- Situations that do not require adjustment

- Device and principle of operation

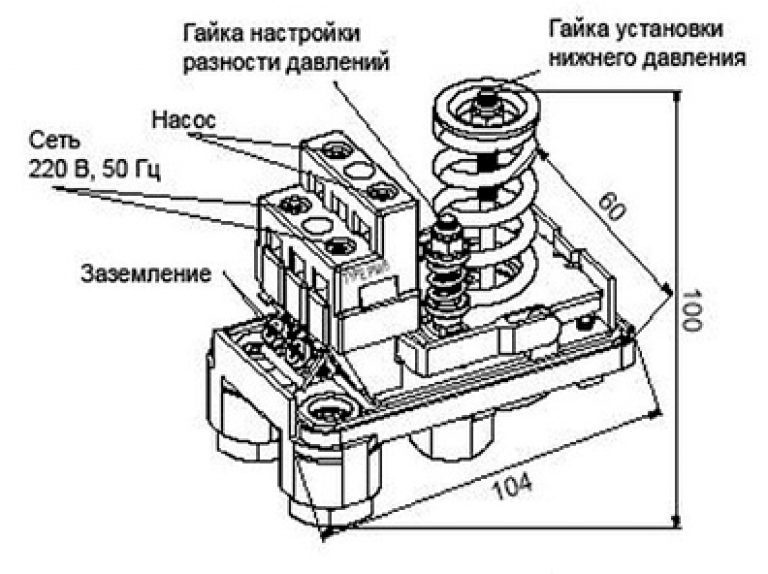

- Pump pressure switch device

- Pressure switch adjustment

- Correction of errors in work

- Violation of the rules of operation

- Engine malfunctions

- Problems with water pressure in the system

- Pressure in the accumulator

- Preparation of the storage tank of the pumping station

- Overview of popular models

- Pump station pressure switch

- Mechanical relays

- Electronic relays

- Device specifications

- Features of work

- Using a relay without a hydraulic accumulator

- Connecting the water pressure switch

- Electrical part

- Do-it-yourself connection to the water supply

Situations that do not require adjustment

There can be many reasons when the pump does not turn off or does not turn on - from a blockage in communications to engine failure. Therefore, before starting to disassemble the relay, you should make sure that the rest of the equipment of the pumping station is working properly.

If everything is in order with the rest of the devices, the problem is in the automation. We turn to the inspection of the pressure switch. We disconnect it from the fitting and wires, remove the cover and check two critical points: a thin pipe for connecting to the system and a block of contacts.

To check if the hole is clean, it is necessary to dismantle the device for inspection, and if a blockage is found, clean it.

The quality of tap water is not ideal, so often the problem is solved by simply cleaning the inlet from rust and mineral deposits.

Even devices with a high degree of protection against moisture can fail due to the fact that the wire contacts are oxidized or burned.

If the cleaning measures did not help, and the adjustment of the position of the springs was also in vain, most likely the relay is not subject to further operation and should be replaced with a new one.

Suppose you got an old but working device in your hands. Its adjustment takes place in the same order as the setting of a new relay. Before starting work, make sure that the device is intact, disassemble it and check that all contacts and springs are in place.

