- Pumping station device

- Primary adjustment of the water pressure switch

- Pump station pressure switch

- Mechanical relays

- Electronic relays

- Device specifications

- Features of work

- Features of the relay settings

- Expert advice

- Features of the relay settings

- Need to know

- 10 Readings inside the accumulator

- How is the pressure switch of the pumping station set up

- How to properly adjust (with hydraulic accumulator)

- Adjustment scheme

- Video: how to adjust the pump relay

- Insufficient water pressure in the system

- Malfunctions of the pumping station

- The need to replace the relay

- Pump keeps turning on/off

- The pump does not turn off for a long time

- There is no water in the system, and the pump does not turn on

- How to set the relay correctly?

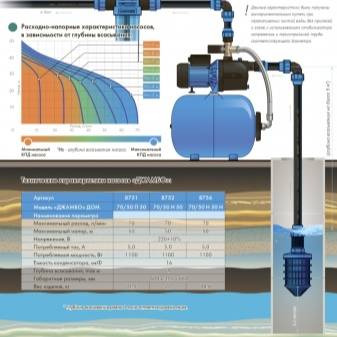

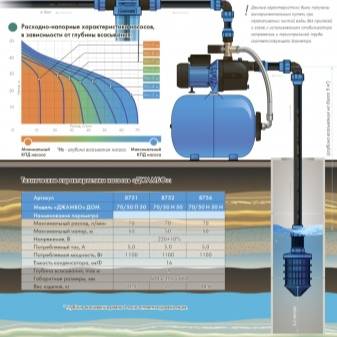

Pumping station device

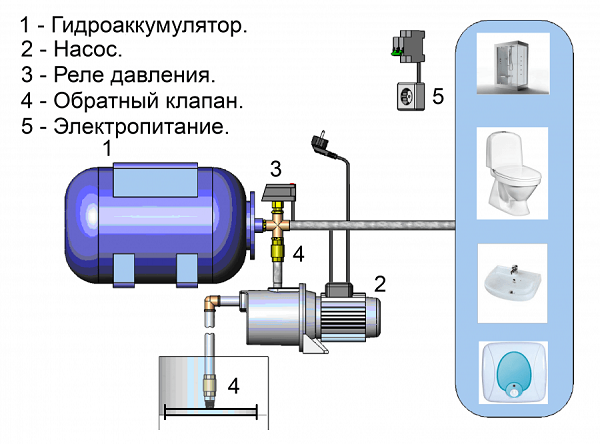

In order to properly adjust this pumping equipment, you must have at least a minimal idea of how it works and on what principle it works. The main purpose of pumping stations consisting of several modules is to provide drinking water to all water intake points in the house. Also, these units are able to automatically increase and maintain the pressure in the system at the required level.

