- Selection criteria and cost

- Electronic control of automatic transformer

- System device

- Collector motor speed controller circuit

- Why use such a device-regulator

- Why adjust the speed

- How to connect?

- Specifications

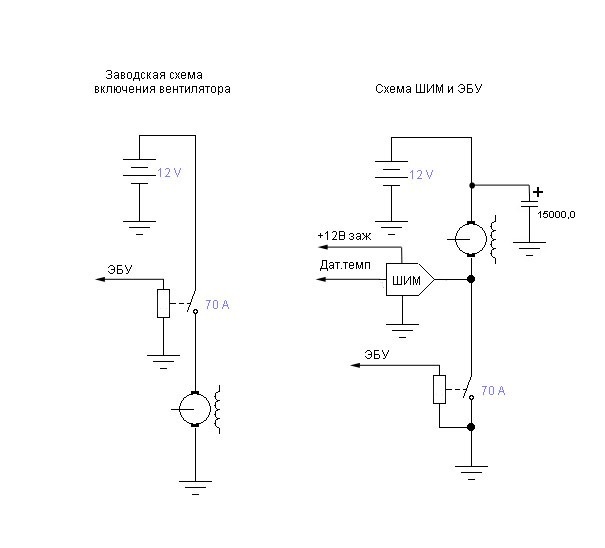

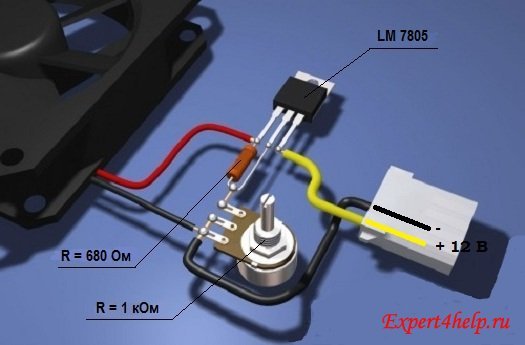

- Wiring diagram for fan speed controller

- Ways to adjust the rotation speed of household fans

- Wiring diagram for a triac or thyristor fan speed controller

- Triac (thyristor) controller circuit

- How to choose?

- How to reduce or increase the speed of the hood fan

- Controller Connection Rules

- How to connect a speed controller to a fan

- Tasks solved by the installation of frequency converters.

Selection criteria and cost

In order to correctly choose the most suitable type of regulator, you need to have a good idea of what varieties of such devices are:

- Various types of control. Can be vector or scalar control system. The former are used more often, while the latter are considered more reliable.

- The power of the regulator must correspond to the maximum possible power of the motor.

- By voltage, it is convenient to choose a device that has the most versatile properties.

- Frequency characteristics.The regulator that suits you should match the highest frequency that the motor uses.

- Other characteristics. Here we are talking about the size of the warranty period, dimensions and other characteristics.

Depending on the purpose and consumer properties, prices for regulators can vary significantly.

For the most part, they are in the range from about 3.5 thousand rubles to 9 thousand:

- Speed controller KA-18 ESC designed for 1:10 scale models. It costs 6890 rubles.

- The MEGA speed controller is collector (waterproof). It costs 3605 rubles.

- Speed regulator for LaTrax 1:18 models. Its price is 5690 rubles.

Electronic control of automatic transformer

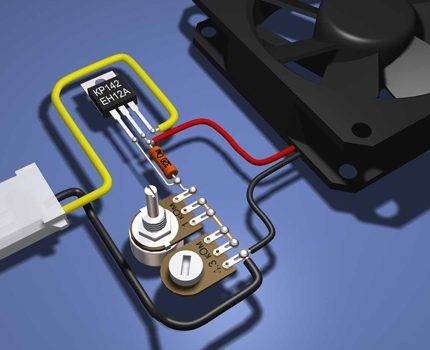

The circuit of an electronic automatic transformer is based on the principle of pulse-width modulation. In this case, the pulse modulation is carried out by a transistor circuit. During the operation of this circuit, a smooth change in the output voltage occurs. The structure of the output stage of the transformer includes field-effect or bipolar transistors. They have an isolation gate and switch at a frequency of approximately 50 kHz.

Power control occurs due to the changing duty cycle of the pulses. This parameter is the ratio between the pulse repetition period and its duration

In this case, the frequency remains unchanged. The decrease in the power supplied to the electric motor occurs due to a decrease in the duration of the pulses and an increase in the pauses between them.

Such models of controllers are compact in size and low cost. As a disadvantage, the limited length of the cable from the device itself to the electric motor should be noted.In this regard, the control unit of the automatic transformer is placed in a separate housing and is placed directly next to the fan.

System device

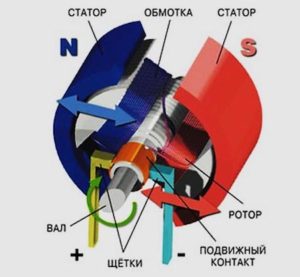

The collector type of the engine consists mainly of a rotor, a stator, as well as brushes and a tachogenerator.

- The rotor is part of the rotation, the stator is an external type of magnet.

- Brushes, which are made of graphite, are the main part of the sliding contact, through which voltage should be applied to the rotating armature.

- A tachogenerator is a device that monitors the rotational characteristics of an instrument. If there is a violation in the regularity of the rotation process, then it corrects the voltage level entering the engine, thereby making it the smoothest and slowest.

