- Drain-overflow system: a little more

- Drain system: what is it made of

- The device and types of strapping

- Construction materials for water drainage

- Traditional system

- Production material

- So, how does a bathtub overflow drain work?

- Let's analyze in more detail the drain overflow for the bath

- Structural features

- How to choose the right drain material

- Bath strapping: principle of operation

- What are the devices made of?

- How to install or change harness

- Dismantling the old harness

- Drain and overflow installation

- Siphon assembly

- Self-installation of strapping for the bathroom

Drain-overflow system: a little more

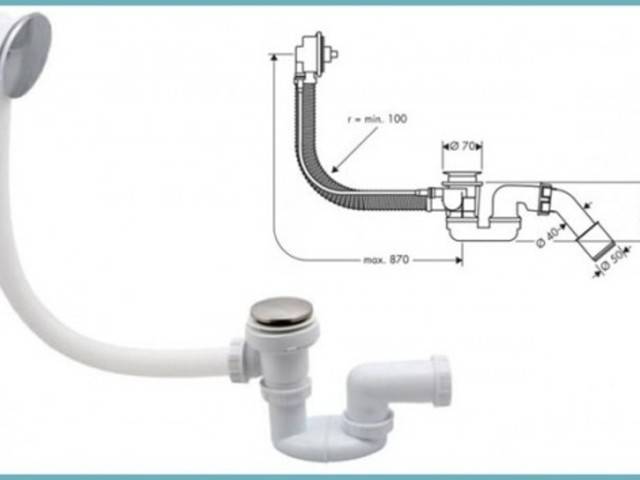

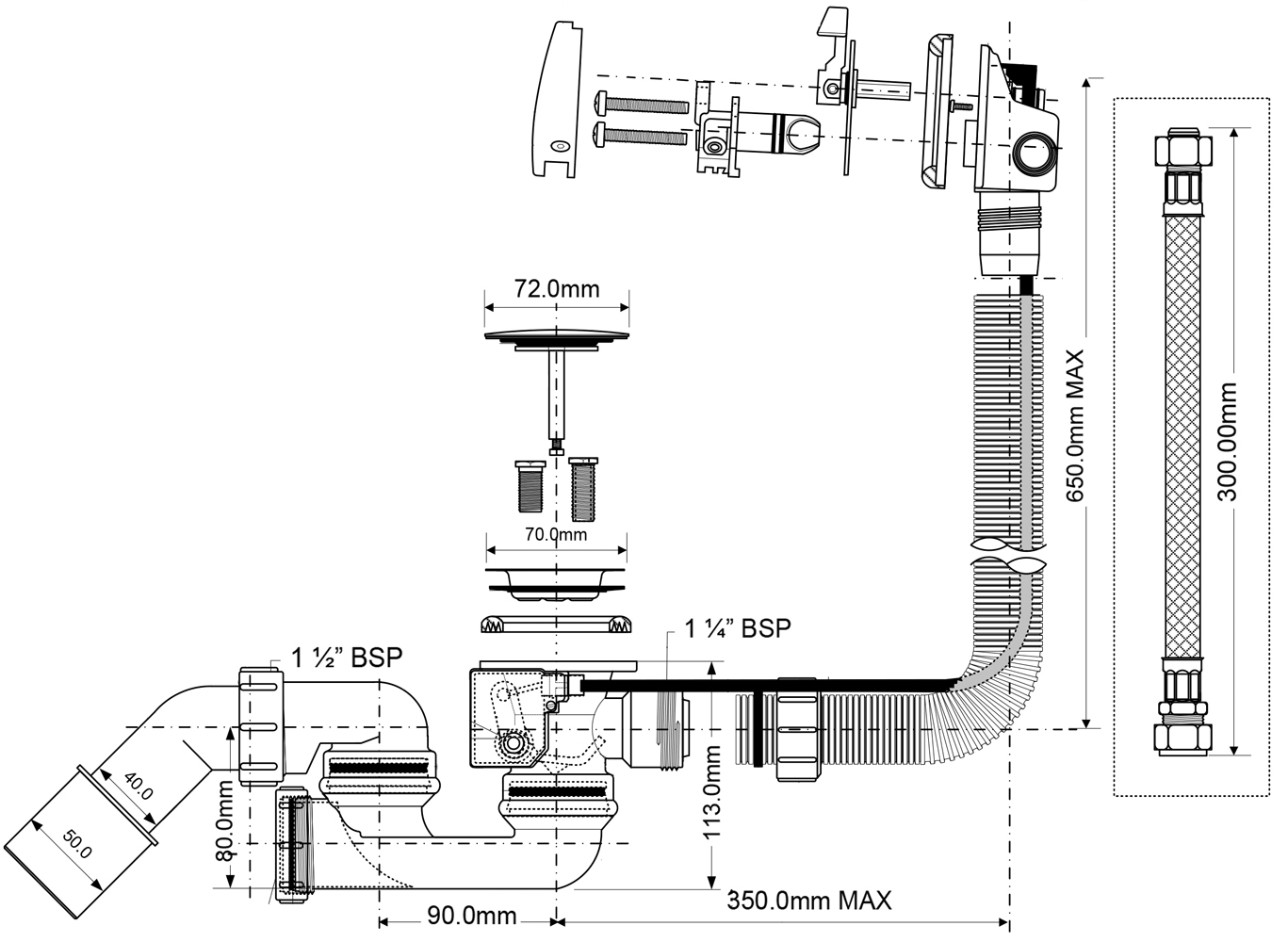

Detailed diagram of a standard drain-overflow device

Detailed diagram of a standard drain-overflow device

If you need to update the drain in the bathroom, it is worth reading reviews of all designs to make a choice. How the drain works in a bathroom with a simple siphon, you already know how the drain-overflow differs too. But there are nuances, the understanding of which is necessary for the correct selection of the design.

The drain-overflow device is a simple device that looks like a pipe, where one end is connected to a round hole under the upper side of the bath, and the second is lowered much lower and inserted into the sewer water pipe. Such a device bathroom floor drain does not take much time and is suitable for all bathrooms.And as it is already becoming clear, the upper part of the pipe is called an overflow, and the lower part is called a drain, but there is another concept practiced by plumbers: a drain-overflow bathroom piping. Such a system is completely closed and never leaks (unless the sewer pipe is clogged). You can see the details of the system in the photo below.

