- Types of engineering communications wiring

- Type #1. Serial type wiring

- Type #2. Collector type wiring

- How to choose pipes?

- plastic pipes

- Metal-plastic pipes

- Steel pipes

- Features of metal structures

- Where to begin?

- Installation of a new pipeline

- Choosing a piping system

- Necessary tools and consumables

- Pipe Installation Instructions

- Pressure testing of the pipeline

- System health check

- Accounting and control

- HMS, aquastop, filter

Types of engineering communications wiring

Before designing the wiring, you should get acquainted with what varieties of such structures exist. There are only three of them. And one, with through sockets, is practically not used. Therefore, we will not consider it.

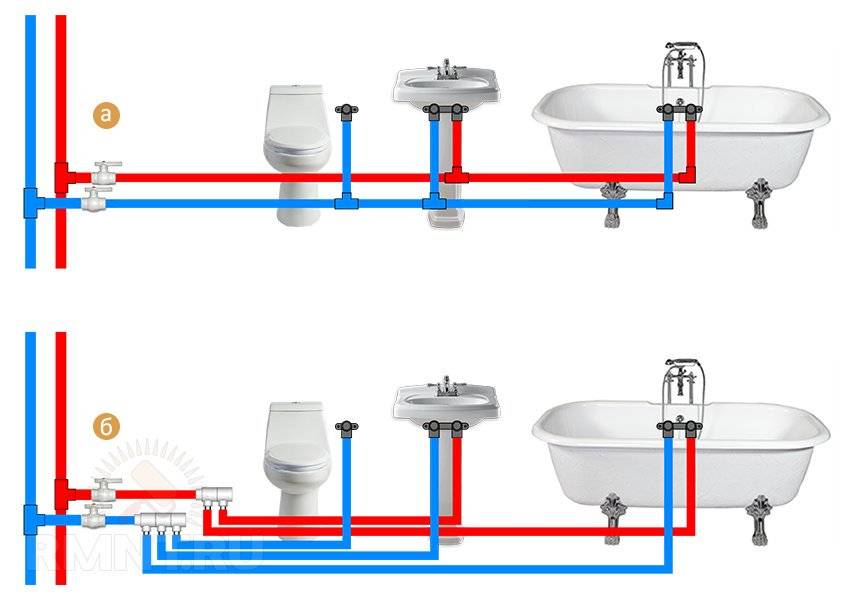

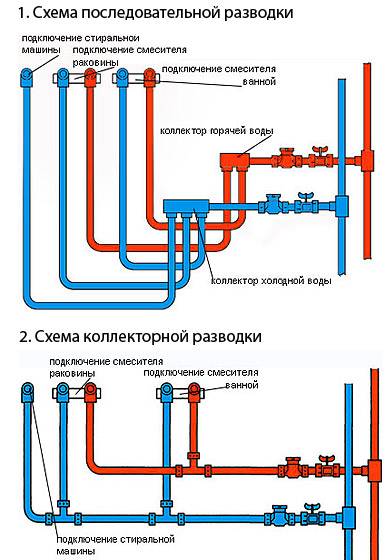

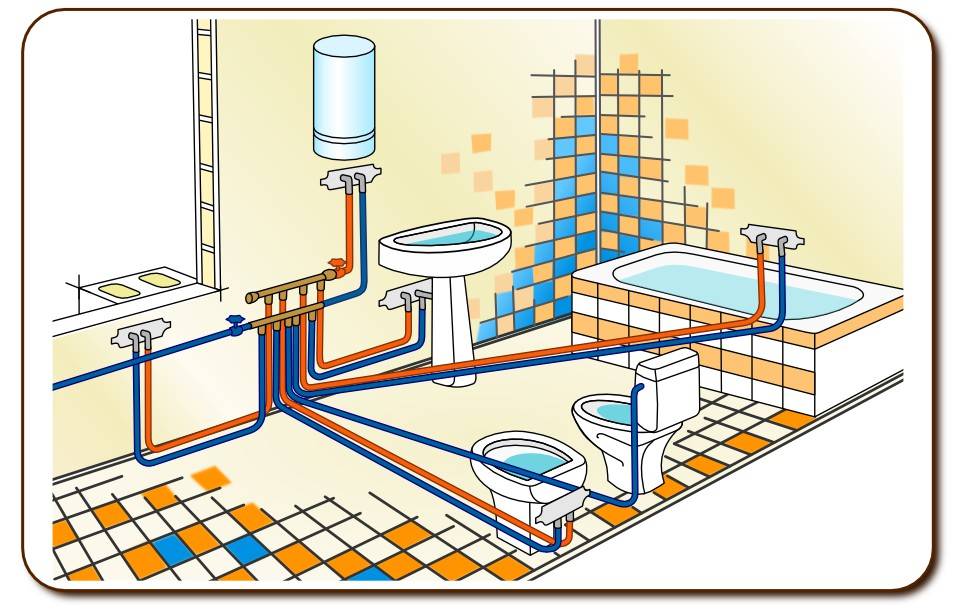

