- How to choose a pressure reducing valve

- Honeywell Water Regulator

- Pressure regulator RD-15

- Far water regulator

- Pressure regulator Valtec

- Material

- Hydraulic accumulator: work and reasons for its failure

- Membrane tank device

- Tasks of the vessel and their implementation

- Symptoms of a malfunctioning hydraulic accumulator

- What it is?

- Water pressure reducer in the heating system adjustment - Engineering systems

- Criterias of choice

- Self-adjusting device

- Which ones can be fixed on their own, and which ones can't?

- Water pressure reducer: purpose and principle of operation

- The use of a pressure reducer in a water supply system

- How to install it yourself - step by step instructions

- In the apartment

- In a private house

- Types of water regulators

- Piston

- Membrane

- Flowing

- Automatic

- Electronic

How to choose a pressure reducing valve

Honeywell Water Regulator

When choosing a Honeywell water regulator (Honeywell), you should pay attention to the following parameters:

- water pressure regulator device;

- specifications;

-

device material.

The correct combination of all these factors will allow you to choose a device that will ensure the normal operation of engineering communications.

| Setting range (bar) | 1,5-6,0 |

| Static pressure PN | 16 |

| Production | Germany |

| Max. medium temperature | 70 |

| pressure reducer | Yes |

| Capacity m3 | 2.9 |

| Connection diameter (inch) | 3/4 |

Honeywell water regulators are considered very reliable, but the cost, respectively, starts from 1,500 rubles for the D04FM model.

Video:

Modern gearboxes are piston and diaphragm. The piston is highly resistant to wear. But, despite this, gearboxes of this type are characterized by low reliability in operation. This is due to the nature of water purification and the possibility of corrosion on the elements of the product. So, if small particles of dirt and sand may be present in the liquid, which will lead to jamming of the device. The only way out is a water pressure regulator with a filter.

Pressure regulator RD-15

The membrane water pressure regulator RD-15 has two working chambers, which are separated by a diaphragm. This makes the device unpretentious in maintenance and reliable in operation. One chamber is completely sealed to prevent water from entering it. It is here that the main part of the structural elements is located. This water pressure regulator circuit protects the device from corrosion and jamming. Proper use of the reducer and the integrity of the diaphragm ensures a long service life. And the cost is in the range from 300 to 500 rubles and has different versions. It is the most frequently used and has a certificate of conformity.

Pressure regulator RD-15

| Parameter name | Meaning |

|---|---|

| Nominal diameter DN | 15 |

| Nominal pressure (kgf/cm2) | 1,0 (10) |

| Regulation zone | 40 |

| Upper setting limit (kgf/cm2) | 0,4 (4) |

| Conditional throughput /h | 1,6 |

| Regulator weight | 0,35 |

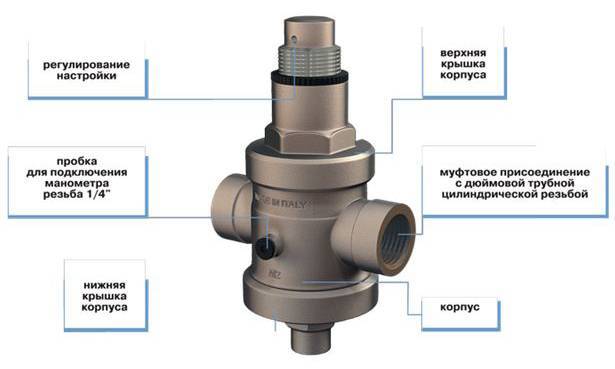

Far water regulator

When choosing a Far water regulator or another company, you should pay attention to its technical parameters. First of all, this concerns the value of inlet and outlet pressure.

Solving this problem is quite simple. You need to find out the requirements that apply to the device in a particular pipeline, as well as study the instructions for the water pressure regulator. It is in it that manufacturers indicate the nominal values \u200b\u200bof the working pressure.

Far water regulator

- Maximum inlet pressure: 16 bar.

- Adjustable pressure: 1 to 6 bar.

- Maximum temperature: 75°C.

- Set pressure: 3 bar.

The operating temperature is also important. So, some models are able to work in temperature conditions from 0 to 40 degrees. Such devices are used only in cold water supply systems. For a hot pipeline, models that operate in the range up to 130 degrees are suitable.

But the cost of a far water regulator already starts at 2,500 rubles.

Video:

