- What you need to know to properly set up a gas boiler

- Setting, adjusting the bypass valve

- Three-way valve for gas boiler

- Controller functions

- Measuring devices for setting heating systems

- Professional gas analysis with testo 330-1 LL h4>

- Professional gas analysis with testo 330-2 LL h4>

- High performance gas analysis with testo 320

- Baseline gas analysis testo 310 h4>

- Particulate number analyzer Testo 308 h4>

- Easy data management with easyHeat h4> software

- Automation from different manufacturers

- Wall mounted gas boiler

- Automation Arbat

- Automation Honeywell

- Automation Eurosit 630 (Eurosit 630)

- Partitions

- What are the automatic settings?

- Room thermostat

- Thermal head

- Weather-dependent automation

- 3 Room temperature control - setting guide

- Automation responsible for safety

- When is a burner flame adjustment required?

- Adjustment and adjustment of gas boilers

- burner flame

- Installing the draft regulator:

- How to set up a draft regulator and other components for solid fuel boilers

- Development of the efficiency of such a boiler

- Video: more about efficiency for a solid fuel boiler

- Conclusions and useful video on the topic

What you need to know to properly set up a gas boiler

correct setting up gas heating equipment starts at the stage of purchase. You need to make sure that its power will be enough to heat the room. Be sure of a stable gas supply, in case of interruptions, no adjustment will help. It is necessary to take into account the number of windows, doors, wall thickness. The correct setting directly depends on these factors.

The thermostat that comes with the electronically controlled boiler will facilitate the setting. In this case, the electronics will do everything by itself. When the temperature drops, the signal from the thermometer will start the burner or intensify its flame. Such a system will maintain the temperature at the most comfortable level, but sometimes it needs to be adjusted.

Setting, adjusting the bypass valve

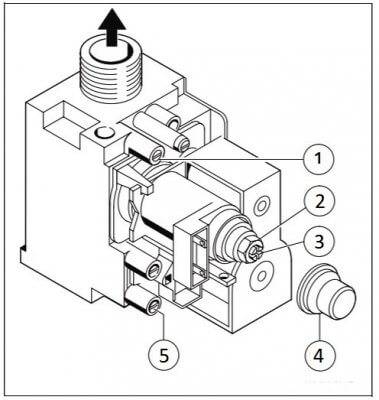

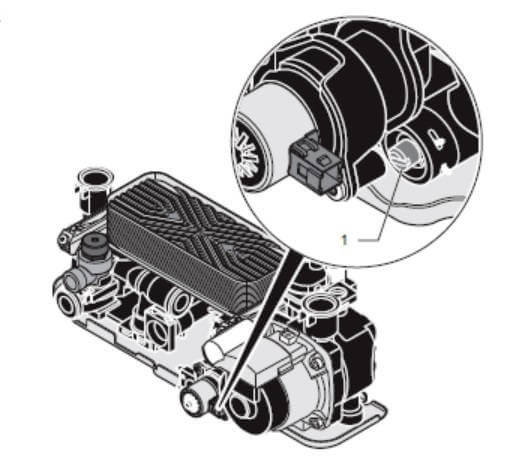

In boilers, the direct and return heating pipelines are interconnected through a bypass valve - bypass, pos. one.

At a certain value of the pressure difference in the forward and return pipelines, the valve opens and part of the water flows from the direct pipeline to the return pipeline. As a result, the difference in water pressure in the forward and return pipelines cannot exceed the value set by the valve setting. The operation of the valve helps to avoid water hammer when the circulation pump is turned on. In addition, the valve setting limits the maximum flow rate (flow) of water in the heating circuit.

The value of the valve actuation pressure is determined by the position of the adjusting screw, pos.1 in the figure. The screw from one extreme position to another can be rotated 10 turns.Factory setting - the screw is set to the middle position by turning 5 turns counterclockwise from the extreme right position. The valve opens at a pressure difference of 0.25 bar.

If heating radiators are heated unevenly in height - the top is hot and the bottom is cold (the difference is more than 15-20 ° C), then it is necessary to increase the speed of water movement in the heating system. To do this, turn the bypass valve adjusting screw clockwise. The opening pressure of the valve is increased to 0.35 bar.

If noise is heard in the radiators or control valves during the operation of the circulation pump, the water flow rate in the heating circuit should be reduced. To do this, turn the screw counterclockwise. The opening pressure of the valve is reduced to 0.17 bar.

The difference in the pressure values that are displayed on the boiler display, during the operation of the circulation pump and immediately after it stops, should not be more than 0.2-0.4 bar. If more, then it is necessary to drain the water from the boiler, unscrew and check the cleanliness of the bypass valve.