Device and principle of operation

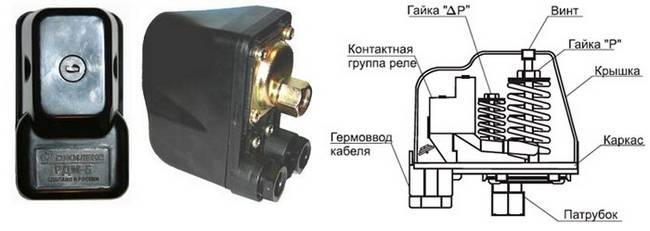

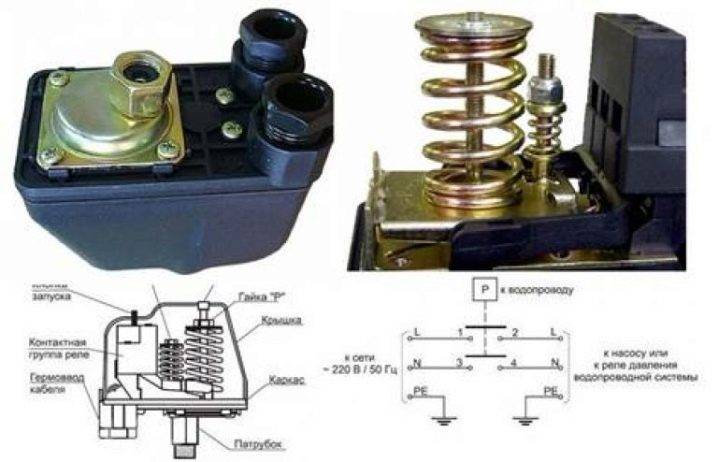

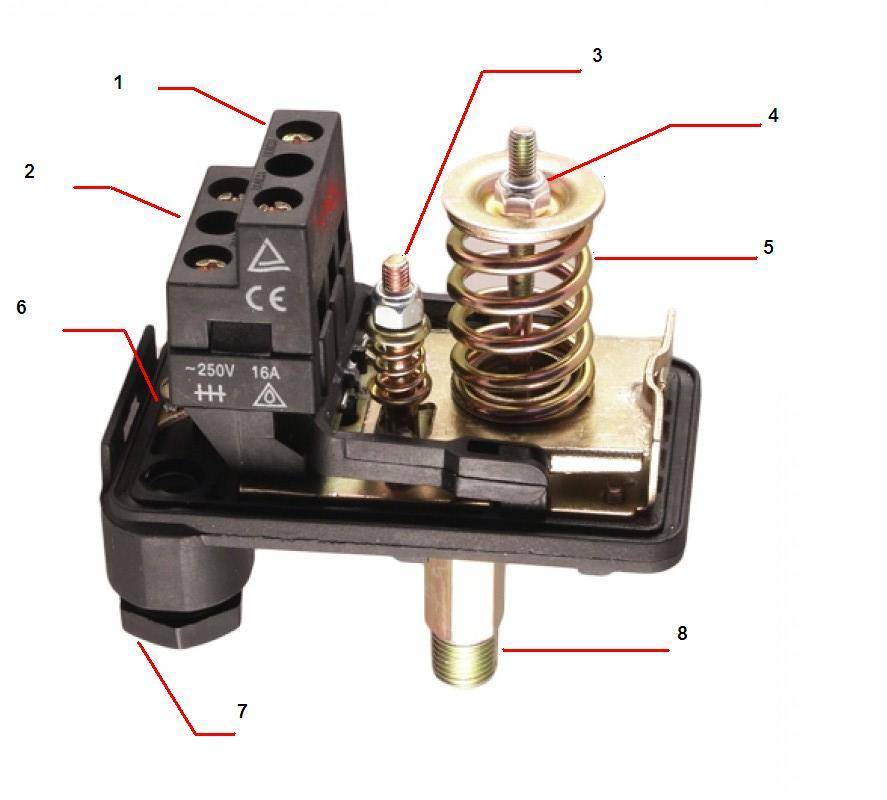

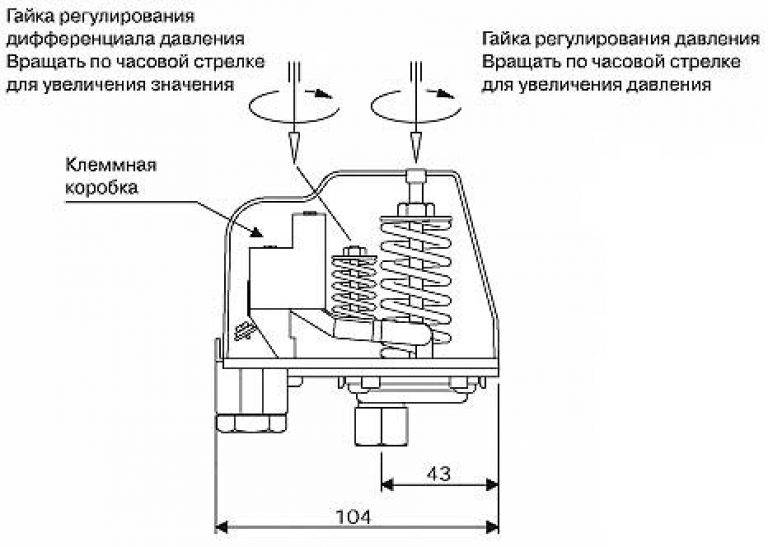

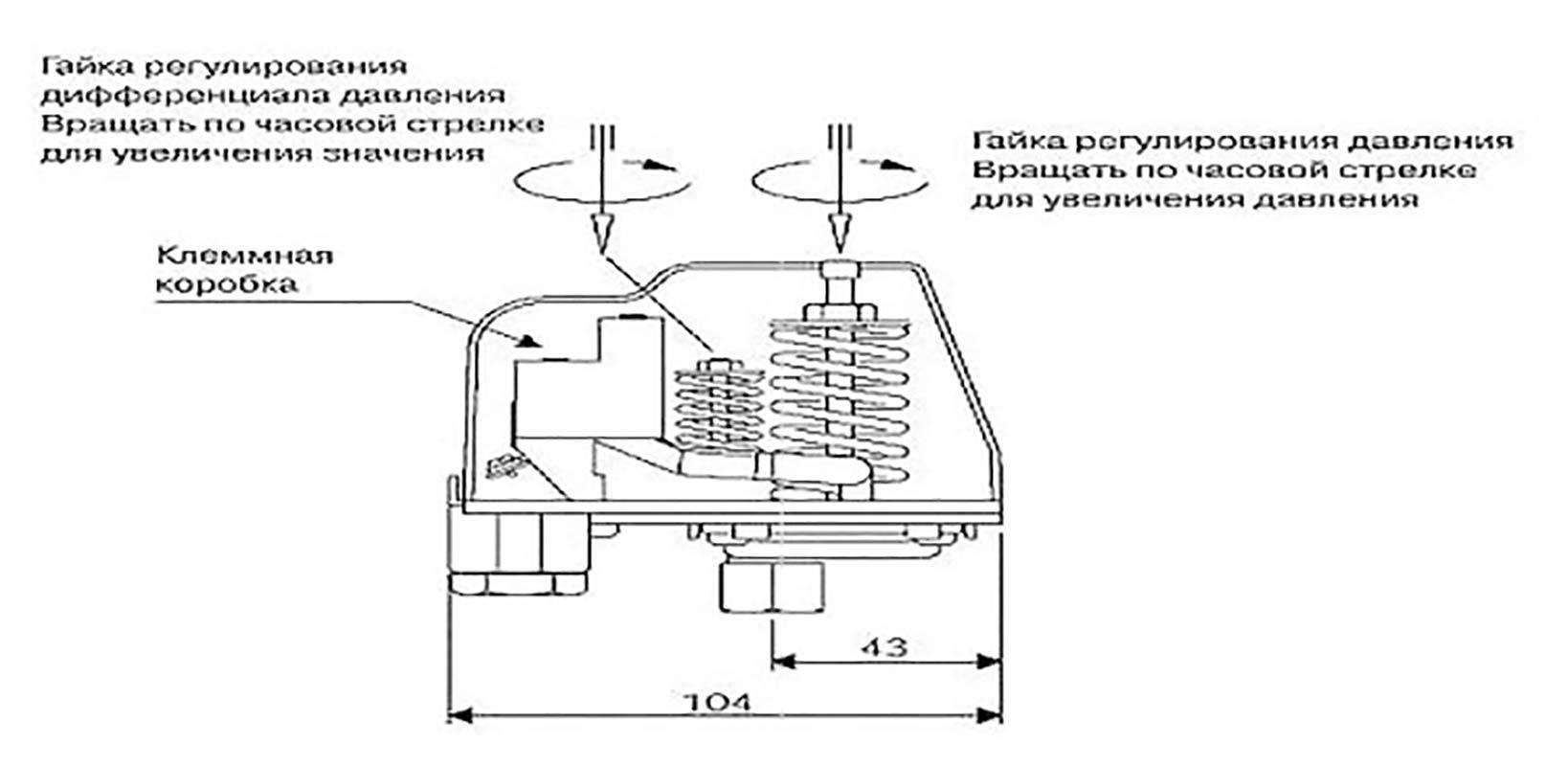

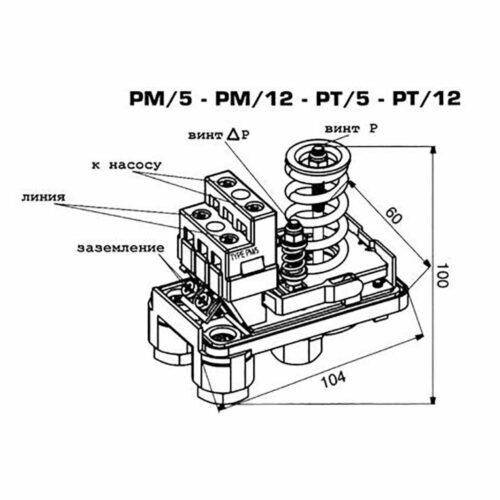

Electromechanical relays consist of a plastic housing, a spring block and contacts controlled by a membrane. The membrane is in direct contact with the pressure pipe and is a thin plate that plays the role of an element of perception. It instantly reacts to changes in the pressure level in the pipeline, which entails the alternating switching on of contacts. The spring block of the water relay consists of 2 elements. The first is a spring that controls the minimum allowable pressure level, and is responsible for containing the main onslaught of water. The lower pressure limit is adjusted using a special nut. The second element is the top pressure control spring, and is also adjustable with a nut.

The principle of operation of the relay is that the contacts, thanks to the membrane, respond to pressure fluctuations, and when they close, the pumps begin to pump water. While when they open, the electrical circuit breaks, the power to the pumping equipment is turned off and the forced water supply stops. This happens due to the fact that the relay has a connection to a hydraulic accumulator, inside which there is water with compressed air. The contact of these two media is due to the flexible plate.

When the pump is turned on, the water inside the tank presses through the membrane on the air, as a result of which a certain pressure is created in the tank chamber. When water is consumed, its quantity decreases and the pressure decreases. In addition to the standard equipment, some models can be equipped with a forced (dry) start button, an operation indicator, a soft start device and special connectors used instead of traditional terminals.