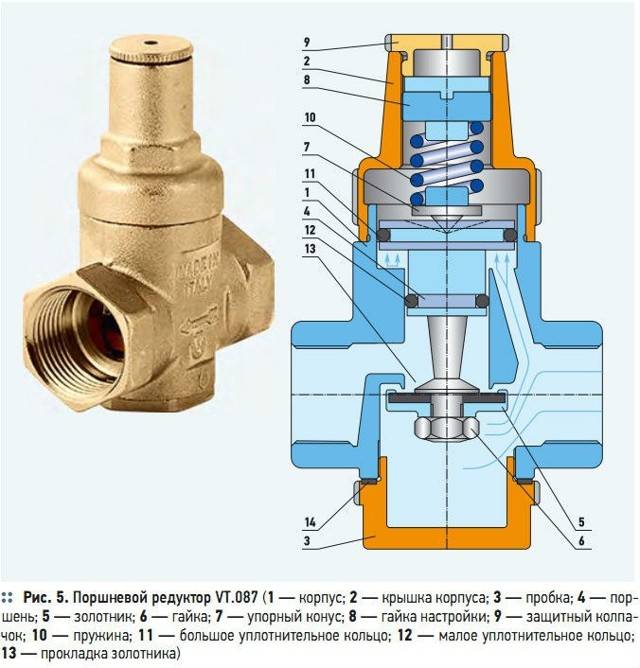

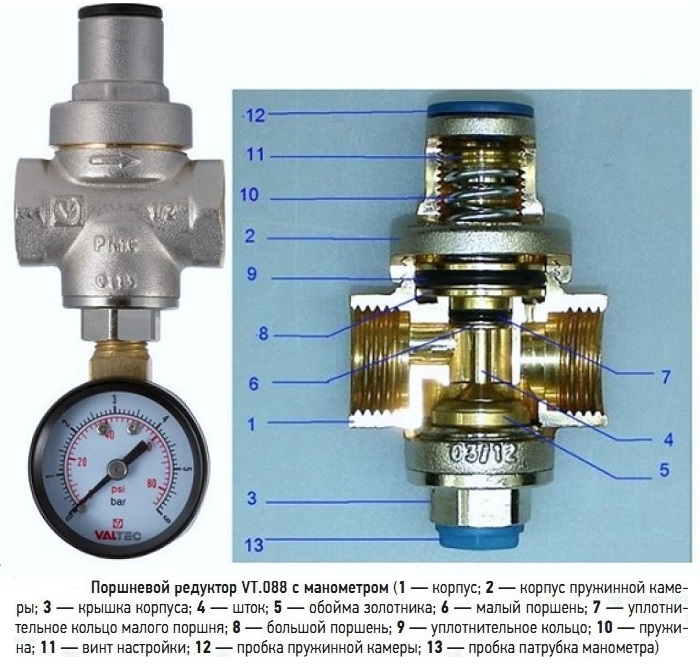

Pressure regulator Valtec

Particularly popular are the Italian pressure reducing valves in the Valtec water supply, which are reliable and delight with their price (from 800 rubles). Perhaps this is the middle price segment for water pressure regulators for multi-storey buildings.

Valtec pressure reducer VT.087

Video:

Material

Such devices must be made of durable material. If we are talking about alloys, then they should contain ligatures that prevent the occurrence of a corrosion process.

Experts recommend paying attention to the best water pressure reducers from well-known manufacturers.Of course, such products will cost a lot, but a long service life is guaranteed.

There are also GOSTs for valves that lower water pressure.

Regulatory requirements for apartment pressure regulators

Hydraulic accumulator: work and reasons for its failure

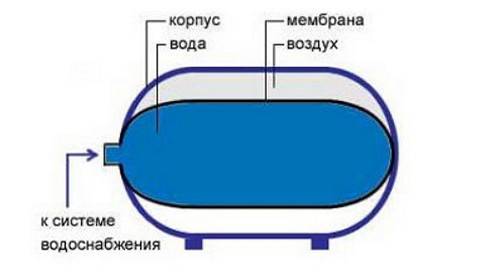

One of the most important "team players" is a hydraulic accumulator, which allows you to create and store a supply of water, protect the system and equipment from force majeure situations. This device is called differently, sometimes not quite correctly: expansion or storage tank, hydraulic tank, expansion tank, membrane tank, or simply - GA. This is a closed container, which has a hydraulic chamber that changes its volume. In order to imagine how a hydraulic accumulator works, it is necessary to consider its design.

Membrane tank device

Any hydraulic tank has a certain number of elements. It includes:

- case made of stainless steel;

- membrane (pear), which is made of special, elastic and durable rubber (EPDM, BUTYL);

- nipple for air supply;

- flange equipped with a valve, it is designed for pumping water;

- special devices - pressure gauge, pressure switch;

- platform (supports).

As you can see, the device is quite simple, but continuous, intensive work can "destroy" even the most reliable designs. Modern high-quality models of storage tanks have a long service life, work for a long time, and without "whims". However, possible malfunctions of the accumulator must be known, since it is still impossible to exclude some breakdowns.

Tasks of the vessel and their implementation

The storage tank consists of two chambers: one contains air, the other contains water.The last section deserves special attention. This is a rubber bag, or membrane. The principle of operation of the storage is based on squeezing the liquid with compressed air. When water is used up in the system, the pressure drops.

The hydraulic tank immediately reacts to the changes that have occurred: it quickly restores the parameters due to the supply of a new portion of the liquid, but without the slightest participation of the pump. Naturally, the rare inclusion in the operation of this main device of the pumping station guarantees its longer operation.

With the help of a relay for a hydraulic tank, two most important parameters of water pressure are set: its upper and lower limits. When the value becomes minimal, the pump “helps” the accumulator: it turns on and works until the pressure again reaches the maximum (preset) mark.

The membrane tank eliminates the most common problems that arise during the operation of autonomous water supply, heating systems or economical solar systems. Water accumulators help:

- stabilize pressure;

- quickly equalize the pressure of water with its intensive use;

- prevent the occurrence of water hammer, which is extremely dangerous for the system;

- guarantee the supply of water in the event of a pump failure due to power outages, but in this case the hydraulic tank must have a large volume;

- significantly extend the life of the main element of the pumping station, since rare periods of operation of the hydraulic machine exclude rapid wear of the equipment.

The peculiarity of the membrane tank is that the efficiency of this device-vessel is not determined. The device either works or it doesn't.

Symptoms of a malfunctioning hydraulic accumulator

The membrane tank is a relatively simple design. Therefore, often possible malfunctions of the accumulator can be detected visually.

One of the signs of his "inaction" is the frequent operation of the safety valve. When the pressure in the system rises to extreme values, it releases water, protecting appliances and pipes. Other malfunction symptoms:

- unjustified inclusion of the pump in operation at each water intake;

- uneven flow of fluid from the tap - in jerks, in small portions;

- a pressure gauge showing that the change in pressure is stepwise: in this case, the arrow of the device first sharply goes up, then drops to zero.

If these signs are found, you can be almost sure that the accumulator is either not working correctly or is faulty. Finding the source of the problem and eliminating it is the next operation that the owners of the hydraulic tank and pump (pumping station) have to do.

It is impossible to delay the repair of a faulty hydraulic tank. Ignoring the incorrect operation of storage equipment will lead to the fact that soon the problem will affect not only the tank, but also other elements of the water supply or heating system. Such a scenario is unlikely to inspire anyone, since in this case the cost of fixing will seriously increase.

What it is?

A water pressure reducer (sometimes called a regulator) is a device designed to stabilize and normalize pressure in cold and hot water supply systems.

Outwardly, this is a small element in the form of a cross, somewhat reminiscent of a tee or a ball valve.