- Stator. Such a part may include not one magnet, but, for example, two pairs of poles. At the same time, instead of static magnets, there will be coils of electromagnets. Such a device is capable of performing work both from direct current and from alternating current.

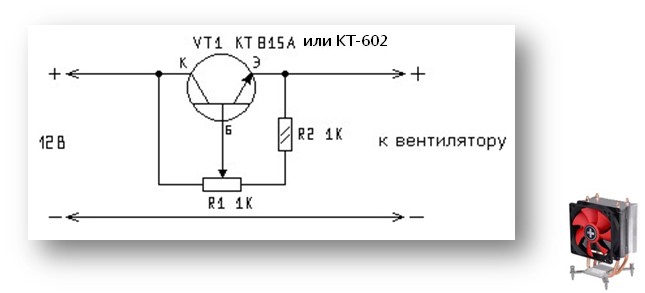

Collector motor speed controller circuit

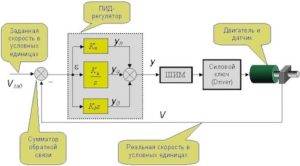

In the form of speed controllers for 220 V and 380 V electric motors, special frequency converters are used. Such devices are classified as high-tech, and they help to make a cardinal transformation of the current characteristics (signal shape, as well as frequency). In their configuration there are powerful semiconductor transistors, as well as a pulse-width modulator. The entire process of implementing the operation of the device occurs by controlling a special unit on the microcontroller. The change in speed in the rotation of the rotor of the engines is rather slow.

It is for this reason that frequency converters are used in loaded devices. The slower the acceleration process, the less load will be placed on the gearbox, as well as the conveyor. In all chastotniks, you can find several degrees of protection: by load, current, voltage and other indicators.

Some models of frequency converters are powered by a single-phase voltage (it will reach up to 220 Volts), creating a three-phase voltage from it. This helps to connect an asynchronous motor at home without the use of particularly complex circuits and designs. In this case, the consumer will be able not to lose power while working with such a device.

Why use such a device-regulator

If we talk about regulator engines, then the revolutions are needed:

- For significant energy savings. So, not any mechanism needs a lot of energy to perform the work of rotating the motor, in some cases it is possible to reduce the rotation by 20-30 percent, which will help to significantly reduce energy costs several times at once.

- For the protection of all mechanisms, as well as electronic types of circuits. With the help of a converter frequency, it is possible to carry out a certain control over the overall temperature, pressure, as well as other indicators of the device. In the case when the engine operates in the form of a certain pump, then in the container into which air or liquid is pumped, it is worth introducing a certain pressure sensor. When the maximum mark is reached, the motor will simply automatically finish its work.

- For the soft start process.There is no special need to use additional electronic types of equipment - everything can be done by changing the settings of the frequency converter.

- To reduce device maintenance costs. With the help of such speed controllers in 220 V engines, it is possible to significantly reduce the possibility of failure of devices, as well as individual types of mechanisms.

The schemes by which frequency converters are created in an electric motor are widely used in most household devices. Such a system can be found in wireless power sources, welding machines, phone chargers, personal computer and laptop power supplies, voltage stabilizers, lamp ignition units for backlighting modern monitors, as well as LCD TVs.

Why adjust the speed

So, a reasonable question arises, for what purpose it is necessary to connect fan to speed controller. First of all, it is worth mentioning the real possibilities and resource of the fan. If, throughout the entire period of its operation, it will operate at its full capacity, this will lead to a reduction in the service life or failure of a number of parts. As a result, breakdowns occur.

Advice! When choosing a fan for a room, be sure to consider the area of \u200b\u200bthe room, because each device has its own maximum. If you install it in a very large room, then it will work under serious load. For this reason, choose a device that has a power reserve.

Modern life requires the use of a large number of household appliances.So, they have various parts and elements that heat up during operation. To prevent them from overheating, fans are installed, for example, in a computer or oven. And it is not always necessary for the connected fan to operate at full capacity. Indeed, often the load on the equipment may increase slightly, and if the fan runs at the same speed, overheating may occur.

Just imagine an office or other room where there is a large accumulation of household appliances. During its operation, noise up to 50 decibels can be generated. And imagine if all the available fans simultaneously work at full capacity. As a consequence, the speed controller is able to reduce all noise. Moreover, this will allow rational use of electricity, because not in all cases the full power of the device is required.

As you can see, there are many reasons why a speed controller is additionally installed on the connected unit. Now we will consider the main features of the three types of speed controllers, and then we will learn how to make the connection with our own hands.

How to connect?

