- The best pyrolysis boilers

- Bourgeois-K MODERN-12

- Bourgeois K TA 20

- Viessmann Vitoligno 100 VL1A025 30 kW

- Kiturami KF-35A

- Geyser PK-20

- Calculation of the power of a gas boiler depending on the area

- Calculation of a single-circuit heating boiler

- How to calculate the power of a double-circuit boiler

- Calculation of the power of an indirect heating boiler

- The best double-circuit gas boilers

- Haier Aquila

- Baxi LUNA-3 Comfort 310Fi

- Options for long-burning home stoves

- Hot air type

- Hot water type

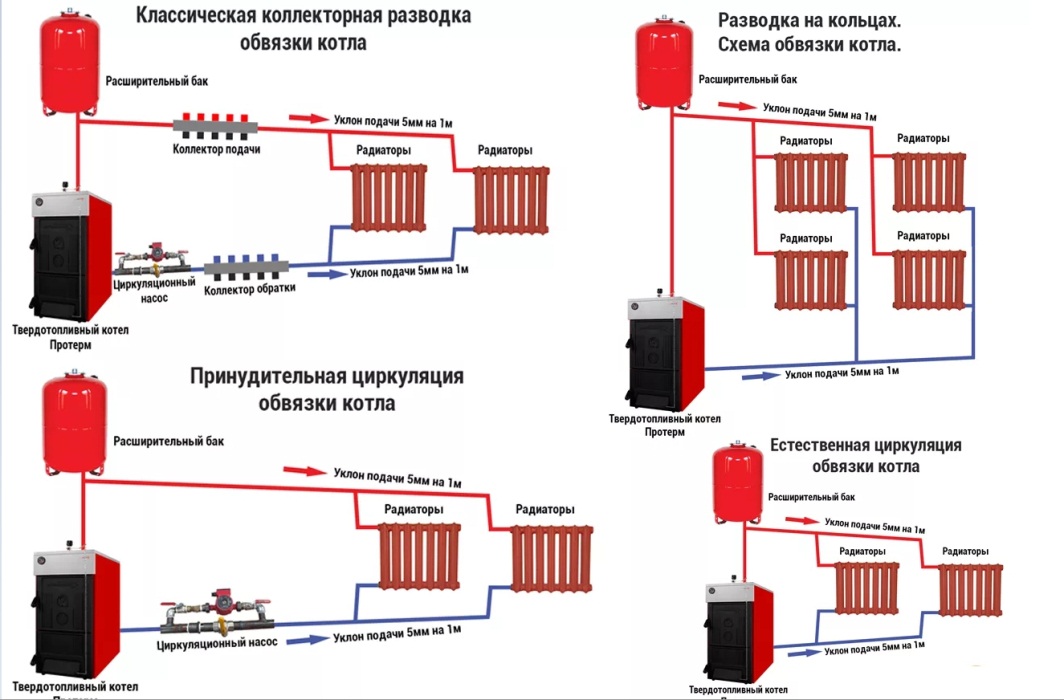

- Forced circulation system

- Application options

- Solid fuel boilers

- Pros and cons

- Long burning boilers

- Choosing a boiler

- Classic boilers

- Pyrolysis boilers

- Automatic boilers

- Long burning boilers

- What to look for when choosing a boiler?

- Types of equipment by design

- How to calculate power correctly?

- Regulator type and price tag

- Technical parameters of solid fuel boilers

The best pyrolysis boilers

Such devices belong to the subspecies of solid fuel boilers, they often run on fuel and can heat the water circuit. Often they are bought and installed at industrial facilities, but some buyers use units for the home.

Bourgeois-K MODERN-12

A good and unpretentious option for 65,000 rubles, which can work with almost any fuel.The efficiency is 92%, and the cost corresponds to the performance. The device can heat up to 120 sq.m., the main drawback is the need to use a large number of consumables and skills to clean the device. Although the price is too high, but the appearance and build quality are very worthy.

Pros:

- High rate of efficiency.

- Complete independence.

- Modern look.

- Small dimensions.

The disadvantage of the boiler is the average efficiency.