Usually, an indicator of 2.6 atmospheres is taken as the upper threshold, and as soon as the pressure reaches this value, the pump turns off. The lower indicator is set at around 1.3 atmospheres, and when the pressure reaches this limit, the pump turns on. If both resistance thresholds are set correctly, the pump will operate in automatic mode, and manual control will not be required. This will eliminate the need for the constant presence of a person and ensure an uninterrupted supply of tap water to the consumer. The relay does not require special expensive maintenance. The only procedure that will need to be performed from time to time is the cleaning of contacts, which oxidize during operation and require care.

In addition to electromechanical models, there are also electronic counterparts, which are distinguished by more precise adjustment and aesthetic appearance. Each product is equipped with a flow controller - a device that instantly turns off pumping equipment in the absence of water in the pipeline. Thanks to this option, the pump is reliably protected from running dry, which prevents it from overheating and premature failure. In addition, the electronic relay is equipped with a small hydraulic tank, the volume of which usually does not exceed 400 ml.

Thanks to this design, the system receives reliable protection against water hammer, which significantly extends the service life of both the relays themselves and the pumps. In addition to a large number of advantages, electronic models also have weaknesses. The disadvantages of products include high cost and increased sensitivity to the quality of tap water. However, the money spent is quickly paid off by the reliability and durability of the devices, and special sensitivity is eliminated by installing a filtration system.

Thus, the pressure switch is an integral component of downhole or downhole pumping equipment, it helps to fill the hydraulic tank and maintain normal pressure in the network without human assistance. The use of a relay allows you to fully automate the process of water supply and eliminates the need to turn on the pump yourself when the pressure drops or the storage tank is empty.