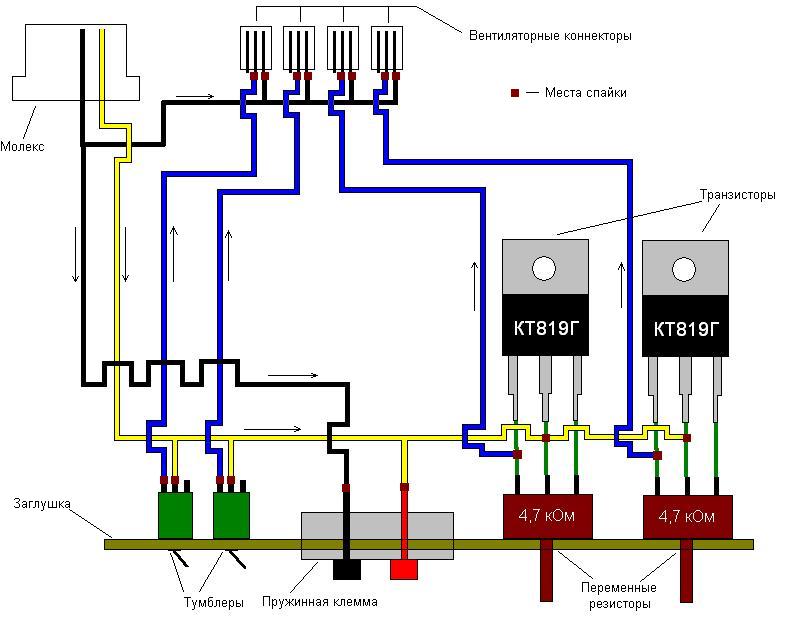

You can connect the speed controller to the fan with your own hands. To do this, you must carefully read the instructions and follow a number of safety measures when working with electrical appliances. Depending on the type of construction and the type of fans being serviced, the controllers can be installed on the wall, inside the wall, inside the ventilation unit or in a stand-alone cabinet of the "smart home" system. Wall and in-wall regulators are fixed with screws or dowels, depending on the dimensions and weight of the device.Fasteners are usually included in the kit along with the device connection diagram.

Connection schemes for models may differ, however, there are still general patterns and sequence of actions. First, the controller must be connected to a cable that supplies current to the fan. The main purpose of this stage is to separate the wires "phase", "zero" and "ground". Then the wires are connected to the input and output terminals. The main thing in this case is not to confuse the wires in places and connect according to the instructions. In addition, you should check that the size of the cross section of the power cable and connection corresponds to the maximum permitted voltage of the connected device.

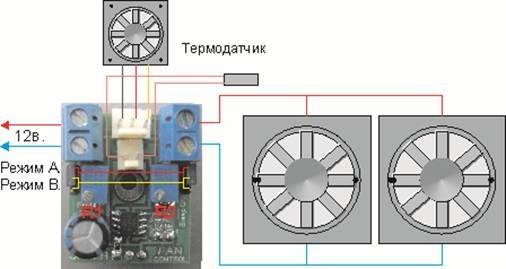

When connecting the speed controller to 12 volt laptop fans, you need to find out the maximum allowable temperatures of the device parts. Otherwise, you can lose your computer, in which the processor, motherboard and graphics card will fail from overheating. When connecting the controller to office equipment, you must also strictly follow the instructions. If you need to connect several fans at once, it is better to purchase a multi-channel controller, since some models are able to serve up to four fans at the same time.

Fan speed controllers are an important multifunctional device. They protect equipment from overheating, extend the life of electric fan motors, save energy and significantly reduce the noise level in the premises. Due to their efficiency and practicality, devices are gaining more and more popularity and growing consumer demand.

