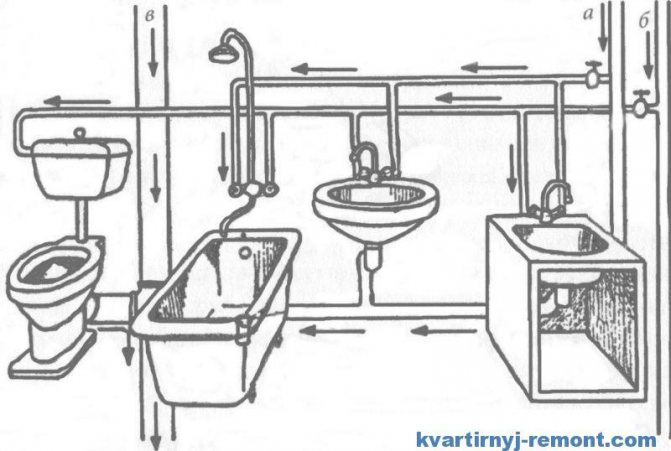

- Types of piping

- The procedure for conducting plumbing

- Plumbing for the bathroom

- Materials and tools

- Sewer installation

- Plumbing installation

- Sewer pipe material

- Necessary parts for sewerage installation

- Welding of polypropylene pipes

- Types of engineering communications wiring

- Type #1. Serial type wiring

- Type #2. Collector type wiring

- Dead-end and closed circuit: pros and cons

- Bathroom installation

- Bathroom grounding

- What materials to prefer

- How to choose pipes?

- plastic pipes

- Metal-plastic pipes

- Steel pipes

Types of piping

At the moment, the following 3 types are recommended for plumbing work:

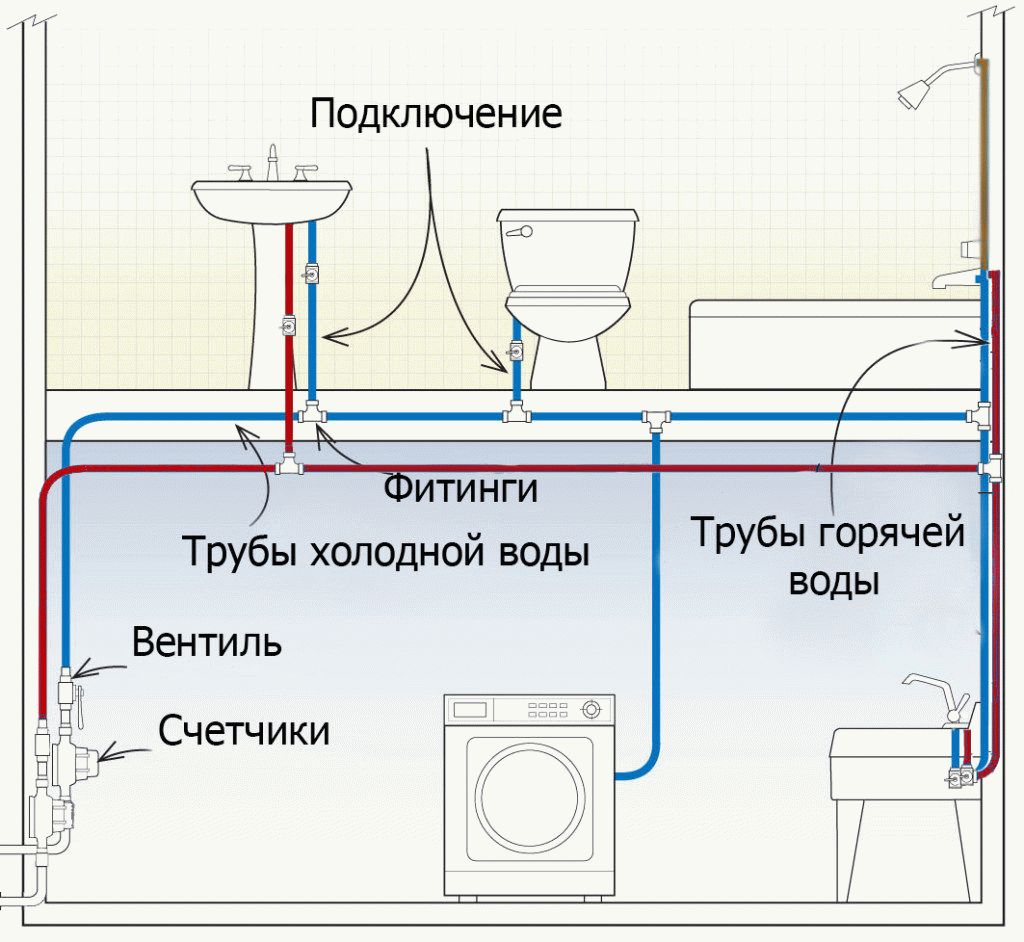

- Collector (with parallel connection of each object to the main pipes);

- Serial (connection of each object to the main pipe through a separate tee);

- With pass-through sockets (similar to serial sockets, but sockets are installed instead of tees).

The last laying scheme is used only in private homes. It will require the installation of an additional pump for water boost and the laying of pipes of considerable length.

In apartments, the first two schemes are used, we will talk about them in more detail.