Drain system: what is it made of

The most common materials for the manufacture of plums

The most common materials for the manufacture of plums

The main raw materials for the manufacture of structures are: non-ferrous metals, copper, brass, bronze. This is practical, raw materials are not afraid of alkalis and acids, are not subject to corrosion and are not deformed under the influence of hot water. How to distinguish when buying? In appearance:

- red tint - copper product;

- yellowish tone - brass drain. It is an alloy of copper and zinc powder;

- yellow with a brown tone (pronounced) - bronze. The most durable composition, which is a combination of tin and copper.

The appearance of polymers allowed to expand the range of pipes and other plumbing equipment. Manufacturers also offer polypropylene structures. For example, a durable plastic water drain system, an acrylic bathtub is a durable and affordable combination that will appeal to almost all buyers.

It is very important that plastic can be cut with a knife, which makes installation especially convenient and can be bought by the meter, without having to remember the dimensions.

The device and types of strapping

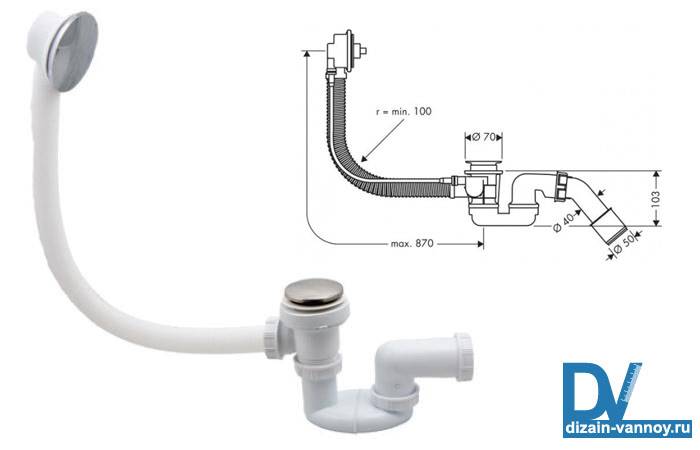

The bathroom piping itself includes a lower and upper hole (drain and overflow). Through the lower hole, water enters the sewer pipe, the upper one performs the functions of controlling the liquid level in the bath in order to prevent overflow.Due to the simple installation, the strapping is often used in everyday life.

