upon visual inspection, the belt seems to be in place, but near the places where the belt passes, as well as on all the underlying planes, a tyrsa resembling dirt is found, and to the touch it resembles an eraser (it also rolls into spools);

- The service life of the washing machine is 6-7 years (the life of the drive belt).

Belts 1270 J3 .. J5 for Samsung washing machines

The reasons listed above should prompt you to think about a preventive technical inspection, and maybe a repair, which is expressed in replacing the drive belt.

This article will describe the process replacing the belt on a Samsung washing machine (Samsung)

. On all models of this brand, the back panel is not removable, which greatly complicates the repair.

So, what you need to replace the belt:

- Purchase (you can by marking on the belt itself, you can provide the old version as a sample);

- Insulating tape (a small piece about 10-15 cm);

- Wire (diameter 0.5-0.8 mm, length about 0.5 m);

- wire cutters;

- Flashlight.

- crosshead screwdriver

Samsung washing machine belt installation diagram

The diagram shows:

- Engine drive gear;

- Washing machine drum rotation pulley;

- Belt;

- Belt fixation.

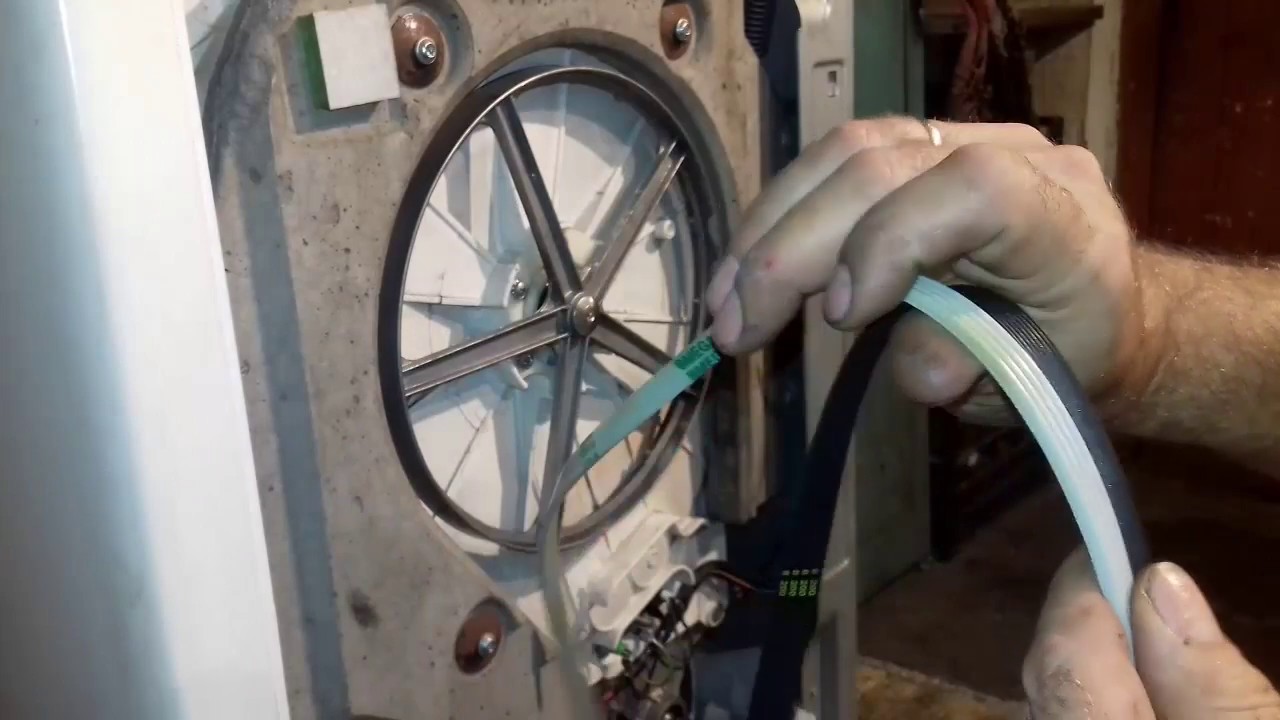

Replace the belt in the following sequence:

- First of all, inspect the drive gear and the drum drive pulley of the machine. You should notice that there are grooves on the gear for reciprocal grooves at the belt, and as a rule, during long-term operation, a trace is formed from the previously installed belt. It is recommended to install the belt for this model of machine from above. Therefore, please note when placing the belt on the drive gear, you need to try to get to the place where the previous belt was . If you have moved the belt too close to the end of the gear, then you will not immediately understand how it will be installed on the drum pulley and it may turn out that part of the belt on the pulley will hang down or be on the edge. Then you have to dismantle and do it all over again, taking into account the initial positioning on the gear.