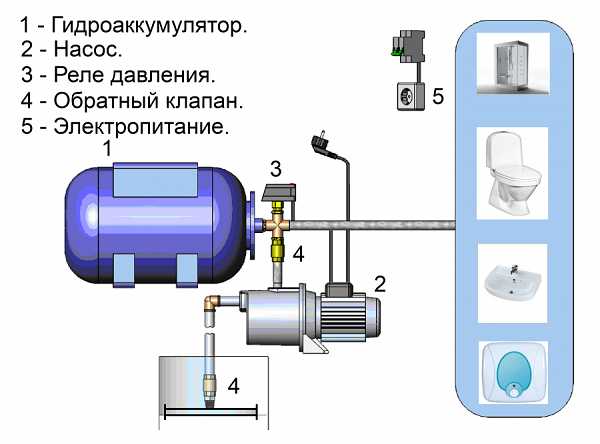

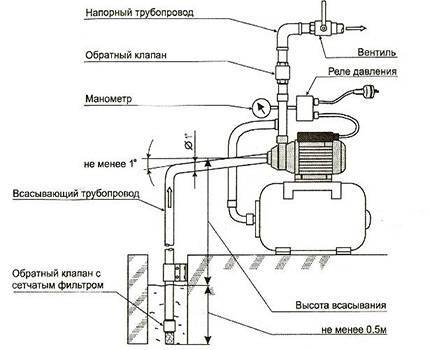

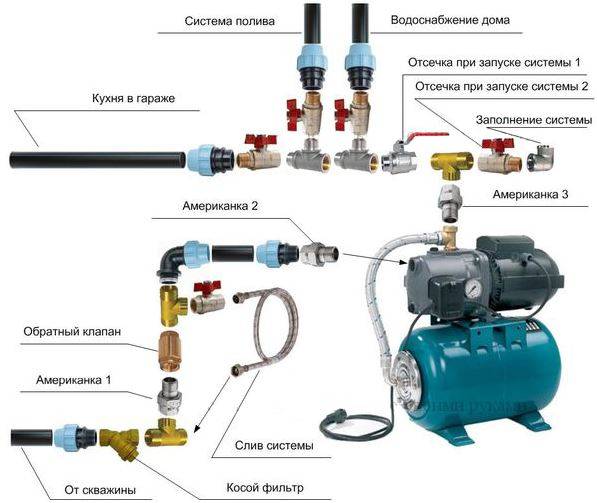

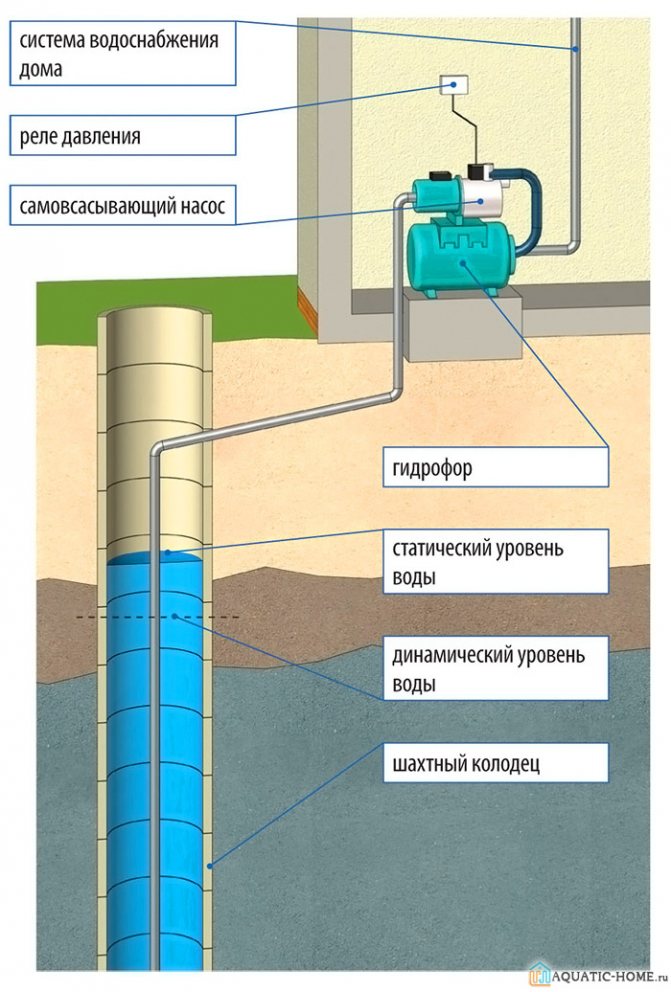

Below is a diagram of a pumping station with a hydraulic accumulator.

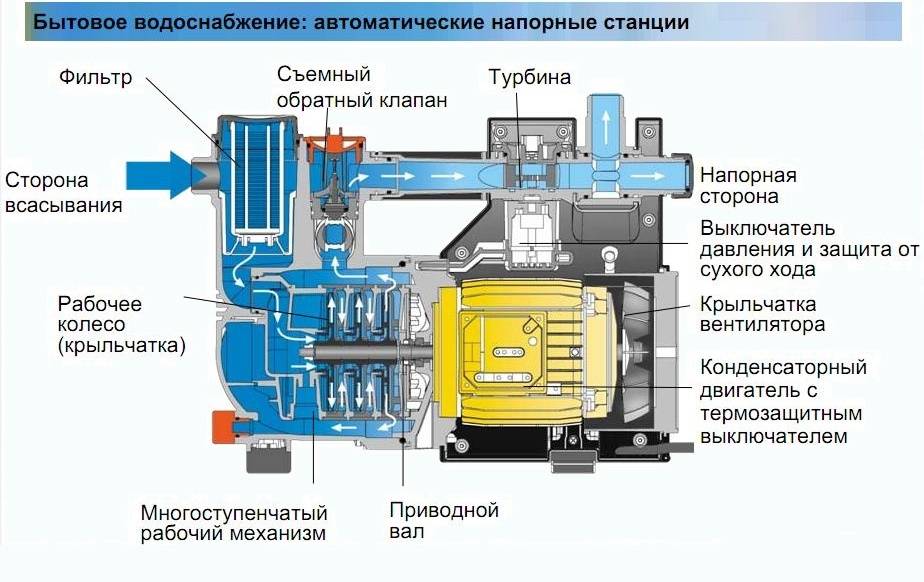

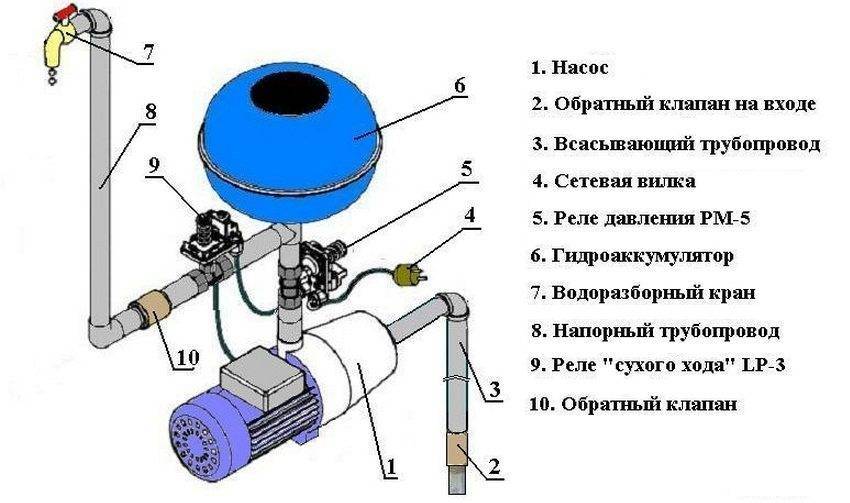

The pumping station includes the following elements (see the figure above).

- Hydraulic accumulator. It is made in the form of a sealed tank, inside of which there is an elastic membrane. In some containers, a rubber bulb is installed instead of a membrane. Thanks to the membrane (pear), the hydraulic tank is divided into 2 compartments: for air and for water. The latter is pumped into a pear or into a part of the tank intended for liquid. The accumulator is connected in the section between the pump and the pipe leading to the water intake points.

- Pump. It can be surface or borehole. The pump type must be either centrifugal or vortex. The vibration pump for the station cannot be used.

- Pressure switch. The pressure sensor automates the entire process by which water is supplied from the well to the expansion tank. The relay is responsible for turning the pump motor on and off when the required compression force is reached in the tank.

- Check valve. Prevents leakage of fluid from the accumulator when the pump is turned off.

- Power supply. To connect the equipment to the electrical network, it is required to stretch a separate wiring with a cross section corresponding to the power of the unit. Also, a protection system in the form of automatic machines should be installed in the electrical circuit.

This equipment works according to the following principle. After opening the tap at the water intake point, water from the accumulator begins to flow into the system. At the same time, compression is reduced in the tank. When the compression force drops to the value set on the sensor, its contacts close and the pump motor starts to work.After the cessation of water consumption at the water intake point, or when the compression force in the accumulator rises to the required level, the relay is activated to turn off the pump.

Primary adjustment of the water pressure switch

The initial adjustment of the relay is carried out at the factory of the company that produces pumping stations. That is why all the "default settings" (1.5 atmospheres of minimum pressure and 2.5 atmospheres of difference) are called "factory".

