- Why is the regulator leaking?

- Service and setup

- Purpose of a household water pressure regulator

- Manufacturers

- Scope of use of the device

- Gas reducer, its types and installation methods

- Type of installation

- Constructions

- How to set up the regulator with your own hands?

- Training

- Setting

- Installation

- Regulatory requirements for apartment pressure regulators

- When is a gearbox needed?

- Which is better?

- Top 3 Models

- For an apartment

- For a private house

- How to choose?

- Water pressure regulator repair

- Kinds

- Mechanical

- flowing

- Electric

- Auto

- Domestic

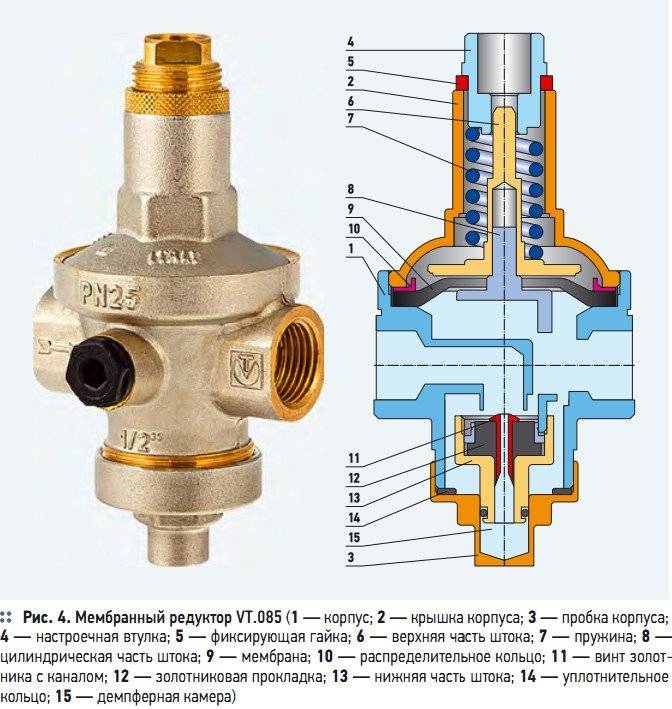

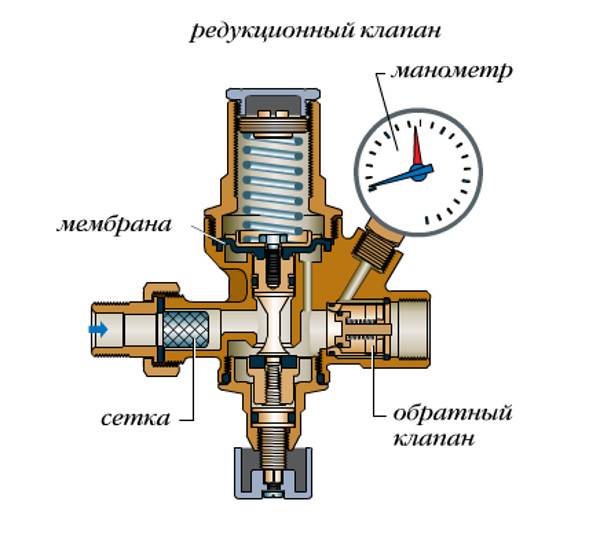

- Membrane

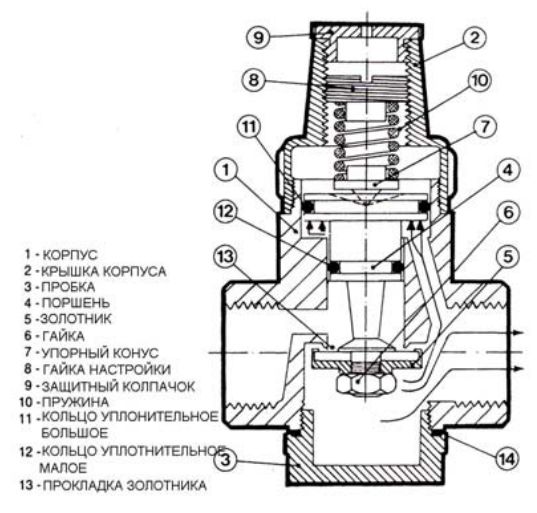

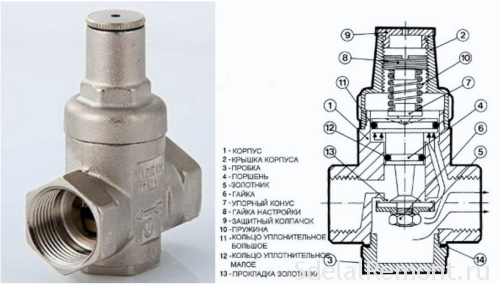

- Piston

- Electronic

- Which type and when to choose?