The procedure for conducting plumbing

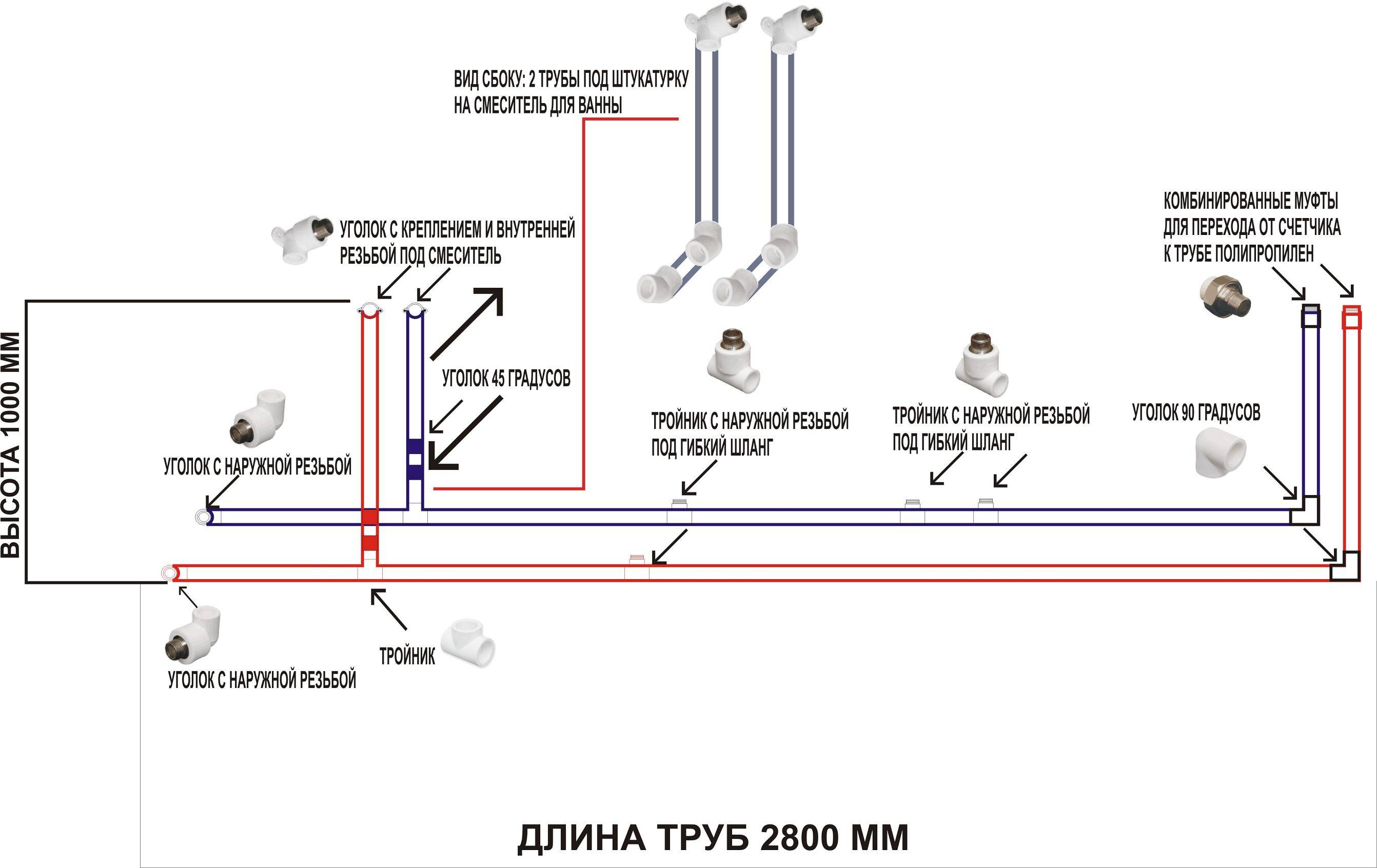

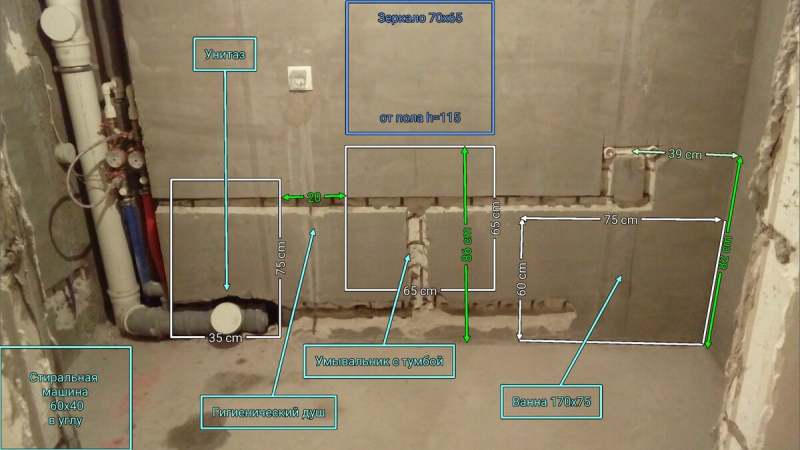

Proper piping in the bathroom with polypropylene provides for the preparation of an installation project for such a design. In this scheme, it is necessary to estimate the optimal paths for the passage of communications, if possible, minimize the number of their turns and corner connections, and also try to avoid crossing highways.

You also need to determine the length of each straight section to calculate the amount of material needed. It would also be useful to indicate the connection points of all devices in order to find out how much connecting fittings are required.

It is very important to stock up on the tools necessary for the work. For example, for conducting water supply from polypropylene pipes, the list is as follows:

- gas plumbing keys No. 1–2;

- wire cutters; knife;

- pliers;

- spanners;

- tape measure and pencil;

- screwdriver;

- soldering iron for pipes;

- turbine and drill.

After completing the necessary preparatory work, you can proceed with the installation. First you need to remove the old communications. To do this, turn off the water supply to them and cut them off.

Slice pipes follow according to the drawn up scheme

Adhering to the drawn up project, you need to measure and cut the fragments of communications you need. Next, you should articulate them by soldering the segments one to the other. To do this, they are cleaned and chamfered at the joints with a knife, then degreased and placed in a soldering machine. When heated to two hundred and seventy degrees, they must be connected. You should be aware that the parts cool down within a few seconds, so try to precisely and accurately articulate the segments as quickly as possible.

Install locking fittings at predetermined places.

The internal method of installing pipes is long and laborious, but as a result you get a completely hidden plumbing system.

Depending on the chosen pipe laying method, either make holes in the walls for them, or fix special clamps on the walls. At the junction of the partitions, it is better to install additional fasteners. Now you can lay the system and secure it.

If the system is working properly, in the case of internal installation, you can start decorating the walls. With external wiring, pipe laying work is considered completed.

Plumbing for the bathroom

Materials and tools

Reinforced polypropylene pipe

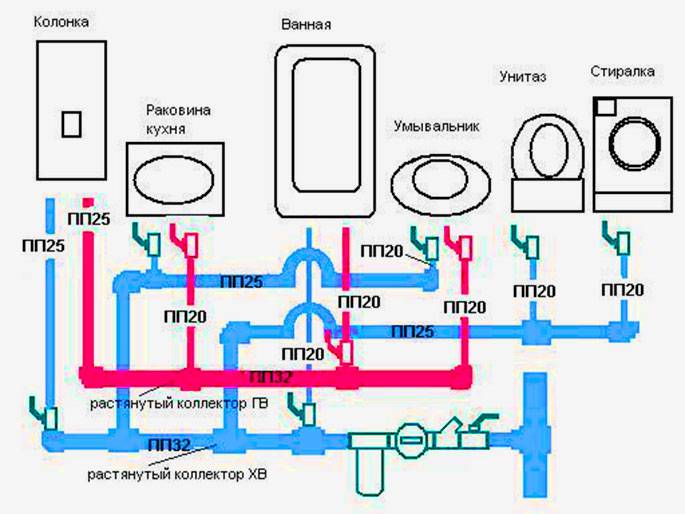

To supply cold water from the main to bathrooms, a boiler or a boiler, the instruction allows the use of a polypropylene (ecoplast) pipe with a monolithic wall, and if we talk about domestic use (a private house or apartment), then a material with an outer section of 20 mm is used. However, most craftsmen in this case tend to use reinforced ecoplastic, which is designed for hot water supply.

Solder fittings and taps made of PP

The pipes are reinforced with fiberglass or aluminum foil - this layer is placed in the middle, as shown in the schematic diagram above. This measure prevents the material from deforming when heated, therefore, similar products are also used for heating. Despite the fact that the price of reinforced pipes is higher, they are used for cold water supply for the purpose of reinsurance - after all, in most cases, the system is made of a hidden type, covering it with plaster, putty, drywall, and so on.

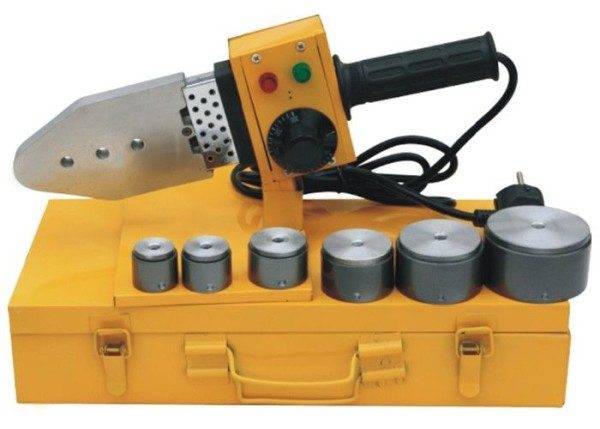

Soldering iron for PP pipes with a set of nozzles

For welding PP, a special soldering iron is used, complete with which nozzles of different diameters are supplied. The quality of this tool is determined by the presence of a thermostat, as well as whether the nozzles are Teflon coated (this directly affects how much the soldering iron costs). The fact is that polypropylene does not burn on Teflon, therefore, in the process of work there is no sticking of material and soot.