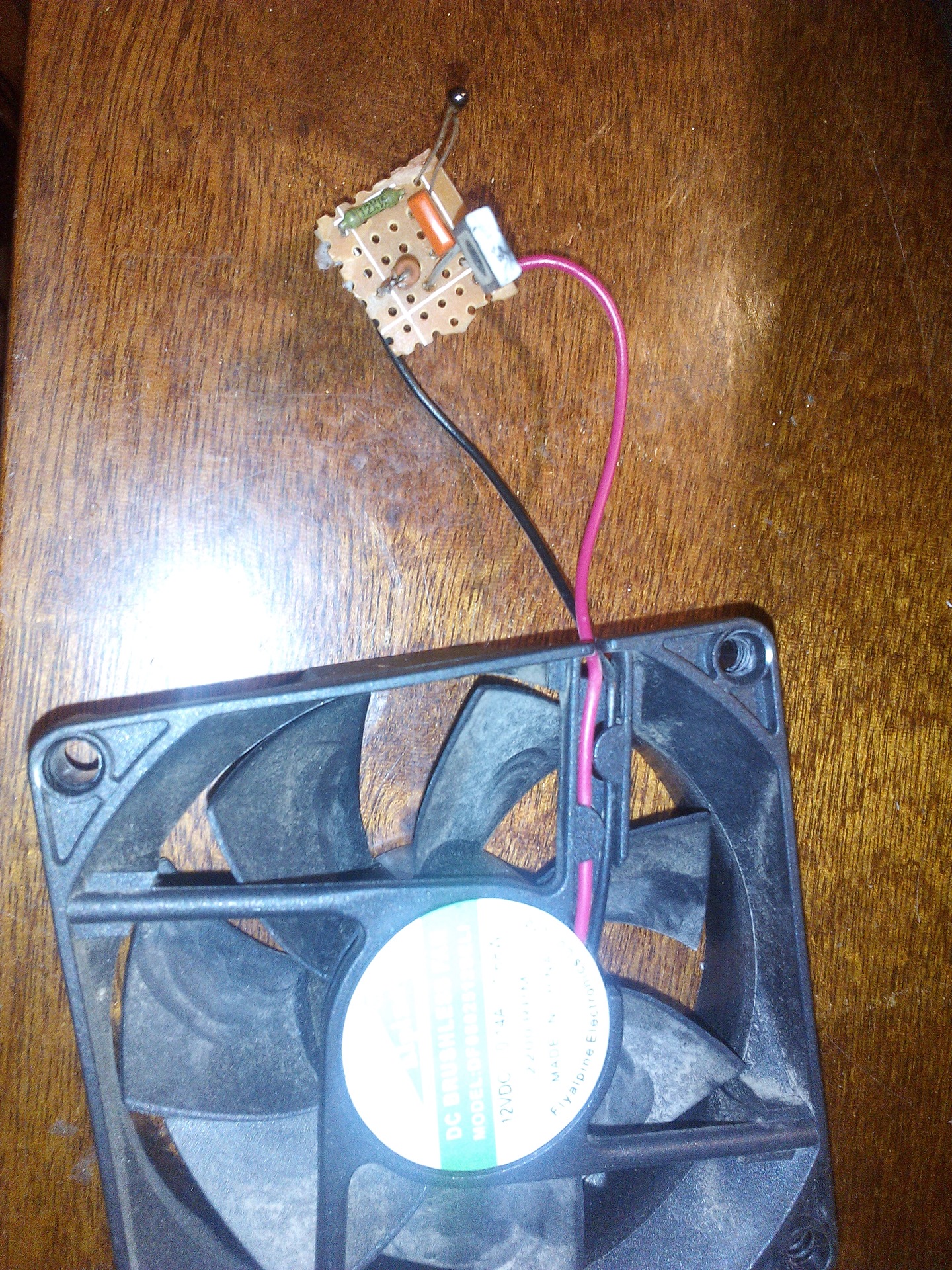

How to make a fan speed controller with your own hands, see below.

Specifications

A fan speed controller is a small device that can reduce or increase the speed of rotation of the working shaft. The controllers are connected to the fans according to a certain scheme and are controlled using a manual method or automation. Automatic models are closely interconnected with other devices of the ventilation unit, for example, with sensors that determine temperature, pressure, movement, as well as photo sensors and devices that determine humidity. Data from these devices is transmitted to the controller, which, based on them, selects the appropriate speed mode.

Mechanical models are controlled manually. Regulation of the rotation speed is carried out using a wheel mounted on the body of the device. Often, controllers are wall-mounted according to the principle of a switch, which makes their use convenient, and allows you to smoothly change the number of revolutions at any time. The devices are produced in a wide range of power and are able to operate on voltages of both 220 and 380 V.

Wiring diagram for fan speed controller

It is not uncommon for households to require the installation of a fan speed controller. It should be noted right away that a conventional dimmer for adjusting the brightness of lighting is not suitable for a fan.

It is important for a modern electric motor, especially an asynchronous one, to have a sine wave at the input of the correct form, but conventional lighting dimmers distort it quite strongly. For effective and correct organization of fan speed control, it is necessary to:

- Use special controllers designed for fans.

- Keep in mind that only special models of asynchronous electric motors can be effectively and safely adjusted, so before buying, find out from the technical specifications about the possibility of adjusting the speed by lowering the voltage.

Ways to adjust the rotation speed of household fans

There are quite a few different ways to adjust the fan speed, but only two of them are practically used at home. In any case, you can only reduce the number of revolutions of the engine only below the maximum possible according to the passport to the device.

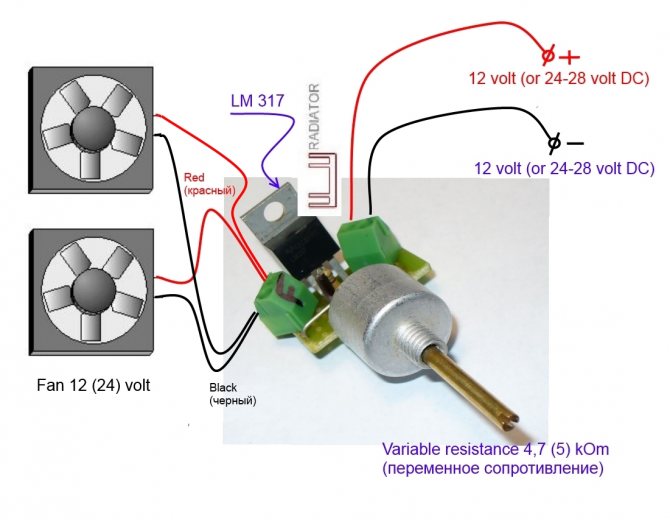

It is possible to disperse the electric motor only using a frequency controller, but it is not used in everyday life, because it has a high cost both in its own right and in the price of the installation and commissioning service. All this makes the use of a frequency controller not rational at home.

It is allowed to connect several fans to one regulator, if only their total power does not exceed the nominal current of the regulator. Consider when choosing a regulator that the starting current of the electric motor is several times higher than the operating one.

Ways to adjust fans in everyday life:

- Using a triac fan speed controller is the most common way, allowing you to gradually increase or decrease the speed of rotation in the range from 0 to 100%.

- If the 220 Volt fan motor is equipped with thermal protection (protection against overheating), then a thyristor regulator is used to control the speed.

- The most effective method of adjusting the speed of rotation of an electric motor is to use motors with multiple winding leads. But I have not yet seen multi-speed electric motors in household fans. But on the Internet you can find wiring diagrams for them.

