- How to dismantle the floor screed yourself

- Preparatory stage

- Dismantling the screed by impact method

- Screed removal by cutting

- Tips from experienced craftsmen

- Dismantle or restore?

- Proper deletion rules

- The consequences of removing the screed

- Stages of work

- How to fix cracks?

- Dismantling the floor cement screed: the main methods

- Why dismantle the screed?

- Choice of method and tools

- Features of dismantling a wooden floor

- impact method

- Do you want to save money and get high-quality special equipment for work?

- How is the screed removed?

- Dismantling the screed price per m2

- Technology and cost of concrete floor dismantling

- Features of the demolition of a cement or concrete screed

- GESNr 57-02-04

- Disassembly of floor coverings: cement

- Dismantling the self-leveling floor: screed, but not quite ordinary

How to dismantle the floor screed yourself

Preparatory stage

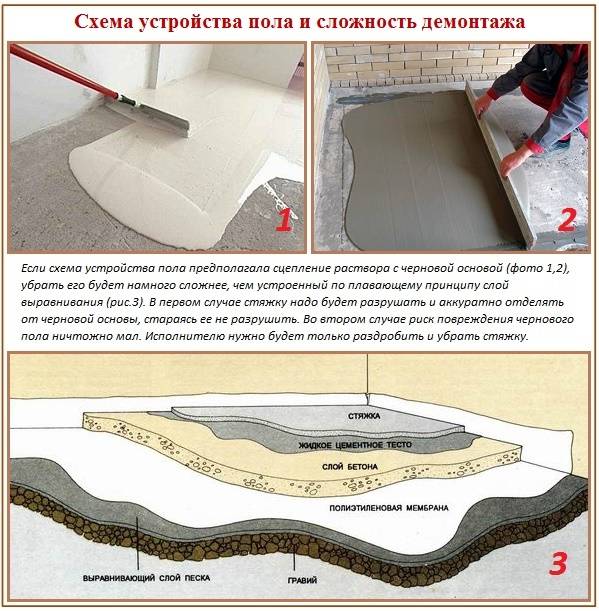

Before the actual process of removing the screed, a number of preparatory works should be carried out. Namely, prepare all the necessary equipment and carry out the dismantling of all floor materials available on the floor.

That is, laminate, linoleum, tiles, floor plinths must be removed before the start of dismantling operations.By the way, with floor tiles, difficulties may arise, which is why its removal is carried out together with the dismantling of the floor screed.

As for the construction tool, its selection should be carried out depending on the type of existing screed (monolithic, multilayer, composite). Most often, concrete cutters, angle grinders, impact devices (jackhammer, puncher) are used to carry out such work, or operations are performed manually using a chisel, crowbar, sledgehammer and hammer (justified for removing a small area screed).

Also, at the preparation stage, it is necessary to determine the places for laying utilities, so that in the process of removing the screed, do not deform them. In standard apartments, the electrical wire of the downstairs apartment lighting system is located on the floor in the top floor apartment. In view of which, before starting work, it is advisable to search for hidden wiring. And without fail, take care of de-energizing the place of work.

If pipelines of heating systems are laid in the thickness of the screed, then it is necessary to take care of the plan for laying them so as not to damage them during the work.

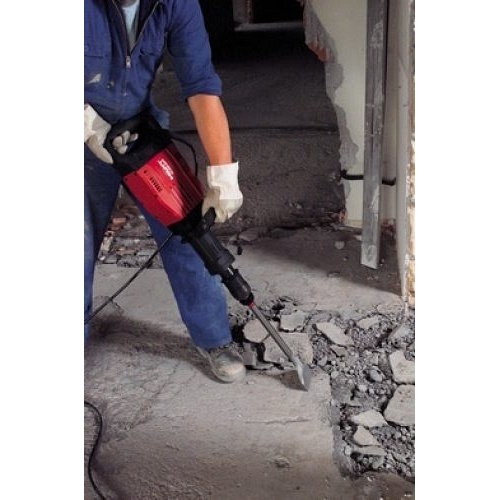

Dismantling the screed by impact method

It involves breaking off pieces of the screed and their gradual removal. This work is done with the help of percussion instruments. In some cases, it is allowed to use a sledgehammer and a crowbar.

