- Checking and correcting pressure

- Nuances of connecting a hydraulic accumulator

- How to choose a hydraulic accumulator for water supply systems of a private house

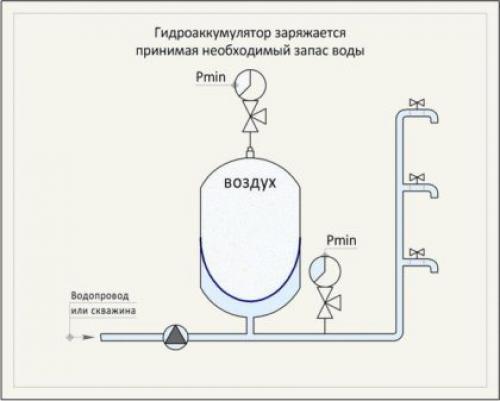

- The principle of operation of the accumulator

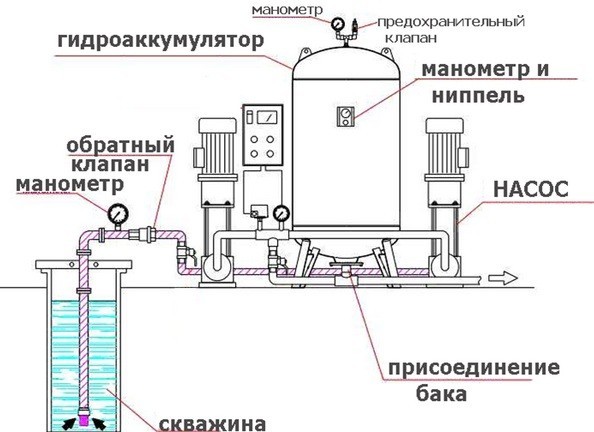

- Connecting a hydraulic tank is a minimum of complexity

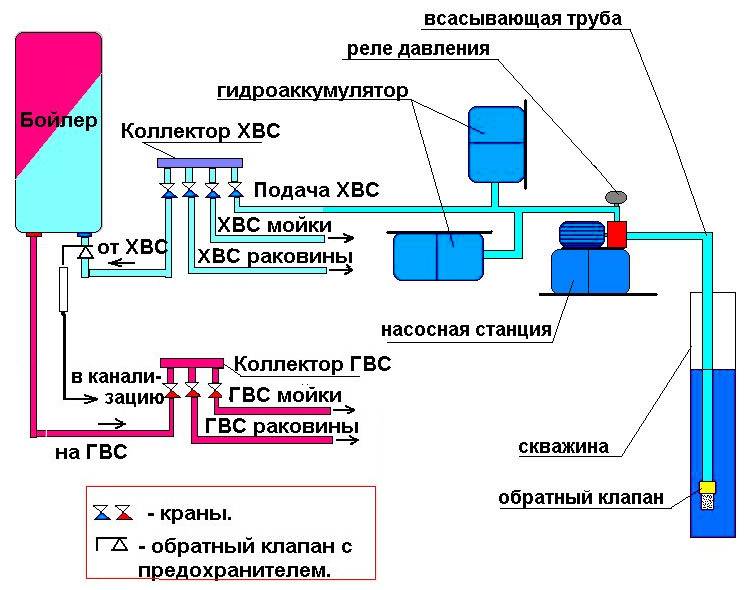

- Where to install a hydraulic accumulator for heating systems

- Procedure

- Installation of a heat accumulator

- Expansion tank piping

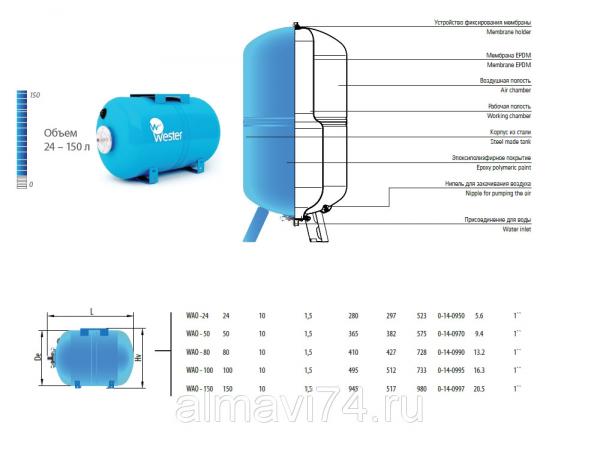

- Hydraulic tank device

- Which accumulator model to choose?