- Types of equipment according to the principle of device and equipment

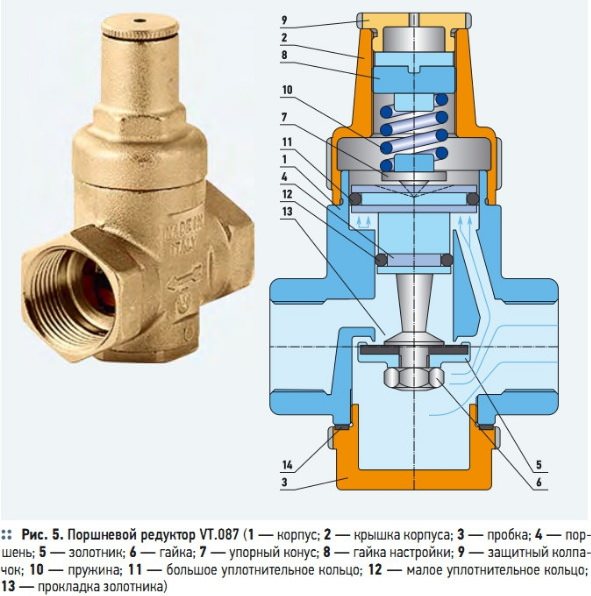

- Piston

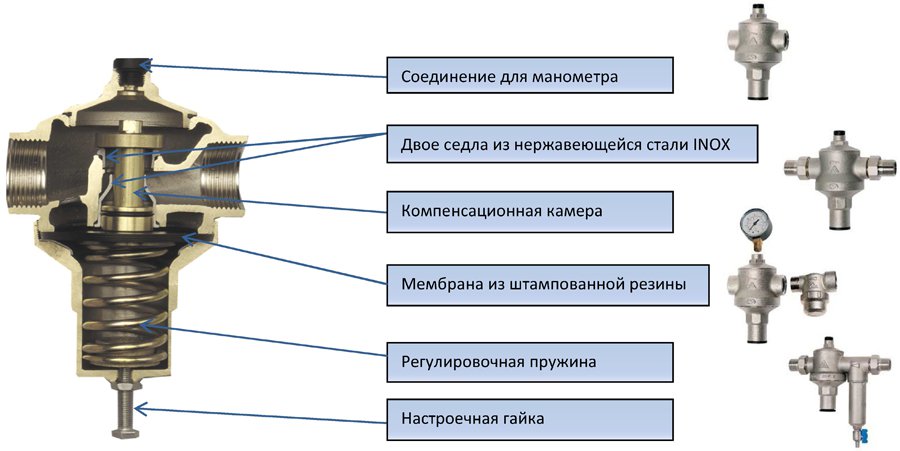

- Diaphragm reducers

- Why is a regulator needed in a water supply system?

- In a multi-storey building

- In a private house

Why is the regulator leaking?

Whatever type of gearbox is used in the water supply network, the main cause of leakage is a violation of its sealing. A leak is the first call indicating that something is wrong with the regulator.

In fact, the device is simple. It functions thanks to a movable mechanism: a piston or a diaphragm, which is simultaneously affected by water pressure and the force of a pressure spring.

There is nothing special to break here, with the exception of automated and electronic mechanisms, which are used, as a rule, for industrial purposes.

The main causes of leaks depend on the design and occur due to:

- abrasion of piston rings (piston type);

- seal failure between the reducer chamber and its diaphragm (membrane type).

The sealing is broken due to corrosion processes inside the device, contamination of its internal mechanism and, as a result, failure of the sealing elements.

Risk factors that increase the wear of equipment can be:

- Increased pressure in the water supply - household fittings, including pressure reducing ones, fail faster if they are too high.

- Sudden pressure surges in the water supply network - the pressure reducer is considered to be equipment that reduces the negative effects of water hammer, but this is not so.

- The vertical position of the piston pressure gauge - this position can cause uneven piston stroke and asymmetric abrasion of its o-rings.

- Damage to the working mechanism when water freezes in the fittings - it is necessary to insulate the technical compartment or transfer it to a heated room.

- Rust and other dirt significantly reduce the life of sealing elements, especially for designs with moving parts, which include all piston variations.

- Turning off the water supply and dehydrating it increases the formation of rust inside and contamination of the gearbox.

There is no fundamental difference in which water supply network the gearboxes are operated.However, if the pressure in the central water supply systems is regulated and controlled by the water utility services, then in the private sector these indicators depend only on the homeowners, and therefore the state of the regulatory units is completely dependent on the latter.

Service and setup

Most regulators come pre-set with 3 bar pressure. If you want to reduce it or, conversely, increase it, you can easily do it yourself. Depending on the gearbox model, you will need a wide screwdriver or wrench. In some, more expensive brands, adjustment is carried out without additional tools, by hand.

Make sure that the pressure regulator is securely installed, that there is water in the system, and that all taps in the apartment are turned off. Locate the adjusting knob at the bottom of the gearbox and slowly begin to adjust.

