- car trailer

- Tank mounting options

- How to avoid huge maintenance costs

- Installation of equipment: rules and regulations

- Nomenclature of acids and salts

- Gas tanks without manhole

- Features of installing a gas tank for a private house

- Placing a horizontal tank

- Placement of the vertical tank

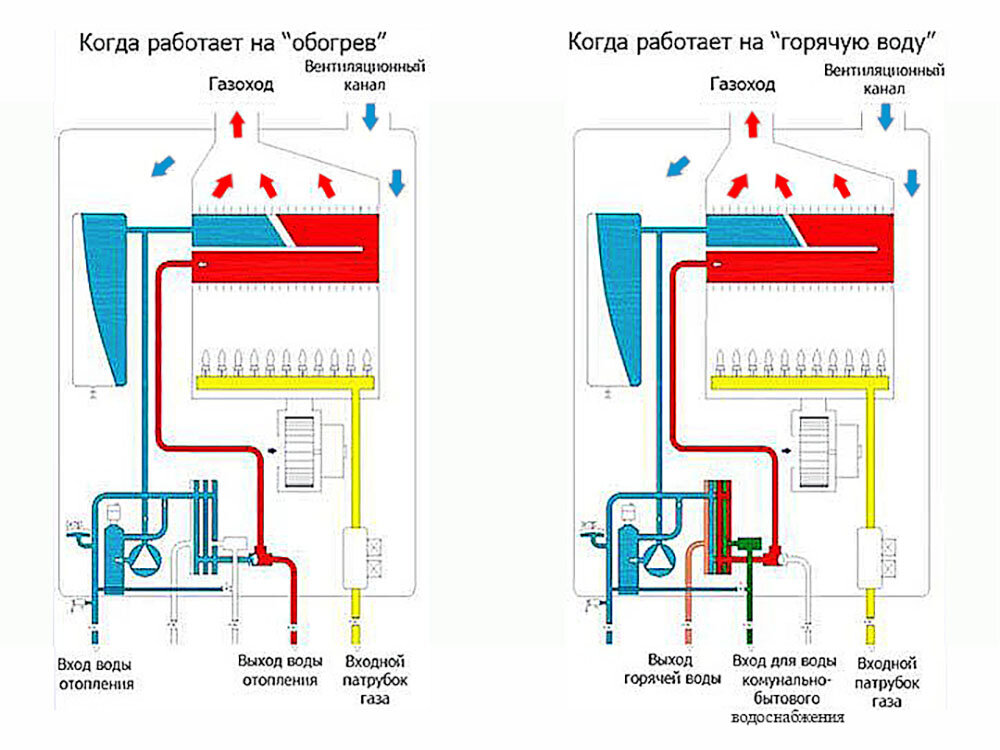

- Device

- Civil works

- The question of profitability

- Comparing all the pros and cons

- Autonomous gasification of a private house: what you need to know?

- fittings

car trailer

The trailer on which the mobile gas tank is installed can be both special and universal. The large cylinder is securely mounted in a galvanized frame and protected by a PVC tarpaulin that is weather and UV resistant. To fix the trailer on the ground, there are four support paws (outriggers). After mounting on the supports, you can remove the trailer drawbar, its rear panel and even the wheels. This will protect the gas tank from theft.

600 liter tank equipped with a vapor phase valve with pressure gauge, safety valve to release excess gas when gas expands in an overfilled tank, a level gauge to measure the gas level and a filling valve.

Heating regulator and two-stage reducer with a maximum capacity of 12 kg/h for supplying gas equipment with a power of up to 100 kW. The pressure at the inlet of the reducer is variable: 0.037 bar - 16 bar, at the outlet - stable 0.037 bar (European standard). A free modification to a pressure of 0.050 bar (German standard) is possible at the request of the consumer. It is possible to adjust the outlet pressure + 0.012 bar from the base.

Special car trailer with hot-dip galvanized anti-corrosion treatment, aluminum bottom. The trailer is equipped with extendable outriggers (supports), quick-release drawbar and rear panel. Removing the tongue and rear panel is the most effective way to prevent trailer theft. In addition, a trailer without a drawbar takes up less space. A PTS is issued for the trailer, the trailer is registered by the buyer with the traffic police. The trailer has a permitted mass of 700 kg and therefore does not require a special category of driving license.