When working with a jackhammer or similar electrical equipment, all safety measures should be strictly observed and protective equipment should be used (respirator, goggles, ear plugs, protective overalls, anti-vibration gloves, etc.).

Also, before starting work, you should check the equipment for operability (fill in oil, install a bit, etc.).

The impact tool should be held only by insulated areas in order to prevent electric shock in case of accidental contact with hidden electrical wiring.

Impact removal of the screed is carried out according to the following algorithm:

- You should firmly take the tool in your hands and take a stable position (nothing should interfere with the work);

- Turning on the tool first at low speed, you should dismantle the screed, starting from the far corner of the room;

- Breaking off small segments of the screed, you should move deeper into the room;

- At the same time, loose pieces of old screed should be removed (which may require construction bags or similar products).

It should be noted that when removing the floor screed by impact, a power tool (perforator, jackhammer) is usually used, which is why the work must be done with interruptions sufficient to cool the electrical equipment. Usually, after 10 minutes of work, a 5-minute break is enough.

Screed removal by cutting

It becomes possible when dismantling a floor screed that does not contain metal inclusions (reinforcement). Most often, such work is performed using a wall chaser or a joint cutter, which in its design resembles a grinder on wheels. However, in some cases (when working at home), cutting the screed can also be done using a conventional grinder equipped with a diamond-coated cutting disc.

The essence of the work in this case boils down to the fact that the screed is first cut into small segments of 10x10mm (20x20mm), and then the “pieces of the pie” are simply picked out of their places with a long chisel or crowbar. The only limitation is the depth of the screed, and if it is greater than the radius of the cutting disc, then it will be very problematic to remove the material by cutting.

The advantage of this method of dismantling the screed over the previous option is that the work does not create much noise and is more accurate. Although dust and dirt still can not get rid of.

Tips from experienced craftsmen

- Carrying out dismantling works requiring the use of impact devices is a very expensive service, since these devices negatively affect human health.

- Dismantling work is always accompanied by the appearance of dust and debris. Therefore, you need to worry about transport for waste disposal in advance.

- It is not recommended to carry out dismantling work on your own without special skills, knowledge, since you can not only harm the entire structure of the structure, but also your health.

- During operation, do not neglect protective equipment. Be sure to wear a helmet, respiratory mask, special goggles, headphones. Because the work ahead is dusty, noisy, and quite dangerous.

Perhaps the main condition for a successful repair, especially the replacement of the floor covering, is the preliminary preparation of the surface. Whatever finish you choose, it should be placed exclusively on a leveled and clean plane

It is also not recommended to install a new floor covering on top of an existing one, this will further affect the strength, appearance and other parameters, so it is important to have enough knowledge to disassemble the “used” floor, while still being able to do it correctly

It will not be difficult for a qualified builder to dismantle various floor coverings, and for those who have not previously encountered this type of repair work, it is better to familiarize yourself with certain conditions and stock up on the necessary tools.

Dismantle or restore?

Dismantling you can easily do it yourself. You should not start repairs if you do not have the necessary skills as a builder, you do not understand anything in this matter. In this case, you need to seek help from the masters from construction organizations. All kinds of newspapers and magazines are just full of offers of construction and dismantling services.

Over time, any floor covering becomes unusable. Concrete may begin to paint, flake and crack. In such a situation, it is worth deciding whether to dismantle the old screed or it will still serve. Basically, the masters advise to dismantle the screed. Such work is cheaper than restoration.

There are points to take into account:

- Is there a need to make the floor lower.

- Poor floor appearance. It might be more beneficial to simply reinstall it.

- Low quality cement.

- Do I need to repair communications or pipes that are located under the floor covering. You may need to install new ones.

- Will the floors of the rooms on the lower floor withstand the additional weight of the upper floor.

- Working with a jackhammer can be dangerous.

Houses that were built in the middle of the 20th century had a wooden or mixed floor: wooden beams were laid on top of metal ones, and there were areas with reinforced concrete elements in the toilet and bathroom. The process of dismantling the concrete floor has its own characteristic features. If you have removed the old cement screed, and now you want to start the process of pouring a new one, then you will not be allowed to implement this project, since the total weight of the cement solution will be large, and the load on the floor will largely exceed the permissible norm. The right choice would be to install the screed on uneven places from lighter building materials.