If you want to decrease the pressure, you need to turn it clockwise, if you want to increase it, counterclockwise. One turn changes the pressure gauge value by about 0.5 bar, you will immediately notice the movement of the pointer. Here, in fact, is the whole setup.

But what if you have a budget gearbox, without a pressure gauge? It is best to borrow a pressure gauge for a while, adjust, then unscrew and replace the plug. Or, be content with setting "by eye", watching the jet from the mixer.

Water pressure regulators do not require any special maintenance. From time to time it is necessary to clean the gearbox seat and filter mesh. In the event of failure, the piston or diaphragm will need to be replaced.

All elements of the leveler are removable, the body of the device remains in place.For this, stopcocks are needed before and after the device - so that, by shutting off the water supply in the apartment, you can safely replace the necessary parts.

A faulty gearbox usually does not let water through at all or simply does not reduce pressure, which can only be noticed when the pressure gauges are installed in pairs or there is a water intake to the gearbox. Maintenance of the device consists only in flushing the mechanism and the built-in filter.

If this does not help, there is a mechanical failure or the effect of time. However, the entire mechanism of the regulator is clearly visible when the stem is removed.

The failure may be a broken spring, wear of the piston or membrane. Not all spare parts can be found on sale, but if they are available or a donor, replacement will not cause difficulties due to the availability of the main gearbox mechanisms for maintenance.

Purpose of a household water pressure regulator

If you install a water pressure regulator in the apartment at the input, this will make it possible to solve several problems.

- Protect the pipeline and equipment connected to it from an increase in fluid pressure in the line above the set value. Quite often, the pressure greatly exceeds the set value and at times goes beyond the maximum allowable parameters. Often this problem affects those living in high-rise buildings. In such houses, in order for water to reach the last floors, it is necessary to increase the pressure several times. Due to the fact that the pipelines passing through the apartments and the equipment that is installed are not suitable for excess pressure, leaks often occur and expensive household appliances fail: dishwashers, washing machines, water heaters and thermostats.

- Protection of pipelines and equipment used in everyday life from water hammer.

- Reducing the inlet pressure to the desired value. Individual devices do not function correctly or do not work at all with an inlet pressure that exceeds the parameters specified by the manufacturer. In particular, some types of instantaneous water heaters have built-in protection, which, in turn, will prevent the device from turning on. If an accumulative boiler is installed in the apartment, its safety valve is set by the manufacturer to 6 atmospheres. Therefore, if the inlet pressure is higher than this value, then all the heated water will simply be drained into the sewer. And this is an overrun of water and expensive electricity spent on heating water.

- Decrease in water consumption. The level of pressure determines how much water flows out of the tap in a set time interval. By lowering the pressure to a suitable level, it is possible to save several cubic meters of water. And for owners of country cottages and houses with independent sewerage, the savings are also associated with a reduced amount of flowing water. And therefore, you will need to use the services of a sewer much less often.

- Reducing the noise level in water folding devices. A large flow of liquid at the inlet to a faucet or mixer leads to hum and noise. But if the pressure is stabilized to the required level even at the entrance to the locking device, it is possible to completely eliminate or at least reduce the noise level to tolerable values.

If we draw a conclusion from the above, then we can understand that with the help of a household regulator it is possible to eliminate most of the unnecessary factors that begin with an increase in pressure in the line.

Manufacturers

Among the leading manufacturers of gearboxes, Italian companies predominate. They are traditionally famous among manufacturers of similar products. However, the Russian company Valtec or the American Honeywell are no less famous.

For a more visual comparison of products from different manufacturers, we will make a table:

| Brand | Pressure (max) | Temperature (max) | Setting limits (Bar) | pressure gauge | Adjustment type |

| Valtec | 16 At | 40° — 70° | 1,5-6 | There is | A pen |

| Honeywell | 25 At | 40° — 70° | 1,5-6 | There is | A pen |

| Watts | 10 At | 30° | 1-6 | There is | A pen |

| Hertz | 10 At | 40° | 1-6 | There is | A pen |

| Caleffi | 10 At | 80° | 1-6 | There is | A pen |

| Giacomini | 16 At | 130° | 1-5,5 | There is | A pen |

Looking at the table, you can see that the parameters of all household devices are more or less similar. Only the maximum temperature and operating pressure differ. This makes it easier for users to choose the right device.

Scope of use of the device

The pressure reducer simultaneously performs several functions. First of all, it is used to protect plumbing fixtures from high pressure. So, most plumbing and household appliances are designed to work when the water pressure in the pipeline does not exceed 3 atm. If this indicator is slightly higher, then the water supply system is under serious stress. Subsequently, valves, connections and other elements of the system and plumbing fixtures suffer

Also, the gearbox is used to combat water hammer, which can occur both in industrial enterprises and in residential buildings. As a result of a sharp jump in water pressure in the water supply system, a water hammer occurs, which can damage the structural elements of the system.There are cases when such a sharp jump led to the rupture of the boiler. Therefore, experts recommend installing a gearbox, as it will prevent the occurrence of such problems.

It is very important to consider the installation in the water supply system of the apartment

The pressure reducer is widely used in homes where the pressure of cold and hot water is constantly jumping. Adjusting the water pressure regulator in the apartment will solve this issue once and for all. Also, lowering the water pressure in the apartment will reduce its consumption by 25% or more. Details on how to choose a water pressure reducer.

Gas reducer, its types and installation methods

A gas pressure reducer is a technical device that serves to reduce the indicator of the same name to the operating value at which it is used, as well as to maintain this value in automatic operation.

Gas reducers are divided into direct and reverse action and differ in:

Type of installation

- network devices - used when connecting a welding post from a centralized gas supply line;

- balloon models - used for individual connection of the welder's workplace;

- ramp - installed on bypass ramps, when connecting gas networks that serve for centralized connection of a gas supply line.

Constructions

- single-stage;

- two-stage;

- with a master;

- with non-flow pneumatic chamber.

When connecting network gearboxes, wrenches and a special gasket are also used, with the only difference being that this group of regulators is mounted not on a cylinder, but on a gas pipe valve.

Ramp reducers are usually installed in the gas pipeline by means of a flange connection with the installation of sealing gaskets between the flanges.

How to set up the regulator with your own hands?

The principle of operation of the devices is the same, but the regulators are different in design.

The principle of operation of the devices is the same, but the regulators are different in design.

Including there are differences in the design of the adjusting screws. Various tools may be needed to rotate them.

For a more precise setting, you can use a pressure gauge. Some devices have special threaded places for their connection.

Training

Depending on the design of the adjusting screw, you may need:

- hexagon 4 or 6 mm;

- standard screwdriver with a flat wide blade;

- special key or steel strip about 2 mm thick and up to 20 mm wide.

For visual control of the pressure at the outlet after the reducer, you may need a pressure gauge with an adapter for connecting to a shower hose or a mixer gander.

The regulator is adjusted at the lowest possible water flow through one tap.

Setting

To set the pressure regulator in the water supply system of the apartment, do the following:

- turn off all taps on the internal water supply;

- install a pressure gauge on the gearbox or connect it to the internal water supply;

- open 1 tap so that the water flow is minimal, that is, a thin stream that does not break up into separate drops;

- visually determine the pressure in the water supply using a pressure gauge, before starting the adjustment;

- remove the plug from the hole in the housing where the adjusting screw is installed;

- insert the tool into the screw, suitable for the configuration;

- to increase the pressure, it is necessary to turn the screw counterclockwise, the spring load on the valve will decrease, and the valve will close at a higher pressure;

- to reduce the pressure, turn the screw clockwise, the spring load on the valve will increase, and the valve will close at a lower pressure;

- make a trial use of tap water to check the comfort of using water;

- adjust the setting if necessary;

- close the plug of the hole plug on the reducer, disconnect the pressure gauge.

Some models have a head for turning the adjusting screw and may even have a scale indicating conventional values.

You can adjust the pressure in the water supply without a pressure gauge. To do this, after each full turn of the adjusting screw, you should check the pressure from the tap, including the impact of the jet on the palms.

One turn of the screw changes the value by approx. 0.5 - 1.0 bar. For more precise adjustment, at the end of the adjustment, half a turn of the screw should be done.

This method may turn out to be even more acceptable, because the pressure is adjusted, first of all, for comfortable use of water, including when washing hands.

Installation

It is not recommended to install pressure regulators on your own, as it requires certain knowledge and skills. Consider the connection diagram of pressure reducers in the water supply system of the apartment.

Explanation:

- mechanical coarse filter;

- check valve;

- hot water and cold water meters;

- washing filter;

- Pressure reducer.

Installation of reducers is carried out in the main cold and hot water supply of the apartment.It is preferable to install pressure reducers on a horizontal section of the pipeline, but installation on a vertical one is also allowed. To ensure trouble-free operation of the gearbox, it is necessary to install a mechanical filter before it.

Usually the reducer is mounted behind the water meter. Behind the reducer, a pipeline of the same diameter with a length of 5xDn must be provided. To ensure the possibility of adjustment and maintenance of the gearbox, shut-off valves are installed behind it. If safety valves are provided in the system, the set outlet pressure of the reducer must be 20% lower than the opening pressure of the safety valves.

The set of rules for water supply and sewerage states that the installation of pressure regulators should be carried out immediately after the shut-off valves at the inlet, that is, before the metering devices.

This sounds sensible, because in this case the gearbox will protect all hydraulic devices, including the meter and the filtration unit.

But when installed up to the metering station, any possibility of water intake should be excluded, which means that the technical plugs for washing the filter and the stem will be sealed, and the gearbox itself will lose the possibility of maintenance.

This can be neglected, but even in this case it is very difficult to provide for different hydrodynamic resistance and achieve pressure equalization in the cold and hot water collectors. It is necessary either to install additional pressure gauges in them for more accurate adjustment, or to place pressure regulators immediately in front of the manifolds, as most experienced plumbers do.