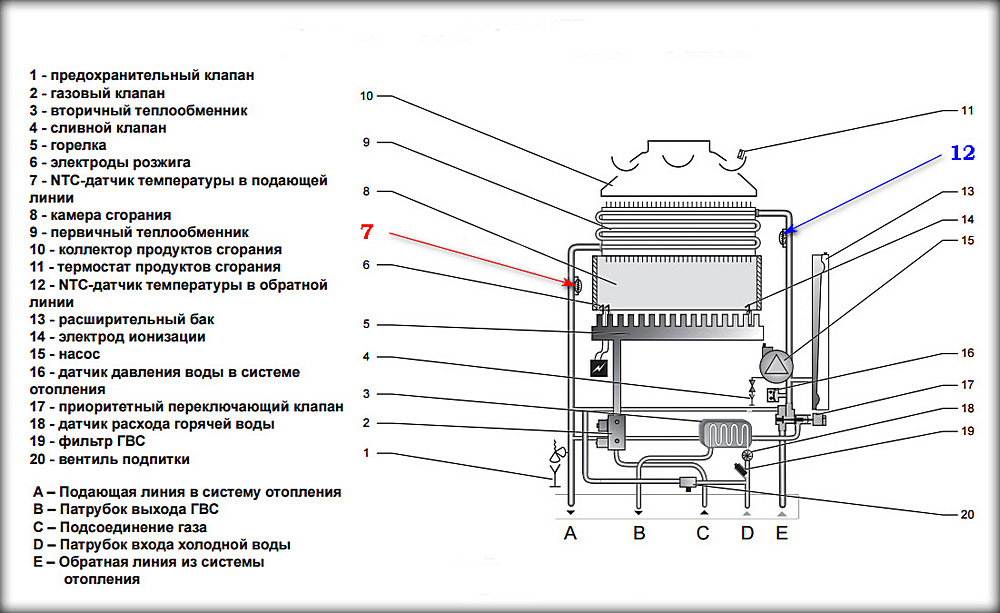

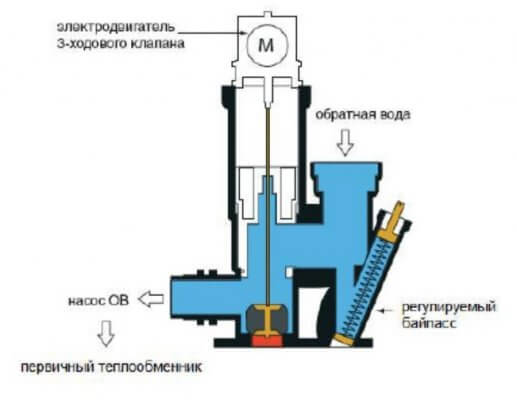

Three-way valve for gas boiler

Three running gas boiler valve in heating mode. In DHW mode, the stem with the valve moves up.

To empty the boiler, the stem with the valve is set to the middle position through the service menu (menu line d.70).

Controller functions

The thermostat for a solid fuel boiler prevents the contents of the water jacket from boiling and causing an explosion due to a sharp increase in pressure in the heating system

Thus, the absence of a device for automatically adjusting the heating of the coolant makes the operation of the boiler unit unsafe - the person responsible for the operation of the boiler requires constant increased attention to the operating mode of the equipment

The traction control has other functions, in addition to protecting the coolant from boiling

- the device helps to maintain a certain temperature of heating water in the heating system, depending on the need for heat in the premises (during frost, heating to maximum temperatures is necessary, in the off-season and during periods of thaw, the degree of heating of the coolant is reduced);

- by changing the air supply intensity, it is possible to increase the combustion time of one fuel load (but at the same time, the combustion conditions are far from optimal and the boiler efficiency decreases).

To avoid boiling of the coolant, instead of a regulator, a safety valve can be installed on a solid fuel unit. It will automatically release the pressure if it exceeds the set value. However, the valve is designed for one-time emergency operation - it will fail if the heat generator regularly heats up to critical temperatures. In addition, without a draft regulator, the heating of the coolant will have to be adjusted manually.

Measuring devices for setting heating systems

Due to rising energy prices, the correct setting up the heating equipment becomes an important component for optimizing utility costs. Testo's portable flue gas analyzers help you complete any task of setting up, commissioning and servicing heating equipment.

Professional gas analysis with testo 330-1 LL

h4>

The testo 330-1 LL gas analyzer with extended sensor life is a reliable tool for diagnosing faults in heating equipment and for monitoring emissions of harmful substances into the atmosphere or for the daily work of heating specialists. It is able to fulfill the highest requirements placed on a gas analyzer: the highest sensor accuracy and sensor lifetime.