Proper deletion rules

When starting to overhaul the floor surface, you will have to dismantle the floor screed, the price of which from construction companies is quite high. But we ourselves are able to remove skirting boards, remove linoleum, dismantle laminate flooring, remove parquet or carpet.

Most often, the dismantling of the floor screed is carried out by the impact method using power tools: perforators, jackhammers, diamond cutting wheels. At home, you can use ordinary crowbar, a sledgehammer, a hammer, a chisel, if the thickness of the coating allows.

Dismantling the floor with the use of electrical devices significantly increases productivity. But such a dismantling of the floor screed will also have an increased price. Specialists using the impact method using powerful pneumatic concrete hammers, perforators, and diamond cutting equipment will quickly, but not cheaply, dismantle the floor screed. And in the case of a heavily metal-reinforced coating, the work is carried out using a special joint cutter.

The dismantling of a cement (concrete) screed in any way is carried out by breaking the base into pieces. For the removal and removal of cement-concrete residues, stock up on bags of durable material in advance.

You need to be prepared not only for a huge amount of construction debris, dust, dirt, but also for increased noise generation, which is better to immediately discuss this with your neighbors. It is better to talk and agree on a schedule of noisy work in advance than to receive "guests" from various authorities later, invited by angry residents of nearby apartments.

Dismantling the floor screed will test the strength of not only the neighbor, but also your patience. All repairmen who have passed this difficult test will no longer be afraid of anything! Good luck with the screed!

The consequences of removing the screed

Since this is a noisy process, if you live in an apartment building, you should talk to your neighbors in advance and warn them about the upcoming work.

In addition, dismantling takes place with a huge amount of dust and debris formed from the removed layer of cement or concrete.

Undoubtedly, removing the screed on your own is a rather laborious process that will take a lot of time and effort. But if you approach this process correctly, you can not only gain invaluable experience, but also save a decent amount of money, which can later be spent on something more necessary.

Stages of work

Initially, it is necessary to properly prepare for the destruction of an unnecessary structure. The preparation process is quite time-consuming, and consists of the following sequential steps:

- Installation of equipment and crumbling of concrete.

The first step is to study the object where dismantling is planned.

Next, you should discuss all the nuances of the work.

All communications are disabled, if any.

The entrance to the facility is being prepared, as well as a free area for the delivered special equipment.

Then this equipment is installed directly at the place of future work.

This is followed by the process of dismantling concrete structures. Various coatings are removed, a monolithic structure crumbles.

At the end of the work, the area should be cleaned. The dismantled pieces are calibrated, loaded into prepared transport, and taken away.

It is very important to take into account issues such as security. To do this, it is necessary to organize the stability of the structure during its collapse, so that there is no premature, unforeseen collapse, due to which people may suffer

Based on this, only knowledgeable, experienced craftsmen should be involved in the work.

How to fix cracks?

The above types of deformation lead to the fact that the screed begins to crack. This is bad because over time, even the smallest recesses expand, because of them you will have to do a major overhaul of the floor. Cracks are one of the most severe types of damage that require emergency removal, so they need to be fixed in a timely manner. Cracks are small and deep.

Small-diameter cracks are considered to be damage up to 2 mm wide.

You can repair the screed with your own hands as follows:

With the help of a grinder, expand and deepen the crack

Particular attention should be paid to the fact that, after expansion, the edges of the crack should not crumble, but should be absolutely solid. If it is not possible to use a grinder, you need to stock up on a hammer and chisel.

After the crack has widened, it needs to be cleaned

For this purpose, only a construction vacuum cleaner is used.

Cleaned areas are covered with epoxy primer. This must be done several times until the mixture is completely absorbed into the concrete.

After the primer has completely dried, the damaged areas are filled with a mixture of "Rizopox 3500" and quartz sand. The mixture should fill the crack just above the surface level.

After the mixture has hardened, the repaired areas are sanded and cleaned.

Repair of minor damage takes a small amount of time and eliminates the need for special tools.

