- Pressure switch adjustment

- Practical examples of relay settings

- Connecting a new device

- Pump stopped turning off

- Situations that do not require adjustment

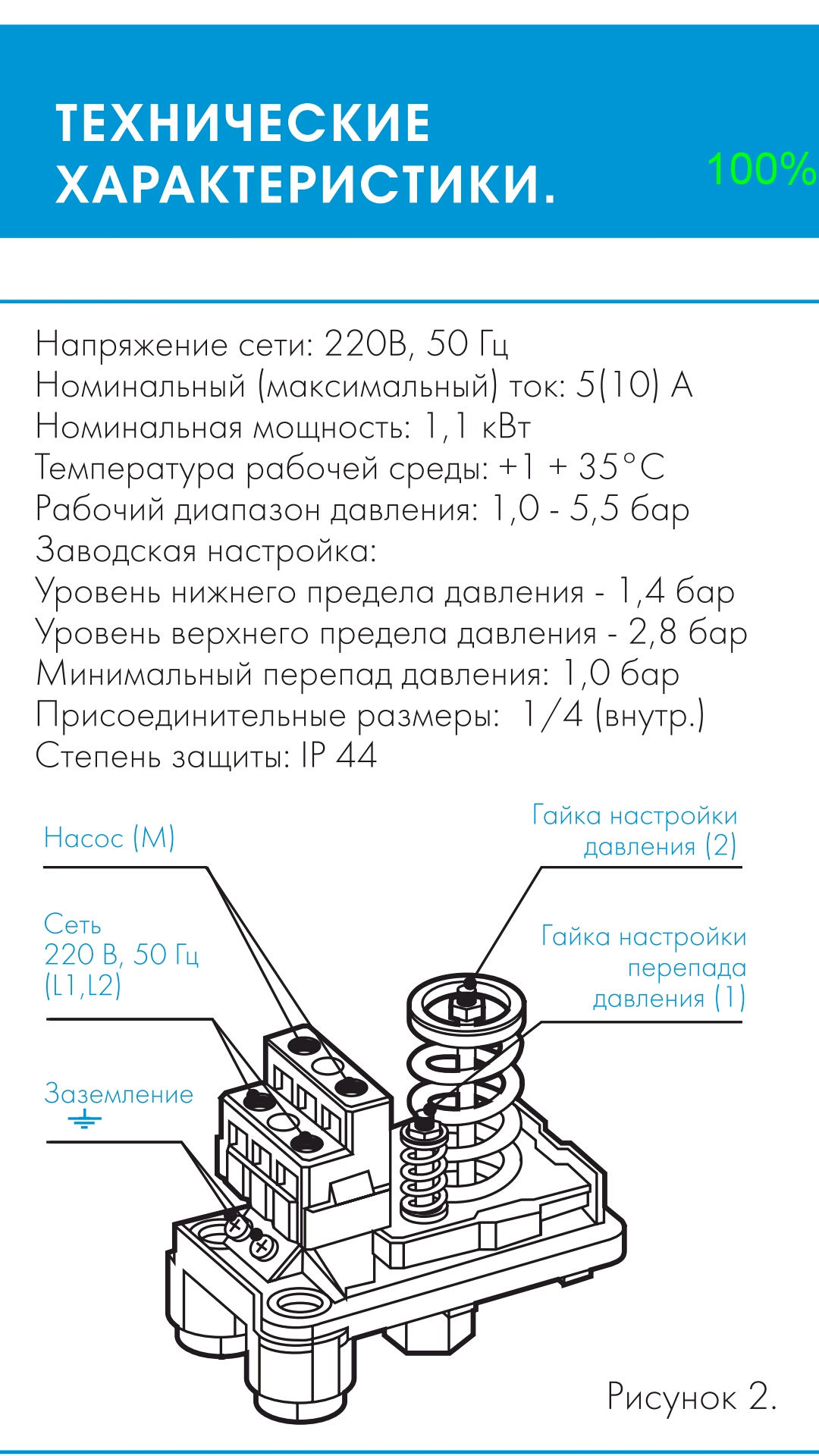

- Water pressure switch adjustment

- How to determine relay thresholds

- Setting the pressure switch for a pump or pumping station

- Advice from experienced professionals

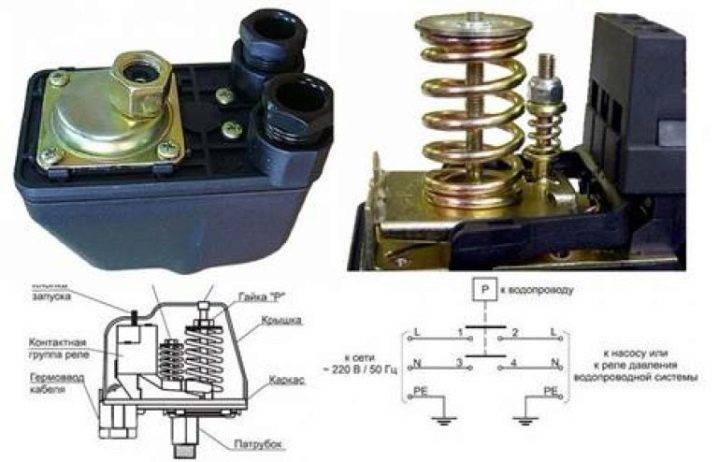

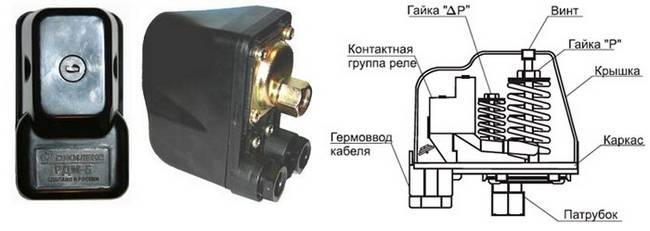

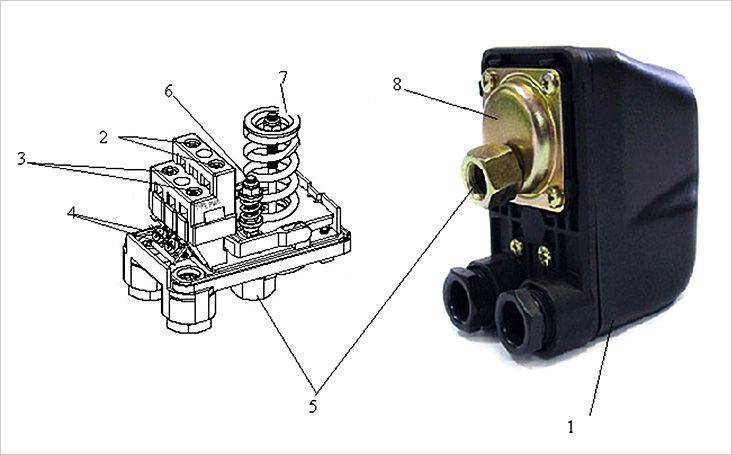

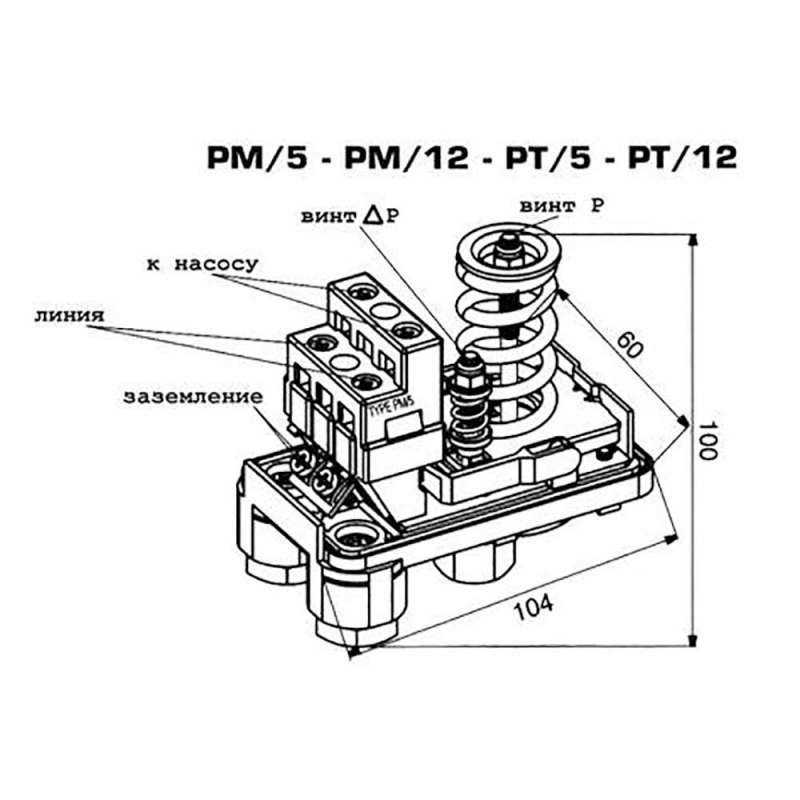

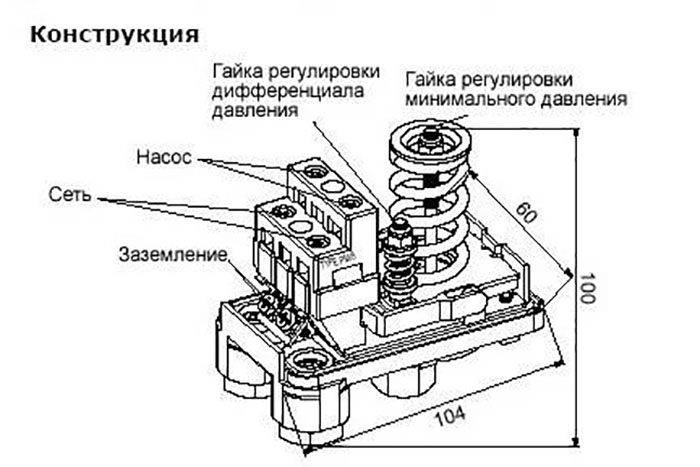

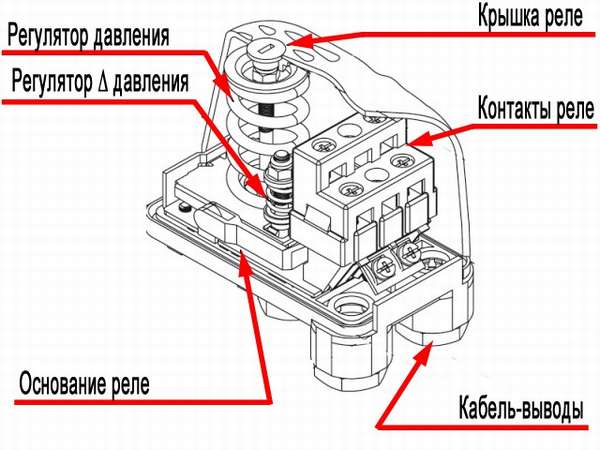

- The design and principle of operation of the pressure switch

- Step by step instructions for adjustment

- Common faults

- Why is there no fluid in the system?

- Need to know

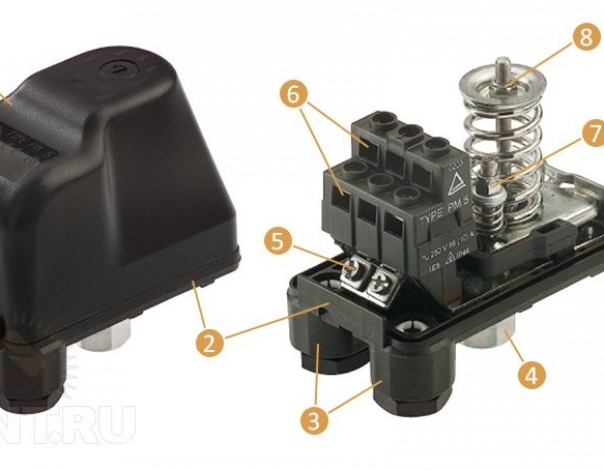

- The device and principle of operation of the relay

- Prices for pumping stations

- Device principle