Bourgeois K TA 20

Excellent economical model with a price of 59,800 rubles. By installing a boiler, you can save 3-4 times more on fuel than when using competitive models. The performance characteristics are excellent, the option is the best in terms of quality and price.

Pros:

- Long service life.

- High economy.

- Efficiency.

- Good thermostat.

The main disadvantage is the large mass of equipment.

Viessmann Vitoligno 100 VL1A025 30 kW

A model that works only with wood and coal. The capacity allows you to load large firewood up to 50 cm long, and the device immediately heats up to 300 sq.m., but its price is 236,000 rubles. An electronic screen was implemented on the case, which helps to adjust the temperature. There are no operational problems.

Pros:

- Good efficiency at 87%.

- Long burning.

- Profitability.

- Thermal insulation indicators.

Among the shortcomings, consumers note the need to use small firewood for decay.

Kiturami KF-35A

This model is considered the best in its class, but can heat up to 100 sq.m. The cost of the unit is 100,000 rubles. Such a boiler for 2 circuits, with a power of 24 kW, its efficiency is 85%, and work is carried out using firewood and briquettes. An open combustion chamber and a single-phase network have been implemented to increase productivity.During operation, no extraneous noise appears, and cleaning is very simple. The high price is caused by a reliable manufacturer.

Pros:

- Impeccable reliability and assembly.

- Great look.

- Silent operation.

- Unpretentiousness in service.

- Proven manufacturer.

- Easy cleansing.

- Power.

No cons were found in the boiler.

Geyser PK-20

The best option if you need to heat large areas. The cost of the model is 55,500 rubles, it works on wood and one load is enough for heating for the whole day. The device is economical, easy to clean and completely self-contained. The main problem is the need to create a foundation for the apparatus.

Pros:

- Profitability.

- High reliability.

- Simple operation.

- Complete autonomy.

Minuses:

- Big sizes.

- The need for a foundation.

Calculation of the power of a gas boiler depending on the area

In most cases, an approximate calculation of the thermal power of the boiler unit is used for heating areas, for example, for a private house:

- 10 kW per 100 sq.m;

- 15 kW per 150 sq.m;

- 20 kW per 200 sq.m.

Such calculations may be suitable for a not very large building with an insulated attic floor, low ceilings, good thermal insulation, double-glazed windows, but no more.

According to the old calculations, it is better not to do it. Source

Unfortunately, only a few buildings meet these conditions. In order to carry out the most detailed calculation of the boiler power indicator, it is necessary to take into account a full package of interrelated quantities, including:

- atmospheric conditions in the area;

- the size of the residential building;

- coefficient of thermal conductivity of the wall;

- the actual thermal insulation of the building;

- gas boiler power control system;

- the amount of heat required for DHW.

Calculation of a single-circuit heating boiler

Calculation of the power of a single-circuit boiler unit of wall or floor modification of the boiler using the ratio: 10 kW per 100 m2, must be increased by 15-20%.

For example, it is necessary to heat a building with an area of 80 m2.

Calculation of the power of a gas heating boiler:

10*80/100*1.2 = 9.60 kW.

In the case when the required type of device does not exist in the distribution network, a modification with a larger kW size is purchased. A similar method will go for single-circuit heating sources, without a load on hot water supply, and can be used as the basis for calculating gas consumption for a season. Sometimes, instead of living space, the calculation is performed taking into account the volume of the residential building of the apartment and the degree of insulation.

For individual premises built according to a standard project, with a ceiling height of 3 m, the calculation formula is quite simple.

Another way to calculate the OK boiler

In this option, the built-up area (P) and the specific power factor of the boiler unit (UMC) are taken into account, depending on the climatic location of the facility.

It varies in kW:

- 0.7 to 0.9 southern territories of the Russian Federation;

- 1.0 to 1.2 central regions of the Russian Federation;

- 1.2 to 1.5 Moscow region;

- 1.5 to 2.0 northern regions of the Russian Federation.

Therefore, the formula for the calculation looks like this:

Mo=P*UMK/10

For example, the required power of a heating source for a building of 80 m2, located in the northern region:

Mo \u003d 80 * 2/10 \u003d 16 kW

If the owner will install a double-circuit boiler unit for heating and hot water, professionals advise adding another 20% of the power for water heating to the result.

