- Pump station pressure switch

- Mechanical relays

- Electronic relays

- Device specifications

- Features of work

- How to properly adjust the relay and calculate the pressure

- Setting the pressure switch

- Do you need a hydraulic accumulator

- How to change the range of the relay

- What is taken into account when making adjustments

- Causes of hardware problems

- Influence of air pressure in the tank

- How to set up the system for 50 liters?

- Correction of errors in work

- Violation of the rules of operation

- Engine malfunctions

- Problems with water pressure in the system

- How to set the relay correctly?

Pump station pressure switch

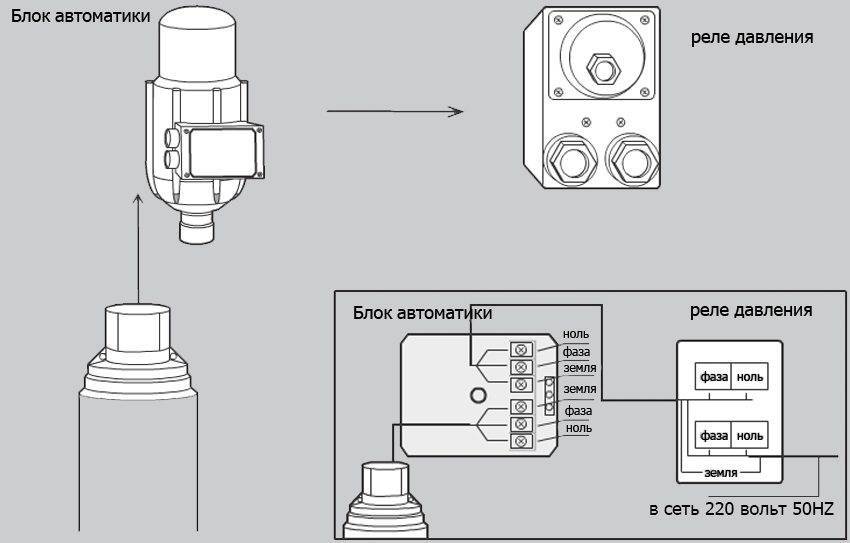

The sensor automatically regulates the process of pumping water in the system. It is the pressure switch that is responsible for turning the pumping equipment on and off. It also controls the level of water pressure. There are mechanical and electronic elements.

Mechanical relays

Devices of this kind are distinguished by a simple and at the same time reliable design. They are much less likely to fail than electronic counterparts, because there is simply nothing to burn out in mechanical relays. Adjustment occurs by changing the tension of the springs.

