- What pressure should the pumping station be regulated to?

- Tank preparation and adjustment

- How to set up the system for 50 liters?

- Pumping station device

- When do you need to adjust and remove the default settings?

- Purpose and device

- Pressure switch device

- Species and varieties

- Peculiarities

- Water pressure regulator repair

- Advice from experienced professionals

- Correction of errors in work

- Violation of the rules of operation

- Engine malfunctions

- Problems with water pressure in the system

- Installation

- Do-it-yourself pumping station repair

- suction line

- Pump

- Hydraulic accumulator

- Relay

What pressure should the pumping station be regulated to?

A very important question, not all consumers understand the intricacies of the operation of the equipment. Incompetent actions always have negative consequences.

By increasing the pressure, consumers hope to solve two problems.

-

Increase the volume of water pumped in at one start. Many believe that the frequent inclusion of an eclectic engine quickly disables it. It is true that during switching on, the starting currents reach critical values and overheat the winding. But in the case of a pump, the dependence is more complicated, which one - we will tell below.

-

Only at high pressure can household appliances work: washing machine, sink, shower, etc.The belief is also only partly true.

In connection with such beliefs, the maximum pressure is set within 3-4 atm., Especially since the technical characteristics allow you to create pressure up to five or more atmospheres. Working values do not exceed 80% of the maximum, which means that everything is normal. But it's not. Which value to choose for optimal operation of the pump and household equipment? This issue must be considered in detail.

The choice of pressure directly affects the quality of equipment operation.

The choice of pressure directly affects the quality of equipment operation.

- As the pressure increases, the volume of water in the accumulator increases. But its increase is too expensive in the literal and figurative sense of the word. For your information, in a 10-liter cylinder, by increasing the pressure by one atmosphere, the amount of water increases by approximately 1 liter. If the initial air pressure in the cylinder is 1 atm., then at the water pressure in the rubber chamber 1 atm. its volume is 4 liters, if the pressure is 2 atm., then the volume increases to 5 liters, and at a pressure of 3 atm. the volume of water is 5.5 liters. Indeed, the pump will turn on less often. But one must understand that each increase in pressure by one atmosphere requires much more electrical energy, in addition, the pump elements work with increased loads. As a result, attempts to achieve savings turn into direct losses - you will have to change expensive equipment more often.

- It is believed that if the pressure is low, then household appliances do not function. This is not true, all washing machines, dishwashers and other appliances work perfectly with a water pressure of 1 atm.

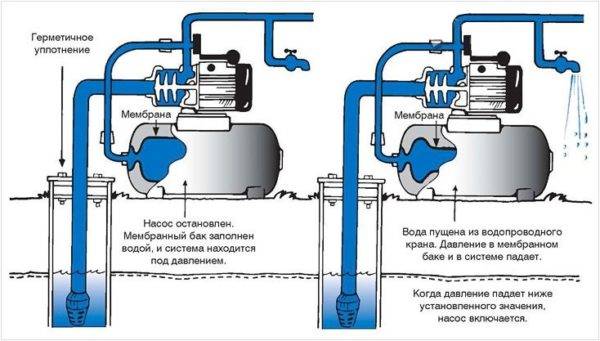

The principle of operation of the pumping station

The principle of operation of the pumping station

Experienced plumbers strongly recommend setting the pump to a pressure in the range of 1.2–1.7 atm.Such parameters are considered the golden mean, the load on the electric motor and pump is acceptable, and everything in the house works as it should.

Tank preparation and adjustment

Before the accumulators go on sale, air is pumped into them at a certain pressure at the factory. Air is pumped through the spool installed on this container.

Under what pressure is the air in the hydraulic tank, you can find out from the label glued to it. In the following figure, the red arrow indicates the line in which the air pressure in the accumulator is indicated.

Also, these measurements of the compression force in the tank can be made using an automobile pressure gauge. The measuring device is connected to the spool of the tank.

To start adjusting the compression force in the hydraulic tank, you need to prepare it:

- Disconnect the equipment from the mains.

- Open any faucet installed in the system and wait until the liquid stops flowing from it. Of course, it will be better if the crane is located near the drive or on the same floor with it.

- Next, measure the compression force in the container using a pressure gauge and note this value. For small volume drives, the indicator should be about 1.5 bar.

In order to properly adjust the accumulator, the rule should be taken into account: the pressure that triggers the relay to turn on the unit must exceed the compression force in the accumulator by 10%. For example, the pump relay turns on the motor at 1.6 bar. This means that it is necessary to create an appropriate air compression force in the drive, namely 1.4-1.5 bar. By the way, the coincidence with the factory settings is not accidental here.

If the sensor is configured to start the engine of the station with a compression force greater than 1.6 bar, then, accordingly, the settings of the drive change. You can increase the pressure in the latter, that is, pump up air, if you use a pump for inflating car tires.

Advice! Correction of the air compression force in the accumulator is recommended to be carried out at least once a year, since during the winter it can decrease by several tenths of a bar.

How to set up the system for 50 liters?

It is this indicator that will provide a good pressure of water. The larger the parameter, the less water can flow.

For measurement, you can use a pressure gauge for a car, which helps to calculate the indicator with the least inaccuracy.

After determining the air pressure, it is necessary:

- Start the pump to establish pressure in the system.

- Determine at what point on the pressure gauge the shutdown occurs.

- Set the switch to disable the mechanism.

- Turn on the tap so that the accumulator gets rid of moisture, and fix the indicator.