- Things to consider when making adjustments

Pressure switch adjustment

So, if you have determined which parameter and how much you want to change, just remove the cover from the relay and slightly turn the corresponding nut. The power cord must first be unplugged from the outlet.

Please note that the small spring is more sensitive than the large one, so you need to tighten it carefully. After adjustment, turn on the power again and check on the pressure gauge how much the relay parameters have changed

If the desired pressure P2 is known exactly, you can go the other way:

- Compress the small spring as much as possible.

- Turn on the pump while watching the pressure gauge. As soon as the arrow stops at the desired mark, turn off the unit by pulling the plug from the outlet.

- Slowly unscrew the small spring nut until the contacts snap into the open position.

P1 is configured in a similar way, if it is known exactly:

- After turning off the pump, open any tap a little and drain the water until the pressure on the pressure gauge drops to the desired value.

- While slowly turning the large spring nut, compress it until the contacts switch to the "closed" position.

- If the contacts close earlier than they should, the large spring must, on the contrary, be loosened.

In the same way, the relay is adjusted even if it is completely misadjusted, for example, the springs are maximally weakened or compressed to the limit.

Practical examples of relay settings

Let's analyze the cases when the appeal to the adjustment of the pressure switch is really necessary. This usually happens when buying a new appliance or when frequent pump shutdowns occur. Also, setting will be required if you got a used device with downgraded parameters.

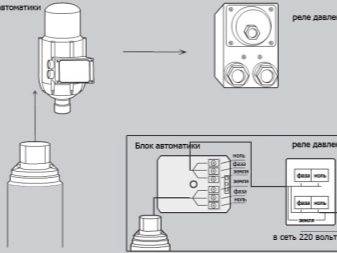

Connecting a new device

At this stage, you should check how correct the factory settings are and, if necessary, make some changes to the operation of the pump.