Example of water distribution with a reducer

If it is not possible to install at the inlet of the system, but some components require protection against overpressure, local installation is also possible. There are quite a few primitive models of gearboxes for 20 mm pipe threads, and even without fine tuning, they do their job well with their protective function.

Regulatory requirements for apartment pressure regulators

Unbalanced pressure drops in the hot and cold water risers lead to a change in the mixed water temperature setting at the mixer spout. Many have probably come across such a fact when the comfortable temperature of the water in the mixer suddenly began to change dramatically either towards boiling water or to absolutely cold water.

The presence of pressure regulators on the apartment inputs will make it possible to get rid of such an unpleasant phenomenon. The domestic regulatory framework governing the requirements for household water pressure regulators is currently represented by the following main documents:

- GOST 55023 Apartment pressure regulators. General specifications

- GOST 12678 Direct acting pressure regulators. Main parameters.

- Guidelines for the selection and use of apartment pressure regulators in residential and public buildings (Research Institute of Sanitary Engineering).

The main requirements for gearboxes set out in the listed documents are presented in the table:

| № | Characteristic name | Unit. | Meaning |

| Conditional throughput, not less than | m3/h | 1.6 (GOST R 55023) 2.5 (GOST 12678) 1.1 (Research Institute of Sanitary Engineering) | |

| Throughput in the operating range of inlet pressures, not less than | m3/h | 1,8 | |

| Throughput at inlet pressures below the operating range, not less than | m3/h | 0,72 | |

| Inlet pressure operating range | bar | 3–10 | |

| Operating range of expenses | m3/h | 0,18÷1,8 | |

| Maximum output pressure in the operating range of flow rates, no more | bar | 2,7±0,2 | |

| Maximum output pressure in non-flow mode, no more | bar | 3,5 | |

| Change in pressure when the flow rate changes by 0.05 l/s in the operating range of flow rates, no more | bar | 0,04 | |

| Full resource | thousand cycles | ||

| Noise level at a distance of 2 m from the device | dBA | ||

| Bending moment on the body, not less than | N m | ||

| Ambient temperature range | ºС | 5–90 | |

| Permissible ambient humidity | % | ||

| Medium temperature range | ºС | 5–90 |

The principle of operation of apartment pressure regulators is based on balancing the forces created by the pressures at the inlet and outlet due to the ratio of the areas affected by these pressures.

The pressure at the inlet Рin acts on the small piston, trying to open it. Due to the throttling in the spool associated with the small piston, the pressure is reduced to Pout. This reduced pressure acts on the large piston to close the spool.

The large piston spring keeps the spool open when the inlet pressure is below the set pressure. A diaphragm can be used instead of a large piston.

When is a gearbox needed?

A ½ inch regulator is needed when, after calculating the water flow, an appropriate value is obtained. They are suitable for small apartments or country houses.

Often, to stabilize the pressure, reducers are selected according to the size of the entry pipe to the dwelling. For example, if the water distribution is equipped with a 20 mm pipe, a half-inch reducer is installed.

But if it has insufficient capacity, it will not be able to provide the specified pressure after itself. Therefore, the size of the device must be selected according to the flow rate of the liquid.

The diameter of the pressure reducer must be correctly calculated, otherwise the system will not work correctly, and the device itself will quickly fail. The correct calculation scheme can be found in the gearbox manual.

The basic principle by which the calculations are made is that the speed of water passing through the reducer should be from 1 to 2 m / s.

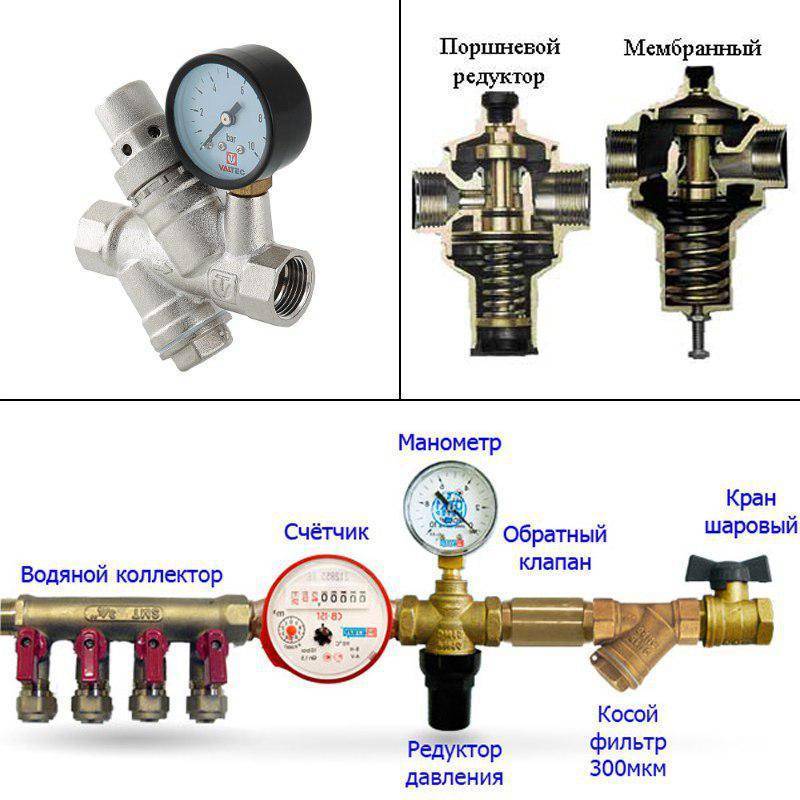

Which is better?