- After you have placed the belt on the drive gear, you need to place the belt on the pulley from the side into which the drive gear is shifted . Look at the diagram and you will understand what I mean. Having brought the belt to the top point, you need to select the position of the pulley when there is support from scrolling the fastener. The mount will not be able to fix the belt from rotation, it will tend to move in the opposite direction from rotation and will be stopped by the stop.

- To fix the belt, first use electrical tape to prevent damage to the belt wire during installation. Then we securely fix the wire on top of the electrical tape. We make 5-10 turns and fix the edges by twisting together. After that, rotate the pulley in the direction of installing the belt.

- After the final installation of the belt on the pulley, there will be a characteristic click of the belt and further rotation will not be possible, since the belt will go onto the gear, but our lock will stop it. We turn in the opposite direction and remove the latch. Everything - the installation of the belt is over. The process itself takes about 20 minutes if you put the belt on the gear correctly. You can check this by turning the pulley a few turns. The belt will take its position on the pulley and align with the position on the gear. And then see how you like it.

Some breakdowns of washing machines can be dealt with on your own. Even if there is no experience in repairing complex household appliances, belt replacement can be carried out within a short time. This operation does not require expensive equipment, and a screwdriver and an adjustable wrench are enough from the tools. How to change the belt on a Samsung washing machine will be described in detail in this article.

How to change the belt on the washing machine Indesit

Buy a strap from the manufacturer from a reliable supplier. Then completely remove the old element and its remnants. Any belt has a cord, which, at the moment of a break, unwinds and is wound on the motor of the device or on nearby wires.

Buy a strap from the manufacturer from a reliable supplier. Then completely remove the old element and its remnants. Any belt has a cord, which, at the moment of a break, unwinds and is wound on the motor of the device or on nearby wires.

The new element must be put on the engine and tightly press its upper part to the pulley. You need to rotate the drum at the same time, pulling a completely new element onto the pulley.

The strap should be located strictly in the center of the pulley, which is located on top. This can be done by shifting the belt 2 tracks on a pulley at the bottom of the equipment. After that, you can start the device for washing clothes.

Description

If your washing machine is not equipped with a direct drum drive, a belt drive is used to transfer the rotation from the motor. The peculiarity of her work is that she works as a reducer. The engine develops a speed of 5000–10,000 rpm, while the required working speed of the drum is 1000–1200 rpm. This imposes certain requirements on the belt: it must be strong, elastic and durable.

When washing, especially with a full load, significant forces act on the drive elements. In addition, vibration can occur at high speeds. Therefore, the belt acts as a kind of fuse. If it flew off, then the load on the drum is higher than the maximum allowable. And additional force is not transferred to the motor, and it is completely protected from overload.

Naturally, drive parts are subject to wear. This is especially true of the belt, because it is not metal, but rubber. Here are a few telltale signs, sorted as they appear:

- squeak and friction sounds;

- uneven rotation of the drum, with jerks and vibration;

- the machine can only wash a small amount of laundry;

- an error code is displayed on the display;

- The motor is running but the drum is not spinning.

Therefore, sometimes there is a need for replacement.

Anyone who knows how to hold a screwdriver in their hands can make such repairs. And it is better not to postpone the work, well, or not to use the car until the repair. The parts work at high speed, and if the belt breaks and flies off on the go, it will hit a random place with great force. And lucky if it is the back wall.

Before removing the old belt and installing a new one, it is advisable to familiarize yourself with the technical parameters of the machine. The fact is that there are several types of belts, and they are not interchangeable.

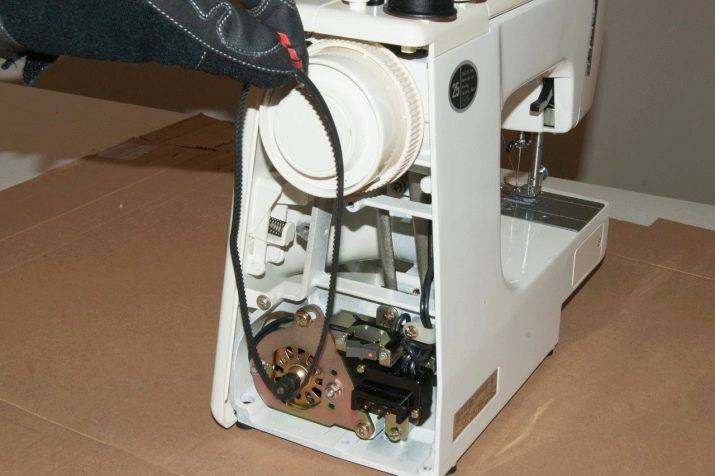

Belt

It is one of the important spare parts for foot or drive sewing machines. Without it, the movement of the main shaft in the foot machine becomes impossible, since the pressure on the pedal sets the flywheel in motion, and it, in turn, starts the entire mechanism. In electric, this is the connection between the flywheel and the motor. Today you can find different materials from which the belt is made: leather, plastic, rubber or textiles. Plastic and leather are considered popular due to their strength and durability. Their variety is determined by the type of machine, they may differ in length, structure and shape.

Belts can meet such.

- textured. Used in electric sewing machines, it has the appearance of jagged, stepped elements located on the inside and outside.

- Leather. Designed for models with a foot drive.Connected with a metal clip at the end.

How to choose?

It is worth considering a number of factors that affect the correct choice of a belt for a sewing machine:

- operating temperature range;

- resistance to mechanical damage;

- noise at work;

- degree of extensibility;

- replacement and care.

Paying attention to all these nuances, you can count on the long-term operation of the consumable and reliability under conditions of constant loads without losing the original properties. The belt pressed from high-quality leather is suitable for foot sewing machines "Podolsk", "Tikka", "Seagull", "Lada", "Köller", "Veritas" and others

The belt is 185 cm long and 5 mm thick.

It is possible to purchase a belt in an individual size.

Signs and causes of malfunction with the drive element in the AGR

If the appliance is overloaded with laundry, the drum may spin more and the strap may fall off.

The main symptoms of a problem

The fact that the drive belt has flown off in an automatic washing machine is evidenced by the following factors:

- lack of rotation of the drum when the engine is running when starting the program;

- there is no scrolling of the drum assembly, although the engine works with tangible effort;

- spinning the drum with only a few things inside;

- no torsion when loading a large batch of laundry;

- extraneous sounds - grinding and friction;

- launching the program and further freezing of the machine.

Important! The main breakdowns of the part are breaks, delaminations, stretching.

Why does the belt on the washing machine fly off

Before troubleshooting, it is worthwhile to fully understand why the belt flies on your washing machine.

- Problems with fastening the pulley.Loose and loose fasteners cause the belt to break and come off, as well as jamming the drum.

- Unreliable motor mount. When the fasteners are loosened, the belt does not stretch well and may slip off. Breakage is eliminated by tightening all fasteners.

- Natural wear of the part. If the machine is used for more than 10 years, the belt will stretch. This is indicated by whistles when scrolling and problems with spinning.

Important! Due to the stretching of the belt, the machine stops running programs. The failure of their bearings. When the bearings of the machine are worn, a strong noise is heard from the vibration of the part itself and the drum pulley

With each wash, the load on the part increases. Operation of the machine with faulty bearings leads to stretching, flying off and breaking the belt

The failure of their bearings. When the bearings of the machine are worn, a strong noise is heard from the vibration of the part itself and the drum pulley. With each wash, the load on the part increases. Operation of the machine with faulty bearings leads to stretching, flying off and breaking the belt.

Important! Breakage associated with a broken strap can lead to broken wiring and damage to electronic sensors

- Pulley or shaft deformation. The geometry of the parts is broken when the motor fasteners are loosened, the shape of the shaft and pulley changes, and the cross breaks. Strong vibration during operation leads to slipping and tearing of the strap, as well as to breakage of complex parts of the CMA.

- The belt is loose. If the element is not sized, it is stretched incorrectly, then it will fall off.

- Rare launch of household appliances. When the machine is used infrequently, the drive belt loses its elasticity - it dries out in a kinked state.A rigid element may crack, break, or stretch as the drum rotates.

- Loosening of the tympanic cross. When the drive belt quickly flies off a working drum of a household washing machine, you need to check the balance of the cross.

- Deformation of the plastic tank. With prolonged use of the technique, the deformed sections of the tank create pressure on the drum pulley. Changing its position relative to the motor leads to the fall of the belt.

Important! Breakage is peculiar only to models with vertical loading. Setting the intensive wash program. When the machine is overloaded with linen and its daily operation in intensive mode (5-10 hours) leads to the belt falling off

Item needs to be put in place.

Setting the intensive wash program. When the machine is overloaded with linen and its daily operation in intensive mode (5-10 hours), the belt will fall off. The item needs to be put in place.

Interesting to know! Belts of narrow models wear out more often due to the compact arrangement of nodes and increased friction.

Where to buy a drive belt?

If any of the above reasons happened to your washing machine, you should not despair, as there is nothing easier than buying and replacing a drive belt. Our specialists, located in the cities of the Moscow region: Balashikha and Mytishchi, Korolev and Shchelkovo, Ivanteevka and Yubileiny, Pushkino and Fryazino, will help you purchase the necessary spare parts - belts made of nylon and neoprene, rubber or polyurethane.

If you know the brand of your washing machine, you can simply contact the consultants of our store, and they will select the type of drive belt you need.

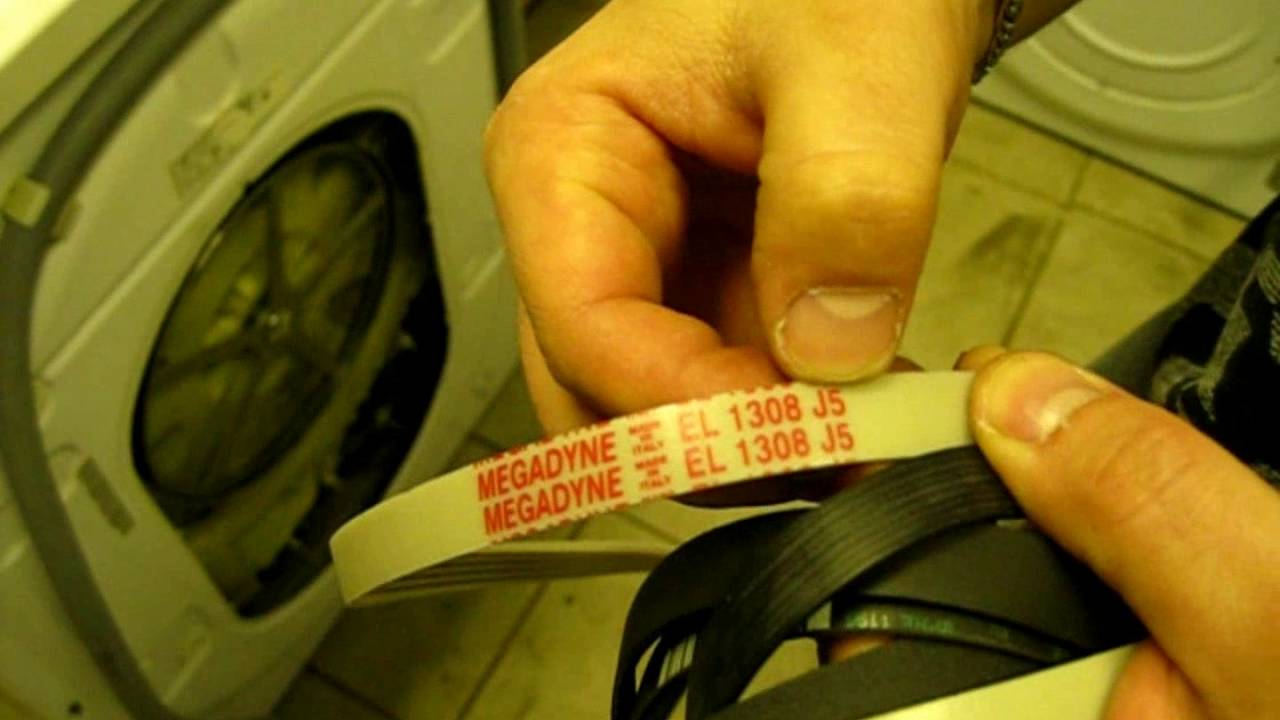

Master repairmen usually pay attention to the marking of the belt itself.Its characteristics are clearly spelled out in alphanumeric code.