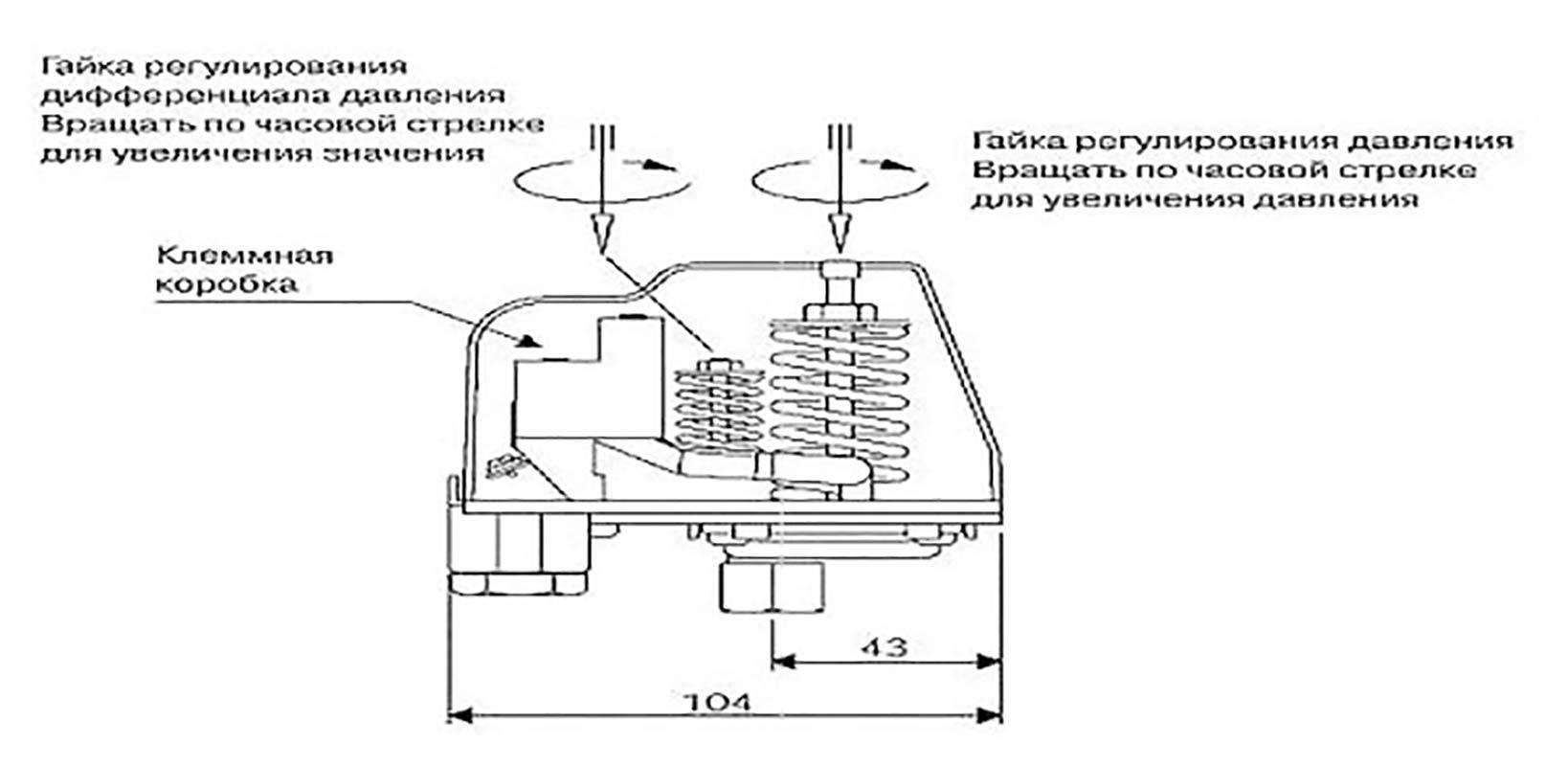

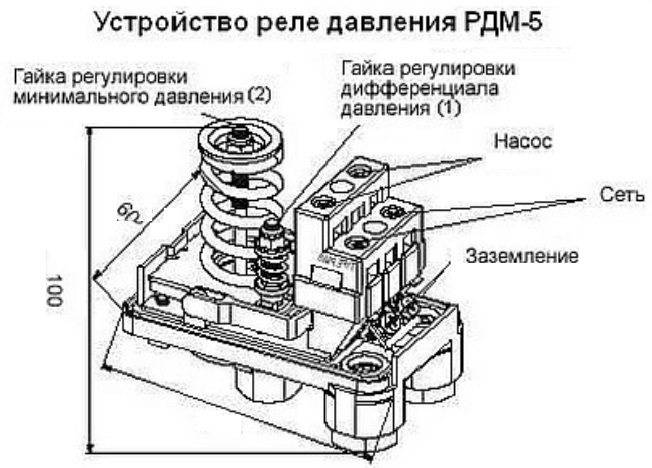

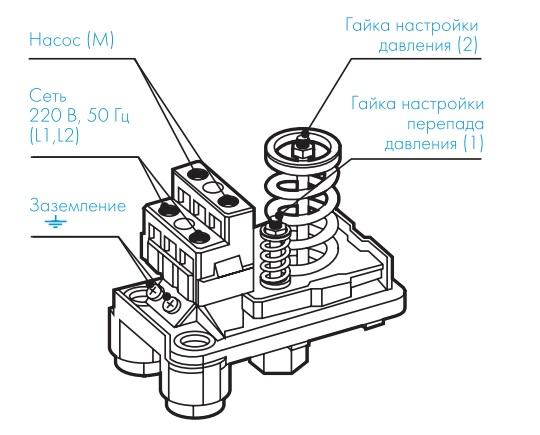

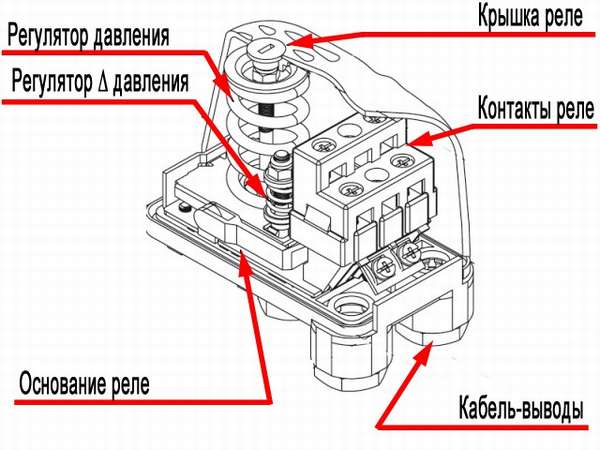

Mechanical pressure switch adjustable by spring tension

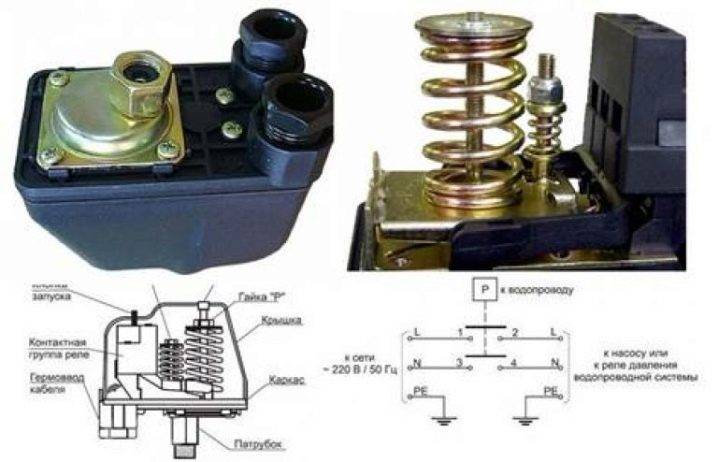

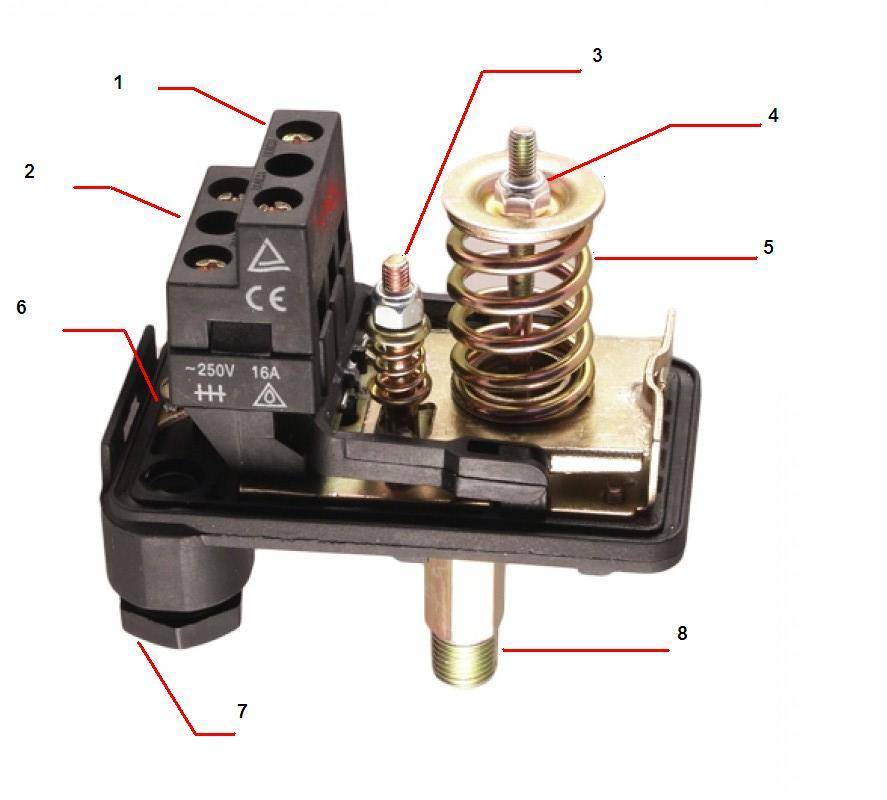

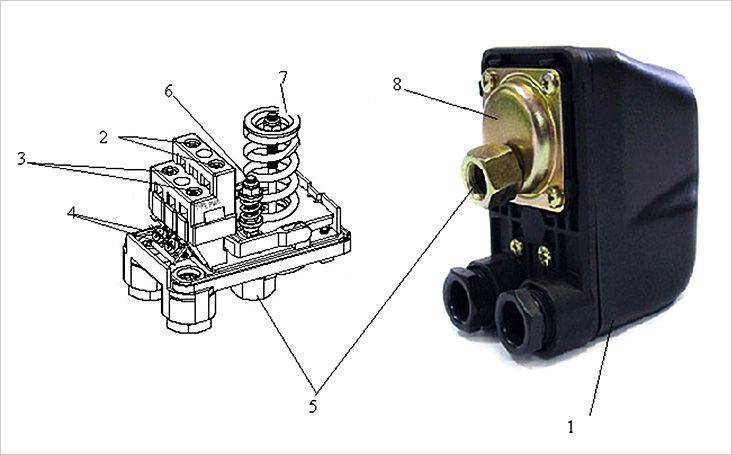

The mechanical relay includes a metal plate where the contact group is fixed.There are also terminals for connecting the device and springs for adjustment. The lower part of the relay is reserved for the membrane and piston. The design of the sensor is quite simple, so there should be no serious problems with self-disassembly and damage analysis.

Electronic relays

Such devices attract primarily by ease of use and their accuracy. The step of the electronic relay is noticeably smaller than the mechanical one, which means that there are more adjustment options here. But electronics, especially budget ones, often break down. Therefore, excessive savings in this case is impractical.

Electronic water pressure switch

Another clear advantage of an electronic relay is the protection of equipment from idling. When the water pressure in the line is minimal, the element will continue to work for some time. This approach allows you to protect the main nodes of the station. Repairing an electronic relay on your own is much more difficult: in addition to technical knowledge, you need a specific tool. Therefore, it is better to leave the diagnostics and maintenance of the sensor to professionals.

Device specifications

Depending on the model of the station and its type, the device can be located both inside the case and mounted outside. That is, if the equipment comes without a relay, or its functionality does not suit the user, then it is always possible to select the element in a separate order.

The sensors also differ in the maximum allowable pressure. A good half of the classic relays are set to 1.5 atm to start the system and 2.5 atm to deactivate it. Powerful household models have a threshold of 5 atm.

When it comes to an external element, it is extremely important to take into account the characteristics of the pumping station.If the pressure is too high, the system may not withstand, and as a result, leaks, ruptures and early wear of the membrane will appear.

Therefore, it is so important to adjust the relay with an eye to the critical indicators of the station.