If large cracks have formed in the screed - more than 2 mm wide - the repair process will take place according to the following scheme:

- As in the first case, cracks must be cut to the full depth.

- After the crack widens across it, several strobes must be made.

- Small repair seams (1.5 cm long) are made along the strobe with an interval of 2 cm.

- Prepared recesses should be cleaned with a construction vacuum cleaner, treated with a primer and left to dry.

- After the primer dries, the repair joints will need to be filled with pieces of reinforcement, metal staples or wire.

- Next, the cavities are filled with a liquid mortar from a mixture of sand and cement. The surface is leveled with a lath and polished after drying.

Reinforcing the screed helps protect it from stress and extends its life. There is also a little trick that will help you know if the cracks are expanding over time or not. To do this, it is necessary to glue a paper strip to the edges, if it breaks after a while, then the forecasts are disappointing. If the paper remains the same as it was, then everything is in order.But this method requires a lot of time.

Dismantling the floor cement screed: the main methods

The masters of our company use the following methods of dismantling the cement screed in residential and non-residential facilities:

| Drilling | Hit | cutting |

| It is used when it is necessary to dismantle a certain section of the floor. Its advantage is a minimum of noise, which is great for renovations in apartment buildings. | It is carried out using an electric jackhammer (less often - a grinder) | Typically, diamond cutting is used, which allows dismantling screeds of any strength. |

Dismantling tools are selected taking into account the type of screed (composite / monolithic), its height (usually 5-8 cm) and other inherent features.

Why dismantle the screed?

There are several reasons for this, among which are the following:

- Urgent need to lower the existing floor height;

- Cracking, chipping and abrasion of the floor screed;

- Urgent repair of engineering and communication networks that are under this very floor material.

One way or another, the dismantling of the floor screed is quite an important matter, so we advise you to take the work seriously and entrust it to professionals in their field.

Choice of method and tools

The dismantling of the cement screed is carried out in three ways. There are tools for everyone:

Shock. This method is noisy and is suitable if there is no armature. You will need a jackhammer, perforator or pneumatic concrete hammer.

Removing the base under the floor with a jackhammer

Removing the base under the floor with a jackhammer

Cutting. Need a seamstress. Cuts concrete with a diamond-coated cutting disc. The method is also suitable for dismantling reinforced screed. A grinder is also suitable for cutting.

Dismantling the screed with a joint cutter

Dismantling the screed with a joint cutter

Drilling.You will need a diamond drilling rig. Only an experienced specialist can use it and not every estimate will withstand the cost of this method of performing work.

Diamond drilling in concrete

Diamond drilling in concrete

When choosing a screed removal method, it is necessary to take into account the basis on which the concrete is made. There are three types of base for concrete: crushed stone (gravel), granite, limestone. The most durable and hard to dismantle is granite concrete. Limestone concrete has the lowest strength. To determine the thickness of the screed, the composition, the presence of reinforcement, a piece of concrete is cut out with a grinder or a joint cutter.

Hand tools suitable for removing the old floor:

- sledgehammer;

- scrap;

- chisel;

- a hammer.

These devices can be used as auxiliary in case of using electrical as the main ones.

Removing the base under the floor without power tools

Removing the base under the floor without power tools

In the process of cutting, drilling and impacting concrete, a large amount of dust is generated. Therefore, the dismantling of the old screed requires the use of protective equipment:

- respirator;

- glasses;

- anti-vibration gloves;

- helmet;

- headphones.

Before starting work, prepare a shovel and strong bags for collecting construction waste, which is formed during the dismantling of the screed in large quantities. Fragments of a concrete or cement-sand coating can be large, so polyethylene bags will not work.

Features of dismantling a wooden floor

Often, there is nothing difficult in dismantling a wooden floor, especially if it was created by professionals. At the very beginning of the process, we need a mount (crowbar), with which large boards will be removed.First of all, wooden floor elements that have significant damage or dried boards are removed. They are the easiest to remove. To do this, just pry the board with a crowbar and pull it towards you.

Also, do not forget that various communications can be located on the floor, as well as under it. First of all, we are talking about wires, which we can easily damage with the help of a mount. Also in old houses you can find underfloor ventilation, which is often clogged and does not function properly. After dismantling, if possible, you can clean the ventilation or get rid of it altogether.

After parsing a wooden floor, you can often find a huge amount of debris that is between the lags.

It is worth noting the fact that the logs can be quite suitable for the construction of a new floor, so the cleaning process must be carried out very carefully. If wood logs are no longer able to perform their functions, you can safely get rid of them.

In this case, you need to pay attention to the condition of the screed. If the cement screed has at least minor flaws, we will have to restore everything, since the quality of the installation of the future coating depends on it.

At the level of the screed, you can also find various pipes that may already need to be replaced. This should be done before the main process of installing a new coating begins.

impact method

The technique under consideration involves breaking off fragments of the screed with their subsequent removal. To perform such work, the performer needs a percussion power tool, which can be replaced with a simple sledgehammer or crowbar - provided that the solution of the problem does not require high performance.It should also be noted that the described method is only suitable in cases where the concrete surface is not reinforced with reinforcing elements.

In order for the performance of work with a jackhammer or other impact electric tools to comply with all safety standards, it is advisable for the performer to use the following personal protective equipment:

- respirator;

- jumpsuit made of dense material;

- anti-noise inserts ("earplugs");

- anti-vibration gloves;

- glasses.

When performing shock dismantling of the old screed, you need to follow the simple sequence of actions presented below:

- the tool must be securely fixed in the hands, while choosing the most stable position;

- it is rational to start removing the leveling layer from the far corner of the room;

- the speed of the equipment used must be increased gradually;

- it is desirable to break off as small fragments as possible from the screed, moving slowly;

- broken off pieces of the old base of the flooring are recommended to be removed immediately using construction waste bags or other suitable products.

Do not forget that the percussion instrument must be held only by those areas that are carefully insulated.

This precaution helps to avoid electric shock to the performer, who accidentally got into hidden wiring with a jackhammer chisel

Another point that needs to be taken into account in such a situation is the inevitable heating of the power tool used. In order to avoid the failure of expensive equipment, it needs to be given a "break", the duration of which is sufficient to cool the equipment.The recommended duration of such breaks is about 5 minutes, after every 10 minutes of tool operation.

Do you want to save money and get high-quality special equipment for work?

You do not have to maintain a whole fleet of construction equipment, just change attachments, and the robot will allow you to do the necessary work at no additional cost.

5 minutes to change attachments and before you is no longer a concrete breaker, but a mini excavator.

- Having studied the design of the building object, we will offer you the most optimal work plan.

- The next step is to develop and approve a project for the dismantling of the floor screed.

- Taking into account the task and conditions set by you, we will prepare a commercial offer for the provision of services for the removal of floor screed.

Here you can get a full range of services for dismantling and quality service. We will deliver and take away the special equipment rented by ourselves.

There are several main criteria, the consideration of which allows you to calculate the price of dismantling the floor screed.

These are:

- the thickness of the removed base;

- number of layers;

- screed material;

- the total area of the dismantled leveling layer;

- the presence of a reinforced base or its absence.

It is also worth adding that in situations where it is necessary to draw up an estimate, it is rational to use data from the following regulatory bases as a guideline:

- Collection GESN-11 Floors;

- Rates FER-11 Floors;

- Collection TER-11 Floors.

The first base is the State elemental estimated norms, and the other two are the Federal and Territorial unit rates, respectively. When making calculations, it is necessary to take into account the transition index - from the federal prices of 2000 to the current ones.

How is the screed removed?

The execution of work begins with preparation, because without a solid plan, it is impossible to succeed. In particular, the specialists of our company inspect the object and determine which tool will have to be used.

Our arsenal includes hand hammers, chisels, as well as electric jackhammers, armature wheels, perforators and many other professional tools.

Getting to work, we always protect the objects and things around us so that they do not deteriorate. We also monitor the safety of communications and engineering networks laid in the screed.

We always try to perform our work as professionally and responsibly as possible.

Dismantling the screed price per m2

When deriving the formula for determining the cost of this work, we take into account the following factors:

- Layer height and thickness of the floor screed;

- Floor screed material (concrete or cement);

- The presence of various additional elements in the screed;

- The total area, if you are interested in the total cost of dismantling the screed;

For example:

Dismantling of a cement-sand screed from 50 mm will cost from 130 rubles

Dismantling of concrete screed from 200 rubm2

We can name it as accurately as possible only after evaluating and analyzing the upcoming work, as well as preparing a working draft.

