- We develop a water supply scheme

- Calculations

- The nuances of assembling metal-plastic pipes

- Tips from builders

- How to calculate the diameter of a pipe for a water supply

- Step-by-step work algorithm

- Features of the tee scheme

- How to connect a pumping station

- Care and repair

- Laying methods - hidden and open system

- To hide pipes or not?

We develop a water supply scheme

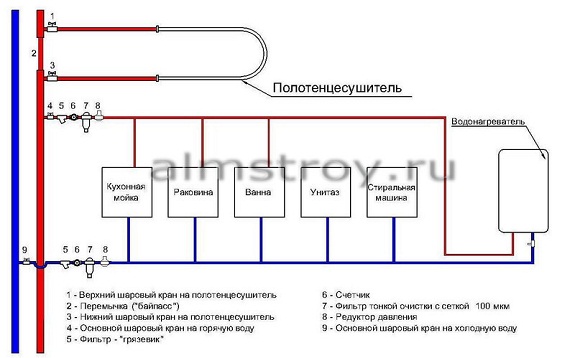

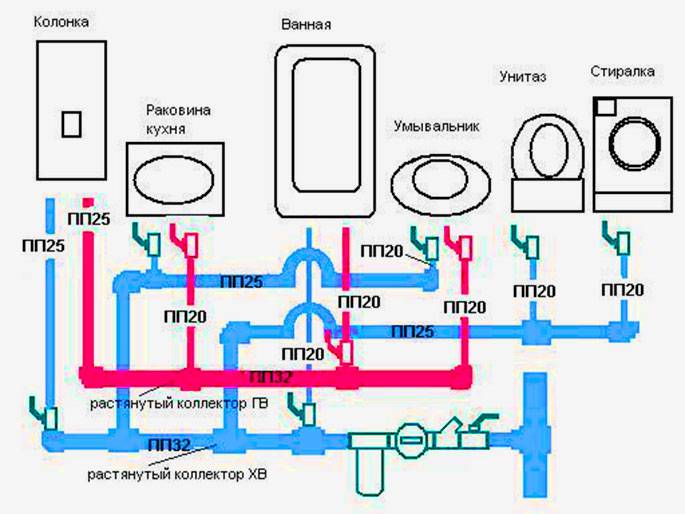

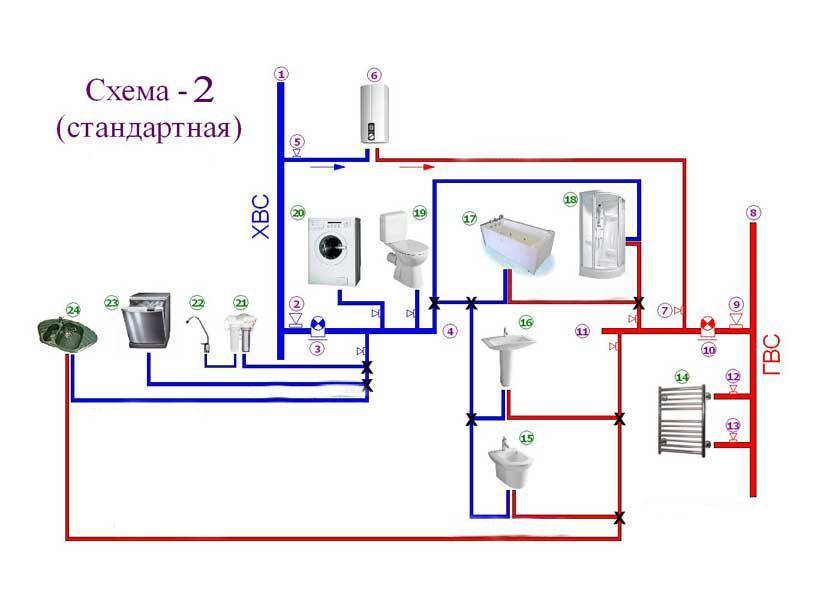

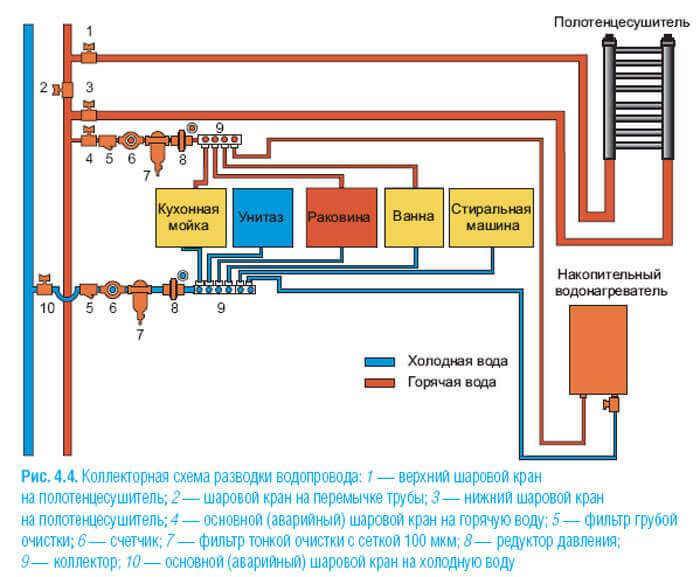

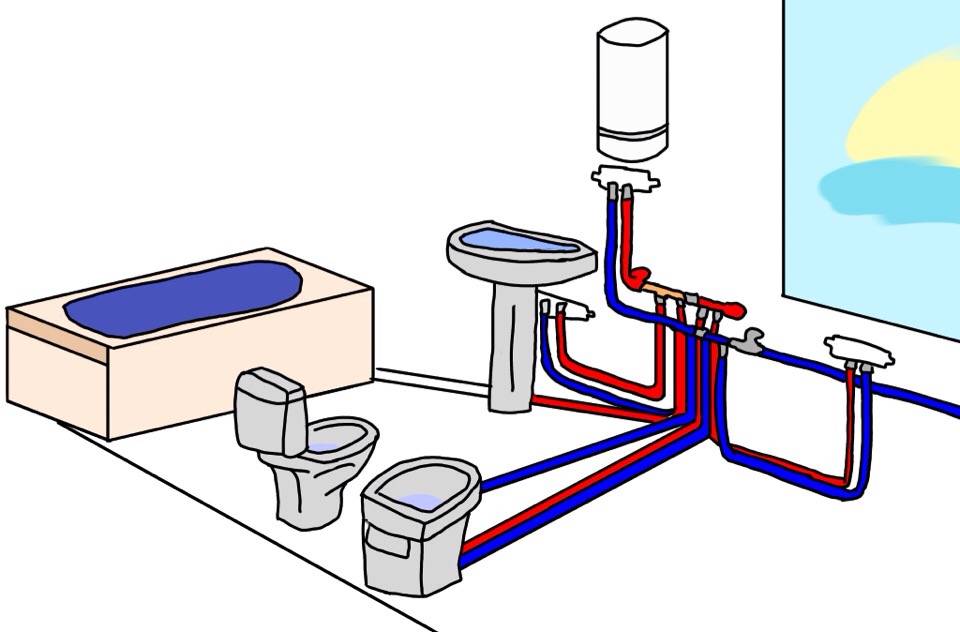

In fact, there are plenty of plumbing schemes, but there are two different methods for connecting consumers:

- Trinity inclusion.

- Collector or parallel connection.

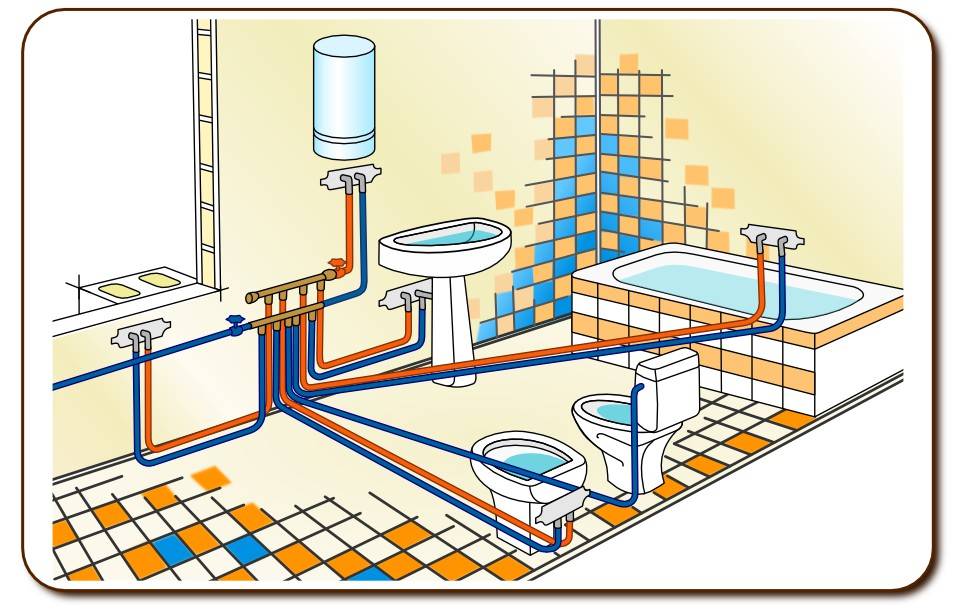

For residents of small private houses, a serial connection will meet their requirements; the plan for such a water supply is simpler. From the source itself, water in order goes from one consumer to the next from one pipeline with a tee outlet (1 inlet, 2 outlets) for each consumer.

Such a switching scheme is characterized by a lack of pressure at the last consumer, during the launch of the previous ones, if several such links are involved in the chain.

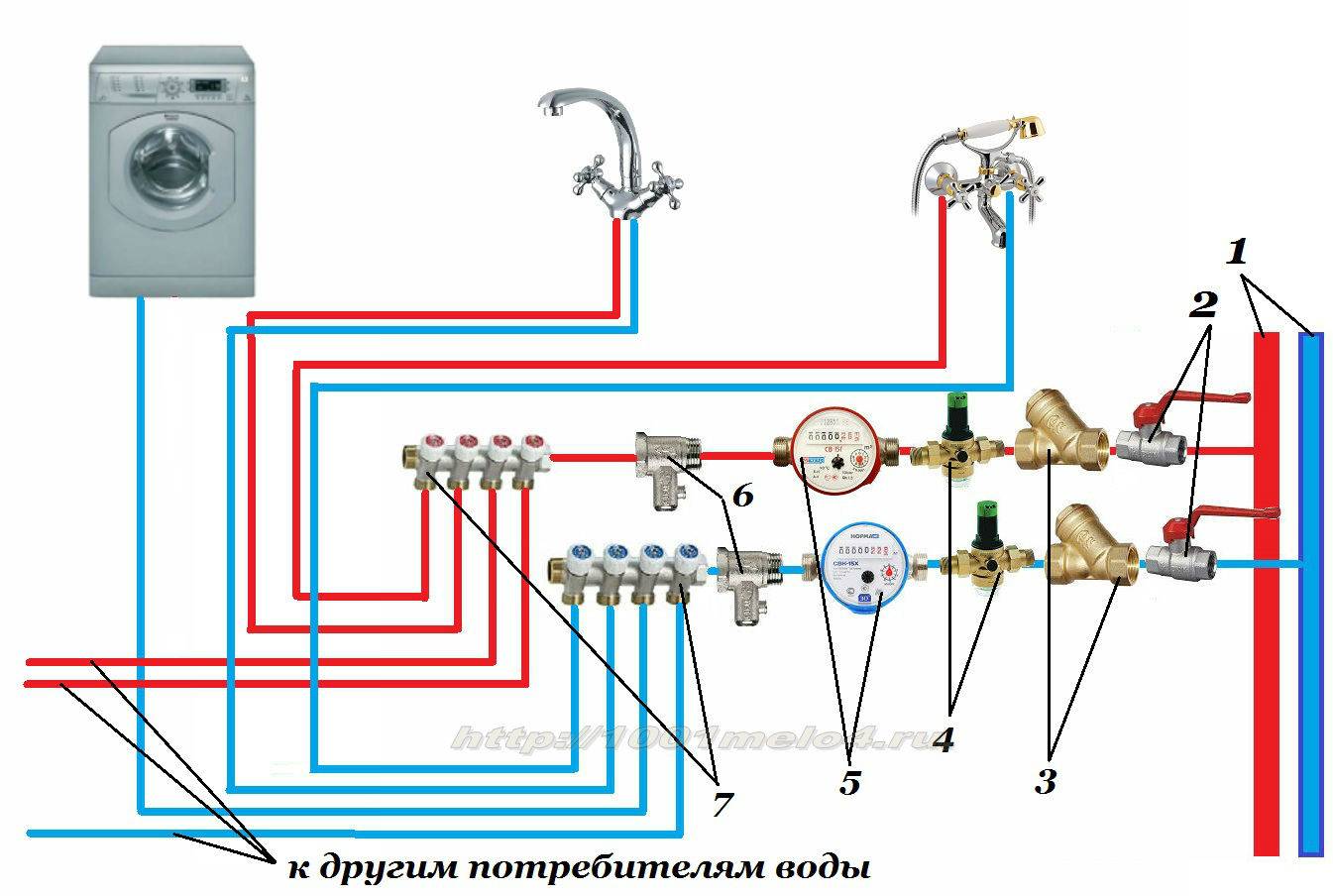

The collector inclusion plan looks fundamentally different.