Image gallery

Photo from

We turn off the energy, completely empty the system of water until the pressure gauge reaches the “zero” mark. Turn on the pump and watch the readings. We remember at what value it turned off. Then we drain the water and remember the parameters at which the pump starts working again

We twist a large spring to increase the lower border. We make a check: we drain the water and remember the value of switching on and off. The second parameter should increase along with the first. Adjust until you get the desired result.

We perform the same actions, but with a small spring. You need to act carefully, since the slightest change in the position of the spring responds to the operation of the pump. Having slightly tightened or loosened the nut, we immediately check the result of the work

Having finished all the manipulations with the springs, we take the final readings and compare them with the initial ones. We also look at what has changed in the work of the station. If the tank began to be filled in a different volume, and the on / off intervals have changed, the setting was successful

Stage 1 - equipment preparation

Stage 2 - adjusting the turn-on value

Step 3 - adjusting the trip amount

Stage 4 - testing the system operation

To track the progress of work, it is recommended to write down all the data received on a piece of paper. In the future, you can return the initial settings or change the settings again.

Pump stopped turning off

In this case, we forcibly turn off the pumping equipment and act in the following order:

- We turn on, and wait until the pressure reaches the maximum mark - suppose 3.7 atm.

- We turn off the equipment and lower the pressure by draining the water - for example, up to 3.1 atm.

- Slightly tighten the nut on the small spring, increasing the value of the differential.

- We check how the cut-off pressure has changed and test the system.

- We adjust the best option by tightening and loosening the nuts on both springs.

If the cause was an incorrect initial setting, it can be solved without buying a new relay. It is recommended to regularly, once every 1-2 months, check the operation of the pressure switch and, if necessary, adjust the on / off limits.

Situations that do not require adjustment

There can be many reasons when the pump does not turn off or does not turn on - from a blockage in communications to engine failure. Therefore, before starting to disassemble the relay, you should make sure that the rest of the equipment of the pumping station is working properly.

If everything is in order with the rest of the devices, the problem is in the automation. We turn to the inspection of the pressure switch. We disconnect it from the fitting and wires, remove the cover and check two critical points: a thin pipe for connecting to the system and a block of contacts.

Image gallery

Photo from

To check if the hole is clean, it is necessary to dismantle the device for inspection, and if a blockage is found, clean it.

The quality of tap water is not ideal, so often the problem is solved by simply cleaning the inlet from rust and mineral deposits.

Even with devices with a high degree of protection against moisture, failures can occur due to the fact that the wire contacts are oxidized or burned.

To clean the contacts, use a special chemical solution or the simplest option - the smallest sandpaper

You have to act very carefully

Plugged hydraulic tank connection

Relay inlet cleaning

Clogged electrical contacts

Cleaning the contact block. If the cleaning measures did not help, and the adjustment of the position of the springs was also in vain, most likely the relay is not subject to further operation and should be replaced with a new one

If the cleaning measures did not help, and the adjustment of the position of the springs was also in vain, most likely the relay is not subject to further operation and should be replaced with a new one.

Suppose you got an old but working device in your hands.Its adjustment takes place in the same order as the setting of a new relay. Before starting work, make sure that the device is intact, disassemble it and check that all contacts and springs are in place.