It is equipped with an adjusting screw, and some models have a pressure gauge for visual control of the operating mode.

Important! Installing a reducer allows you to equalize and stabilize the water pressure, eliminate water hammer and sudden drops. This provides nominal mode of operation of household appliances, protects a flexible eyeliner from a rupture at occurrence of hydroblows.

Water pressure reducer in the heating system adjustment - Engineering systems

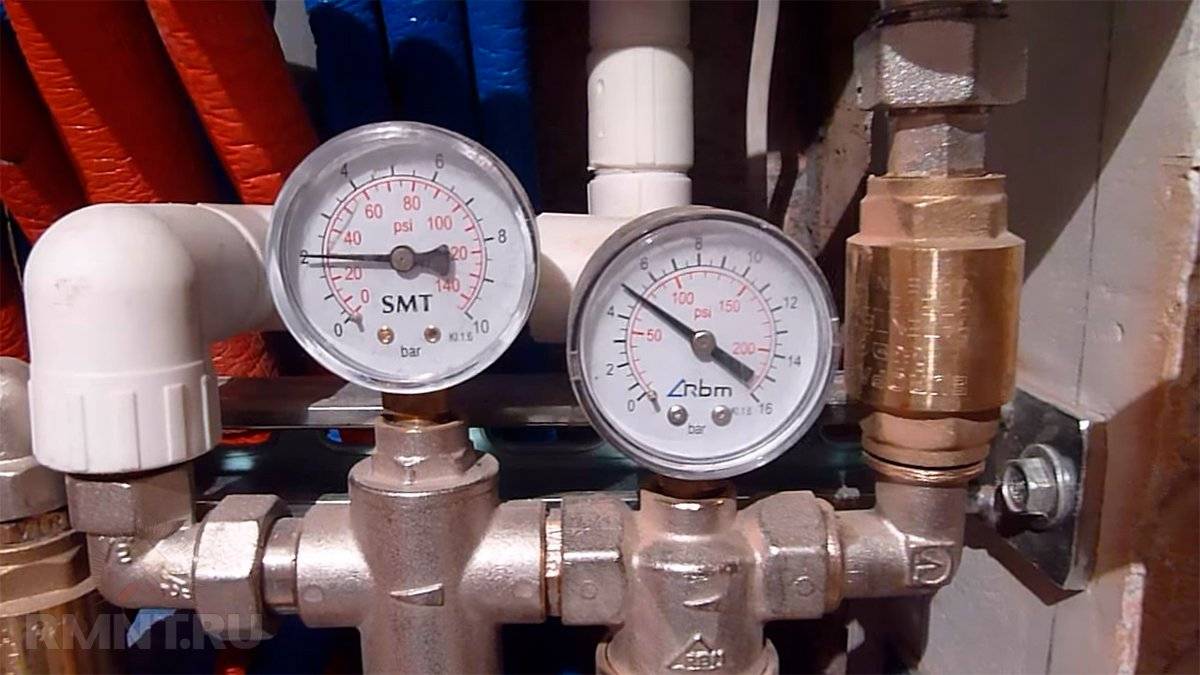

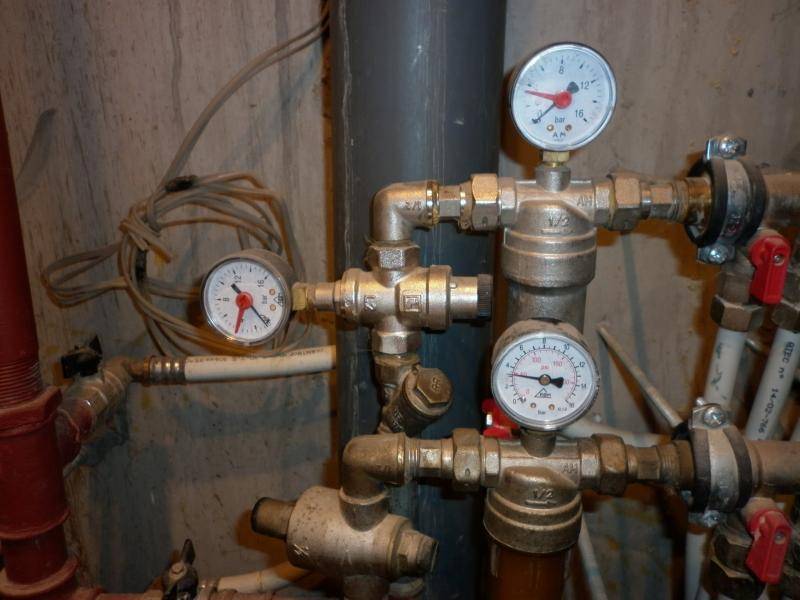

In the apartment buildings of microdistrict 4A in Lytkarino, water pressure regulators were installed at the entrance to the apartment of the Russian company Betar RD-15 (photo 1).

Photo 1. Dismantled pressure regulator (reducer) Betar RD-15 with a coarse filter.

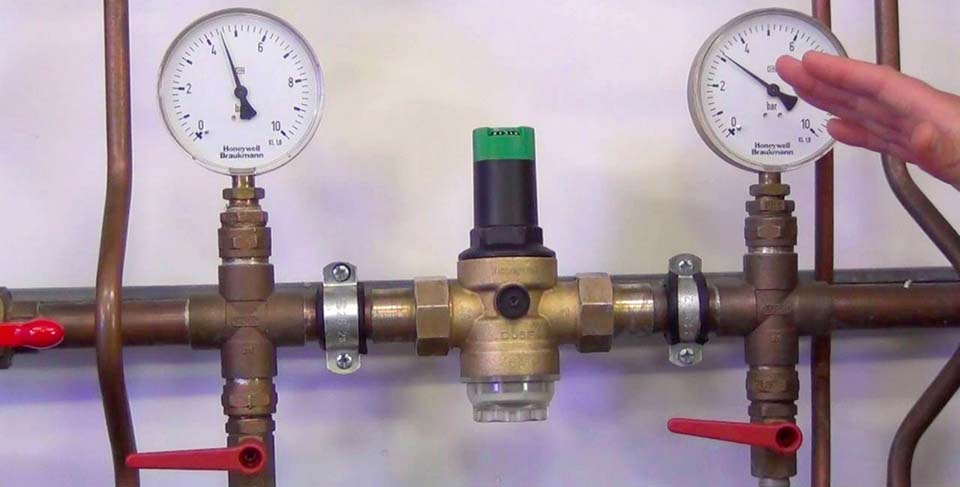

The pressure regulator lowers the pressure to the required level (usually up to 3 bar) in the hot and cold water supply system and prevents possible water hammer in the system. By setting the minimum pressure value, you can save water consumption.