Pump pressure switch device

Each pumping station includes a pressure switch, it controls its operation depending on how much water is in the storage tank.Timely turning on / off of the pump allows you to maintain the necessary pressure in the water supply, and all this happens automatically.

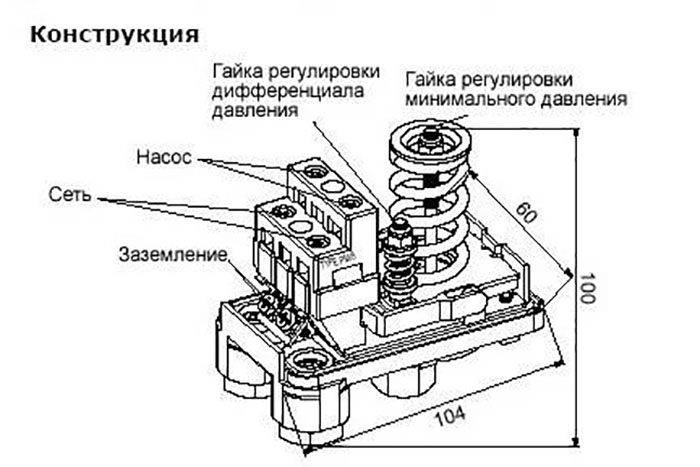

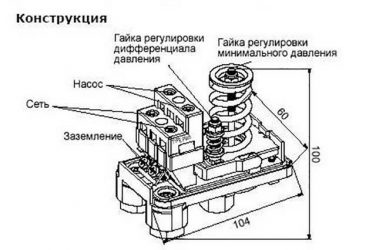

The main elements of the pressure switch:

- frame;

- 2 adjustable springs;

- membrane;

- contact plate;

- terminals for power supply and ground connection;

- flange for connection to the water supply.

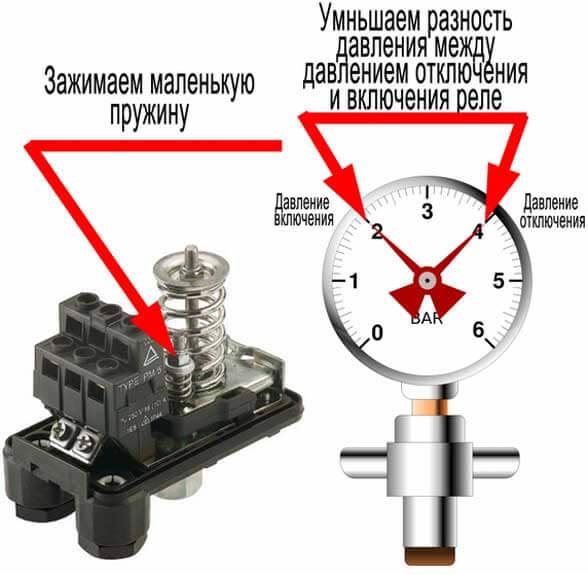

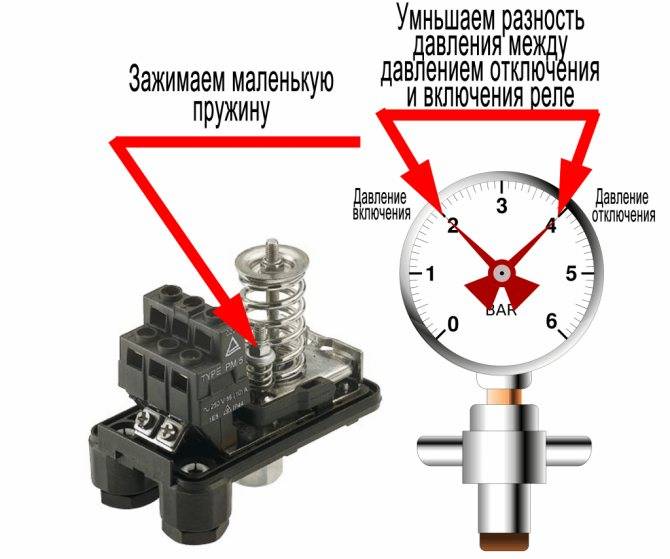

A larger spring serves to adjust the response threshold, i.e. is responsible for turning on the equipment, and the smaller one is for setting the upper limit, i.e. to turn off the pump.

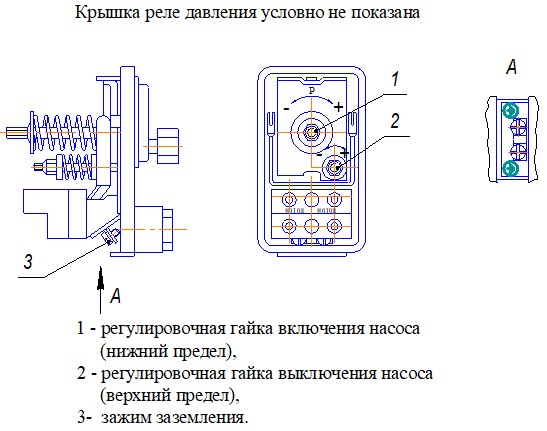

Pressure switch adjustment

Now let's talk directly about the adjustment of the relay. Its process cannot be called difficult, but some points will have to get used to. In our example, you need to set the upper threshold to 3 atmospheres, and the lower threshold to 1.7 atmospheres. It is adjusted like this:

- it is necessary to turn on the pump and pump water up to a value of 3 atmospheres;

- turn off the pumping station;

- remove the relay cover and slowly turn the small nut until the relay starts. If you rotate it clockwise, the pressure increases, if it is counterclockwise, it decreases;

- open the tap and drain the water until the pressure gauge shows a value of 1.7 atmospheres;

- close the faucet;

- remove the relay cover and also slowly turn the large nut until the contacts work.