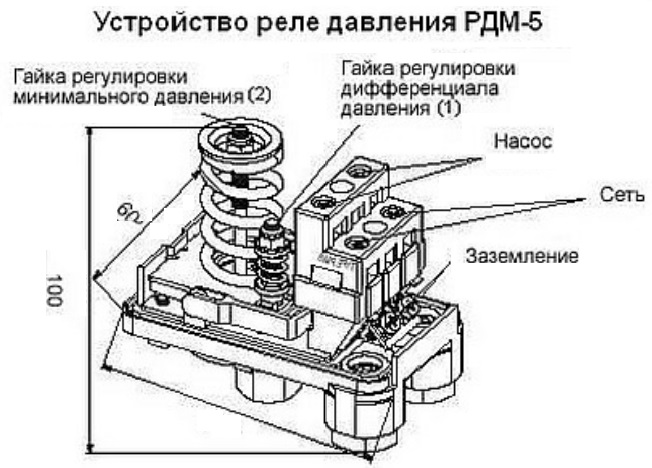

Water pressure switch adjustment

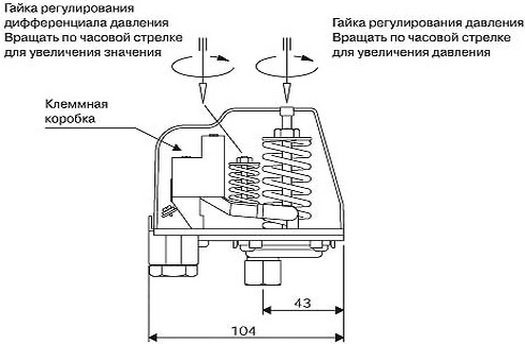

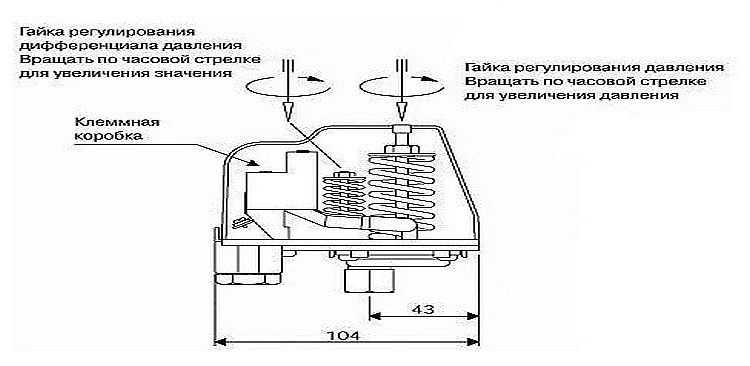

Let's analyze the adjustment of the pressure switch using the example of RDM-5, which is one of the most common devices. It is produced with a setting of a smaller barrier of 1.4-1.5 atmospheres and a larger one - 2.8-2.9 atmospheres. During installation, these indicators must be adjusted depending on the length of the pipeline and the plumbing used. You can change one or both limits in either direction.

In our device there are 2 springs of different sizes, with which you can set the limits for the start and stop of the pumping device. The large spring changes both barriers at the same time. Smaller - the width in the specified range. Each one has a nut. If you turn it and twist it - it increases, if you unscrew it - it falls. Each turn of the nut corresponds to a difference of 0.6-0.8 atmospheres.

How to determine relay thresholds

The smaller barrier is tied to the volume of air in the storage tank, more than 0.1-0.2 atmospheres is recommended. So, when there are 1.4 atmospheres in the accumulator, then the shutdown threshold should be 1.6 atmospheres. In this mode, there is less load on the membrane, which increases operation.

It is important to pay attention to the nominal operating conditions of the pumping device, recognizing them in the performance characteristics. The lower barrier of the pumping device is not less than the selected indicator in the relay

Before installing the pressure switch - measure it in the storage tank, often it does not correspond to the declared characteristics. To do this, a pressure gauge is connected to the control fitting. In the same way, the pressure is controlled during regulation.

The highest barrier is set automatically. The relay is calculated with a margin of 1.4-1.6 atm. If the smaller barrier is 1.6 atm. - the larger one will be 3.0-3.2 atm. To increase the pressure in the system, you need to add a lower threshold. However, there are limitations:

- The upper limit of household relays is no more than 4 atmospheres, it cannot be increased.

- With its value of 3.8 atmospheres, it will turn off at an indicator of 3.6 atmospheres, as this is done with a margin to save the pump and system from damage.

- Overloads adversely affect the overall operation of the water supply system.

Essentially everything. In each case, these indicators are set individually, they depend on the source of water intake, the length of the pipeline, the height of the water rise, the list and technical features of plumbing.

Setting the pressure switch for a pump or pumping station

For a qualitative adjustment of the operability of the water supply, a proven pressure gauge is required, which is connected near the relay.

Adjustment of the pumping station consists in turning the nuts supporting the relay springs. To adjust the lower limit, the nut of the larger spring is rotated. When it is twisted, the pressure increases, when it is unscrewed, it decreases. The adjustment is half a turn or less. Setting up a pumping station consists of the following steps:

- The water supply is turned on and with the help of a pressure gauge the barrier to start and stop the pump is fixed. A large spring is being clamped or released.Restart the system and check both pressure limits. Both values are shifted by the same difference.

- Thus, the adjustment continues until it is completed. After setting the lower limit, the upper indicator is adjusted. To do this, adjust the nut on the smaller spring. It is as sensitive as the previous adjustment. All actions are similar.

When setting up the relay, it is important to know that not all models have the technical ability to adjust the difference between the lower and upper limits. In addition, there are models in a sealed housing that can be installed directly on the pump housing.

They can also be submerged in water.

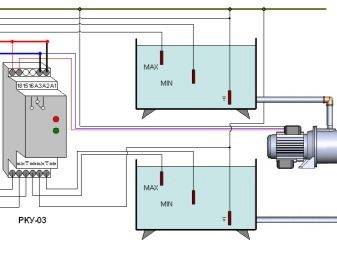

There are instances that are combined with an idle relay that can turn off the pump in the absence of water. They protect the engine from overheating. This is how the water pressure for the pump is regulated, which provides a gentle mode for the water supply.

Advice from experienced professionals

It is recommended to connect the pressure switch of the accumulator to the electrical panel of the house through a separate line with its own RCD.

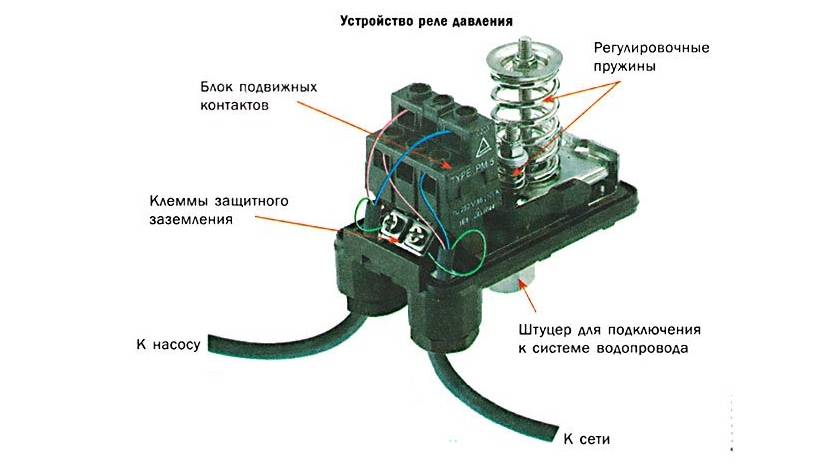

It is also mandatory to ground this sensor, for this it has special terminals.

It is permissible to tighten the adjusting nuts on the relay until it stops, but it is highly not recommended. The device with rigidly tightened springs will work with large errors according to the set Rstart and Pstop, and will soon fail

If water is visible on the case or inside the relay, then the device should immediately be de-energized. The appearance of moisture is a direct sign of a ruptured rubber membrane. Such a unit is subject to immediate replacement, it cannot be repaired and continue to operate.

Cleaning filters in the system must be installed without fail. Nothing without them. However, they need to be cleaned regularly.

Also, once a quarter or six months, the pressure switch itself should be flushed. To do this, the cover with the inlet pipe from below is unscrewed on the device. Next, the opened cavity and the membrane located there are washed.

The main reason for breakdowns of the accumulator relay is the appearance of air, sand or other contaminants in the pipes. There is a rupture of the rubber membrane, and as a result, the device must be replaced

Checking the pressure switch for correct operation and general serviceability should be done every 3-6 months. At the same time, the air pressure in the accumulator is also checked.

If, during adjustment, sharp jumps of the arrow on the pressure gauge occur, then this is a direct sign of a breakdown of the relay, pump or hydraulic accumulator. It is necessary to turn off the entire system and start its full check.

The design and principle of operation of the pressure switch

The relay is a small block with maximum and minimum pressure springs. Its adjustment is carried out by means of the same springs that respond to changes in the pressure force. Having reached the minimum values, the spring weakens, and at the maximum, it compresses even more. Thus, it causes the relay contacts to open, and accordingly turns the pumping station on and off.

If there is water in the water supply, the relay allows you to create a constant pressure in the system and the required pressure. Proper adjustment ensures automatic operation of the pump, which can significantly extend its life.

But before proceeding to the setup, let's go through the device and the principle of operation of the pumping station.

It includes the following components:

- an electric pump that draws water from an external source. It can be submersible, permanently under water or outdoor;

- non-return valve that prevents water from leaving;

- pressure switch;

- water storage tank;

- piping system, which consists of various auxiliary components such as filters, pipes, etc.

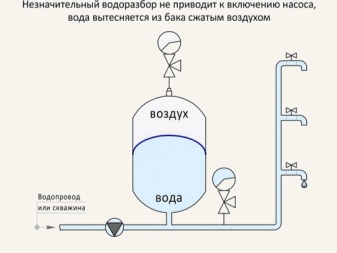

As for the principle of operation, there is nothing complicated in this device. Inside the reservoir or tank there is a pear-shaped balloon made of modified food rubber, and air is pumped between it and the walls of the container. The pump fills the "pear" with water, because of which it expands and compresses the outer air layer, which begins to put pressure on the wall. By adjusting the relay, the owner of the pumping station can set the tank filling limit and the moment it is turned off. All this is controlled by a manometer.

To prevent water from going back into the well or into the system, a spring-loaded valve is provided in the pump. It is enough just to open it and the water that has collected in the "pear" will go through the system. The pressure will drop as the water is consumed, and after it drops below the threshold set in the relay, the pumping station will automatically turn on and fill the tank with water.

The relay is connected between the outlet of the tank and the check valve on the pipeline. In order to save money, all splitters are usually assembled from separate components, but in fact it is easier to buy a five-way fitting, where threads are provided for all parts, including a pressure gauge

In this case, it is extremely important not to confuse the inlets for the check valve and the fitting, since the pump setting will be impossible in this case. But the use of standard spare parts allows you to minimize such errors.

Step by step instructions for adjustment

Conventional plumbing gaskets are rated at 6 bar, and can withstand up to 10 bar maximum and for a short time. And the operating pressure in the water supply and heating systems of residential buildings in most cases ranges from 2–3.5 bar.

It is not worth setting Rstop above 4 bar on the relay. Most household models of this device on the market have a maximum Pstop of 5 bar. However, it is not recommended to set this parameter to the maximum at "five".

It is impossible to tighten or relax the springs on the device to the stop, this can lead to incorrect operation. It is necessary to leave a small margin for tension / loosening.

A circuit from the 220 V network to power the pump passes through the pressure switch of the accumulator; before starting to adjust the device, it must be de-energized

A circuit from the 220 V network to power the pump passes through the pressure switch of the accumulator; before starting to adjust the device, it must be de-energized

Large spring - setting the pressure to start the pump. Small spring - setting the pressure difference to turn off the pumping station.

The accumulator relay is configured as follows:

- Water is draining from the plumbing. Then, in the hydraulic accumulator, the working pressure is set in the pear with air - 10% less than the planned Рstop.

- The power to the relay turns on, the pump starts to work. The pressure gauge records the pressure when it is turned off (Pstop).

- A little faucet in the sink opens with a small trickle. The pressure is fixed when the pump is switched on again (Pstart).

To increase the Rpusk value, tighten the large spring clockwise. To increase the difference between Rstart and Rstop, tighten the small spring.

Reducing these settings is done by loosening the springs counterclockwise.

The passport for the relay indicates the minimum pressure difference between Rstop and Rstart (usually 0.8 or 1 bar), it is impossible to set a small spring to smaller parameters

The passport for the relay indicates the minimum pressure difference between Rstop and Rstart (usually 0.8 or 1 bar), it is impossible to set a small spring to smaller parameters

After setting the required Rstart and Rstop, the relay with the pump is connected to the network. If, according to the pressure gauge, everything works as it should, then the setting is complete. Otherwise, the above three steps are repeated again.

Common faults

The most common cause of breakdowns in pumping stations is a lack of water in the system. The load that appears with a lack of water disables the pump in a very short time. In order not to spend money on the constant replacement of pumps, you should immediately buy a good relay model and do not worry about this cause of failure.

Why is there no fluid in the system?

The main reason for this problem is the high volume of fluid consumption, when the volume of the well or reservoir is simply not enough. During the summer, problems often occur that cause interruptions in the delivery of water. Drought or repair of pipes can cause an unexpected interruption in the water supply.

The most unpleasant cause is an accident at the pumping station. In this case, you will have to change the pump and all related parts, and at the same time, for a certain period of time, the house remains without water supply.

Corrosion can cause failure of pumping equipment

It was to protect against these unpleasant situations that a water pressure switch for a pump with dry-running protection was invented.This function of the device is able to open the contacts, and completely turn off the pump. The pump motor will start again only when the water flow returns to normal. The indicator, which includes protection against dry running, is set at the factory during manufacture. Most often it is 0.5 atm. This number cannot be changed.

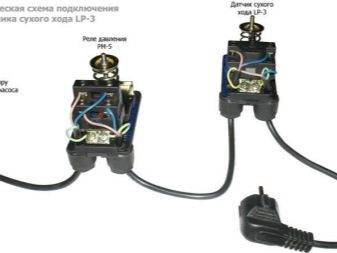

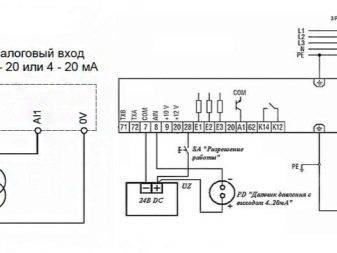

Wiring diagram for dry running sensor

In addition, manufacturers offer a flow switch that combines its functions with a pressure switch. This version of the device is also able to ensure the correct operation of the water supply.

Note! During adjustment work, you should definitely pay attention to the power specified by the manufacturer. The station should not be tuned to the pressure that it cannot withstand, according to the manufacturer

Need to know

With a high pressure setting, the suction equipment is turned on much more often, which leads to accelerated wear of the main parts. However, this pressure allows you to use even a shower with hydromassage without any difficulties.

A visual diagram of the supply of a residential building with water from a well

At low pressure, the device that supplies liquid from a well or well wears out less, but in this case you will have to be content with an ordinary bath. All the delights of a jacuzzi and other devices that require a sufficiently strong pressure are unlikely to be appreciated.

Thus, the choice must be made depending on the goals pursued. Everyone decides for himself what to prefer in a particular case.

The device and principle of operation of the relay

Pumping station for a private house

Prices for pumping stations

Pumping stations

The pumping station is quite compact and has a simple device. The relay itself consists of several elements.

Table. Components of the pressure switch.

| Element name | Purpose and brief description |

|---|---|

| Switching pressure adjustment spring and nut | This spring sets the pump shutdown parameters. When it is compressed, the maximum pressure increases. Adjustable with a nut. When the nut is loosened, the pressure drops. The spring is mounted on a movable plate that turns on/off the terminals. The movable plate is connected by a metal pipe to the hydraulic accumulator. The pressure of the water lifts it, the contacts open. |

| Frame | Made of metal, used to fix all relay elements. |

| metal flange | With its help, water is supplied from the accumulator to the relay. At the same time fixes the device on the pumping station. |

| Cable entry sleeves | One is supplied with mains power, and the second supplies voltage to the electric motor. |

| Cable terminals | The phase and zero of the engine are connected to the lower ones, the mains supply to the upper ones. It is not necessary to follow this order. |

| grounding | Connects the metal case of the pumping station to the grounding of a house or apartment. Do not confuse the neutral wire and grounding, they are different concepts. |

Factory settings do not always meet the wishes of consumers, in this regard, it is very often necessary to make an independent setting of the parameters.

Adjusting the relay parameters allows you to achieve maximum efficiency of the equipment

The principle of operation of the pressure switch

This is interesting: How to make plumbing on cottage from the well: circuits and device

Device principle

The most common mechanical pressure switch of a pumping station is a metal plate on which there is a contact group on top, two spring-loaded regulators and connection terminals. The membrane cover is installed on the bottom of the metal plate. It directly covers the membrane and the piston attached to it. And also on the cover there is a threaded connection for installation on the adapter, which is located on the pumping equipment. All of the above construction details are covered with a plastic cover.

On the working part of the regulator, this cover is fixed with screws.

Relays can have a different configuration, shape, and even differ in the location of some elements or the connection diagram. There are relays that have additional protective elements that keep the device dry when running and allow you to protect the motor from overheating.

For the water supply of a private house, station designs are used in which RM-5 or its foreign analogues act as a pressure regulator. Such a model of the pressure switch inside has a movable plate and two springs on its opposite sides. The plate is moved by the water pressure in the system using a membrane. By turning the clamping nut of one or another spring block, it is possible to change up or down the limits at which the relay operates. The springs, as it were, help to ensure that the water pressure displaces the plate.

The mechanism is made in such a way that when the plate is displaced, several groups of contacts open or close. If we consider the scheme of work, then it will be as follows. When turned on, the pump supplies water to the accumulator. Power is supplied to the motor through the closed relay contacts.This increases the water pressure in the tank.

When the pressure reaches the value set by the upper limit springs, the mechanism is activated, the contact opens, and the pump is turned off. The liquid from the pipeline does not drain back into the well due to the check valve. As the water is used, the pear becomes empty, the pressure drops, and then the lower parameter spring is activated, which closes the contacts, including the pump. Then the cycle repeats.

During the operation of the entire pumping station, the operation of the pressure switch is as follows:

- a tap with water opens, and it comes from a filled hydraulic tank;

- in the system, the pressure begins to decrease, and the membrane presses on the piston;

- contacts close and the pump turns on;

- water enters the consumer, and when the tap closes, it fills the hydraulic tank;

- when water is drawn into the hydraulic tank, pressure rises, it acts on the membrane, and it, in turn, on the piston, and the contacts open,

- the pump stops working.

The relay settings also determine how often the pump will turn on, the water pressure, and the service life of the entire system as a whole. If the parameters are set incorrectly, the pump will not work correctly.

Things to consider when making adjustments

If you are going to independently adjust the operation of the relay of the pumping station, you must not miss some important points:

- You can not set the "upper" pressure, which is more than 80% of the maximum for this relay model. It is usually indicated in the instructions or on the packaging and, most often, is 5-5.5 bar (atm.). If you need to set it to a higher level in your home system, then you need to choose a switch with a higher maximum pressure.

- Before increasing the pressure on the pump (“upper”), it is necessary to look at its characteristics, whether it can develop such pressure. Otherwise, the pump, being unable to create it, will work without turning off, and the relay will not turn it off, because the set limit will not be reached. Usually the pump head is given in meters of water column. Approximately 1 m of water. Art. = 0.1 bar (atm.). In addition, it is necessary to take into account the hydraulic losses in the system.

- When adjusting, it is not necessary to tighten the nuts of the regulators to failure - the relay may generally stop working.