However, the connection of the pressure switch to the pump (with the introduction of factory settings) is performed at the last stage of the assembly of the station. And the sale of the unit will not take place soon. And over the past months from the moment of manufacture to the moment of sale, the springs and membranes of the relay and drive can weaken.

Therefore, with a newly purchased pump, it is worth checking the pressure in the accumulator and the minimum and maximum pressure indicators set at the factory.

Well, the drive itself is checked as follows:

- A pressure gauge is connected to the nipple of the accumulator or tank. Moreover, in this case, you can use a conventional automotive device with which to check tire pressure.

- The arrow on the pressure gauge will indicate the air pressure behind the membrane of the empty accumulator. And this value cannot be less or more than 1.2-1.5 atmospheres.

If the pressure gauge shows a higher value, then the air from the tank is “bled”, but if it is less, then the tank is “pumped up” with a car pump. Indeed, the “starting” indicator of the relay (minimum pressure) will depend on the level of pressure behind the membrane.

After checking the pressure in the hydraulic tank or accumulator is completed, you can start inspecting the pressure switch, during which the actual values of the minimum and maximum pressure are compared with the values set on the control unit.

Moreover, this operation is carried out very simply, namely:

- A pressure gauge is attached to the collector mounted on the neck of the tank or accumulator.

- Next, turn off the pump and empty the drive (by opening the tap). The pressure on the pressure gauge should drop to 1.5 atmospheres.

- After that, close the valve and turn on the pump. The pump should raise the pressure in the tank to the maximum value and turn off. After turning off the pump, you need to compare the pressure on the pressure gauge with the factory indicators declared in the passport.

If the actual values on the pressure gauge do not match those declared in the passport, or the factory settings do not meet the needs of the consumer, then in this case, an individual setting of the relay is necessary. We will discuss the nuances of the individual setup process below in the text.

Pump station pressure switch

The sensor automatically regulates the process of pumping water in the system. It is the pressure switch that is responsible for turning the pumping equipment on and off. It also controls the level of water pressure. There are mechanical and electronic elements.

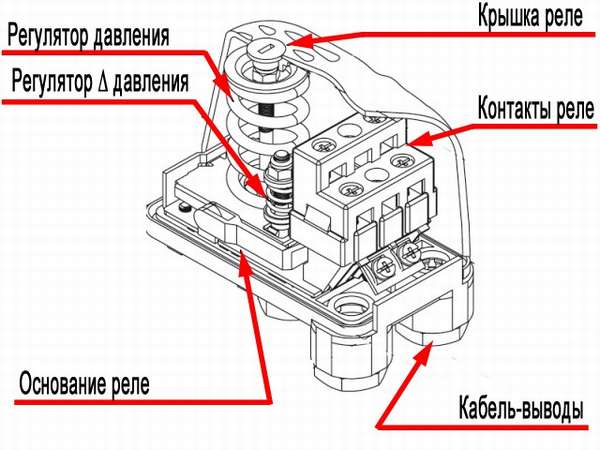

Mechanical relays

Devices of this kind are distinguished by a simple and at the same time reliable design. They are much less likely to fail than electronic counterparts, because there is simply nothing to burn out in mechanical relays. Adjustment occurs by changing the tension of the springs.

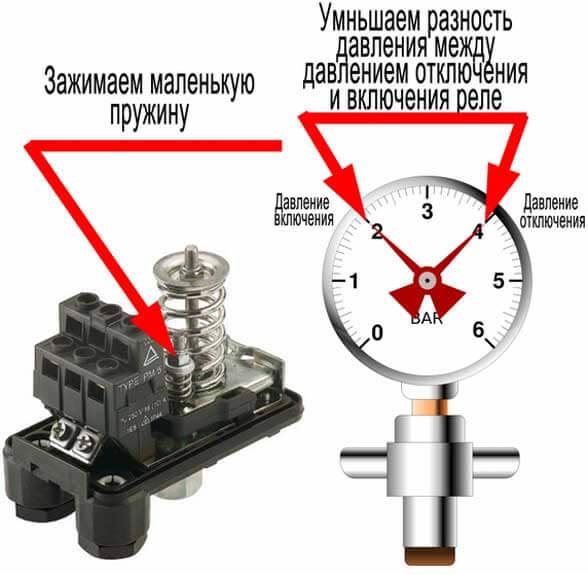

Mechanical pressure switch adjustable by spring tension

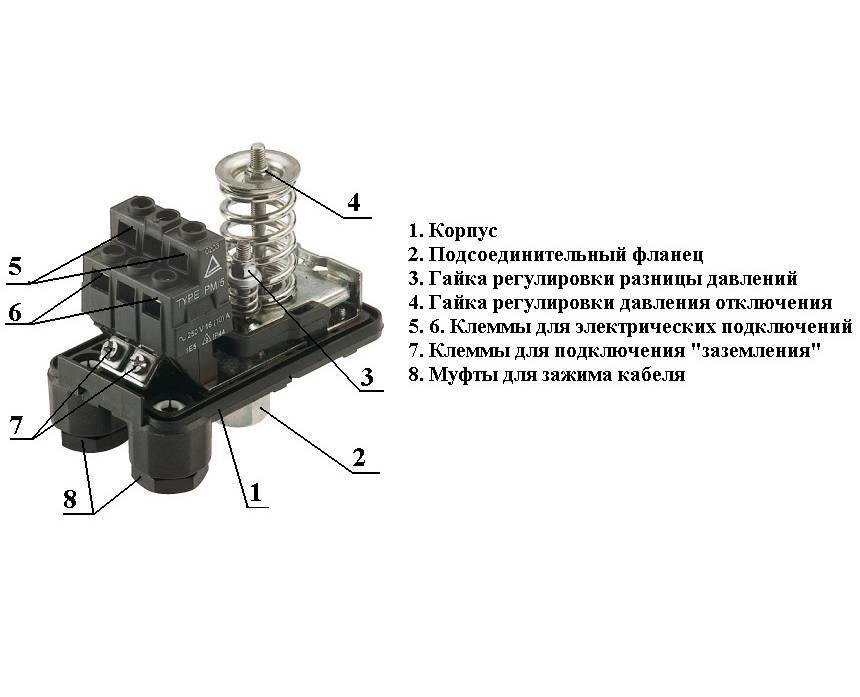

The mechanical relay includes a metal plate where the contact group is fixed. There are also terminals for connecting the device and springs for adjustment. The lower part of the relay is reserved for the membrane and piston. The design of the sensor is quite simple, so there should be no serious problems with self-disassembly and damage analysis.