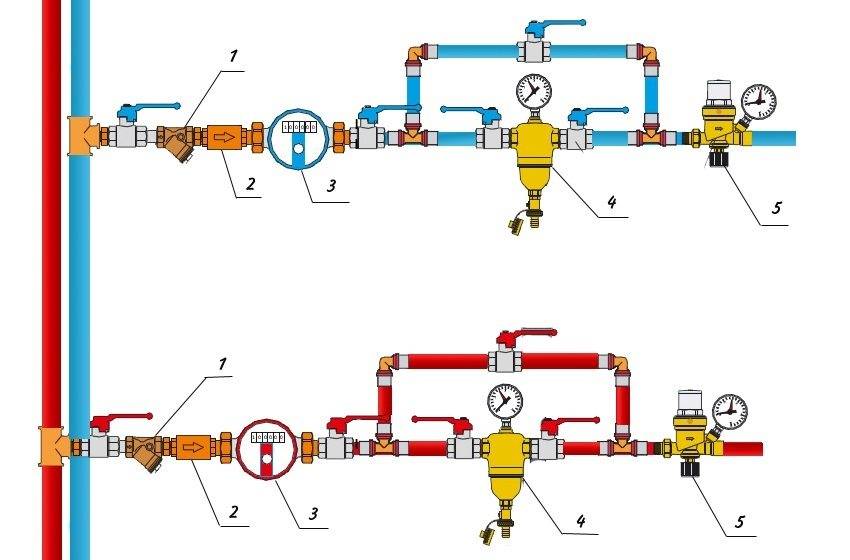

Such a regulator is installed in each apartment after the shut-off valve and coarse filter and in front of the consumed water meter (photo 2). A non-return valve can be installed after the coarse filter, but it is not required.

Check valves are built into many faucets and prevent water from flowing back into the system.

Photo 2. Approximate layout of the components of the water supply system in the apartment.

In the water supply system of the houses of microdistrict 4A, a supply pressure of approximately 6 bar is installed. For plumbing, this pressure is critical. Each plumbing manufacturer sets its own allowable water pressure value and in most cases it is about 3 bar.

The pressure reducer, together with the installed pressure gauge, allows you to set the desired pressure for hot and cold water.To do this, it is necessary to start up a thin, weak stream of cold or hot water in such a way that this stream is about to turn into drops.

Thus, equal pressure of hot and cold water in the mixer is set.

What to do if the pressure from the mixer is weak?

Most likely the pressure regulator is "closed". To do this, turn the hex wrench counterclockwise to the desired pressure. If the pressure does not change, then the gearbox is faulty.

Photo 3. Faulty pressure reducer Betar RD-15 after 2 years of operation and 45 cubic meters of water.

The analogue in size is the gearbox of the Italian company Valtec (photo 4). At a cost, this gearbox is slightly more expensive than the Betarovsky one and slightly better. Given the quality of the water supply in many apartment buildings in Russia, Valtec gearboxes offer good value for money.

Photo 4. Reducer (regulator) of water pressure Valtec with the same standard size with reducer Betar RD-15.

Remember that working pressure reducers save your plumbing, save water and provide comfort when used with running water.

Hydraulics, hydraulic drive / Hydraulic equipment / The principle of operation of the hydraulic drive

2015-11-15

Criterias of choice

At the moment, many types of water pressure regulators for apartments and private houses are being produced, but their quality does not always correspond to the declared one. Therefore, you need to know some criteria for choosing devices to protect hydraulic equipment from high pressure and water hammer.

The body of the instruments is made of expensive materials such as stainless steel, brass and bronze. It is recommended to take several regulators and compare their weight.It is necessary to choose the device that is heavier and without sagging with burrs

You need to pay special attention to the connecting seams. Low-quality regulators are often sprayed

When choosing the best option for the regulator, it is necessary to take into account such parameters as throughput - water consumption per hour (in m3) and the unit of account, which makes it possible to reduce the pressure in the system. Local resistance formed on the site, slightly affects the operation of the entire water supply system. The adjustable regulator depends on the sensitivity of the membrane, and its quality depends on the degree of compression of the spring and the material of manufacture. If there is only one spring, the tuning limit will be one. If the manufacturer has provided several springs that differ in the degree of rigidity, the device will more accurately respond to any changes in environmental conditions.

Normally, during operation, the reducer generates noise due to cavitation, which occurs due to an increase in the head velocity when entering the device. If the flow area is too narrow, then the likelihood of cavitation is very high. Therefore, when choosing a regulator, it is necessary to know the degree of cavitation and the regulated flow rate. These values can be viewed in the device passport.

When buying a pressure regulator, it is not recommended:

- Buy a device in the market, where all spare parts are laid out on improvised flooring. This means that the equipment is counterfeit and quite inexpensive.

- Complete with the product must be a passport and a certificate of quality. Otherwise, you should refrain from purchasing a dubious device.

- Acquire a device that is designed for other operating conditions.

Self-adjusting device

To adjust the unit, you will need an installed pressure gauge. To adjust, turn the adjusting screw until the desired value appears on the pressure gauge display. The adjustment screw is usually installed on the body of the product. Use a hex wrench to make turning the screw easier.

Adjustment is carried out in the following sequence:

- First you need to open the valve.

- Check that all water intake points are closed.

- The desired pressure indicator is set.