Thus, if you set the pressure to high to turn off and low to turn on, more water will be filled into the tank, which will reduce the use of the pump. A slight inconvenience may occur if a large pressure difference is observed, in cases where the container is full or almost empty.Otherwise, when the pressure range is small, the pump will have to be used more often. But on the other hand, water will flow into the system evenly and thus a stable and comfortable pressure will be provided.

It is possible to repair the pumping station relay, but keep in mind that this is only a temporary measure. Since this element protects the pump itself from overloads, and the membrane inside the tank from damage. With this in mind, it would be better to immediately purchase a new relay. Therefore, the only exception will be only routine maintenance, namely the lubrication of rubbing parts to reduce resistance and ensure the most accurate operation.

Correction of errors in work

Before embarking on a more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing to do is to adjust the pressure in the accumulator tank and adjust the pressure switch.

The following are the most common malfunctions in the domestic pumping station, which the user can try to solve on his own. For more serious problems, contact the service center.

Violation of the rules of operation

If the station runs continuously without shutting down, the likely cause is an incorrect relay adjustment - high pressure set shutdown. It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is broken or an air lock has formed in the pipe or in the suction valve. To find a specific cause, it is necessary to make sure that: the foot valve and all connections are tight, there are no bends, narrowings, hydraulic locks along the entire length of the suction pipe. All malfunctions are eliminated, if necessary, replace damaged areas.

- The equipment works without access to water (dry). It is necessary to check why it is not there or to identify and eliminate other causes.

- The pipeline is clogged - it is necessary to clear the system of contaminants.

It happens that the station very often works and turns off. Most likely this is due to a damaged membrane (then it is necessary to replace it), or the system does not have the pressure required for operation. In the latter case, it is necessary to measure the presence of air, check the tank for cracks and damage.

Before each start, it is necessary to pour water into the pumping station through a special funnel. She must not work without water. If there is a possibility of the pump running without water, you should purchase automatic pumps equipped with a flow controller

Less likely, but it can happen that the check valve is open and blocked due to debris or a foreign object. In such a situation, it will be necessary to disassemble the pipeline in the area of \u200b\u200bpossible blockage and eliminate the problem.

Engine malfunctions

The household station engine does not run and does not make noise, possibly for the following reasons:

- The equipment is disconnected from the power supply or there is no mains voltage. You need to check the wiring diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, then it is jammed. You need to find out why.

- Relay damaged. You need to try to adjust it or, if it fails, replace it with a new one.

Engine malfunctions most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The pressure of water or air in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Piping or pump impeller blocked. Cleaning the elements of the pumping station from contamination may help solve the problem.

- Air enters the pipeline. Checking the elements of the pipeline and their connections for tightness will be able to confirm or refute this version.

Poor water supply can also be caused by air being drawn in due to leaky water pipe connections or the water level has dropped so much that air is being pumped into the system when it is taken.

Poor water pressure can create significant discomfort when using the plumbing system

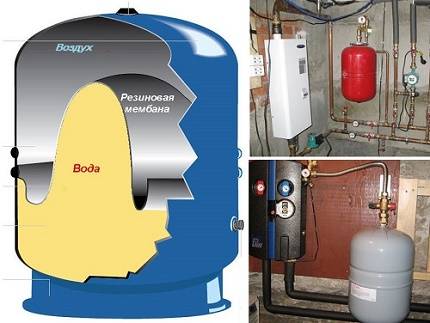

Pressure in the accumulator

Understanding how a hydraulic accumulator works will help you better deal with self-configuring control equipment.

There are two types of hydraulic tanks: with a rubber insert resembling a pear, or with a rubber membrane. This element divides the container into two non-communicating parts, one of which contains water and the other air.

Inside the hydraulic tank is a pear-shaped rubber insert or rubber membrane. The pressure in the hydraulic tank can be adjusted by pumping or bleeding air

In any case, they work about the same. Water enters the tank, and the rubber insert presses on it to ensure the movement of water through the plumbing system.

Therefore, a certain pressure is always present in the hydraulic tank, which varies markedly depending on the amount of water and air in the tank.

Before setting air pressure relay in the hydraulic tank, connect the pressure gauge to the nipple connection provided on the body of the device

There is usually an automotive nipple on the tank body. Through it, you can pump air into the hydraulic tank or bleed it to adjust the working pressure inside the tank.

When connecting the pressure switch to the pump, it is recommended to measure the current pressure in the hydraulic tank. The manufacturer defaults to 1.5 bar. But in practice, part of the air usually escapes, and the pressure in the tank will be lower.

To measure the pressure in the accumulator, use a conventional automobile pressure gauge. It is recommended to choose a model with a scale that has the smallest gradation step. Such a device will allow more accurate measurements. It makes no sense to measure pressure if there is no way to take into account one tenth of a bar.

In this regard, it makes sense to check the pressure gauge that is equipped with an industrial pumping station.

Often manufacturers save and install inexpensive models. The accuracy of measurements with such a device can be questionable. It is better to replace it with a more reliable and accurate device.