Professional gas analysis with testo 330-2 LL

h4>

In addition to all the advantages of the Testo 330-1 LL gas analyzer, you can use the testo 330-2 gas analyzer at higher CO concentrations in flue gases. This is achieved by the built-in function of automatic dilution of the flue gas sample by a factor of 5. Additional convenience is achieved by using the zeroing function of the pressure/draft sensor with the probe remaining in the chimney.

High performance gas analysis with testo 320

h4>

Gas analyzer Testo 320 is a multifunctional flue gas analyzer for heating specialists. The intuitive menu structure and ease of use of the testo 320 gas analyzer, combined with the high-resolution color display, allow you to carry out all the necessary measurements during installation, commissioning, service and maintenance of heating boilers and burners.

Base level gas analysis testo 310

h4>

The testo 310 gas analyzer combines ease of use with high measurement accuracy and is ideally suited for all basic measurements on gas boilers and burners. A long battery life guarantees the possibility of long-term use of the device, including for a series of flue gas concentration measurements

Particulate number analyzer Testo 308

h4>

The Testo 308 soot analyzer helps you measure your soot. The built-in pump and the automatic display of the measured value on the backlit display provide information on the soot content in the chimney using a modern measurement method. This measurement method is comparable to traditional methods for measuring soot using a hand pump.

Easy data management with easyHeat software

h4>

With the dedicated Testo software you can easily transfer the data from your gas analyzer to a PC for further processing. A wide range of functions, such as customer data and metering data management, allows you to optimize the work of planning service activities at your customers' sites.

Automation from different manufacturers

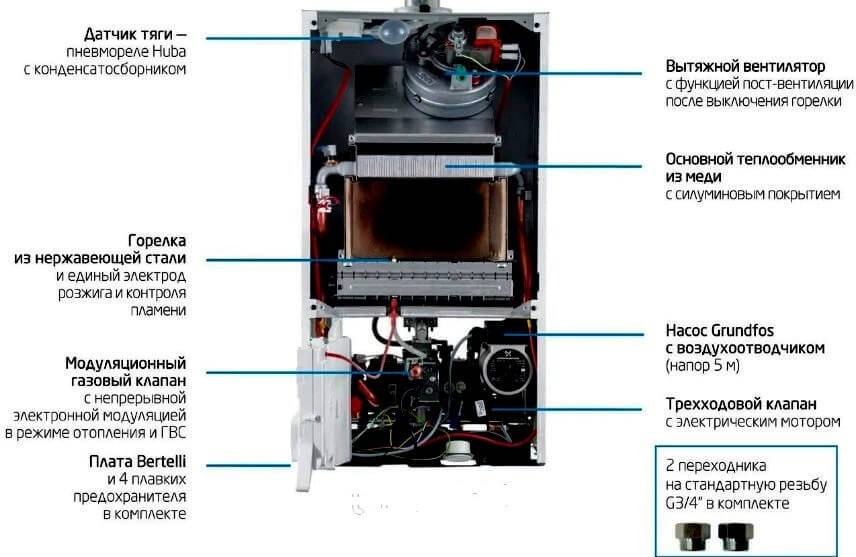

Wall mounted gas boiler

If we talk about a standard wall-mounted gas boiler, then it can work according to the temperature of the coolant. A room thermostat or chronothermostat can be connected to it. It is also possible to connect an openterm protocol regulator (openterm).

A special case of the operation of wall-mounted boilers is the possibility of using weather-dependent automation. Due to the use of an outdoor temperature sensor, additional variables appear that allow you to more quickly adjust the burner power, supply temperature, depending on changing conditions outside the building.

Automation Arbat

Devices have 5 degrees of protection. There is a thermoelectric flame protection. The gas supply is blocked when switched off.The modulating thermostat will provide comfort in use, and the coarse mesh filter will extend the service life.

Some models are equipped with a circulation pump. The device distributes the coolant evenly throughout the heating system. And it is also possible to connect to an external thermostat inside or outside the room.

Automation Honeywell

Honeywell has a wide range of automation for gas boilers from the most budgetary (mechanical) to multifunctional automatic systems.

Key features:

- the coolant automatically maintains the temperature;

- turning off the boiler in case of interruptions in the gas supply;

- shutdown in the absence of traction or with reverse traction;

- blocking the gas supply when the gas burner goes out.

Some models are equipped with programmable automation with the ability to set temperature periods depending on the time of day, weather, and even develop a heating / cooling mode for the days of the week. And the models of the Smile series control several temperature circuits at once (heating, ventilation, "warm floor", hot water, etc.).