- Fit the small spring under the formed thresholds.

| Index | Action | Result |

| 3.2-3,3 | Rotation of the screw on a small spring until the motor is completely turned off. | Decrease in indicator |

| Less than 2 | Add pressure | Increase in indicator |

The recommended value is 2 atmospheres.

By adhering to these recommendations, acceptable indicators of the water supply system can be established.

Pumping station device

In order to properly adjust this pumping equipment, you must have at least a minimal idea of how it works and on what principle it works. The main purpose of pumping stations consisting of several modules is to provide drinking water to all water intake points in the house.Also, these units are able to automatically increase and maintain the pressure in the system at the required level.

Below is a diagram of a pumping station with a hydraulic accumulator.

The pumping station includes the following elements (see the figure above).

- Hydraulic accumulator. It is made in the form of a sealed tank, inside of which there is an elastic membrane. In some containers, a rubber bulb is installed instead of a membrane. Thanks to the membrane (pear), the hydraulic tank is divided into 2 compartments: for air and for water. The latter is pumped into a pear or into a part of the tank intended for liquid. The accumulator is connected in the section between the pump and the pipe leading to the water intake points.

- Pump. It can be surface or borehole. The pump type must be either centrifugal or vortex. The vibration pump for the station cannot be used.

- Pressure switch. The pressure sensor automates the entire process by which water is supplied from the well to the expansion tank. The relay is responsible for turning the pump motor on and off when the required compression force is reached in the tank.

- Check valve. Prevents leakage of fluid from the accumulator when the pump is turned off.

- Power supply. To connect the equipment to the electrical network, it is required to stretch a separate wiring with a cross section corresponding to the power of the unit. Also, a protection system in the form of automatic machines should be installed in the electrical circuit.

This equipment works according to the following principle. After opening the tap at the water intake point, water from the accumulator begins to flow into the system. At the same time, compression is reduced in the tank.When the compression force drops to the value set on the sensor, its contacts close and the pump motor starts to work. After the cessation of water consumption at the water intake point, or when the compression force in the accumulator rises to the required level, the relay is activated to turn off the pump.

When do you need to adjust and remove the default settings?

The input power does not always correspond to the standard 5.0 - 6.0 bar. If the pressure in the supply network differs significantly from the standard, then the pressure of the water after the reducer will be different from the factory settings.

For example, consider a regulator set to 3.0 bar with an inlet pressure of 5.0 bar. That is, a difference of 2.0 bar.

By the way, it is this value, the difference between the inlet and outlet water pressure, that is the actual value of the spring load setting on the valve.

By the way, it is this value, the difference between the inlet and outlet water pressure, that is the actual value of the spring load setting on the valve.

If the inlet pressure is 2.5 bar, then the output value will be only 0.5 bar, which is very low for normal use. Setup required.

If the inlet head is 7.0 bar, then the output value will be 5.0 bar, which is a lot. Setup required.

Deviation from the standards can be under the following conditions:

- water consumption significantly exceeds the capacity of central networks and pumping stations, the pressure will be low;

- upper floors of tall buildings, low pressure;

- the lower floors of tall buildings, the pressure will be high;

- incorrect operation of booster pumps in the building, the pressure may be low or high.

In such situations, it is necessary to reconfigure the gearbox. A change in the inlet water pressure can also occur during the long-term operation of water supply networks.Including due to a decrease in the flow area of pipes in the building due to the formation of deposits and corrosion.

Adjustment may be required more than once, during long-term use of water.

Gearboxes are subject to wear resulting in water leakage. They can be repaired, which requires disassembly. After assembling the device, it will need to be adjusted.

Purpose and device

In order to maintain a constant pressure in the water supply system of a private house, two devices are needed - a hydraulic accumulator and a pressure switch. Both of these devices are connected to the pump through the pipeline - the pressure switch is located in the middle between the pump and the accumulator. Most often, it is located in the immediate vicinity of this tank, but some models can be installed on the pump housing (even submersible). Let's understand the purpose of these devices and how the system works.

One of the pump connection diagrams

A hydraulic accumulator is a container divided by an elastic pear or membrane into two halves. In one, air is under some pressure, in the second, water is pumped. The water pressure in the accumulator and the amount of water that can be pumped there is regulated by the amount of air pumped. The more air, the higher the pressure maintained in the system. But at the same time, less water can be pumped into the tank. Usually it is possible to pump no more than half of the volume into the container. That is, it will be possible to pump no more than 40-50 liters into a hydraulic accumulator with a volume of 100 liters.

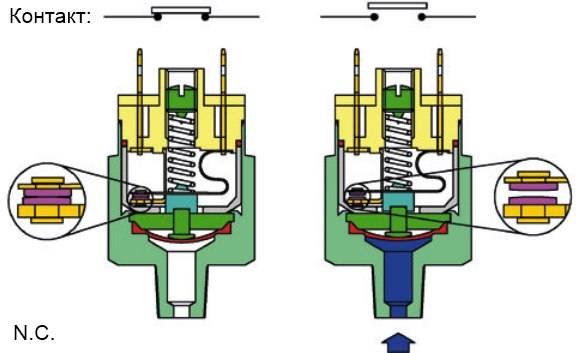

For normal operation of household appliances, a range of 1.4 atm - 2.8 atm is required. To support such a framework, a pressure switch is required. It has two operation limits - upper and lower.When the lower limit is reached, the relay starts the pump, it pumps water into the accumulator, and the pressure in it (and in the system) increases. When the pressure in the system reaches the upper limit, the relay turns off the pump.