Very often the electric motor buzzes at low speeds when using the first two methods of adjustment - try not to operate the fan for a long time in this mode. If you remove the cover, then with the help of a special regulator located under it, you can rotate it to set the lower limit of the engine speed.

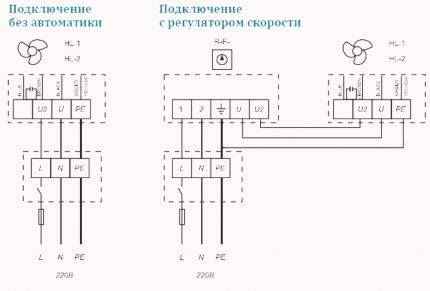

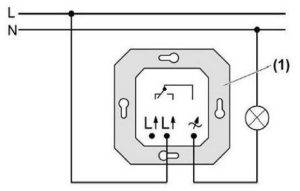

Wiring diagram for a triac or thyristor fan speed controller

Almost all regulators have fuses inside that protect them from overload or short circuit currents, in the event of which it burns out. To restore functionality, it will be necessary to replace or repair the fuse.

The controller is connected quite simply, like a regular switch. On the first contact (with the image of an arrow), a phase is connected from the electrical wiring of the apartment. On the second (with the image of an arrow in the opposite direction), if necessary, a direct phase output without adjustment is connected. It is used to turn on, for example, additional lighting when the fan is turned on. The fifth contact (with the image of an inclined arrow and a sinusoid) is connected to the phase that goes to the fan. When using such a scheme, it is necessary to use a junction box to connect, from which Zero and, if necessary, Earth are connected directly to the fan, bypassing the regulator itself, which requires only 2 wires to connect.

But if the electrical wiring junction box is far away, and the regulator itself is next to the fan, then I recommend using the second circuit. A power cable comes to the regulator, and then it goes directly to the fan. Phase wires are connected in the same way. And 2 zeros sit on contacts No. 3 and No. 4 in any sequence.

Connecting a fan speed controller is quite simple to do with your own hands, without calling specialists. Be sure to study and always follow the rules of electrical safety - work only on a de-energized section of electrical wiring.

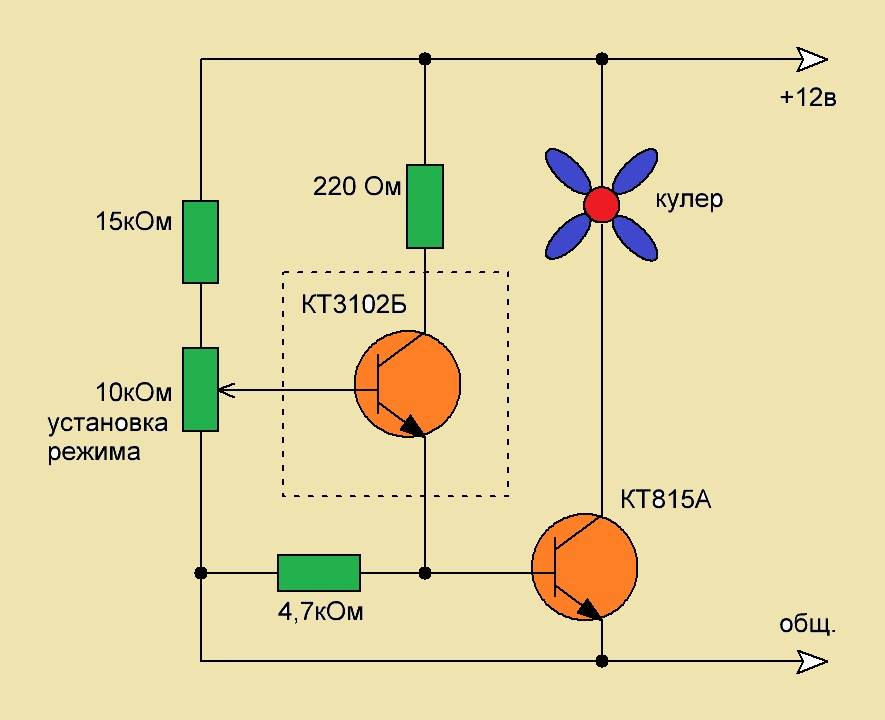

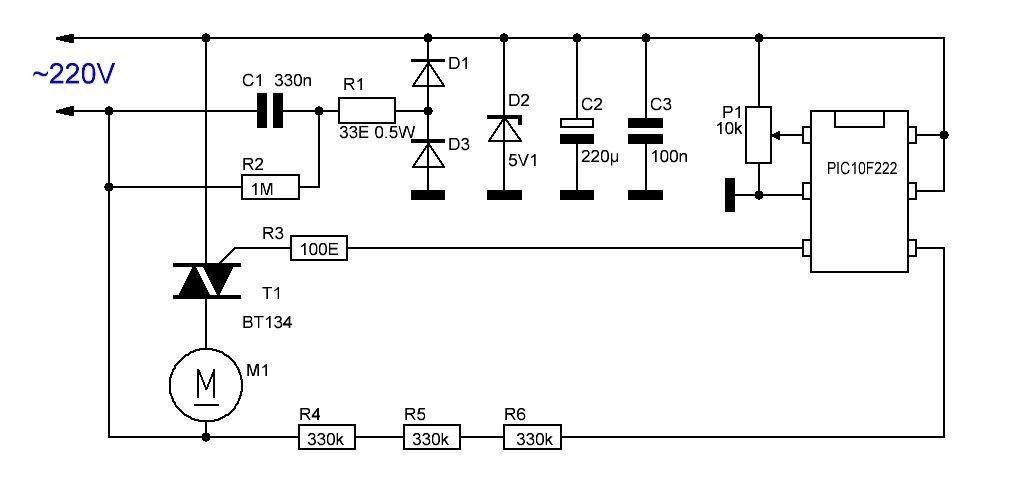

Triac (thyristor) controller circuit

The operation of these devices is based on phase voltage regulation due to the changing opening angle of the thyristors. As a result, waves having a sinusoidal shape arrive at the electric motor, in which the initial half-cycle turns out to be cut off. The adjustment is done with a symmetrical triac, known as a triac.