Elements of a mobile gas tank trailer: tank 600 liters, two-stage gearbox, transport protective frame, PVC tarpaulin tarpaulin, car trailer, liquid tank heating system with heating control valve, quick-release click connections of the gas tank with the house heating system and with the gas boiler, automatically closed when disconnected, remote refueling a device for refueling from a AGZS column pistol, a valve for refueling with a gas carrier.

Number of blocks: 18 | Total characters: 21937

Number of donors used: 4

Information for each donor:

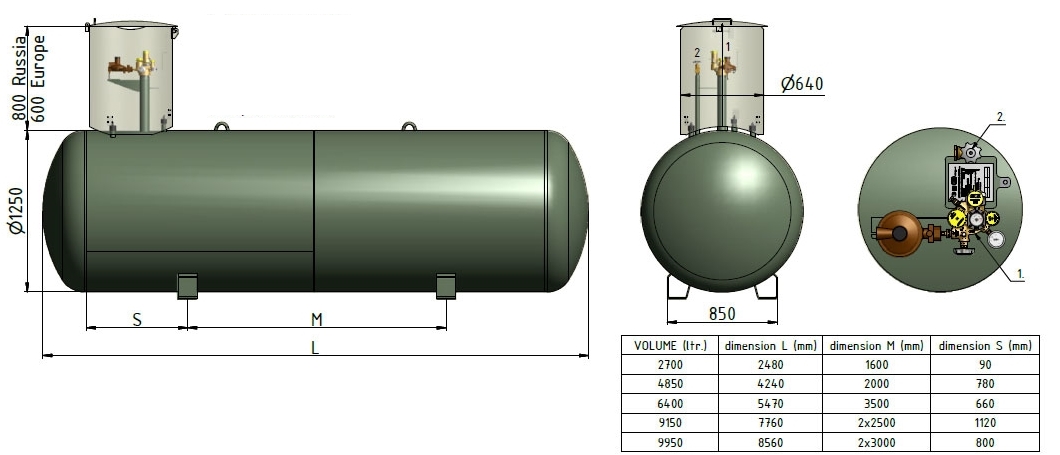

Tank mounting options

Variations in the installation of gas tanks are limited in two ways:

- Surface installation.

- Underground installation.

For the first installation option, a characteristic condition is installation in places on the territory of a private economy, where the sun's rays penetrate in a small volume. Also, a section of the territory is selected, as much as possible protected from the influence of external natural factors (strong winds, landslides, soil movements, etc.).

There are no specific requirements for the capacity of the tank. The volume of the gas tank is completely determined by the consumer needs and wishes of the owners of a country house.

Pit with a domestic gas tank immersed in it. The tank is fastened with straps. The body of the tank is treated with a protective coating. Automation is mounted under the neck cover

Underground gas tanks are mounted below the ground surface. The deepening of the tanks is carried out to a depth when the upper level of the vessel is at the point of deepening at least 0.6 m from the ground level.

Only the filler neck of the tank remains at the same level with the ground surface or slightly higher. Under such conditions of deepening, the possibility of freezing of the tank in the winter period is excluded, plus the tank of the gas tank is reliably protected from possible mechanical influences.

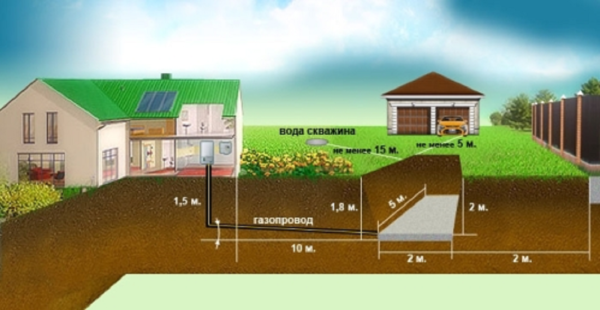

Regardless of the type of installation, the location of gas tanks in the household area is allowed no closer than 10 meters from residential buildings and various technical communications.

The project for installing a tank for liquefied gas should provide for easy convenient approaches / entrances for gas refueling and maintenance. The presence of any engineering communications in the immediate vicinity of the structure is not allowed.

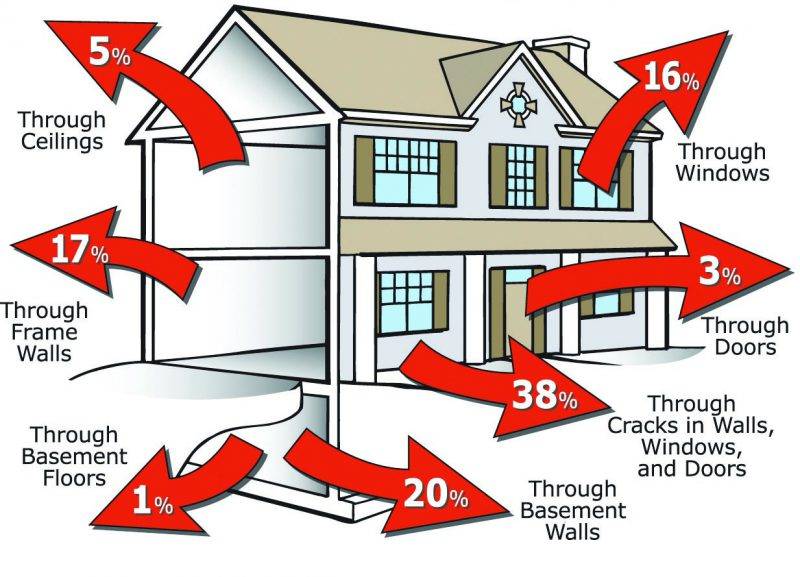

The main design parameter for installation in a private household is the volume of the gas tank. According to the standards, the calculation is carried out with an emphasis on the square meter of the usable area of \u200b\u200bthe dwelling. The average figure for gas consumption for regions with a temperate climate does not exceed 35 m3 per 1 m2. From here you can calculate the approximate volume of the tank.

Standard parameters that should be used for the installation of domestic gas tanks. Some deviation from the standards in the direction of increase is possible, but insignificant. The parameters directly depend on the size of the tanks

A more accurate volume figure is obtained if the calculation is based on the value of gas consumption by the heating boiler. Here, the indicator of the rated power of the heating equipment is simply taken from the passport information and multiplied by the required gas flow. Then the annual fuel requirement is calculated.

When performing calculations, one should take into account the fact that gas tanks are filled with liquid gas no more than 85% of the tank volume.

How to avoid huge maintenance costs

The main reason why gas tanks can require expensive maintenance is corrosion. The worse the gas tank is protected from corrosion, the higher the cost of maintaining its full operation.

Gas holders AvtonomGaz are made of selected steel, which is not subject to corrosion, and covered with an impact-resistant polyurethane coating. For safety net, a passive electrochemical protection system is used, but the corrosion rate is so low that it is necessary to change the protection protector no more than once every fifteen years.

This powerful corrosion protection reduces repair and maintenance costs to a minimum while extending the service life of the gas tank to fifty years.

The steel of VPS and Deltagaz gas tanks made in the Czech Republic is less protected from corrosion, and the brittle epoxy coating quickly cracks and peels off. As a result, corrosion spreads faster and the tread has to be changed every five years. If the coating is damaged, a new tread is required every year.

Russian gas tanks Faskhimmash, RP and RPG, as well as Ukrainian Phobos, are made from cheap low-quality steel that does not have anti-corrosion additives. To slow down the spread of corrosion, an active electrochemical protection system is required. It constantly consumes electricity. For several years, the maintenance of such a gas tank will eat hundreds of thousands of rubles.

Installation of equipment: rules and regulations

It is necessary to install a gas tank, focusing on certain norms and rules. So, an underground-type tank should be located at a distance from a residential building (at least 10-12 m, according to SNiP - at least 10 m) and, of course, in stable ground. It is also impossible to allow any engineering communications near the gas tank.