Electronic relays

Such devices attract primarily by ease of use and their accuracy. The step of the electronic relay is noticeably smaller than the mechanical one, which means that there are more adjustment options here. But electronics, especially budget ones, often break down. Therefore, excessive savings in this case is impractical.

Electronic water pressure switch

Another clear advantage of an electronic relay is the protection of equipment from idling. When the water pressure in the line is minimal, the element will continue to work for some time. This approach allows you to protect the main nodes of the station. Repairing an electronic relay on your own is much more difficult: in addition to technical knowledge, you need a specific tool. Therefore, it is better to leave the diagnostics and maintenance of the sensor to professionals.

Device specifications

Depending on the model of the station and its type, the device can be located both inside the case and mounted outside. That is, if the equipment comes without a relay, or its functionality does not suit the user, then it is always possible to select the element in a separate order.

The sensors also differ in the maximum allowable pressure.A good half of the classic relays are set to 1.5 atm to start the system and 2.5 atm to deactivate it. Powerful household models have a threshold of 5 atm.

When it comes to an external element, it is extremely important to take into account the characteristics of the pumping station. If the pressure is too high, the system may not withstand, and as a result, leaks, ruptures and early wear of the membrane will appear.

Therefore, it is so important to adjust the relay with an eye to the critical indicators of the station.

Features of work

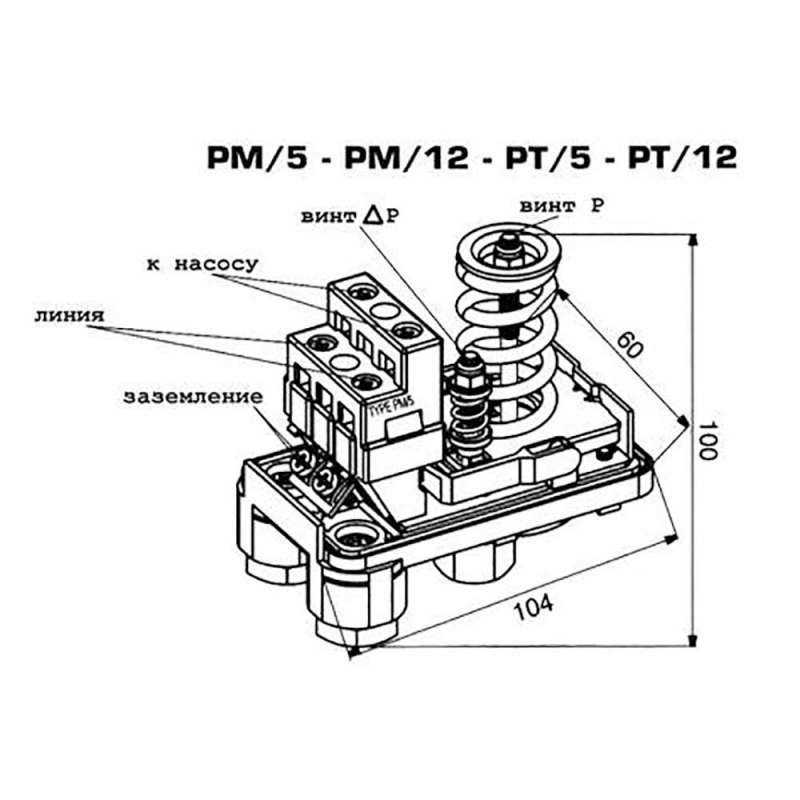

Consider the principle of operation of the device using the example of one of the most common relays for pumping stations - RM-5. On sale you can also find foreign analogues and more advanced solutions. Such models are equipped with additional protection and offer enhanced functionality.

PM-5 includes a movable metal base and a pair of springs on both sides. The membrane moves the plate depending on the pressure. By means of a clamping bolt, you can adjust the minimum and maximum indicators at which the equipment turns on or off. RM-5 is equipped with a check valve, so when the pumping station is deactivated, water does not drain back into the well or well.

Step-by-step analysis of the pressure sensor:

- When the faucet is opened, water begins to flow from the tank.

- As the liquid in the pumping station decreases, the pressure gradually decreases.

- The membrane acts on the piston, and it, in turn, closes the contacts, including the equipment.

- When the tap is closed, the tank is filled with water.

- As soon as the pressure indicator reaches its maximum values, the equipment turns off.

The available settings determine the frequency of the pump: how often it will turn on and off, as well as the pressure level. The shorter the interval between the start-up and deactivation of the equipment, the longer the main components of the system and all the equipment as a whole will last. Therefore, competent adjustment of the pressure switch is so important.

But not only the sensor affects the operation of the equipment. It happens that the device is configured correctly, but other elements of the station nullify the operation of the entire system. For example, the problem may be due to a faulty engine or clogged communications. Therefore, it is worth approaching the inspection of the relay after diagnosing the main elements, especially when it comes to mechanical sensors. In a good half of the cases, to eliminate problems with pressure spread, it is enough to clean the relay from accumulated dirt: springs, plates and contact groups.

Features of the relay settings

When buying a pumping station, many people want to immediately get acquainted with its device. Each element is important. Directly for turning off and on the pump when certain pressure values \u200b\u200bin the hydraulic tank are reached, the pressure switch is responsible.

According to the principle of operation, relays are divided into electronic and mechanical. It is easier to use electronic relays in terms of operation, but the service life of mechanical relays is longer. Therefore, mechanical relays are in great demand.

Relays can be either initially built into the pumping station, or go separately. Thus, according to the characteristics, it is easy to select a relay for the efficient operation of the pumping system.