The company "Vash-master" sells wholesale and retail a wide range of belts made of high quality materials for washing machines of any type, size and brand. Our stores support a range of washing machine drive belts of almost all sizes for Ardo or Candy, Ariston or Electrolux, Bosch or Indesit, LG or Samsung, Zanussi or Whirlpool. We invite to cooperation not only retail, but also wholesale buyers. To check the availability and order belts of specific models, please call: 8(495) 782-66-02.

Why does the drive belt fly off (jump off)?

The causes of the problem will help to identify errors in operation, as well as quickly restore the operation of the equipment. Typical signs of jumping off are:

- Stopping the operation of the equipment, the drum stops rotating.

- The drum does not rotate well.

Of course, such problems are also associated with a breakdown of the engine or electronic module. But the belt is the easiest to check. Why is he falling?

- Wear. Most often it happens in washing machines with a narrow body. All parts inside are located as compactly as possible. Including the rear wall of the tank is close to the panel. Over time, dampers that dampen vibrations during spinning weaken. Therefore, the tank begins to beat on the lid. As a result, the drive cable breaks.

- Pulley damage. Although the wheel is made of an alloy of metals, it can crack. Therefore, the drive cable flies off.

- Bearing wear. In addition to strong noise, the breakdown is accompanied by a strong vibration of the equipment during the spin cycle. The belt stretches, breaks, falls off.

- Imbalance. The situation is similar with the bearing: the linen is lumped together, the drum starts to vibrate and shake strongly.

- Deformed tank. The problem is typical for models with vertical loading. Service center masters note that they encounter such a breakdown more often in Brandt washing machines. After about 8 years of operation, the tank is deformed, causing the large pulley to move away from the small pulley. The rope starts to sag and falls off.

- Drying and deformation of the cable. After a long break in using the machine, the cable dries out and becomes stiff. At the next start, the part breaks.

If one of the above problems occurs, it is necessary to carry out repairs. Features of replacing the drive belt in a washing machine (CM) depend on the type of this element. Let's look at how to change and install a drive cable with your own hands.

Installing the belt on the machine

The course of work depends on the type of engine that is in your CMA model. Before changing the product, you should make sure that the old element is faulty.

- Pull the plug out of the socket.

- Close the water inlet valve.

- Remove the top cover. To do this, unscrew the fastening bolts from behind, slide the panel back and remove from the case.

- Unscrew the bolts around the perimeter of the back cover.

- Remove her from her place.

Now you can inspect the components. Before you put in a new part, look at the condition of the one that is already used in the machine. If the cable is not broken, but simply flew off, then you need to restore its landing. When deformed and worn, you need to buy another belt.

wedge type. Used in models with asynchronous motor. It is made of hard material, so it rarely wears out and breaks.In cross section, its shape is similar to a truncated triangle.

How to insert the belt:

- First, put the product on the motor.

- Now pull on part of the large tank pulley.

- Scrolling the wheel by hand, put on the rest.

- Make sure the part is well seated in the groove.

If the old element is just stretched, then read on how to tighten the drive belt. This will help the motor:

- Loosen motor mounts.

- Move it away from the tank so as to increase the tension.

- Fasten the bolts.

polyclinic variety. Operated with a collector motor. It consists of several wedges, the number of which depends on the engine pulley. The shape is of type J and H. The length of the product and its shape are embossed on the side.

How to replace this belt? Repair is carried out in the same way. First put it on the engine, then on the tank wheel. The middle part should also be slightly loose so that it can be rotated 360 degrees. The rest of the pieces are tight.

To avoid such problems, follow these simple rules:

- Do not overload the drum with laundry.

- Place the body of the washer on a hard, level surface.

- Avoid imbalance by loading things properly.

The video shows an example of the work:

Carry out repairs in sequence. It is better to remove the old part first and go to the store with it. Or rewrite the designations and belt number.