Features of work

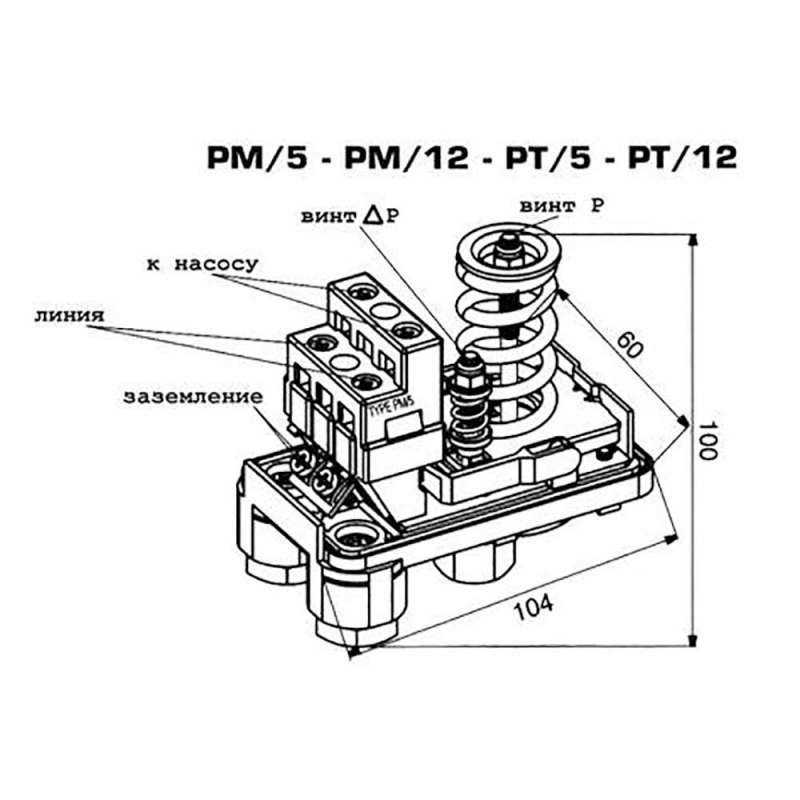

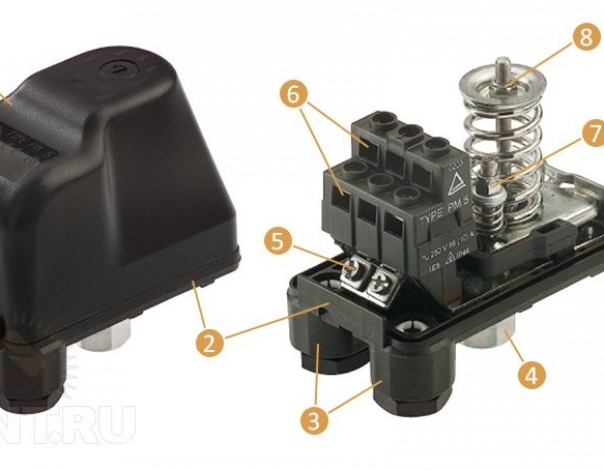

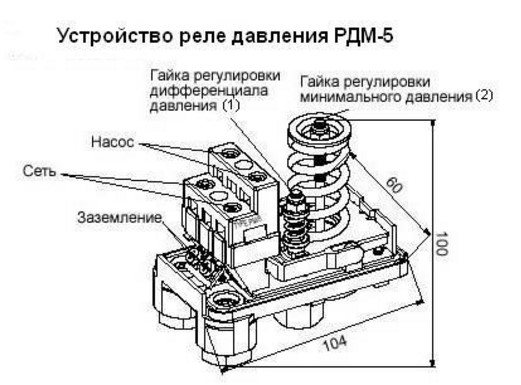

Consider the principle of operation of the device using the example of one of the most common relays for pumping stations - RM-5. On sale you can also find foreign analogues and more advanced solutions. Such models are equipped with additional protection and offer enhanced functionality.

PM-5 includes a movable metal base and a pair of springs on both sides. The membrane moves the plate depending on the pressure. By means of a clamping bolt, you can adjust the minimum and maximum indicators at which the equipment turns on or off. RM-5 is equipped with a check valve, so when the pumping station is deactivated, water does not drain back into the well or well.

Step-by-step analysis of the pressure sensor:

- When the faucet is opened, water begins to flow from the tank.

- As the liquid in the pumping station decreases, the pressure gradually decreases.

- The membrane acts on the piston, and it, in turn, closes the contacts, including the equipment.

- When the tap is closed, the tank is filled with water.

- As soon as the pressure indicator reaches its maximum values, the equipment turns off.

The available settings determine the frequency of the pump: how often it will turn on and off, as well as the pressure level. The shorter the interval between the start-up and deactivation of the equipment, the longer the main components of the system and all the equipment as a whole will last. Therefore, competent adjustment of the pressure switch is so important.

But not only the sensor affects the operation of the equipment. It happens that the device is configured correctly, but other elements of the station nullify the operation of the entire system. For example, the problem may be due to a faulty engine or clogged communications. Therefore, it is worth approaching the inspection of the relay after diagnosing the main elements, especially when it comes to mechanical sensors. In a good half of the cases, to eliminate problems with pressure spread, it is enough to clean the relay from accumulated dirt: springs, plates and contact groups.

How to properly adjust the relay and calculate the pressure

All devices leave the production line with certain settings, but after purchase, additional verification must be performed. When buying, you need to find out from the seller what values the manufacturer recommends using when adjusting the depth pressure. In other words, the pressure at which the contacts close and open.

If the station fails due to improper adjustment of the pressure switch of the jumbo pumping station, then it will not be possible to use the manufacturer's warranty.

When calculating the cut-in pressure values, the following parameters are taken into account:

- Required pressure at the highest draw-off point.