How to calculate the power of a double-circuit boiler

The calculation of the heat output of a double-circuit boiler unit is carried out on the basis of the following proportion:

10 m2 = 1,000 W + 20% (heat loss) + 20% (DHW heating).

If the building has an area of 200 m2, then the required size will be: 20.0 kW + 40.0% = 28.0 kW

This is an estimated calculation, it is better to clarify it according to the rate of water use of hot water supply per person. Such data are given in SNIP:

- bathroom - 8.0-9.0 l / min;

- shower installation - 9 l / min;

- toilet bowl - 4.0 l / min;

- mixer in the sink - 4 l / min.

The technical documentation for the water heater indicates what heating output of the boiler is required to guarantee high-quality water heating.

For a 200 l heat exchanger, a heater with a load of approximately 30.0 kW will suffice. After that, the performance sufficient for heating is calculated, and at the end the results are summarized.

Calculation of the power of an indirect heating boiler

In order to balance the required power of a single-circuit gas-fired unit with an indirect heating boiler, it is necessary to establish how much heat exchanger is required to provide hot water to the residents of the house. Using the data on the norms of hot water consumption, it is easy to establish that the consumption per day for a family of 4 will be 500 liters.

The performance of an indirect heating water heater directly depends on the area of \u200b\u200bthe internal heat exchanger, the larger the coil, the more heat energy it transfers to water per hour. You can detail such information by examining the characteristics of the passport for the equipment.

Source

There are optimal ratios of these values for the average power range of indirect heating boilers and the time to obtain the desired temperature:

- 100 l, Mo - 24 kW, 14 min;

- 120 l, Mo - 24 kW, 17 min;

- 200 l, Mo - 24 kW, 28 min.

When choosing a water heater, it is recommended that it heats the water in about half an hour. Based on these requirements, the 3rd option of the BKN is preferable.

The best double-circuit gas boilers

Double-circuit boilers simultaneously heat water for both the heating system and the hot water supply. In this section, we will look at the best units without a built-in boiler.

Haier Aquila

4.9

★★★★★

editorial score

89%

buyers recommend this product

A series of wall-mounted double-circuit boilers includes 4 models of boilers with a capacity of 14, 18, 24 and 28 kW. In central Russia, this is enough to heat an area of 100-200 square meters. The burner and heat exchanger here are made of stainless steel and are not afraid of corrosion. The tube of the second circuit is copper so that the running water has time to heat up.

The control in all Haier models is electronic: an LCD display is placed on the body, which simplifies communication with the boiler automation. It is possible to connect a remote room regulator - with it, the unit will be able to automatically adjust the burner power to maintain the set temperature. The manufacturer did not forget about the full range of protections: from overheating, freezing, extinguished flame, reverse thrust.

Advantages:

- Small dimensions 750x403x320 mm;

- Daily and weekly programmer of the operating mode;

- Work on the external temperature sensor;

- Possibility of switching to liquefied gas;

- Built-in pump with electronic control and protection against dry start;

- Room sensor already included;

- Heat carrier heating up to +90 °С.

Flaws:

Non-Russian menu.

Well-made and attractive in appearance, the boiler will perfectly fit into a city apartment.With it, it will not only become warm, but it will also be possible to solve the problem of hot water.

Baxi LUNA-3 Comfort 310Fi

4.8

★★★★★

editorial score

88%

buyers recommend this product

See review

The main highlight of this model is a removable control panel, made in a separate case. You can leave it on the boiler, or fix it in any convenient place. The panel has another secret - a built-in temperature sensor. Thanks to him, the boiler can automatically adjust the burner power within 10-31 kW, focusing on the specified parameters. You can also set the water temperature in the second circuit - from 35 to 65 degrees.

Advantages:

- Convenient control from the remote panel;

- Rapid heating of the heating system (relevant for the northern regions);

- Automatic restart in case of network interruptions;

- The built-in pump pumps the coolant up to the 3rd floor;

- A good efficiency indicator is 93%.

Flaws:

No hot water circulation in the secondary circuit.