- Determination of tank parameters

- Optimal Performance

- Optimum air pressure

- Hydraulic tank open type

- Selection of a hydraulic accumulator

- Hydraulic tank maintenance rules

Checking and correcting pressure

So, just before connecting, it is recommended to check the pressure level in the accumulator itself. Due to this information, you will be able to correctly configure the pressure switch.

Moreover, it is extremely important to carry out future control of the pressure level. For this purpose, a manometer is intended. Some home craftsmen temporarily use a car pressure gauge

Its error is minimal, so it is quite a normal option.

Some home craftsmen temporarily use a car pressure gauge. Its error is minimal, so it is quite a normal option.

If necessary, the pressure level can be reduced or added.For this purpose, there is a nipple on the top of the accumulator. A car or bicycle pump is connected to it. Due to this, the pressure rises. If the air pressure, on the contrary, needs to be lowered, then there is a special valve in the nipple. You should take a sharp and thin object and press on it.

Nuances of connecting a hydraulic accumulator

A device with a pear-shaped container assumes that there is water inside it, and not air. This feature gives an advantage over the flat diaphragm version. The reason is that in the latter case, the liquid comes into contact with the metal from which the tank body is made. As a result, foci of corrosion appear. This must be taken into account when choosing a model.

In addition, the “pear” is easier to change if it fails. This usually happens 10-15 years after connecting the circulation pump with a hydraulic accumulator. In addition to the problem of choice, the following aspects must be taken into account during installation:

- The mount point should be at the highest possible height. Ideally, this is the attic of the house. This factor allows you to increase the pressure in the pipeline.

- Despite the fact that the flanges are galvanized and the body is painted, the room where the accumulator is installed must be dry. High humidity will cause condensation, rust and premature equipment failure.

- It is better to connect using flexible hoses in a stainless steel braid. Fasten with union inch nuts.

- The inlet pipe is a tie-in place for a coarse filter, which will prevent rust, scale and other suspended solids from entering the tank and damaging the membrane.

- A ball valve is mounted at the inlet, with which you can cut off the wiring from the supply line if you have to repair it or service the pump. Water in the house will be all the same.

Before buying, you need to make preliminary calculations. They consist in determining the required operating parameters and characteristics of the hydraulic tank. Be sure to watch this video, where a person tells how to choose a tank yourself.

The opinion “the larger the capacity, the better” is incorrect. Too much water will cause it to stagnate. As a result, harmful bacteria can multiply, sediment can form, and an unpleasant odor can appear. Such a tank takes up a lot of space, weighs responsibly. If the consumption is small, and the electricity is rarely turned off, the purchase of such equipment is not advisable.

Too small capacity is inefficient, as the pump will be turned on frequently, which adversely affects the service life. A special formula is used for calculations. As an alternative method for determining the required volume of the tank, the correspondence between the power of the pumping station and the size of the tank is used. More performance means more tank size.

For this, special tables are used. If the conditions are quite cramped, it makes sense to consider purchasing a pump with a soft start, and not spend money on a hydraulic accumulator. But if it is possible to install both elements, the benefits will also be in savings. But most importantly, such a system will work for a long time and uninterruptedly.

How to choose a hydraulic accumulator for water supply systems of a private house

Before buying, you should consider all the parameters of the hydraulic tank

Particular attention should be paid to:

- tank volume;

- location type;

- type of energy storage;

- nominal pressure;

- the cost of the selected model.

When buying, you should ask the sales assistant about the availability and cost of replacement membranes or cylinders for the selected model and how affordable they are in principle. It would be useful to check the accompanying documentation and the certificate of conformity, as well as clarify the warranty period for the device.

Important information! If you plan to install it yourself, you need to find out if this is a reason to nullify the warranty. Some manufacturers oblige buyers to hire professional installers - this is prescribed as one of the clauses of the warranty service agreement.