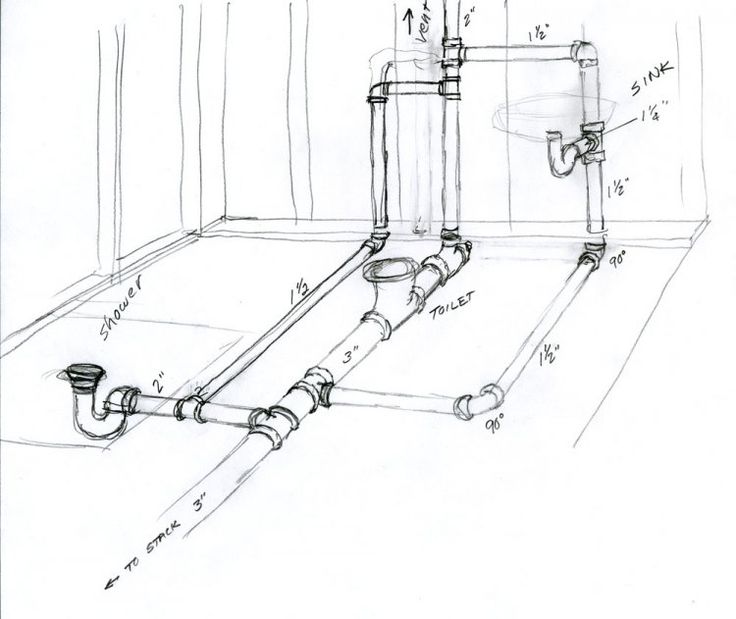

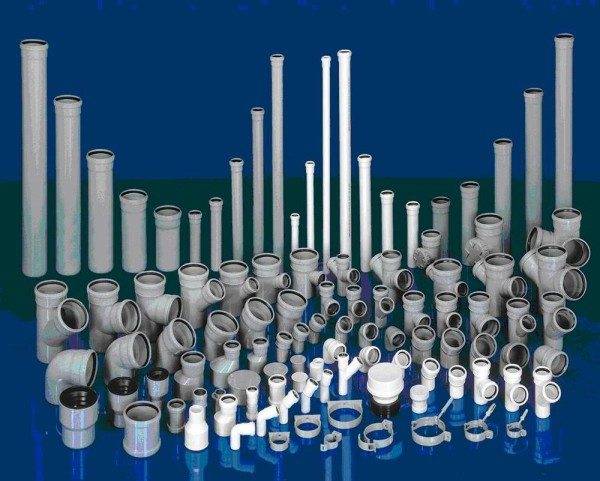

PVC for sewerage - pipes, brackets, fittings

In addition, the piping layout in the bathroom and toilet also includes sewerage, for which products with a diameter of 10 mm are used. 50 mm, 32 mm, as well as connecting, turning and decoupling fittings for them. Currently, both at the domestic and industrial levels, polyvinyl chloride is used for manufacturing, although steel, cast iron and bronze are still found. However, PVC is much cheaper and lighter, and for low pressure pipes, is perhaps the most cost effective and practical.