When choosing a pressure gauge for a pumping station or a pump with a hydraulic tank, you should pay attention to mechanical models with an accurate gradation scale

Mechanical car gauges do not look very presentable, however, judging by the reviews, they are much better than newfangled electronic devices. If, nevertheless, the choice is made in favor of an electronic pressure gauge, you should not save. It is better to take a device manufactured by a reliable manufacturer than a cheap plastic craft that does not give accurate data and can break at any time.

Another important point - the electronic pressure gauge requires power supply, this will have to be monitored. Checking the pressure in the hydraulic tank is very simple.

A pressure gauge is attached to the nipple and the readings are measured. Normal pressure is considered to be between one and one and a half atmospheres. If the pressure in the hydraulic tank is too high, the water supply in it will be less, but the pressure will be just fine.

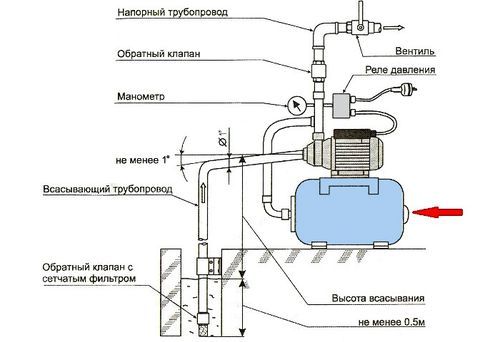

In this The diagram clearly shows the connection pressure switch and pressure gauge to the submersible pump and hydraulic tank to automate the operation of pumping equipment

It should be remembered that too high pressure in the system can be dangerous. In this case, all components of the water supply system are constantly working under increased load, and this leads to rapid wear of the equipment. In addition, in order to maintain increased pressure in the system, it is necessary to pump water into the tank more often, and therefore turn on the pump more often.

This is also not very useful, as the likelihood of breakdowns increases. When setting up the system, a certain balance is needed. For example, if the accumulator pressure is too high or too low, the rubber seal may be damaged.

Preparation of the storage tank of the pumping station

Before adjusting the pressure switch itself, it is necessary to prepare the accumulator. It consists of a sealed container and a rubber pear that divides this tank into two parts inside. When pumping water into the first pump, air pressure rises in the second. Then this air mass, with its pressure on the pear, will maintain the pressure in the water supply pipe.

Hydraulic accumulator (storage tank)

In order for the pumping station to work in the optimal mode, it is necessary to correctly select the air pressure for the accumulator. If you make it too high or too low, then the hydraulic pump will start up too often. This setting is a direct path to rapid equipment wear.

The required air pressure in the accumulator is set after it is completely empty of water. After its descent, air is pumped at the rate of 1.4–1.7 atmospheres for a tank of 20–25 liters and 1.7–1.9 atmospheres with a larger volume. Specific values should be viewed in the technical passport of the station.

Overview of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and rarely used. A wide range of devices from domestic and foreign manufacturers is presented on the market, facilitating the choice of the required model.

RDM-5 Dzhileks (15 USD) is the most popular high-quality model from a domestic manufacturer.

Characteristics

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A.;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ ($10) is a Spanish-made budget model.

Characteristics

- case material: plastic;

- pressure: top 10 atm.;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

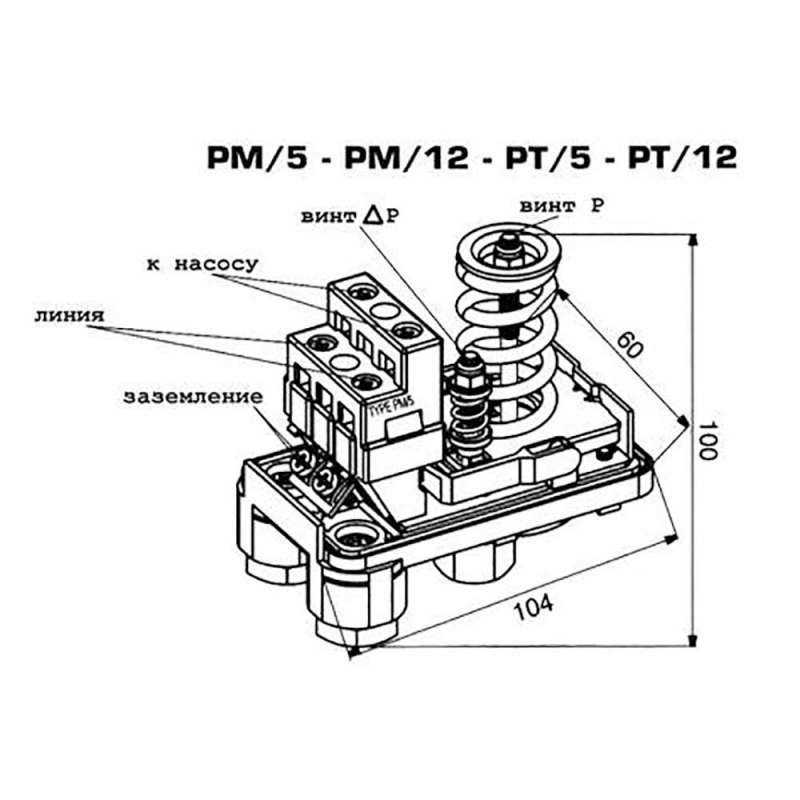

Italtecnica PM / 5-3W (13 USD) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Characteristics

- maximum current: 12A;

- working pressure: maximum 5 atm.;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

The pressure switch is the most important element in the water intake system, which provides automatic individual water supply to the house. It is located next to the accumulator, the operating mode is set by means of adjusting screws inside the housing.