Water inevitably contains foreign particles, and they are the main reason for the failure of electronic relays.Therefore, it is better to use a special separate filter for water purification. The main advantage of using an electronic relay is that it prevents the pumping station from running idle. After turning off the water supply, the electronic device continues to work for some time. In addition, such relays are easier to configure and install.

Often, pressure sensors immediately have factory settings. As a rule, they are set to 1.5-1.8 atmospheres to turn on, and 2.5-3 atmospheres to turn off. The maximum allowable pressure value for the relay is 5 atmospheres. However, not every system can withstand it. If the pressure is too high, it can cause leaks, wear of the pump diaphragm and other malfunctions.

The initial adjustment is not always suitable for certain operating conditions of the station, and then you have to adjust the relay yourself. Of course, for proper adjustment, it is best to become more familiar with what this small device is and how it works.

Expert advice

To properly adjust the pressure switch, you must follow these recommendations:

- power to the relay is connected through a separate line with an RCD;

- be sure to use grounding;

- if water appears inside or on the relay, then it must be urgently turned off; this is a sign of a ruptured membrane;

- filters must be used in the water supply system; they require regular cleaning;

- 1-2 times a year, the relay is unscrewed and washed;

- the smaller spring element is more sensitive than the large one, so when adjusting it, turn the nut more slowly;

- a small spring serves to set the difference between the upper and lower thresholds for the relay;

- delta should be within 2 atm - this ensures the normal filling of the drive with water.

Proper installation, configuration and timely maintenance of the pressure switch guarantees corrective and uninterrupted operation of the pumping station for many years and ensuring a stable water pressure in the system.

Features of the relay settings

When buying a pumping station, many people want to immediately get acquainted with its device. Each element is important. Directly for turning off and on the pump when certain pressure values \u200b\u200bin the hydraulic tank are reached, the pressure switch is responsible.

According to the principle of operation, relays are divided into electronic and mechanical. It is easier to use electronic relays in terms of operation, but the service life of mechanical relays is longer. Therefore, mechanical relays are in great demand.

Relays can be either initially built into the pumping station, or go separately. Thus, according to the characteristics, it is easy to select a relay for the efficient operation of the pumping system.

Water inevitably contains foreign particles, and they are the main reason for the failure of electronic relays. Therefore, it is better to use a special separate filter for water purification. The main advantage of using an electronic relay is that it prevents the pumping station from running idle. After turning off the water supply, the electronic device continues to work for some time. In addition, such relays are easier to configure and install.

Often, pressure sensors immediately have factory settings.As a rule, they are set to 1.5-1.8 atmospheres to turn on, and 2.5-3 atmospheres to turn off. The maximum allowable pressure value for the relay is 5 atmospheres. However, not every system can withstand it. If the pressure is too high, it can cause leaks, wear of the pump diaphragm and other malfunctions.

The initial adjustment is not always suitable for certain operating conditions of the station, and then you have to adjust the relay yourself. Of course, for proper adjustment, it is best to become more familiar with what this small device is and how it works.

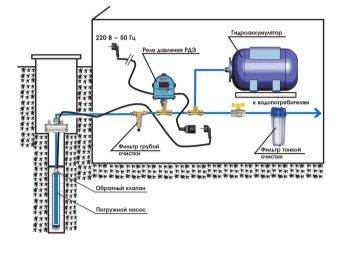

Need to know

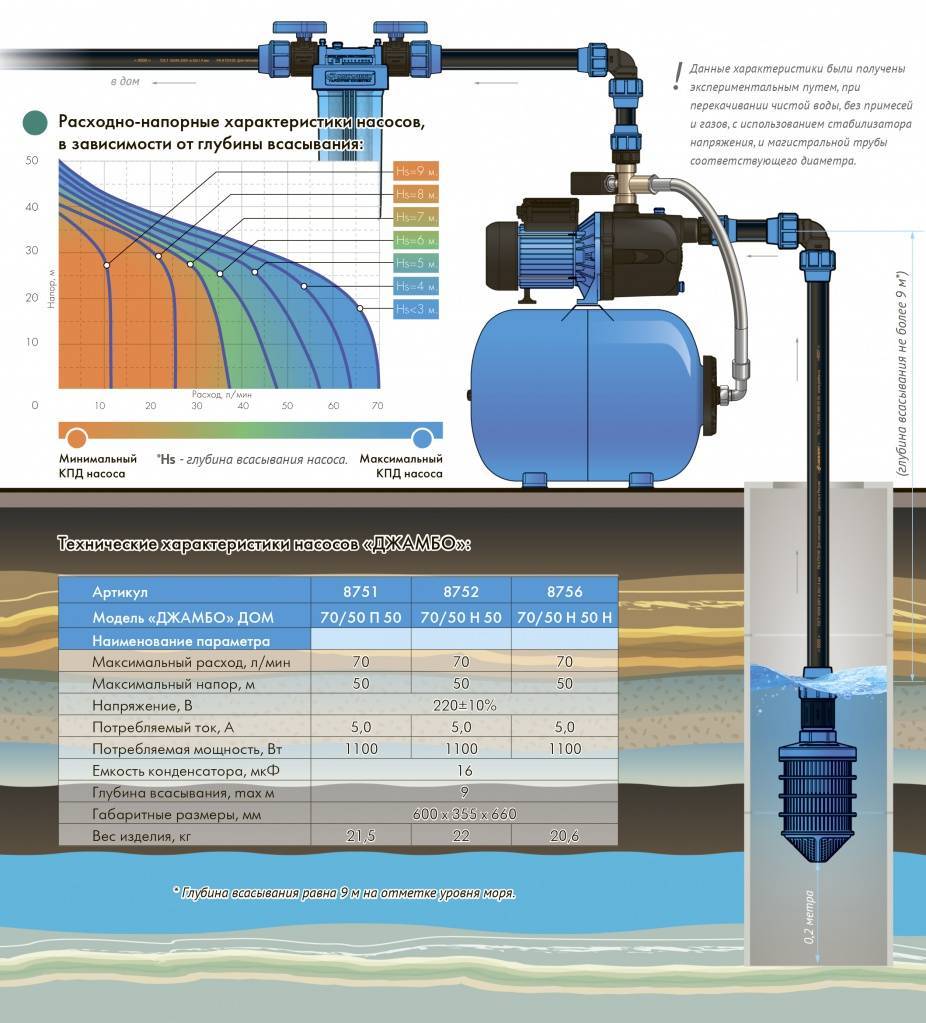

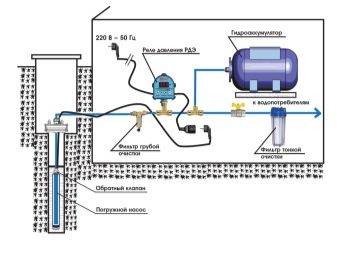

With a high pressure setting, the suction equipment is turned on much more often, which leads to accelerated wear of the main parts. However, this pressure allows you to use even a shower with hydromassage without any difficulties.