In a circuit with a hydroaccumulator, for some time water is consumed from the tank. When enough flows out so that the pressure drops to the lower threshold, the pump will turn on. That's how this system works.

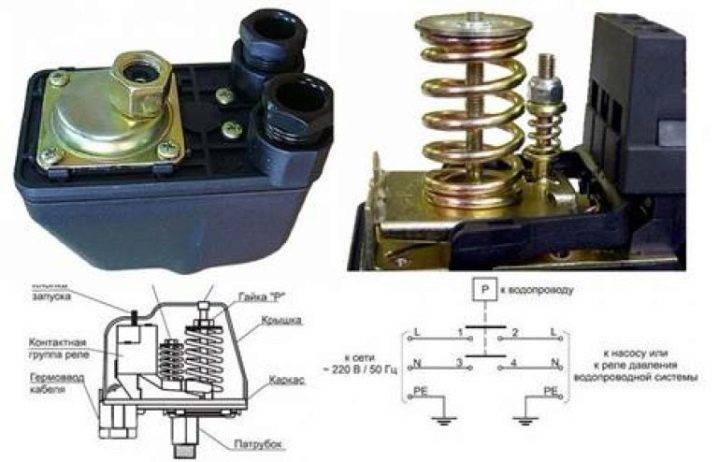

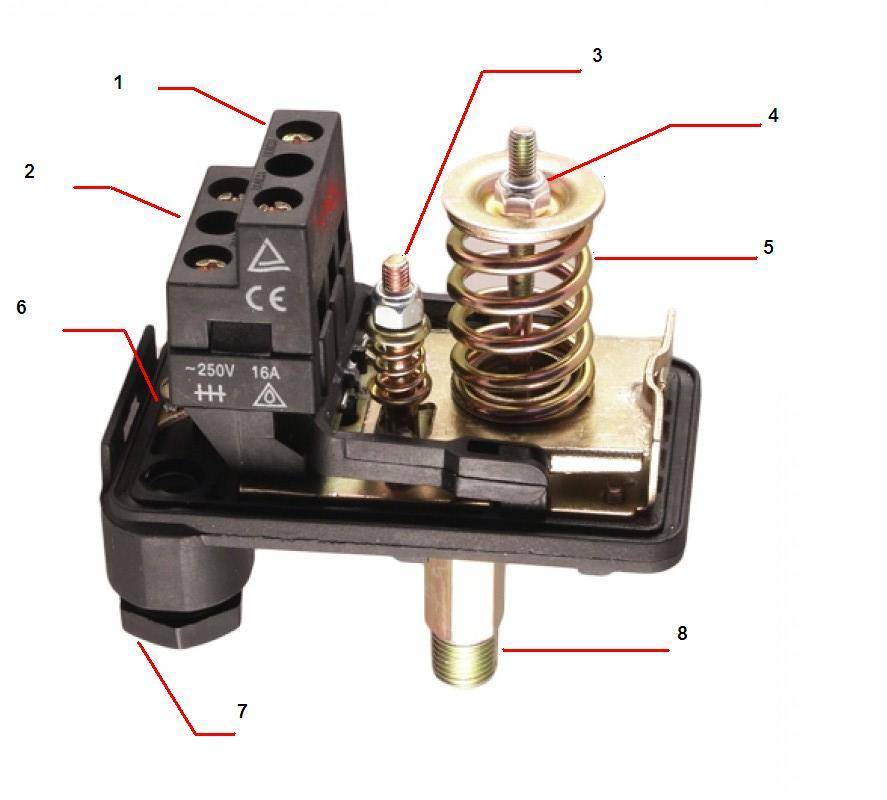

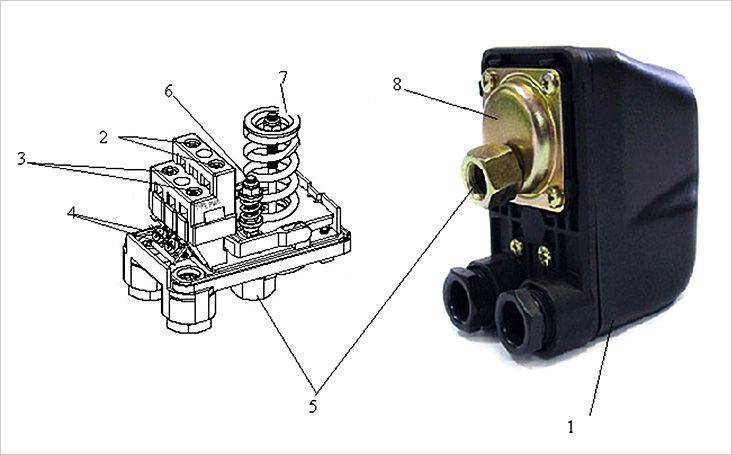

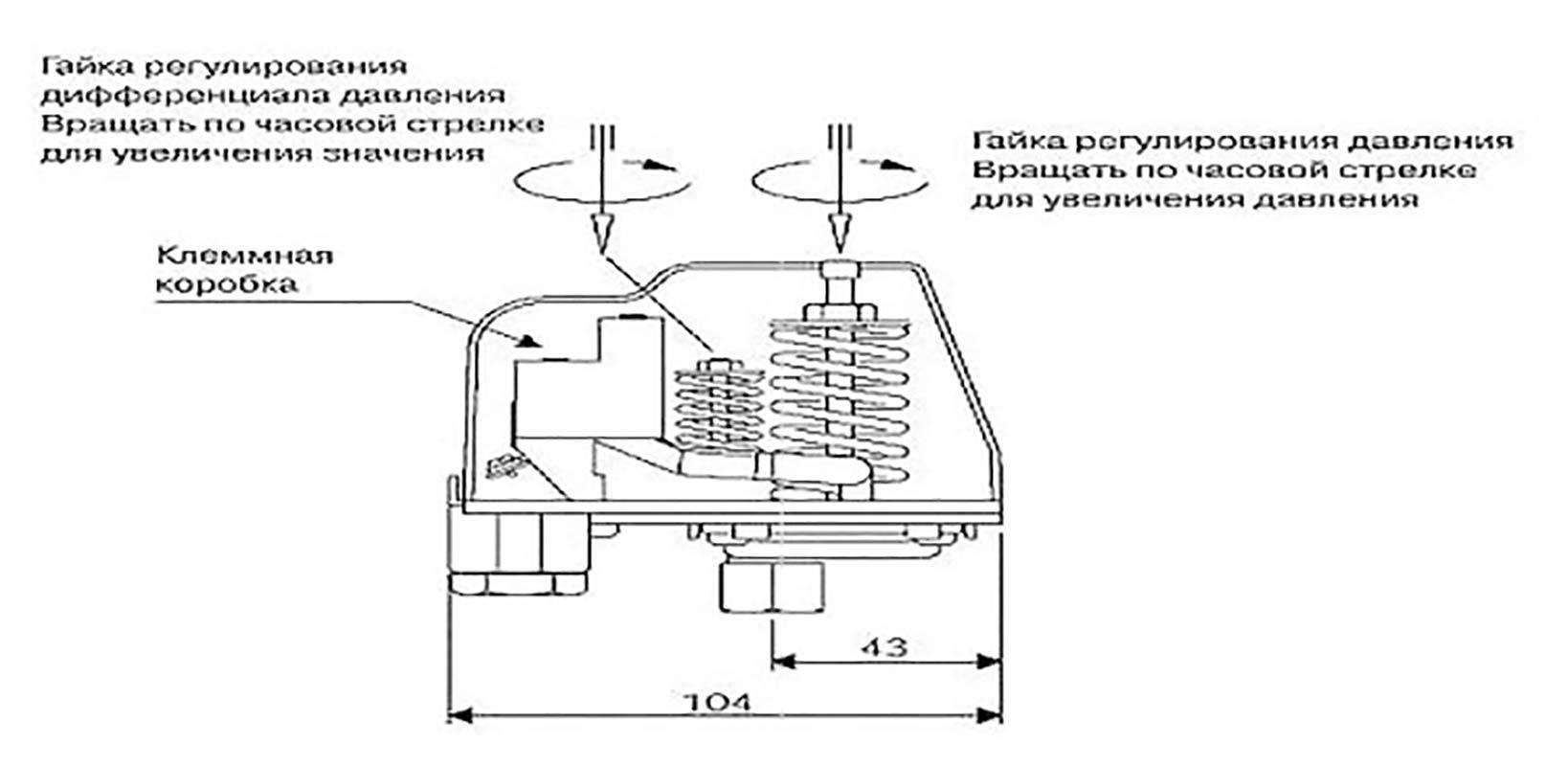

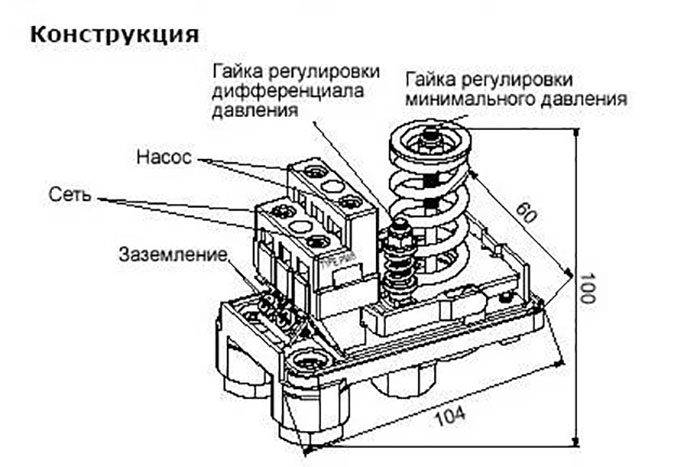

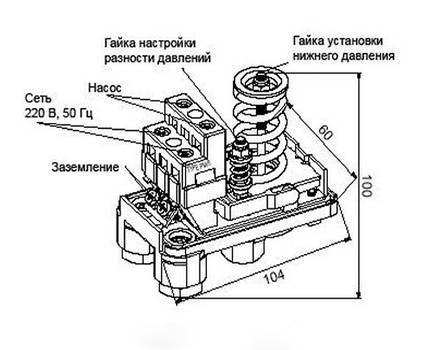

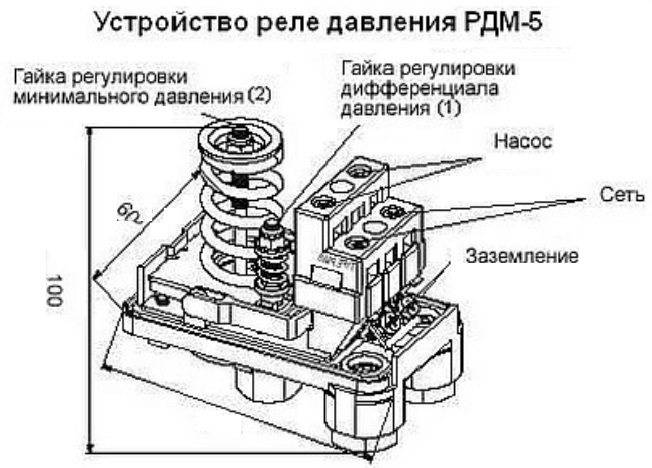

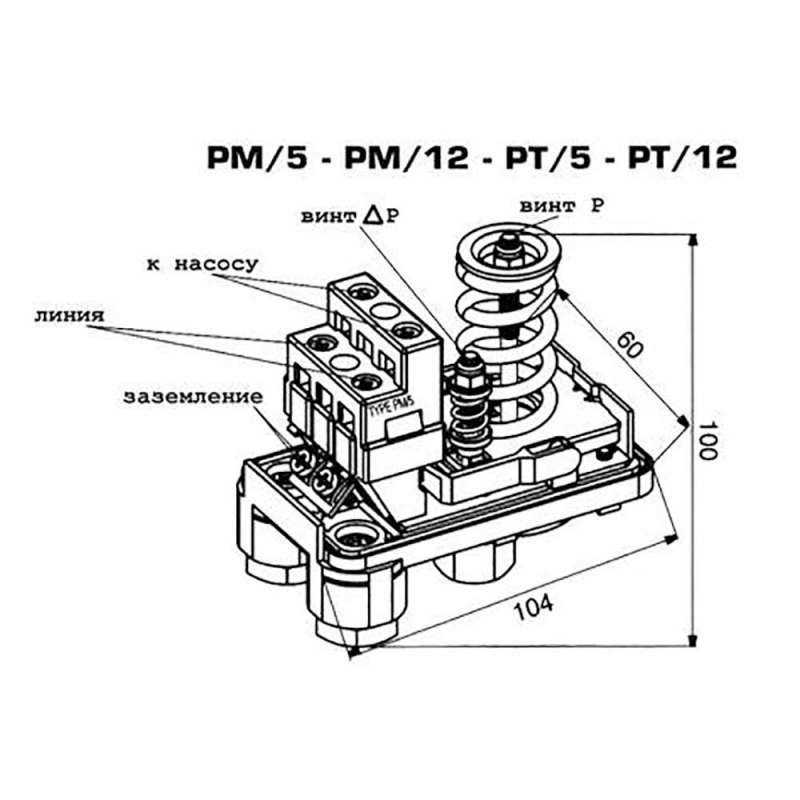

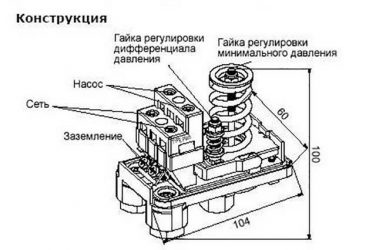

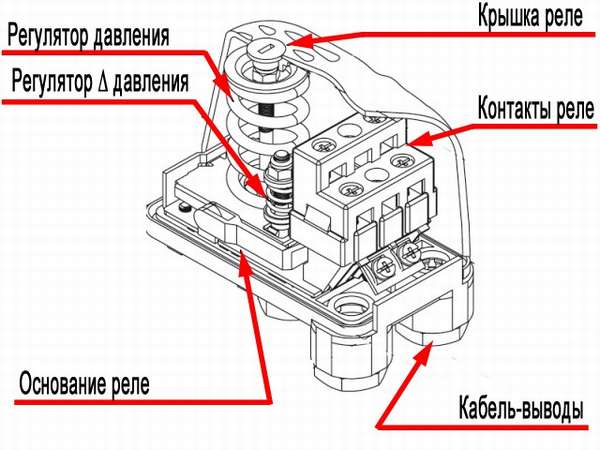

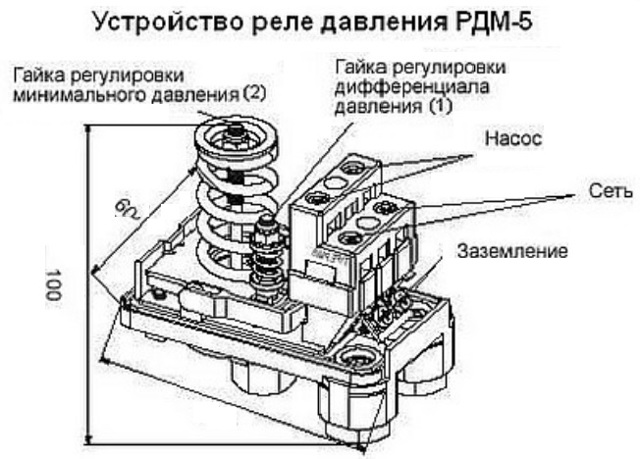

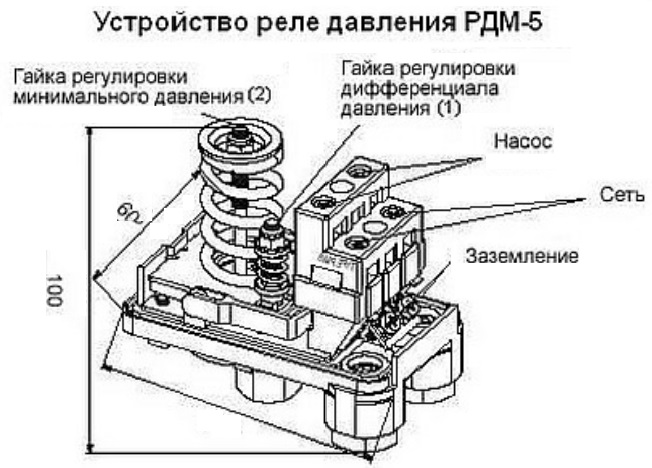

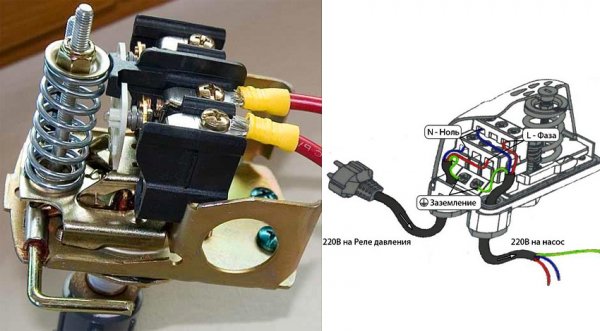

Pressure switch device

This device consists of two parts - electrical and hydraulic. The electrical part is a group of contacts that closes and opens on / off the pump. The hydraulic part is a membrane that exerts pressure on the metal base and springs (large and small) with which the pump on / off pressure can be changed.

Water pressure switch device

The hydraulic outlet is located on the back of the relay. It can be an outlet with an external thread or with a nut like an American. The second option is more convenient during installation - in the first case, you either need to look for an adapter with a union nut of a suitable size or twist the device itself by screwing it onto the thread, and this is not always possible.