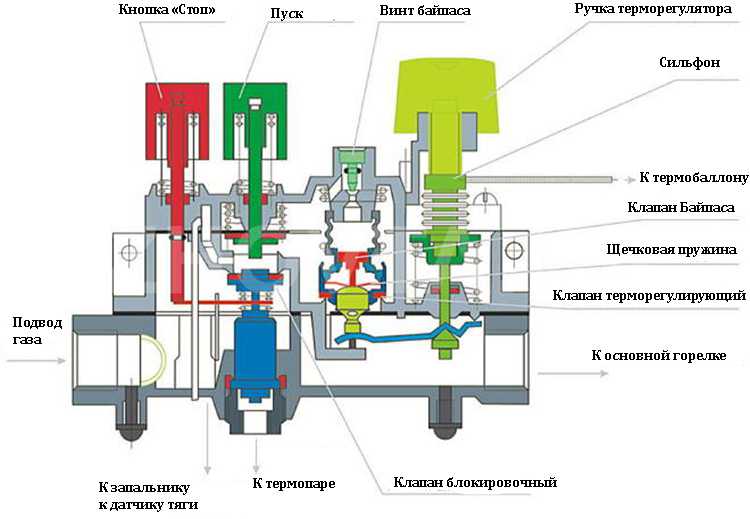

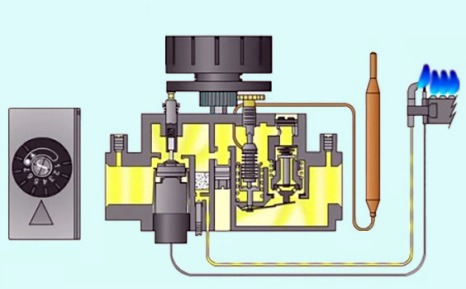

Automation Eurosit 630 (Eurosit 630)

The Eurosit gas valve is one of the most used. It can be found on both domestic and imported boilers. The main advantages: the multifunctionality of the gas supply regulator, the modulation thermostat and the function of full modulation switching on of the main burner. It works both from cylinders with liquefied fuel and from a gas tank, without the use of electricity. It is used in various types of gas-consuming equipment that require precise temperature control.

The basic principles of operation of Eurosit 630 automation.

Ignition of the pilot burner.

- Check that the position of the knob corresponds to the "off" icon.

- Move the control knob to the "asterisk" position.

- Keep the control knob pressed down for a few seconds. Then release and make sure that the pilot burner turns on. If the pilot burner goes out, repeat step 3.

Temperature selection.

Use the control knob to set the temperature. The gas will begin to flow into the main burner, where it will be ignited using the pilot burner.

power modulation.

The thermostatic system regulates the gas flow and gas pressure in the main burner depending on the capillary sensor of the system. The colder the sensor, the more power and vice versa. The graph schematically shows how the power changes from maximum to minimum and further, until the burner is completely turned off.

Duty position.

Move the control knob from the set temperature to the "asterisk". The main burner will go out, but the pilot burner will remain lit.

Shutdown.

Set the knob to the off position. The valve closes completely, but the thermoelectric protection magnet remains temporarily activated until the thermocouple sensor cools down. During this period of time, a restart of the thermoelectric system is mechanically prevented. The function is called "interlog". It ensures ventilation of the combustion chamber before the next burner start-up.

Read also:

Partitions

The interior of the kitchen and living room begin to think over from the docking of the two zones.

- Here are some of the ways and objects that delimit space:

- installation of a bar counter;

- kitchen island;

- big table;

- installation of a low partition.

Designers advise installing a wide rack, since it will be possible to sit at it like at a regular table, and high chairs are quite suitable for the whole family.

However, narrow racks are installed in small rooms (16 sq. sq m or 30 sq. m). Capital low partitions are installed only if it is decided in advance what they will be used for (for example, as a TV stand).

What are the automatic settings?

At the moment, the market presents the consumer with a wide range of control devices. Therefore, it is necessary to know what kind of automation for home heating systems generally exist, what to give preference to.

Room thermostat

According to the installation criteria, there are:

- Wired thermostats. The advantage of this type is the ability to conduct power up to approximately 50 meters through wires.

- Wireless thermostats. The advantage is that it is not necessary to create a hole for the wires. However, they have a significant drawback - reinforced concrete walls reduce the signal strength.

By functionality, they distinguish:

- simple thermostats. They keep the right level of warmth.

- Programmable thermostats. Such devices are able to set a certain number of degrees for a whole week in advance (the period depends on the model) with a maximum accuracy of seconds. The advantages can also be counted as cost savings due to weekly programming.

There are also thermostats:

- Electronic thermostats. The kit contains three components: temperature sensor, signal transmitter, relay. The main advantage of the device is the maximum accuracy of the equipment.Don't forget ease of use.

- Mechanical thermostats. The basis of the devices is the ability to change properties under the influence of the temperature level. Due to temperature changes in the gas membrane, the circuit closes or opens, forcing certain mechanisms to work.