When organizing autonomous water supply in a private house, pumping equipment is used to raise water. In order for the water supply to be stable, it is necessary to select it correctly, since each type has its own technical characteristics and features.

For efficient and trouble-free operation of the pump and the entire water supply system, it is necessary to purchase and install an automation kit for the pump, taking into account the characteristics of the well or well, the water level and its expected flow rate.

The vibration pump is chosen when the amount of water spent per day does not exceed 1 cubic meter. It is inexpensive, does not create problems during operation and maintenance, and its repair is simple. But if water is consumed from 1 to 4 cubic meters or water is located at a distance of 50 m, it is better to purchase a centrifugal model.

Usually the kit includes:

- operating relay, which is responsible for supplying and blocking voltage to the pump at the time of emptying or filling the system; the device can be immediately configured at the factory, and self-configuration for specific conditions is also allowed:

- a collector that supplies and distributes water to all points of consumption;

- pressure gauge for measuring pressure.

Manufacturers offer ready-made pumping stations adapted to specific requirements, but a self-assembled system will work most efficiently. The system is also equipped with a sensor that blocks its operation during dry running: it disconnects the engine from power.

The safety of the equipment operation is ensured by overload protection sensors and the integrity of the main pipeline, as well as a power regulator.

Pump station pressure switch

The sensor automatically regulates the process of pumping water in the system. It is the pressure switch that is responsible for switching on and off the pump equipment. It also controls the level of water pressure. There are mechanical and electronic elements.

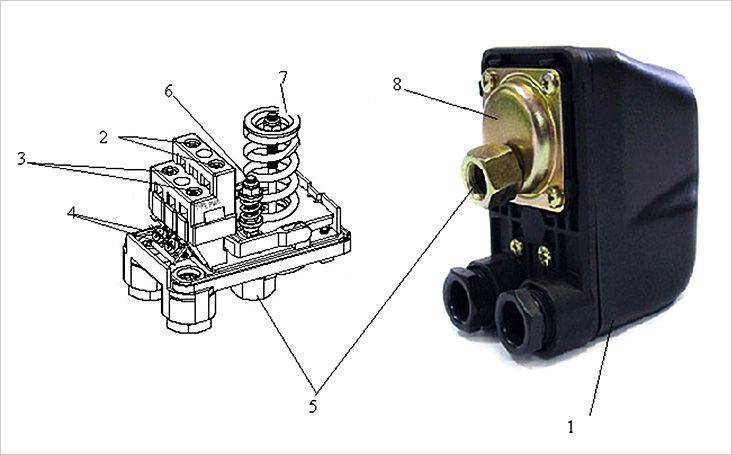

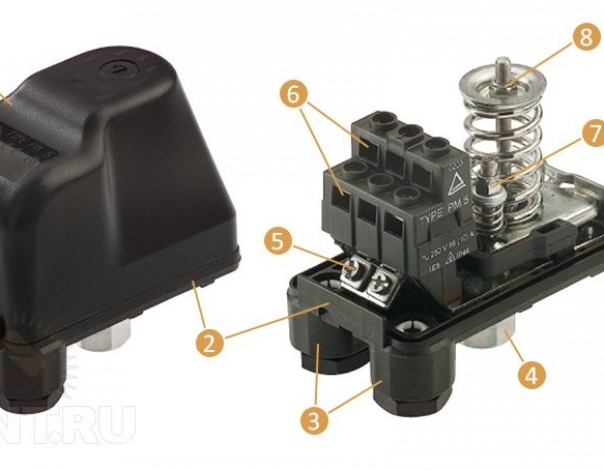

Mechanical relays

Devices of this kind are distinguished by a simple and at the same time reliable design. They are much less likely to fail than electronic counterparts, because there is simply nothing to burn out in mechanical relays. Adjustment occurs by changing the tension of the springs.

Mechanical pressure switch adjustable by spring tension

The mechanical relay includes a metal plate where the contact group is fixed. There are also terminals for connecting the device and springs for adjustment. The lower part of the relay is reserved for the membrane and piston. The design of the sensor is quite simple, so there should be no serious problems with self-disassembly and damage analysis.

Electronic relays

Such devices attract primarily by ease of use and their accuracy. The step of the electronic relay is noticeably smaller than the mechanical one, which means that there are more adjustment options here. But electronics, especially budget ones, often break down. Therefore, excessive savings in this case is impractical.

Electronic water pressure switch

Another clear advantage of an electronic relay is the protection of equipment from idling. When the water pressure in the line is minimal, the element will continue to work for some time. This approach allows you to protect the main nodes of the station. Repair the electronic relay on your own much more difficult: in addition to technical knowledge, a specific tool is needed. Therefore, it is better to leave the diagnostics and maintenance of the sensor to professionals.

Device specifications

Depending on the model of the station and its type, the device can be located both inside the case and mounted outside. That is, if the equipment comes without a relay, or its functionality does not suit the user, then it is always possible to select the element in a separate order.

The sensors also differ in the maximum allowable pressure. A good half of the classic relays are set to 1.5 atm to start the system and 2.5 atm to deactivate it. Powerful household models have a threshold of 5 atm.

When it comes to an external element, it is extremely important to take into account the characteristics of the pumping station. If the pressure is too high, the system may not withstand, and as a result, leaks, ruptures and early wear of the membrane will appear.

Therefore, it is so important to adjust the relay with an eye to the critical indicators of the station.