The electrical inputs are also located on the back of the case, and the terminal block itself, where the wires are connected, is hidden under the cover.

Species and varieties

There are two types of water pressure switches: mechanical and electronic. Mechanical ones are much cheaper and usually prefer them, while electronic ones are mostly brought to order.

| Name | Pressure adjustment limit | Factory settings | Manufacturer/country | Device protection class | Price |

|---|---|---|---|---|---|

| RDM-5 Gileks | 1- 4.6 atm | 1.4 - 2.8 atm | Gilex/Russia | IP44 | 13-15$ |

| Italtecnica RM/5G (m) 1/4″ | 1 - 5 atm | 1.4 - 2.8 atm | Italy | IP44 | 27-30$ |

| Italtecnica RT/12 (m) | 1 - 12 atm | 5 - 7 atm | Italy | IP44 | 27-30$ |

| Grundfos (Condor) MDR 5-5 | 1.5 - 5 atm | 2.8 - 4.1 atm | Germany | IP 54 | 55-75$ |

| Italtecnica PM53W 1″ | 1.5 - 5 atm | Italy | 7-11 $ | ||

| Genebre 3781 1/4″ | 1 - 4 atm | 0.4 - 2.8 atm | Spain | 7-13$ |

The difference in prices in different stores is more than significant. Although, as usual, when buying cheap copies, there is a risk of running into a fake.

Peculiarities

An important condition for the effective operation of the relay is the correct choice of its installation location. Experienced experts advise placing the device near the outlet to the accumulator, that is, in a place where