It is quite difficult to understand the range of such products. Today, on the shelves of shops are products of various companies. In order to help the reader, consider the most famous and popular among the population.

The principle of operation of the accumulator

The hydraulic accumulator works like this. The pump supplies water under pressure to the accumulator membrane. When the pressure threshold is reached, the relay turns off the pump and the water stops flowing. After the pressure begins to drop during water intake, the pump automatically turns on again and supplies water to the accumulator membrane. The larger the volume of the hydraulic tank, the more effective the result of its work. The operation of the pressure switch can be adjusted.

During the operation of the accumulator, the air dissolved in water gradually accumulates in the membrane, which leads to a decrease in the efficiency of the device. Therefore, it is necessary to carry out preventive maintenance of the accumulator by bleeding the accumulated air.The frequency of preventive maintenance depends on the volume of the hydraulic tank and the frequency of its operation, which is approximately once every 1-3 months.

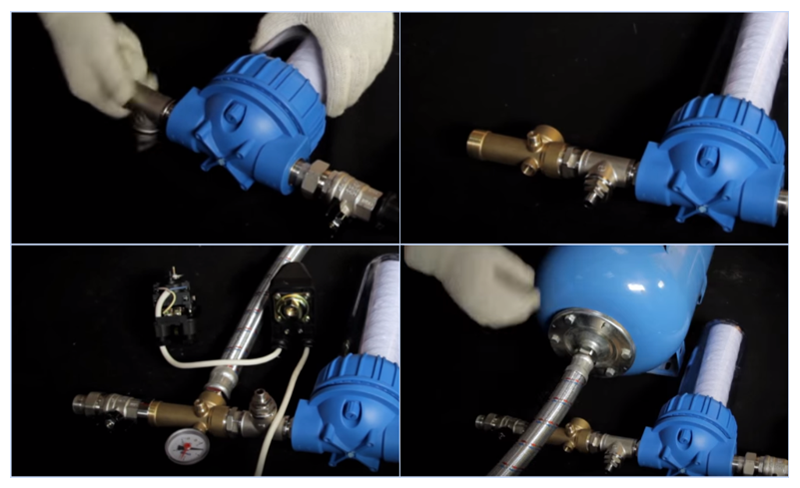

Connecting a hydraulic tank is a minimum of complexity

Self-installation of the accumulator in the water supply system does not cause any serious problems. If the device is connected to networks with surface-type pumping equipment, the procedure will be as follows:

- Measure the pressure inside the accumulator. Its value should be 0.2-1 bar less than the pressure of the pump start switch.

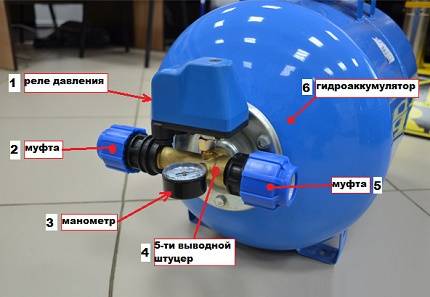

- Prepare a fitting for connecting the relay, hydraulic tank, pressure gauge and pump into one circuit. Nuance. Take a fitting with five outlets. An "extra" entrance will be required to connect the water pipe.

- Buy a relay for adjusting pressure, as well as fluoroplastic sealing material (FUM tape) or tow with.

- Connect the fitting to the tank using a flange (it must have a bypass valve) or a rigid hose.

- Screw in turn all parts of the system. The last connection is made to the pipe that leads to the pumping device.

The installed tank should be checked for leaks. If there are any, it is necessary to additionally seal the junctions of the individual elements of the device with FUM tape or a suitable sealant.

When using a hydraulic tank in systems with a submersible pump, it must be taken into account that the latter is installed directly in the place where water enters the residential building (in a well, a well). Such a scheme is potentially unsafe. There is a high probability of "rollback" of water back to the source.How to avoid it? Quite simply - by installing a special check valve. It is placed directly on the pump in front of the water pipe. The procedure for connecting the hydraulic tank will be similar to the scheme described above. But with one change. First you need to install a check valve. And only after that connect all elements of the hydraulic accumulator to the water supply network.

Choose and install a hydraulic tank in your home so that you never know problems with an autonomous water supply system!

The hydraulic accumulator is an expansion membrane tank suitable for operation with drinking water in water supply systems.

What then can fail there, does it make sense to overpay for a brand and are all hydraulic accumulators really the same?

In this article, we will consider how some hydraulic accumulators can differ from others, and most importantly, we will understand what factors affect their cost.

Where to install a hydraulic accumulator for heating systems

In the classical scheme of an open heating system, when water is circulated under the condition of heating the coolant, the expansion tank is installed in the immediate vicinity of the heating boiler. This arrangement is due to the need for a rapid decrease in pressure, with a sharp increase in pressure in the boiler, the liquid with such an arrangement of the heating circuit could quickly go beyond the contour.

In the classical scheme of an open heating system, when water is circulated under the condition of heating the coolant, the expansion tank is installed in the immediate vicinity of the heating boiler. This arrangement is due to the need for a rapid decrease in pressure, with a sharp increase in pressure in the boiler, the liquid with such an arrangement of the heating circuit could quickly go beyond the contour.

In a closed system, when using a circulation pump, there is no need to place a hydraulic accumulator immediately after the boiler. The pressure here is created by the pump and, if necessary, it will turn off automatically, but it is easier to release excess pressure at the lowest point of the system, in the outlet of the return pipe before entering the boiler.In this segment, the fluid flow has a constant value and the smallest jumps, therefore, the accumulator is also switched on sporadically when the pressure rises as much as possible or drops too low.

Procedure

There are several connection options in total, which depend on the type of pump used:

- submersible option, which must be placed in the water;

- surface, attached closer to the accumulator.

Due to the peculiarities of their design, the schemes for connecting storage systems differ.

So, using a surface pump, the procedure will be as follows:

- First, the air pressure is measured in the state where the membrane is empty.

The indicators should not be higher than the pressure at which the pump can turn on.

The second indicator must be set on the control relay, setting it one atmosphere more than the value obtained from the air pressure level.

- Next, the assembly itself begins. First of all, a manifold with 5 connectors is mounted to the flange fitting of the tank.

- Now, the pipe coming from the pump is connected in series first, and the water supply itself is turned on in the second. Next, the control relay, pressure gauge and the last fitting of the hydraulic tank (it should already be connected).

All threaded connections sit on the FUM tape, in accordance with generally accepted rules for such connections. After that, you can start operating the installed accumulator.

Please note: it is desirable to install such units closer to pumping stations, for greater efficiency.

Connection using a submersible pump is as follows:

- First of all, the pump itself must be immersed in water.After that, the pressure hose coming from it is connected to the water pressure switch in the same collector as described above.

- Further from the same collector we make a tap for the accumulator.

- The last step is to connect another pipe to the water supply, and the rest to the pump control system.

It is necessary to place a check valve between the collector and the pump to prevent the water from draining back into the well after the water supply is turned off.

Watch the video in which the specialist explains how to install a hydraulic accumulator for a water supply system with your own hands:

Installation of a heat accumulator

Improving the operation of heating with additional devices with your own hands will make it necessary to carry out the following work:

Make a detailed diagram

When developing a drawing, you need to take into account where the heating accumulator is located, the insulating layer, the height of the accumulator capacity, the presence of drainage for drainage - factors to reduce heat loss;

Build a manifold-distributor into the system, making sure that the various systems are connected correctly;

Having connected the parts of the pipeline, check the tightness of the connections;

Connect the storage tank;

Connect the circulation pump;

After completing the assembly work with your own hands, conduct a test control of the tightness and correctness of the connections.

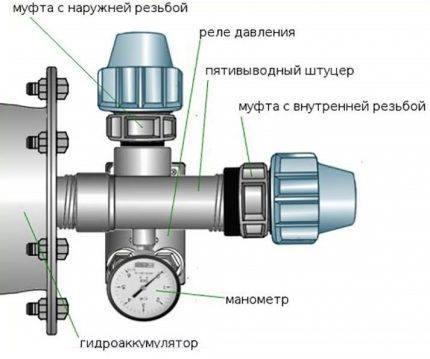

Expansion tank piping

Before connecting a hydraulic accumulator for individual water supply systems, components are prepared: automatic devices, filters and adapters for connecting HDPE pipes.After connecting the electric pump to the HDPE water supply using transitional plastic couplings and placing it in the well, further assembly work is carried out in the following sequence:

- At the outlet of the water pipe from the pump, a ball valve and a coarse filter are installed to remove sand from the water.

- After the filter, a tee is installed with a hole diameter suitable for connecting automation. An adapter sleeve is screwed into its upper outlet to connect the relay.

- To connect a pressure switch and pressure gauge to the electric pump, a standard five-inlet fitting is used, which is connected to a tee using an adapter.

- At the outlet of the fitting with an external thread with a diameter of 1 inch, a ball valve with a union nut is installed - this will allow you to repair and replace components without draining water from the entire water supply line.

- A hydraulic accumulator is connected to the outlet of the fitting with an internal thread of 1 inch using a flexible hose.

- Next, a pressure gauge and a pressure switch are installed in the five-pin fitting, and a dry-running relay is screwed into the tee.

- At the end, the electrical power cable is connected to the relay - the installation of automation on this can be considered complete.

Many people prefer to install all automation using connecting fittings directly at the outlet of the accumulator - this technique does not require an underwater hose.

The hydraulic tank is the main unit in automatic control systems for electric pumps, necessary to reduce the load on the water main and reduce the operation cycles of pumping equipment.Its connection to the pipeline and setting up is quite simple to do with your own hands using the simplest plumbing tool. For the correct choice of the expansion tank, you can use a not too complicated formula or determine its parameters approximately depending on the volume of supply or the power of the pumping equipment.

Hydraulic tank device

The hydraulic accumulator for water supply by its design is a sealed steel tank, inside of which a membrane is placed, due to which the internal space is divided into two independent chambers. Water is pumped directly into the membrane, which eliminates interaction with the metal inner surface of the tank. The membrane material complies with the sanitary and hygienic requirements applicable to drinking water.

There is air around the membrane. The air pressure is regulated by a pneumatic valve. Water accumulating under pressure stretches the membrane, which in turn compresses the air around, and in the reverse process, compressed air displaces water from the membrane, providing a given pressure.

An example of using a hydraulic accumulator:

Which accumulator model to choose?

Manufacturers, responding to consumer requests, produce equipment of various sizes. The "corridor" of volume indicators is 24-1000 liters. What should be considered when choosing?

The volume of the tank depends on the amount of water consumed

The determining factor is the amount of water needed to service the house (possibly a personal plot)

The minimum tank volume - 24 liters - is enough for a family of 2, if we take into account the shower, toilet, kitchen and watering the crops on the site

More significant water consumption requires a tank with a volume of 50 liters or more. You should calculate how many household appliances use water at the same time, add the number of people who also use water, and, based on this, select the necessary model.

It happens that the number of users has increased or a new household appliance has appeared that uses water. In this case, you should simply replace the tank with a large tank, since connecting a hydraulic accumulator with your own hands is a quick and easy process.

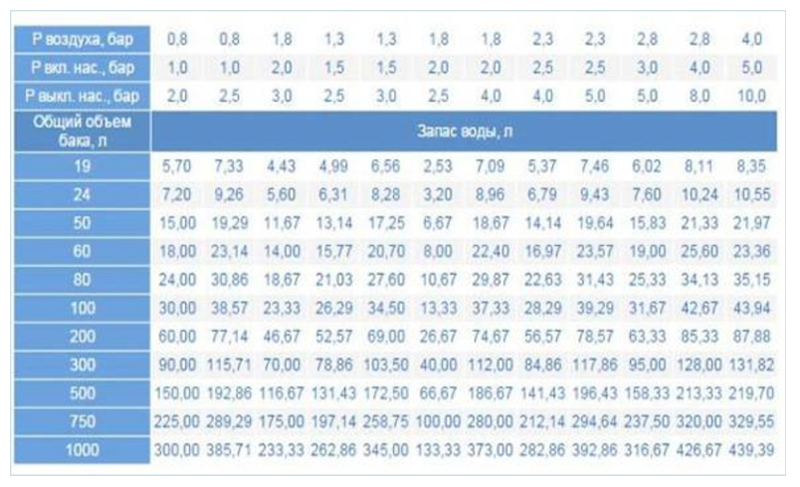

Determination of tank parameters

In most cases of inclusions, hydraulic tanks for water supply are installed according to the principle: the larger the volume, the better. But too much volume is not always justified: the hydraulic tank will take up a lot of useful space, the water will stagnate in it, and if power outages are very rare, there is simply no need for it. Too small a hydraulic tank is also inefficient - if a powerful pump is used, it will often turn on and off and quickly fail. If a situation arises where installation space is limited or financial resources do not allow the purchase of a large storage tank, you can calculate its minimum volume using the formula below.

Rice. 6 How to correctly calculate the volume of the hydraulic tank in the water supply system

Another calculation method is the calculation of the required volume of the hydraulic tank according to the power of the electric pump used.

Recently, modern high-tech electric pumps with soft start and stop, frequency regulation of the speed of rotation of the impellers depending on water consumption have appeared on the market.In this case, the need for a large hydraulic tank is eliminated - soft start and adjustment do not cause water hammer, as in systems with conventional electric pumps. Automatic control units of high-tech devices with frequency control have a built-in hydraulic tank of a very small volume, designed for its pumping group.

Fig.7 Table of calculated values of pressure and volume of the hydraulic tank depending on the operating modes of the water supply line

Optimal Performance

In addition to the capacity, just as important is a suitable pressure indicator in an unfilled reservoir. This value is usually marked on the body of each individual model. It will not be difficult to calculate which parameter will be ideal in a particular case. It is detected based on hydrostatic pressure, because it depends on the height to which it is necessary to raise the liquid. For example, if the height of the pipes in the dwelling reaches 10 m, then the pressure parameter will be 1 bar

In addition, it is very important to consider that the working pressure of the hydraulic tank should not be more than the starting pressure of the pump.

For example, to ensure a stable supply of liquid in a house with two floors, you will need a high-quality hydraulic tank with an operating power level of 1.5 bar and a top power of up to 4.5 bar. In most cases, manufacturers form an air pressure in the accumulator of 1.5 bar. However, in certain cases, the values may be different. That is why, before starting to use the unit, you need to check these values using a pressure gauge. This part connects to the hydraulic accumulator nipple.

Optimum air pressure

In order for household appliances to work normally, the pressure in the hydraulic tank must be in the range of 1.4-2.8 atm. For better preservation of the membrane, it is necessary that the pressure in the water supply system be 0.1-0.2 atm. exceeded the pressure in the tank. For example, if the pressure inside the membrane tank is 1.5 atm, then in the system it should be 1.6 atm.

It is this value that should be set on the water pressure switch, which works in conjunction with the accumulator. For a one-story country house, this setting is considered optimal. If we are talking about a two-story cottage, the pressure will have to be increased. To calculate its optimal value, the following formula is used:

Vatm.=(Hmax+6)/10

In this formula, V atm. is the optimum pressure, and Hmax is the height of the highest draw point. As a rule, we are talking about the soul. To get the desired value, you should calculate the height of the shower head relative to the accumulator. The resulting data is entered into the formula. As a result of the calculation, the optimal pressure value that should be in the tank will be obtained.

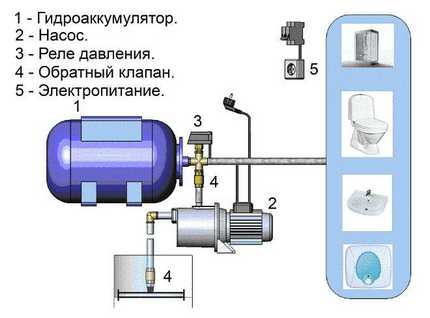

Please note that the value obtained should not exceed the maximum allowable characteristics for other household and plumbing fixtures, otherwise they will simply fail. If we talk about an independent water supply system at home in a simplified way, then its constituent elements are:

If we talk about an independent water supply system at home in a simplified way, then its constituent elements are:

- pump,

- accumulator,

- pressure switch,

- check valve,

- manometer.

The last element is used in order to be able to quickly control the pressure. Its permanent presence in the water supply system is not necessary. It can only be connected at the moment when test measurements are being made.

As you can see, it is on this diagram that the pressure gauge is not displayed, but this does not mean that it is not needed at all. Just turn it on at the time of the control measurements.

When participating in the surface pump scheme, the hydraulic tank is mounted next to it. At the same time, the check valve is installed on the suction pipeline, and the remaining elements form a single bundle, connecting to each other using a five-outlet fitting.

The five-terminal device is ideally suited for this purpose, since it has terminals of various diameters. The incoming and outgoing pipelines and some other elements of the bundle can be connected to the fitting with the help of American women in order to facilitate preventive and repair work in certain sections of the water supply system.

However, this fitting can be replaced by a bunch of connecting elements. But why?

In this diagram, the connection order is clearly visible. When the fitting is connected to the accumulator, it is necessary to make sure that the connection is tight

In this diagram, the connection order is clearly visible. When the fitting is connected to the accumulator, it is necessary to make sure that the connection is tight

So, the accumulator is connected to the pump as follows:

- one inch outlet connects the fitting itself to the hydraulic tank pipe;

- a pressure gauge and pressure switch are connected to the quarter-inch leads;

- there are two free inch outlets, to which the pipe from the pump is mounted, as well as the wiring going to the water consumers.

If a surface pump works in the circuit, then it is better to connect the accumulator to it using a flexible hose with a metal winding.

To those parts that end with couplings, a pipe from the pump and plumbing will be connected, which will go to water consumers

The accumulator is connected to the submersible pump in the same way. A feature of this scheme is the location of the check valve, which has nothing to do with the issues that we are considering today.

Hydraulic tank open type

Such designs are considered obsolete, as they do not provide absolute autonomy, and can only increase the period between maintenance. The heated liquid evaporates, and its shortage must be eliminated by periodically adding coolant, replenishing its volume. No diaphragms or pears are used. The pressure in the system appears due to the fact that the open hydraulic tank is mounted on a hill (in the attic, under the ceiling, etc.).

Naturally, there is no air pressure in the open-type expansion tank. When calculating, it is taken into account that one meter of water column creates a pressure of 0.1 atmospheres. However, there is a way to automate water collection. To do this, a float is installed, which, when lowered, opens the tap, and after filling the tank, it rises and blocks the access of water to the tank. But in this case, you still need to control the operation of the system.

Selection of a hydraulic accumulator

The volume of the selected accumulator tank must be greater than or equal to the volume obtained as a result of the calculation. There are no negative consequences from overestimating the volume of the accumulator, in excess of the calculated value, no matter how much it is exceeded.

When choosing a hydraulic accumulator, one should take into account its temperature and strength characteristics.The maximum tank pressure must be greater than or equal to the maximum pressure at the connection point.

If the installation of hydraulic accumulators is provided for indoors, then it should be taken into account that tanks with a diameter of more than 750 mm and a height of more than 1.5 m may not pass through the doorway, and mechanization will be required to move them. In this case, it is better to give preference to not one, but several tanks of hydraulic accumulators of a smaller capacity.

When choosing a hydraulic accumulator, it should be remembered that the volume of water stored in it averages 40-50% of the volume of the tank.

Hydraulic tank maintenance rules

A scheduled inspection of the expansion tank is to check the pressure in the gas compartment. It is also necessary to inspect the valves, shutoff valves, air vent, check the operation of the pressure gauge. To verify the integrity of the tank, an external inspection is carried out.

During preventive maintenance, the pressure in the hydraulic tank should be measured and corrected if necessary.

Despite the simplicity of the device, expansion tanks for water supply are still not eternal and can break. Typical causes are diaphragm rupture or air loss through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump, the appearance of noise in the water supply system. Understanding how a hydraulic accumulator works is the first step to proper maintenance and troubleshooting.