A visual diagram of the supply of a residential building with water from a well

At low pressure, the device that supplies liquid from a well or well wears out less, but in this case you will have to be content with an ordinary bath. All the delights of a jacuzzi and other devices that require a sufficiently strong pressure are unlikely to be appreciated.

Thus, the choice must be made depending on the goals pursued. Everyone decides for himself what to prefer in a particular case.

10 Readings inside the accumulator

The air pressure inside the storage tank of the pumping equipment affects the operation of the entire system, but has nothing to do with the adjustment of the relay. When there is no air in the membrane tank and the liquid compartment is completely filled, the pump stops almost immediately.With any opening of water taps, the pumping station will also turn on.

This will lead to the fact that, due to the reduced pressure, the membrane will begin to stretch more than expected, and due to the increased pressure, the tank will not be fully filled with water. Optimal operation of the unit and maintenance of the membrane is possible when the air pressure is set to ten percent below the switch-on values.

Checking the pressure in the hydraulic accumulator is carried out after removing the liquid from the system by opening the bottom valve. It is not recommended to overfill the container with water or allow the pressure to drop so that its readings are less than one atmosphere.

This setting prevents optimal filling with liquid and contributes to premature wear of the rubber bulb, which leads to incorrect operation of the equipment as a whole.

With a competently performed adjustment of the pumping station with your own hands, the pressure in the taps will be able to meet the requirements of consumers.

How is the pressure switch of the pumping station set up

The owners of private houses understand that if the relay malfunctions, the entire system may fail. The stability of the entire system, and hence the comfort of all residents of the house, depends on the competent adjustment of the water pressure switch of the household water supply station.

Pressure control unit with mini pressure gauge

Setting up the relay should begin with checking the factory-set indicators. Usually, the minimum pressure level is 1.5 atm, and the maximum is 2.5 atm. The check is carried out using a manometer. At this point, it is necessary to turn off the pump and ensure that the tank is empty.To measure pressure, a manometer is attached to an empty tank and readings are taken from it.

A pressure gauge will help check the relay performance

Expert opinion

Valery Drobakhin

Water supply and sewerage design engineer, ASP North-West LLC

Ask a specialist

“This check can be avoided by buying a ready-made unit. But when purchasing all the components separately, it will be necessary to carry out the first adjustment of the water pressure switch for the pumping station.”

How to properly adjust (with hydraulic accumulator)