pressure surges and flow turbulence during pump start-up and operation are minimal. It is allowed to install the relay on storage tanks and surface-type pumps. In addition, some products are designed for operation in strictly defined conditions with acceptable temperature and humidity. Therefore, when choosing a model, you should carefully read the accompanying documentation so that it does not turn out that the relay purchased for the external pipeline can only work indoors.

First of all, this applies to models designed for surface pumps, which is why it is recommended to install such equipment in a caisson, basement or any other insulated place.In addition to working together with centrifugal surface pumps, relays can be installed on borehole, submersible drainage and submersible vibration pumps, as well as on pumping equipment of water supply stations and hydraulic accumulators. The device can be included with the pump or purchased separately.

Relays can be produced with both external and internal threads, having a standard diameter of 1/4 inch. This makes the device fully compatible not only with domestic, but also with foreign pumping equipment. The cost of devices depends entirely on the manufacturer, and varies from 200 rubles for Chinese models to 2 thousand for products of famous Italian brands. Domestic models belong to the middle price category, and are the best value for money. So, the Russian "Dzhileks RDM-5" can be purchased for only 700 rubles, while the Danish Grundfos will cost one and a half thousand.

Water pressure regulator repair

The purpose of the reducer is to maintain the set outlet pressure as accurately as possible, regardless of changes in the inlet and the consumed water flow. This is necessary so that consumers do not feel discomfort at different degrees of water intake, and at each point of water intake, with the help of fittings, it would be possible to independently regulate the water flow over a wide range.

Maintenance:

- Once a month, it is recommended to check the settings, the response speed and the accuracy of maintaining pressure by the regulator. They check the operation of the regulator by changing the flow rate of water passing through it - smoothly closing the fittings installed on the same pipeline.

- With a frequency of once every six months, the pulse selection line should be cleaned.To do this, the area where the regulator is installed should be disconnected, drained, and the impulse line should be blown out, having previously disconnected from the regulator and the pipeline.

- The mesh filter installed in front of the regulator is cleaned as it gets dirty. The clogging of the filter is determined by the readings of the pressure gauges provided before and after it, comparing the actual pressure drop across the filter with the drop in a clean filter.