- Electromechanical thermostats. The mechanism of the device is much simpler than electronic. The main element is the relay. The node looks like a tube, which is filled with a special substance that reacts to temperature. If the cauldron heats up, then the substance expands; similarly, the cauldron cools down - the substance contracts. And the substance-dependent drive, thanks to the electrical circuit, regulates the temperature.

Connection can be made to:

- boiler;

- pump;

- Servo drive;

Thermal head

This is a thermostatic element that, under the influence of the external environment, slightly opens or closes the radiator. Inexpensive type of automation for home heating. A significant plus is that the thermal head is very convenient for local heating, and there are also significant cost savings. Of the minuses: firstly, the adjustment takes place by the standards, consisting of abstract numbers, not degrees. Secondly, the sensor measures the degree of heat around the installation, but not the room, which reduces the accuracy of the device.

Weather-dependent automation

The design of weather-compensated automation for heating a house is simple: the weather outside decreases, the temperature of the coolant increases. However, the weather-dependent installation has a very significant drawback - the system sometimes does not have time to adapt to the temperature, and, therefore, the effect is delayed. Especially the mentioned minus is manifested if an addition is connected - heated floors.The disadvantages include the fact that the devices do not work quite correctly, approximately, so the change is noticeable only with a seasonal change in climate. It is worth noting that the prices for the unit are relatively high. But the units will be very convenient in production, large-scale houses (over 500 square meters).

3 Room temperature control - setting guide

Setting the gas boiler allows you to set the optimum temperature in the premises. The only condition is the presence of a thermostat, the task of which is to regulate the power of the burner. The thermostat is connected to a temperature sensor located in the room. First you need to set the desired temperature value that is comfortable for you. After that, you can enjoy the warmth by reading books or watching your favorite movies.

By setting the gas boiler, you can set the right temperature in the room

There are some limitations when using thermostats. For example, this device allows you to set the temperature in only one room. To eliminate this disadvantage, it is required to install a thermostatic valve in the supply pipe in front of each heating radiator. Due to the narrowing or expansion of the working medium located inside the valve, there is a change in the cross-sectional area of the pipe. Such valves react to the slightest temperature measurement, even an increase in the number of people in the room can lead to a narrowing of the working medium.

The failure of the thermostats can cause the simultaneous shutdown of all heating radiators.This will lead to the termination of the circulation of the coolant in the circuit of the heating equipment. It is necessary to install a jumper tube or bypass beforehand to avoid such problems.

Automation responsible for safety

According to the rules set out in the regulatory documentation (SNiP -87, SNiP, SP), a security system must be provided in gas boilers. The task of this block is an emergency shutdown of the fuel supply in the event of any breakdown.

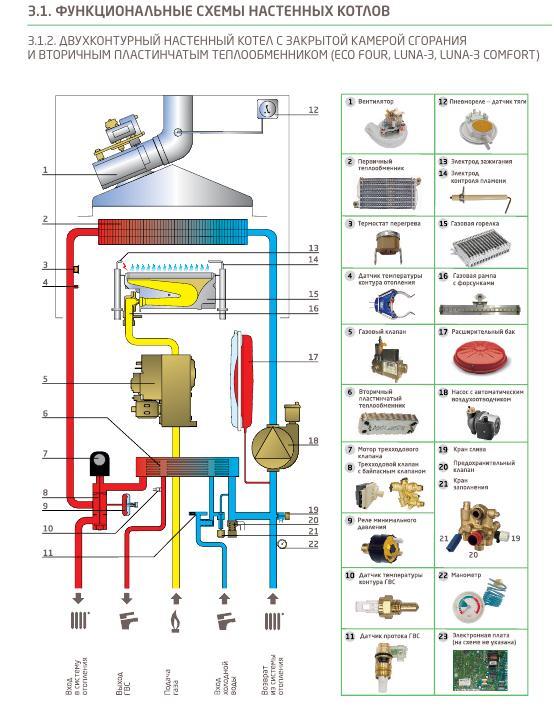

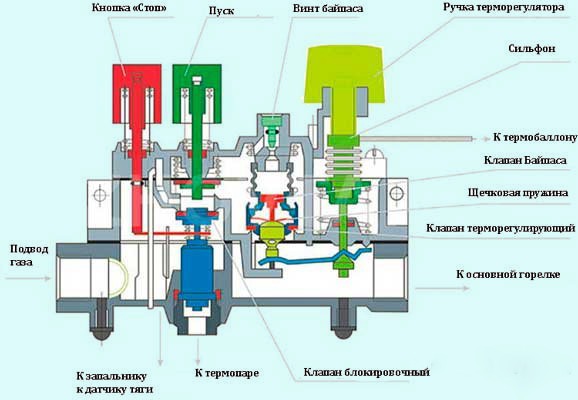

The presented diagram shows an automation system that allows you to adjust the functions of a gas device, with a detailed image of all the constituent elements

The principle of safe operation of the gas boiler automation system is based on control over instrument readings. The control unit monitors the following factors:

- Gas pressure. When it falls to a critical level, the supply of combustible substance immediately stops. The process takes place automatically with the help of a valve mechanism, pre-configured to a certain value.

- Responsibility for this property in volatile devices lies with the maximum or minimum relay. The mechanism of operation consists in bending the membrane with the rod with an increase in the number of atmospheres, which leads to the opening of the contacts of the heater.

- No flame in the burner. When the fire is extinguished, the thermocouple cools down, which stops the generation of current, and the gas supply stops due to the electromagnetic damper closing the gas valve.

- The presence of traction. With a decrease in this factor, the bimetallic plate heats up, which causes a change in its shape.The modified element presses on the valve, which closes, stopping the supply of combustible gas.

- Heat carrier temperature. With the help of a thermostat, it is possible to maintain this factor at a given value, which makes it possible to prevent overheating of the boiler.

The above possible malfunctions can cause the main burner to go out, resulting in the possibility of gas entering the room, leading to fatal consequences.

This figure shows a schematic device for the functioning of the control automation, designed to prevent overheating of the system or other disturbances in its operation.

To avoid this, all boiler models must be equipped with automatic devices. This is especially true for outdated samples, where such devices have not yet been provided by manufacturers.

When is a burner flame adjustment required?

Atmospheric gas burner for heating equipment often fails. It is equipped with models of both wall-mounted and floor-standing boilers. The injection burner of outdoor equipment reduces its efficiency for various reasons:

- Burner power too high. It happens when a high-power burner is purchased for small heating equipment. At the same time, there is not enough space for combustion, the air flow for such a power is weak, which leads to the transition of the flame from blue to yellow, sooting of the combustion chamber, chimney.

- If the chimney is poorly cleaned, the draft of the boiler deteriorates. At the same time, the spent combustion products are poorly removed, the air flow is small. This worsens combustion, the flame turns yellow.

- The defect of the burner itself does not make it possible to correctly adjust the complete combustion of the fuel.

- Due to pressure fluctuations in the gas supply system, well-regulated equipment can emit large amounts of unused gas into the chimney. Partially, it settles with soot, soot. A large layer of soot reduces traction, increases fuel consumption.

- Starting heating equipment after repair.

- The presence of extraneous noise during the operation of the boiler, gas burner.

- Change of type of fuel.

Adjustment and adjustment of gas boilers

A comfortable cottage, a spacious garage, a private cottage, a multi-level apartment - gas boilers warm the lives of millions of people. The heat of powerful units is constant, habitual, and you don’t think about it until the temperature in your home or workroom suddenly drops. Adjustment and adjustment of gas boilers carried out from time to time will help to avoid accidents and breakdowns.

What is good for a Russian is 20 mbar for a European

In the countries of Russia and Europe, the main gas pressure standards differ. Abroad, this value is constant and is defined as 20 mbar. However, keeping the same level of heating in Russia both in summer and in winter is a utopia. So, in the warm season, the indicator drops to about 13 mbar, and with the advent of frost, pressure surges and interruptions in the supply of gas fuel are observed in the network.

Foreign manufacturers of gas boilers could not turn a blind eye to the climatic conditions of their neighbors and adjust imported boilers to certain sensitivity ranges. This operation is performed at the factory during the assembly of the movement. In addition, a special gas valve has been created that allows you to adjust the pressure if necessary.Initially, it was conceived as a way to save fuel consumption, but Russian citizens use it as a means of preventing an emergency shutdown of a gas boiler due to a pressure drop in the line.

The main actions for setting up and adjusting the operation of a gas boiler of any configuration must be carried out by a specially trained person. But there are a number of operations that the consumer of thermal energy can also handle - for example, while waiting for the arrival of the master.

- Problem: burner power too high. Description: A "dancing" flame smoking a chimney. Solution: close the gas valve on the descent.

- Problem: low boiler draft. Description: air does not enter the boiler, the processed gas does not go outside. Solution: close the gas cock on the downstream, thereby reducing the power of the burner.

- Problem: lack of air to support combustion. Description: yellow flame, soot accumulation. Solution: reduce the burner power in the manner suggested above.

- Problem: high gas pressure. Description: soot settles on the walls of the chimney and furnace, gas consumption increases. Solution: install a pressure regulator, close the gas cock.

The actions that are collectively called the adjustment and adjustment of gas boilers also include heating the boiler, opening the chimney damper, checking the safety automation, and transferring the dial gauge installed on the gas pipeline.

