Pouring underfloor heating screed.

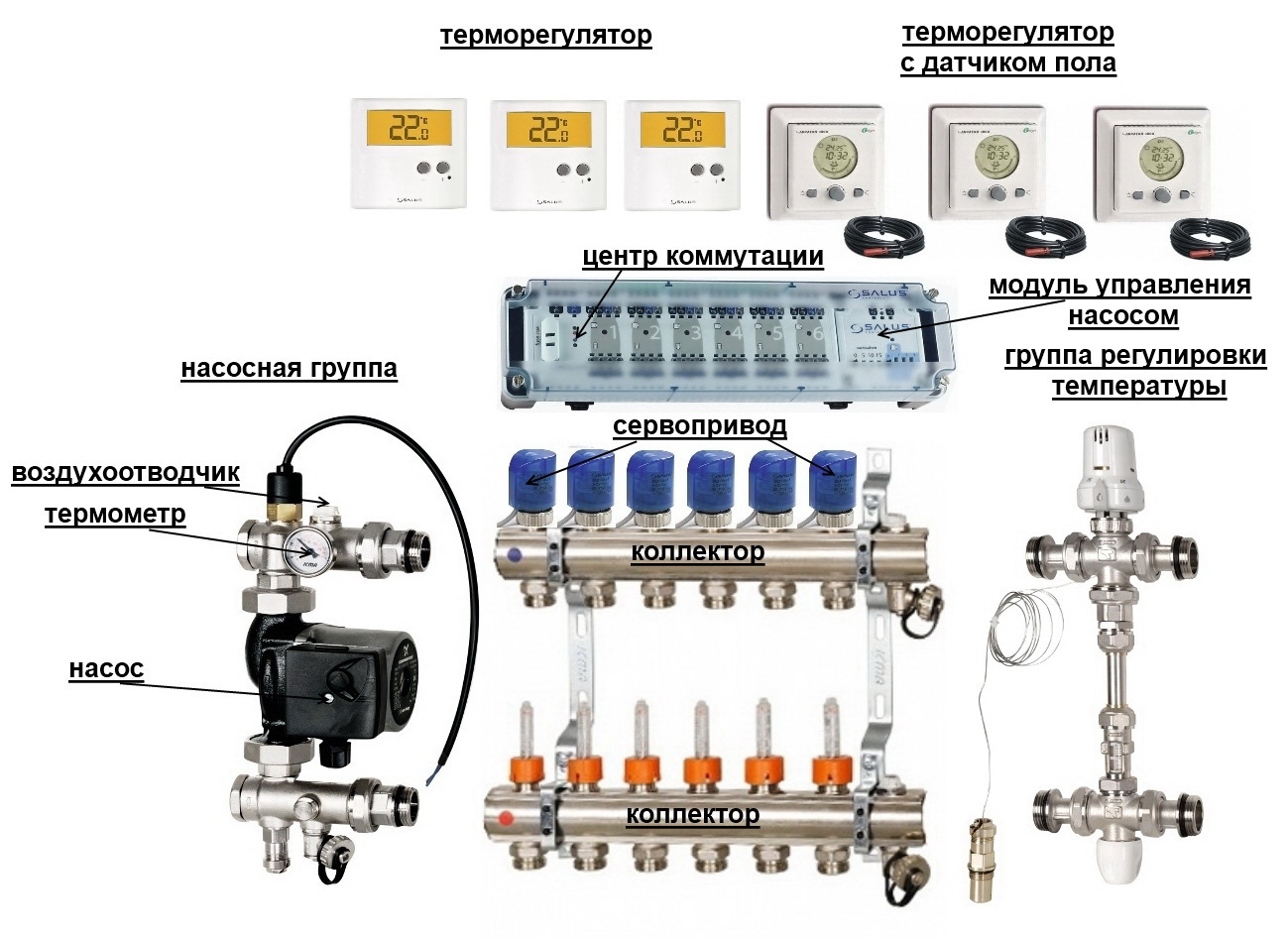

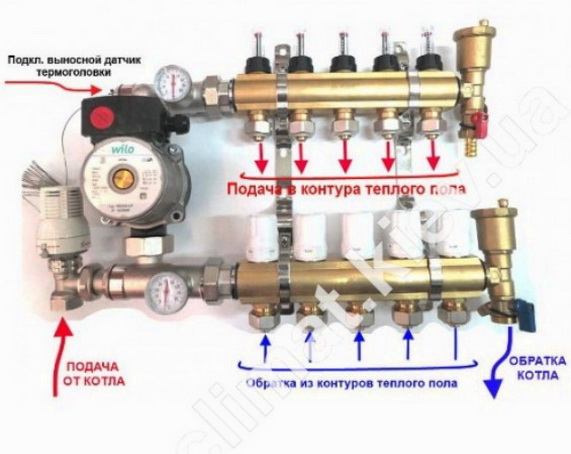

Here comes the moment when it is no longer possible to retreat further - this is the moment of pouring the screed. By this time, the entire pipe should be laid, secured and under pressure (the water in the pipe should be at room temperature). Speaking of connection! I recommend that you read the article that is devoted to.

The main mistake that can be made when pouring is the wrong thickness of the screed. It cannot be made thinner than 3 cm and thicker than 10 cm. In addition, there are requirements for the composition of the mixture - it must be at least brand 400. Of course, this requirement is not always observed, but you need to know about it. There is nothing much more to say here, I propose to see how it is done:

Incorrect installation of damper tape.

Let me remind you that the damper tape is needed in order to compensate for the thermal expansion of concrete, which occurs due to an increase in its temperature. Often people forget to attach it to the walls or choose the wrong tape width. The damper tape should be 2-3 cm higher than the level of the final screed.The tape is attached to the wall with dowel-nails, if it does not have an adhesive side. The tape along the entire length should be equally adjacent to the wall. Watch the following video:

The video shows the installation of self-adhesive tape, so the installer does not use dowel-nails. But in the next video they will be:

The main parameters affecting the determination of the pipe layout step

The distance between the pipes of the underfloor heating is determined based on the following parameters, which are the main ones:

- room area;

- type and diameter of pipes used in the heating system;

Determining the area of a room

Area = width * length.

Experts recommend reducing the resulting figure by the area occupied by large furniture. Heating the floor under the furniture is not advisable, as it can lead to deformation, and reducing the area will save the money required for arranging the floor.

Taking into account the results obtained, it is possible to determine the most optimal step for laying the turns of the pipeline.

View Influence

The pitch of the pipes of a water-heated floor is also determined based on the material of the product, or rather on the coefficient of its thermal conductivity, and the pipe.

Copper and corrugated stainless pipes have the highest coefficient value. Further, the decrease of the considered parameter occurs according to the following scheme:

- polyethylene;

- polypropylene.

That is, polypropylene pipes have the lowest heat transfer coefficient, which are recommended to be used to organize a heating system only in exceptional cases.

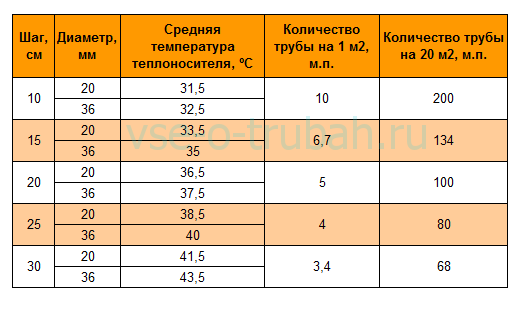

The higher the heat transfer coefficient, the greater the distance pipes can be laid and vice versa. Thus, the smaller diameter pipes are used, the smaller the laying step should be.

The relationship between step and coolant temperature is shown in the table.

For a certain pipe diameter, the laying step should be the higher, the higher the average temperature of the coolant in the system.

The most popular are pipes with a diameter of 16 mm. At the same time, the laying pitch is 250 mm - 300 mm in the living room, 100 mm - 150 mm in the bathroom and 300 mm - 350 mm in other premises.