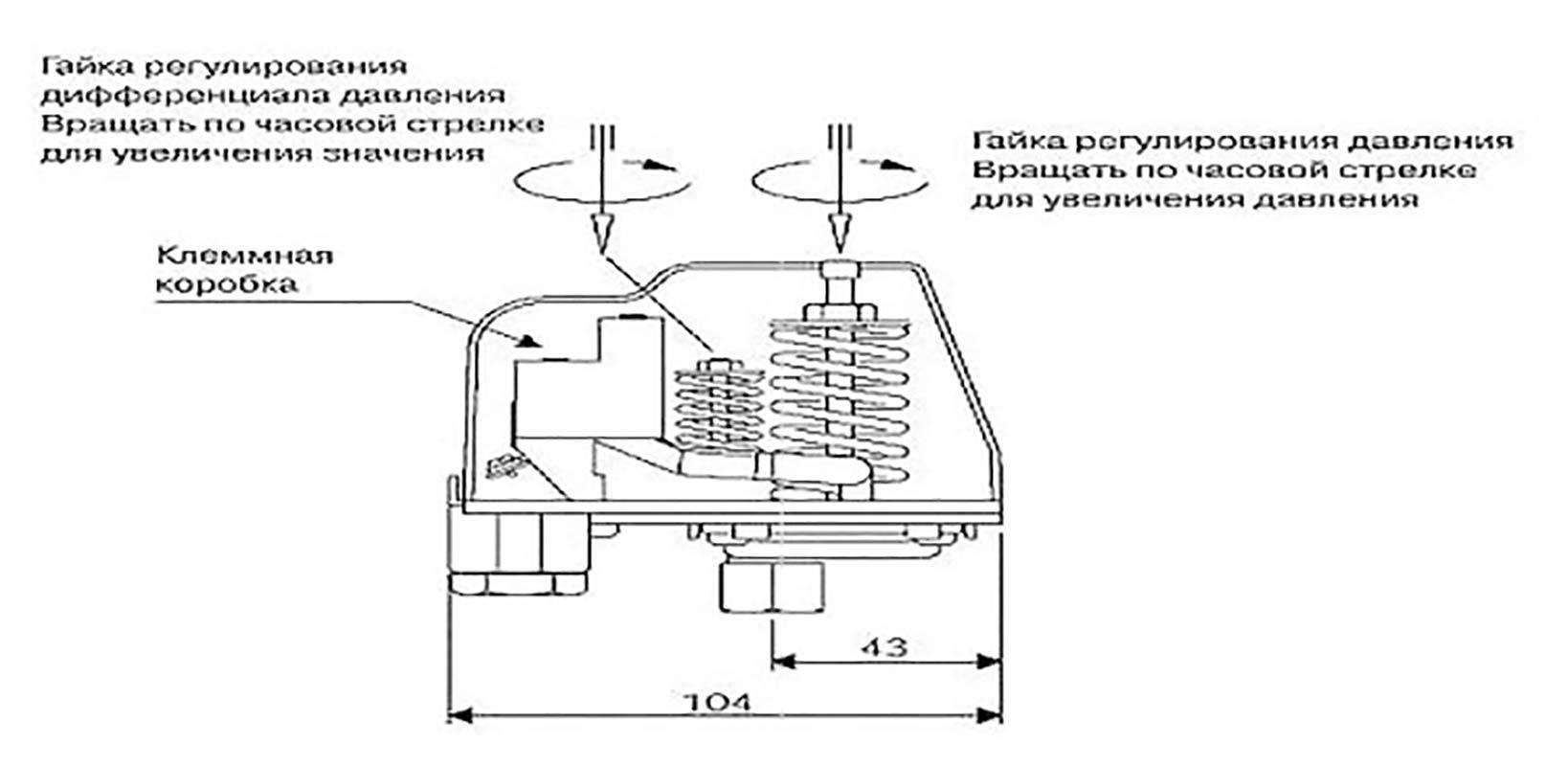

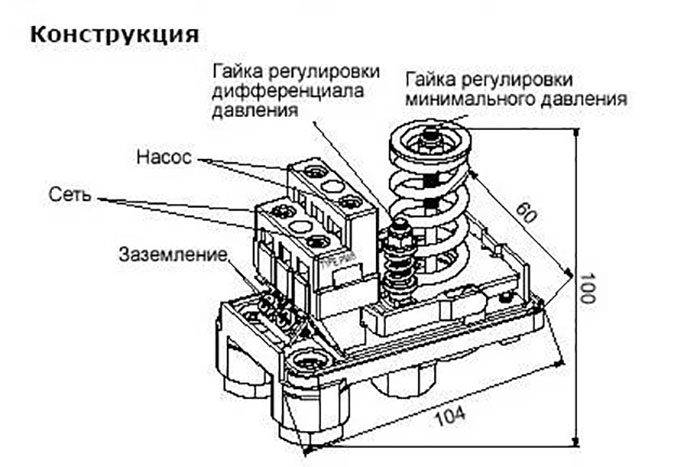

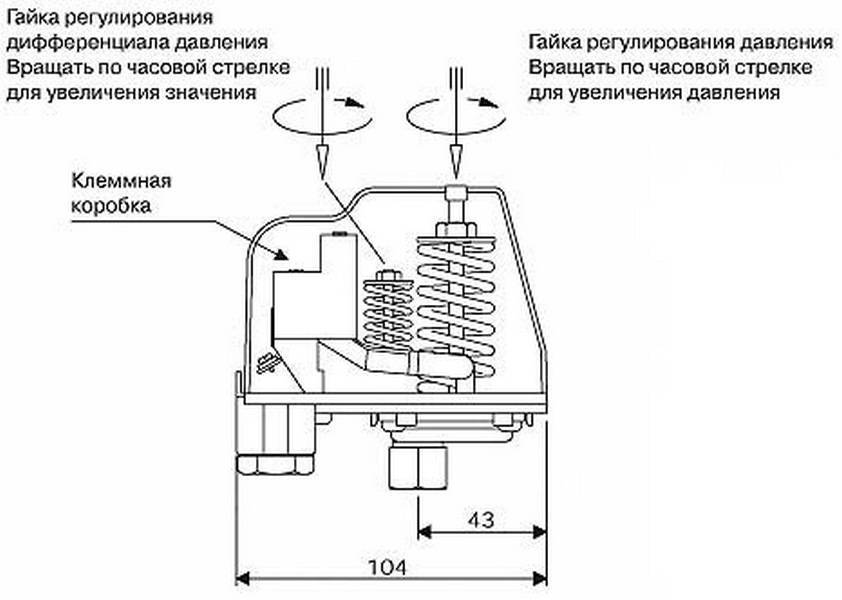

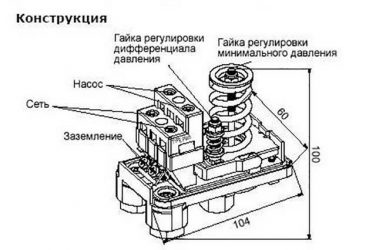

Before setting up the relay, it is necessary to remove the cover, under which there are two springs with nuts: a large one and a small one. By turning the large nut, the lower pressure in the accumulator (P) is adjusted. By turning the small nut, set the pressure difference (ΔP). The reference point is the position of the large spring, with which the lower pressure limit is set.

Before you start setting up the pressure switch for the pump, you must remove the top cover from the device, which hides the large and small springs

After the required air parameter is reached in the accumulator, the tank should be connected to the system and turned on, observing the readings of the water pressure gauge. Note that the technical documentation for each pump indicates the operating and limiting pressure indicators, as well as the permissible water flow rate. It is not allowed to exceed these values when setting the relay. If the operating pressure of the accumulator or the limit value of the pump is reached during the operation of the system, the pump must be switched off manually. The limiting head is considered reached at the moment when the pressure stops increasing.

Fortunately, conventional household pump models are not so powerful as to pump the tank to the limit. Most often, the difference between the set on and off pressures is 1-2 atmospheres, which fully ensures the optimal use of equipment.

After the water pressure gauge shows the required lower pressure, the pump should be turned off. Further adjustment is made as follows:

Carefully turn the small nut (ΔP) until the mechanism starts to work.

Open the water to completely free the system from water.

When the relay turns on, the value of the lower indicator will be reached

Please note that the pump turn-on pressure should be approximately 0.1-0.3 atmospheres higher than the pressure reading in an empty hydraulic tank. This is to protect the "pear" from premature damage.

Now you need to rotate the large nut (P) to set the lower pressure limit.

After that, the pump is turned on again and they are waiting for the indicator in the system to rise to the desired level.

It remains to adjust the small nut (ΔР), after which the accumulator can be considered tuned.

Adjustment scheme

Here is a diagram that will work for most devices:

Pressure switch adjustment for pump is carried out using two nuts: large and small

They must be handled very carefully so as not to damage the device.

Video: how to adjust the pump relay

In addition to the initial setup when connecting the relay to the pump, the home owner needs to periodically check the operation of the system and adjust the settings.At least once every three months, experts recommend completely draining the water from the hydraulic tank and checking the air pressure, pumping up the required amount or bleeding off the excess.

Insufficient water pressure in the system

Problems with water pressure can occur due to improper adjustment of the automation of the pumping station, but most often this happens in the following cases:

- When setting up the system, values were set below the recommended minimum parameters. The problem is solved by simply adjusting the pumping station pressure regulator in accordance with the manufacturer's instructions (read: "Proper adjustment of the pumping station pressure switch - norms, tips and examples").

- Blockage of pipeline or pump impeller due to accumulated impurities. You can fix the problem by cleaning the elements of pumping equipment.

- Air intrusion into the pipeline. After checking the tightness of the joints and elements of the pipeline, the problem almost always loses its relevance. In rare cases, major intervention may be required.

Sometimes you may encounter a situation where poor tightness of water pipes causes air to be drawn in by the pump. A similar situation occurs when the water level is too low, which causes air to be pumped into the system when water is taken.

Malfunctions of the pumping station

During the operation of the pumping station, various malfunctions may occur in its operation, the cause of the violations is the incorrect switching on / off of the electric motor.

The need to replace the relay

Replacement is performed in the following order.

Turn off the power and completely drain the water from the accumulator. Leave the taps in the open position.

After that, close all water taps or the main valve at the outlet, turn on the pump and fine-tune the water pressure according to the algorithm described above. Never rush. The work is simple, but the consequences of mistakes can be very sad.

Pump keeps turning on/off

This means that the water pressure rises sharply to maximum values, while the engine turns off. The pressure drops just as sharply to the minimum and the unit turns on again.

In this case, the pressure switch does not need to be touched, it is not to blame. The reason is in the accumulator - the rubber membrane located inside the cylinder is torn or greatly stretched. It does not expand, does not accept water and does not compensate for the increase in pressure.

For normal operation of the pump, it is recommended to set the air pressure in the metal cylinder approximately 10% below the switch-on parameter of the electric motor. The pressure is checked only after the complete descent of water from the accumulator. If it is, then the values rise and distort the adjustment indicators.

The pump does not turn off for a long time

At first everything was fine, but then there was such a problem. The reason is the wear of the pump, it can no longer create the necessary pressure. The adjustment is simple - slightly reduce the maximum value until the pump is turned off. In order to have a safety margin, it is recommended that the pressure be further reduced by a few tenths of an atmosphere. If, as a result of adjustment, the indicators drop to critical ones, then the water pump will have to be changed.

There is no water in the system, and the pump does not turn on

There are three reasons: the wiring is faulty, the connection terminals are sour, or the electric motor has burned out. To check, you must have a tester and ring the electrical equipment, the work should be done strictly according to the rules of the PUE.

How to set the relay correctly?

There is a cover on the pressure switch housing, and under it there are two springs equipped with nuts: large and small. By rotating these springs, the lower pressure in the accumulator is set, as well as the difference between the cut-in and cut-out pressures. The lower pressure is regulated by a large spring, and a small one is responsible for the difference between the upper and lower pressure.

There are two adjusting springs under the cover of the pressure switch. The large spring regulates the activation of the pump, and the small spring regulates the difference between the on and off pressure.

Before starting the setup, it is necessary to study the technical documentation of the pressure switch, as well as the pumping station: the hydraulic tank and its other elements.

The documentation indicates the operating and limiting indicators for which this equipment is designed. During the adjustment, these indicators should be taken into account so as not to exceed them, otherwise these devices may soon break down.

Sometimes it happens that during the adjustment of the pressure switch, the pressure in the system still reaches the limit values. If this happens, you just need to turn off the pump manually and continue tuning. Fortunately, such situations are extremely rare, since the power of household surface pumps is simply not enough to bring the hydraulic tank or system to its limit.

On the metal platform where the adjusting springs are located, the designations “+” and “-“ are made, which allow you to understand how to rotate the spring in order to increase or decrease the indicator

It is useless to adjust the relay if the accumulator is filled with water. In this case, not only the water pressure will be taken into account, but also the parameters of the air pressure in the tank.

To adjust the pressure switch, follow these steps:

- Set the operating air pressure in the empty accumulator.

- Turn on the pump.

- Fill the tank with water until the lower pressure is reached.

- Switch off the pump.

- Turn the small nut until the pump starts.

- Wait until the tank is full and the pump is turned off.

- Open water.

- Rotate the large spring to set the cut-in pressure.

- Turn on the pump.

- Fill the hydraulic tank with water.

- Correct the position of the small adjusting spring.

You can determine the direction of rotation of the adjusting springs by the signs “+” and “-”, which are usually located nearby. To increase the switching pressure, the large spring must be rotated clockwise, and to decrease this figure, it must be rotated counterclockwise.

The pressure switch adjusting springs are very sensitive, so they need to be tightened very carefully, constantly checking the condition of the system and the pressure gauge

The rotation of the adjusting springs when adjusting the pressure switch for the pump must be done very smoothly, about a quarter or half a turn, these are very sensitive elements. The pressure gauge should show lower pressure when switched on again.

With regard to indicators when adjusting the relay, it will be useful to remember the following points:

- If the hydraulic tank is filled, and the pressure gauge remains unchanged, it means that the maximum pressure in the tank has been reached, the pump should be turned off immediately.

- If the difference between the cut-off and turn-on pressures is about 1-2 atm, this is considered normal.

- If the difference is greater or less, the adjustment should be repeated, taking into account possible errors.

- The optimal difference between the set lower pressure and the pressure determined at the very beginning in an empty accumulator is 0.1-0.3 atm.

- In the accumulator, the air pressure should not be less than 0.8 atm.

The system can turn on and off properly in automatic mode and with other indicators. But these boundaries make it possible to minimize the wear of equipment, for example, the rubber lining of a hydraulic tank, and extend the operation time of all devices.