Firstly, when making such a connection, you will need a collector. From it, a water pipe is laid directly to each consumer.Thanks to this, you will be able to create more or less the same pressure in any link in the pipeline chain.

Please note that serial connection will cost you more.

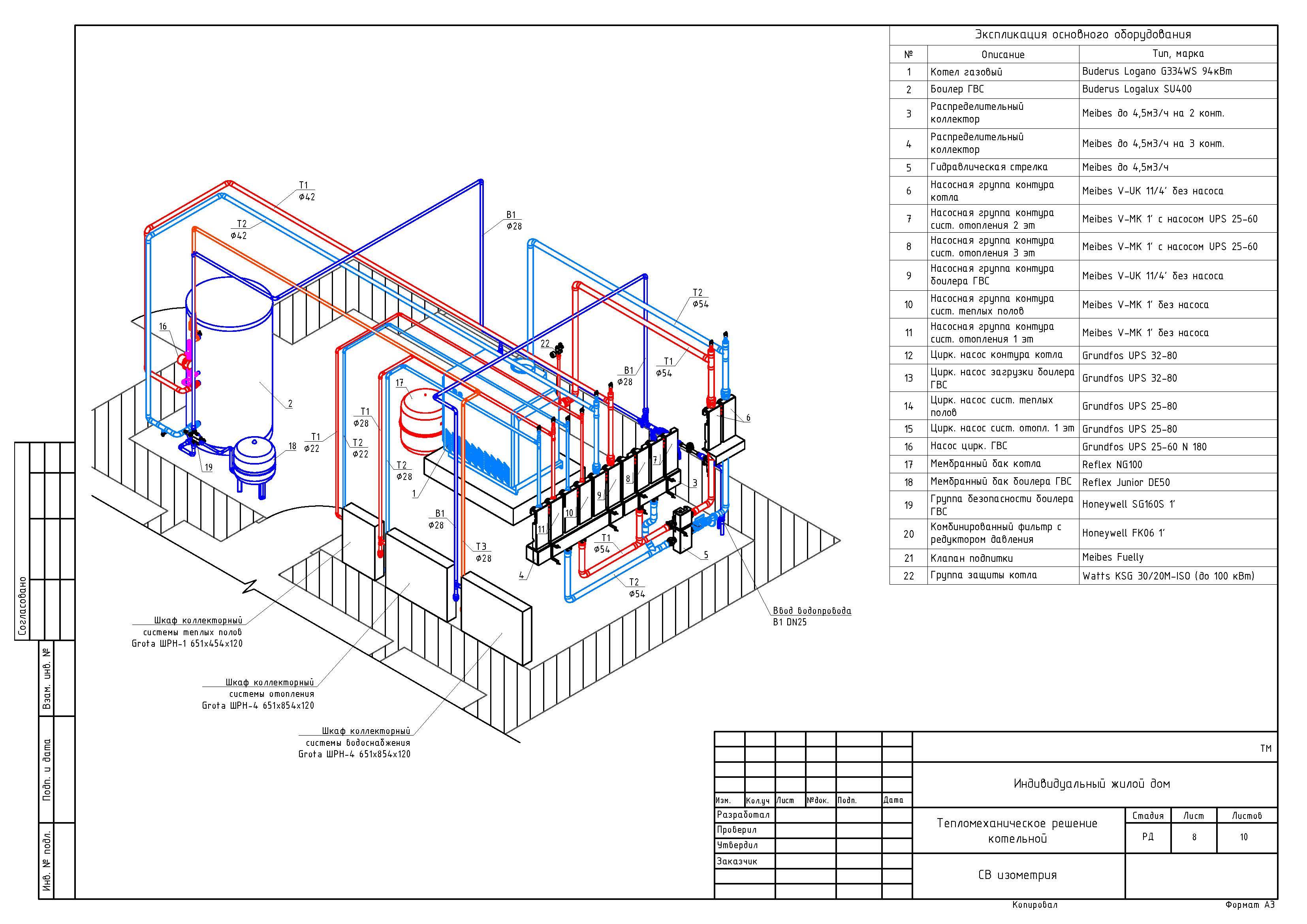

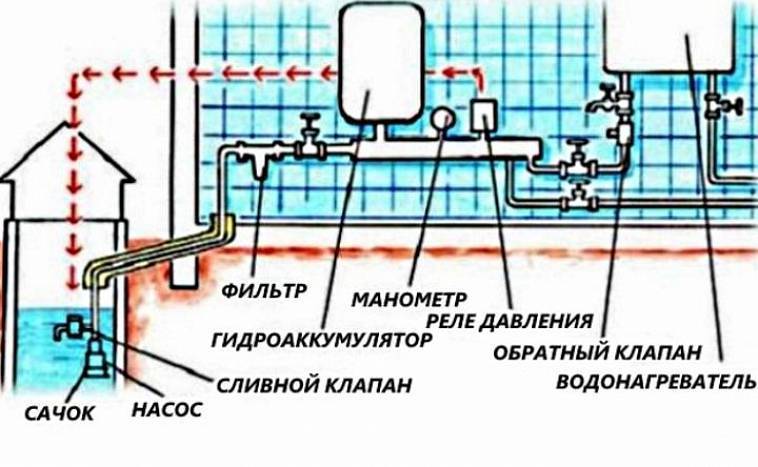

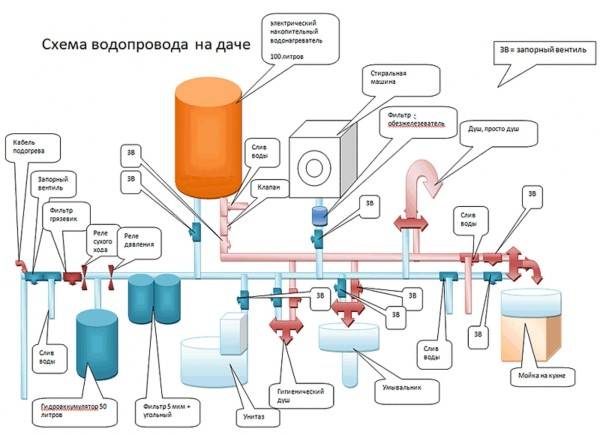

Any water supply system consists of a well, a pump, a hydraulic accumulator to protect the pump. And if desired, a filter or several filters before or after the accumulator.

