- The main elements of the water heating system

- Boiler selection by the number of circuits

- Boiler selection by type of fuel

- Boiler selection by power

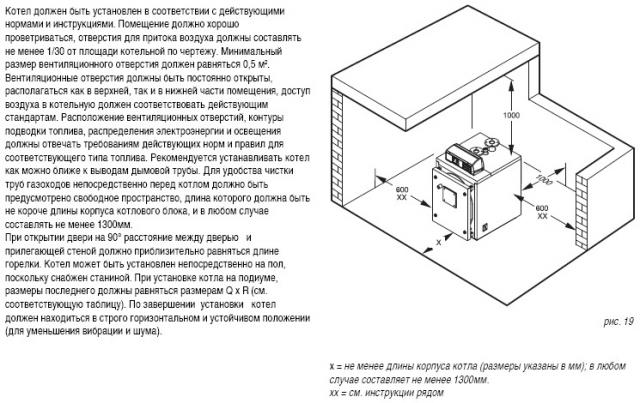

- Installation and connection of equipment - how to install the boiler

- Which home heating system to choose

- Pros and cons of a single-pipe scheme

- What is required for installation

- Heat source selection

- Pipes

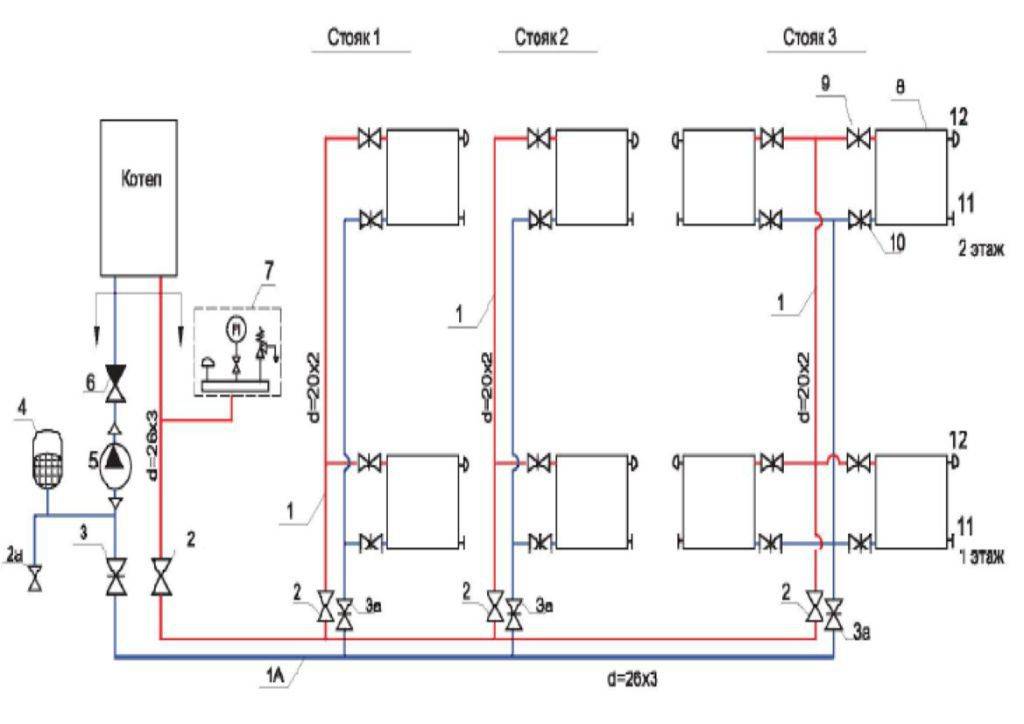

- Features of the use of vertical wiring of heating pipes

- The main constituent elements of vertical heating distribution

- Advantages of organizing vertical heating from two pipes in an apartment

- How is a heating radiator replaced for a vertical two-pipe system?

- More about the coolant and its properties

- The latest heating systems

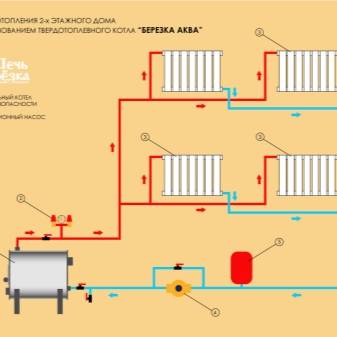

- How to connect a solid fuel boiler

- How the scheme works

- Way to reduce the cost of strapping

- The principle of operation of closed CO

- Calculation of heat consumption for ventilation

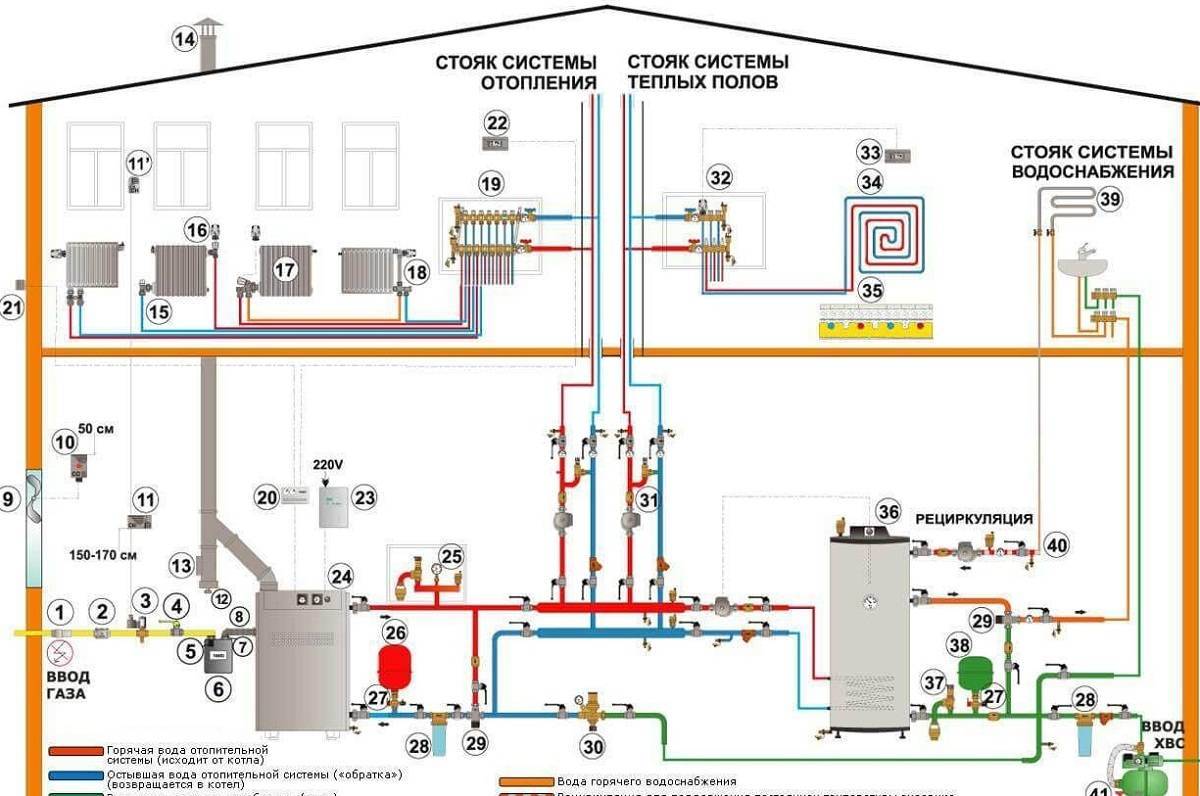

The main elements of the water heating system

The main elements of the water heating system include:

- boiler;

- a device that supplies air to the combustion chamber;

- equipment responsible for the removal of combustion products;

- pumping units that ensure the circulation of the coolant through the heating circuit;

- pipelines and fittings (fittings, shut-off valves, etc.);

- radiators (cast iron, steel, aluminum, etc.).

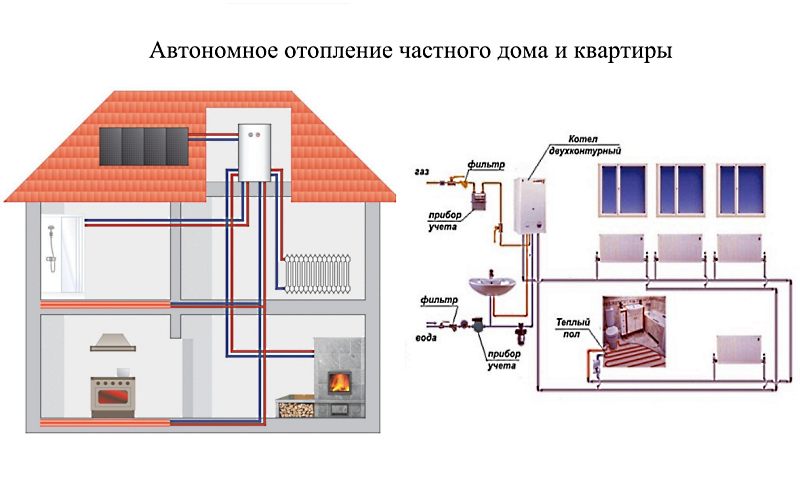

Boiler selection by the number of circuits

For heating the cottage, you can choose a single-circuit or double-circuit boiler. What is the difference between these models of boiler equipment? A single-circuit boiler is designed only for heating the coolant intended for circulation through the heating system. Indirect heating boilers are connected to single-circuit models, which supply the facility with hot water for technical purposes. In dual-circuit models, the operation of the unit is provided in two directions that do not intersect with each other. One circuit is responsible only for heating, the other for hot water supply.

Boiler selection by type of fuel

The most economical and convenient type of fuel for modern boilers has always been and remains main gas. The efficiency of gas boilers is not disputed, since their efficiency is 95%, and in some models this figure goes off scale for 100%. We are talking about condensing units capable of "pulling" heat from the products of combustion, flying away in other models simply "into the pipe".

Heating a country cottage with a wall-mounted gas boiler is one of the most popular ways to heat living space in gasified regions.

However, not all territories are gasified, therefore, boiler equipment operating on solid and liquid fuels, as well as on electricity, is very popular. It is even more convenient and safer to use electric boilers for heating a cottage than gas, provided that the stable operation of the power grid is established in the region. Many owners are stopped by the cost of electricity, as well as the limitation of the rate of its release for one object.The requirement to connect an electric boiler to a three-phase network with a voltage of 380 V is also not to everyone's liking and affordability. It is possible to make electric heating of cottages more economical by using alternative sources of electricity (windmills, solar panels, etc.).

In cottages built in remote regions, cut off from gas and electric mains, liquid fuel boilers are installed. As fuel in these units, diesel fuel (diesel oil) or used oil is used, if there is a source of its constant replenishment. Solid fuel units operating on coal, wood, peat briquettes, pellets, etc. are very common.

Heating a country cottage with a solid fuel boiler that runs on pellets - granulated wood pellets that have a cylindrical shape and a certain size

Boiler selection by power

Having decided on the type of boiler equipment according to the fuel criterion, they begin to select a boiler of the required power. The higher this indicator, the more expensive the model, so you should not miscalculate when determining the power of the unit purchased for a particular cottage. You can't follow the path: the less, the better. Since in this case the equipment cannot fully cope with the task of heating the entire area of a country house to a comfortable temperature.

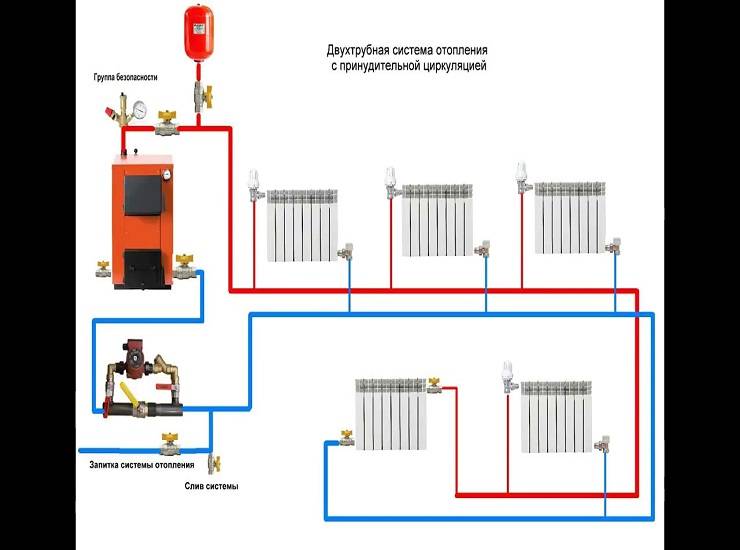

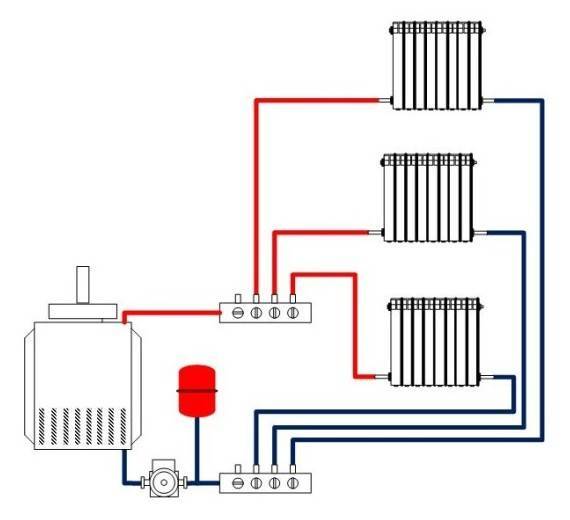

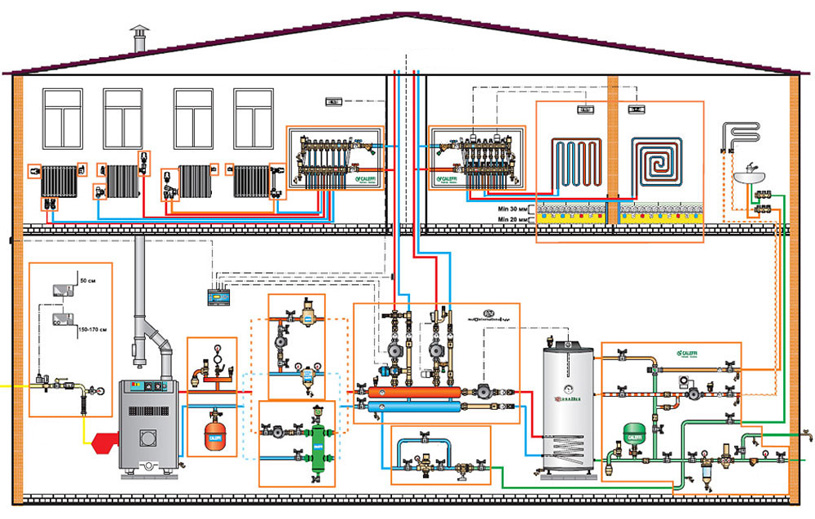

Installation and connection of equipment - how to install the boiler

Gas, diesel and electric boilers are obliged in almost the same way. The fact is that almost all wall-mounted models have built-in circulation pumps and expansion tanks. The simplest and most common piping scheme provides for the location of the pump with a bypass line and a sump on the return line.An expansion tank is also mounted there. A manometer is used to control the pressure, and air is vented from the boiler circuit through an automatic air vent. An electric boiler that is not equipped with a pump is tied in the same way.

If the heat generator has its own pump, and its resource is also used to heat water for hot water, pipes and elements are bred in a slightly different way. The removal of flue gases is carried out using a double-walled coaxial chimney, which goes out through the wall in a horizontal direction. If the appliance uses an open type firebox, then a conventional chimney duct with good natural draft will be required.

Extensive country houses quite often provide for the docking of a boiler and several heating circuits - a radiator, underfloor heating and an indirect hot water heater. In this case, the best option would be to use a hydraulic separator. With its help, you can achieve high-quality organization of autonomous circulation of the coolant in the system. At the same time, it acts as a distribution comb for other circuits.

The great complexity of tying solid fuel boilers is explained by the following points:

- The risk of overheating due to the inertness of the appliances, as the heating system in a private house works on wood, which does not go out quickly.

- When cold water enters the tank of the unit, condensation usually appears.

So that the coolant does not overheat and does not boil, a circulation pump is placed on the return line, and a safety group is placed on the supply immediately after the heat generator. It consists of three elements - a pressure gauge, an automatic air vent and a safety valve.The presence of a valve is of particular importance, since it is used to relieve excess pressure in case of overheating of the coolant. When firewood is used as a heating material, the firebox is protected from liquid condensation by a bypass and a three-way valve: it retains water from the network until it heats up above +55 degrees. In heat generating boilers, it is desirable to use special buffer tanks that act as heat accumulators.

Often, furnace rooms are equipped with two different heat sources, which provides for a special approach to their piping and connection. Usually, in this case, in the first scheme, a solid fuel and electric boiler are combined, synchronously supplying the heating system. The second option involves a combination of a gas and wood-fired heat generator that feeds the home heating system and hot water supply.

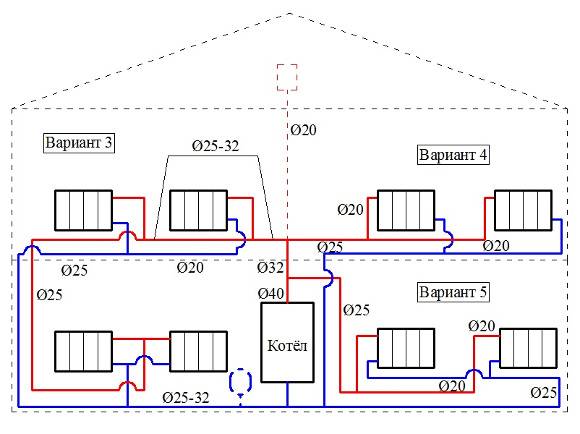

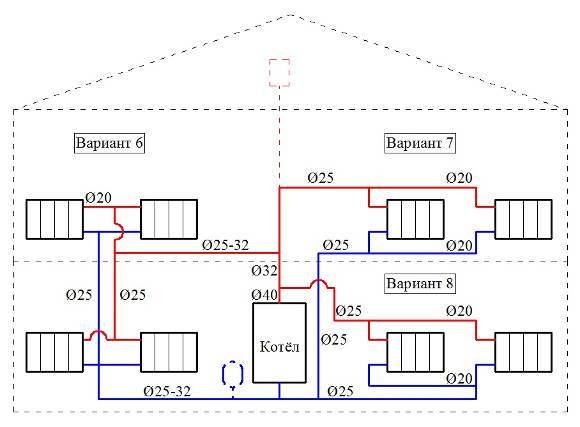

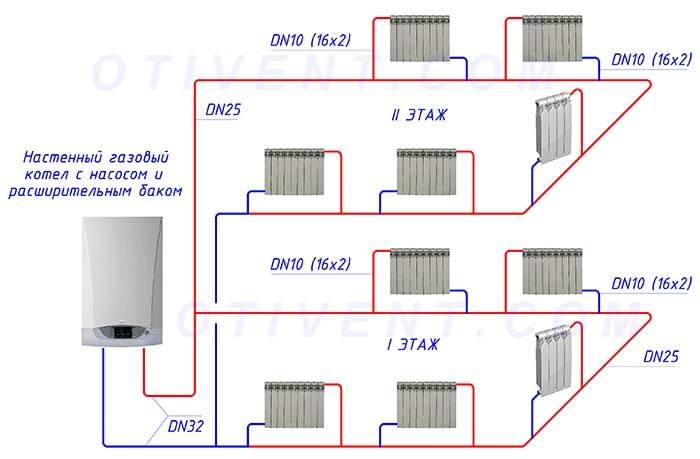

Which home heating system to choose

There are several types of heating systems. They differ in piping, how radiators are connected, and how the coolant moves in them. Competently choosing the most effective option is possible only if you have knowledge in heat engineering. It is necessary to make complex calculations and prepare a project. For a small cottage, the simplest one-pipe scheme is quite suitable. In other cases, it is better to entrust the design to a professional. But installation work can be done independently.

Pros and cons of a single-pipe scheme

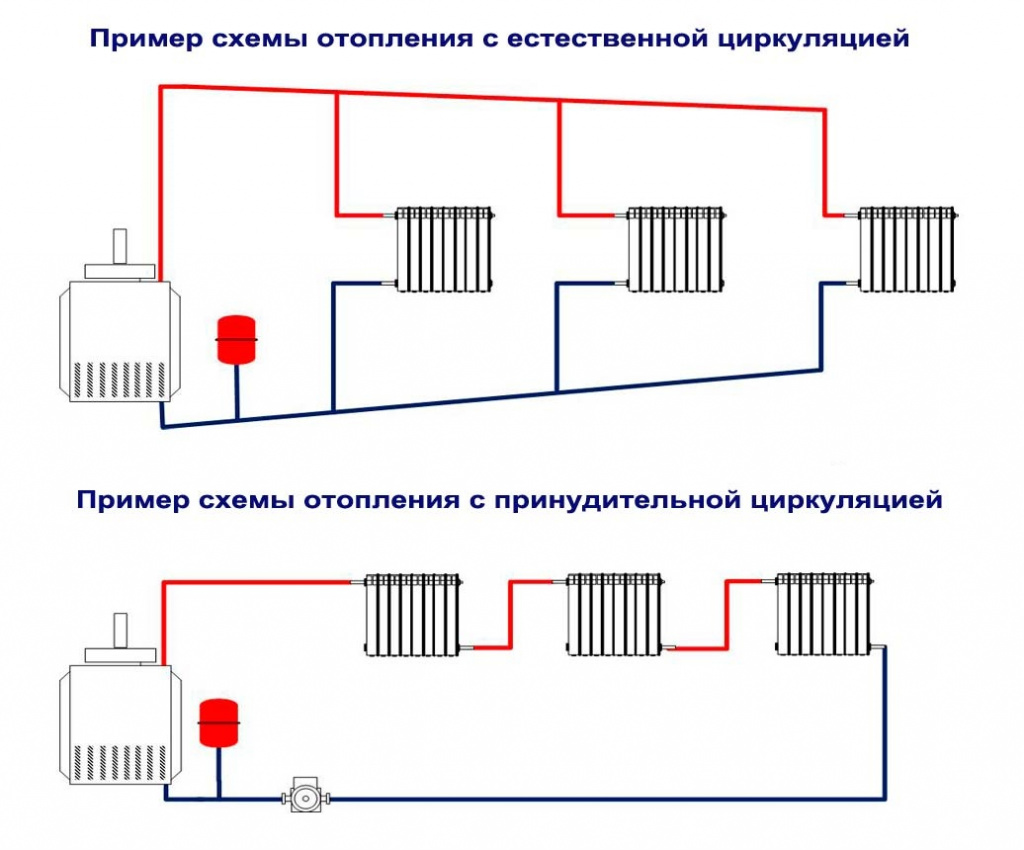

Single pipe heating system of a two-story private at home is able to function normally only with forced circulation from the pump.The design is as follows: one highway runs along the perimeter of the floor, where all the batteries are connected. That is, the collector simultaneously plays the role of supply and return.

The Leningradka system is compact and works great with a small number of heaters

The work of a single-pipe scheme, called "Leningradka", is quite complicated:

- If the pipelines are calculated correctly, then approximately 1/3 of hot water flows into each radiator. The remaining 2/3 of the volume moves further along the highway.

- The coolant that has passed the battery gets rid of heat and returns to the collector, lowering the flow temperature by 1–2 °C.

- The cooled water flows to the next radiator, where the process of separation and merging of flows is repeated. The temperature of the coolant in the collector drops again. How many batteries are connected to the ring main, so many times the water will cool.

- Having passed the last heater, the cold coolant returns to the boiler.

Supporters of "Leningradka" call its main advantage the low cost of materials and installation. We agree with the statement, but with a caveat: if the assembly is made with cheap polypropylene.

Single-pipe wiring is easier to lay in building structures

A single-pipe heating scheme made in a two-story house made of metal-plastic, cross-linked polyethylene or metal will cost more than a two-pipe one due to the price of fittings. The exact calculation will be provided by our expert Vladimir Sukhorukov in the video below.

Cons of "Leningradka" look like this:

- since each subsequent radiator receives a cooler coolant, it is necessary to increase the number of sections for heating distant rooms;

- in order not to select the number of sections at random, it is necessary to calculate the cooling of the water;

- the maximum number of efficiently operating batteries on one branch is 5-6 pieces, otherwise it will be necessary to increase the diameter of the distributing pipe to 40-50 mm;

- a looped highway is more difficult to run around the house - doorways interfere, especially on the second floor;

- heating devices influence each other, which makes it difficult to organize automatic control.

A small plus of single-pipe wiring: one branch is easier to hide in a wall or under the floor than two. The heating network can be easily combined with other types of forced circulation systems.

What is required for installation

In a private house, a do-it-yourself heating device begins with drawing up a working diagram of the entire heating system with the exact linear dimensions of each section of the pipeline and the area of \u200b\u200bthe premises. The drawing data is necessary to visualize the general heating scheme and to calculate the required number of pipes.

It is not necessary to be a professional draftsman to draw up an executive scheme. It is enough to draw an arbitrary simple drawing, place heating radiators on it and calculate the number of pipes for the combined circuit.

Based on the initial data and a preliminary calculation of the required amount of thermal energy to heat the house, you can begin the selection of materials for the device of a home autonomous system.

Heat source selection

The boiler is the main element of thermal energy generation. The main criterion for choosing a heat generator depends on the type of fuel as the source of its operation. The power of the boiler is calculated according to several factors:

- The volume of heated rooms.

- Climatic features of the region.

- The thickness of the outer walls.

- The presence of thermal insulation of the main structural elements of the building.

- Basement and attic space available.

When choosing a heating boiler, it is important to pay attention to the adaptation of the selected model to domestic conditions and the availability of a quality certificate

Pipes

Properly selected type of pipe for heating eliminates technical operational problems, guarantees a high degree of reliability of the heating line. More recently, steel metal pipes were used for laying heating pipelines. It was difficult to assemble such a heating network, individual pipes had to be welded together.

Properly selected type of pipe for heating eliminates technical operational problems, guarantees a high degree of reliability of the heating line. More recently, steel metal pipes were used for laying heating pipelines. It was difficult to assemble such a heating network, individual pipes had to be welded together.

Currently, piping is best done from the following materials:

- polypropylene with internal reinforcement of aluminum or fiberglass;

- metal-plastic;

- cross-linked polyethylene;

- polyethylene with PE-RT additives;

- copper.

Of the listed list, polypropylene pipes are considered the most popular, which are durable, flexible, resistant to temperature extremes and corrosion. This material is easy to mount and connect to heating radiators.

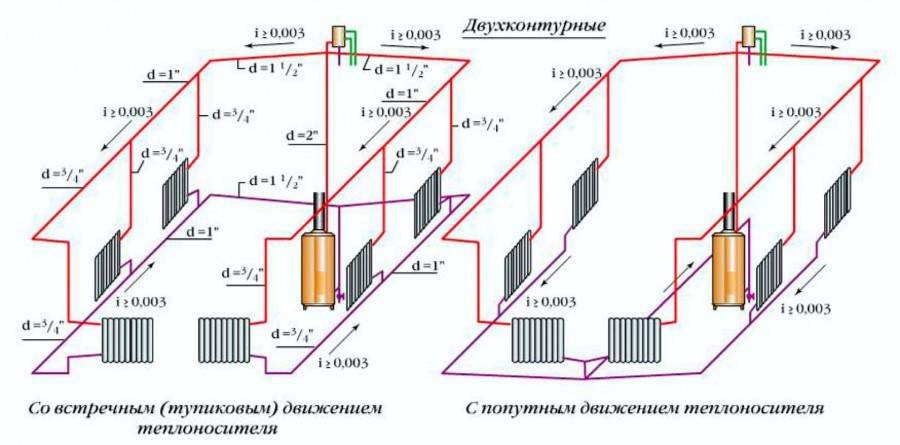

Features of the use of vertical wiring of heating pipes

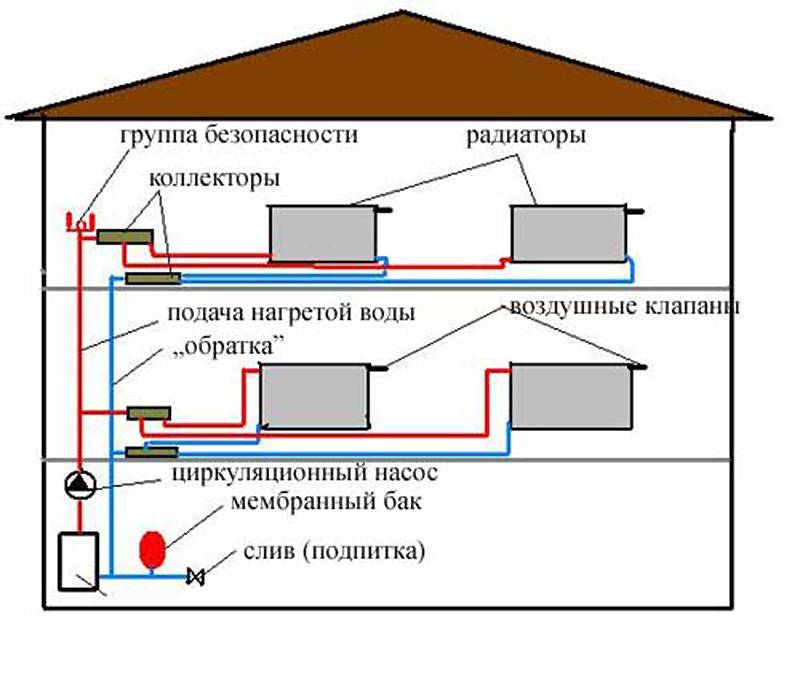

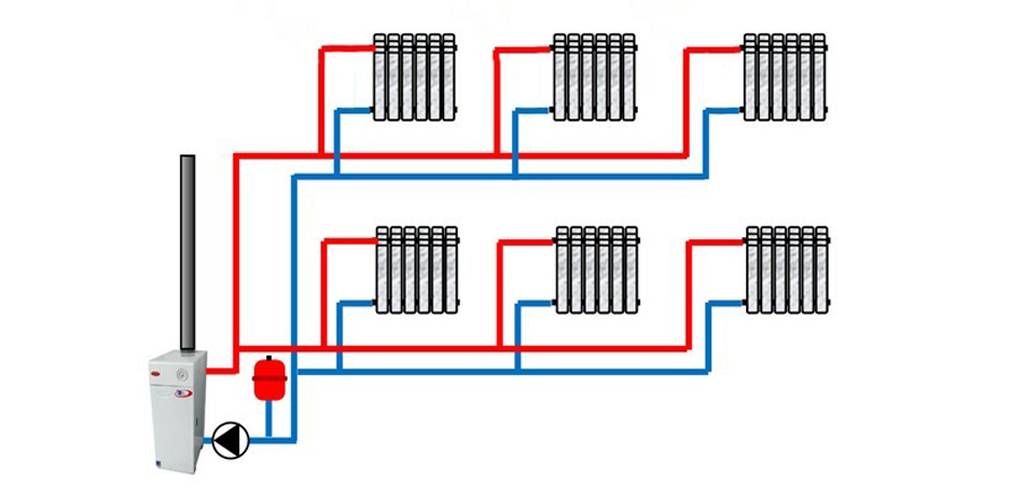

The vertical organization of the heating system involves the connection of all used devices to the main riser. Each floor is connected to the general system separately. During the operation of this system, air pockets almost never form.

When operating a heating system from two pipes with an upper wiring, you can create various installation schemes. These schemes will differ depending on the place where the expansion tank is located, while taking into account the height from the floor.

An organized system can contain pipes of various diameters, since the top of the pipe responsible for the supply is located at the beginning of the wiring.

The main constituent elements of vertical heating distribution

The vertical type wiring scheme currently prevails in residential buildings. The most commonly used heating system consists of two pipes. One of the pipes serves for direct heat supply, and the other for reverse. Such systems usually consist of the following elements:

- Pump;

- Batteries;

- Boiler;

- Bucky;

- Temperature gauge;

- valve;

- Valve guard;

- thermostatic valve;

- Air vent;

- Balancing device.

Advantages of organizing vertical heating from two pipes in an apartment

A vertical heating system is used in rooms where a single accounting of heat consumption is kept. In such systems it is impossible to install individual meters. The use of wiring provides the following benefits:

- Convenient adjustment of the heating system;

- Possibility to turn off autonomous heating elements;

- Ability to connect a system of two pipes floor by floor;

- Elimination of the possibility of overexpenditure of heating devices;

- Relative cheapness of installation of systems;

- It is possible to regulate and prevent noise generation;

- There is no need for expensive adjustment of the heating system;

- Good system stabilizers in the long run.

How is a heating radiator replaced for a vertical two-pipe system?

Work related to the heating system is always better to trust an experienced specialist. This will ensure an excellent result, get the result of work in the shortest possible time and save money.All experienced craftsmen have already developed an algorithm for the implementation of installation work. It is possible to highlight the main points of the work with the wiring of two pipes:

- Minimization of violations of the installation scheme to eliminate problems with the heating network;

- Using the services of a welder when replacing a radiator for a two-pipe system;

- Only polypropylene is used for heating "shtabi";

- For proper organization of installation, it is best to calculate in advance the pressure exerted on the pipes.

More about the coolant and its properties

There is no liquid ideal for any heating system. Each of the options presented on the heat transfer market has specific characteristics, for example, Operating temperature range.

If you violate the boundaries of the specified range, the heating system will simply “stand up”, and in the worst case, pipes will burst and expensive equipment will fail.

In addition to temperature parameters, pipeline fluid has properties such as viscosity, anti-corrosion, and the ability to release toxic substances. An analysis of the required qualities showed that the best liquid heat carriers are purified water and a special chemical solution - antifreeze.

The table shows the main advantage of ethylene glycol antifreeze - a maximum freezing point of -40 ° C, while water turns into ice already at 0 ° C

Filling antifreeze is necessary in homes that are not permanent residences. Usually, when leaving the building during the cold season, the owners drain the water to avoid an accident and equipment breakdown.Antifreeze does not need to be removed - upon return, you can immediately turn on the boiler without fear of leakage or rupture.

At extreme temperatures, the chemical coolant, having changed its structure, retains its previous dimensions. Simply put, it turns into a gel that retains its properties unchanged. When the temperature reaches a comfortable level, the gel-like structure becomes liquid again, completely retaining its original volume.

Some more useful information about antifreeze:

- serves at least 5 years, one filling is able to withstand 10 heating seasons;

- fluidity is 2 times higher than that of water, therefore, it is required to monitor the tightness of the joints;

- increased viscosity requires the insertion of a more powerful circulation pump;

- the ability to expand when heated entails the installation of a large expansion tank.

And you must always remember that the chemical solution is toxic and dangerous to human health.

Antifreeze for pouring into home heating systems is sold in plastic canisters from 10 liters to 60 liters. The average cost is from 750 to 1100 rubles. for 10 l

Despite the outstanding characteristics of antifreeze, water as a coolant is more popular. It has the maximum possible heat capacity, which is approximately 1 kcal. This means that the coolant heated to 75ºС, when cooled in the radiator to 60 ºС, will give the room about 15 kcal of heat.

Water is available. If you supply the water supply system with reliable filters, you can use the free option - water from your own well. It does not contain hazardous chemical compounds and will not cause poisoning in case of an accident.

The negative side of water is the content of certain mineral salts that cause corrosion. The problem is solved by simply boiling or using rainwater instead of well water (or thawed).

There are complex water purification and treatment systems for a private house: in addition to universal purification, water goes through several stages to become drinkable or suitable for pouring into a heating circuit (+)

There are complex water purification and treatment systems for a private house: in addition to universal purification, water goes through several stages to become drinkable or suitable for pouring into a heating circuit (+)

Water is not recommended for use in homes for periodic residence.

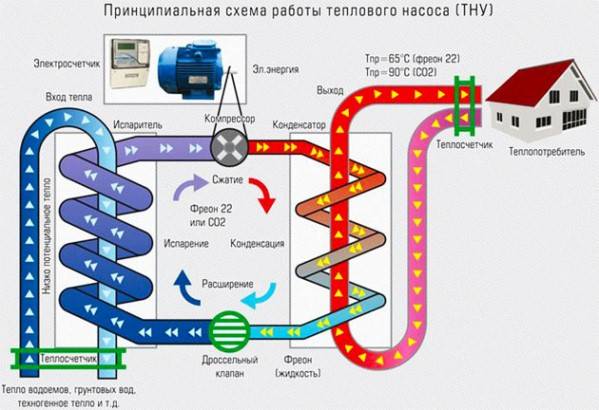

The latest heating systems

An example of a fairly affordable and at the same time effective system, suitable for both a country house and an apartment, is an electric underfloor heating. Having incurred relatively small expenses for the installation of such heating, it is possible to provide a home with heat and not buy any boilers. The only drawback is the cost of electricity. But given that modern floor heating is quite economical, yes, if you have a multi-tariff meter, this option may be acceptable.

For reference. When installing an electric floor heating, 2 types of heaters are used: a thin polymer film with coated carbon elements or a heating cable.

In the southern regions with high solar activity, another modern heating system performs well. These are water solar collectors installed on the roof of buildings or other open places. In them, with minimal losses, water is heated directly from the sun, after which it is fed into the house. One problem - the collectors are absolutely useless at night, as well as in the northern regions.

Various solar systems that take heat from the earth, water and air and transfer it to a private house are installations in which the most modern heating technologies are implemented. Consuming only 3-5 kW of electricity, these units are able to "pump" from the outside 5-10 times more heat, hence the name - heat pumps. Further, with the help of this thermal energy, you can heat the coolant or air - at your discretion.

An example of an air heat pump is a conventional air conditioner, the principle of operation is the same for them. Only the solar system is the same well heats a country house in winter and cool in summer.

It is a well-known fact that the more efficient an innovation in a heating system is, the more expensive it is, although it requires lower operating costs. Conversely, high-tech electric heating systems that are cheap to install make us pay later for the electricity we use. Heat pumps are so expensive that they are not available to most citizens of the post-Soviet space.

The second reason why homeowners gravitate towards traditional systems is the direct dependence of modern heating equipment on the availability of electricity. For residents of remote areas, this fact plays a big role, because they prefer to build brick ovens and heat the house with wood.

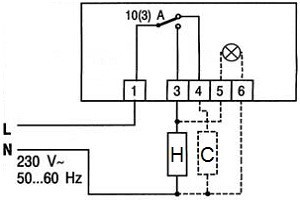

How to connect a solid fuel boiler

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. Here conditionally not shown expansion tank, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one. You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar). This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the remote-type overhead sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late. For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head.A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note. Similar valves that maintain a fixed temperature of mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.

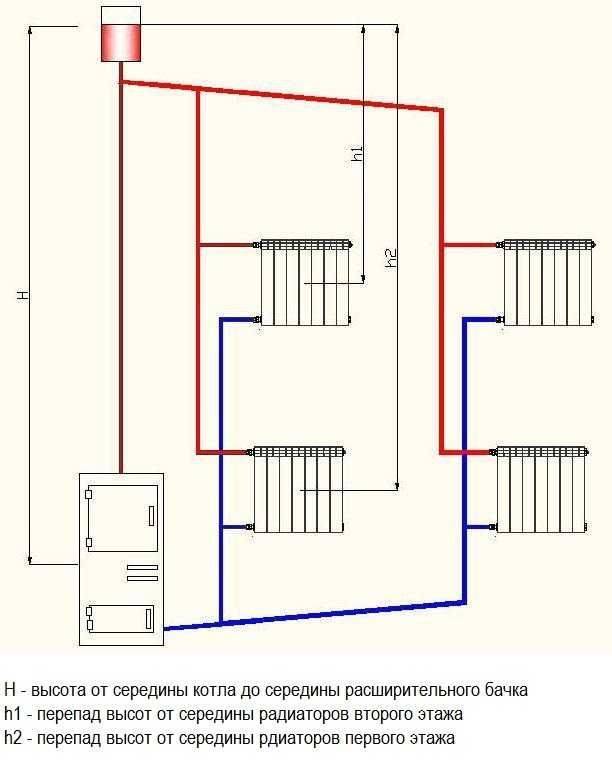

The principle of operation of closed CO

A closed (otherwise - closed) heating system is a network of pipelines and heating devices in which the coolant is completely isolated from the atmosphere and moves forcibly - from the circulation pump. Any SSO must include the following elements:

- heating unit - gas, solid fuel or electric boiler;

- safety group consisting of a pressure gauge, safety and air valve;

- heating devices - radiators or contours of underfloor heating;

- connecting pipelines;

- a pump that pumps water or non-freezing liquid through pipes and batteries;

- coarse mesh filter (mud collector);

- closed expansion tank equipped with a membrane (rubber "pear");

- stopcocks, balancing valves.

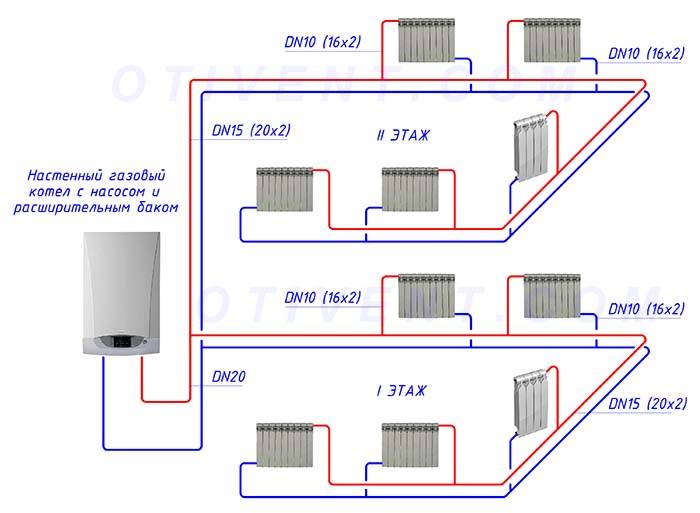

Typical diagram of a closed heating network of a two-story house

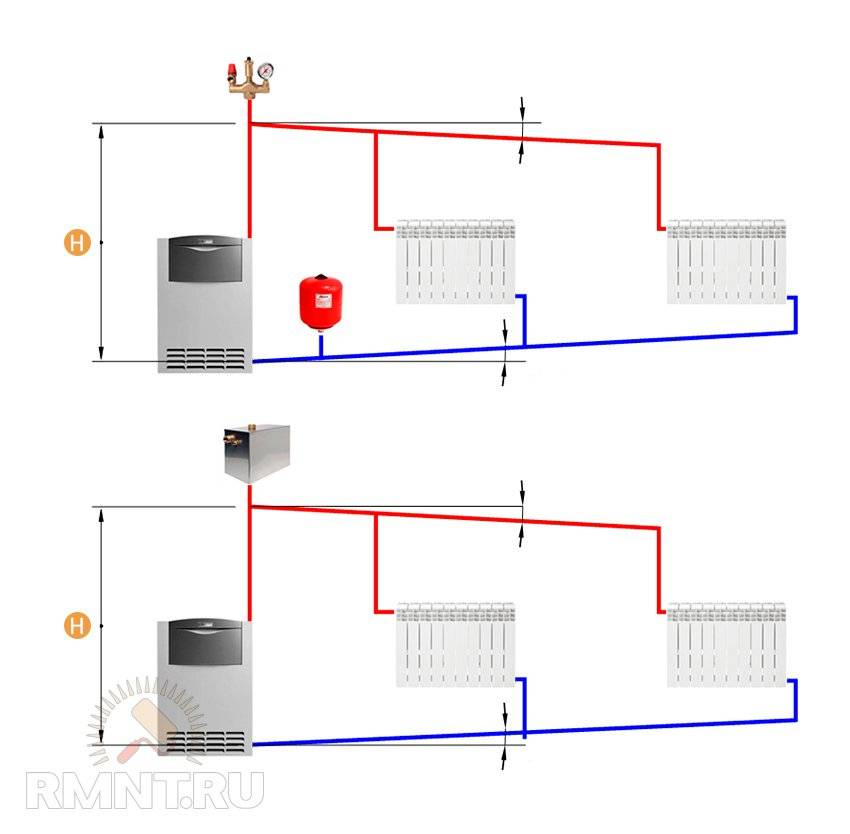

The algorithm of operation of a closed-type system with forced circulation looks like this:

- After assembly and pressure testing, the pipeline network is filled with water until the pressure gauge shows a minimum pressure of 1 bar.

- The automatic air vent of the safety group releases air from the system during filling. He is also engaged in the removal of gases that accumulate in pipes during operation.

- The next step is to turn on the pump, start the boiler and warm up the coolant.

- As a result of heating, the pressure inside the SSS increases to 1.5–2 bar.

- The increase in the volume of hot water is compensated by a membrane expansion tank.

- If the pressure rises above the critical point (usually 3 bar), the safety valve will release excess fluid.

- Once every 1-2 years, the system must undergo a procedure for emptying and flushing.

The principle of operation of the ZSO of an apartment building is absolutely identical - the movement of the coolant through pipes and radiators is provided by network pumps located in an industrial boiler room. There are also expansion tanks, the temperature is controlled by a mixing or elevator unit.

How a closed heating system works is explained in the video:

Calculation of heat consumption for ventilation

To obtain a general indicator of heat loss at home, the losses of each room separately are summed up. To complete the picture, it is also necessary to take into account the heating of the ventilation air. The simplest formula for calculating this parameter is Qair \u003d cm (tv - tn), where:

- Qair - calculated amount of heat for ventilation, W;

- m - the amount of air by mass, is determined as the internal volume of the building, multiplied by the density of the air mixture, kg;

- (tv - tn) - as in the previous formula;

- c is the heat capacity of air masses, taken equal to 0.28 W / (kg ºС).

To determine how much heat is needed for the whole house, the QTP value for the house as a whole is added to the Qair value. The power of the boiler must be taken, taking into account the margin for the optimal level of functioning (a coefficient of 1.3 is used). In the event that the boiler will provide not only heating of the coolant for the heating system, but also water for hot water supply, it will be necessary to increase the margin of safety. It is necessary to ensure the efficient operation of the boiler for 2 circuits at once, which implies the use of a safety factor of 1.5.