- Points of consumption are opened, and the indicator on the pressure gauge is checked. It must match the set value. The permissible deviation should not exceed 10 percent.

Installing the reducer allows you to optimize the operation of the water supply pipeline and create comfortable conditions for the use of plumbing equipment, as well as the existence of people in the house.

Which ones can be fixed on their own, and which ones can't?

The vast majority of faults occur due to hard water and the presence of limestone impurities in it. The more mineralized the water, the faster the pressure reducers begin to fail.

However, this difficulty is easily resolved. The device can be quickly disassembled, cleaned, gaskets or o-rings replaced, and it will work as good as new.

There are not so many irreparable damages. Mainly - these are mechanical defects of the body and internal filling. These include breakage of a spring or rod, as well as cavitation destruction of the seat and the walls of the gearbox.

About cavitation it is necessary to explain a little.This phenomenon occurs when the control device is chosen incorrectly, namely, its throughput characteristics do not correspond to one or another pipeline.

If the regulator makes noise during operation, then this is the first sign of cavitation and that it must be changed.

Cavitation processes occur when the spool is almost always in a half-closed state - the collector cross section is minimal. In this position, an area of increased pressure appears in the connecting manifold.

Under such conditions, all the prerequisites for the chemical decomposition of the metal begin to arise. It actively destroys the seat for the spool - the contact of the piston becomes loose.

Under such conditions, all the prerequisites for the chemical decomposition of the metal begin to arise. It actively destroys the seat for the spool - the contact of the piston becomes loose.

As plumbers put it, fittings begin to be ruthlessly cut, i.e. she starts skipping. It is very difficult, if not impossible, to correct this defect on your own - most often a complete replacement is required.

To prevent this from happening, you need to follow one rule - do not lower the pressure in the pipeline with one reducer by more than 2.5 times. If this cannot be done, then the “cascade” method must be applied, i.e. use two step-down devices.

So, a decrease from 10 to 3 atmospheres with one unit cannot be done without violating this rule. Then you need to use 2 devices - the first will lower from 10 to 6 atm., And the second from 6 to 3. In this case, the risk of cavitation and noise generation is guaranteed to be eliminated.

Water pressure reducer: purpose and principle of operation

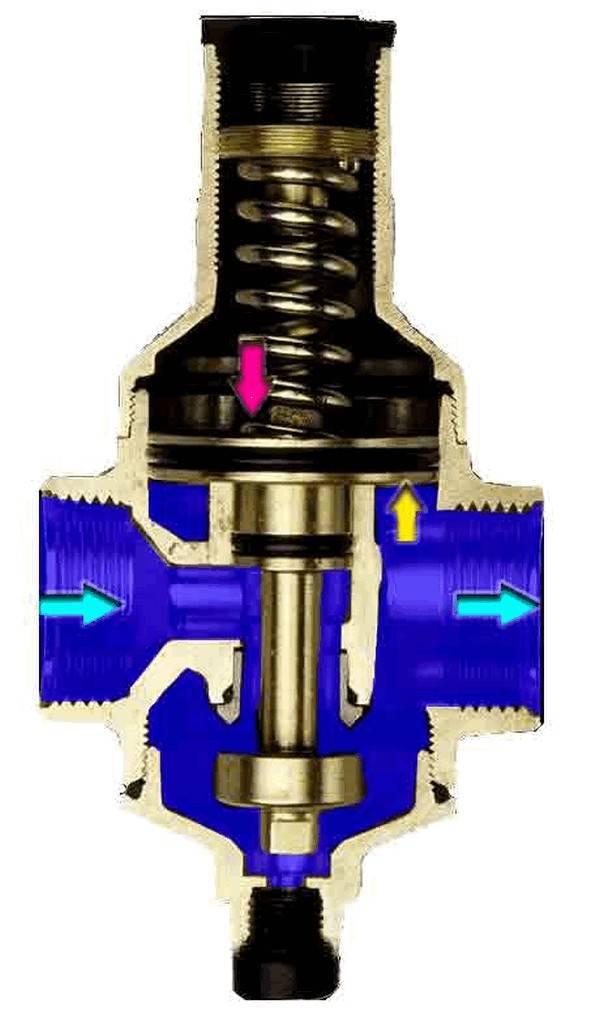

With the purpose of the water reducer, everything is more or less clear - as a rule, it is used to stabilize pressure and thus prevent the failure of some plumbing equipment. In most cases, the installation of a water pressure reducer is done when devices such as storage water heaters and thermostatic mixers are involved in the operation of a home plumbing - in general, units that are sensitive to fluid pressure. Everything is simple and clear here, which cannot be said about the principle of operation of the water pressure reducer - we will deal with it in more detail, since in this respect there are as many as three varieties of such devices.

- Piston water pressure reducer - its main advantage lies in the simplicity of design. A small spring-loaded piston is responsible for regulating the pressure in the plumbing system, which, by reducing or increasing the through hole, regulates the water pressure in the system - setting the outlet pressure in such gearboxes is carried out by weakening or compressing the spring by rotating a special valve. If we talk about the shortcomings of such gearboxes, then it is necessary to highlight such a moment as the need for preliminary filtration of the liquid - without cleaning the water from debris, such devices become clogged and fail very quickly. Due to this behavior, manufacturers quite often equip such devices with a complete filter element - a piston water pressure reducer with a filter is capable of adjusting the pressure in the range from 1 to 5 atm.