Now that it has become clear what a tub piping is, let's look at different types of equipment. The strapping differs in material, design and installation method. Usually plastic or metal is used as the material. The service life of plastic strapping can be long, despite the low price.

Such material is resistant to various chemicals and is in demand in the plumbing market. Contrary to the listed advantages, the construction of the plastic strapping is fragile and problematic to install. This is due to the need for cutting and soldering plastic elements and the formation of various kinds of burrs and notches that must be removed.

Metal strapping also copes well with its functional duties and, like plastic, has its drawbacks. These include the complex installation of the structure, the frequent occurrence of blockages with grease and dirt during use. In addition, you can add a high cost.

Basically, the metal strapping consists of an alloy of metals such as copper, brass or polished stainless steel.

The plumbing for the bathroom drain-overflow is divided into:

- Universal strap for the bath. Such designs are the cheapest and simplest. Are established on cast-iron bathtubs, or on bathtubs from steel and acryle. The set includes a plug with a chain, and four elements: a siphon, a drain with a metal lining for installing the lid, an overflow neck with a metal lining, and a corrugated hose. This hose connects the drain and overflow.

- Strapping for a bathtub a semiautomatic device.In these designs, the overflow neck is equipped with a special swivel lever connected by a cable to the cork. The drain opening opens or closes when the lever is rotated. Disadvantages - the fragility of the system and frequent breakdowns of plastic parts.

- Strapping for a bathtub the automatic machine. Such designs do not contain any cables or fragile parts. The drain is opened and closed by pressing on the plug. Disadvantages - the presence of a large hole under the drain plug, which in a short time becomes clogged with small debris and hair.

There is almost no difference in the design of the bath piping from the system that is mounted on washbasins. In both systems, the drain and overflow are connected to different parts of the equipment. Thanks to the drain pipe, excess water leaves and flooding of the apartment is prevented.

The drain hole is located at the bottom, and for overflow on the side, five centimeters below the rim of the bath. The overflow system is very important for a bathtub. The correct operation of the drain depends on the quality of the material, proper installation and sealing of the structure.

Construction materials for water drainage

Siphons can be made of various materials and installed on different bathtubs of any configuration. All designs can be divided into two large groups: plastic and metal products. Different materials have the same requirements. Such structures must be durable, resistant to moisture.

According to these parameters, they are not inferior to plastic products, but they are more expensive. Thus, drain systems made of different materials differ in cost and have their own individual technical parameters, advantages and disadvantages.

Cast iron bath overflow drain has become very popular due to its low cost, strength and corrosion resistance. In the past, standard cast-iron bathtubs, which were installed inside the bathrooms of standard apartments, were equipped with such products of the same type. Holistic structures had clear standards for size and configuration, so the slightest inconsistency in these parameters led to leaks. The main disadvantage of such systems is the rapid "overgrowth" of the internal lumen, difficulties in cleaning, repair and dismantling.

The siphon for a modern bath in various materials is often made from various types of plastics. Such materials are durable, good resistance to corrosion, aggressive chemicals, moisture and high temperatures. Various contaminants are poorly deposited on such surfaces, they are easy to clean using strong chemicals. Also, such structures are easily disassembled without the use of physical effort. The main disadvantage of such siphons is their limited service life.

A bathtub siphon made of copper or brass is a quality durable product. These materials are distinguished by high aesthetic appeal, as well as excellent technical characteristics. Such systems have chrome parts that decorate the appearance. Despite the external beauty, the best materials for siphons are still cheaper ferrous alloys.

Polypropylene structures made of transparent materials have taken their rightful place in the market.Resin piping for a modern bathroom, providing a reliable overflow drain, is a durable, relatively inexpensive siphon option that is easy to install by adjusting the dimensions with a trim.

Traditional system

This bathtub overflow has been installed for several decades - it is thanks to him that people have the opportunity to take a bath simply by plugging the drain with a stopper. The device is assembled from the following parts:

- The drain neck is the bottom hole, which is usually located at the bottom. Serves for direct water drainage.

- The overflow neck is installed higher, usually on the wall of the bathroom, it is connected to the general network using a side drainage hose.

- Siphon - a curved tube that acts as a shutter. It prevents the appearance of sewage odors in the apartment.

- The connecting hose is a corrugated pipe through which water from the overflow enters the siphon.

- The drain pipe is the last part of the system, from which water, in fact, enters the sewer.