Baxi LUNA-3 is a premium class in everything: from the appearance of the boiler to its equipment and safety level.

Options for long-burning home stoves

Almost simultaneously, Canadian stoves appeared that had a more efficient device than domestic potbelly stoves. The design provides for convection channels, ⅔ immersed in the combustion chamber.

Modern stove models are actually modified and redesigned for greater efficiency, derived from and. All offered stoves are divided into two classes according to the principle of space heating.

Hot air type

Modern convection ovens for a long-burning wood-fired home have several features that affect thermal efficiency and ease of use:

- Increased burning time - in a classic potbelly stove, firewood burned out in 1.5-2 hours. After modernization, the pyrolysis or gas generation process began to be used in the furnaces, the combustion chamber was enlarged. Working time from one bookmark increased to 4-8 hours.

- Efficient space heating - the design provides for convection channels, the walls of which are in contact with the firebox. Cold air is taken in and hot air is discharged through the channels. The design increased the efficiency of stoves from 80 to 92%.

- The principle of operation of the furnace is to increase heat transfer, the process of gas generation or pyrolysis is used. In fact, the fuel does not burn, but smolders. As a result of gas generation, the burning time increases and additional thermal energy appears from the afterburning of the released carbon dioxide.

Initially, stoves were designed to heat only the room in which they were installed. Adjoining rooms were not heated. There are solutions that allow you to heat the entire residential building. To do this, air ducts are connected to the air convection channels of the furnace, laid in each heated room. Wiring around the house effectively solves the problem of heating the entire building.

Hot water type

Heating stoves for a long-burning house with a water circuit, designed to be connected to a radiator heating system or underfloor heating (after installing additional equipment).

The principle of operation is in many ways similar to how it functions. However, there is one advantage. Most stoves are equipped with a hob for cooking, and also have glass built into the firebox door, which allows you to observe the flame.

Long-burning solid fuel stoves with a water circuit can be connected to any type of heating system, with a few exceptions. Allowed to use:

- in open and closed systems.

- and heat carrier.

Connecting batteries in furnaces with a built-in water circuit is carried out using special taps located on the body. The supply and return pipes are clearly marked in the operating instructions.

Forced circulation system

Equipment of this type for two-story cottages is considered more preferable. In this case, the circulation pump is responsible for the uninterrupted movement of coolants along the mains. In such systems, it is allowed to use pipes of smaller diameter and a boiler of not too high power. That is, in this case, a much more efficient one-pipe heating system for a two-story house can be arranged. The pump circuit has only one serious drawback - dependence on electrical networks. Therefore, where the current is turned off very often, it is worth installing the equipment according to the calculations made for a system with a natural coolant current. By supplementing this design with a circulation pump, you can achieve the most efficient heating of the house.

A gas boiler without electricity is a traditional model of a floor appliance that does not require additional energy sources to operate. It is advisable to install devices of this type if there are regular power outages. For example, this is true in rural areas or summer cottages. Manufacturing companies produce modern models of double-circuit boilers.

Many popular manufacturers produce different models of non-volatile gas boilers, and they are quite efficient and of high quality. Recently, wall-mounted models of such devices have appeared. The design of the heating system must be such that the coolant circulates according to the principle of convection.

This means that the heated water rises and enters the system through the pipe. In order for the circulation not to stop, it is necessary to place the pipes at an angle, and they must also be large in diameter.

And, of course, it is very important that the gas boiler itself is located at the lowest point of the heating system.

It is possible to separately connect a pump to such heating equipment, which is powered by the mains. By connecting it to the heating system, it will pump the coolant, thereby improving the operation of the boiler. And if you turn off the pump, then the coolant will again begin to circulate by gravity.

Application options

Solid fuel boilers can serve as the main or backup source of heat, in some cases this type of equipment allows not only to obtain cheap thermal energy, but also significantly save on the disposal of production waste, for example, at woodworking enterprises.

In addition to the industrial and residential areas, the use of this heating option is very important for agriculture, both due to the lack of an alternative, and due to the presence of a large amount of waste that can be used for heating. Among the main advantages are:

- relatively low price;

- various options for fuel material;

- availability of non-volatile models;

- environmental friendliness and safety;

- no special requirements and easy installation.

As in every “honey barrel” of positive qualities, there should be a “fly in the ointment” in the form of disadvantages, and these units have them:

- the need for additional space for fuel storage;

- the tendency of some models (usually the cheapest ones) to accumulate soot, which requires frequent cleaning of the chimney;

- manual fuel loading mode in most models;

- low, at the level of 70%, efficiency for long-burning boilers;

- the impossibility of using a coaxial type chimney in the chimney system.

Solid fuel boilers

Despite all the shortcomings, solid fuel boilers for heating a private house are used in most cases. Probably, this is largely due to habit and traditions, but the fact remains that there are more solid fuel boilers in our country than all others.

Solid fuel boilers work mainly on wood and coal

Basically, two types of solid fuels are used for heating - wood and coal. What is easier to get and cheaper to buy, so they basically drown. And boilers - for coal and firewood, you need to use different ones: in wood-burning solid fuel boilers, the loading chamber is made larger - so that more firewood can be laid. In TT coal boilers, the furnace is made smaller in size, but with thicker walls: the combustion temperature is very high.

Pros and cons

The advantages of these units include:

- Inexpensive (relatively) heating.

- Simple and reliable design of boilers.

- There are non-volatile models that work without electricity.

Serious disadvantages:

- Cyclic operation. The house is either hot or cold. To level this shortcoming, a heat accumulator is installed in the system - a large container with water.It stores heat during the active combustion phase, and then, when the fuel load burns out, the stored heat is spent to maintain a normal temperature.

- The need for regular maintenance. Firewood and coal must be laid, kindled, then the intensity of combustion must be regulated. After burning out, the firebox must be cleaned and the process restarted. Very troublesome.

The principle of operation of a conventional solid fuel boiler - Inability to leave the house for a long time. Due to the cyclical operation, the presence of a person is necessary: fuel must be thrown up, otherwise the system may freeze during prolonged downtime.

- The process of loading fuel and cleaning the boiler is a rather dirty task. When choosing an installation site, this should be taken into account: the boiler should be placed as close as possible to the front door so as not to carry dirt through the entire room.

Generally speaking, the use of a solid fuel boiler for heating a private house is an inconvenient solution. Although the purchase of fuel, as a rule, is relatively inexpensive, but if you calculate the time spent, it is not so cheap.

Long burning boilers

Long-burning boilers were developed to increase the interval between fuel fillings. They use two technologies:

- Pyrolysis. Pyrolysis solid fuel boilers have two or three combustion chambers. The fuel filling in them burns with a lack of oxygen. In this mode, a large amount of flue gases are formed, most of which are combustible. Moreover, when burning, they emit much more heat than firewood or the same coal. These gases enter the second chamber, where air is supplied through special openings. Mixing with it, combustible gases ignite, releasing an additional portion of heat.

The principle of operation of the pyrolysis boiler - Top burning mode. In traditional solid fuel boilers, fire spreads from bottom to top. Because of this, most of the bookmark burns, the fuel burns out quickly. During active combustion, the system and the house often overheat, which is very uncomfortable. When using top burning, the fire is kindled only in the upper part of the bookmark. At the same time, only a small part of the firewood burns, which evens out the thermal regime and increases the burning time of the bookmark.

Top burning boiler

How effective are these technologies? Pretty effective. Depending on the design, one bookmark of firewood can burn from 6-8 to 24 hours, and coal - from 10-12 hours to several days. But to obtain such a result, it is necessary to use high quality fuel. Both firewood and coal must be dry. This is the main requirement. When using wet fuel, the boiler may not even enter the smoldering mode, that is, it will not start heating. If you have a woodcutter with a two to three year supply of firewood or a large shed that stores coal, a long-burning boiler for heating a private house is a good choice. Better than normal.

Choosing a boiler

After you have decided on the fuel that will use the solid fuel heating of a country house, you should choose a boiler. Conventionally, solid fuel boilers can be divided into the following groups:

- classic;

- automatic;

- pyrolysis;

- prolonged burning.

Classic boilers

Classical boilers imply the following principle of operation: solid fuel burns in a flame in order to get heat, as is the case with an ordinary fire.Combustion is optimized by a special grate in order to supply combustion air from below. And the amount of this air is regulated by the settings of the scraper and the supply of air mass to the combustion chamber manually. Fuel is loaded through the top door, and the ash is removed and combustion is regulated through the bottom one. The boiler heat exchanger can be made of steel or cast iron. The advantages of classic boilers: the ability to operate on 2 types of fuel (minimum), often it is also possible to mount a gas or liquid fuel burner, independence from energy. Among the disadvantages: frequent loading of fuel is required, a place to store fuel and a separate room for the boiler room are also needed.

Classic solid fuel boiler

Pyrolysis boilers

Pyrolysis boilers - used for combustion gases from the decomposition of fuel. This is due to the action of high temperature with insufficient air. The structure of the boiler includes two chambers, which are separated by grates: the lower one for loading and the combustion chamber.

The combustion process here is as follows: the fuel is laid and ignited, the combustion chamber door closes. A blower fan is activated in the upper chamber, which serves to mix the smoldering air of the lower chamber with clean air. The mixture begins to ignite and directs fire through ceramic nozzles to the fuel. Without access to oxygen, the fuel is burned - this is how pyrolysis happens, that is, decomposition and gasification of the fuel. So, the process will continue until the fuel is completely burned. This is how solid fuel heating works. Advantages of pyrolysis boilers: high efficiency (up to 90%), fuel burns on one load up to 10 hours, reduced requirements for the chimney, high level of environmental friendliness.Disadvantages: high cost, dependence on energy, unstable combustion at partial load, very high requirements for the dryness of firewood, etc.

pyrolysis boiler

Automatic boilers

Automatic boilers - processes such as fuel loading and ash removal are automated here. In boilers of this type there is a bunker for automatic fuel supply - conveyor or screw. For combustion to be stable, the fuel must be uniform in composition and size. The advantages of such boilers: high efficiency (up to 85%), duration of operation, limited capacity of the hopper designed for automatic feeding, and fuel homogeneity provide the ability to fine-tune the combustion process. Among the disadvantages: high price, dependence on energy, the need for a separate room, a separate fireproof ash collector, as well as qualified service.

Automatic solid fuel boiler

Long burning boilers

Another type of boilers that uses solid fuel heating of a country house is long-burning boilers. Here, long-term combustion is maintained by special techniques. Such combustion can be provided by two systems: the Canadian system of boilers Buleryan and the Baltic system Stropuva. Buleryan is a two-chamber wood burning stove, which is divided horizontally. Smoldering takes place below, the gases go to the upper chamber, where they mix with secondary air through the jet, after which the fuel is burned. Stropuva is a high barrel up to 3 m high, filled with firewood and covered with a movable lid with a chimney.First, firewood is set on fire, after which they burn economically, heating the heat carrier along the barrel jacket, the air supply is regulated automatically.

Long burning boiler

What to look for when choosing a boiler?

Due to the simply huge demand for boilers that work on one tab of firewood for more than 12 hours, manufacturers are actively replenishing the market with new models. As a result, almost every buyer has a number of questions related to the choice of manufacturer, design, type of fuel.

In addition, not everyone will be able to correctly calculate the power. In order not to encounter these problems in the store, we will deal with all the nuances in more detail.

Types of equipment by design

There are three types of solid fuel boilers on the market. These include classic models, pyrolysis, as well as pellet units. The first type will be an excellent choice for both home and industrial or commercial use.

The advantages of such models include:

- Versatility. The equipment can work on heating granules (pellets), firewood, peat and coal.

- Multifunctionality. Classic boilers are great not only for space heating, but also for heating water.

- Efficiency. The efficiency of the presented devices in most cases varies between 80-85%. This allows you to use them both as the main source of heat and as an additional one.

Pyrolysis models are most often used for heating water. This kind of device runs on organic fuel.

The performance coefficient of pyrolysis boilers mainly depends on the quality of the fuel used. The most optimal choice are briquettes, pellets, as well as brown coal

It should be noted that pyrolysis boilers are quite demanding on the moisture content of the fuel feedstock. If this indicator is higher than 25-35%, then the heating efficiency will decrease significantly.