Incorrect laying of underfloor heating pipes.

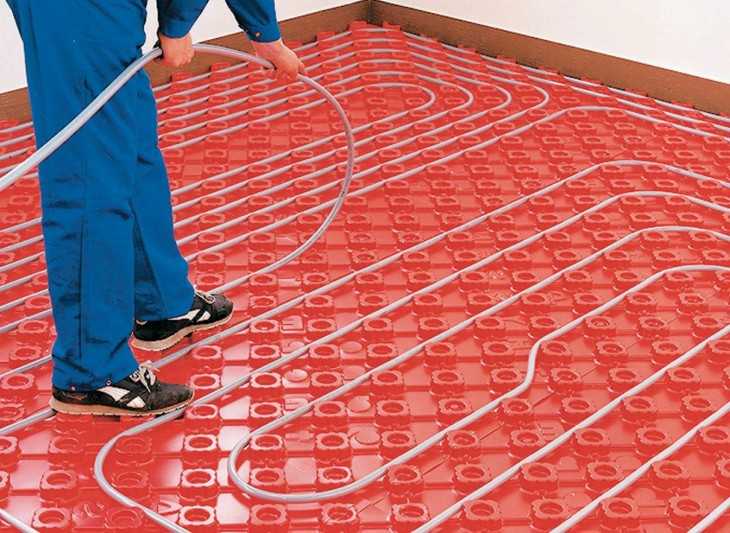

Laying ETP pipes is not an easy task for an inexperienced "homemade" who decided to save on installation and do everything himself. Here it all starts with laying thermal insulation on a rough screed. As thermal insulation, polystyrene foam of different thicknesses, or foil-foamed polyethylene is used. The latter is used where it is not possible to lay a thick insulation. It is worth saying that the alkaline environment of the screed quickly corrodes the foil, so it will not be of much use. Although at the moment there are samples of such a heater, where the foil is covered with a layer of polyethylene on top, which should protect aluminum from the action of alkali.

foil insulation

Styrofoam insulation

The insulation must be laid tightly without any play.

Now we turn directly to the problems of laying pipes of the ETP. I will list them as a list:

- Lack of a preliminary plan - when installing an ECP, it helps a lot to have a preliminary plan.The plan marks the entry and exit points of the pipes, the laying step, the distance from the walls and other things.

- Failure to comply with the laying step - many people save on the pipe and make the laying step more than 30 cm. In this case, a "zebra" appears. This means that the floor will be either cold or warm. The laying step is in the range from 10 to 30 cm.

- Too long warm circuits - for a water-heated floor made by a pipe 16 mm in diameter, the length limit will be 100 meters, and for the 20th pipe, the loop length will be 120 meters. If you make the loop longer, then the coolant will most likely not circulate through it.

I suggest you watch this video:

After laying, it is necessary to pressure test the pipes with water. Pressure testing is done with a pressure of at least 3 atmospheres. The screed is also poured onto the pipe under pressure. This is necessary so that the solution does not flatten the pipe with its weight. Since we are talking about the screed, let's look at this process carefully.

Conclusion.

Water heated floor is a complex engineering system. You can save here, but almost certainly it will be at the expense of the quality of either materials or work performed. It is worth carefully selecting people for such work, it is desirable that they have some kind of “portfolio” where you can see his success in this matter. If you are interested, read the article about

On materials, too, you need to save carefully. What you pour into concrete should be of good quality so that you don’t have to open it all up later.

On this we will say goodbye for now, I'm waiting for your questions in the comment

It often happens that after working properly for one or two seasons, the electric underfloor heating suddenly stops heating. If he played the role of additional heating for you, then you can still somehow postpone this.

Call a specialist, wait for repairs. But when, this is the only and main source of heating in the house, is it possible to find the reason do-it-yourself breakdowns and fix it yourself?

In most cases it is possible, but a lot depends on the location of the damage and the cause. Here are the main three: