- Classification of gas regulators

- Principle of operation

- Mounting Features

- Types of working gas

- Housing color and regulator type

- Gas setting and regulation

- Rating of the best models

- For private houses

- Honeywell D04FM-¾A - Universal

- Honeywell D06FM

- OR0232 and OR0233

- Models of water pressure regulators for apartments

- WATTS DRVN and HEIZ 1268221

- CALEFFI 5330

- VALTEK

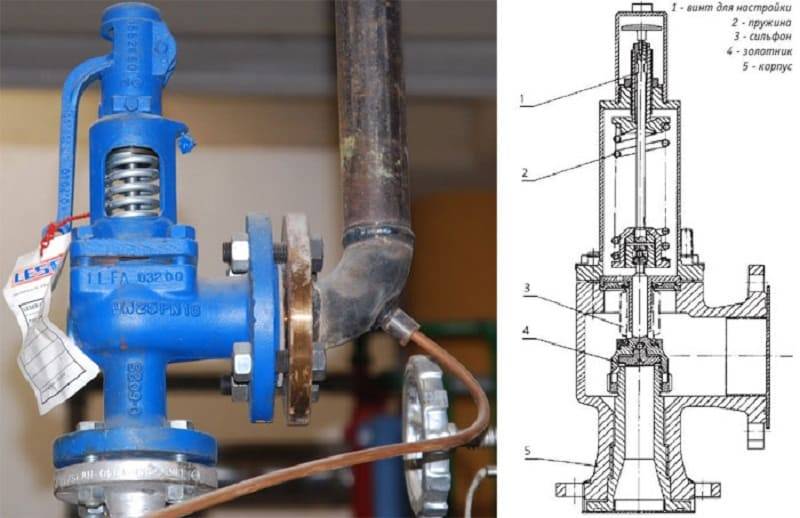

- Design and types

- What is a low pressure gas reducer for?

- Gas connection

- What is a pressure regulator

- At what time of the year can a gas tank be installed?

- On what principle does the device work?

- Butane

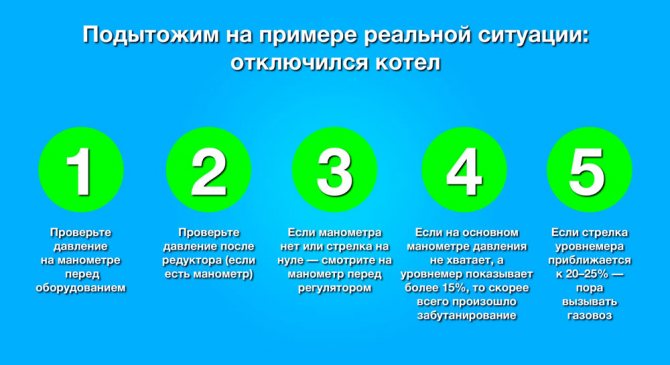

- Let's summarize on the example of a real situation: the boiler turned off

- Instructions for replacing the regulator

- Setting the pressure level

- Water pressure switch adjustment

- How to determine relay thresholds

- Setting the water pressure switch for a pump or pumping station

- Application of gas reducers

- Regulator operation in different modes

- Conclusions and useful video on the topic

Classification of gas regulators

Before using a pressure reducer, you should familiarize yourself with its varieties and the main parameters by which these devices are classified.

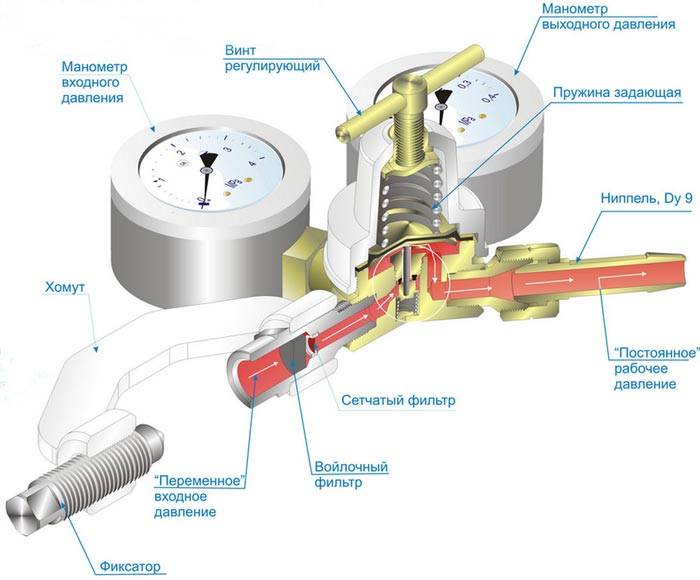

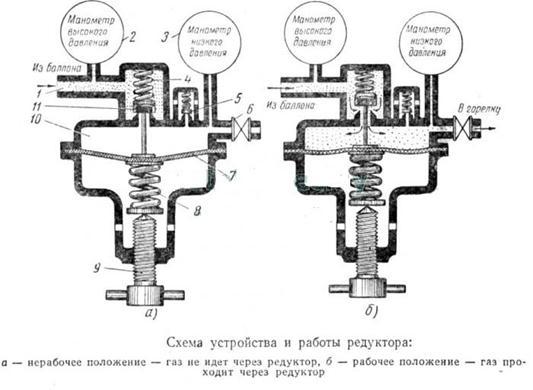

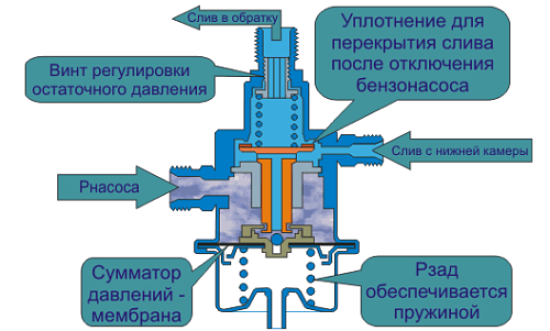

Principle of operation

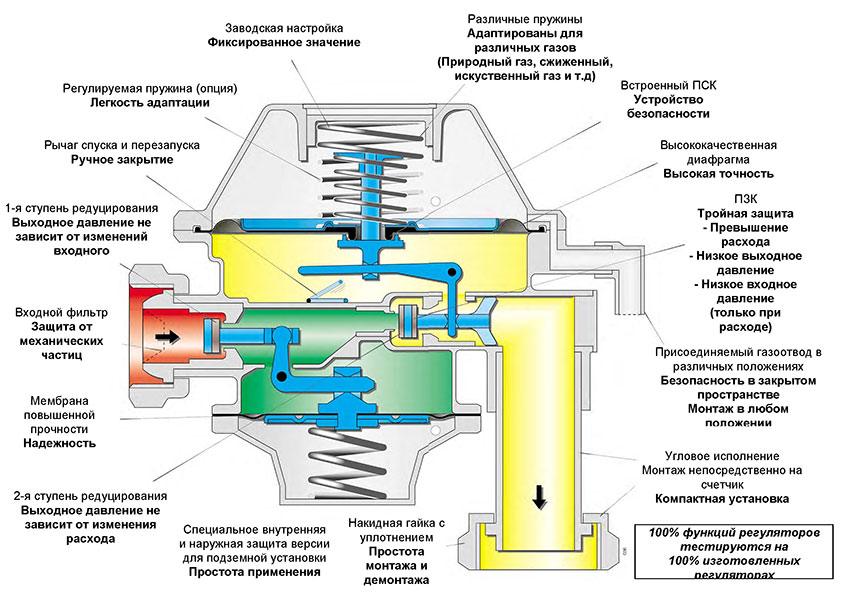

According to the principle of operation, gas appliances are of direct and reverse type.

According to the principle of operation, gas appliances are of direct and reverse type.

In direct-type gearboxes, the gas passing through the fitting acts on the valve with the help of a spring, pressing it to the seat, thereby blocking the entry of high-pressure gas into the chamber. After the valve is squeezed out from the seat by the membrane, the pressure gradually decreases to the operating level of the gas appliance.

The principle of operation of the reverse type device is based on compressing the valve and blocking further gas supply. With the help of a special adjustable screw, the pressure spring is compressed, while the membrane is bent, and the transfer disc acts on the return spring. The service valve is lifted and the flow of gas to the equipment is resumed.

When the pressure of the system (cylinder, reducer, working equipment) increases in the reducer, the membrane is straightened with the help of a spring. The transfer disc, going down, acts on the return spring and moves the valve to the seat.

It should be noted that domestic reverse-acting gas cylinder reducers are safer.

Mounting Features

By positioning and installation features, the devices are divided into ramp, network and balloon.

By positioning and installation features, the devices are divided into ramp, network and balloon.

Ramp gas regulators are needed to reduce and stabilize the pressure level of gas supplied by a single source. Devices tend to lower the working pressure of the gas supplied from the central line or a number of sources. They are used for large volumes of welding work. Network stabilizers hold the low pressure value of the gas supplied from the distribution manifold.

Types of working gas

The specifics of operation, as well as the method of connecting the pressure regulator to the source, depend entirely on the properties of the working gas. According to the material used, the devices are as follows:

The specifics of operation, as well as the method of connecting the pressure regulator to the source, depend entirely on the properties of the working gas. According to the material used, the devices are as follows:

acetylene (A);

propanobutane (P);

oxygen (K);

methane (M).

Devices working with acetylene are fixed with a clamp and a stop screw, while for others they use a union nut with a thread identical to the thread of the fitting at the valve.

Housing color and regulator type

Propane regulators are painted red, acetylene regulators are white, oxygen regulators are blue, and carbon dioxide regulators are black. The body color corresponds to the type of working gas medium.

Pressure stabilization devices are available for both flammable and non-flammable media. The difference between them lies in the direction of the thread on the cylinder: in the first it is left-handed, in the second it is right-handed.

Gas setting and regulation

The working mechanism contains a regulating element in the form of a sensitive device for comparing the pulses of the generator and the indicator of the coordinated pressure. The node receives the command, sets the control gate in motion due to the action of the working environment.

Depending on the type of regulation, gearboxes are distinguished:

If the adjustment force is large, the sensing element controls a direct acting regulator using a spring. The energy of the moving gas can also act as a head size generator. The device sends a command to the actuating element in the form of coordinating pressure - such gearboxes are called pilot.

Rating of the best models

The division of the WFD into “for private houses” and “for apartments” is conditional.

The choice of model depends on several factors:

- required differential pressure;

- the number of plumbing consumers;

- multifunctionality;

- equipment cost and reliability.

Therefore, we will consider the best options for houses and apartments based on its throughput or throttle section size.

For private houses

Let's analyze the most popular models.

Honeywell D04FM-¾A - Universal

Membrane design, equipped with a manometer outlet, materials: body - DZR brass, LSTR membrane. Adjustment range 1.5-6 bar, temperature up to 70°C.

Advantages:

- increased operational resource,

- suitable for hot and cold water supply,

- convenient pressure adjustment,

- double thread: ½" female or ¾" male.

Flaws:

- rather high cost - overpayment for a global brand - from 2.6 thousand rubles;

- delicate membrane - when adjusting, loosening the fixing screw is required, otherwise the diaphragm may break through.

Honeywell D06FM

Improved modification. This valve has an integrated filter element.

It has two varieties:

- D06FM A - with transparent polymer bulb (cold water supply: up to 40 °C)

- D06FM B - solid brass (up to 60 °C).

The design is equipped with convenient adjustment - it allows you to fine-tune without using a pressure gauge. Also, unlike other analogues, it is designed with two outlets for connecting a pressure gauge, located below and on the side.

Of the shortcomings:

- Over time, the adjustment of the adjustment divisions does not correspond to the actual one.

- High price - about 4 thousand rubles.

OR0232 and OR0233

Piston variations of powerful and compact regulators.

Adjustment with a key, equipped with an input for connecting pressure gauges, have small dimensions.

The difference between these modifications lies in the limiting inlet pressures: the dimensions of the chamber and piston are different, so 0232 works with a value of no more than 16 bar, and 0233 is limited to an inlet pressure of 25 bar.

Also, OR 0233 is equipped with two holes for connecting pressure gauges: from below and from the side.

Advantages:

- Small dimensions, durability and operation up to 130 С° (cold and hot water supply).

- It is used where lowering from high pressure values is required - it is optimal for private houses.

- Relatively low cost - no more than 1.5 thousand rubles.

Since the regulator is a piston type, it has the disadvantages of this design: installation in only one position (vertical piston), leakage through the sealing rings, the risk of jamming during water hammer.

Models of water pressure regulators for apartments

Below is an overview of the best representatives in this category.

WATTS DRVN and HEIZ 1268221

Decent regulators for apartment buildings. These analogues have a similar design with HONEYWELL D06FM:

- adjusting knob with adjustable pressure scale,

- convenient location for connecting the pressure gauge.

However, the throughput values are somewhat lower, which is quite sufficient for individual apartments.

CALEFFI 5330

With replaceable cartridge and removable strainer. The body of the device is made of CW602N brass, resistant to washing out.

The adjustment is made using a key with the obligatory installation of a pressure gauge.

The design of the device is very practical, convenient for the prevention and replacement of the internal mechanism.

The inclined housing contains a replaceable membrane cartridge, equipped with a mesh filter. The mechanism and mesh can be easily removed and simply cleaned.

Advantages:

- small sizes, are made in different modifications: with and without a pressure gauge, for internal and external threads;

- it is possible to install on a copper tube.

The disadvantage lies in the advantage: if the adjustment mechanism fails, an original repair kit is required.

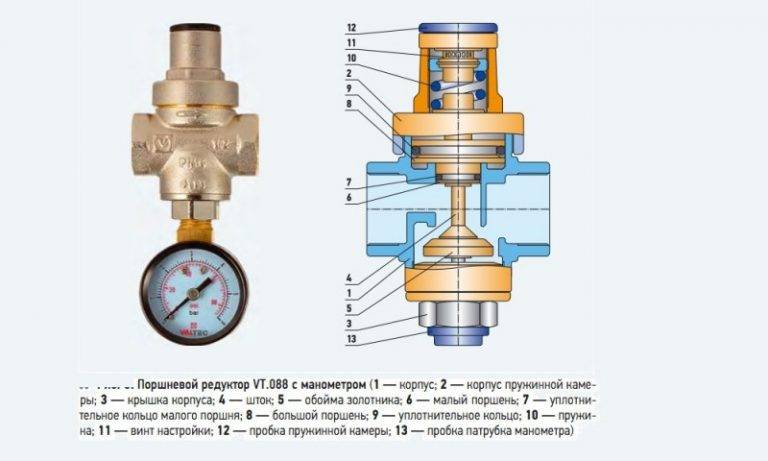

VALTEK

The St. Petersburg company specializes in piston and diaphragm gearboxes. All models are made in Italy (good quality), except for VT.298.N and VT.082.N which are made in China.

However, the latter have their advantages - multifunctionality and compact size. In addition, VT.082.N has a convenient knob adjustment - keep in mind that it is fixed at 2 and 3 bar.

Product advantages:

- varied assortment;

- acceptable quality

- affordable price.

Among the shortcomings, one can single out the use of an “outdated” material: brass, which does not have an increased ability to wash out deposits.

A detailed review of Valtec gearboxes in our article.

Design and types

Propane (CH3)2CH2 is a natural gas with a high calorific value: at 25°C, its calorific value exceeds 120 kcal/kg

At the same time, it should be used with special precautions, since propane is odorless, but even at its concentration in air of only 2.1% it is explosive

It is especially important that being lighter than air (the density of propane is only 0.5 g / cm3), propane rises, and therefore, even at relatively low concentrations, is a danger to human well-being

A propane reducer must perform two functions - to provide a strictly defined pressure level when any device is connected to it, and to guarantee the stability of such pressure values during further operation.Most often, gas welding machines, gas heaters, heat guns and other types of heating equipment are used as such devices. This gas is also used for the propane cylinder of a car running on liquefied fuel.

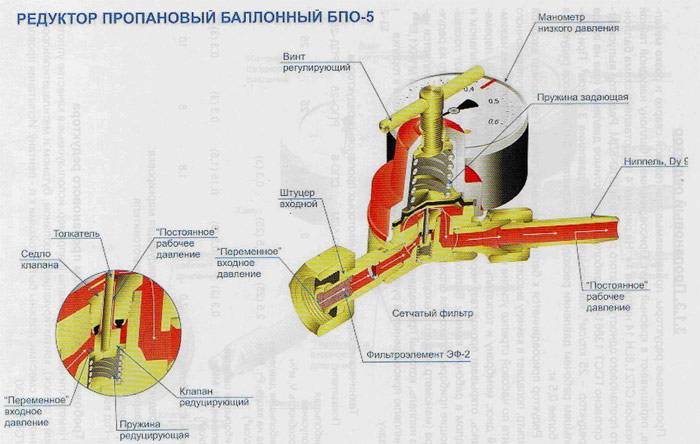

There are two types of propane reducers - one- and two-chamber. The latter are used less frequently, since they are more complex in their design, and their distinctive ability - to consistently reduce the gas pressure in two chambers - is used in practice only with increased requirements for the permissible level of pressure drops. BPO 5-3, BPO5-4, SPO-6, etc. are considered common models of gearboxes. The second digit in the symbol indicates the nominal pressure, MPa, at which the safety device is triggered.

Structurally, a single-chamber propane reducer of the BPO-5 type (Balloon Propane Single-chamber) consists of the following components and parts:

- Corps.

- pusher.

- Valve seat.

- Reducing spring.

- membranes.

- Reducing valve.

- Connecting nipple.

- Inlet fitting.

- setting spring.

- mesh filter.

- pressure gauge.

- Adjusting screw.

The main technical characteristics of propane reducers are:

- Maximum throughput in terms of gas volume per unit of time, kg / h (marked with a number located immediately after the letter abbreviation; for example, a propane reducer of the BPO-5 type is designed to pass no more than 5 kg of propane per hour);

- Maximum inlet gas pressure, MPa. Depending on the size of the device, it can be in the range from 0.3 to 2.5 MPa;

- Maximum output pressure; in most designs, it is 0.3 MPa, and adapted to the same indicator for a gas-consuming unit.

All manufactured propane reducers must fully comply with the requirements of GOST 13861.

What is a low pressure gas reducer for?

In the conditions of our harsh climate, in order to maintain a comfortable temperature in the winter and the smooth functioning of gas equipment throughout the year, it is necessary to take care of a number of problems. Gas mixtures have a number of physical properties. The owner, when purchasing fuel, must take into account precisely these properties. Usually, in the cold season, more propane is used, so you need to buy LPG, in which the percentage of propane is higher.

Complete with a gas appliance, there must be a passport for this device, which specifies the minimum operating pressure at which the equipment will operate in normal mode. If there is a lack of pressure, the gas stops flowing into the device, or it flows intermittently, which can be dangerous.

Low pressure gas reducers are designed to stabilize the gas pressure to a working state, regardless of the change in the pressure of the gas mixture in the gas pipeline or cylinder. They can also be equipped with the function of a pressure relief valve, reducing the pressure of a gas mixture or gas.

The reducer is installed at the inlet, regulating the flow of gas into the system, and the valve at the outlet of the system, providing relief from excessive pressure. This approach gives the whole system stability.

Gas connection

If you are an amateur, your actions can lead to a serious accident.

What you should pay attention to when connecting to the gas supply:

- installation of shut-off valves - a gas valve that will shut off the supply;

- a gas filter is installed behind the tap according to the relevant standards;

- through the filter, a pipe from the boiler, strictly metal, is connected to the line. It is preferable to use a flexible corrugated stainless steel pipe in this capacity;

- the pipe is connected to the corresponding boiler nozzle using a union nut with a paronite seal;

- the joints of the elements must be hermetically sealed. To seal these areas, tow and paint or their modern counterparts are used. Synthetics are excluded.

To check the tightness of the gas connection, the connections are moistened with soapy water and look for bubbles.

What is a pressure regulator

The pressure regulator is a small device that is used to deal with water hammer. It can also be used to control and, if necessary, adjust the water pressure in a particular system. The use of this device allows you to optimize the work and increase the service life of engineering communications. Often, a pressure reducer is used at such facilities:

- skyscrapers;

- work shops;

- technological facilities;

- residential buildings.

Devices used to adjust the pressure in the system are divided into dynamic and static products. The first type is used in main pipelines in industrial enterprises. They allow you to regulate the flow of fluid in systems. As for statistical products, they are installed in pipelines with unstable water supply.That is why statistical gearboxes are used in multi-storey and country houses.

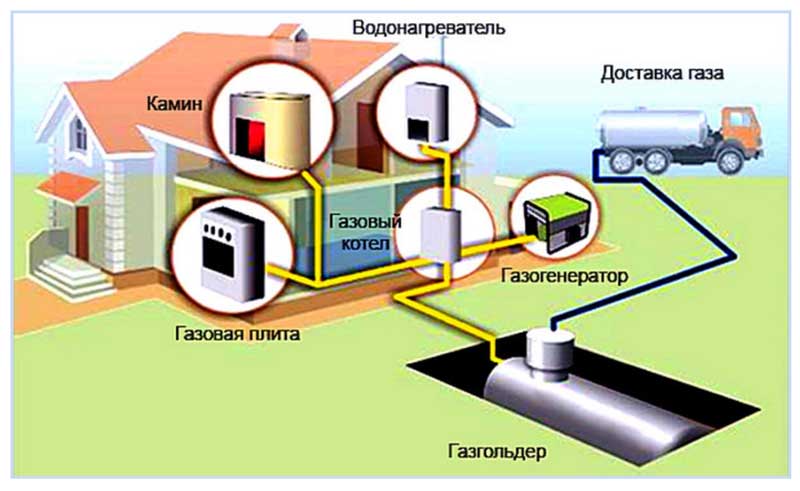

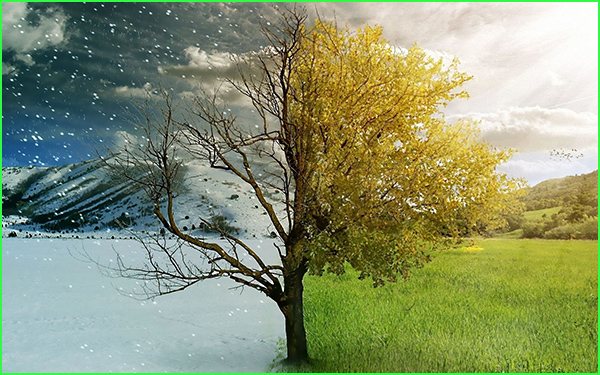

At what time of the year can a gas tank be installed?

At any.

When it comes to autonomous gasification of private farmsteads (cottages, country houses, dachas), we mean the installation of a horizontal type underground gas tank in conjunction with a set of other works that fully ensure the concept of "turnkey work".

And not only imply.

strongly recommends just such a configuration when implementing the project "from" and "to" by the company.

For the optimal functioning of an autonomous gas supply, it is necessary to create conditions under which the system will be constantly in favorable environmental temperature conditions.

This is possible when below the freezing level of the soil.

Consequently, there is a large amount of excavation to be done:

- a pit for a gas tank;

- trenches for the pipeline.

What time of year is best for digging?

Of course, warm - spring-autumn.

Two more arguments in favor of summer jobs:

- The quality of the concrete cushion on which the tank is to be based is important. Concrete hardens and is responsive to pre-tamping only at positive temperatures.

- The gas main from the tank to the house is made of plastic pipes, the joints of which are welded with a special tool. The ambient temperature for this type of work is standardized by the technical specifications.

At the same time, the cold season is not an obstacle for the installation of autonomous gasification. Why wait for the onset of spring if you decide to order a SAG when a blizzard howls outside. Enjoy comfort right away.

We carry out work at a temperature of minus 40.

And our people are hardened, with experience in working in the conditions of the north, and the equipment is appropriate for solving such problems.