- Difference in height between the top draw point and the pump.

- Loss of water pressure in the pipeline.

The value of the switching pressure is equal to the sum of these indicators.

The calculation of the turn-off pressure to solve the question of how to set up the pressure switch is performed as follows: the turn-on pressure is calculated, one bar is added to the value obtained, then one and a half bar is subtracted from the amount. The result should not exceed the value of the maximum allowable pressure that occurs at the outlet of the pipe from the pump.

Setting the pressure switch

During the assembly process of the pumping station, special attention is paid to setting the pressure switch. The ease of operation of the water supply system, as well as the terms of the trouble-free service of all components of the device, depend on how correctly its limiting levels are set.

At the first stage, you need to check the pressure that was created in the tank during the manufacture of the pumping station. Typically, the factory setting is set to on at 1.5 atmospheres, and off at 2.5 atmospheres. This is checked with an empty tank and the pumping station disconnected from the mains. It is recommended to check with an automotive mechanical pressure gauge. It is placed in a metal case, so the measurements are more accurate than using electronic or plastic pressure gauges. Their readings can be affected by both the air temperature in the room and the level of battery charge. It is desirable that the scale limit of the pressure gauge be as small as possible. Because on a scale of, for example, 50 atmospheres, it will be very difficult to accurately measure one atmosphere.

Another option is also possible - carefully monitor the shutdown pressure of the pump. If it has increased, this will mean a decrease in air pressure in the tank. The lower the air pressure, the more water can be created.However, the pressure spread from a completely filled to a practically empty tank is large, and all this will depend on the preferences of the consumer.

Having chosen the desired mode of operation, you need to set it by bleeding excess air for this, or pump it up additionally. It must be borne in mind that one should not reduce the pressure to a value of less than one atmosphere, and also pump it too much. Due to the small amount of air, the rubber container filled with water inside the tank will touch its walls and be wiped. And excess air will not make it possible to pump in a lot of water, since a significant part of the tank volume will be occupied by air.

Do you need a hydraulic accumulator

A reasonable question: is it possible to do without a hydraulic accumulator? In principle, this is possible, but with a conventional automation unit, the pump will turn on and off very often, reacting even to a slight flow of water. After all, the amount of water in the pressure pipeline is small, and the slightest flow of water will lead to a rapid drop in pressure and its same rapid increase when the pump is turned on. It is precisely because of the fact that the pump does not turn on for each of your "sneezes" that they put a hydraulic accumulator, at least a small one. Since water is an incompressible substance, air is pumped into the accumulator, which, unlike water, compresses well and acts as a kind of damper that regulates the accumulation and flow of water. If there is no or too little air in the accumulator, then there will be nothing to compress, that is, there will be no accumulation of water.

Ideally, the capacity of the accumulators should be only slightly less than the debit of your water source, and the pump, in this case, will turn on only when some fairly decent supply of water is used up, i.e.very rarely, but for a long time. But then it will be very expensive in cost.

Now pumping stations with improved automation units with built-in dry-running protection have appeared on sale, which smoothly start and stop the pump, regulate its power depending on the given pressure. It is believed that the accumulator, in principle, they do not need. But all this works well only in the absence of power surges, which our remote areas and summer cottages cannot boast of. And, unfortunately, stabilizers do not always save from this trouble. In addition, the price of such a station is very often much higher than usual, which, in my opinion, does not justify itself.