Start-up and adjustment works of a gas boiler are inconceivable without an analysis of the waste and gas flows going to the supply. The adjustment cannot be considered completed if the optimum balance of air and gas has not been found.Who wants to pay for fuel that escapes into the atmosphere without a trace? Who will be warmed by inefficient heat? Are there citizens interested in deliberately reducing the life of the heater?

In order to divert an accident from your home or office, you need to make adjustment work a routine matter. Make it a rule: once in a certain period to carry out a thorough comprehensive inspection of the gas boiler, its parts and components. The maximum achievable efficiency of the boiler will be maintained with an acceptable quality of operation of the device. When setting up a wall-mounted or floor-standing heating boiler, make sure that no additional thermal insulation is required in the furnace room, and that the heat losses inevitable during the operation of the boiler are at an acceptable level.

burner flame

One of the indicators of the correct operation of the burner is the color of the flame. Gas equipment is characterized by an even bluish flame without impurities of other colors. The presence of inclusions of yellow, red indicates that the burner is not working well, this reduces the efficiency of heating equipment.

First of all, this applies to injection burners, but sometimes it is also typical for fan burners. The flame simply lacks oxygen. Also, along with the air, dust and other small debris can get in, which will clog the device, reducing the efficiency of the boiler. All this directly affects the flame. If it hums, the burner is loud, the fire has changed color - you need to set up the correct operation of the device.

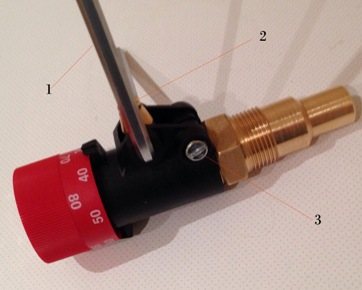

Installing the draft regulator:

The draft regulator can be installed in three ways: vertically and horizontally (from the side or front of the boiler).

1 Install the draft regulator in a vertical or horizontal position in a special 3/4 hole in the boiler body. Use special means for sealing threaded connections.

2 If necessary, align the draft regulator with the boiler body, loosen screw 3 and bring the draft regulator to the required position. Fix screw 3.

3 Use the screw (2) to fix the lever (1) in the draft regulator housing so that the hole for the chain is above the shutter.

How to set up a draft regulator and other components for solid fuel boilers

Solid fuel boiler in schematic form

These methods help to adjust the temperature and thrust of the device. They are:

- The unit heats up to +80°C.

- With the help of the setting handle, the temperature is set on the draft controller, which is reflected on the boiler thermometer.

- A chain is pulled on the air damper. The damper must take such a position that the boiler can reach the desired temperature. Under such conditions, the void between the damper and the housing varied in the range of 2–50 mm.

- The traction controller is checked for other temperature data: the parameter is set to 90 ° C in the settings. You need to figure out how the controller will support this parameter. When the parameter reaches 95°C at the boiler outlet, the controller must close the gap damper 2–5 mm. If the boiler has a restrictive screw, it will prevent the damper from closing. Use it to adjust the gap.

- Action for a boiler with two circuits. After calibrating the thrust controller, set the desired temperature parameters at the outlet of the apparatus, within 85°C.

Development of the efficiency of such a boiler

The efficiency of this boiler is mainly determined by the type of fuel and its structural specifications.

For example, when coal, firewood or pallets burn, a lot of heat energy is generated. The technological method of fuel combustion in the corresponding compartment and the type of heating system have a huge impact on the efficiency.

When burning anthracite, hard coal and peat briquettes, the average efficiency is 70–80%. When burning pallets - up to 85%. When burning pellets, there is a high efficiency and an incredible amount of thermal energy.

If your solid fuel boiler needs to develop efficiency over time, you can study the instructions for understanding. Usually manufacturers indicate ordinary methods. But over time, they work extremely poorly. And today, such a method of increasing the efficiency of solid fuel boilers has gained great fame: another heat exchanger is mounted. It must remove thermal energy from the volatile combustion products.