When professionals get down to business, the time of year does not matter in the slightest.

Order at least in the summer, even in the winter.

Enjoy the warmth!

On what principle does the device work?

The temperature of the antifreeze should rise to 40. The operation of the gas reducer is possible only after the machine has warmed up well. How does a gas reducer work on a car?

- Liquid gas from the tank enters the filter and is cleaned. There it is while the solenoid valve is closed.

- The fuel then passes through the 1st stage valve seat and turns into steam. The membrane under its pressure pulls the rocker of the valve, it falls on the seat and the gas flow stops. So get a working pressure of 0.4 atm. It is adjusted by a spring mechanism.

- Automotive gas fuel moves further to the 2nd stage valve seat. Then, through the outlet fitting, the fuel goes to the engine.

Butane

The mixture is many times more thermally conductive than propane. Before filling with gas, check the temperature standards. Butane is considered a cheaper gas, one of its varieties is C4H10. It differs from other gases only by low elasticity, so it can only be used at positive temperatures. This criterion seriously affects the vaporization of LPG in the natural environment. To ensure such indicators, the tank can be installed underground. Actual in the conditions of private and country houses.

Butane (C4H10)

- cheaper gas, but differs from propane in low vapor pressure, therefore it is used only at positive temperatures. The boiling point of butane at atmospheric pressure is minus 0.5°C.

The gas temperature in the tanks of the autonomous gas supply system must be positive, otherwise the evaporation of the butane component of the LPG will be impossible. To ensure gas temperatures above 0°C, geothermal heat is used: a gas tank for a private house is installed underground.

Let's summarize on the example of a real situation: the boiler turned off

- Check the pressure on the pressure gauge upstream of the equipment. If the pressure is normal (from 37 mbar) - the reason is the breakdown of the boiler. We need to call the repairmen. If there is no pressure, we move along the chain to the next point.

- Check the pressure after the reducer (if there is a pressure gauge). If everything is in order here, then the gas pipeline is clogged: the condensate collector is full, a plug has formed, the condensate has frozen in the basement inlet. Call experts for cleaning, blowing.

- If there is no pressure gauge or the arrow is at zero, look at the pressure gauge in front of the regulator. There must be at least 1.5 bar, otherwise the gearbox will not work. Is the pressure normal? So the problem is in the gearbox - most likely frozen. Call specialists to turn off the gas, remove, warm up and purge the regulator.

- If there is not enough pressure on the main pressure gauge, and the level gauge shows more than 15%, then most likely there has been clogging. Most of the propane is used up, and butane cannot provide the necessary pressure in cold weather. Order a delivery of propane-rich winter formula.

- If the pointer of the level gauge approaches 20–25%, it is time to call the gas carrier. Less than 15% of the liquid phase cannot be left.

Result: after checking the main points, you find the cause of the outage and take the necessary measures. In three cases, the intervention of maintenance specialists will be required, in the rest, a tanker truck with LPG will be called.

During normal use, monitor the level of the liquid phase during filling - no more than 85%. And call the gas carrier when the LPG level drops to 20-25%.

At the same time, check the pressure gauges. Such control will be enough to detect a malfunction in time. The remaining nodes are inspected by technicians during regular maintenance.

Manufacturers recommend checking the operation of the system annually. And once every 8 years, call specialists for a deeper control with an assessment of the coating, seams and the general condition of the gas tank.

How it works for us

When installing a gas tank, we conclude a contract for a year of free service. List of services: 2 preventive specialist visits (in winter and autumn) + one urgent emergency call within 24 hours. Then the service contract can be extended.

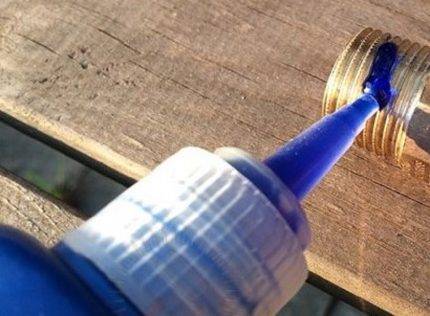

Instructions for replacing the regulator

Two-stage reducers are connected to the vapor recovery valve with a threaded fitting and a union nut. The type of thread at the inlet of the reducer depends on the type of thread at the outlet of the valve.

If the nature of the connection was not taken into account at the time of purchase, an appropriate adapter will be required. The connection of the device with the gas hose is carried out through a threaded outlet on the reducer, using an adapter or a union nut.

A gas wrench is required to replace the stabilization device. If the connection is rusted, then two adjustable gas wrenches will be needed to remove the gearbox.

Replacing or repairing a gas reducer is more often done in winter, when the resulting condensate freezes at the junction of the valve and the reducer. To prevent such problems, it is necessary to provide electric heating at the stage of installation of the gas system.

Replacing or repairing a gas reducer is more often done in winter, when the resulting condensate freezes at the junction of the valve and the reducer. To prevent such problems, it is necessary to provide electric heating at the stage of installation of the gas system.

To replace the gas reducer, you must perform the following sequence of work:

- Shut off the gas supply with the valve located on the gas vapor phase selection valve.

- Unscrew the metal hose.

- Unscrew the union nut connecting the valve and stabilizer.

- Remove gearbox with connecting hose.

- If the stabilizer is beyond repair, twist the bellows hose.

- After cleaning the ice, repairing or replacing, the regulator should be screwed to the complex valve with a nut.

- If the device was disconnected from the supply, it is necessary to gradually connect the gas hose, first to the reducer, then to the line.

- After fixing the connections, you can turn on the gas supply.

When starting fuel into the system, after replacing the fittings, it is necessary to check the outlet pressure, it must be within acceptable limits and be suitable for the operation of the heater, stove or boiler.

When properly installed and under normal operating conditions, the regulator will typically last at least 10 years.

For high-strength sealing of threaded connections, it is recommended to use a blue anaerobic sealant. The material should not be used at low temperatures due to the increased cure time, but if the joints are processed in the summer, they can be 100% sealed.

For high-strength sealing of threaded connections, it is recommended to use a blue anaerobic sealant. The material should not be used at low temperatures due to the increased cure time, but if the joints are processed in the summer, they can be 100% sealed.

You can diagnose problems with the stabilizer using a level gauge and pressure gauge on the tank.If the devices show that there is enough gas, but there are interruptions in the network, then one of the problems with the gearbox is to blame.

In this case, the device can be disassembled and dried. This will help solve the problem, but temporarily. If you install a new gearbox and protect the device from moisture, you can forget about interruptions in the system.

In order to avoid possible problems with the gearbox in the future, it is also important to take care of the correct installation of the gas tank on the site. You can read about how to do it right here.

Setting the pressure level

After installing the device it is adjusted in order to set the required pressure. This procedure is carried out at zero water consumption. Therefore, it is necessary to close the inlet valve and open the outlet valve. The gearbox has an adjusting screw. The device is equipped with a special key, with which the adjustment is carried out. To increase the pressure in the water supply system, the screw is turned with a key in the clockwise direction. Then it is necessary to slowly unscrew the adjusting screw in the opposite direction until the pressure reaches 3 atmospheres.

The device is installed immediately after the water flow meter, if any. In the absence of a water meter, the unit is mounted before the first branching of the water supply system. If there is no coarse filter at the inlet of the water supply, then it is mandatory to install it in front of the gearbox.

The reducer is an automated device for the water supply network. There are no specific requirements for its maintenance and care. You need to configure it 1 time after installation.During further operation, once every six months, you can independently adjust the pressure if necessary. Depending on the quality of the incoming water, the device will need to be removed once a year or 2 years and cleaned with water pipe products that dissolve salt accumulations. You can also add oil to the hole under the adjustment bolt to make the valve work efficiently. When choosing a device that stabilizes the pressure of water in the water supply system, preference should be given to well-known manufacturers. It is desirable that a pressure gauge be included in its design.

Read also:

Water pressure switch adjustment

Consider the process of adjusting the most popular instance - RDM-5. It is produced by different factories. Adjustment limits vary, as different sizes of water pipes require different pressures. This device leaves the factory with a basic setting. Usually it is 1.4-1.5 atm - the lower threshold and 2.8-2.9 atm - the upper threshold. If you do not like some parameter, you can reconfigure it as required. Such a procedure is usually necessary when installing a hot tub: a standard pressure of 2.5-2.9 atm is not enough for the desired effect. In most other cases, reconfiguration is not required.

The RDM-5 water pressure switch has two springs that regulate the pump off / on threshold.

These springs differ in size and purpose:

- large regulates the limits (immediately upper and lower);

- a small one changes the delta - the gap between the upper and lower borders.

The parameters are changed when tightening or loosening the nuts on the springs.If you tighten the nuts, the pressure increases, if you loosen it, it drops. There is no need to turn the nuts strongly one turn - this is a change of about 0.6-0.8 atm, and this is usually a lot.

How to determine relay thresholds

The threshold for turning on the pump (and the lower pressure threshold on the water pressure switch) are related to the pressure in the air part of the accumulator - the minimum pressure in the system should be 0.1-0.2 atm higher.

For example, if the pressure in the tank is 1.4 atm, the shutdown threshold is 1.6 atm.

With these parameters, the tank membrane will last longer.

Shutdown thresholds depend on system components

The upper threshold - pump shutdown - is set automatically during adjustment. The relay in the initial state is set to some kind of pressure difference (delta). This difference is usually 1.4-1.6 atm. So if you set the switch on, for example, to 1.6 atm, the shutdown threshold will be automatically set to 3.0-3.2 atm (depending on the relay settings).

If you need a higher pressure (to raise water to the second floor, for example, or the system has many draw-off points), you can increase the shutdown threshold.

But there are limitations:

- The parameters of the relay itself. The upper limit is fixed and in household models usually does not exceed 4 atm. It just won't work anymore.

- The upper limit of the pump pressure. This parameter is also fixed and the pump must be turned off at least 0.2-0.4 atm before the declared characteristic. For example, the upper pressure threshold of the pump is 3.8 atm, the shutdown threshold on the water pressure switch should not be higher than 3.6 atm. But in order for the pump to work for a long time and without overloads, it is better to make a larger difference - overloads have a too bad effect on the lifespan.

Setting the water pressure switch for a pump or pumping station

To set up the system, you will need a reliable pressure gauge, the readings of which can be trusted. It is connected to the system near the pressure switch.

The adjustment process consists in twisting two springs: large and small. If you need to raise or lower the lower threshold (turn on the pump), turn the nut on the large spring. If you turn it clockwise, the pressure rises, counter-clockwise - it falls. Turn by a very small value - half a turn or so.

The water pressure switch is adjusted using springs

The sequence of actions is as follows:

- The system is started, the pressure gauge monitors at what pressure the pump turned on and turned off.

- Press or release the large spring.

- They turn on and check the parameters (at what pressure it turned on, at what pressure it turned off). Both values are shifted by the same amount.

- If necessary, make adjustments (adjust the large spring again).

- After the lower threshold is set the way you want to see it, proceed to adjust the pump shutdown threshold. To do this, press or lower a small spring. Do not turn the nut on it too much - half a turn is usually enough.

- Turn the system back on and look at the results.

Application of gas reducers

Reducers are used where it is necessary to reduce excess inlet pressure and stabilize the outlet.In everyday life, we meet them in autonomous gas supply systems (this applies to both stationary systems and ordinary gas cylinders), since liquefied gas, in order to remain liquid, must be under a pressure of about 15 bar, and household appliances operate at a pressure of 36 mbar, 20 mbar, or even 10 mbar.

Here is a selection of materials for you:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, firewood, electricity). Do-it-yourself ovens. Heat carrier, radiators, pipes, floor heating, circulation pumps. Chimney cleaning. Conditioning

Reducers are part of the car's gas equipment, since liquefied gas is also used there, the pressure of which must be reduced and stabilized before being supplied to the engine.

Powerful reducers are used to divert natural gas from main pipelines to the gas networks of settlements, since the gas pressure in main networks is much higher than is acceptable for domestic consumers.

Reducers or more advanced devices (gas proportional valves) are used at the gas inlet to heating and welding equipment.

Regulator operation in different modes

If we consider the principle of operation in a simplified way, then it is quite simple. The pump pumps fuel into the rail, from which it also enters the fuel chamber of the regulator. As soon as the pressure force exceeds the spring stiffness, the membrane begins to move towards the vacuum cavity, dragging the valve along with it. As a result, the drain channel opens and part of the gasoline flows into the tank, while the pressure in the rail drops.Because of this, the spring returns the valve with the membrane to its place, and the return channel closes.

But as already mentioned, the RTD adjusts to the mode of operation of the motor. And he does this due to the vacuum in the intake manifold. The greater this rarefaction, the stronger will be its effect on the membrane. Essentially, the vacuum created creates an opposing force on the spring.

In fact, everything looks like this: for the engine to idle, an increase in the amount of fuel is not necessary, and therefore no increased pressure is required.

In this operating mode, the throttle valve is closed, so there is not enough air in the intake manifold and a vacuum is created. And since the vacuum chamber is connected to the collector by a pipe, a vacuum is created in it as well. Under the influence of vacuum, the membrane presses on the spring, so less gasoline pressure is needed to open the valve.

Under load, when the throttle is open, there is practically no vacuum, which is why the membrane does not participate in creating force on the spring, so more pressure is required. Thus, this element functions in the power system, depending on the mode of operation of the motor.

Conclusions and useful video on the topic

This is how the gearbox is adjusted using a differential pressure gauge:

This video shows how to eliminate minimal freezing of condensate in the controller:

How to remove, disassemble and clean the gearbox, as well as prevent it from flooding / freezing will be discussed in the following video:

Pressure reducer for a gas tank, reduces the pressure of blue fuel vapors, maintains its stable value in the engineering network.Each regulator is equipped with a safety relief valve that vents excess gas when the pressure at the fuel outlet rises dangerously from the safety circuit.

Therefore, it is the gearbox that is the main mechanism for preventing emergencies in an autonomous gas supply system.

In the event of a malfunction, you need to know how the device works and how to replace an unusable device. Therefore, the rules for replacing the gearbox will definitely come in handy for owners of private houses who have gasified their houses from a gas tank.

If you had to install, change a gas reducer or adjust the gas pressure in an autonomous system. If you know any subtleties and nuances that arise during the replacement of the stabilizer, be sure to share your experience and relevant photos with readers in the block below.