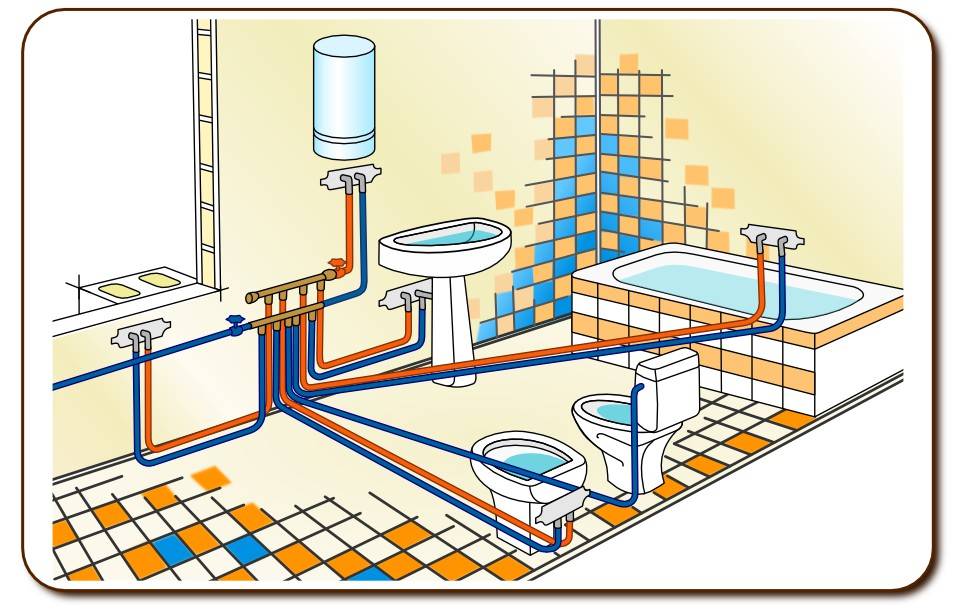

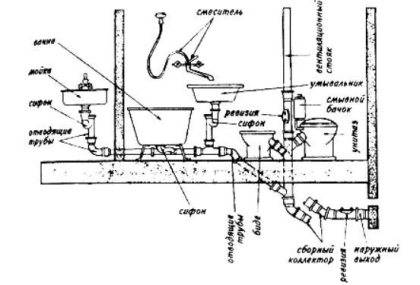

Sewer installation

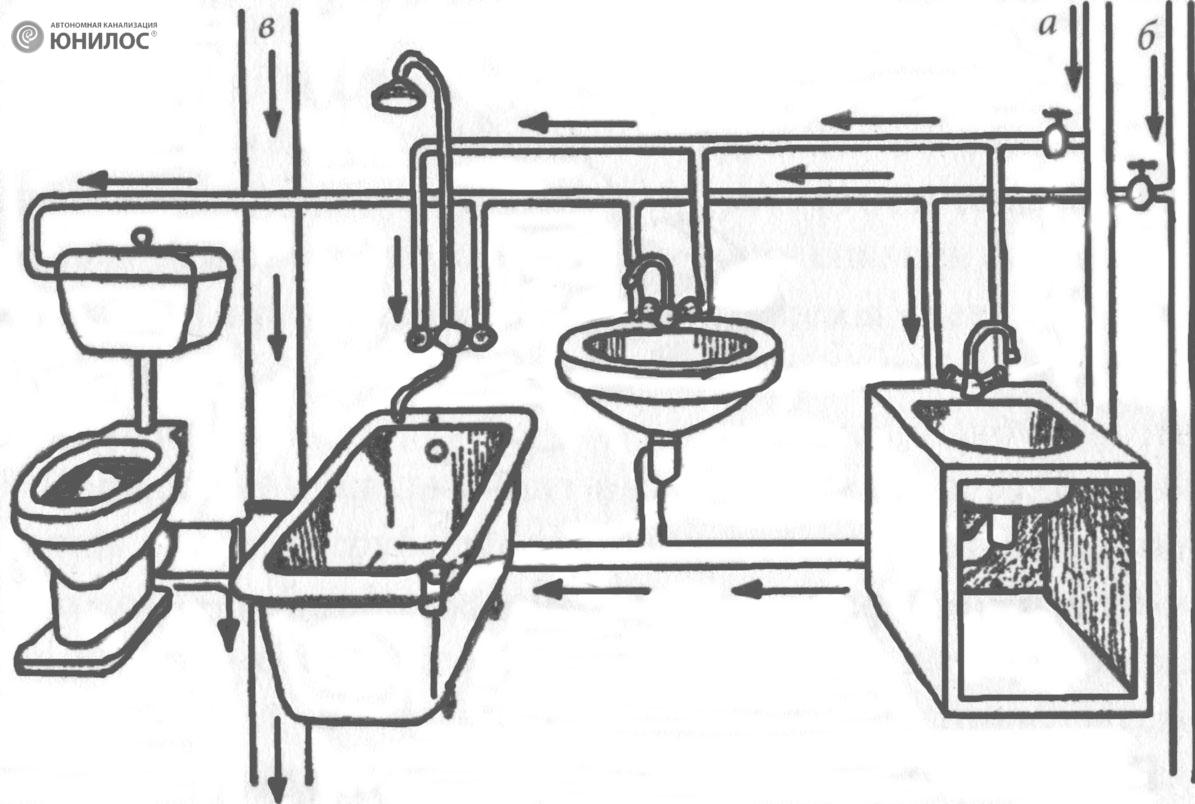

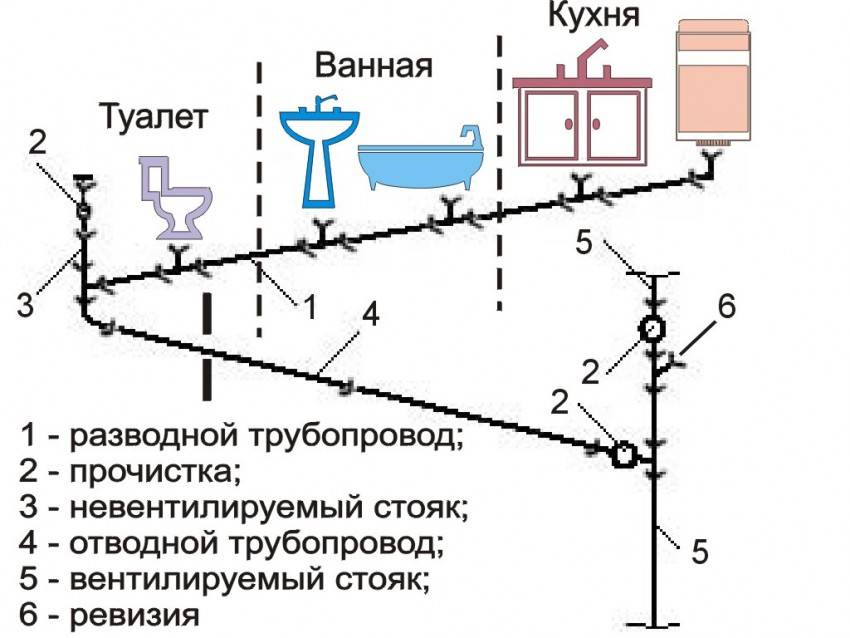

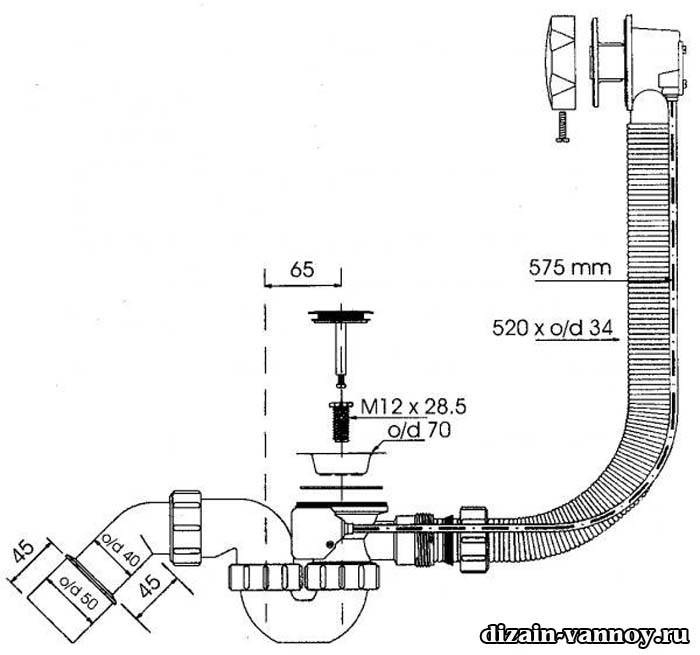

Approximate sewer installation scheme

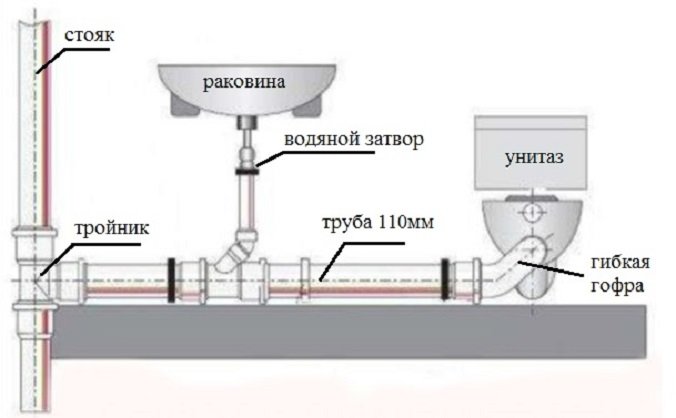

As we have already said, do-it-yourself piping in the bathroom also affects the toilet and the kitchen, because the drain will come from the kitchen through the bath and end in the toilet riser, regardless of whether you have a joint unit or a separate one.

Let's start with the toilet - if you left there old cast iron, then all the same you will put a tee there with one 100 mm outlet to the toilet and 50 mm - to all other bathrooms. To install a plastic fitting into a cast-iron socket, a rubber reduction is used, which serves as both an adapter and a seal.

A 50 mm bend is made towards the kitchen and passes through the bathroom, and tees cut into its length sink drain, bath and kitchen sink.

The automatic washing machine can be connected to a special siphon that you can use under the bath, sink or sink, but you can also make a tap - a reduction for a 32 mm pipe is inserted into the socket of the 50 mm tee, which you lay in the right direction.