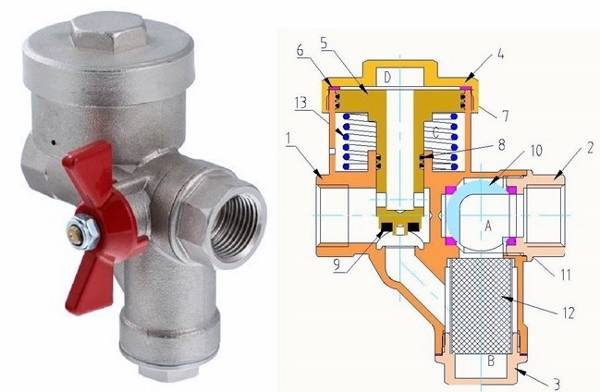

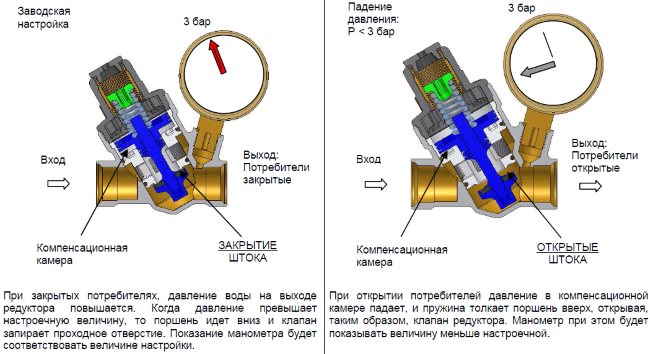

- Membrane pressure reducer.This type of gearboxes is distinguished by high reliability and unpretentiousness in operation - they stand out from all other similar devices with a wide range of throughput. As a rule, they are able to provide a working fluid flow rate ranging from 0.5 to 3 cubic meters per hour, which is quite a lot, especially when it comes to their use in everyday life. A spring-loaded membrane is responsible for the operation of such a gearbox, which, in order to prevent blockages, is placed in a separate sealed chamber - depending on the degree of compression of the spring, it exerts one or another pressure on a small valve, which reduces or increases the throughput of the device.

- Flow reducer for reducing water pressure. Devices of this type are distinguished by the fact that they do not have any moving parts, which increases their reliability and durability - pressure reduction is achieved here due to the internal labyrinth of a mass of small ducts. Passing countless turns of these channels, splitting into several streams and again combining into one, the water velocity is extinguished, and, as a result, the pressure of the liquid at the outlet of such devices decreases. In everyday life, such devices are usually used for irrigation systems - their main disadvantage is the need to install an additional regulator at the outlet.

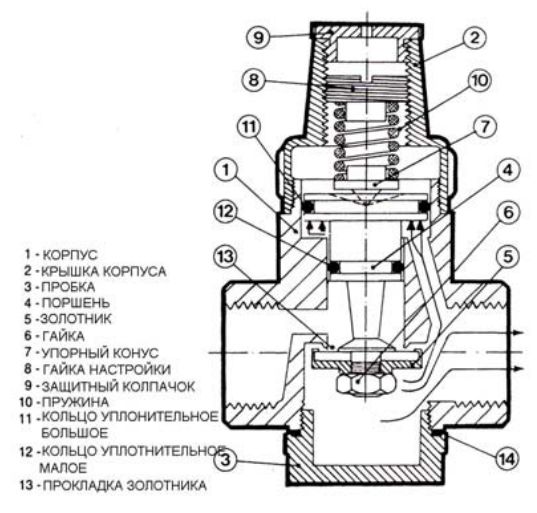

The principle of operation of the water pressure reducer photo

In general, this is all that can be said about the water pressure reducer, or rather its principle of operation, studying which we involuntarily touched on the topic of their varieties. But, as they say, this is only the beginning, and the types of these devices are not limited to this.

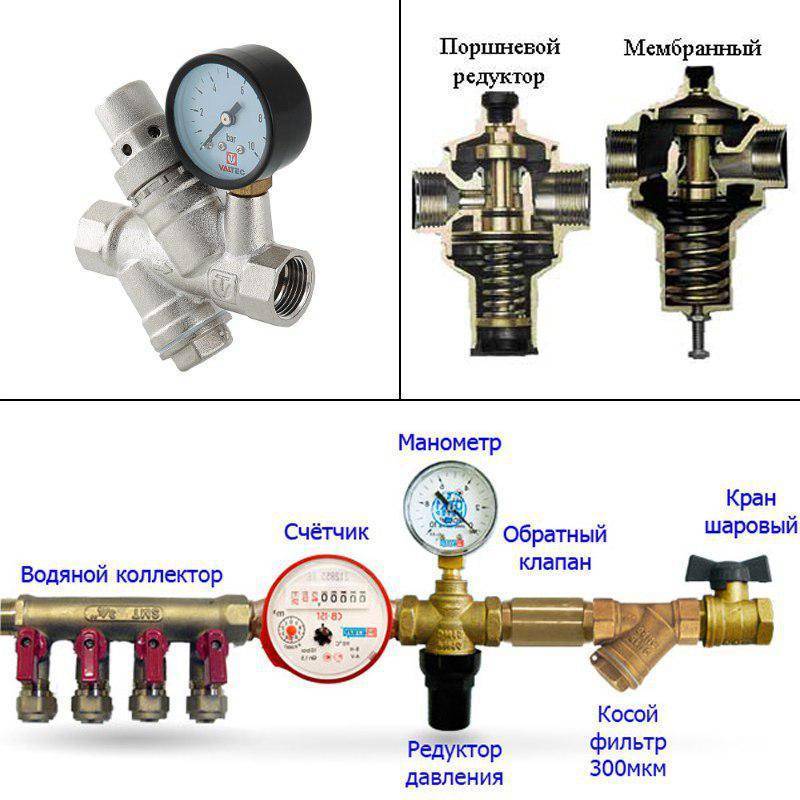

A water pressure reducer is a device that stabilizes and reduces the pressure in the water supply network, thereby protecting both the pipeline itself and the household equipment connected to it from high pressure and water hammer. The pressure reducer is a compact device in a sealed metal case with two threaded holes at the inlet and outlet. Sometimes, for convenience, a pressure gauge and a screw to adjust the pressure are connected.