Features of work

Consider the principle of operation of the device using the example of one of the most common relays for pumping stations - RM-5. On sale you can also find foreign analogues and more advanced solutions. Such models are equipped with additional protection and offer enhanced functionality.

PM-5 includes a movable metal base and a pair of springs on both sides. The membrane moves the plate depending on the pressure. By means of a clamping bolt, you can adjust the minimum and maximum indicators at which the equipment turns on or off. RM-5 is equipped with a check valve, so when the pumping station is deactivated, water does not drain back into the well or well.

Step-by-step analysis of the pressure sensor:

- When the faucet is opened, water begins to flow from the tank.

- As the liquid in the pumping station decreases, the pressure gradually decreases.

- The membrane acts on the piston, and it, in turn, closes the contacts, including the equipment.

- When the tap is closed, the tank is filled with water.

- As soon as the pressure indicator reaches its maximum values, the equipment turns off.

The available settings determine the frequency of the pump: how often it will turn on and off, as well as the pressure level. The shorter the interval between the start-up and deactivation of the equipment, the longer the main components of the system and all the equipment as a whole will last. Therefore, competent adjustment of the pressure switch is so important.

But not only the sensor affects the operation of the equipment. It happens that the device is configured correctly, but other elements of the station nullify the operation of the entire system. For example, the problem may be due to a faulty engine or clogged communications.Therefore, it is worth approaching the inspection of the relay after diagnosing the main elements, especially when it comes to mechanical sensors. In a good half of the cases, to eliminate problems with pressure spread, it is enough to clean the relay from accumulated dirt: springs, plates and contact groups.

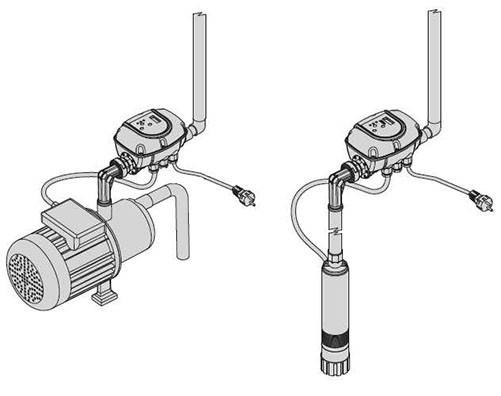

Using a relay without a hydraulic accumulator

For some equipment models, a borehole pump connection scheme with a pressure switch without a storage tank is used. A special automatic controller starts and stops the unit when the limit values are reached. The electronic unit has the function of protection against "dry running" and ensures the safe operation of the system.

Electronic pressure switch for surface and submersible pump

The device starts the pump when the tap is opened, after the water supply is stopped, the equipment works for some time to create the set pressure level. Advantages of the automatic controller:

- compactness;

- costs for the purchase of a hydraulic accumulator are excluded;

- stable pressure in the system.

Among the disadvantages is the frequent switching on of the pump, leading to premature wear. This type of automation is suitable for a network used for a long turn-on mode (watering, filling a large capacity).

Installation and correct adjustment of the pressure switch of the pumping station provide a stable water pressure in the system. Correct adjustment of the device helps to extend the life of the equipment and prevents the occurrence of emergencies.

Connecting the water pressure switch

Step-by-step installation of a pressure switch in the water supply system

Step-by-step installation of a pressure switch in the water supply system

At the same time it is connected to the power supply and water consumption, intended for permanent connection.Before you start connecting the pressure switch, understand the details.

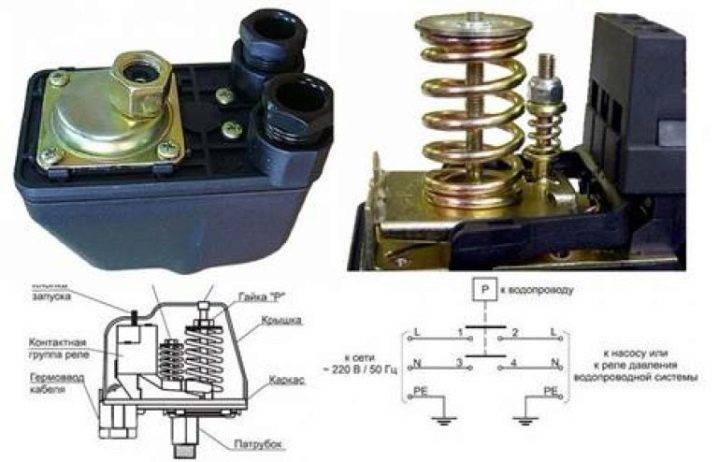

Electrical part

Separate electrical wiring is desirable - it gives more chances to increase the service life. You will need a single-core copper cable with a cross section of 2.5 square mm. It is recommended to install an automatic machine and an RCD in the complex. The main characteristics are selected according to the current consumed by the pump, because the relay itself does not require a lot of electricity.

The pressure switch device for the pumping station is equipped with:

- phase and zero connectors from the power source;

- the same contacts from the pumping station;

- grounding is connected to the same wiring from the power source and the station that sets the pressure.

All wires are firmly fixed according to the standard connection requirements. After an hour, the contacts should be checked and tightened at

need.

Do-it-yourself connection to the water supply

There are various schemes for connecting the relay to the water supply:

- for convenience, a special device with a five-pin fitting is used;

- various fittings are used;

- it is recommended to complete the water supply with filters that ensure the duration of operation.

As a result, high-quality water supply with the same pressure is obtained. It allows you to use various plumbing.