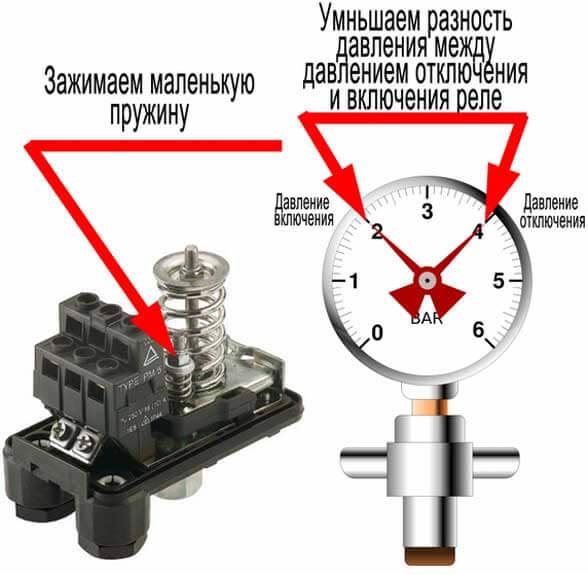

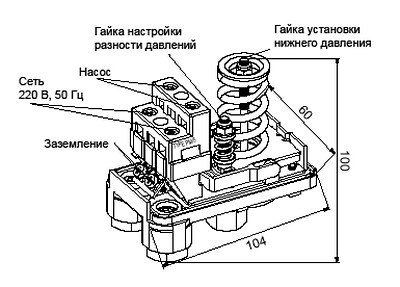

How to change the range of the relay

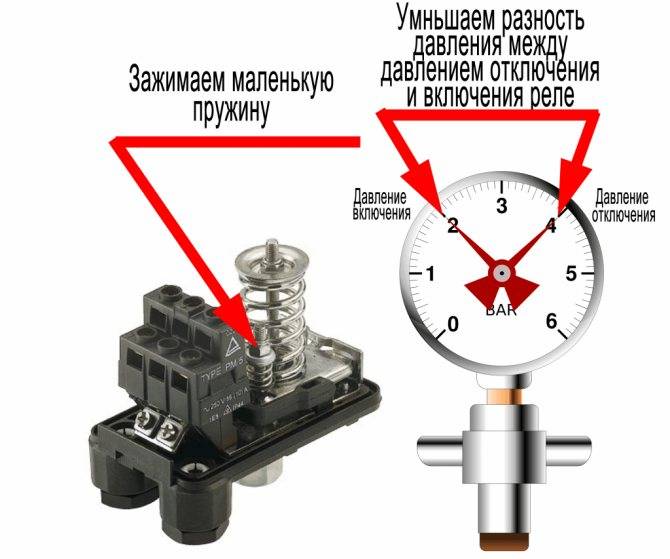

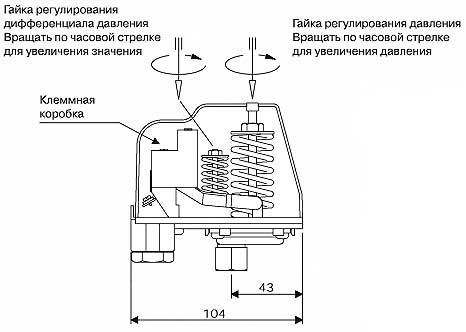

If the “lower” pressure is normal, but you only need to increase or decrease the “upper” pressure, you need to use a smaller regulator. In this case:

- Tightening the nut for this regulator clockwise will increase the "upper" pressure, while the "lower" pressure remains unchanged.

- Unscrewing is the opposite: in this case, the difference between them will decrease or increase - ∆P.

- After changing the adjustment, the power is turned on and the moment is noticed on the pressure gauge when the pump is turned off - the “upper” pressure.

- If the results are satisfactory, the adjustment can be stopped at this point, if not, the process is repeated until the desired result is obtained.

If both the “lower” pressure and the relay operation range are not satisfied at the same time, it is necessary to first adjust with a large regulator, and after that with a smaller one, the whole process is controlled by the station pressure gauge.

What is taken into account when making adjustments

When adjusting the operation of the equipment relay on your own, it is necessary to take into account such important points:

- It is impossible to set the "upper" pressure, which is more than 80% of the maximum for the product, on this model. As a rule, it is indicated on the packaging or in the instructions, and ranges from 5 to 5.5 bar.

To set a higher level in the system of a private house, it is necessary to select a relay with a higher maximum pressure. - Before increasing the pressure to turn on the pump, it is necessary to get acquainted with its characteristics, whether it can develop such pressure. Otherwise, if it cannot be created, the unit will not turn off, and the relay will not be able to turn it off, because the set limit cannot be reached.

The pump head is measured in meters of water column: 1 m of water. Art. = 0.1 bar. In addition, hydraulic losses in the entire system are also taken into account. - It is impossible to tighten the nuts of the regulators to failure during regulation, otherwise the relay may completely stop working.

Causes of hardware problems

The statistics of malfunctions in the operation of domestic pumping stations says that most often problems arise due to a violation of the integrity of the accumulator membrane, pipeline, water or air leakage, and also due to various contaminants in the system.

The need to intervene in its work may arise due to many reasons:

- Sand and various substances dissolved in water can cause corrosion, lead to malfunctions and reduce equipment performance. To prevent clogging of the device, it is necessary to use filters that purify the water.

- The decrease in air pressure in the station causes frequent operation of the pump and its premature wear.It is recommended to measure the air pressure from time to time and adjust it if necessary.

- The lack of tightness of the joints of the suction pipeline is the reason that the engine runs without turning off, but cannot pump liquid.

- Improper adjustment of the pressure of the pumping station can also cause inconvenience and even breakdowns in the system.

To extend the life of the station, it is recommended to periodically audit. Any adjustment work must begin with disconnecting from the mains and draining the water.

The power consumption and maximum head should be checked periodically. An increase in energy consumption indicates friction in the pump. If the pressure drops without leaks detected in the system, then the equipment is worn out

Influence of air pressure in the tank

The normal operation of the equipment depends on the air pressure in the accumulator (see Diagram for connecting the accumulator to the submersible pump: which is better), but it has nothing to do with adjusting the relay. In any case, it will start to work at a certain “lower” and “upper” pressure, regardless of its presence in the tank.

In the absence of air in the membrane tank, it can only lead to complete filling with water and the pressure in the system will begin to rise instantly to the “upper” one and the pump will immediately turn off after the fluid intake stops. Each time the tap is opened, the pump turns on, it will immediately fall to the "lower" limit.

In the absence of a hydraulic accumulator, the relay will still work. Reduced air pressure leads to a strong stretching of the membrane, and increased air pressure leads to insufficient filling of the tank with water. In this case, excess air pressure will displace the liquid.

For the normal operation of the pumping station and the long service life of the membrane, it is necessary that the air pressure be 10% less than the “lower” one set during the adjustment. Then the accumulator will be normally filled with water, and the membrane will not stretch too much, which means it will last for a long time. In this case, the pump will turn on at intervals corresponding to the ∆P adjusted in the relay. In addition, it is necessary to check the air pressure in the tank of the pumping station if there is no liquid pressure in it. In this case, you need to open the tap located in the system below everything and drain all the water.

The details of adjusting the pressure switch are well shown in the video in this article.

By following these simple recommendations, the pumping station will be in good condition for a long time.

How to set up the system for 50 liters?

After the calculations, it is necessary to measure the air pressure indicator inside the station, the value of which should not exceed 1.5 atm.

It is this indicator that will provide a good pressure of water. The larger the parameter, the less water can flow.

For measurement, you can use a pressure gauge for a car, which helps to calculate the indicator with the least inaccuracy.

After determining the air pressure, it is necessary:

- Start the pump to establish pressure in the system.

- Determine at what point on the pressure gauge the shutdown occurs.

- Set the switch to disable the mechanism.

- Turn on the tap so that the accumulator gets rid of moisture, and fix the indicator.

- Fit the small spring under the formed thresholds.

| Index | Action | Result |

| 3.2-3,3 | Rotation of the screw on a small spring until the motor is completely turned off. | Decrease in indicator |

| Less than 2 | Add pressure | Increase in indicator |

The recommended value is 2 atmospheres.

By adhering to these recommendations, acceptable indicators of the water supply system can be established.

Correction of errors in work

Before embarking on a more serious intervention in the operation of the equipment, it is necessary to take the simplest measures - clean the filters, eliminate leaks. If they do not produce results, then proceed to further steps, trying to identify the root cause.

The next thing to do is to adjust the pressure in the accumulator tank and adjust the pressure switch.

The following are the most common malfunctions in the domestic pumping station, which the user can try to solve on his own. For more serious problems, contact the service center.

Violation of the rules of operation

If the station runs continuously without shutting down, the likely cause is incorrect relay adjustment - a high shutdown pressure is set. It also happens that the engine is running, but the station does not pump water.

The reason may lie in the following:

- When first started, the pump was not filled with water. It is necessary to correct the situation by pouring water through a special funnel.

- The integrity of the pipeline is broken or an air lock has formed in the pipe or in the suction valve. To find a specific cause, it is necessary to make sure that: the foot valve and all connections are tight, there are no bends, narrowings, hydraulic locks along the entire length of the suction pipe. All malfunctions are eliminated, if necessary, replace damaged areas.

- The equipment works without access to water (dry). It is necessary to check why it is not there or to identify and eliminate other causes.

- The pipeline is clogged - it is necessary to clear the system of contaminants.

It happens that the station very often works and turns off. Most likely this is due to a damaged membrane (then it is necessary to replace it), or the system does not have the pressure required for operation. In the latter case, it is necessary to measure the presence of air, check the tank for cracks and damage.

Before each start, it is necessary to pour water into the pumping station through a special funnel. She must not work without water. If there is a possibility of the pump running without water, you should purchase automatic pumps equipped with a flow controller

Less likely, but it can happen that the check valve is open and blocked due to debris or a foreign object. In such a situation, it will be necessary to disassemble the pipeline in the area of \u200b\u200bpossible blockage and eliminate the problem.

Engine malfunctions

The household station engine does not run and does not make noise, possibly for the following reasons:

- The equipment is disconnected from the power supply or there is no mains voltage. You need to check the wiring diagram.

- The fuse has blown. In this case, you need to replace the element.

- If you cannot turn the fan impeller, then it is jammed. You need to find out why.

- Relay damaged. You need to try to adjust it or, if it fails, replace it with a new one.

Engine malfunctions most often force the user to use the services of a service center.

Problems with water pressure in the system

Insufficient water pressure in the system can be explained by several reasons:

- The pressure of water or air in the system is set to an unacceptably low value. Then you need to configure the relay operation in accordance with the recommended parameters.

- Piping or pump impeller blocked. Cleaning the elements of the pumping station from contamination may help solve the problem.

- Air enters the pipeline. Checking the elements of the pipeline and their connections for tightness will be able to confirm or refute this version.

Poor water supply can also be caused by air being drawn in due to leaky water pipe connections or the water level has dropped so much that air is being pumped into the system when it is taken.

Poor water pressure can create significant discomfort when using the plumbing system

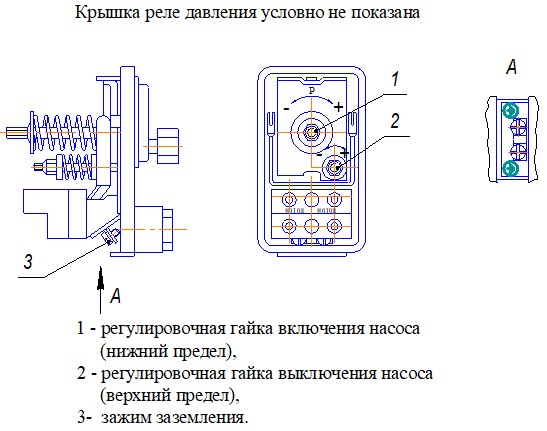

How to set the relay correctly?