Appearance and diagram of the gearbox

- Frame

- Lid

- filter grid

- Spring

- Adjusting screw

- Adjusting nut

- pressure gauge

- Central caliper

- Piston

- Diaphragm

- Piston disc

- Clamp bolt

- Valve

- valve gasket

- O-ring, small

- O-ring large

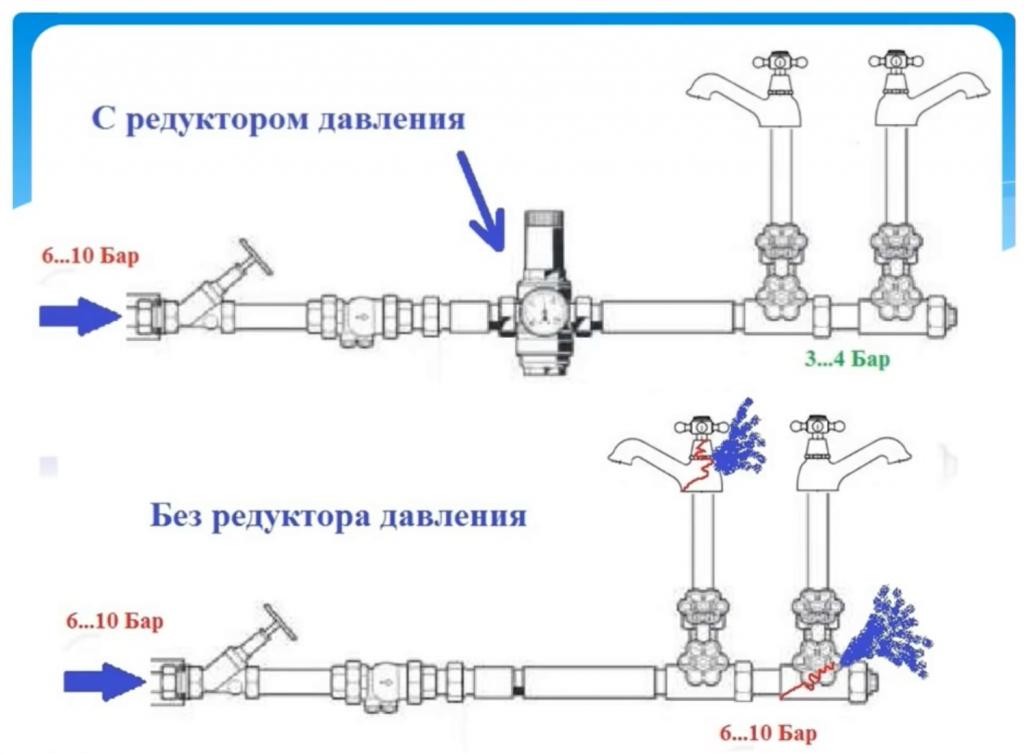

The use of a pressure reducer in a water supply system

Water hammer in the water supply network can cause failure of appliances and devices connected to the water supply system. Such a nuisance can be caused by a sharp jump in pressure in the water pipes, which is due to the work and tests performed by specialists of special services (Vodokanal or the like), as well as the operation of special equipment that increases pressure in the water supply networks (circulation and other pumps).

Installation water pressure regulator in the apartment avoids breakage of shut-off valves, as well as special equipment, in normal operation of the water supply network under nominal pressure: dishwashers and washing machines, showers and other equipment.

Another reason why installing such a device would be useful is to eliminate leaking faucets and valves.installed in the water supply network.

This is due to the fact that at night the water intake is significantly reduced, which leads to an overpressure that is greater in value than the operating pressure during daylight hours, when water is actively used by consumers.

Under the influence of increased pressure, taps and other shut-off elements installed in the water supply network may begin to leak. In this case, such a leak can lead to flooding of neighbors or an increase in the amount of bills issued by water supply organizations, both in terms of water consumption and its diversion.

How to install it yourself - step by step instructions

Having some skills in the production of plumbing work, it is not at all difficult to mount a pressure regulator with your own hands. If all the necessary elements and a set of tools are available, then the installation process itself will be easy to implement.

Consider the sequence of actions for installing the RFE in an apartment and in a private house. To understand the principle, it is enough to imagine the simplest option, when the pipelines have not yet been routed through the premises.

That is, there is no need to crash into the finished system. There is a riser and a shut-off valve. From these conditions we will proceed.

In the apartment

Mounting should be carried out in a horizontal plane so that the WFD itself and the pressure gauge are in a vertical position. Before starting work, you need to take care of materials and tools. Also do some preparation.

You will need to have:

- gearbox (preferably with a pressure gauge);

- shut-off valves (2 pcs.);

- coarse filter;

- check valve;

- fittings (set and quantity, depending on the wiring diagram).

- wrenches;

- screwdrivers;

- tow (linen) and adhesive composition for gluing it (FUM tape);

- when using polypropylene pipes, stock up on all connecting parts and a soldering unit.

It is strongly recommended to use ball valves as shut-off valves when mounting the gearbox, as they are the most acceptable.

In order to avoid unforeseen situations, it is better to follow the sequence of steps indicated below exactly:

- Make sure the water supply is securely shut off.

- Check out the gearbox. Install plugs on the side holes (the holes are intended for the subsequent placement of pressure gauges).

- At the inlet, after the main shut-off valve, install a filter.

- Install a non-return valve (eliminates return flow in the absence of pressure in the system).

- Fix the first shut-off valve.

- Install the pressure regulator so that the plug that determines the position of the pressure gauge is at the top. After the regulator, it is necessary to leave a straight section of pipe with a length of at least 5 working diameters. This will help stabilize the work of the RFE.

- Install a second shut-off valve.

- Next, a water meter is connected and further wiring is arranged.

All threaded connections must be tight. For this, tow is used with the addition of glue (FUM tape)

It is important not to overtighten the nuts. They are made of brass

If overloaded, they may burst.

In principle, the scheme for including the RFE in the water supply system of the apartment, in a simplified form, looks like the one shown in the photo below:

Scheme of connecting pressure reducers to the apartment's water supply system: 1- mechanical coarse filter; 2 - check valve; 3 - DHW and cold water meters; 4 - washing filter; 5 - pressure reducer

However, for ease of operation and adjustment of the reducer, it should be placed between two shut-off ball valves, as shown in the following figure.

All installed elements must be fixed in accordance with the direction of the water flow. The arrow on each product will prevent mistakes.