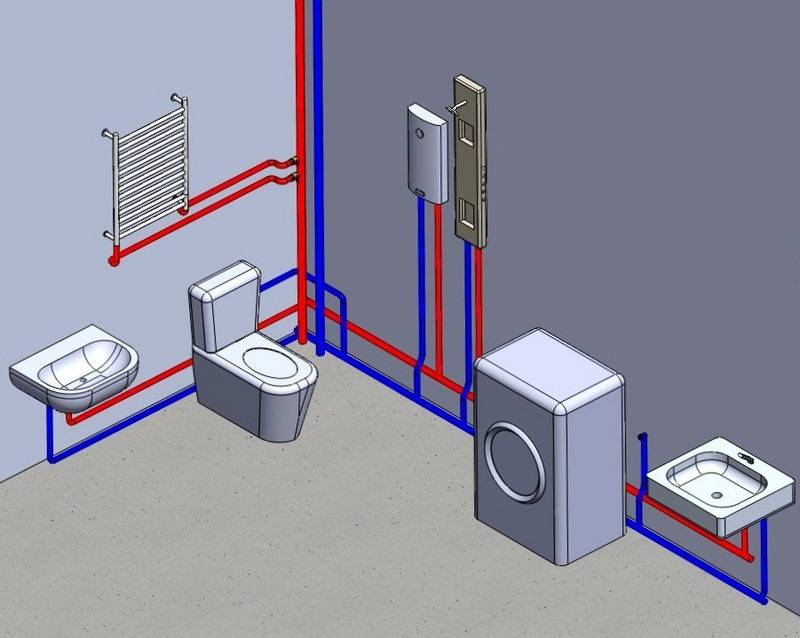

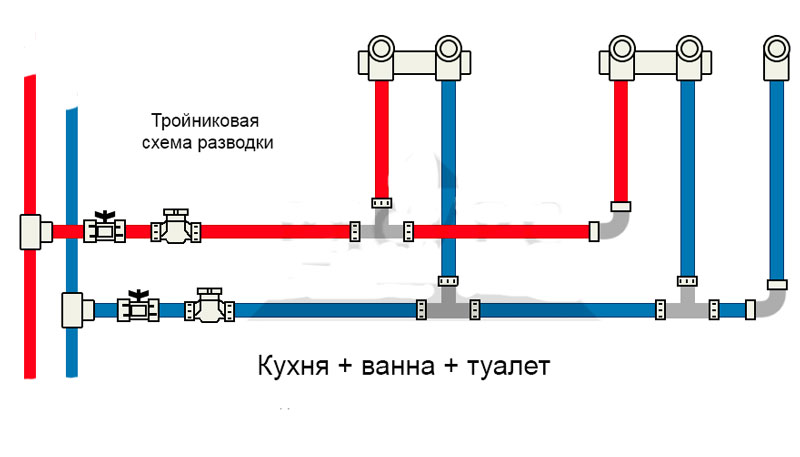

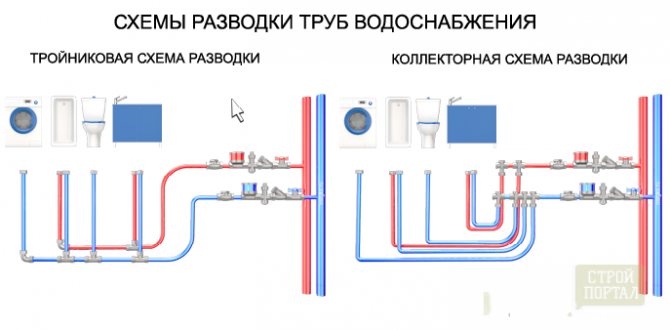

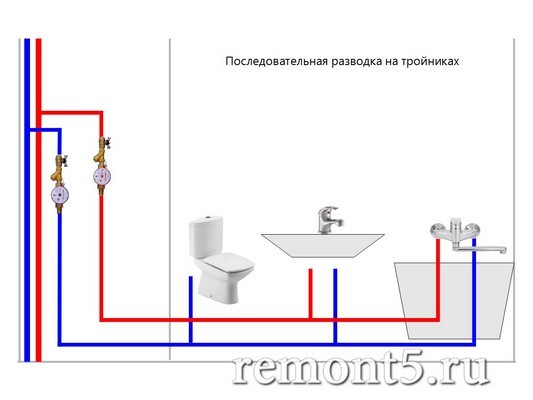

Type #1. Serial type wiring

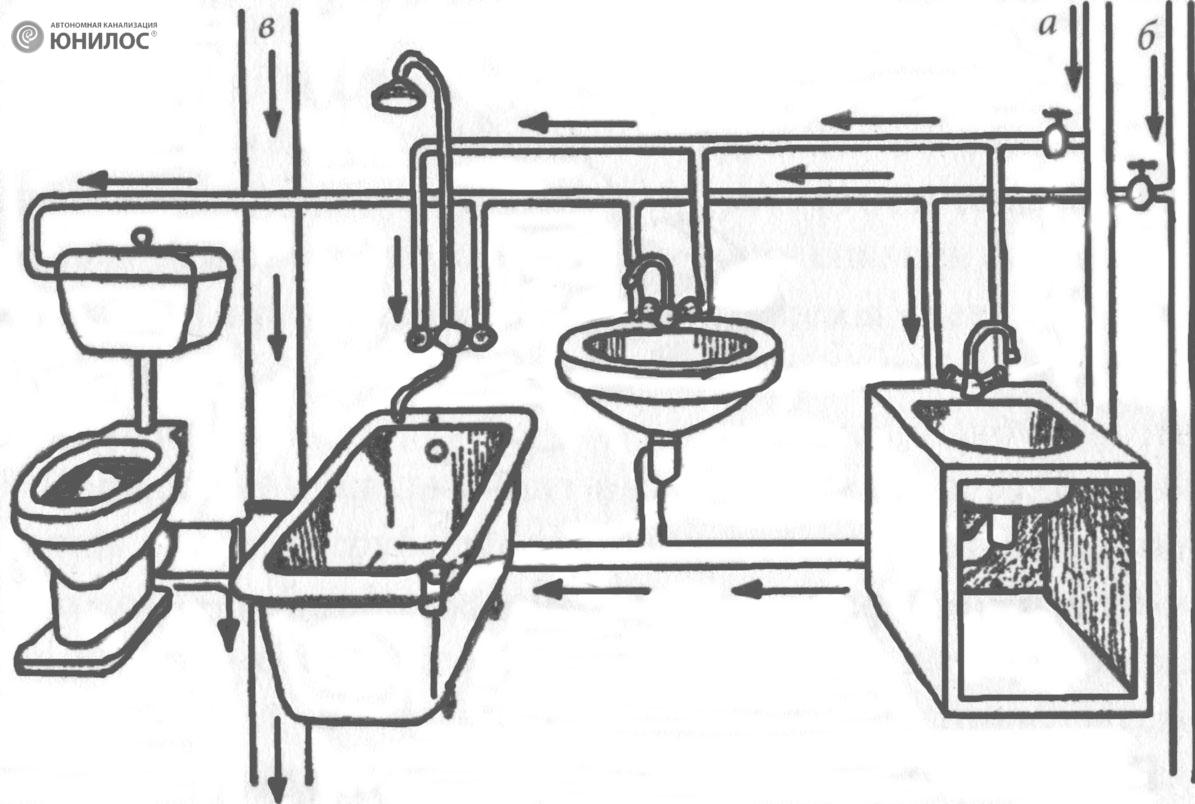

For its implementation, taps are made from the risers of cold and hot water supply, leading to the first consumer. Pipes are laid from it to the second and further. Each tapping point is equipped with a tee, to one of the outlets of which the consumer is connected.

In general, this is a very simple scheme. It can be used only where the number of water consumers is small.

This is due to the fact that with the simultaneous activation of several points of water intake at once, the pressure in them will weaken, and may not be sufficient for the correct operation of the equipment. This is the main disadvantage of serial wiring.

However, for apartments with one bathroom and a small amount of used plumbing, this option may be the best. A significant drawback of the system is the inability to turn off one of the plumbing fixtures for replacement or repair.

Serial wiring is extremely easy to implement, but not very convenient to use. However, for small bathrooms, this solution may be quite acceptable.

The advantages of serial wiring are much greater. First of all, it is simplicity in design and installation. There will be no complicated schemes, everything is very simple.

In addition, such wiring is considered the most economical option. The consumption of pipes and other elements will be significantly lower than in other systems, installation costs are also minimal.

Even a novice plumber can handle the design and subsequent arrangement of a consistent, otherwise tee wiring