Badly

Interesting

Super

1

Troubleshooting

Replacing the belt of a Samsung washing machine will require the mandatory removal of the back panel, disconnecting the appliance from electricity and plumbing, so the first thing to do is to make sure that the drive belt is the cause of the inoperability of the household appliance.This malfunction may have the following symptoms:

- The motor runs but the drum does not rotate.

- The drum spins jerkily, the air smells of burnt rubber.

- Extraneous sounds are heard when the drum is rotating.

This important part of the washing machine does not always fail so much that the household appliance stops working. In the early stages of wear of this part, problems can only be observed when the washing machine is fully loaded. If in such a situation the drum starts to jam, then you should not wait for the situation when the engine jams or the loose belt breaks the internal wiring wires. If you suspect a similar problem, you should immediately begin troubleshooting.

Before proceeding with the repair of a household appliance, it should be disconnected from the electrical network and communications. If it is not possible to remove the back panel of the washing machine without changing its location, then the device extends in such a way that it is most convenient to carry out the work of replacing the belt during operation. Then you should prepare slotted and Phillips screwdrivers. The drive belt is replaced in the following sequence:

- Unscrew the screws holding the back cover and carefully remove the panel.

- With a slotted screwdriver, it is necessary to pry the part, bend it to the side and remove it from the pulley, slightly turning it clockwise.

- A new belt is installed in place of the worn part. To do this, first it should be brought under the lower pulley, and then, placing the belt on the grooves of the pulley on one side, rotate it half a turn.

- Rotate the upper pulley 1 to 2 turns to check the belt drive.

- Assemble the washing machine.

After all communications are connected, the washing machine should be run in test mode to make sure it works.

On some models of washing machines, it is not possible to remove the back cover, so many craftsmen are interested in the question of how to tighten the belt in a Samsung washing machine. In this case, in fact, the process of replacing the part is much more complicated. To carry out such an operation, you will need to open access to the internal parts of the household appliance from below or from above. The second option is more preferable, because to remove the top panel, it is enough to unscrew two self-tapping screws. Then the cover is slightly moved back and up, after which access to the belt drive will be opened. Before proceeding with this operation, it is also necessary to disconnect the appliance from the electrical and water mains.

To remove the old belt, it will be enough, as described above, to pry it with a sharp object and, by scrolling the pulley, remove it from the household appliance. Installing a new part, in this case, will require the use of auxiliary tools. The engine pulley located at the bottom is at a considerable distance, so it is not possible to hook it on top with a belt. In order for the part to lie in the recesses of the pulley, you should take a piece of thick wire, bend it with the letter U, hang a new belt on it and lower it down, hook it on the lower pulley. Then you should install it on the upper pulley of a larger diameter and scroll clockwise to complete the process of installing a new part.

After the belt is in place, you need to replace the top cover of the appliance and connect the washing machine to electricity and plumbing.Before using the household appliance, it is necessary to make a test run of the washing machine.

How to determine that it is time to change the belt in the washing machine?

The first reason: your machine has stopped spinning the drum, although you can hear that the engine is running. The problem, most likely, is that the belt has broken or fallen off.

The second reason is that with a small load, the drum twitches in place and the engine cannot turn it. Cause: the belt has become thin, lost its stiffness and stretched.

The third reason is that the drum rotates at low load and does not rotate at full load. The reason is also in the belt.

The fourth reason is that when the drum rotates, there are extraneous sounds, as if inside, something scurries or hurts. The reason is that the belt has stratified, and its fragments hit the walls of the case and the parts of the washing machine. This situation is the most unpleasant and can lead to serious consequences. Fragments of the belt can catch wires and break them, as well as wrap around the engine and cause it to fail.

These are the main reasons why belt replacement is vital!

Self-replacing the drive belt of the washing machine

Replacing the washer drive belt is not the worst task. It may seem or sound worse.

Washing machines with an asynchronous motor are equipped with V-belts, on the outside of which their number and brand are indicated. In cross section, the belt looks like a trapezoid.

V-belts are made of chlorine-resistant materials with high strength (rubber, polyester, cotton materials).

To change the belt yourself, you first need to unscrew the bolts that fix the cover on the back of the washing machine housing (with an ordinary screwdriver). After removing the cover, we will see a pulley on which the old belt is fixed. Turning the pulley, remove the wear by pulling it towards you.