This method allows you to adjust the heating of heating devices and the brightness of the glow of incandescent bulbs. However, it is not at all suitable for asynchronous motors found in many fan designs. This is due to a strong distortion of the output voltage waveform going to the load, causing various malfunctions, up to a complete failure of the device.

In this regard, controllers based on triacs are subject to mandatory modification, which makes it possible to further use them in conjunction with fans. First of all, the minimum value of the voltage supplied to the load is set. Mains noise is reduced by using an additional noise suppression capacitor.The value of the maximum operating current of the thyristor must be approximately 4 times higher than the operating current of the motor.

The use of thyristor regulators is well suited for single-phase motors with built-in thermal protection. For direct control, a special adjusting wheel is used, with the ability to set the minimum fan speed. The maximum allowable power of such electric motors is 220 watts.

How to choose?

A specific model of the speed controller should be selected in accordance with the type of connected electric machine - a collector motor, a three-phase or a single-phase electric motor. In accordance with this, a certain frequency converter is selected.

In addition, for the speed controller, you must select:

- Type of control - there are two ways: scalar and vector. The first of them is tied to the load on the shaft and is simpler, but less reliable. The second is tuned in feedback from the magnitude of the magnetic flux and acts as the complete opposite of the first.

- Power - should be selected not less or even more than the rating of the connected electric motor at maximum speed, it is desirable to provide a margin, especially for electronic regulators.

- Rated voltage - is selected in accordance with the magnitude of the potential difference for the windings of an asynchronous or collector motor. If you connect one electric machine to a factory or homemade regulator, it will be enough just such a rating, if there are several of them, the frequency regulator must have a wide voltage range.

- Speed range - selected in accordance with the specific type of equipment. For example, from 500 to 1000 rpm is enough to rotate the fan, but the machine may need up to 3000 rpm.

- Overall dimensions and weight - choose in such a way that they correspond to the design of the equipment, do not interfere with the operation of the electric motor. If an appropriate niche or connector is used for the speed controller, then the dimensions are selected in accordance with the amount of free space.

How to reduce or increase the speed of the hood fan

In exhaust systems, increasing or decreasing the fan speed allows you to change the flow rate, which affects the overall air exchange. To control it, one of the methods already considered is used (by changing the voltage or frequency of the current).

In practice, the first of the methods is used, since the frequency controller in this case will cost more than the fan itself.

The peculiarity of this method lies in its simplicity and low cost, which is very important for household systems and devices used in public premises.

Hood regulator

It is possible to increase or decrease the drawing speed in a simple mechanical way. To do this, in some samples of control modules, a small wheel is provided, through which the engine speed changes in steps or smoothly.

Controller Connection Rules

To connect the fan speed controller, you can use the services of specialists or try to cope on your own.There are no fundamental features in the connection - it is quite possible to cope with such a task on your own.

All bona fide manufacturers must attach instructions for the use and installation of their products.

Depending on the design features and the type of equipment being serviced, controllers can be installed:

- on the wall, like a surface outlet;

- inside the wall;

- inside the equipment case;

- in a special cabinet that controls smart devices at home. This is usually a terminal block;

- connect to a computer.

To personally connect the regulator, you must first carefully read the instructions offered by the manufacturer. Such a document usually comes with the device and contains useful recommendations for both connection, use and maintenance.

Wall and in-wall models will have to be fixed with screws and dowels to the wall. Components are most often supplied by the manufacturer along with the main device. Also in the instructions for the regulator you can see the connection diagram. This will greatly facilitate further work on its correct installation.

Connection diagrams for regulators may vary from manufacturer to manufacturer. Therefore, you should carefully study the recommendations before installation.

Connection diagrams for regulators may vary from manufacturer to manufacturer. Therefore, you should carefully study the recommendations before installation.

The speed controller is connected to the cable that feeds the fan, according to the manufacturer's diagram. The main goal is to cut the wire of phase, zero and earth and connect the wires to the input and output terminal blocks, following the recommendations. In the case when the fan has its own separate switch, it will have to be replaced with a regulator, having dismantled the first one as unnecessary.

Do not forget that the cross section of the supply and connecting cables must correspond to the maximum voltage current connected device.

It is important to find inlets and outlets on the device to be connected for connecting the supply cable of the appropriate section. The diagram supplied by the manufacturer will help with this. If you have to connect the controller to a PC, then first you have to find out what is the maximum allowable temperature of the individual components of the equipment

Otherwise, you can irretrievably lose your computer, which will overheat and burn important parts - the processor, motherboard, graphics card, and others.