Ground gas holders should be mounted in the shade at a distance of about 2-3 m from the border of the territory and at least 20 m from the house itself (according to SNiP). Trees should be no closer than 10 m. Also, a well with water should be located near the equipment (no more than 15 m)

It is important to understand that in winter the above-ground gas tank in Russia will not work due to harsh climatic conditions, and you need to buy and install a special evaporator

Subject to all installation rules, gas tanks do not pose any danger to residents of the house and equipment users. The gas inside is stored without air access, and in the event of a depressurization of the cylinder, no explosion will still occur - the gas will simply escape into the atmosphere and dissipate. By the way, one of the security measures is the location of the tank on the street, and not indoors. This is necessary in case a fuel leak does occur. Gas accumulation may occur in the room. And so that there is no excess pressure, the gas tank is equipped with a special safety valve, which, if necessary, will simply relieve excess pressure (for example, in case of gas heating).

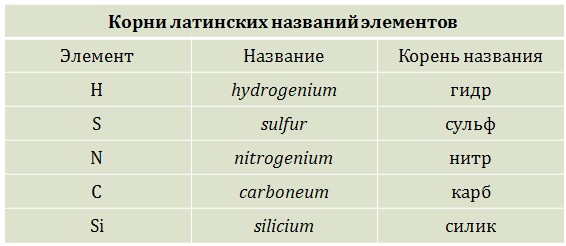

Nomenclature of acids and salts

The names of acids are constructed as follows: postfixes -naya, -nisty or -hydrogen are added to the root of the name of the central element in Russian, depending on the degree of oxidation of the central element.

If you do not remember what an oxidation state is and how to determine it, then you first need to study the corresponding article.

The names of salts are constructed as follows: postfixes -at, -it or -id are added to the root of the name of the central element in Latin, depending on the degree of oxidation of the central element. Then indicate the name of the metal in the genitive case. If the metal (or metal-like ion) is characterized by a constant valency, then nothing more needs to be indicated. If the metal is characterized by variable valency, then after the name it is necessary to indicate in brackets its valency in this salt; valency is indicated by Roman numerals.

The roots of the Latin name for most elements coincide with the roots of the Russian name. For some elements they are different. They should be remembered:

C - carb, S - sulf, N - nitr, etc.

Let's consider the main cases.

1. If the central element in the acid has the highest oxidation state, i.e. the acid residue of this acid contains the maximum number of oxygen atoms, then the postfix -naya or -vaya is added to the name of the acid.

For example: H2S+6O4 – sulfuric acid, H3P+5O4 - phosphoric acid.

In this case, the postfix -at is used in the name of the salt.

For example: Na2S+6O4 – sodium sulfate, K2C+4O3 - potassium carbonate.

2. If the central element in the acid has an intermediate oxidation state, i.e. the acid residue of this acid does not contain the maximum number of oxygen atoms, then the postfix -nistaya is added to the name of the acid.

For example: H2S+4O3 – sulfurous acid, H3P+3O3 - phosphorous acid.

In this case, the postfix -it is used in the name of the salt.

For example, Na2S+4O3 – sodium sulfite, KN+3O2 - potassium nitrite.

3. If the central element in the acid has the lowest oxidation state, i.e. the acid residue of this acid does not contain oxygen atoms, then the postfix -hydrogen is added to the name of the acid.

For example: H2S-2 - hydrosulphuric acid, HCl - - hydrochloric acid.

In this case, we use the postfix -id in the name of the salt.

For example, Na2S-2 is sodium sulfide, KCl— is potassium chloride.

Nomenclature of acid salts.

If in an acid salt there is one hydrogen atom per acid residue, then the prefix hydro- is added to the name of the acid residue. If there are two hydrogen atoms per acid residue, then the prefix dihydro- is added.

For example, K2HPO4 – potassium hydrogen phosphate, KH2PO4 - potassium dihydrogen phosphate. But: Ca(HCO3)2 - calcium bicarbonate.

Nomenclature of basic salts.

If in the basic salt there is one hydroxo group per metal cation, then the prefix hydroxo- is added to the name of the acid residue. If there are two hydroxo groups per metal cation, then the prefix dihydroxo- is added.

For example, AlOHCl2 – aluminum hydroxochloride, Al(OH)2Cl is aluminum dihydroxochloride. But: (CuOH)2CO3 – copper(II) hydroxocarbonate.

In the name of a double salt, metal cations are listed with a hyphen. In the name of mixed salts, anions of acidic residues are listed with a hyphen.

For example, KAl(SO4)2 – aluminum-potassium sulfate, CaClBr – calcium bromide-chloride.

Trivial nomenclature also applies. Trivial inorganic names must be learned by heart.

Gas tanks without manhole

Gas holders AvtonomGaz economy class and some models of Czech manufacturers do not have a flange manhole. This reduces their cost, but complicates the survey.

In economy-class AvtonomGaz gas tanks, the neck is replaced by high pipes, which guarantee that after the tank is installed at a depth sufficient for Russia, the fittings will be above the ground.

In Czech gas burners, the fittings are placed directly on the body of the tank. This makes it difficult to operate them in regions where the temperature drops below zero in winter, including the Moscow region.

| AvtonomGas | Eurostandard gas holders | Sold under the FAS brand | RP, RPG and other Russian gas holders | |

|---|---|---|---|---|

| Maximum installation depth (from the upper generatrix of the cylinder) | 60 | 30 | — | — |

| Fitting tube height | 50 | 10 | — | — |

| Reinforcing hull rings to relieve stress from the ground | Available | Not | — | — |

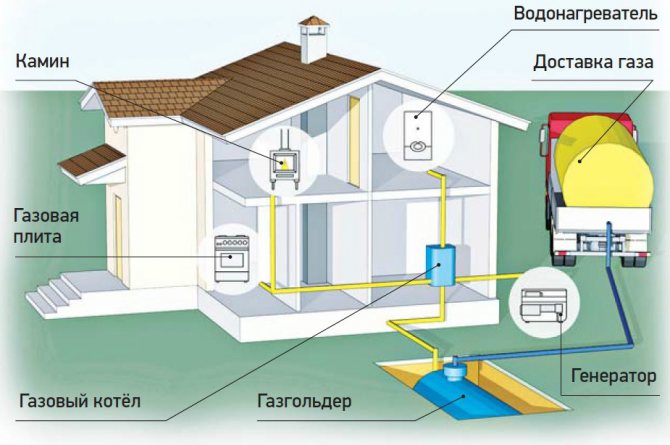

Features of installing a gas tank for a private house

Returning to the topic of installing and locating an autonomous gas supply system, let us once again remind you of the nuances of the vertical and horizontal placement of tanks.

Placing a horizontal tank

The pit for a horizontal tank should have a margin of about half a meter in order to make it convenient to install the tank. This design takes up more space, but, as we have already mentioned, it is more productive.

For an idea of the nuances of installation, we offer you video material:

Watch this video on YouTube

Placement of the vertical tank

Vertical tanks take up less space, but otherwise their installation is not much different from the installation of horizontal models. Given that the vertical tank is buried deeper in the ground, it is better preserved and can serve you faithfully for up to half a century.

In the following video you can read the reviews of the owners of vertical gas tanks:

Watch this video on YouTube

Watch this video on YouTube

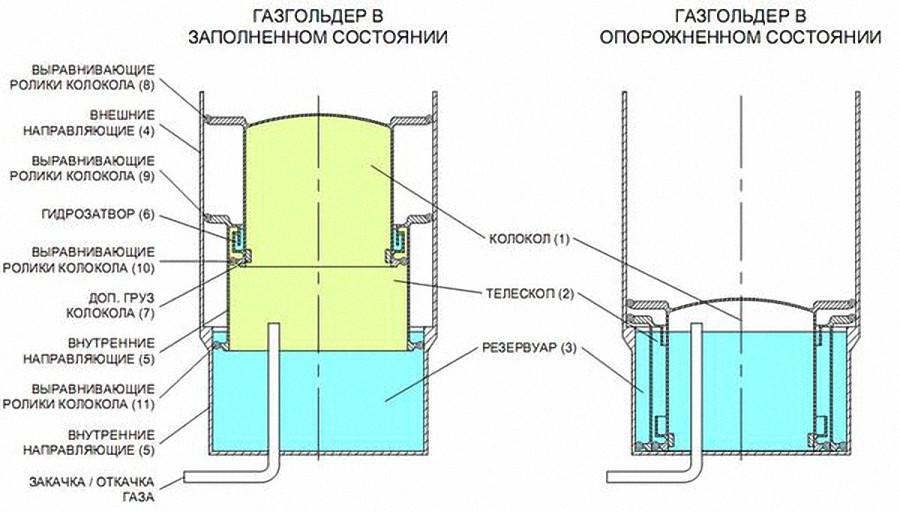

Device

According to the principle of gas storage, all gas holders are divided into tanks with constant and variable volume.

Previously, such gas holders were used not so much for long-term gas supply, but to maintain a constant pressure. Now they are gradually going out of use, however, some continue their work in large enterprises. So, for example, a variable volume gas tank is still operating at the domestic chemical enterprise Kazanorgsintez, as well as at the Obvodny Canal in St. Petersburg.

Unlike the gas tanks described above, which contained gas with a pressure slightly higher than atmospheric pressure, modern fixed-volume gas storage facilities can withstand pressures up to 18 atmospheres.Modern technologies make it possible to create strong alloys that can withstand huge loads, the environment of liquefied propane, as well as to exercise full control over gas pressure. All modern gas tanks have a constant volume.

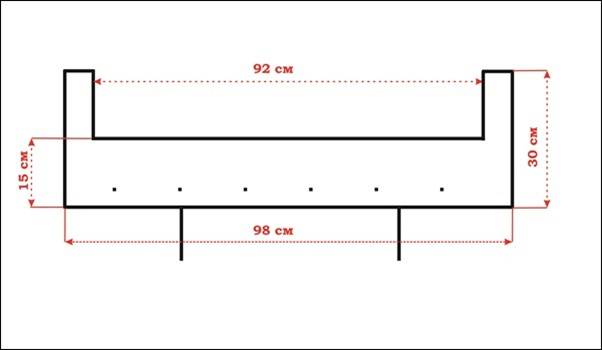

Civil works

To begin with, they choose a suitable place that meets the safety requirements regarding the remoteness of the gas tank from buildings and communications at the site. In the case of private houses and cottages, gas tanks are most often installed underground. The dimensions of the pit are determined by the terms of reference, depending on the model of the gas tank. The design of an autonomous gasification system should take into account convenient approaches for refueling and maintenance of the gas tank.

The standard excavation depth from the ground level is 2700 mm, while the tank neck cover will protrude slightly from the surface. This ensures the location of a part of the gas tank below the freezing level and the convenience of filling and servicing the tank.

Before installing the gas tank, the pit is additionally prepared. At the bottom of the pit, a sand and gravel pad is equipped, which is the basis for pouring a reinforced concrete slab. The concrete slab serves as an anchor for the tank, the fastening is provided by steel cables and anchors.

Life hack: do not use hollow slabs as a base for a gas tank, they will not provide protection against ascent.

The question of profitability

Is a mobile gas tank really that cheap? The cost of some models reaches 240 thousand rubles, which is equivalent to the turnkey purchase of a stationary gas storage facility with a volume of 2500 liters. That is, you won’t get much benefit from buying a mobile unit.

If the installation of an underground tank is not possible due to a small area, or the facility will be operated on a temporary basis, it is better to use a group balloon installation. It is cheaper and easier to use. And most importantly, in the case of using certified containers, there will be no problems with refueling.

I remind you that this is the opinion of Maxim Danilin,

director of Promtechgaz company

Comparing all the pros and cons

Among the advantages of gas tank heating are:

- Complete autonomy of the heating system (as long as there is gas).

- Long service life of the gas tank - 30 years is not the limit.

- Environmental friendliness and lack of burning with soot.

- A minimum of time for installation and connection (a couple of days for turnkey work is enough for experienced installers in abundance).

- Lack of approvals and the need to wait for connection to the gas main.

- Safety when used correctly.

- Quiet operation of gas equipment.

Compared to diesel fuel and electricity, heating a private house with gas from a gas tank is more economical. And LPG wins greatly over coal and firewood in terms of environmental friendliness.

Under no circumstances should you buy a used gas tank. The metal of the tank located in the ground gradually corrodes, no one will give a guarantee against gas leakage from an already used tank

At the plant, gas tanks are tested at pressures up to 25 atm. At the same time, safety valves are installed on them, designed to operate at 15–16 atm. And liquefied gas inside the gas tank creates a pressure of only 4–6 atm.

The equipment in question is completely safe to break.It is only necessary to ensure that propane and butane do not leak through the valves and do not accumulate nearby until a dangerous concentration is formed.

The disadvantages of heating with a gas tank are as follows:

- High initial cost.

- The presence of a potentially explosive zone on a personal plot near the house.

- A sharp "gas" smell when filling the tank.

- The need to pump out the tank and dispose of the unevaporated condensate at least once a year.

- The risk of obtaining low-quality gas when contacting an unverified supplier.

- Due to the low prevalence of gas tanks, there is a lack of competent installers and specialists in all regions of Russia for the proper maintenance of this equipment.

- The susceptibility of the LPG tank to corrosion due to the impact on the metal of condensate inside and groundwater outside.

Another important point - for a house of 200 m2, you will need a horizontal cylindrical gas tank with a volume of about 3000 liters. Under it, you will need to take a plot of 2x3 meters in size. Plus, next to it, you still need free space for a car with LPG for the time of refueling the tank.

If there are only 3–4 acres of adjacent territory near the cottage, then it will be difficult to allocate even a small piece of land for them for gas equipment.

If you fill the gas tank with a propane-butane mixture of poor quality, then its service life will be greatly reduced. Buy LPG only from trusted suppliers

In order for the gas tank to serve as long as possible, it is recommended to equip it with active or passive electrochemical protection. Such systems slow down corrosion and fully justify the cost of them.

Autonomous gasification of a private house: what you need to know?

The fact that gas is the most cost-effective type of fuel is beyond doubt, but the possibility of connecting to a pipe is not always available. And even if the highway runs in close proximity to a suburban village, connection to it is not always possible for technical or administrative-bureaucratic reasons.

There is only one way out: the organization of an autonomous gas supply, and for this you need a gas tank. A simpler and more affordable option is to use household gas cylinders with propane-butane, but their operation is cost-effective only when used for a stove, they are not suitable for organizing a heating system.

The gas holder itself is a steel container, which is a storage of gas reserves. The latter, as a rule, is represented by liquefied propane-butane, in contrast to natural gas transported via pipelines to the final consumer.

This is due to technical difficulties: natural gas is more difficult to store in containers, since its liquefaction requires special conditions that are difficult to meet: a pressure of 200 bar and a temperature of -160 °C.

Therefore, in order to organize an autonomous gas supply to a country house or cottage, propane-butane is used, which at the same time has a high calorie content, that is, when burned, it releases three times more heat even compared to natural gas, not to mention other types of fuel.

Difficulties in the operation of gas tanks can arise in the cold season - an intensive formation of condensate occurs in the tank, which prevents the supply of gas to the system.Therefore, during the design and installation, this fact is taken into account and solved by installing the tank underground, which eliminates the impact of sub-zero temperatures on the gas tank.

fittings

The gas flow control equipment used in Eurostandard gas tanks is produced either by the American company Rego or by European manufacturers. Rego is the same manufacturer of valves that are installed on AvtonomGaz gas tanks, but the modification of equipment on AvtonomGaz gas tanks is more expensive due to the use of protection against accidents that occur when valves are knocked down.

If in AvtonomGaz gas tanks there are safety high-speed valves for protection against vandal influences on all valves, then on Eurostandard gas tanks it is only on the vapor phase valve. In addition, fittings of Eurostandard gas tanks do not prevent filling the tank by more than 90%.

The use of cheap fittings on Eurostandard gas tanks adversely affects safety.