The third variation of long-burning boilers was patented in Europe relatively recently. But in a fairly short period of time, such devices have won recognition among hundreds of thousands of customers.

Pellet boilers work on wood pellets. Fuel is made from compressed chips, sawdust, as well as a number of other types of waste from the woodworking industry.

The advantages of this type include:

- durability - the average life of the device is more than 20 years;

- autonomy - the device independently and quite well maintains the temperature indicated by the owner;

- efficiency - the efficiency of models on pellets reaches 90%.

As for the shortcomings, only one stands out - a high and inaccessible price for many. But this minus is fully paid off by the ease of maintenance and performance of the equipment.

An article devoted to this interesting issue will acquaint you with the features of the operation and operation of solid fuel boilers.

How to calculate power correctly?

If you need to determine the performance of the boiler, it is important to take into account the area, the quality of wall insulation, the type of fuel used, as well as the length of the heating circuit. Calculations can be greatly simplified

To do this, you just need to use the following formula:

1 kW per 1 m2 of the room.

In this case, the height of the ceilings should not exceed 3 meters. A more convenient option would be to use a special table when calculating. Below is one of them.

| Boiler power | Heating area, sq. m. |

| 15 kW | up to 150 |

| 20 kW | up to 200 |

| 30 kW | up to 300 |

| 50 kW | up to 500 |

| 70 kW | up to 700 |

With its help, you can find out the right power in a matter of minutes. In this case, the only parameter that you need is the area of \u200b\u200bthe room in cubic meters.

Regulator type and price tag

If you have constant interruptions in the electrical network in your house, then it would be advisable to choose a boiler with a mechanical regulator. It does not need to be supplied with current, since its principle of operation is based on air circulation in a natural way.

Automation is suitable for those who do not want to bother once again and waste their time going to the boiler room. This kind of regulator pumps air with a fan.

A reasonable choice would be to purchase a heater from an authorized dealer or directly from the manufacturer. This will allow not only to purchase goods at a reasonable price, but also to receive a long-term warranty and rely on after-sales service in the event of a unit breakdown.

The cost of heating equipment largely depends on the material from which the device is made, brand, as well as power.

It is important to understand that this kind of equipment is bought for decades. Therefore, do not even look towards cheap models.

Remember - an efficient boiler cannot be cheap.

Technical parameters of solid fuel boilers

So, what should you pay attention to if you decide to choose the best solid fuel boiler:

- Type of fuel. Different models may consume one or more types of fuel. Firewood, coal, peat briquettes, sawdust, pellets, straw or recycled waste are suitable for use.

- Power. It must be calculated in such a way that it is enough to heat the entire area of \u200b\u200bthe house and auxiliary premises.

- The volume of the combustion chamber.This is one of the main indicators affecting the performance of the unit, the frequency of fuel loads.

- Automation. The presence of such a mechanism allows you to free the owners from constant monitoring of the boiler.

- Safety. The main elements necessary in any boiler are an alarm and an auto-shutdown function in case of a malfunction.

- The need for access to electricity. Some models of heaters are simply not able to work without access to electricity. But most of the boilers can still carry out heating completely autonomously.

- useful factor. this indicator is calculated as the ratio between the actual power of the device and the heat capacity of the fuel used. The higher the efficiency, the less fuel is required to generate one unit of heat.

- Operating time on one load. The inability to control the process makes the burning period of the fuel very short. You are unlikely to like a boiler that needs fuel every 4-5 hours. Modern models can work on one load for several days.

- Ease of maintenance. Even the most wonderful boiler needs to be cleaned of soot and ash, purged and loaded with a new portion of fuel. The simpler all these processes are arranged, the more satisfied the owner will be.

- Price. Boilers for heating a house are not the equipment that is worth saving on. In this case, you should not choose a heater, focusing only on a low price. The technical characteristics of cheap boilers are often far from ideal.

Only by comprehensively approaching the study of all the main parameters, we can choose for ourselves the best long-burning solid fuel boiler in 2019.