Pipes for water supply are of several types, the most common materials for them are polypropylene, polyethylene (crosslinked), steel. The most expensive ones are made of copper, because they last the longest.

Pipes for water supply are of several types, the most common materials for them are polypropylene, polyethylene (crosslinked), steel. The most expensive ones are made of copper, because they last the longest.

In case of mounting them, you will have to call a specialist. The best choice is polypropylene in terms of price-quality ratio

Please note that plastic as a material is absolutely not suitable, as it releases harmful elements into the water.

The diameter of the pipe depends on the length of the pipeline of a private house: from 30 meters, a material with a diameter of 25 mm is enough, if more than 30 meters, then 32 mm will do, and in the case when the length is less than 10 meters, the diameter varies between 16-20mm.

Next on the list, you will need a submersible pump, as it is more durable and more productive than a pumping station. The height of the pump is measured along with the hose and then they are connected by a threaded connection. The pump can be placed in any position on stainless steel cables. It hangs from the top of the well.

Water from the pump enters the filter to the accumulator, which is the next element of the circuit. It creates a stable pressure and allows you to turn the pump on and off as needed. The volume depends on the amount of water consumed.

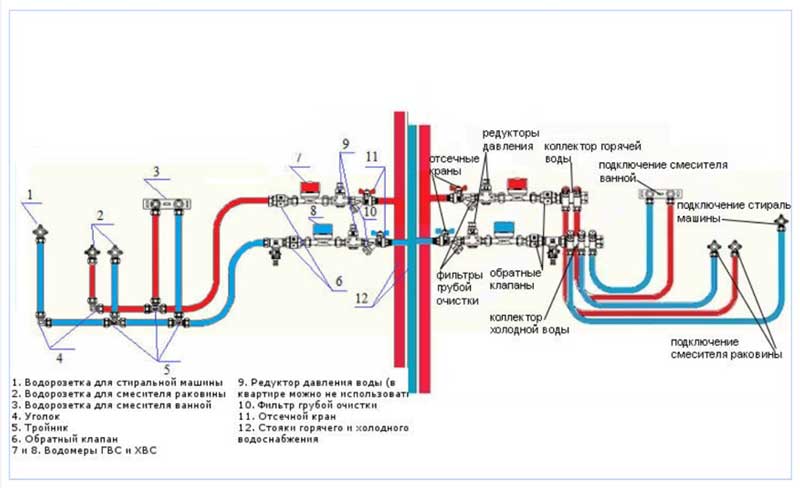

The water is again filtered and divided into two streams: one of them will go to the boiler and heat up, and the second will remain cold in the collector.

It is necessary to mount shut-off valves up to the collector, as well as install a drain cock.

The pipe going to the water heater is equipped with a fuse, an expansion tank, and a drain valve is also installed. The same tap is mounted at the outlet of the water heater, and after that the pipe is connected to a collector with hot water and then distributed to all points in the house.

Boilers may vary. Water can be heated by gas or electricity. A gas instantaneous water heater differs from an electric one in that the water is constantly heated.

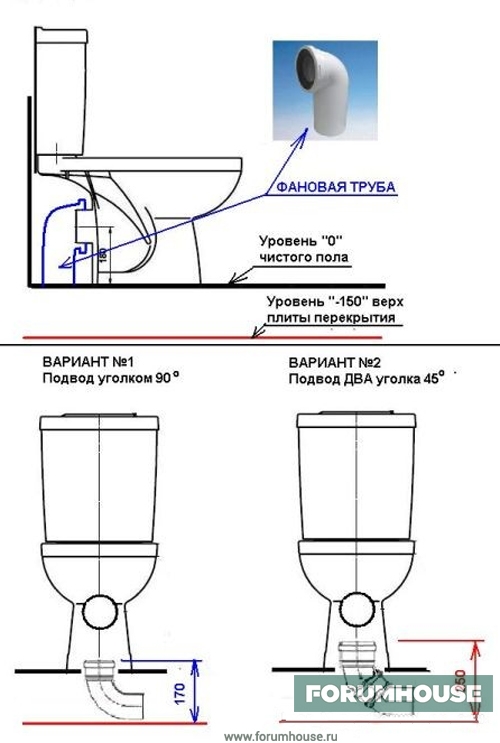

Special mention deserves plumbing. The process of connecting the toilet begins with the installation of a corrugated pipe, which is lubricated with silicone at the junction. Next, the reliability of the connection is checked, holes are drilled into which the dowels are inserted. The toilet is attached to the corrugation and twisted.

Calculations

Any construction begins with drawing up a project. Make all the necessary calculations at the design stage. A detailed plan will help determine the required amount of materials and fixtures: a pump, a filter, a pressure sensor, a meter, taps, and more.

At the stage of drawing up the pipe layout, some nuances should be taken into account:

- water pipes must not cross or touch gas pipelines or electrical wiring;

- the water intake point should be located at a remote distance from the sewerage or cesspool;

- do not lay pipes under the foundation, mount them in walls or floors;

- water pipes must be laid taking into account the level of soil freezing and the climatic features of your region.

Calculate the approximate amount of water consumption per day. Based on these calculations, the power of the equipment for servicing the water supply system is selected.

When installing a private water supply system, the width of the trenches is not regulated. The pipe laying depth must be below the freezing depth of the soil. For regions with severe winters, it is recommended to lay pipes at a level of more than two meters from the surface. For the middle lane, a depth of 1.5-2 meters will suffice. In the southern regions - up to one and a half meters.

When laying several systems in parallel, follow the norms for laying communications established by SNiP.

Distance between pipes:

- between water pipes - 1.5 m;

- between the water supply and sewerage - 0.2 m from the outer walls;

- between the water supply and the gas pipeline - 1m;

- between power cables and a water pipe - 0.5 m;

- between heating networks and water supply - 1.5 m.

The nuances of assembling metal-plastic pipes

Installation is carried out with a special tool: pipe cutters, calibrator, mandrels for pipe bending (internal and external), press tools and wrenches.

The connection of metal-plastic pipes is usually made by compression or press fittings. The principle of mounting spurs through compression fittings is quite simple, based on a threaded connection. Assembly using press fittings is more complicated, we will consider it in more detail.