This is interesting: Laying laminate without floor screed: we analyze the essence

Technology and cost of concrete floor dismantling

The most common type of base for flooring is a layer of cement-sand mixture, which is located on the floor. If defects appear in the screed or its reconstruction is required, it is necessary to dismantle the concrete floor. Pouring the next layer of mortar is not always effective, as the solidity of the structure is lost and the load on the floors increases (more details here).

- Demolition technology

- How much does demolition cost

In what cases is the screed dismantled

The concrete layer is multifunctional: it fills in the irregularities of the ceiling, levels the surface, provides strength, thermal and waterproofing of the floor, and durability of the top coating. The quality of the screed depends on the correct percentage of the components of the concrete mixture, the presence of a lower layer of crushed stone or expanded clay, reinforcing mesh (more on this here). If one of these conditions is not met, the concrete is destroyed.

The screed is removed under the following circumstances:

- the performance of the floor has deteriorated - signs of breaking (cracks and delaminations) have appeared, irregularities have arisen, cement seeps through the seams of the finish coating;

- it was decided to replace the floor tiles, as voids appeared under it;

- Reinforced screed required

- repair or installation of pipes, cables in the concrete layer;

- it is necessary to change the level of the floor;

- house is undergoing a major renovation.

Dismantling methods

- Manual. It is advisable for small amounts of work, as it requires a lot of physical effort. Work is carried out with the help of a pick, crowbar, sledgehammer, hammer, chisel.

- Mechanized. It is carried out by construction companies using mechanical and electrical tools - a perforator with a “shovel” nozzle is usually enough in an apartment. In difficult cases and with a large thickness of the concrete layer, electric platforms, diamond cutting equipment, a grinder, pneumatic concrete breakers of high power are used.

- Combined. It is a manual method with the connection of equipment.It is practiced for the accurate and delicate removal of concrete in multi-storey buildings, so as not to cause inconvenience to residents of neighboring apartments. Manual work is carried out on problem areas.

Features of the demolition of a cement or concrete screed

Preliminary disassembly of parquet, laminate, skirting boards, removal of linoleum. Depending on the chosen method of dismantling, tools are prepared. Doing the work with your own hands, most often use hand tools. In addition to them, you can rent a puncher. The process of destruction of concrete is associated with a large amount of cement dust, harmful to the organs of vision and respiration - goggles and a respirator should be prepared. Don't forget to wear gloves to protect your hands from injury.

The main technique for self-removal of the screed is breaking it into small pieces, carried out with extreme care so as not to spoil the structure of the floors. To reduce the amount of dust, it is recommended to moisten the concrete

The resulting construction waste is packed into bags and taken out of the housing.

Dismantling work with the involvement of specialists

Removing a concrete screed is a complex technological process that requires sufficient technical and physical training

A specialized team has powerful tools at their disposal that do not create a lot of noise - this is important for multi-apartment residential buildings. To quickly cut out a certain fragment of the coating, diamond cutting and drilling are used.

At the same time, there is no additional load on the ceiling and the amount of dust is reduced.

The average price of dismantling the old concrete floor in Moscow

| Company | Price, rubles/m2 |

| KP "Repair" | 290 – 390 |

| PRO Team | 260 |

| "Smooth floor" | 500 |

The cost of demolition of the floor depends on the thickness of the screed, the presence of reinforcing elements in it, the material (class of cement and concrete), and the area of \u200b\u200bthe room. Therefore, to agree on a price, it is necessary for the master to visit the object.

GESNr 57-02-04

Disassembly of floor coverings: cement

LOCAL RESOURCE STATEMENT GESNr 57-02-04

| Name | unit of measurement |

| Disassembly of floor coverings: cement | 100 m2 coverage |

| Scope of work | |

| 01. Dismantling of coatings with cleaning of materials and bases. 02. Laying at the construction site. |

PRICE VALUES

The price lists the direct costs of the work for the period March 2014 for the city of Moscow, which are calculated on the basis of standards 2014 with additions 1 by applying indexes to the prices of the resources used. Indices applied to federal prices 2000.