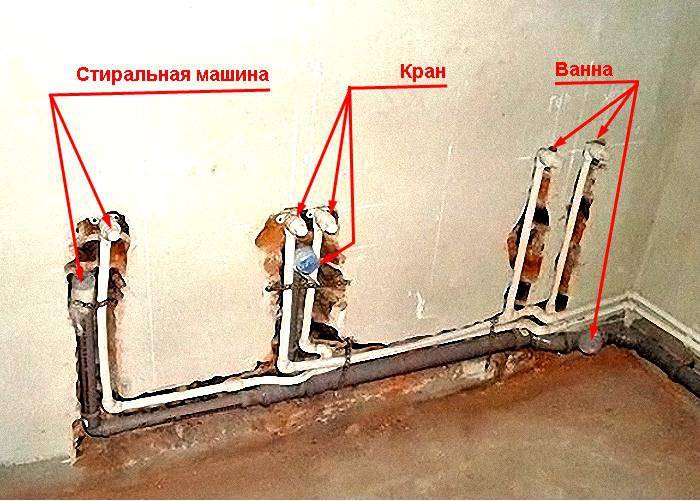

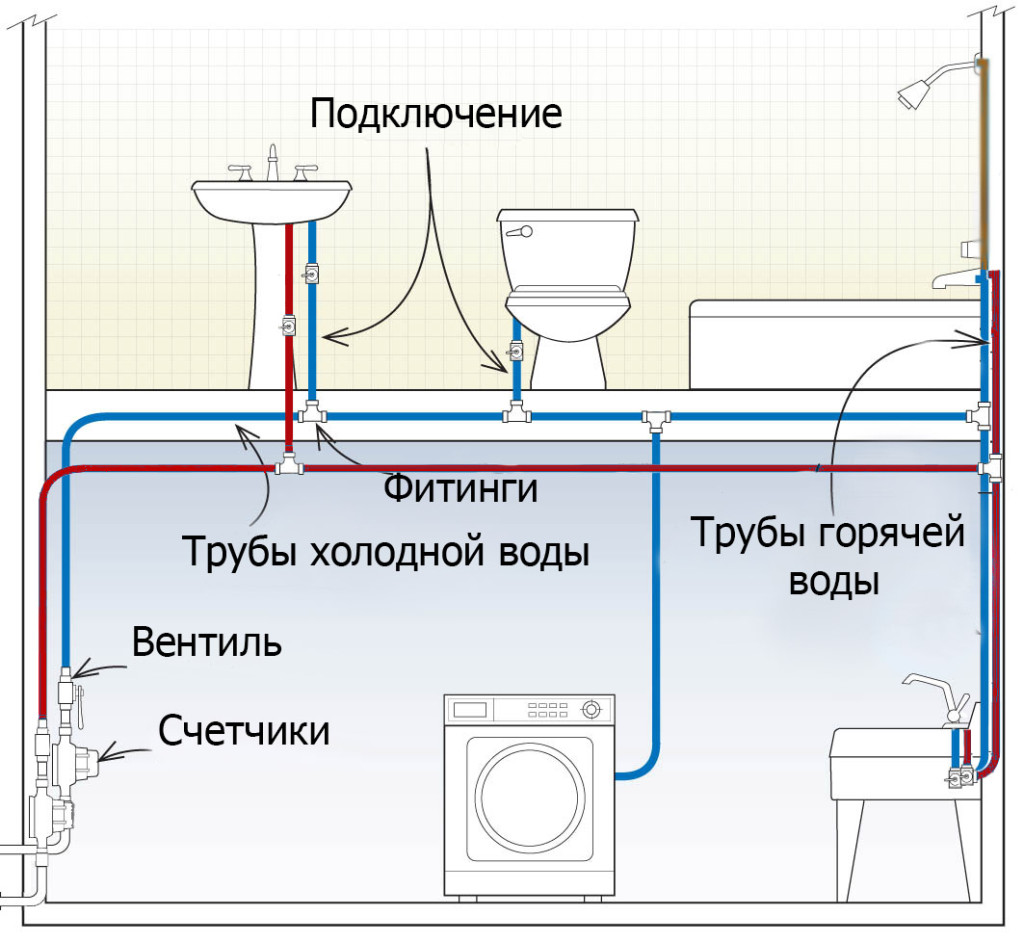

Plumbing installation

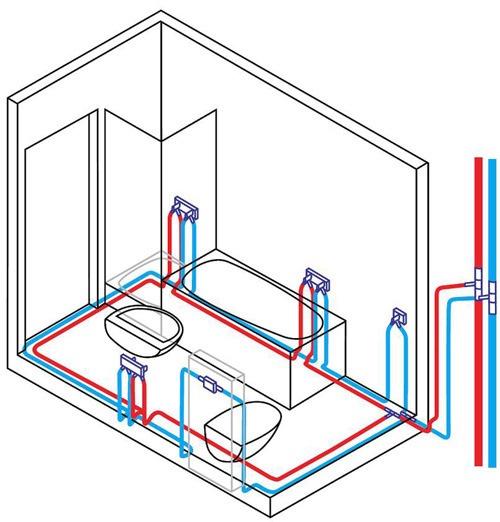

Laying plumbing in strobes

Now let's see how to properly piping in the bathroom, toilet and kitchen with external and internal installation. You can make strobes under polypropylene and hide it in them, as shown in the top photo (after that, the water supply is sealed with a solution), but you can also put it on top, fixing it in metal brackets or plastic clips.

When marking, try to ensure that all threaded fittings for connecting to taps take the most advantageous position and are firmly fixed.

soldering work

We are considering how to make piping in the bathroom, and now let's pay attention to soldering, with the help of which polypropylene is joined through fittings of various configurations. A pipe is applied to the soldering iron nozzle, heated to 280-290⁰C, on one side, and a fitting on the other, and held for 5-6 seconds (make sure that the pipe does not sink into the nozzle deeper than 15-20 mm), then they are simultaneously removed and dock

After docking, it is also desirable to hold them for 5-6 seconds so that they turn into a homogeneous mass

A pipe is applied to the soldering iron nozzle, heated to 280-290⁰C, on one side, and a fitting on the other, and held for 5-6 seconds (make sure that the pipe does not sink into the nozzle deeper than 15-20 mm), then they are simultaneously removed and join. After docking, it is also desirable to hold them for 5-6 seconds so that they turn into a homogeneous mass.

Sewer pipe material

For domestic needs, sewerage is carried out with metal-plastic and plastic products. Their main difference is in resisting corrosion.

Products have the following advantages:

- thermal conductivity at a low level;

- installation is not difficult;

- high reliability in operation;

- affordability.

Polypropylene or polyethylene pipes have these advantages. Their choice for distributing the sewer system will be the most optimal. When working with them, you must have a special "welding soldering iron".

PVC products - the walls are thin. Recommended for laying sewers.

Products made of polypropylene - tolerate boiling water. Disadvantage: under the influence of high temperature increase in size. Most popular mounting option for sewerage.

Made of polyethylene - these are main pipes.

Necessary parts for sewerage installation

For a quality job, additional elements will be required.

For the complete arrangement of water consumption points and sewerage distribution in the bathroom, not only the necessary pipes, sink, toilet bowl, shower stall are purchased, but also additional important appliances:

- water consumption meter - water meter;

- regulation of the movement of water flows is carried out by separate valves;

- for cleaning the water supplied to the bathroom plumbing - a coarse water filter, internal pipeline filters;

- couplings, corners and other elements are purchased as connecting parts or adapters;

- a device that helps maintain water pressure in the water supply and thereby protects the sewerage system from high pressure or surges;

- depending on the configuration of the sewer, plastic parts are purchased (tees, bends, elbows, and others);

- compensator;

- if the pipes are laid along the walls of the room, then special clamps with cushioning pads will be needed. This will help remove noise when draining the liquid;

- for the riser, a revision must be mounted;

- all joints are recommended to be treated with sealant;

- cement.

Welding of polypropylene pipes

The connection of pipes made of polypropylene, including reinforced ones, is made by welding:

- Pipes are cut with special scissors, obtaining segments of a certain length.

- Mark the welding spots to be cleaned using a damp alcohol wipe.

- Having installed the necessary nozzles on the welding machine, turn on the device and set the temperature on it.

- After heating the apparatus (the lights go out), we push the pipe sections onto the nozzles to the marks, but without turning.

When the pipes are already wound up, wait a few seconds and remove the nozzles (let your assistant hold the device), after which we connect the pipes clearly and quickly and hold them together a little. The result will be a smooth connection. When you don’t like the result, the connection section is cut off, and the procedure is carried out again. Welded pipes are left to cool for a short time and then used.

Types of engineering communications wiring

Before designing the wiring, you should get acquainted with what varieties of such structures exist. There are only three of them. And one, with through sockets, is practically not used. Therefore, we will not consider it.