Repair of the regulator may be required if, during operation or maintenance, a pressure deviation was detected at the point where the pulse was taken from the set value. Do-it-yourself gearbox repair is impractical, it is easier to replace it with a new one, but you can try the simplest operations.

| The regulator does not respond to changes in pressure at the connection point | Plugged impulse line | Blow out with compressed air or water pressure, having previously disconnected from the regulator |

| — | A foreign object has entered the flow path | Clean the plug and seat after dismantling the regulator |

| — | Sticky stock | Descale and work out the stem manually, having previously dismantled the regulator and hydraulic actuator |

| Regulator closed all the time | Missing spring or adjusting nut through which the spring holds the stem in the open position | no comments |

| Regulator open all the time | Water pressure upstream of regulator, below set pressure | Change the set pressure with the adjusting screw or wait for the pressure to increase |

| — | Membrane torn | Need to replace the original membrane |

The most common questions on the repair forums:

- water pressure reducer leaking what to do?

- how to clean the gearbox

Advice from experienced professionals

It is recommended to connect the pressure switch of the accumulator to the electrical panel of the house through a separate line with its own RCD.

It is also mandatory to ground this sensor, for this it has special terminals.

It is permissible to tighten the adjusting nuts on the relay until it stops, but it is highly not recommended. The device with rigidly tightened springs will work with large errors according to the set Rstart and Pstop, and will soon fail

If water is visible on the case or inside the relay, then the device should immediately be de-energized. The appearance of moisture is a direct sign of a ruptured rubber membrane. Such a unit is subject to immediate replacement, it cannot be repaired and continue to operate.

Cleaning filters in the system must be installed without fail. Nothing without them. However, they need to be cleaned regularly.

Also, once a quarter or six months, the pressure switch itself should be flushed. To do this, the cover with the inlet pipe from below is unscrewed on the device. Next, the opened cavity and the membrane located there are washed.

The main reason for breakdowns of the accumulator relay is the appearance of air, sand or other contaminants in the pipes. There is a rupture of the rubber membrane, and as a result, the device must be replaced

Checking the pressure switch for correct operation and general serviceability should be done every 3-6 months. At the same time, the air pressure in the accumulator is also checked.

If, during adjustment, sharp jumps of the arrow on the pressure gauge occur, then this is a direct sign of a breakdown of the relay, pump or hydraulic accumulator. It is necessary to turn off the entire system and start its full check.

Correction of errors in work

Before embarking on a more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing to do is to adjust the pressure in the accumulator tank and adjust the pressure switch.

The following are the most common malfunctions in the domestic pumping station, which the user can try to solve on his own. For more serious problems, contact the service center.

Violation of the rules of operation

If the station runs continuously without shutting down, the likely cause is incorrect relay adjustment - a high shutdown pressure is set. It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is broken or an air lock has formed in the pipe or in the suction valve. To find a specific cause, it is necessary to make sure that: the foot valve and all connections are tight, there are no bends, narrowings, hydraulic locks along the entire length of the suction pipe. All malfunctions are eliminated, if necessary, replace damaged areas.

- The equipment works without access to water (dry). It is necessary to check why it is not there or to identify and eliminate other causes.

- The pipeline is clogged - it is necessary to clear the system of contaminants.

It happens that the station very often works and turns off. Most likely this is due to a damaged membrane (then it is necessary to replace it), or the system does not have the pressure required for operation. In the latter case, it is necessary to measure the presence of air, check the tank for cracks and damage.

Before each start, it is necessary to pour water into the pumping station through a special funnel. She must not work without water. If there is a possibility of the pump running without water, you should purchase automatic pumps equipped with a flow controller

Less likely, but it can happen that the check valve is open and blocked due to debris or a foreign object. In such a situation, it will be necessary to disassemble the pipeline in the area of \u200b\u200bpossible blockage and eliminate the problem.

Engine malfunctions

The household station engine does not run and does not make noise, possibly for the following reasons:

- The equipment is disconnected from the power supply or there is no mains voltage. You need to check the wiring diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, then it is jammed. You need to find out why.

- Relay damaged. You need to try to adjust it or, if it fails, replace it with a new one.

Engine malfunctions most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The pressure of water or air in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Piping or pump impeller blocked. Cleaning the elements of the pumping station from contamination may help solve the problem.

- Air enters the pipeline. Checking the elements of the pipeline and their connections for tightness will be able to confirm or refute this version.

Poor water supply can also be caused by air being drawn in due to leaky water pipe connections or the water level has dropped so much that air is being pumped into the system when it is taken.

Poor water pressure can create significant discomfort when using the plumbing system

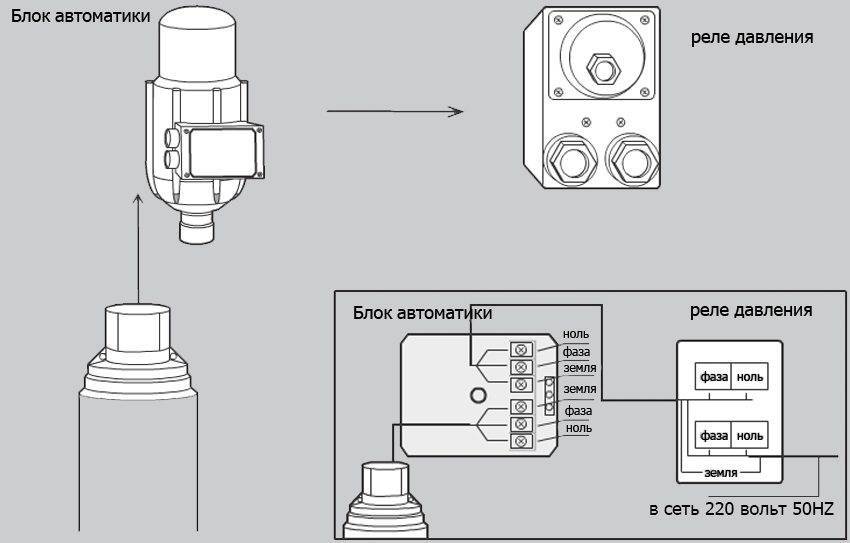

Installation

Often, the GA kit is sold in a disassembled state, and the control unit needs to be mounted by yourself.