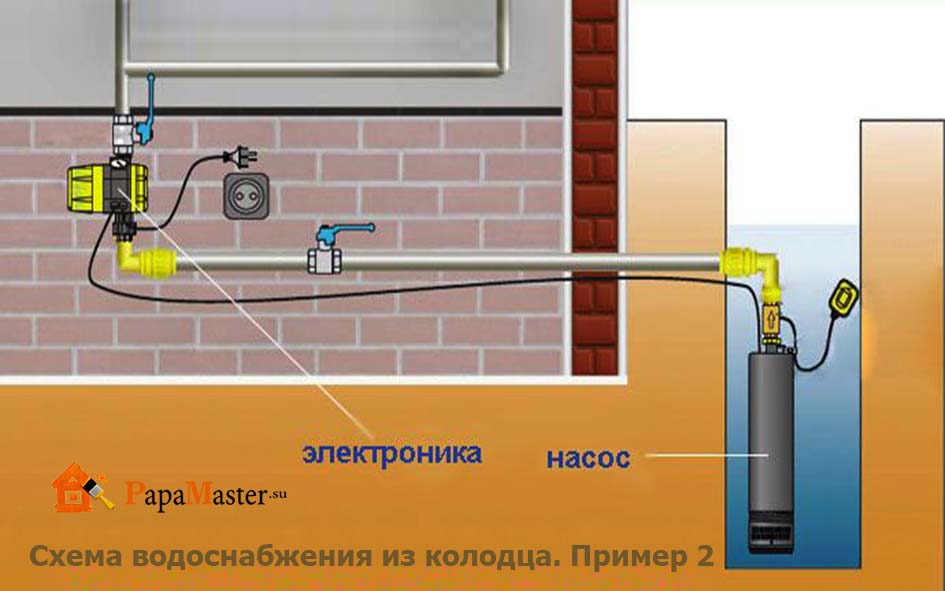

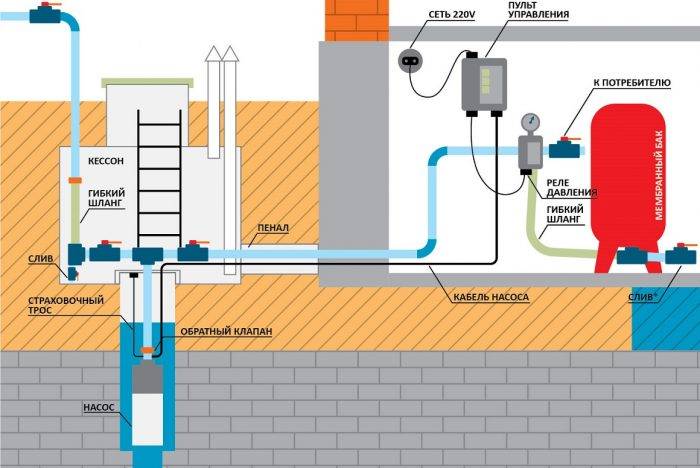

In a private house

With autonomous water supply at home, one should take into account the fact that an electric pump is included in the plumbing system to maintain the required pressure. Water intake is carried out from a well.

Pressure surges during pump operation inevitable, therefore, in order to normalize the functioning of the water supply network and protect household appliances, a pressure reducer is simply necessary.

If we proceed from the fact that the piping around the house has not yet been completed, then the task of installing the WFD comes down to preparing tools, plumbing components, and directly to installation.

You will need:

- wrenches,

- filter,

- check valve,

- reducer,

- tow,

- adhesive composition (FUM tape).

Having determined the location of the devices, you can get to work. Connect to the pipeline coming from the pump:

- filter;

- check valve;

- reducer on a horizontal section of the pipe, so that the pressure gauge is in the upper position.

Installation of devices must be made in accordance with the watercourse. Next is the rest of the wiring.

If a private house is connected to a centralized water supply, then the WFD is placed at the entrance to the building after the filter, before the water meter.Often, Vodokanal employees categorically disagree with such an installation sequence, despite the regulatory rules.

Alternatively, the gearbox can be installed after the metering unit. In this case, its prevention is facilitated by free access.

In the first case, the water supply organization can seal the pressure regulator.

Types of water regulators

Depending on the throughput, the relay can be domestic (0.5-3 m3), commercial (3-15 m3) or industrial (over 15 m3). For greater efficiency, the element is used in conjunction with pressure gauges, coarse filters, shut-off valves and ball valves. The main difference between water pressure regulators in the water supply system lies in the design features.

Piston

The composition has a characteristic element - a piston. It takes root lived, and in the closed position completely closes the inlet (outlet) holes. The principle of operation of a piston-type pressure regulator is that when the pressure changes, the piston stabilizes this parameter automatically. There is a valve for adjustment. It is used to set up and check performance.

Membrane

The locking element is a spring-loaded membrane installed in a special hermetic chamber. After its operation, the force is transferred to the valve, which shuts off the flow. A complex device makes products of this type more expensive than piston ones. The membrane can be damaged not only by the stem and spring, but also by rust. To prevent this from happening, you need to install a coarse filter or a shut-off valve with a strainer at the inlet.

Flowing

The essence of the work is that the incoming stream is divided into several small ones, which rush through special channels. Then they merge together, forming a new one, but not so powerful. Plus - the absence of mechanical components, and as a result, durability. The downside is a lower degree of control, and in some cases it is necessary to install an additional water reducer.

Automatic

There is also a membrane here, but there are already two springs. The essence of the work is that when the pressure in the automatic regulator drops, it weakens, and when it rises, the pressure increases. This mechanical action closes or opens the contacts. As a result, the circulation pump is turned on or off. The device is applicable in forced water supply systems.

Electronic

The main difference is the fluid motion sensor. The device is controlled by a digital block that determines when to turn on the pump. All information about operating parameters is displayed. There are control buttons nearby. The task of the device is not only to protect the system from surges, but also to maintain a constant pressure in the system. The only drawback of such devices is the price due to the complexity of the device.