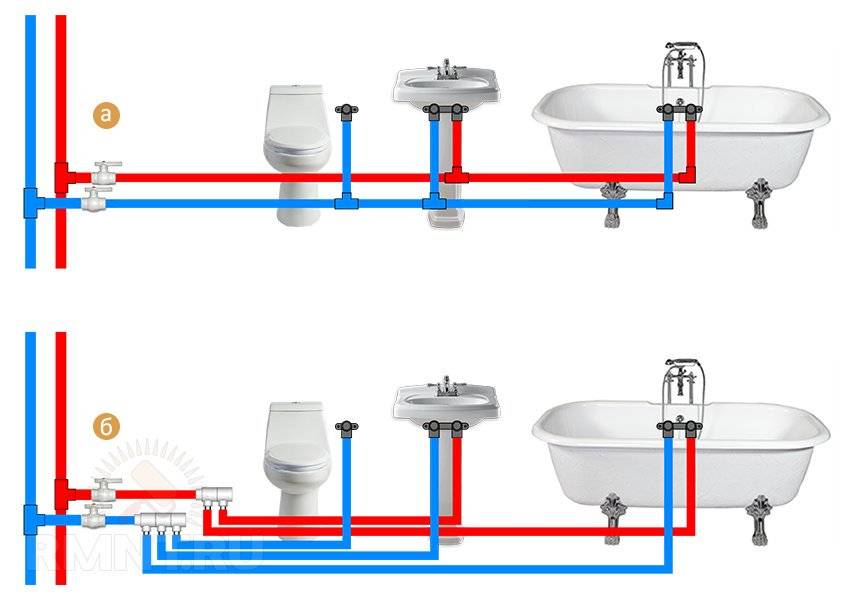

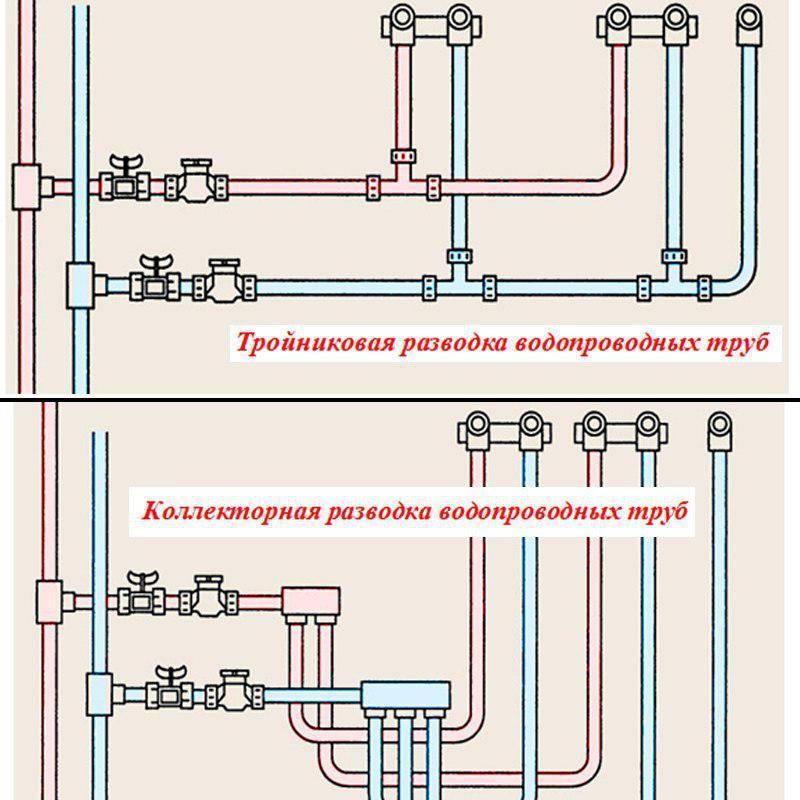

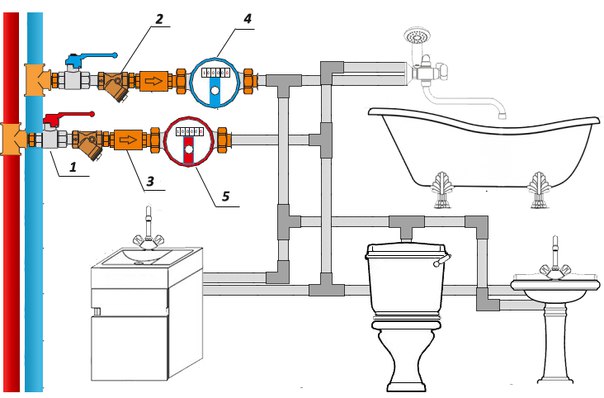

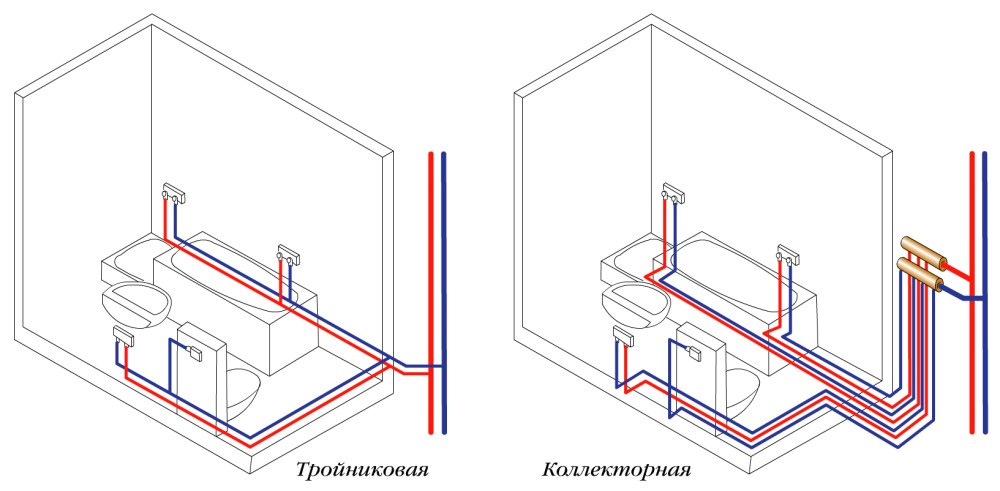

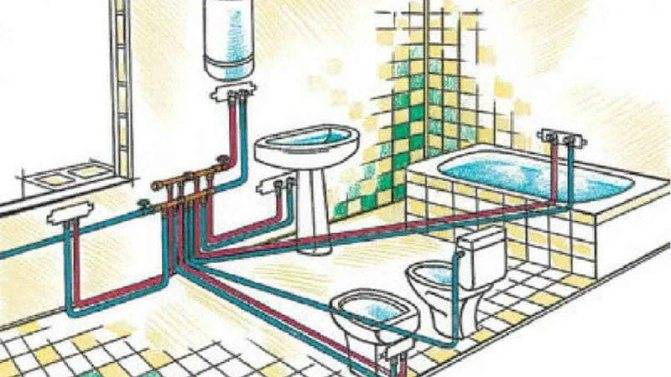

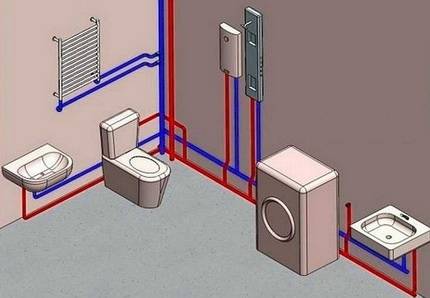

Type #1. Serial type wiring

For its implementation, taps are made from the risers of cold and hot water supply, leading to the first consumer. Pipes are laid from it to the second and further. Each tapping point is equipped with a tee, to one of the outlets of which the consumer is connected.

In general, this is a very simple scheme. It can be used only where the number of water consumers is small.

This is due to the fact that with the simultaneous activation of several points of water intake at once, the pressure in them will weaken, and may not be sufficient for the correct operation of the equipment. This is the main disadvantage of serial wiring.

However, for apartments with one bathroom and a small amount of used plumbing, this option may be the best. A significant drawback of the system is the inability to turn off one of the plumbing fixtures for replacement or repair.

Serial wiring is extremely easy to implement, but not very convenient to use. However, for small bathrooms, this solution may be quite acceptable.

The advantages of serial wiring are much greater. First of all, it is simplicity in design and installation. There will be no complicated schemes, everything is very simple.

In addition, such wiring is considered the most economical option.The consumption of pipes and other elements will be significantly lower than in other systems, installation costs are also minimal.

Even a novice plumber can handle the design and subsequent arrangement of a consistent, otherwise tee wiring

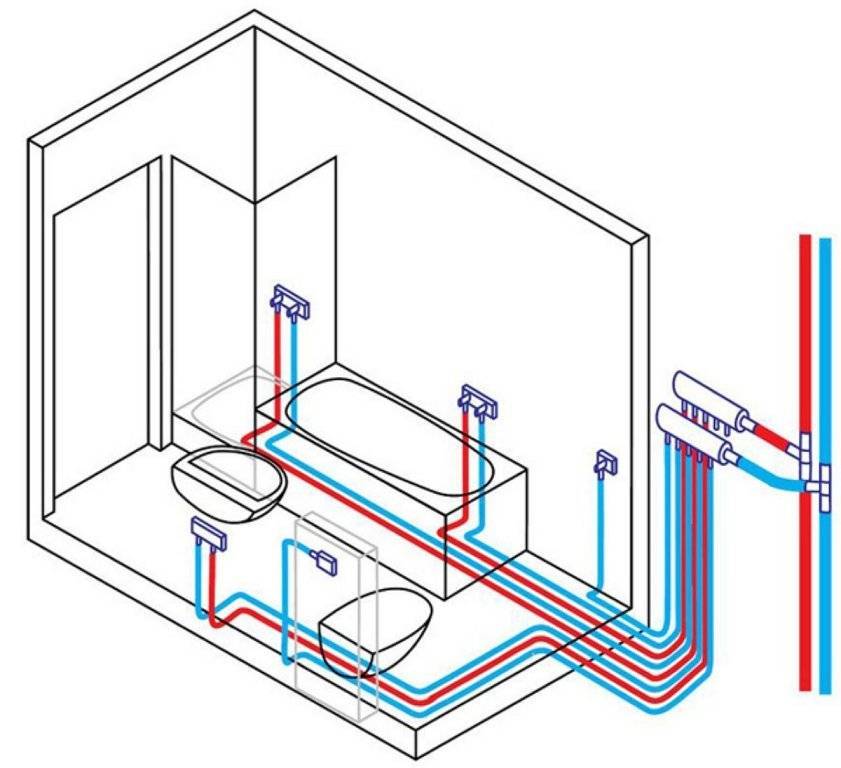

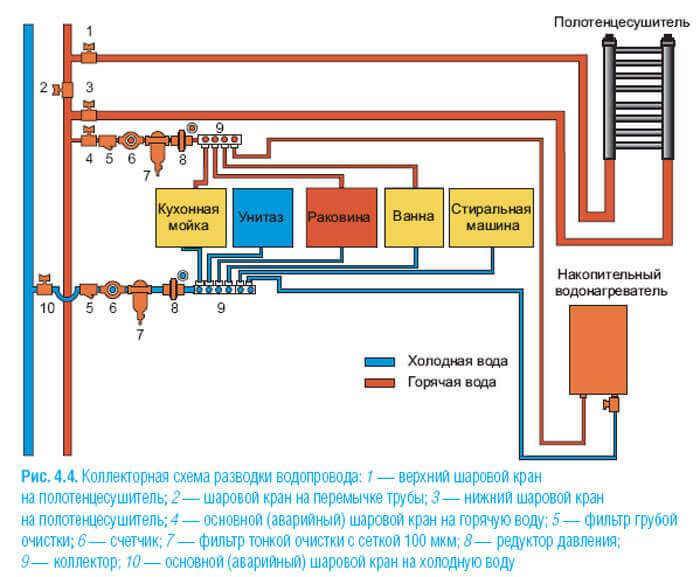

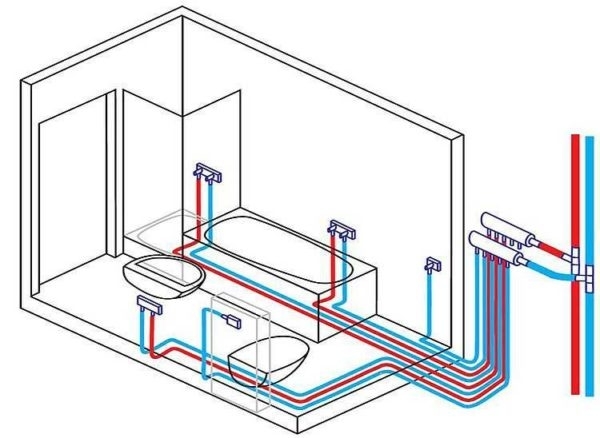

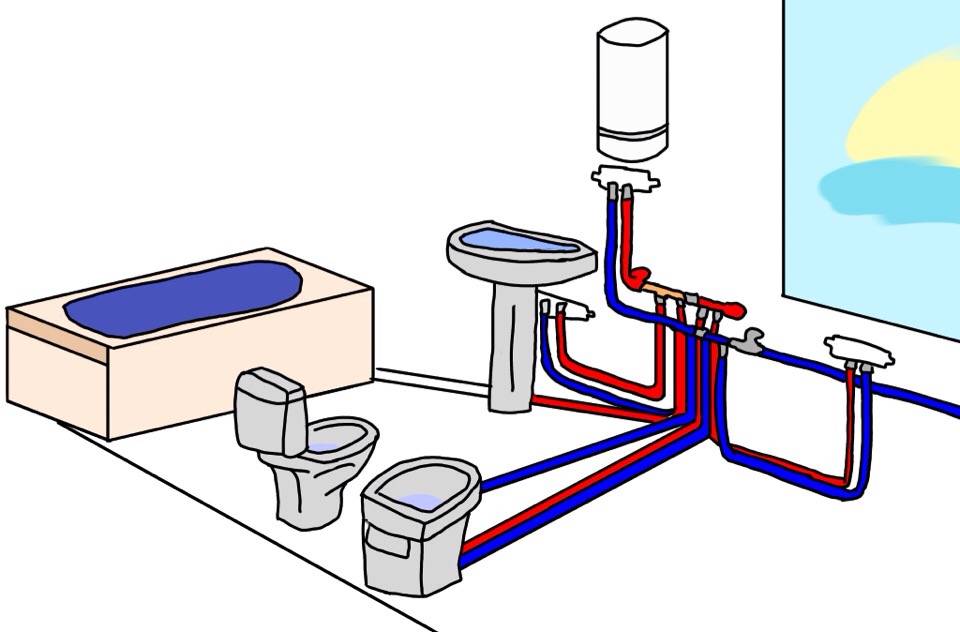

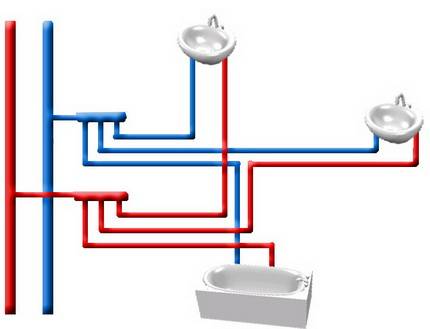

Type #2. Collector type wiring

The collector type scheme involves connecting each of the consumers to the main highway. For this, a special element is used, which is called a collector - a device that distributes water flows.

In a more complex version, and this is best, each collector outlet is equipped with a shut-off valve. Collector-type wiring can be considered the most convenient option to use. There are several reasons for this.

First, the absence of pressure drops in the system. All consumers receive equally good water pressure, even if all draw-off points operate simultaneously.

If the pressure in the system of an apartment or a private house, or for some reason is too low, you can temporarily limit the water supply to one of the consumers, for example, to the toilet, in order to thereby increase the pressure for others.

The collector type of wiring is more convenient to use than the serial one. In this case, a separate line goes to each consumer, which ensures that there are no pressure problems. However, in the design and installation of such a system is more complex.

Secondly, the ability to turn off plumbing fixtures from the water supply if they need to be replaced or repaired.

Thirdly, reliability. In fact, a single pipe goes to each consumer, without any connections and other elements. A leak can appear only in the area of \u200b\u200bthe collector or near the device itself. Here it will be very easy to find.For this reason manifold pipes can be safely mounted by a hidden method.

Fourth, ease of use. If there is a problem with a plumbing fixture and a leak appears, for example, at a mixer, you do not need to crawl under the sink. It is enough to block the shut-off valve leading to the faulty device. manifold valve and wait for the arrival of specialists.

Even a woman or child unfamiliar with plumbing intricacies can do this. In this case, all other equipment will work properly.

Professionals recommend using manifolds with stopcocks for installation in plumbing systems. With their help, if necessary, you can easily stop the water supply to a branch or plumbing fixture in need of repair.

However, collector wiring also has some disadvantages. First of all, it will cost the owner more than the serial circuit, the amount. This is due to the fact that you need to lay a branch to each consumer. It will take a lot more material.

In addition, the installation of manifolds and shut-off valves will be required if the distributors are not equipped with them. And the circuit itself will be much more complicated than the sequential one.

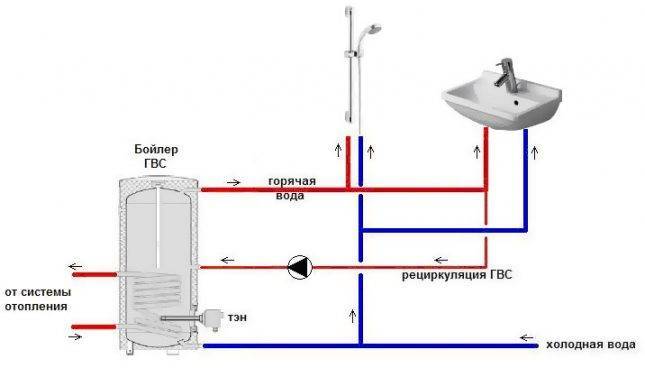

Dead-end and closed circuit: pros and cons

The sequential and collector-beam circuits discussed above refer to the so-called deaf (dead-end) methods of distributing water pipes. In them, each branch of the water supply ends with a consumption point (dead end). Such a network configuration is good in terms of saving materials and space, but loses in comfort when it comes to hot water supply.The water in the main will constantly cool down, so before taking advantage of all the benefits of hot water supply, you will have to drain several liters of liquid into the sewer each time. It would seem that not such a big expense for the year will result in several wasted cubic meters. In addition, the delay in supplying water at a suitable temperature takes time and causes discomfort.

A water supply system with constant circulation of hot liquid will save several cubic meters of water per year

A way out of this situation can be found in the installation of closed-type wiring. A characteristic feature of this scheme is the constant circulation of hot water in a circle. Since at the same time it has a constant temperature at each point of the pipeline, the consumer will receive hot water as soon as the valve is opened.

The obvious advantage of this method is complemented by another plus - the absence of sudden temperature changes, which is important for hot water systems. It has a closed circulation wiring and disadvantages. A more intricate scheme complicates installation and requires additional costs of materials and equipment

So, when arranging it, you will need almost twice as many pipes, and in addition, you will have to install a separate circulation pump, which will ensure the forced movement of fluid through the system

A more intricate scheme complicates installation and requires additional costs of materials and equipment. So, when arranging it, you will need almost twice as many pipes, and in addition, you will have to install a separate circulation pump, which will ensure the forced movement of fluid through the system.

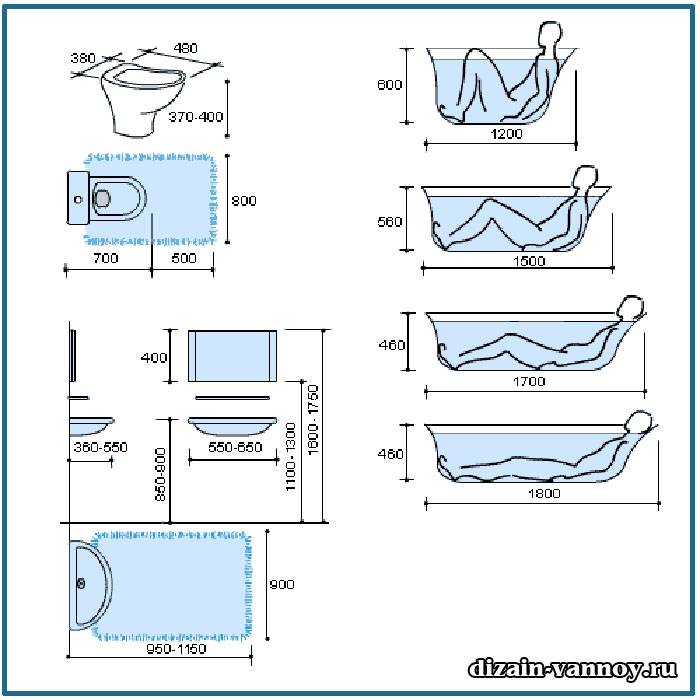

Bathroom installation

When making any type of repair in the bathroom, the plumbing layout in the bathroom is designed from the location of the bathroom itself, since it is the most massive item and occupies the most free space. The arrangement of plumbing in the bathroom also begins with this element, since in most small rooms, after installing the washbasin and toilet bowl, the bathroom bowl may simply not fit or damage other elements during installation.

Scheme of the installed bathroom

The installation process itself is extremely simple, but requires a certain sequence. Today, there are a huge number of models of bathtubs from different materials and with different dimensions, however, the plumbing connection scheme in the bathroom is the same for all products. The first step is to carefully bring the product into the room and install it at a distance of 50-60 cm from the wall in order to provide free access from all sides. If the bathroom has an overflow protection hole, then first of all we install it and lower the pipe to the lower drain siphon.

Before you do plumbing in the bathroom, make sure that the bathroom you bought is equipped with a drain siphon, all the necessary pipes and seals, as well as instructions for installing them. If this is not included in the kit, then it is recommended to purchase all the necessary items in the same store in order to properly connect the plumbing in the bathroom.

Siphon connection diagram

Siphon connection diagram

Next, install the lower siphon and connect it to the sewerage system, for this it is best to use a corrugated hose.Then, before placing plumbing in the bathroom, we check the tightness of the connection of the lower siphon, for this we close the drain hole and pour some water into the bathroom, about ¼ of its total volume. We put a dry rag under the siphon and wait 15-20 minutes. If the rag is dry, then open the hole and drain the water, simultaneously checking the entire drain line for leaks.

Today, almost all manufacturers of bathroom models, washbasins and toilet bowls, try to adhere to the established overall standards, so that the placement of plumbing in the bathroom can be conveniently calculated. Looking at the diagram below, you can draw up a preliminary layout of the total area, since almost all models of different plumbing elements rarely go beyond the dimensions indicated below.

Standard dimensions for advance planning

Standard dimensions for advance planning

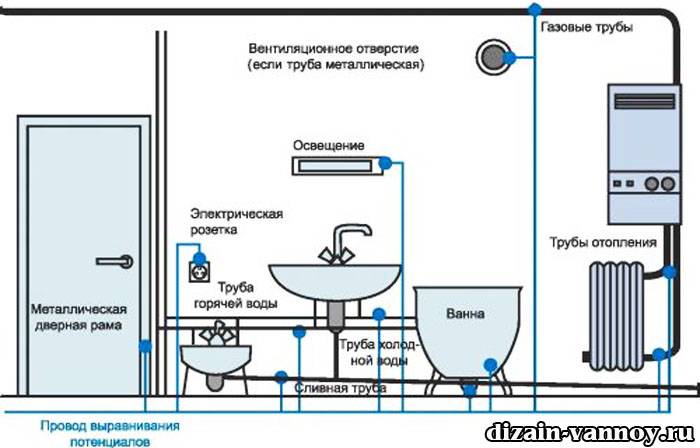

Bathroom grounding

Replacing plumbing in the bathroom necessarily involves laying a grounding system, especially if various electrical appliances are installed in the room. If the house has a potential equalization system, then new plumbing is connected to this system. If there is no such system, then before changing the plumbing in the bathroom, you must invite an electrician who will give advice or install a grounding system according to the diagram below.

Grounding scheme for plumbing elements

Grounding scheme for plumbing elements

What materials to prefer

Before piping in the bathroom and toilet, you should decide on the material from which it will be made. It is difficult to give an exact answer which material is better, because there are many factors that affect a particular situation.

It is only worth noting that most often consumers prefer polypropylene and PVC pipes. In places where it is planned to supply hot water, it is better to choose pipes made of metal-plastic. When choosing a heated towel rail, it is better to give preference to a product made of stainless steel than brass, as it will last much longer.

In this article, we looked at how to lay pipes in the bathroom, as well as what rules should be followed in order to avoid a number of mistakes. Additionally, you can visually study the basic processes of laying pipes in the bathroom in the corresponding video.

How to choose pipes?

The defining parameter is reliability. Pipes in the bathroom must withstand maximum pressure. For centralized systems, it fluctuates from 2 to 7 atm. at a rate of 4 atm. In autonomous - up to 5 atm. It is necessary to take into account not only the wall thickness of the line, but also the reliability of the connecting elements - fittings, welded or threaded structures.

Overview of pipes for arranging water supply in the bathroom:

- Plastic. Production material - PVC, polypropylene (PP). To increase reliability, they have a multilayer structure - reinforcement with aluminum foil or fiberglass, a barrier against air entering water. Connected by welding, cold or hot. An example is the Rehau universal pipes of the Rautitan Flex series.

- Metal-plastic. By contraction they are similar to plastic ones, the material is PE (polyethylene), PE-X (cross-linked polyethylene) or PE-RT (for heating and hot water supply). The connection is mechanical, using steel couplings. They have better flexibility than plastic ones, the ability to quickly replace individual sections of the water supply system.

- Metal.They are rarely used, the reasons are rusting, large mass, laborious installation. The connection is welded, threaded couplings are less commonly used.

The diameter affects the water pressure, which is important for water supply systems. The smaller it is, the more pressure

For piping in the bathroom, pipelines with a diameter of up to 20 mm are used. If the total length of the line exceeds 30 m, you need to increase this parameter to 32 mm. When installing plumbing in a bathroom from polypropylene pipes, it is necessary to take into account the thermal expansion of the material. For extended sections, installation is required compensation loops.

plastic pipes

- Long service life, up to 30 years

- No corrosion

- Quick installation

- Good thermal insulation

- Thermal expansion, compensatory loops needed

- Part is destroyed by exposure to sunlight

- A welding machine is required for connection

Plastic pipes for water supply: dimensions and diameters, characteristics of materials The use of plastic pipes for water supply made it possible to get rid of bulky steel networks, which were previously equipped with almost all residential buildings and public buildings. Sturdy and comfortable to…

Metal-plastic pipes

- Impermeable to oxygen, will not air

- Mechanical resistance

- No special tools are required to install the couplings

- Minimum bending radius up to 5 diameters

- Maximum water temperature up to +95°С

- combustibility

- Different bore diameters for pipes and fittings

Steel pipes

- High strength

- Work in high pressure systems

- Good tightness, no air leakage

- Maximum water temperature up to +95°С

- combustibility

- Different bore diameters for pipes and fittings

When connecting steel pipes with fittings made of other metals, rapid oxidation will occur at the junction.