If you have to connect the controller to a PC, then first you have to find out what is the maximum allowable temperature of the individual components of the equipment. Otherwise, you can irretrievably lose your computer, which will overheat and burn important parts - the processor, motherboard, graphics card, and others.

The model of the selected reobas also has instructions and recommendations for connection from the manufacturer

It is important to adhere to the diagrams given on its pages when installing the device yourself.

If there is a need to connect more than 1 fan, then you can buy a multi-channel reobas

There are built-in regulators and devices that are purchased separately. To connect them correctly, you should follow the instructions.

For example, the built-in controller has on/off buttons on the outside of the system unit. The wires coming from the regulator are connected to the wires of the cooler. Depending on the model, reobas can control the speed of 2, 4 or more fans in parallel.

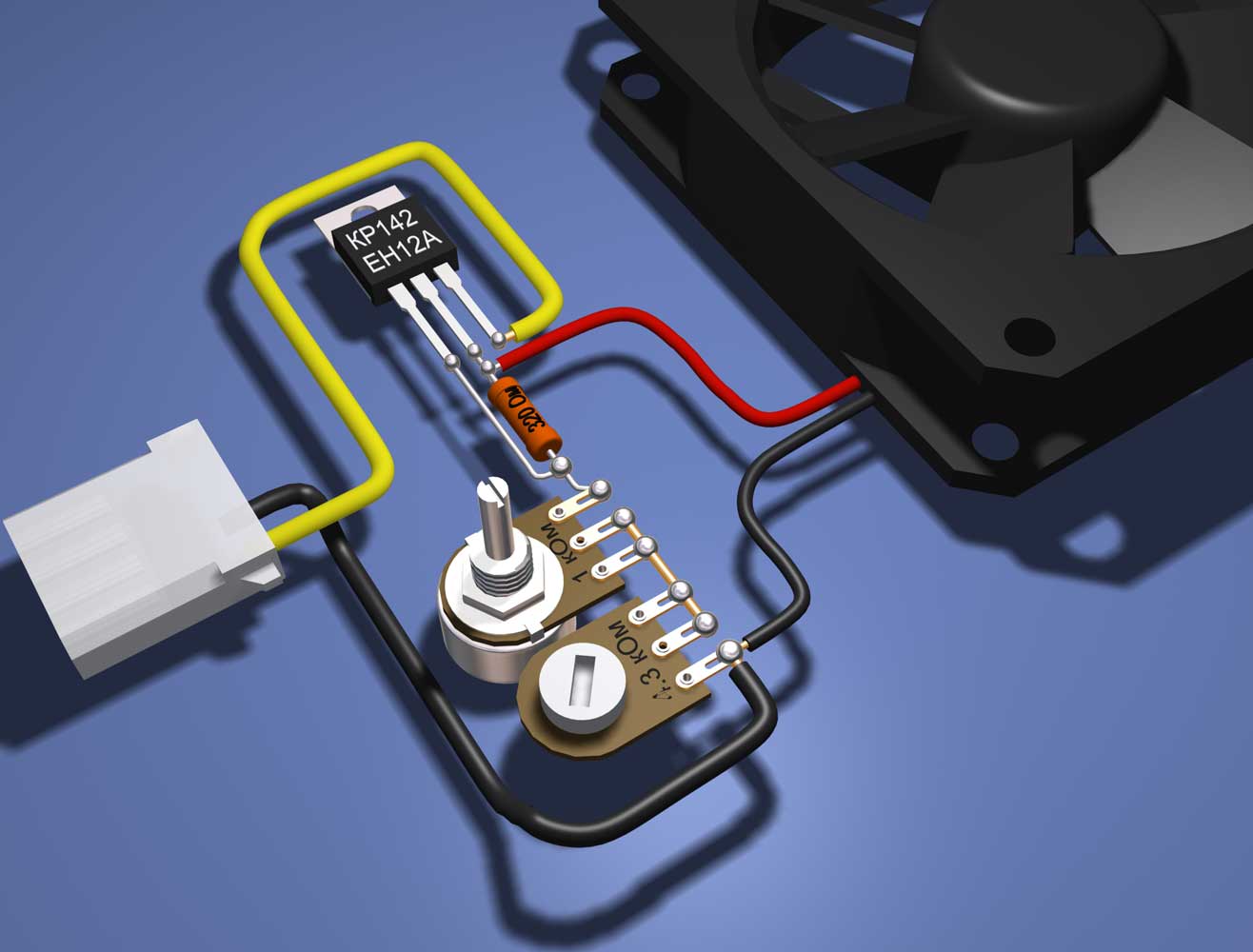

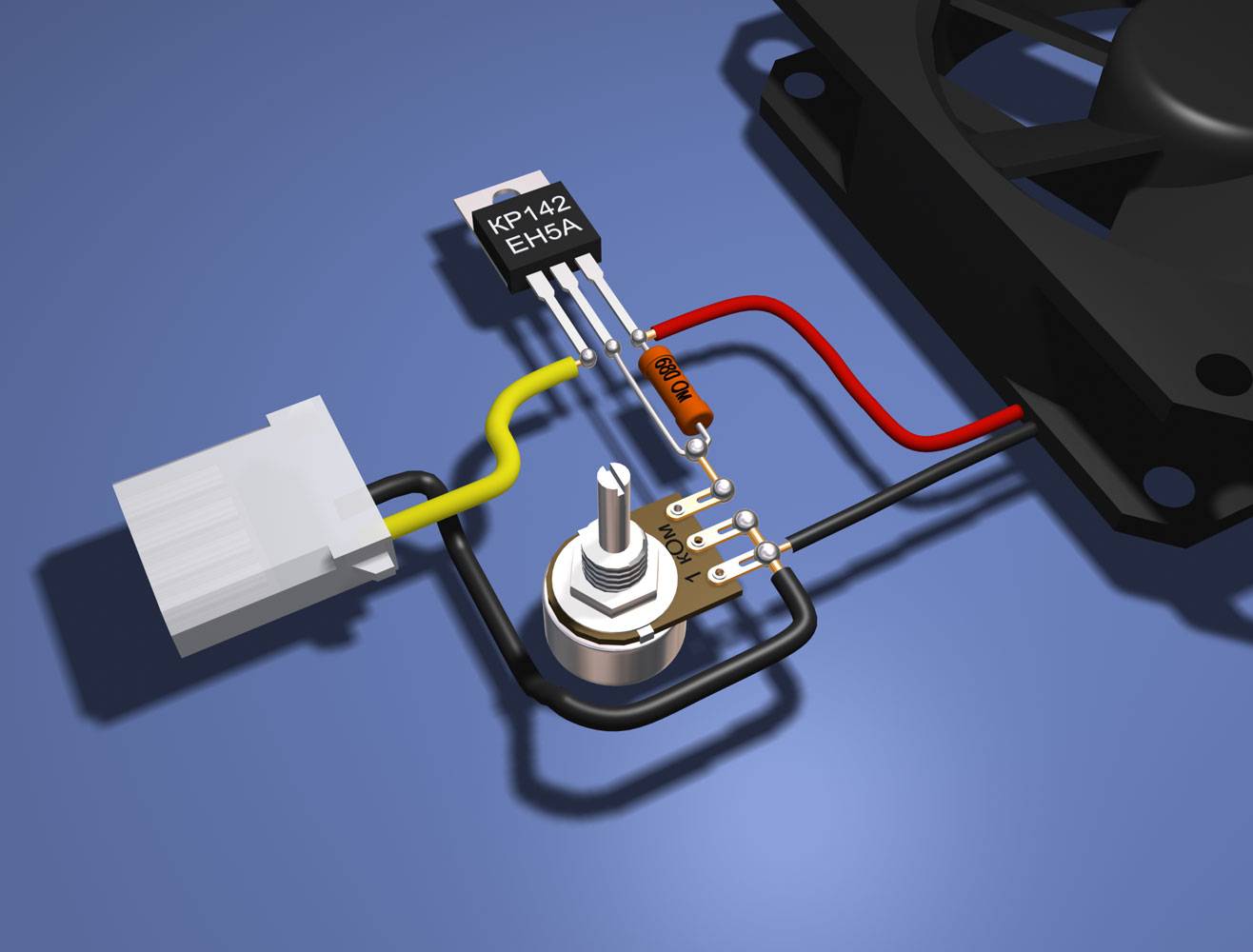

For computer fans and others used at home, you can make a regulator yourself

A separate regulator for the cooler is installed in a 3.5 or 5.25-inch bay. Its wires are also connected to coolers, and additional sensors, if they are included, are connected to the corresponding components of the system unit, the state of which they will have to monitor.

How to connect a speed controller to a fan

It is quite possible to install household rotation regulators on your own, without resorting to the services of a professional electrician. This procedure is comparable in complexity to replacing an outlet or switch.

All control devices have three main modifications. The first two types are wall-mounted and can be installed without a recess or in a recess. The third option involves mounting the device on a DIN rail. Connecting the fan speed controller in any case will not cause any difficulties.

Each contact is marked with its own marking, additional wires are not needed at all. In most cases, a speed controller is installed in place of a conventional fan switch. Additional wiring is required only when the controller and control unit are located in separate housings. The power cable is connected to the controller directly from the switchboard, and a low-current signal wire is used to connect the controller.

power regulator

Bathroom fan connection diagrams - errors and rules for installing an exhaust switch in the bathroom

current regulator

What is a PID controller

Collector motor speed controller

How to wire a dimmer switch

Tasks solved by the installation of frequency converters.

The main tasks in the design of these systems are to ensure efficient air exchange at the lowest cost, to coordinate operation with the operating modes of other building engineering systems. The use of a variable frequency drive allows you to:

- Provide protection of fan motors from overloads, unbalanced load, increase or decrease in supply voltage, other abnormal and emergency modes of operation without the use of additional protection circuits.

- Monitor system performance from a remote location, coordinate with smoke and fire protection systems. Danfoss VLT dedicated frequency converters support common communication protocols and are also compatible with the Cloud-Control web service.

- Adjust system performance according to load. Frequency converters allow you to control the air supply without the use of dampers and expensive fans with a variable blade angle. The power consumption is proportional to the actual load.

- Respond promptly to incidents and troubleshoot operational issues. Danfoss inverters for ventilation systems have the functions of monitoring a broken drive belt, air flow, temperature, humidity and other air parameters. These devices also record the accident in the built-in memory.

- Increase the overhaul period of ventilation equipment. Soft start, limitation of starting currents, regulation of the rotational speed of the drive motor reduce the load on the electrical network, the kinematic circuit.