In order to give an overall impression of the two types of gearboxes, the table below shows their main comparative characteristics:

| Characteristic | Diaphragm reducer | Piston |

| Bandwidth | 2.5 m3/hour | 1.6 m3/hour |

| Adjustment accuracy | ±5% | ±10% |

| Sensitivity to water quality | No | There is |

| Installation position requirements | Any position (vertical, horizontal, angled) | in a horizontal position to avoid abrasion of the piston o-ring |

| Noise level | Short | High (due to the large number of metal components) |

| Case dimensions | Larger | More compact |

| Life time | Virtually unlimited | ±1 year before repair or replacement |

| Price | 35-45$ | 15-25$ |

As can be seen from the table, the advantages of diaphragm reducers are obvious. This type of regulator can be recommended for installation in any conditions, with any water quality. Of course, if you plan to install the device once and forget.

If a temporary installation is needed, or the budget for the purchase of a pressure reducer is limited, a piston one can be considered.

Top 3 Models

Consider the most popular gearbox models.

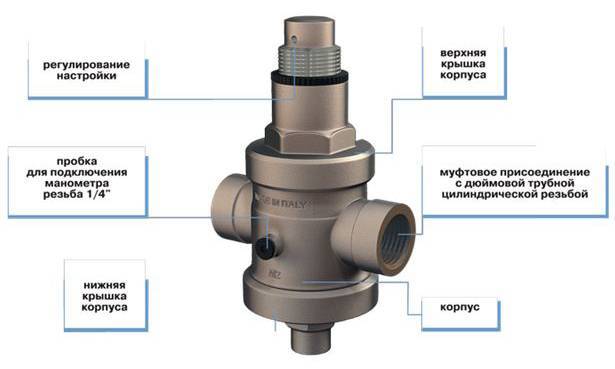

For an apartment

Household models are suitable for an apartment:

Household models are suitable for an apartment:

- Honeywell D04FM (for domestic hot water). Price from 2000 rubles.

- RD-15 (for cold water). Price - 1200 rubles.

- Valtec VT-087 (wagon). Price - from 1000 rubles.

These models are most in demand, although other samples do their job quite well.

For a private house

For a private house, the following models are recommended:

- Watts DRV/N (membrane). Price - from 3500 rubles.

- RDV15-2A-M (universal HVS / GVS). Price - from 1300 rubles.

- HoneywellD06F-1/2″ A. Price - from 3400 rubles.

More information about which pressure reducer to choose can be found here.

Important! In autonomous systems of private houses, only one reducer can be used on the cold water supply line. Modern models of boilers or boilers are equipped with their own control structures, so the task is only to ensure the nominal inlet pressure.

How to choose?

Questions to consider before choosing a regulator:

Questions to consider before choosing a regulator:

- What is the diameter of the pipe, in inches, on which the instrument will be installed?

- Do you need internal or external threaded fittings?

- Do I need to install a hard filter before the gearbox?

- Do you need a manometer?

Now you need to decide on the pressure regulators, which are worth paying attention to. The market has already formed a list of manufacturers that supply quality products with excellent reviews.

As of today, these are:

- Valtec (Russia),

- Zelmer (Germany),

- Herz (Austria),

- Honeywell (Germany).

You can buy products from these manufacturers without fear of getting a low-quality product. However, before buying, you should familiarize yourself with the passport that comes with any quality product.

You need to pay close attention to the lines where the materials of the housing and metal parts of the internal filling of the gearbox are indicated, as well as to the materials of the membrane and the sealing ring.

The membrane should be made only from EPDM, if it is a really high-quality product from the manufacturer, and not a fake, which can also come across.

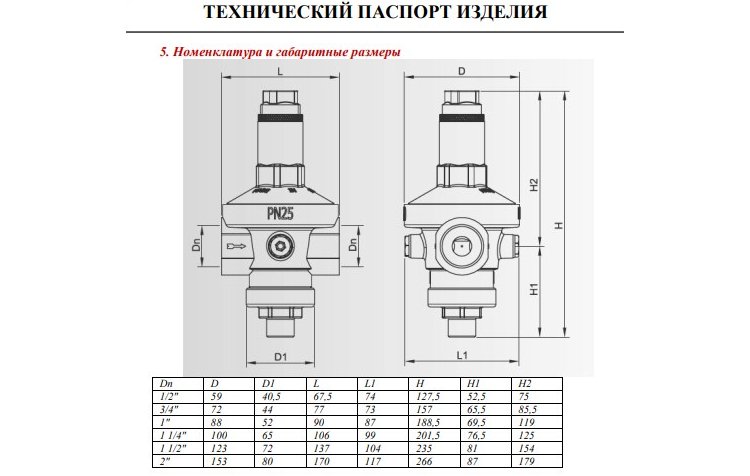

Also, the overall dimensions of the product are indicated in the passport, depending on the diameters of the thread of the nozzles.

Water pressure regulator repair

The purpose of the reducer is to maintain the set outlet pressure as accurately as possible, regardless of changes in the inlet and the consumed water flow. This is necessary so that consumers do not feel discomfort at different degrees of water intake, and at each point of water intake, with the help of fittings, it would be possible to independently regulate the water flow over a wide range.

Maintenance:

- Once a month, it is recommended to check the settings, the response speed and the accuracy of maintaining pressure by the regulator. They check the operation of the regulator by changing the flow rate of water passing through it - smoothly closing the fittings installed on the same pipeline.

- With a frequency of once every six months, the pulse selection line should be cleaned. To do this, the area where the regulator is installed should be disconnected, drained, and the impulse line should be blown out, having previously disconnected from the regulator and the pipeline.

- The mesh filter installed in front of the regulator is cleaned as it gets dirty. The clogging of the filter is determined by the readings of the pressure gauges provided before and after it, comparing the actual pressure drop across the filter with the drop in a clean filter.

Repair of the regulator may be required if, during operation or maintenance, a pressure deviation was detected at the point where the pulse was taken from the set value. Do-it-yourself gearbox repair is impractical, it is easier to replace it with a new one, but you can try the simplest operations.

| The regulator does not respond to changes in pressure at the connection point | Plugged impulse line | Blow out with compressed air or water pressure, having previously disconnected from the regulator |

| — | A foreign object has entered the flow path | Clean the plug and seat after dismantling the regulator |

| — | Sticky stock | Descale and work out the stem manually, having previously dismantled the regulator and hydraulic actuator |

| Regulator closed all the time | Missing spring or adjusting nut through which the spring holds the stem in the open position | no comments |

| Regulator open all the time | Water pressure upstream of regulator, below set pressure | Change the set pressure with the adjusting screw or wait for the pressure to increase |

| — | Membrane torn | Need to replace the original membrane |

The most common questions on the repair forums:

- water pressure reducer leaking what to do?

- how to clean the gearbox

Kinds

There are many designs and sizes of such devices on the market that are designed to work in various networks or systems.

When choosing, you need to pay attention to the main parameters of the gearbox:

- Connecting dimensions. This is an important characteristic, since all household networks have a standard size of threaded connections - 1/2 inch.

As a rule, gearboxes are installed as part of an assembly - a ball valve filter and a coarse cleaning counter.

All of these devices have a 1/2 inch thread and are connected in series with each other.

If the gearbox has a different thread, you will have to complicate the assembly, look for adapters. In addition, extra connections will appear, which will increase the risk of leaks.

- The maximum allowable temperature. This characteristic will help determine whether the reducer is suitable for a hot or cold line.

- Device design.

Mechanical

The pressure is adjusted using a special valve that changes the size of the passage for the water flow. A spring acts on the valve, the force of which balances the water pressure.

As soon as it changes, the spring will either stretch or compress in response to the jump that has occurred. Mechanical devices are simple, easy to install and adjust. In addition, devices of this type are inexpensive, which increases their popularity among users.

flowing

This is a specific design designed to reduce excess water pressure while reducing flow. There are no moving parts inside such a device, which makes it almost eternal.

The water pressure is reduced due to the branching of the flow into a network of small channels. At the output, they are again combined into a single stream, but with changed parameters.

Note! The only problem with such devices is the dependence on water quality. Small particles gradually clog the channels, gradually putting the gearbox out of action.

Electric

This is a group of devices that provide precise and instantaneous adjustment of flow parameters.They have a different design, from fairly simple mechanisms with a servo pushing a stem with a valve, to complex devices with pressure sensors, actuators and a host of additional functions.

Despite their capabilities, electric gearboxes are not in high demand. They require power, maintenance and frequent adjustments. The price of these devices is much higher than that of mechanical models.

Auto

All gearboxes operate on an automatic principle. Therefore, absolutely any device can be attributed to this category, regardless of its design and technical parameters. This is precisely the value of the device - an automatic change in pressure that does not require human intervention.

However, there are also automatic gearboxes with a circulation start function. When the pressure increases, they stop the pump, and when it decreases, they start it, ensuring the nominal operation of the system.

Important! Are used in autonomous systems of water supply and heating.

Domestic

Household reducers are designed to work with flows of a certain pressure and temperature. Unlike industrial models, they are able to regulate pressure only up to 15 atmospheres. In residential buildings, apartment buildings or private houses, this is quite enough, and household appliances and plumbing require even less.