Phones by promo codes inside:

A new V-belt must be sunk into the recesses of the pulley and, gradually turning it, press the belt until it is fully seated.

V-ribbed belts are used in washing machines with commutator motors. In cross section, such a belt has a toothed shape formed by rows of wedges. Its marking is indicated on the outside of the belt. Installing a V-ribbed belt is no different from installing a V-belt. The only thing you need to additionally check is that the tension is a little weaker and the belt itself lies strictly in the center of the groove of the engine pulley and drum

The rotation of the pulley should be carried out around the axis by 360 degrees, carefully, without overdoing it. When replacing the belt on close-fitting models, be careful to avoid minor injury to the limbs.

The belts of narrow washing machines wear out much faster than their "relatives" due to the dense configuration of all components of the product. There is an increase in friction of parts and assemblies against each other. Over time, the belt stretches and begins to rub against the back wall of the machine, thereby wearing out even more. The same goes for other details that get loose after the expiration of a certain term.

The role of the belt

The task of the drive belt is to transfer the energy of the engine to the drum. A quality part will not fail for a long time if you follow the operating rules of the washing machine recommended by the manufacturer.If you do not forget to close the drum door and do not try to wash more than the maximum allowable weight at a time, you will be able to use the belt for a long time.

Types of belts

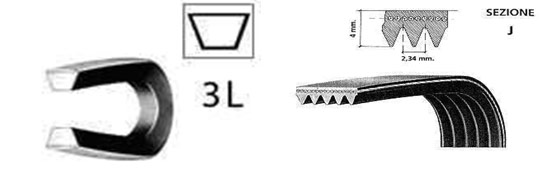

There are the following types of drive belts:

- wedge-shaped for washing machines of foreign manufacturers (section 3 L);

- wedge-shaped for Russian cars (sections - "Z", "A");

- poly-wedge for large machines (section "J") and for small machines (section "H")

Belts are divided into elastic and rigid. The former are ideal for new models of washing machines. They have the ability to stretch. The use of an elastic belt allows the motor to be fixed rigidly to the tank, but it does not make it possible to adjust the tension.

Rigid belt practically does not stretch. To tighten it, you need to adjust the position of the motor in relation to the tank. This modification is found in old washers.

Knowing the features of the products, you can accurately choose the option for your Ariston washing machine.

How to fix a broken washing machine belt

For work, it is worth preparing two small bars that will need to be twisted together. Future vise must be wider than the belt itself. Take four self-tapping screws, a screwdriver, glue moment, acetone and a penknife.

First, consider the repair using the example of a poly-V-belt:

To begin with, it is worth cleaning the entire part with water and acetone.

Pay special attention to the places of future gluing

Trim any uneven edges of the torn belt so that the edge angle is 90 degrees.

Lay the belt wedges up, and with a penknife, carefully cut 10-12 wedges from one end of the belt. If possible, clean this place with fine emery.

Turn the belt upside down, grasp the two ends of the belt and bring them together so that the 10-12 teeth on one side take up place with the sheared teeth on the other side.

Apply glue to the place of the old teeth and firmly, but as evenly as possible, press these ends.

Place wooden blocks on top and bottom of the gluing area

Fix them with self-tapping screws, but so that they do not touch the belt itself.

Leave the belt to dry completely.

Please note that with this gluing option, the belt will become shorter. If the design of your machine does not allow you to change the tension by moving the engine, then this method is only suitable in case of a stretched belt

Therefore, in this matter it is better to trust professionals, and not save on the purchase, installation of a new part.

To glue the V-belt, we need a construction stapler with thin staples, acetone and moment glue.

-

Trim the belt breaks evenly.

-

Clean the ends of the edges with acetone.

-

Apply glue to the edges of the moment, and putting the belt on the table, tightly join the edges one to one.

-

Without moving the belt, fasten the gap with a construction stapler in two places.

-

Wait for the glue to dry completely.

-

Remove metal brackets.

Before installing the glued belt, be sure to check it for strength at the junction. Stretch the edges as much as possible, it should withstand a small application of force.

Bonded belts won't last as long as a new part can, but for light use for a few months it should be enough.

Once again, we draw your attention to the fact that without special skills, you should not make repairs on your own, but rather turn to specialized services or professionals. Now you know what to do if the washing machine belt breaks