The reliability of assembling a water supply system from plastic pipes is largely related to fittings, the quality of their manufacture and installation on communications. Choosing fittings based only on price is wrong (+)

The reliability of assembling a water supply system from plastic pipes is largely related to fittings, the quality of their manufacture and installation on communications. Choosing fittings based only on price is wrong (+)

The design of press fittings used in the assembly of metal-plastic communications includes an internal fitting and a crimping sleeve. In the center of the press fitting there is a ring made of dielectric plastic.

Before starting the installation, the pipe is cut, while the place of the cut on it changes its shape to an oval one. To return the end of a round metal-plastic pipe, a special tool is used - a calibrator.

Outwardly, it resembles a multi-tiered children's pyramid, only the rings are not removable. To align the cut end of the pipe to a certain radius, the calibrator is screwed into it using a handle.

To mount the compression fitting, it is required to sequentially install a nut with a split ring on the pipe, carefully insert the fitting into the pipe until it stops, then screw the nut. To make a connection with a press fitting, a compression ring is inserted onto the pipe, then a fitting is inserted and, using press tongs, the sleeve is crimped

To make a connection with a press fitting, a compression ring is inserted onto the pipe, then a fitting is inserted and, using press tongs, the sleeve is crimped.

The fastening of the metal-plastic pipe on the surfaces is carried out on special clips, previously fixed to the floor or walls.

Since metal-plastic pipes bend well, cutting them with installing a fitting in the bend zone is not necessary. To give such a pipe a curved shape, internal or external flexible mandrels are used.

Tips from builders

- To quickly shut off part of the system, so-called stopcocks must be installed.

- The same fittings, splitters and fasteners must be used throughout the system.

- Slope towards the faucet when installing drain cocks.

- Use threaded connections.

- Use spacers to pass through the walls. Gaskets will protect the pipes from abrasion.

You can carry out the installation of wiring in the house yourself. To carry out such work, tools and materials will be required.

The work is carried out in several stages:

- Schema selection.

- Choice of materials.

- Plumbing.

The layout of water supply pipes is quite accessible to beginners for understanding.

How to calculate the diameter of a pipe for a water supply

Before you understand how the section size is calculated, you need to understand the manufacturer's designations. A person who does not understand is used to seeing everything in the usual units of measurement - millimeters, centimeters, meters. In this case, experts and manufacturers consider the diameter in inches.

1 inch - 25.4 mm. If we talk about the usual system of calculations, the section is denoted something like this - 27/2. This means that the outer diameter is 27 mm, the wall thickness is 2 mm, therefore, the inner dimension is 25 mm.

The diameter depends on the length of the pipes, the number of exit points, connections, bends and material.

It is very important to be able to calculate throughput. To do this, you can use three methods:

- Use of exact technical formulas. In this case, only averages should be used.With this calculation option, you need to know to show the roughness of the inner surface, the length of the system, the selected material, diameter, slope angles, the number of household appliances connected to the system, as well as how many mixers are installed in the house. The figures for the calculation associated with the materials of manufacture can be found in special tables.

- Tables are the most accurate options for calculating various ratios. For example, in them you can find the dependence of the throughput on the inner diameter of the pipe, or the material from which it is made. Shevelev's table shows the ratio of water supply with glass, asbestos, plastic and steel pipes.

- For the calculation, you can use a special program. This method is the simplest and most convenient. It is necessary to specify the following data: internal diameter, roughness index, resistance in connecting and branching elements, as well as the total length of the pipeline. The program will independently calculate the throughput of water, taking into account all connected equipment.

Table of water consumption by diameter:

| Section in millimeters | Water flow liters per second |

| 10 | 0,12 |

| 15 | 0,36 |

| 20 | 0,72 |

| 25 | 1,44 |

| 32 | 2,4 |

| 40 | 3,6 |

| 50 | 6 |

The proposed diameters can be conditionally divided between plumbing and household appliances for washing and dishwashers, an excellent choice would be a pipe with a cross section of 25 mm, showers, bathtubs and washbasins, the size will be slightly larger - 32 mm, toilet bowls would be best of all a pipe of 50 mm, and for risers it is better to use 200 mm. These are the most common sizes when connecting a house to a water supply system. You can put pipes of large sizes, but this is impractical.