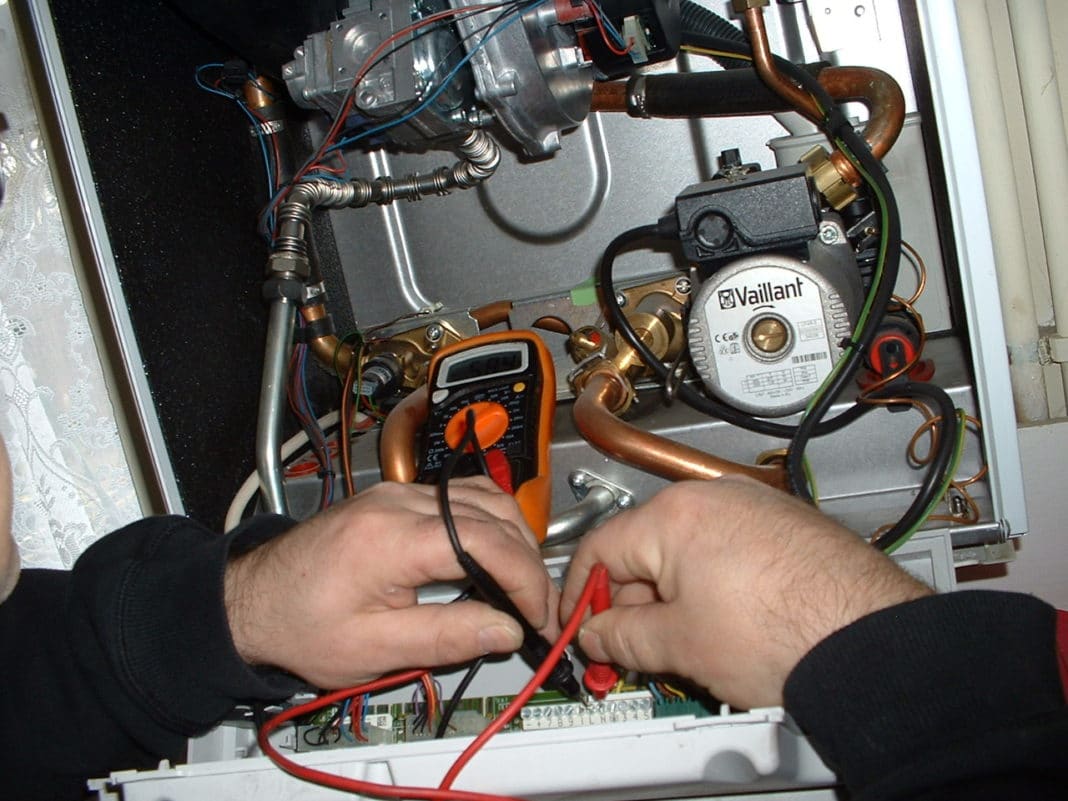

Before installation, be sure to find out the temperature data of the smoke at the outlet. To do this, use a multimeter. His position is in the middle of the chimney. Information about the potential amount of heat that can be obtained will help to calculate the area of \u200b\u200bthe additional heat exchanger.

The further algorithm of operations is as follows:

- A certain amount of firewood is loaded into the combustion chamber.

- Determine how long this amount of fuel will burn through.

Example: 14.2 kg of firewood loaded. The duration of their burning is 3.5 hours. The smoke parameter at the outlet is 460 C.

In an hour, 4.05 kg of firewood burned down. This is the result of such a calculation: 14.2: 3.5.

To calculate the volume of smoke, use the general value - 1 kg of firewood equates to 5.7 kg of smoke gases. Further, the previous result of 4.05 is multiplied by 5.7. It turns out 23.08. This is the mass of volatile combustion products.Start from this value for others by calculating the amount of heat energy that will be needed to heat the new, attached heat exchanger.

Knowing the heat capacity parameter of volatile heated gases (this is 1.1 kJ / kg), it is possible to calculate the power of the heat flux. This is necessary when the smoke parameter decreases to 160 0С (from 460 0С).

The following formula works here

So the exact parameter of additional power is displayed. It is created by combustion products. It turns out like this: q \u003d 8124/3600 \u003d 2.25 kW. This is a decent indicator. It can drastically increase the efficiency of your boiler.

Knowing how much energy is being wasted, adding a second heat exchanger makes sense. New thermal energy is created. Both the efficiency of the boiler and the entire heating system increase.

Video: more about efficiency for a solid fuel boiler

Setting up, as well as increasing the efficiency for any stand-alone device, is not always a difficult, but very responsible undertaking. Where there should be no hint of doubt. Therefore, in case of difficulties that arise in the process of refinement or even repair, it is advisable to get advice from a master on this class of equipment.

Conclusions and useful video on the topic

On the presented video you will find a brief instruction for installing a gas boiler equipped with an automatic Eurosit system.

A modern gas boiler is a rather complex design, which provides for many useful functions. Automation of most models greatly facilitates their operation, takes over the management of mechanisms and control over their work.

This significantly increases the level of safety during the operation of the heating system, and also increases its efficiency by selecting the optimal mode.

Do you need to adjust the automation of your gas boiler? Do you want to solve this problem yourself and want to clarify some points? Feel free to ask your questions under this article, and our experts will try to help you.

Or have you successfully completed the automation adjustment and want to share your experience with other users? Write your advice, add a photo showing the main points - your recommendations will be very useful to other owners of the same boiler.