Membrane

The role of the valve is played by an elastic membrane, which is balanced by a spring. Diaphragm reducers are less dependent on water quality, so the demand for them is higher.

For a full specification of membrane regulators, click here.

Piston

Piston devices are a classic type of mechanical gearboxes.The functions of the valve are performed by a piston that closes the passage for the flow of water.

The force is balanced by a spring, the tension of which is regulated by a screw. The simplest, cheapest and most popular design.

Electronic

Electronic gearboxes are the most expensive and complex devices. They have high accuracy, but are rather capricious and require the creation of good working conditions.

Reference! Used in conjunction with expensive imported plumbing or household appliances.

Full information about electronic water pressure regulators in our article.

Which type and when to choose?

The choice of gearbox depends on the conditions of its operation, the features of plumbing and other factors. If the house has a lot of imported plumbing fixtures, dishwashers, washing machines, showers, etc., you need a high-quality and accurate gearbox with a guarantee of performance.

For a simple reduction in drops and cutoff of water hammer, a simpler mechanical model is suitable.

Types of equipment according to the principle of device and equipment

Regulators are distinguished by the type of device of the mechanism used to drive the rod, into piston and membrane. Each of them has its own advantages and disadvantages.

Piston

On the one hand, the spring acts on the piston, on the other hand, the pressure. To ensure tightness, elastic rings, usually made of rubber, are put on the piston.

However, the service life of rubber rings due to constant friction against the walls of the gearbox housing is much lower than that of a rubber membrane.

At the same time, such rings can be selected and replaced, extending the life of the gearbox. And the cost of piston regulators is almost 2 times cheaper.

Due to the presence of rubbing parts, piston regulators are much more sensitive to the presence of suspended matter in the water than diaphragm regulators. Service life up to 20 years. But the overhaul period rarely exceeds 5 years and is highly dependent on water quality.

Diaphragm reducers

Instead of a piston, an elastic membrane is installed. Therefore, there are no rubbing parts, which significantly increases the service life.

The principle of operation is the same, on the one hand, a spring acts on the membrane, on the other hand, the force of water pressure.

The membrane itself ensures the tightness of the gearbox. However, the size of the regulator body is larger than that of the piston type.

They are more sensitive to water hammer than the piston type. If sudden pressure surges often occur in the external water supply system, then membrane restrictors are not recommended to be installed.

Membrane regulators can also be repaired, but for this it is necessary to select a membrane for the corresponding gearbox model, which is very difficult due to the lack of repair kits on sale.

The service life is from 15 to 20 years. The overhaul period is over 10 years, depending on the frequent sudden changes in pressure (water hammer).

Why is a regulator needed in a water supply system?

Reducing the pressure in the pipes leads to a decrease in water consumption per unit of time.

With an excessively high pressure, excess H2O flows into the sewer, which leads to its overspending and, accordingly, to increased cash costs.

At excessive pressure, water with its weight pushes through gaskets, seals, which leads to leaks. And this, on the one hand, is the probability of flooding the neighbors, and on the other hand, again, the overspending of water and money.

Thus, the main purpose of the regulator is to protect the plumbing system from damage and save water.

In a multi-storey building

In high-rise buildings, a gearbox is needed on the lower floors to maintain the standard pressure.

The fact is that according to SNiP 2.04.01-85, which establishes standards for internal water supply and sewerage, the pressure in DHW pipelines should not exceed 4.5 Atm., For cold water - 6 Atm. And in order for the water to rise to the last floors, an overpressure is set for the entire system.

On the middle floors of skyscrapers, it is also desirable to install control valves that work to reduce pressure.

In a private house

In urban private homes, water comes from urban water supply systems.

And the regulator is necessary if private low-rise buildings are surrounded by skyscrapers, for which increased pressure is set in the system.

In this case, the reducer should be mounted at the junction of the domestic pipeline with the central line. If the gearbox is not equipped with a coarse filter, it is advisable to install it before the control device. Shut-off valves are installed in front of the filter and the gearbox.

In rural and settlement houses, water supply is autonomous, provided by pumps from their own wells. In the absence of pressure regulation, water is overused, leading to energy overruns and wear of pumping equipment.

Gearboxes are included in the package of some models of pumping equipment. And when they are not there, it is necessary to purchase additionally, since every time the pump is turned on, there is a possibility of water hammer in the water supply.

It is important to know that when installing a boiler boiler, a device that regulates water pressure must be cut into the pipeline in order to avoid water hammer and boiler failure. This must be prescribed in the instructions for the heaters.

It has been noticed that if a high-pressure hose is embedded in the water heating system, which stabilizes the water pressure, the boiler equipment lasts longer, and its parts and assemblies do not run out of their resources so quickly.

In addition, the action of sudden pressure surges on the boiler provokes the discharge of hot water into the sewer, which affects the consumption of water and electricity and, ultimately, financial costs.