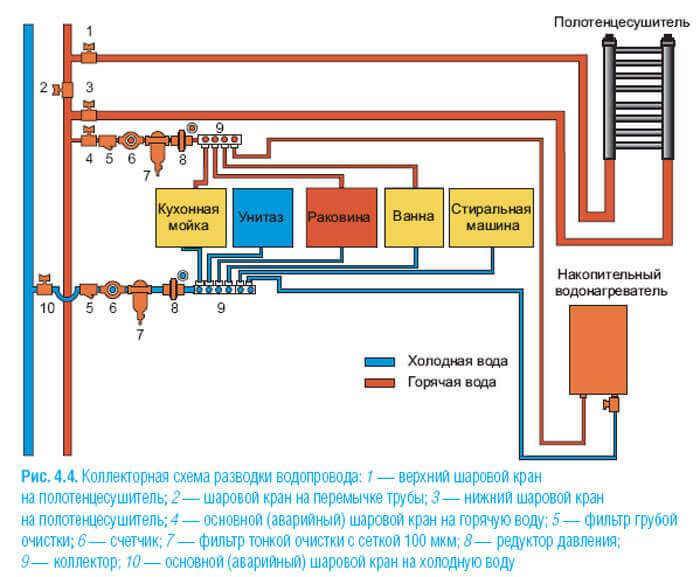

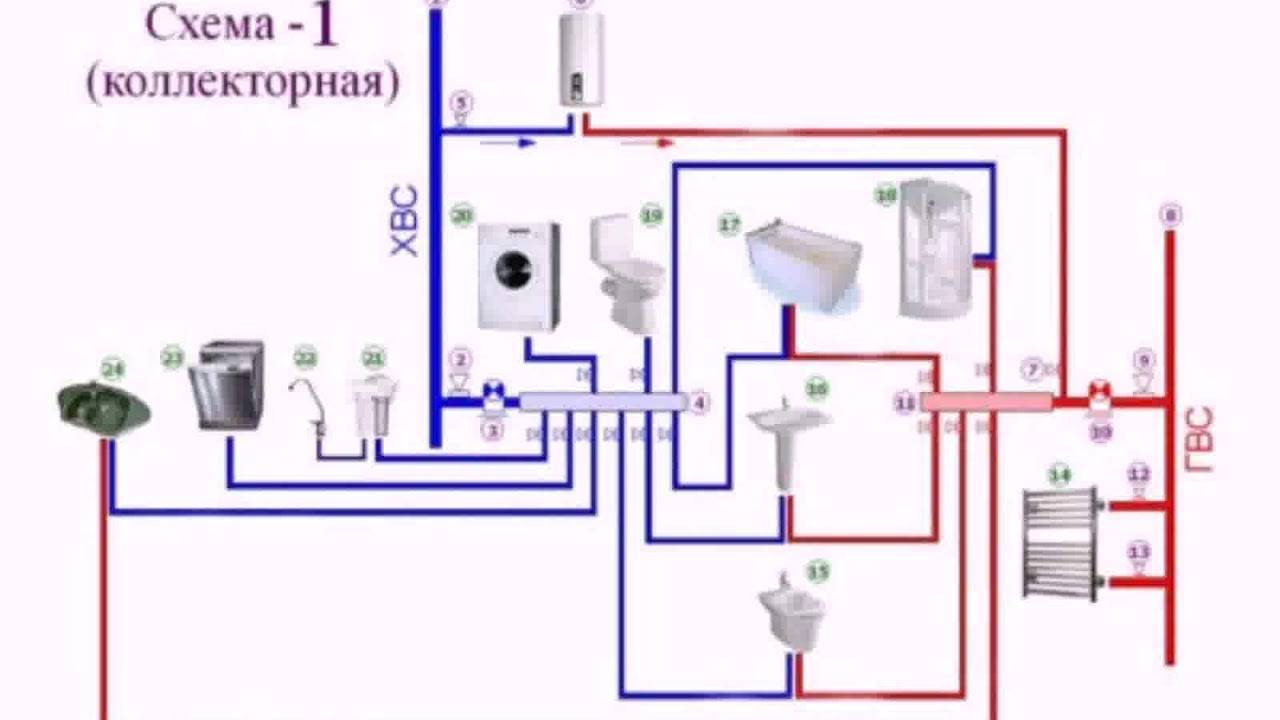

Type #2. Collector type wiring

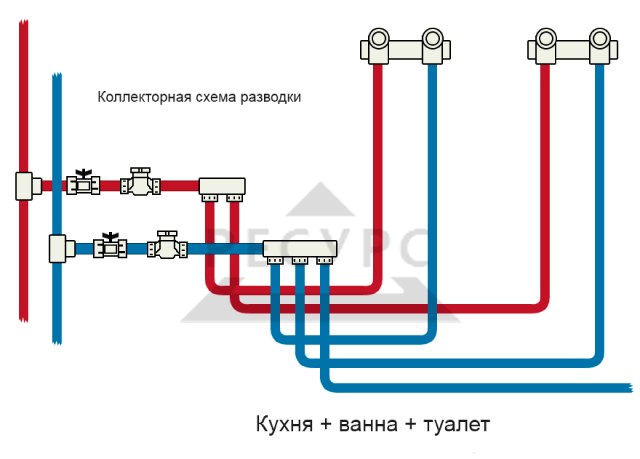

The collector type scheme involves the connection of each of the consumers to the main line. For this, a special element is used, which is called a collector - a device that distributes water flows.

In a more complex version, and this is best, each collector outlet is equipped with a shut-off valve. Collector-type wiring can be considered the most convenient option to use. There are several reasons for this.

First, the absence of pressure drops in the system.All consumers receive equally good water pressure, even if all draw-off points operate simultaneously.

If the pressure in the system of an apartment or a private house, or for some reason is too low, you can temporarily limit the water supply to one of the consumers, for example, to the toilet, in order to thereby increase the pressure for others.

The collector type of wiring is more convenient to use than the serial one. In this case, a separate line goes to each consumer, which ensures that there are no pressure problems. However, in the design and installation of such a system is more complex.

Secondly, the ability to turn off plumbing fixtures from the water supply if they need to be replaced or repaired.

Thirdly, reliability. In fact, a single pipe goes to each consumer, without any connections and other elements. A leak can appear only in the area of \u200b\u200bthe collector or near the device itself. Here it will be very easy to find. For this reason, pipes with collector wiring can be safely installed using a hidden method.

Fourth, ease of use. If there is a problem with a plumbing fixture and a leak appears, for example, at a mixer, you do not need to crawl under the sink. It is enough to close the shut-off valve on the collector leading to the faulty device and wait for the arrival of specialists.

Even a woman or child unfamiliar with plumbing intricacies can do this. In this case, all other equipment will work properly.

Professionals recommend using manifolds with stopcocks for installation in plumbing systems.With their help, if necessary, you can easily stop the water supply to a branch or plumbing fixture in need of repair.

However, collector wiring also has some disadvantages. First of all, it will cost the owner more than the serial circuit, the amount. This is due to the fact that you need to lay a branch to each consumer. It will take a lot more material.

In addition, the installation of manifolds and shut-off valves will be required if the distributors are not equipped with them. And the circuit itself will be much more complicated than the sequential one.

How to choose pipes?