Step-by-step work algorithm

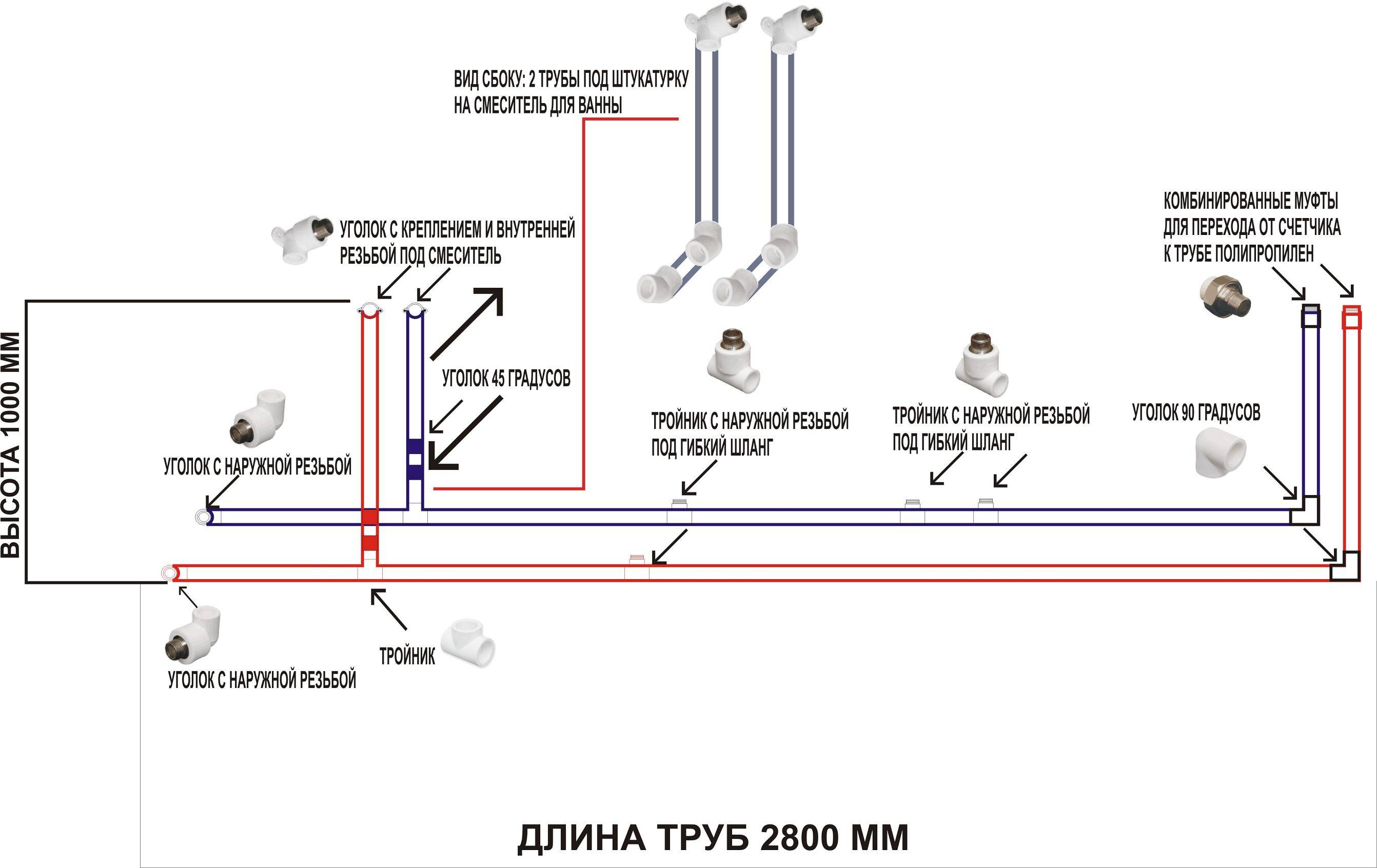

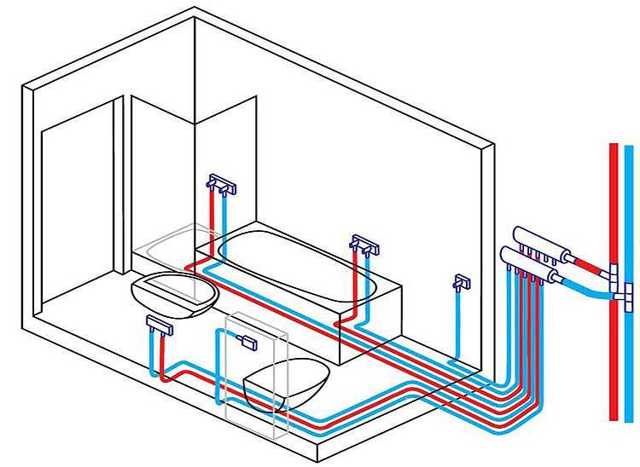

How to make water distribution in apartments? To replace the old water supply in the apartment, you can turn to a professional and you do not have to choose the material, the wiring diagram and install the system, however, such services are quite expensive. In turn, the organization water distribution in the apartment do-it-yourself requires careful observance of building codes and regulations. This event is divided into several main stages:

First, experts recommend preparing a plan for future work. Such a plan should include two main points:

- choice of material. Many people are interested in one question: which pipes to choose for plumbing? Pipes can be made of metal, metal-plastic or plastic. Each material has its own characteristics, which must be carefully studied in order not to encounter unexpected problems in the future. Which material is better suited for the installation of water supply: polypropylene or metal-plastic? For self-distribution of water supply, metal-plastic pipes are most suitable. Mounting metal-plastic communication is quite simple, so even a beginner can do such work. In any case, polypropylene or metal-plastic are the best suited for water pipes;

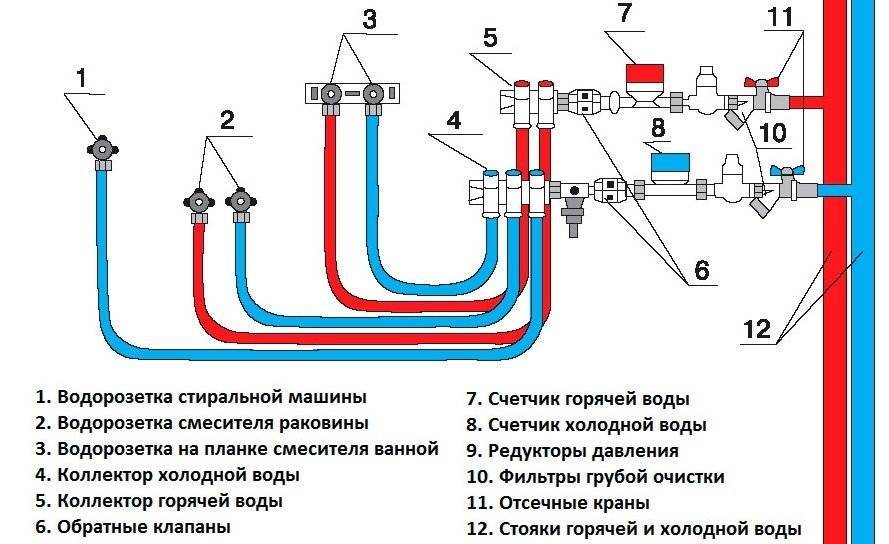

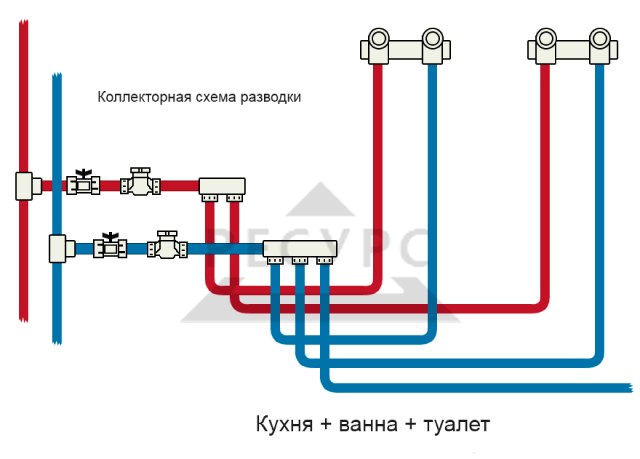

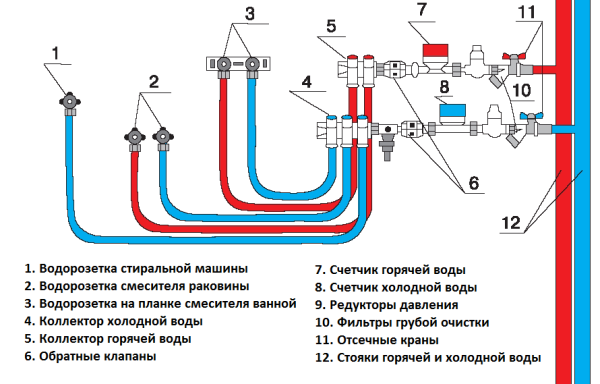

- choice of water distribution scheme in the apartment. The scheme of installation of water communication is determined depending on the type of multi-storey building. To date, the most popular are two schemes: serial and parallel. A sequential wiring diagram is used if the water pressure in the apartment is always stable, however, this is extremely rare.Therefore, most often for the installation of a water supply structure, the second option is used, namely: parallel or collector wiring of water supply and sewerage.