Connecting the pressure switch to the accumulator in stages looks like this:

- The station is disconnected from the network. If water has already been pumped into the drive, then it is drained.

- The device is fixed permanently. It is screwed onto the 5-pin fitting of the unit or onto the outlet and must be firmly fixed.

- The wiring diagram is the usual one: there are contacts for the network, the pump, and also grounding. The cables are passed through the holes on the housing and connected to the terminal blocks with terminals.

Electrical connection to the pump

Electrical connection to the pump

Do-it-yourself pumping station repair

To resume the work of the National Assembly, you must do the following:

suction line

Do-it-yourself repair of a check valve usually consists of removing dirt or long-fibre inclusions that prevent the damper from closing. For more complex breakdowns, the part is changed.

If cracks appear on the reinforced hose through which the pump sucks in air, they must be sealed with reinforced tape to repair pipelines.

Pump

Impeller sticking usually occurs after a long period of inactivity. To revive the unit, the impeller must simply be turned by hand, not forgetting, of course, to disconnect the pump from the mains.

There are models in the cavity of which a stainless liner is installed. It is much cheaper to change it than the whole body.

A failed capacitor with an electric motor is also subject to replacement. Attempting to rewind the motor winding yourself may result in degraded pump performance.

Hydraulic accumulator

A crack in the accumulator housing is a good reason to contact the service department. But if its dimensions are not large, you can try to seal the hole with a composition such as "cold welding". If the membrane or balloon breaks, the part will definitely have to be changed.

When choosing NS, it is better to give preference to models with a balloon accumulator. Replacing the rubber "pear" in such tanks, regardless of the model, is very easy. As for membrane accumulators, in many models of this type, only a service engineer can install a new membrane.

Old and new rubber membranes

Most often, to normalize the operation of the National Assembly, you just need to pump air into the cavity of the accumulator. This is done using a conventional pump with a spool hose. In this case, the pressure should be monitored with a manometer.

A change house, equipped with a bathroom and a shower, makes your stay at a summer cottage comfortable. Change houses country two-room with a toilet and a shower - everything from materials to final furnish.

The rules for the manufacture and installation of Zolotukhin cages for keeping rabbits are described in this publication.

Its recommended value is indicated in the characteristics of the accumulator (usually 1.5 atm.), But it is not necessary to strictly adhere to this value. Ideally, the air pressure in the tank should be no more than 10% of the pump cut-in pressure.

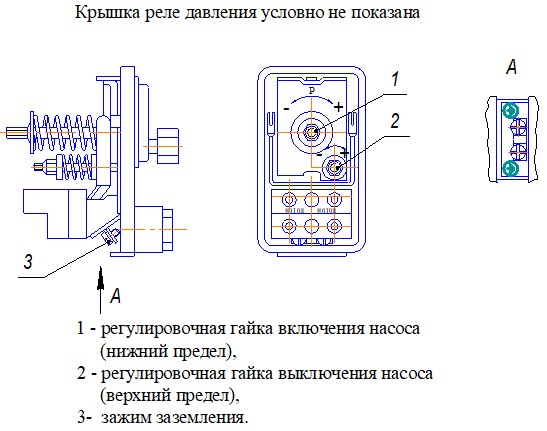

Relay

Cleaning the contact group and the connecting pipe from dirt usually does not cause difficulties for users.

By the way, plaque from contacts is best removed with a soft school eraser.

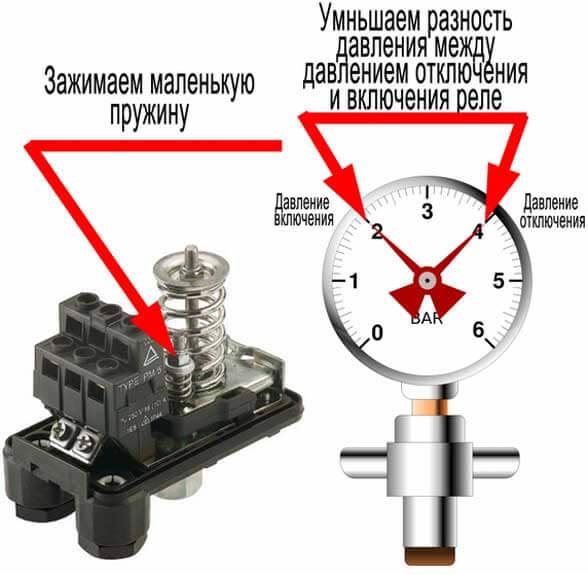

The adjustment of the relay is carried out by rotating two nuts screwed onto the rods with springs put on them.

If the pump, due to wear, cannot develop enough pressure to turn off, you need to wait until the pressure gauge needle freezes at the maximum mark, and then manually turn off the power to the unit. Then slowly loosen the nut of the small spring until the contacts click.

This will mean that the upper limit of the operating range of the relay corresponds to the maximum pressure that the pump can currently provide. For a margin, the small spring can be weakened a little more. When tightening the nut, the range, on the contrary, will increase.

Similar actions can be performed with a large spring, if, for example, it is weakened.

Please note that with a decrease in the cut-off pressure, the volume of water that the pump can pump into the accumulator will also decrease. To correct the situation, release some of the air from the accumulator.