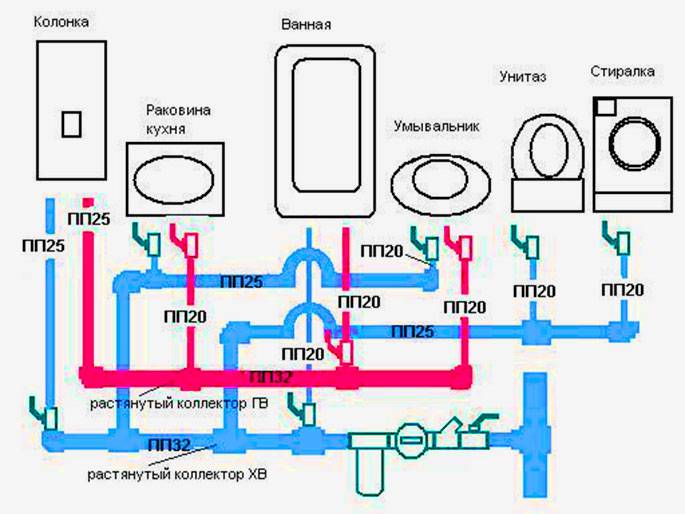

The defining parameter is reliability. Pipes in the bathroom must withstand maximum pressure. For centralized systems, it ranges from 2 to 7 atm. at a rate of 4 atm. In autonomous - up to 5 atm. It is necessary to take into account not only the wall thickness of the line, but also the reliability of the connecting elements - fittings, welded or threaded structures.

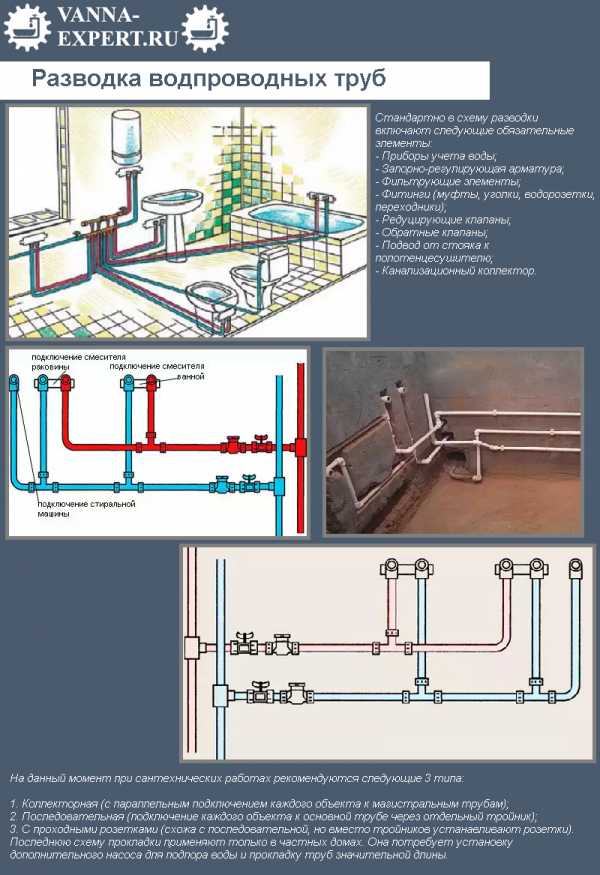

Overview of pipes for arranging water supply in the bathroom:

- Plastic. Production material - PVC, polypropylene (PP). To increase reliability, they have a multilayer structure - reinforcement with aluminum foil or fiberglass, a barrier against air entering water. Connected by welding, cold or hot. An example is the Rehau universal pipes of the Rautitan Flex series.

- Metal-plastic. By contraction they are similar to plastic ones, the material is PE (polyethylene), PE-X (cross-linked polyethylene) or PE-RT (for heating and hot water supply). The connection is mechanical, using steel couplings. They have better flexibility than plastic ones, the ability to quickly replace individual sections of the water supply system.

- Metal. They are rarely used, the reasons are rusting, large mass, laborious installation.The connection is welded, threaded couplings are less commonly used.

The diameter affects the water pressure, which is important for water supply systems. The smaller it is, the more pressure

For piping in the bathroom, pipelines with a diameter of up to 20 mm are used. If the total length of the line exceeds 30 m, you need to increase this parameter to 32 mm. When installing plumbing in a bathroom from polypropylene pipes, it is necessary to take into account the thermal expansion of the material. For extended sections, the installation of compensation loops is necessary.

plastic pipes

- Long service life, up to 30 years

- No corrosion

- Quick installation

- Good thermal insulation

- Thermal expansion, compensatory loops needed

- Part is destroyed by exposure to sunlight

- A welding machine is required for connection

Plastic pipes for water supply: dimensions and diameters, characteristics of materials The use of plastic pipes for water supply made it possible to get rid of bulky steel networks, which were previously equipped with almost all residential buildings and public buildings. Sturdy and comfortable to…

Metal-plastic pipes

- Impermeable to oxygen, will not air

- Mechanical resistance

- No special tools are required to install the couplings

- Minimum bending radius up to 5 diameters

- Maximum water temperature up to +95°С

- combustibility

- Different bore diameters for pipes and fittings

Steel pipes

- High strength

- Work in high pressure systems

- Good tightness, no air leakage

- Maximum water temperature up to +95°С

- combustibility

- Different bore diameters for pipes and fittings

When connected steel pipes with fittings from other metals at the junction, rapid oxidation will occur.

Features of metal structures

Today, piping in the bathroom practically does not provide for cast-iron and galvanized plumbing and drain systems. The reason for this is the complexity of the installation of structures. However, sewer communications made of cast iron are distinguished by good noise insulation and high wear resistance compared to products made of polymers.

Galvanized steel plumbing structures completely lose to plastic counterparts. They are susceptible to corrosion during prolonged and intensive use. In addition, a frequent problem of such products is the formation of plaque inside the pipe.

Metal pipes lose to plastic ones, since the latter are not subject to corrosion.

It is possible to connect metal products only with the help of a welding machine, which is not always possible at home.

Where to begin?

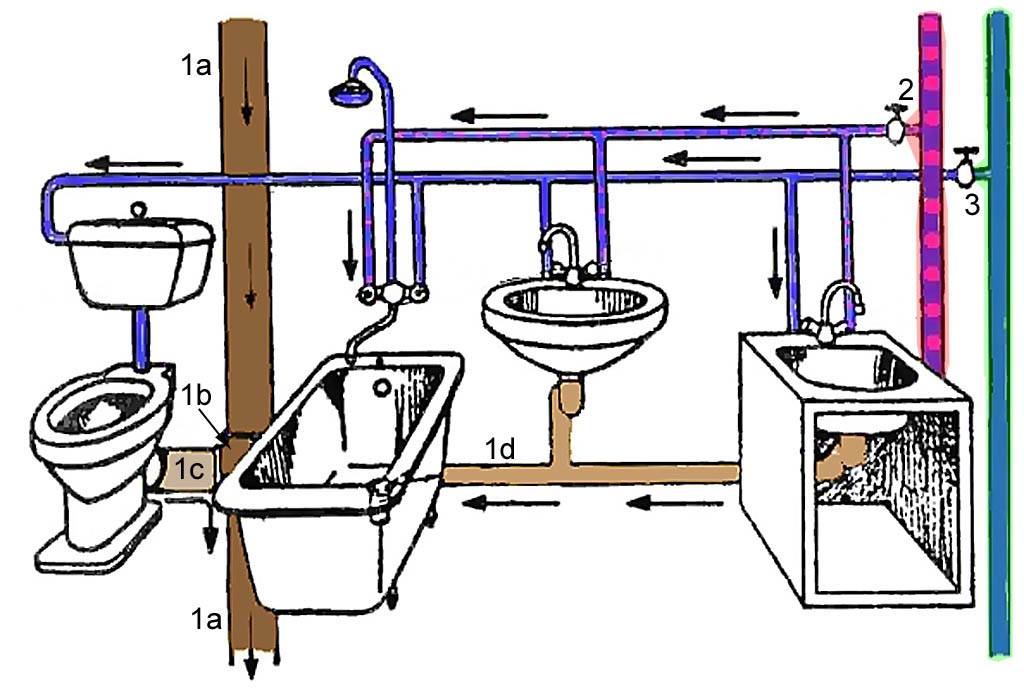

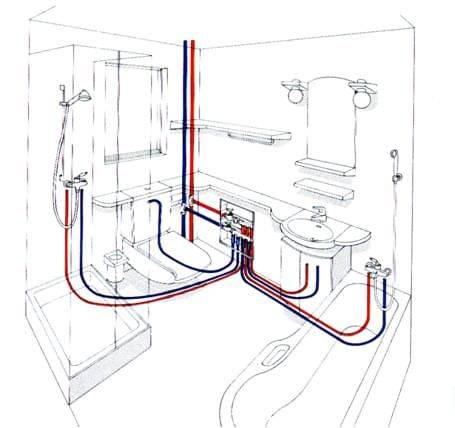

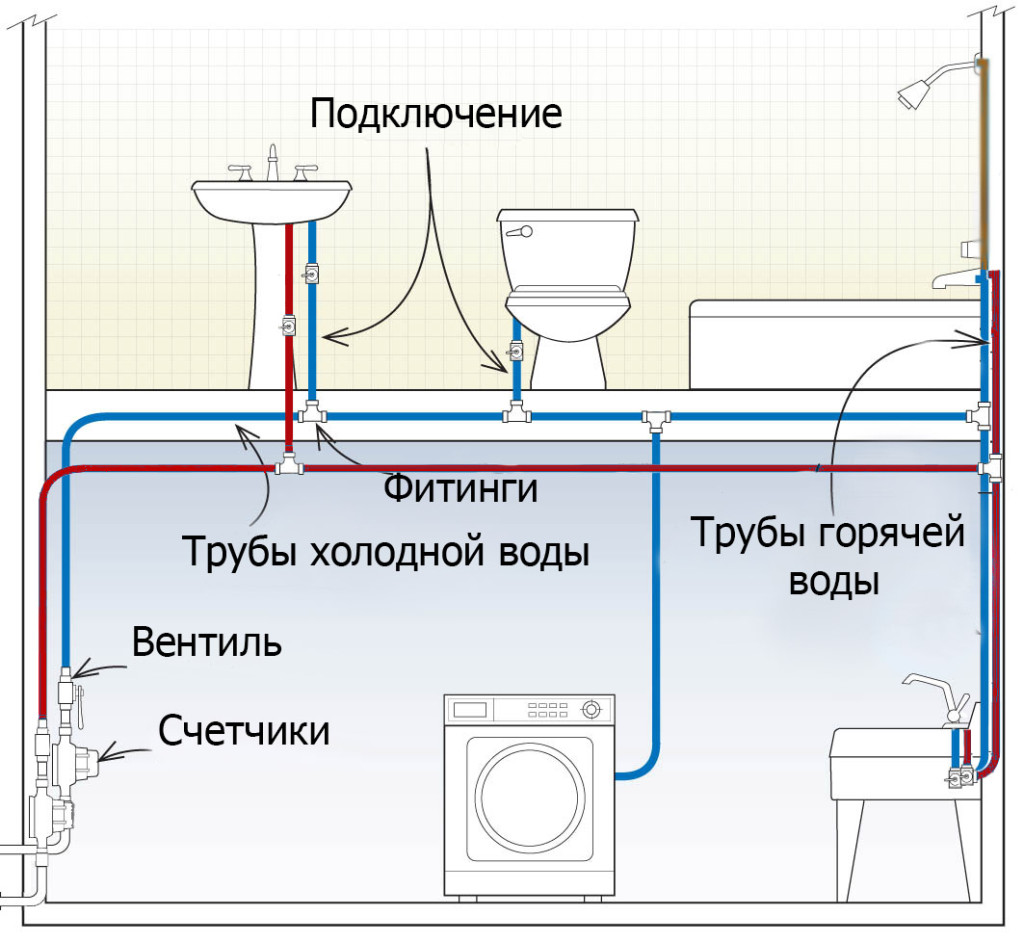

First you need to decide what plumbing equipment needs to be placed in the bathroom and toilet or in a combined room, if such a solution is intended. Then find out which engineering communications should be connected to each of the devices.

In practice, it looks like this:

- Toilet. We supply sewerage and cold water.

- Bidet. Cold and hot water, sewerage are connected.

- Shower or bath. Hot and cold water and sewerage are supplied.

- Washbasin. We connect cold and hot water, sewerage.

- Washing machine. Cold water and sewerage are supplied.

Having decided on the number and type of plumbing equipment, you can begin to develop a wiring diagram.

This is what a properly executed piping in the bathroom looks like. All communications are hidden in the walls

Installation of a new pipeline

The choice of the type of pipeline laying is carried out exclusively by the owner of the housing.

Choosing a piping system

Each type of wiring has different features, advantages and disadvantages, but does not determine the type of room. You can choose any layout scheme.

Necessary tools and consumables

Solving the problem of how to replace pipes with your own hands, prepare the following tool:

- hacksaw for metal;

- special scissors for metal-plastic products;

- open-end wrenches, gas, adjustable;

- puncher or drill for drilling holes for holding anchors;

- sealant - tow, fum tape, sanitary flax, sealant (paste or glue);

- silicone gaskets;

- special soldering iron for soldering pipes;

- marker;

- measuring tape.

To replace the pipes, you need a hacksaw for metal.

There are 3 types of consumables: straight, angled and tees. They may have the same or different type of thread - external or internal. The first is needed for the installation of valves. The second is for connecting parts to each other.

Pipe Installation Instructions

For proper installation of the pipeline, you need to follow simple rules and work consistently. It is easy to connect pipes, but it is difficult to achieve a lack of leakage at the joints.

Installation is recommended according to the following algorithm:

- Markers are placed on the walls, which are approximate locations for faucets and other water sources.