In fact, almost every person is able to understand such a simple system, even without special education. Current repair usually consists of replacing the gasket or several of them.

Production material

The choice of material for making the strapping is more dependent on the personal preferences of the owner of the bath.

Conventionally, all materials can be divided into three groups:

1. Plastic or polypropylene. The most commonly used material. The choice in favor of such models is made when a screen is installed on the bath, which hides all plumbing wiring.

The advantages of polypropylene strapping include: - no corrosion and plaque formation on the inner surface; - ease of installation and dismantling. In their design there is a corrugated pipe, so the length can be simply adjusted; - low price. Of all types of strapping, this one is the cheapest, while in terms of service life it is in no way inferior to its counterparts.

Important! Despite its good performance, the overflow drain can be damaged or clogged. Therefore, when installing the screen, you must leave access to it in case of unforeseen repairs.. 2

Black metal. It does not have a very presentable appearance, therefore, to use it, it is also desirable to cover the bath with a screen. But, this disadvantage is justified by its reliability and long service life.

2. Ferrous metal. It does not have a very presentable appearance, therefore, to use it, it is also desirable to cover the bath with a screen. But, this disadvantage is justified by its reliability and long service life.

strapping materials

strapping materials

3. Non-ferrous metal (copper, bronze, brass). The strapping of such materials is often chrome-plated and has a rather attractive appearance. Due to its rather high cost, it is also used as a decorative element - for bathtubs that do not provide for a screen. For example, on beautiful carved legs or irregular shape.

Advantages of models made of non-ferrous metals: - high corrosion resistance (especially for copper); - attractive appearance; — reliability and long service life.

Disadvantages - a more complicated installation process than, for example, polypropylene.

So, how does a bathtub overflow drain work?

Without knowing how the drain in the bathroom is arranged, you will not be able to solve some everyday situations, such as poorly draining water from the bath or an unpleasant smell.

Surely everyone knows that there are two openings in the bathroom - upper and lower. The bottom one is drain and the top one is overflow. Therefore, they are called so-called drain-overflow.

The bathtub overflow device is actually quite simple.

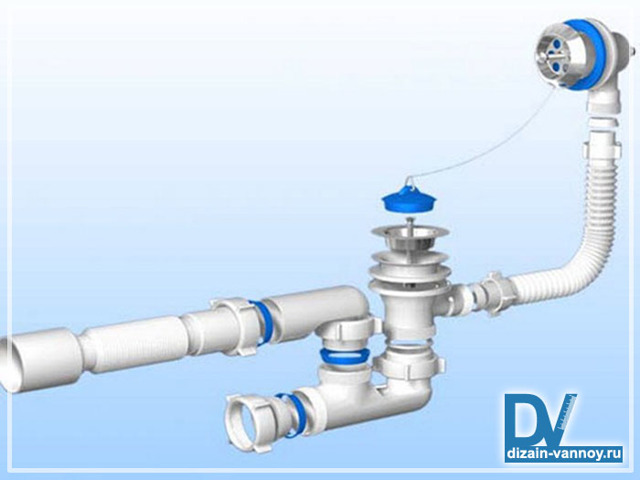

The product can be divided into 4 parts (if you take into account additional connecting elements, you can get more parts), which do not really matter, except for ease of connection and assembly

- Drain - it is located at the bottom of the bath and consists of 2 parts. Its lower part is a branch pipe with an extension and a built-in nut. The top part is made in the shape of a chrome plated cup. These parts are placed at the top and bottom of the bath and are connected to each other with a long metal screw. In such an attachment, tightness is achieved by a special sealing gasket.

- Overflow neck - in principle, it has the same device as the drain. The only difference is that the outlet for water is not straight, but lateral. It is designed to remove excess water from the bath if the bath suddenly overflows uncontrollably. But do not count on the overflow hole at 100%. The overflow pipe is small and with a large pressure of water, it may not be able to cope.

- Siphon - can be made in different configurations, but almost always it is a removable curved pipe, in which water always remains. This is precisely the water seal that prevents the unpleasant smell of the sewer from entering.Here it is worth noting one important factor - the volume of the water seal is of great importance. If the ventilation of the sewer riser does not work well, then this water (besides, if it is not enough) can be sucked out of the siphon, in which case an incredible stench is provided to you. It is better to choose a siphon with a deeper water seal, which will fit no less than 300-400 ml of liquid.