The collector wiring system is a modern and more practical option, in such a water supply system the pressure will be stable

Calculation of fittings and other auxiliary elements, as well as the indicator of the pipeline section. It is recommended to install shut-off valves in front of each source of water intake.

It is important to remember that the pipe cross-sectional index must be less than that of the connecting elements

The fourth paragraph of the scheme includes a list of tools necessary for wiring.

Dismantling of the old communication and laying a new one

During the dismantling of the old structure, it is very important to take care of observing the cross-sectional index of all outlets and pipes, otherwise you will have to use special adapters

As a rule, in standard apartments, rooms where plumbing structures are located have a limited area. In this regard, it is recommended to give preference to the most compact option for laying water supply. As mentioned above, pipes made of different materials can be used for plumbing in an apartment.

Features of the tee scheme

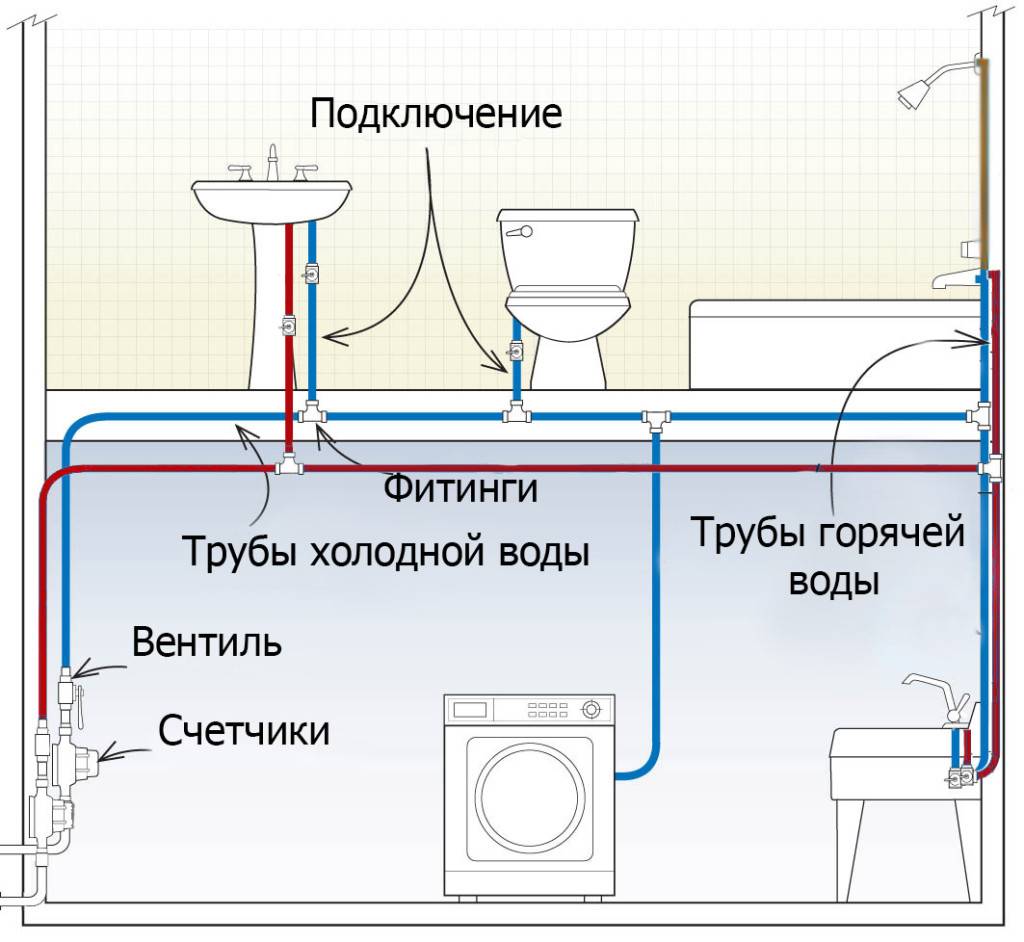

The essence of this method of distributing water supply is the serial connection of the elements of plumbing communications in the apartment, that is, one pipeline leads from the riser, to which other devices that consume water are connected through tees.

Advantages of the tee method:

- cost savings - the number of connecting fittings is reduced to a minimum;

- simple installation work.

The method has its drawbacks:

- difficult search for leaks due to the large number of connections;

- high probability of a change in the pressure level of the system, and consequently a decrease in the current pressure of water in pipelines remote from the riser;

- when repairing, it is required to turn off the entire water supply;

- inconvenient installation of water supply in the apartment, when the room has a small area.

Several nearby points of consumption reduce the risk of pressure surges. During installation, as a rule, a hidden installation of tees is chosen, which makes it difficult to inspect and repair communications.

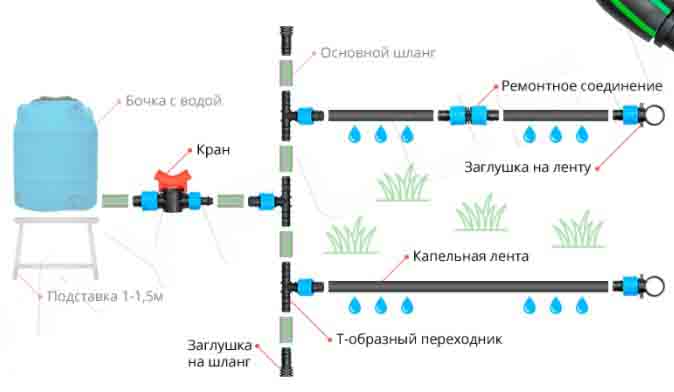

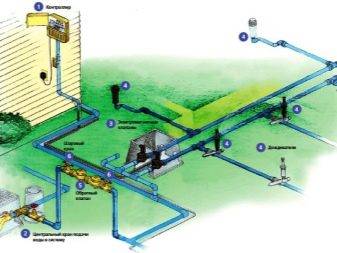

How to connect a pumping station

In order for the necessary amount of water to enter the room, a pumping station is connected. With the help of this device, the liquid rises from the well. The station cannot operate at low temperatures, so it should be located in annexes or basements.

When installing the system, a pipe is supplied to the equipment, on which there is an adapter. A tee is attached to it, at one end of which there is a drain device. A ball valve and a coarse filter are installed. If necessary, it is possible to turn off and drain the water. A non-return valve is built into the tee. It is necessary to prevent backflow of liquid.

To accurately direct the pipe towards the pumping station, a special corner is used. The connection of structural elements is using knots called "American".

When connecting the station, a damping tank and a pressure switch are being installed. The pump is located in the well, and all other equipment is located indoors. The damper tank is located at the bottom, and the pressure switch is installed on top of the pipes.

An important element of the plumbing system is the dry running sensor. Its job is to stop the pump when there is no water. This eliminates the risk of equipment failure. At the last stage, an adapter with a diameter of 25 mm is installed.

The installed pumping station must be checked. To do this, the system is being launched. If all nodes work properly, then the installation was carried out correctly. In the event of interruptions, it is necessary to stop the work and eliminate the malfunctions.

Care and repair

The operation of the system must be constantly monitored. In the event of a malfunction, it is required to immediately turn off the water supply of a private house from the central water supply. If a leak is detected, repair work should be carried out:

- A clamp is cut out of rubber, a hole in the pipe is wrapped and fixed with wire.

- Repairs are carried out using cold welding. Then the surface is degreased and lubricated with acetone.

- If the hole is small, then a bolt is screwed into it. For old pipes, this method is not suitable.

Maintenance of the system consists in monitoring the pressure and purity of the water. Often a decrease in pressure is associated with clogged filters. To do this, they are cleaned. If this is not possible, then they are replaced with new ones.

Do-it-yourself installation of a plumbing system in the private sector is possible. To do this, you need to understand the installation system, prepare a diagram, purchase the necessary materials and begin the assembly process.

Laying methods - hidden and open system

Pipes in the water supply system can be laid in a closed and open way. The choice of one of the methods does not affect either the quality of the connections or the functionality of the entire system and depends only on personal preferences.

It would seem that it is not difficult to decide and the closed method is preferable as more aesthetic and allows you to save up to 10 cm of usable space. Why is an open pipeline still used in the installation of a water supply system? Let's try to give an answer.

Image gallery

Photo from

Metal-plastic is a leader in the construction of water supply systems, used in the organization of hot water and cold water circuits. Resistant to corrosion, no deposits on the walls inside, do not need to be painted

Non-reinforced versions of PP pipes are used in the laying of cold water lines, reinforced ones are used in the DHW device. Plumbing is assembled using fittings

As before, steel water and gas pipes are used in the organization of water supply systems. Steel water pipes are connected by welding, the disadvantages include a tendency to rust, the need for external painting

The advantages of flexibility, resistance to temperatures and aggressive environments are pipes made of copper and stainless steel. Connected by soldering and crimping, serve about 50 years, but are expensive

Plumbing from metal-plastic pipes

Polypropylene water supply system

Water supply device with VGP pipes

Copper and stainless steel plumbing

Hidden wiring allows you to hide pipes and not spoil the aesthetic perception of the interior of a house or apartment. They hide it behind a decorative wall, for example, made of drywall, or ditch the walls and lead the pipes into the formed niches, sealing them with facing material or plaster along the grid.

The pipeline should not be tightly adjacent to the surfaces - always leave a small gap for possible repairs.When installing a pipeline in a monolith, it is recommended to place them in a casing, inserting a pipe into a pipe.

The disadvantage of the method manifests itself when it becomes necessary to repair or replace the hidden elements of the system - the plaster or tiling has to be opened and then re-decorated.

In addition, in the event of damage and leaks, the problem may not be detected immediately and lead first to the loss of operational technical characteristics of structures, then to flooding of the premises.

It is better to proceed with the installation of the water supply system with a pre-drawn scheme - otherwise, errors in calculations or assembly will lead to the fact that you will have to ditch new grooves and re-mount the pipes

To avoid such difficulties, when installing the wiring, only whole sections of the pipe are hidden, placing the docking fittings in open areas. In places of installation of shutoff valves, invisible doors are made. This gives access for maintenance to pipe connections, which are the weakest links in the system.

It should also be noted that pipes made of not all materials can be hidden under a layer of plaster - only products made of polypropylene, metal-plastic or copper are suitable for this.

Pipe laying in an open way is carried out after finishing is completed. The method involves the uncovered laying of pipes and water supply elements. It looks ugly, reduces the usable area of the room, but at the same time this method is very convenient for maintenance, repair and dismantling of elements.

Redevelopment and rearrangement of plumbing in the house with such a plumbing device will also not cause difficulties.

Open wiring makes it possible to quickly detect a leak and eliminate the cause of breakage or damage to system elements

To hide pipes or not?

A question that often arises during the complete renovation of the bathroom. After all, having laid a fashionable tile and installing expensive plumbing, you don’t really want this beauty to be diluted with external piping. Referring to SNiP 2.04.-85 "Internal water supply and sewerage of buildings", as well as its updated version of SP 30.13330.2012, we find that:

To properly perform hidden laying of communications, a number of points should be considered:

- First of all, you need to choose material made by well-known manufacturers and purchase it at official points of sale. Ask the seller for certificates of conformity, a description of the scope and confirmation of warranties for sanitary ware.

- Preference should be given to boxes, false panels with inspection hatches or removable decorative and protective screens.

- You should ask about which pipe models can be completely walled up in concrete structures at the stage of their purchase. However, the general rules do not allow the embedding of collapsible units, including fittings. They should be provided with free access for control and prevention. It is allowed to seal homogeneous joints made by the diffusion welding method, while it is desirable to provide a minimum number of joints.

In addition, when immuring in the structure, the temperature and mechanical properties of pipelines should be taken into account. They must either have a low coefficient of thermal expansion, or provide conditions for their free deformation.Therefore, in view of the foregoing, for embedding in the structure, the best solution would be to use solid sections made of metal-plastic, polybutene or all-cross-linked polyethylene.

It is also allowed to wall pipes into the floors or walls of soldered polypropylene pipes. Preference is given to reinforced products, since they have a coefficient of linear expansion 5 times lower than non-reinforced products. Pipes are laid in protective covers made of elastic material (Energoflex type) or with a margin of diameter in plumbing corrugations. Such measures help to compensate for the temperature deformations of the DHW lines, and prevent the formation of condensate on the cold water lines.