- Pieces of products are measured with a tape measure. Then the material is cut with scissors or sawn with a hacksaw for metal.

- Depending on the type of wiring, soldering or connection with fittings is carried out.

- There is a connection to the consumer system - a drain tank, a toilet bowl, a bathroom, a sink, etc.

- The reliability of the connections and the sealing of the structure are checked by supplying water to it.

- The pipeline is attached to the walls with anchors-holders.

- Additionally, a check is carried out, because During installation, parts are subjected to physical stress.

Pressure testing of the pipeline

Pressurization with air is its supply to a closed water supply system. It is carried out in order to apply pressure several times higher than natural during operation. If the system passes such a test, then it is considered suitable for further use. The procedure allows you to identify places that may soon form a leak, and eliminate holes or cracks.

Pressure testing of the pipeline is carried out in order to apply high pressure.

To do this, use a special pump or a circulation pump, which is part of autonomous heating. Pressure testing is carried out both with air and water. More often - the first, since the liquid can get outside the system.

The procedure must be performed by an employee who has passed certification. The completion of pressure testing by a specialist is accompanied by the drawing up and signing of an act on testing the water supply system.

Pressurization is necessary in the following cases:

- at enterprises where a complex plumbing system is being installed;

- before the first start-up;

- after repair of the system or replacement of its part;

- after idle time without operation.

Also, pressure testing is part of a scheduled inspection of some pipelines and sewers, consisting of polymer parts.It is also carried out after flushing the system if aggressive chemicals were used. They can weaken the walls of plastic products and leak at the joints.

System health check

Functional testing without pressure testing is carried out from the riser to the end of the system

In this case, you should pay attention to checking:

- Joints on the pipeline and sewerage.

- Tightness when supplying hot water.

- The correctness and reliability of the installation of plumbing devices - sinks, toilet bowls, hoses, metering devices.

- Pressure in the system - whether it was clogged during installation.

Checking the system performance is carried out from the riser to the end of the system.

At first, it is recommended to keep the taps closed to determine the tightness at the joints, and then open them one by one.

It is worth making sure that the sewerage and pipeline are designed in accordance with the project. Each element of the system must be in the place indicated in the plan.

It is better to use pressure testing with water, as the high pressure fluid will flush out any remaining construction debris in the system. This is especially true for high vertical sections. If a place with a leak or weak tightness is found, the problem should be corrected and the test should be repeated.

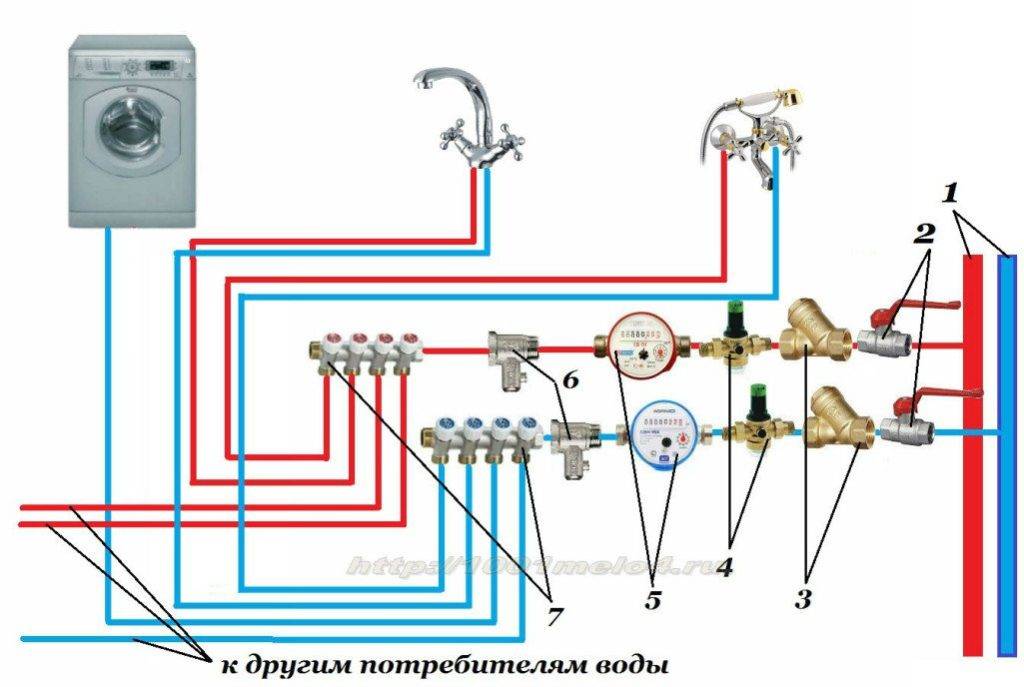

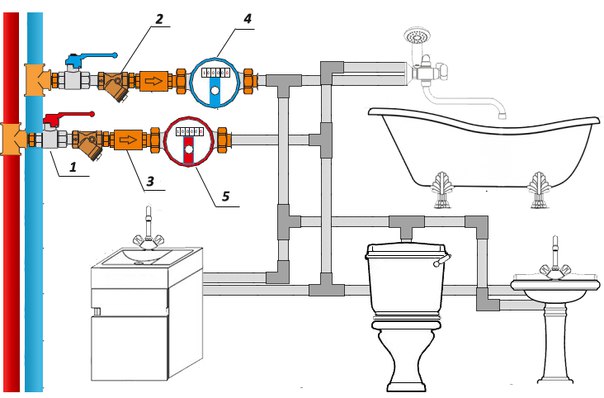

Accounting and control

The selection and accounting unit consists of a shut-off valve, a coarse filter, a water meter and a check valve. Assembled as shown in the picture. Each of the devices indicates the direction of the water flow for it, it must be observed during assembly.

Selective-accounting water supply unit, assembly

The assembly is assembled with waterproofing of the joints with FUM tape and is also connected to the riser, having previously blocked the water; Remember to close the shut-off valve before supplying water. This is the only operation, and a short one, that requires turning off the water supply to the neighbors in the riser.

Separate meter units are needed for cold and hot water. It is highly desirable that the counters and valve handles be highlighted in color. The meter readings should be clearly readable without any additional operations (hatch removal, etc.), so it is often necessary to pre-assemble a part of an integral pipeline, sometimes of a rather bizarre configuration, to connect metering devices to the riser. In addition to pipes and a soldering iron, for this you will need transitional couplings from plastic to metal MPV - a threaded inner coupling. Plastic is connected to metering units using MRN - external threaded couplings.

The meters are sold sealed, but this does not mean that you can immediately call the water utility and pay for water according to consumption. The factory seal is for this (the Russian land is rich in craftsmen) so that no one gets into the meter and twists or files anything there. The factory seal must be protected; without it, the meter is considered unusable, as well as without a certificate for it.

When installing water meters, you need to declare to the water utility and call its inspector. You can use water before he arrives, the inspector does not need zero readings, he will write down the initial ones, seal the meter and drain the filter with his seal. Payment for water consumption will go after registration of metering devices.

HMS, aquastop, filter

Although the design of the HMS is non-separable and does not allow stealing water with its help, and this device is not subject to sealing, connecting the HMS to the meter is unacceptable: the meter impeller can become clogged with sludge. HMS with a flask filter is connected after metering devices; filter - immediately after HMS. An aquastop can be connected immediately after the filter, but if it is electrodynamic, the magnetic field of the HMS can cause its false operation, but it makes no sense to attribute the aquastop far from the riser: it does not react to a breakthrough before it.