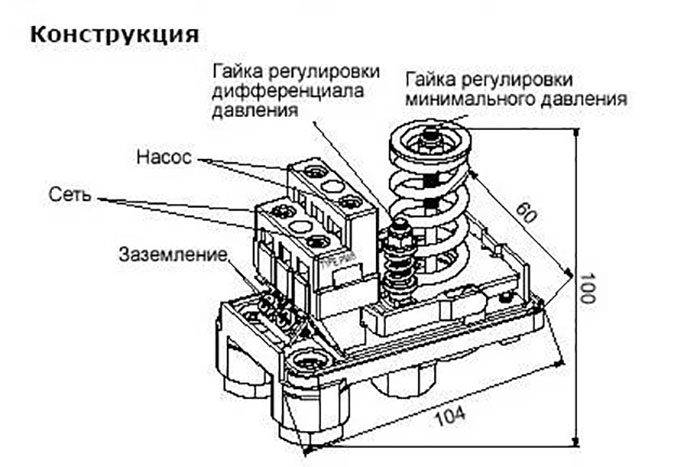

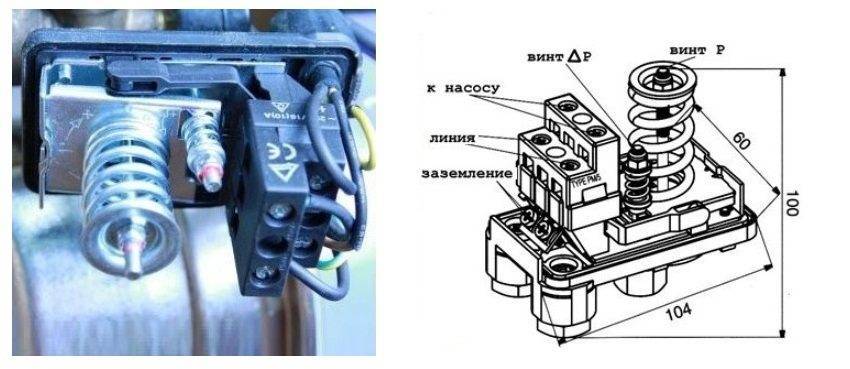

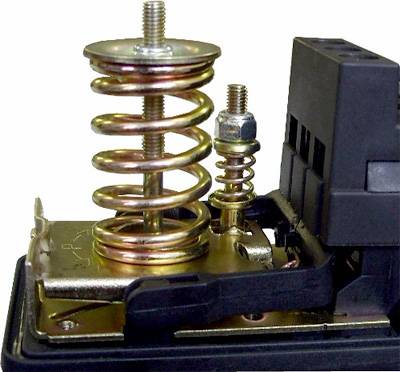

There is a cover on the pressure switch housing, and under it there are two springs equipped with nuts: large and small. By rotating these springs, the lower pressure in the accumulator is set, as well as the difference between the cut-in and cut-out pressures. The lower pressure is regulated by a large spring, and a small one is responsible for the difference between the upper and lower pressure.

There are two adjusting springs under the cover of the pressure switch. The large spring regulates the activation of the pump, and the small spring regulates the difference between the on and off pressure.

Before starting the setup, it is necessary to study the technical documentation of the pressure switch, as well as the pumping station: the hydraulic tank and its other elements.

The documentation indicates the operating and limiting indicators for which this equipment is designed. During the adjustment, these indicators should be taken into account so as not to exceed them, otherwise these devices may soon break down.

Sometimes it happens that during the adjustment of the pressure switch, the pressure in the system still reaches the limit values. If this happens, you just need to turn off the pump manually and continue tuning. Fortunately, such situations are extremely rare, since the power of household surface pumps is simply not enough to bring the hydraulic tank or system to its limit.

On the metal platform where the adjusting springs are located, the designations “+” and “-“ are made, which allow you to understand how to rotate the spring in order to increase or decrease the indicator

It is useless to adjust the relay if the accumulator is filled with water. In this case, not only the water pressure will be taken into account, but also the parameters of the air pressure in the tank.

To adjust the pressure switch, follow these steps:

- Set the operating air pressure in the empty accumulator.

- Turn on the pump.

- Fill the tank with water until the lower pressure is reached.

- Switch off the pump.

- Turn the small nut until the pump starts.

- Wait until the tank is full and the pump is turned off.

- Open water.

- Rotate the large spring to set the cut-in pressure.

- Turn on the pump.

- Fill the hydraulic tank with water.

- Correct the position of the small adjusting spring.

You can determine the direction of rotation of the adjusting springs by the signs “+” and “-”, which are usually located nearby. To increase the switching pressure, the large spring must be rotated clockwise, and to decrease this figure, it must be rotated counterclockwise.

The pressure switch adjusting springs are very sensitive, so they need to be tightened very carefully, constantly checking the condition of the system and the pressure gauge

The rotation of the adjusting springs when adjusting the pressure switch for the pump must be done very smoothly, about a quarter or half a turn, these are very sensitive elements. The pressure gauge should show lower pressure when switched on again.

With regard to indicators when adjusting the relay, it will be useful to remember the following points:

- If the hydraulic tank is filled, and the pressure gauge remains unchanged, it means that the maximum pressure in the tank has been reached, the pump should be turned off immediately.

- If the difference between the cut-off and turn-on pressures is about 1-2 atm, this is considered normal.

- If the difference is greater or less, the adjustment should be repeated, taking into account possible errors.

- The optimal difference between the set lower pressure and the pressure determined at the very beginning in an empty accumulator is 0.1-0.3 atm.

- In the accumulator, the air pressure should not be less than 0.8 atm.

The system can turn on and off properly in automatic mode and with other indicators. But these boundaries make it possible to minimize the wear of equipment, for example, the rubber lining of a hydraulic tank, and extend the operation time of all devices.