- Corrugated hose for connection - used to divert water into the siphon from overflow. In this area, the water pressure is relatively low, so most often this hose is pulled onto special pipes (brushes) without crimps. In more serious siphons of this type, the overflow and hose connection is sealed with a gasket and a compression nut.

- Pipe for connecting the siphon to the sewer - it can be of 2 types: corrugated and rigid. The first is more convenient to connect, but the second is more reliable. In addition, the advantage of the corrugated pipe is the length, which can be adjusted according to your needs.

Let's analyze in more detail the drain overflow for the bath

We have listed all the parts into which almost all bathtub drains offered today can be divided. The only additional thing you need to know in order to assemble a bathroom overflow drain is how to connect the individual parts. There are 2 types of fastening: with a flat sealing gasket and with a conical one. In both cases, a union nut is used to fasten the drain parts.

If we talk about cone gaskets, then they are mounted with a sharp edge from the nut. The thin part should go inside the opposite part, but not vice versa.If on the contrary, then leaks will begin, you will have to use silicone, and in the end everything will end up calling a plumber and you will have to pay extra money. Unfortunately, these situations happen quite often.

Now let's look at the types of drain siphons for the bath. There are not very many of them. If you do not take into account some design and technological features, then siphons can be divided into a conventional one with a plug and a drain-overflow machine. They differ in the plug opening system, which consists in turning the lever on the overflow. This system allows you to get the plug from the bathroom drain without bending over to it. You will only need to turn the round lever, which is located on top of the tub. As for simple drains, they can differ in the shape of the pipes (the shape can be round or rectangular), the method of attachment to the sewer (rigid pipe or corrugation) and the type of sealing of the attachment (straight or conical gaskets).

Structural features

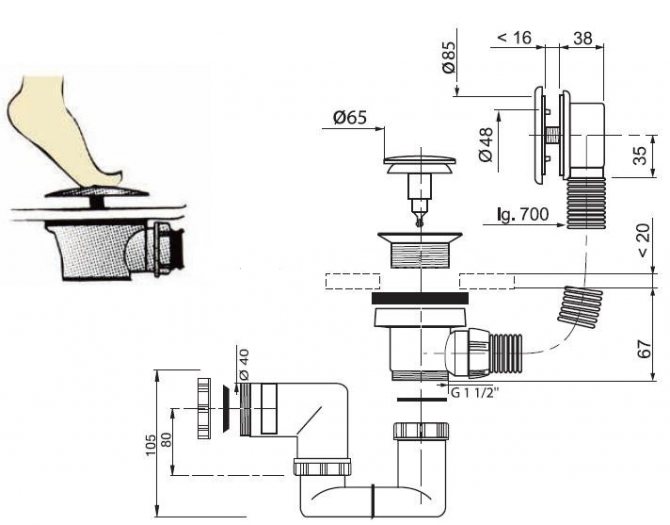

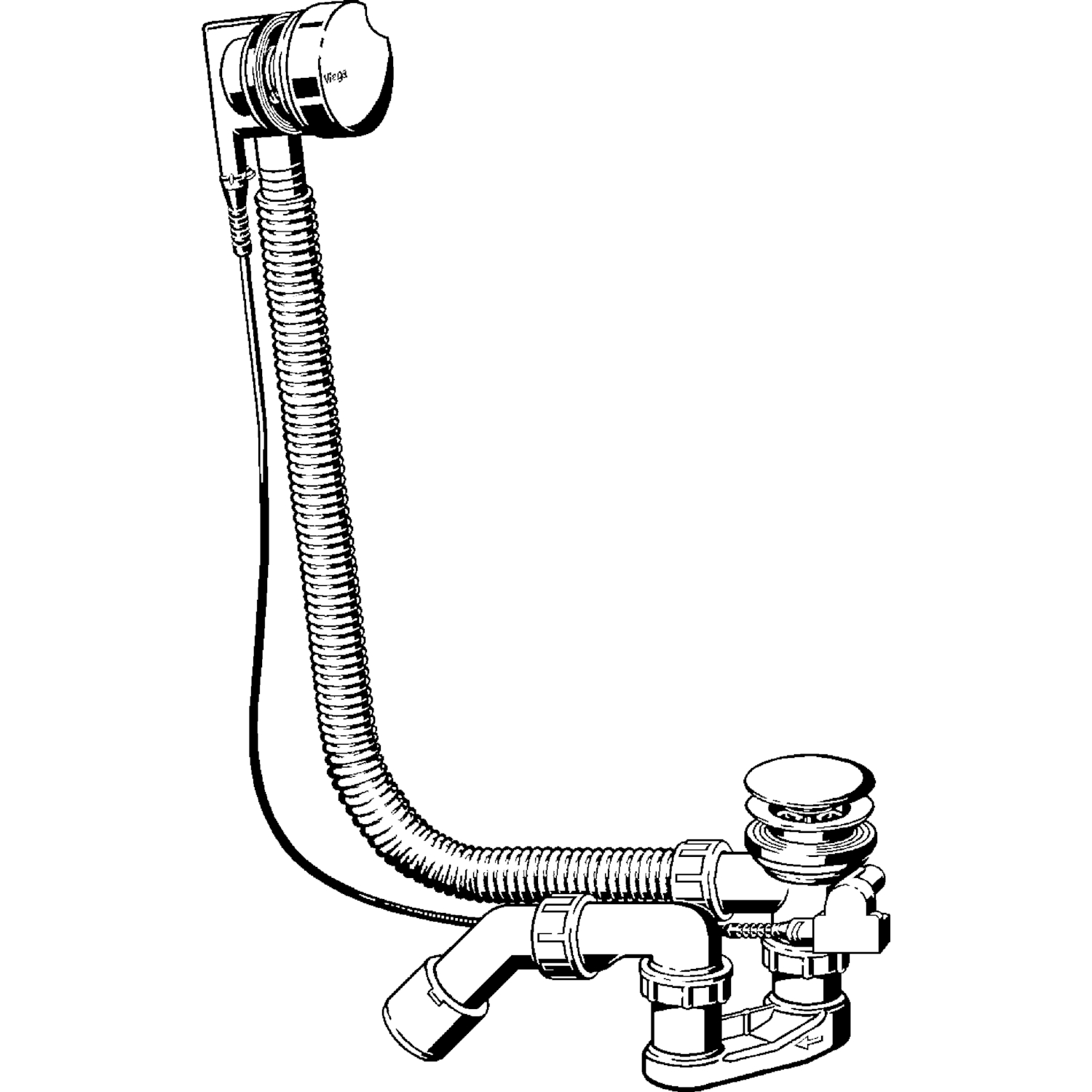

The bathtub drain-overflow system is divided into two types according to the type of design: automatic and semi-automatic.

The siphon machine is quite easy to use. It has a different name - "click-clack" and is launched by simply pressing the cork at the bottom. After that, the drain opens, with a subsequent press, it closes. The main part of such a mechanism is a spring attached to the cork. The whole structure is located in such a way that it is very convenient to drain the water while lying down only by pressing the foot after the bath procedure.

Semi-automatic drain-overflow is also started manually. A special swivel head closes the hole on the wall of the bath, and it is also connected to the drain mechanism.They are connected by a cable mechanism, which allows opening the drain mechanism when unscrewing the head on the bath wall. The main disadvantage of these designs is the jamming of the mechanism.

The main difference between these two designs is the price. Which option suits you best is just a matter of taste and comfort.

How to choose the right drain material

Build quality, wear resistance of all parts of the equipment - the key to successful operation of the product for many years:

- Plastic is a relatively inexpensive raw material for the manufacture of budget plums. It does not rust, but at the same time, the whole system as a whole has an unpresentable appearance, resistance to mechanical stress, strength may be desired.

- The ideal option for drainage systems is metal. It is durable, increases the warranty period of the product, has an attractive design. As a rule, copper, brass or bronze is used.

During construction, it is preferable to use equipment from these materials, although you will not see a big difference between plastic and metal in the “short distance”, it will appear with prolonged use.

Bath strapping: principle of operation

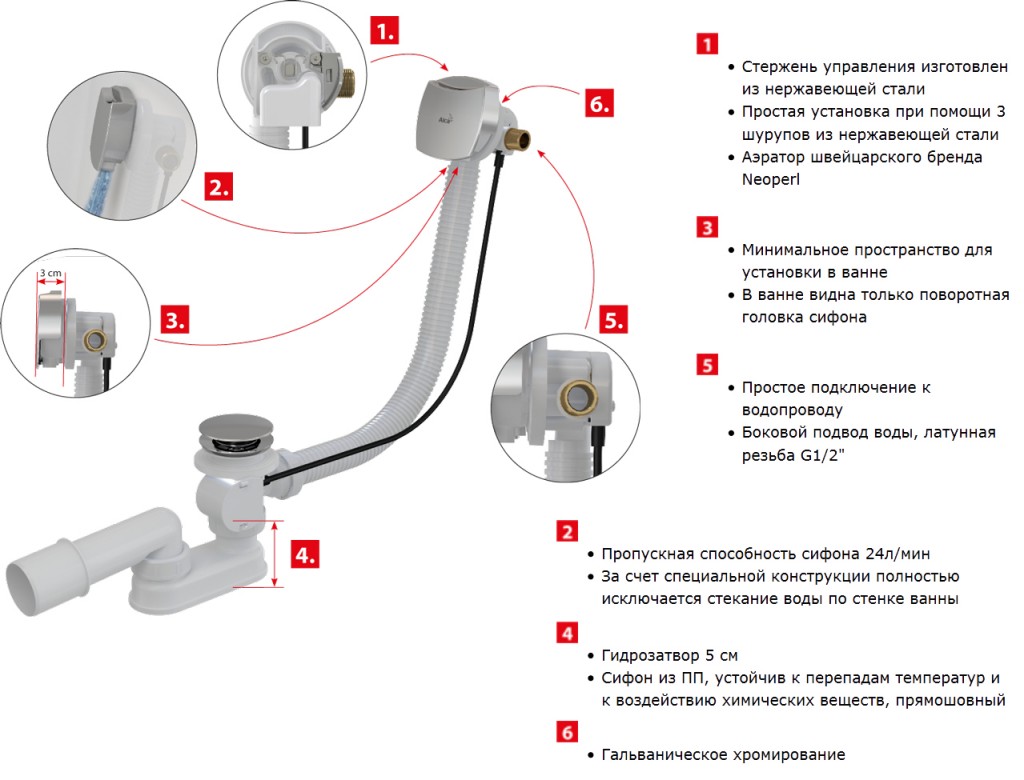

Those who have never seen the tub piping can look at the photo. For those who are more or less aware, a description will suffice.

A device designed to drain and pour water is actually an ordinary siphon. This siphon has a branch attached to the top hole. Such a branch or simply a tube should drain water from an overflowing sink.

In modern piping options, the upper drain hole is equipped with a rotary lever, and the lower one is equipped with a valve.The lever and the valve are connected by a cable, which, when pulled, regulates the amount of liquid passed through the hole.

In such a drain system, a plug is not needed, by turning the lever, we slightly open the valve in this way or close it.

Inlet hose for washing machine with aquastop

What are the devices made of?

In previous years, when the plumbing equipment market was not very diverse, the main elements of the system were made of ferrous metal.

In principle, such structures are regularly capable of serving for decades; their only drawback is their unattractive appearance

In principle, such structures are regularly capable of serving for decades; their only drawback is their unattractive appearance

The material for the manufacture of the main elements of modern systems are most often:

- sanitary plastic;

- non-ferrous metals.

Polypropylene is available in price. It is famous for not rusting and resistant to water, "rich" in salt content. But in comparison with metal, when arranging a bathroom, sanitary plastic looks very budgetary.

And in the bathrooms, decorated in an exquisite design - and completely ridiculous. Plastic strapping should be chosen if you plan to install a screen under the bathroom.

In terms of design and superior performance, metal harnesses lead the way: although they are more expensive, they allow you to maintain the desired style.

In terms of design and superior performance, metal harnesses lead the way: although they are more expensive, they allow you to maintain the desired style.

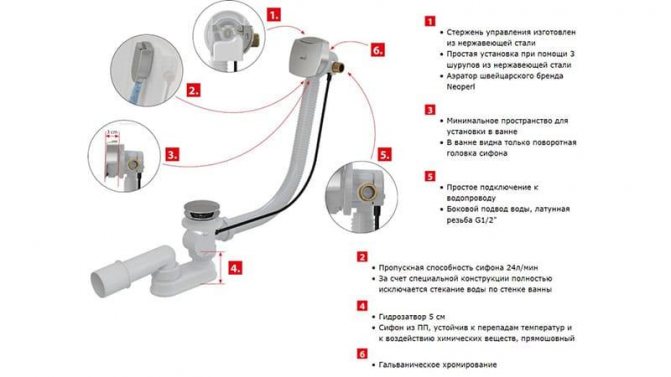

Among the non-ferrous metals with high corrosion resistance, the most widespread are: copper, bronze and brass. In their pure form, they are usually not used.

Opening mechanisms, gratings of drain holes and other visible parts are coated with nickel or chrome using electroforming technology.

Metal strappings are beneficial in that they practically do not deteriorate over time, the service life of such products is more than 10 years. They need timely cleaning, which is not difficult to perform by disassembling the washer connection.

Chrome-plated parts are "vulnerable" to mechanical stress. The slightest scratch can ruin the protective nickel-plated film; over time, the coating will simply “wash off”.

Nickel parts are renowned for their durability. But they are significantly inferior to plastic in terms of resistance to mechanical stress. Bronze products are much harder and stronger.

It is easiest to visually determine what metal the elements of the system are made of by the color of the metal:

- copper is a rather soft and ductile metal with a reddish tint;

- bronze - a durable alloy of copper and tin, which is closer to dark brown in color;

- brass - is a harder alloy of zinc and copper, painted in a yellowish tint.

Brass or bronze trims will look good in classic and retro interiors.

Brass or bronze trims will look good in classic and retro interiors.

For modern styles, nickel-plated models with a shiny surface are more suitable.

How to install or change harness

You can install a universal system of simple execution yourself. Installation of a more complex semi-automatic or automatic system is best left to professionals.

To carry out the work you will need:

- installed drain system;

- grinder or hacksaw;

- flat or Phillips screwdriver;

- cotton napkins;

- silicone sealant.

The installation of the strapping for the bathroom is carried out in several stages.

Dismantling the old harness

Before proceeding with the installation of new drain equipment, it is necessary to thoroughly clean the surface of the bath and dismantle the failed device.

Plastic systems will not be difficult to unwind, in extreme cases - to break. To extract the metal strapping, you will have to use a grinder.

To dismantle the metal structure, first cut out the drain of the old siphon, trying not to damage the enamel of the bottom of the bathroom

If it will be difficult to crawl under the bath, we advise you to turn the container upside down. You can remove dirt by wiping the surface with a cotton cloth soaked in detergent.

Drain and overflow installation

Both necks have the same structure. They consist of a faceplate, the neck itself, a screw and a gasket. First of all, all burrs are removed from the surface of the neck by treating the surface with sandpaper, a file or a knife.

The drain hole is wiped dry. The grids are disconnected from the drain/overflow tubes.

A rubber gasket is inserted into each neck, having previously treated the contact points with a sealing compound

Having passed the coupling bolt through the center of the front lining, insert it from the other side into the overflow neck, tightening it with a wide screwdriver.

Tighten the screw lightly so as not to damage fragile elements.

By the same principle, the upper overflow is collected.

Siphon assembly

The bathtub siphon has two main parts that need to be connected.

A plastic nut is first inserted into the small part, then a rubber seal is inserted under it, placing it with the wide side towards the docking point

A small part is inserted into a large workpiece, tightening the nut until it stops.Even when the nut is tightened to the stop, a small part must move along its axis, due to which, during the installation of the structure, the corrugation can be placed in any convenient direction.

A rubber seal is inserted into the second nut, located with an element that fixes a small part, and another part of the siphon is inserted, which will subsequently be attached to the bottom of the bathroom

The second nut is also screwed all the way so that the rubber gasket is pressed tightly against this part of the siphon. After that, you can screw the revision cover into the siphon, after inserting a rubber seal into it.

The presence of this element simplifies the procedure for eliminating blockage.

Self-installation of strapping for the bathroom

bathtub piping schematic diagram

The piping in the bathroom must first be completed, which is important. If, however, a plastic strapping model is installed, then you can install it yourself

And, for this you need to follow just a few step-by-step recommendations:

- Dismantle parts of the old system;

- Eliminate all kinds of deposits and contamination from the holes (main and overflow);

- Carefully detach the grate of the overflow pipe, as well as the main drain pipe;

- On the front side, attach a grate to the drain pipe and fix it with a screed bolt;

- Carry out all the above steps and in the same sequence.

You should also pay attention to the fact that the kit should include rubber gaskets for the main drain pipe and a spare overflow, these gaskets must be installed not from the front, but from the back of the bath (shower cabin).Otherwise, leaks are to be expected.