The following indexes and hourly rates from the "Union of Estimators" were used:

Index to the cost of materials: 7,485

Index to the cost of cars: 11,643

Used hourly rates:

In parentheses are the wages per month at a given hourly rate.

Hourly rate of the 1st category: 130.23 rubles. in hour (22 920) rub. per month.

Hourly rate 2 categories: 141.21 rubles. in hour (24 853) rub. per month.

Hourly rate 3 categories: 154.46 rubles. in hour (27 185) rub. per month.

Hourly rate 4 categories: 174.34 rubles. in hour (30 684) rub. per month.

Hourly rate of the 5th category: 200.84 rubles. in hour (35 348) rub. per month.

Hourly rate of the 6th category: 233.96 rubles. in hour (41 177) rub. per month.

By clicking on this link, you can see this standard calculated in 2000 prices.

The basis for the use of the composition and consumption of materials, machines and labor costs are GESN-2001

LABOR

| № | Name | Unit Change | Labor costs |

| 1 | Labor costs of construction workers Category 3 | man-hour | 111,2 |

| 2 | Labor costs of machinists (for reference, included in the cost of EM) | man-hour | 21 |

| Total labor costs of workers | man-hour | 111,2 | |

| Wages of workers = 111.2 x 154.46 | Rub. | 17 175,95 | |

| Salary of machinists = 2531.82 (for calculating invoices and profits) | Rub. | 2 531,82 |

We make a resource estimate for HPES with our own hands.

OPERATION OF MACHINES AND MECHANISMS

| № | Cipher | Name | Unit Change | Consumption | St-st unit Rub. | TotalRUB. |

| 1 | 030954 | Lifts with a carrying capacity of up to 500 kg, single mast, lifting height 45 m | mash.-h | 1,8 | 363,96 | 655,13 |

| 2 | 050101 | Mobile compressors with internal combustion engine pressure up to 686 kPa (7 atm), capacity 2.2 m3/min | mash.-h | 19,2 | 1047,87 | 20 119,10 |

| 3 | 330804 | Hammers when working from mobile compressor stations, pneumatic jackhammers | mash.-h | 38,4 | 17,81 | 683,90 |

| Total | Rub. | 21 458,14 |

CONSUMPTION OF MATERIALS

| № | Cipher | Name | Unit Change | Consumption | St-st unit Rub. | TotalRUB. |

| 1 | 509-9900 | Construction garbage | t | 6,6 | 0,00 | |

| Total | Rub. | 0,00 |

TOTAL PRICED: RUB 38,634.09

You can see this standard calculated in 2000 prices. by following this link

The price was compiled according to the standards of GESN-2001 edition 2014 with additions 1 in prices March 2014.To determine the intermediate and final values of the price, the DefSmeta program was used

Estimate for the construction of a house, for the repair and decoration of apartments - the program DefSmeta

Program rentalThe program provides an assistant who will turn the budgeting into a game.

Dismantling the self-leveling floor: screed, but not quite ordinary

As a rule, the self-leveling floor lasts quite a long time, and it appeared with us relatively recently - few of the masters faced the issue of dismantling it. There are still no old coatings that need to be replaced, and if such a floor has to be dismantled, then only if the customer does not like it. But that's not the point - the self-leveling floor is different.At least two global varieties can be distinguished.

- Self-levelling cement-based flooring (known as self-leveling floor screed). It is not much different from a standard floor screed - except perhaps for its improved characteristics. It is a little stronger, denser, but this does not mean that it cannot be removed with a perforator. Quite the opposite - it pricks into pieces very well.

-

Polymer bulk floors. This is a completely different story - in most cases, polymers are not a brittle material and problems can arise with their dismantling. It is for this that a cement-sand base is poured under them - as a rule, the same self-leveling screed, which removes the issue of complex installation. In general, a self-leveling polymer floor breaks off in pieces along with a cement-sand base with almost no problems.

In general, the dismantling of modern floors cannot be called difficult - in principle, as far as I understand, manufacturers take care of this, just like that the floors do not serve for too long. Unfortunately, this is how the world works today, and you can’t get away from it.