- Installation rules

- How to calculate tank volume

- How to make a competent choice of an expansion tank?

- Installation Requirements

- Performing expansion tank installation

- Installation of a heat accumulator

- Expansion tank device

- The fight against water hammer

- Kinds

- open type

- closed tank

- Required water flow

- Expansion tank with diaphragm

- Installation of the membrane device

- Correct container position

- Features of choosing an installation site

- Setting up the instrument before use

- Tank as additional capacity

- Advantages and disadvantages of various types of expansion tanks for heating

- Do-it-yourself open tank

- Installation and connection

- Expansion tank pressure?

- Tank device

- Membrane

- Types of expansion tanks

Installation rules

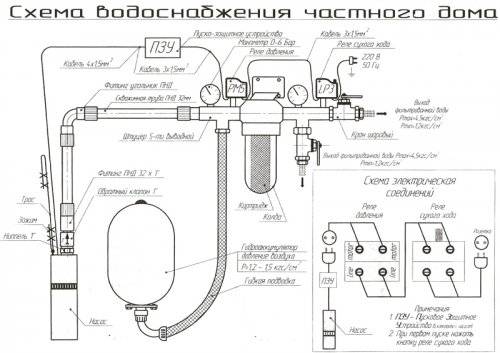

When installing a hydraulic accumulator, you must strictly adhere to certain rules.

The first thing to do is to select a site in the heating network where the device will be mounted.

Experts strongly advise mounting the expansion tank in the return pipe through which chilled water circulates.

Important! The unit must be installed before the pumping equipment.In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

The valve has the same purpose as the hydraulic accumulator, but it is able to withstand higher pressure drops.

The expansion tank normalizes the operation of the heating system with slight surges in water pressure.

Before proceeding with the installation, you need to select the installation location of the device. Do not forget that the device must be freely accessible, nothing should prevent you from getting to the air compartment control valve.

Shut-off and control valves cannot be installed between the expansion tank and the pump; they can significantly modify the hydraulic resistance.

In the room where the accumulator will be located, the air temperature must be at least 0 degrees. The surface of the device is not allowed to be exposed to mechanical loads.

The actuation of the reducer for removing air from the heating system of a private house must be carried out in accordance with the parameters of the heating system.

If you follow all the above recommendations, you will be able to install an expansion tank on your own, without outside help.

Why do we need a hydraulic accumulator in heating systems, how to install and configure it - we suggest watching it in the video.

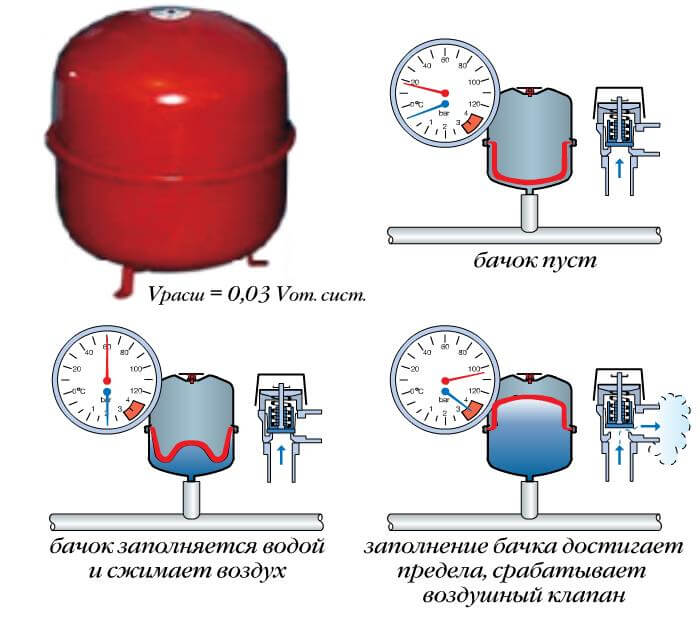

How to calculate tank volume

When calculating the volume of the expansion tank, several factors must be taken into account:

- capacity and power of the heating system;

- type of heating system;

- expansion tank type.

To calculate the capacity of the tank, the formula is used:

Vb \u003d (Vs * K) / D, where:

Vb - reservoir capacity;

Vc is the volume of coolant in the system;

K is the expansion coefficient of the liquid. For water, this figure is 4%, so 1.04 is used in the formula;

D - expansion coefficient of the tank itself, depends on the material of manufacture and the temperature difference during heating. To accurately establish "D", you can use the formula:

D \u003d (Pmax - Pini) / (Pmax + 1), where:

Pmax is the value of the maximum pressure inside pipes and radiators;

Pnach is the pressure inside the tank, planned by the manufacturers (usually 1.5 atm.).

Thus, the volume of the reservoir depends largely on its own characteristics.

Attention! All indicators and characteristics should not exceed the established standards. When calculating the volume of the device, the data should be equal to or slightly larger than the results obtained. Many sites offer online calculations for expansion tanks

Many sites offer online calculations for expansion tanks.

How to make a competent choice of an expansion tank?

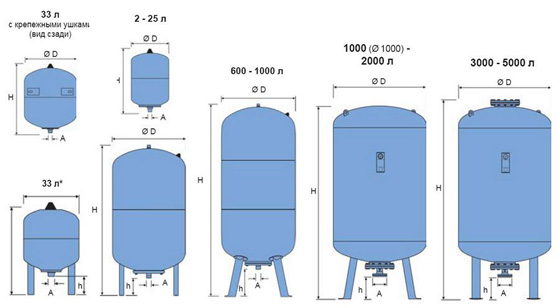

No matter what, the main technical characteristic when choosing an expansion tank is its volume. And already the need for a certain amount of volume is dictated by a wide variety of conditions:

-

How many people should the system supply with water?

- The number of points for water intake in the house (take into account not only those where faucets and a shower cabin are attached, but also a washing machine, other appliances whose operation is associated with the use of water).

- The need to supply water from one system to several consumers at once.

- Maximum frequency of cyclic start-stops per hour per pump.

Approximate figures given by leading experts as an example:

The most common average family, which includes no more than three people, needs water supply, the pump capacity does not exceed 2 cubic meters. m / h, then the most reasonable choice would be to purchase an expansion tank with a capacity of 20 to 24 liters. With an increase in the number of consumers to eight people, it is worth purchasing a device with a volume of less than 50 liters. There are more than ten consumers - at least 100 liters are needed. These are the most optimal values - and not a lot, and not a little. In the event that you are in doubt, it is better to take with a margin, a little more - this certainly will not damage your autonomous water supply system in any way.

Installation Requirements

Installing the tank can not be called a difficult job, so you can do it on your own.

When installing, you must strictly comply with the following requirements:

do not install the tank in rooms with a negative temperature;

you can install the tank at any point in the system before branching;

special attention must be paid to the reliability of fastening, since when filling the tank with liquid, its weight increases significantly;

all connections must be tight;

the use of sealants is not allowed, as they worsen the friction between the housing and the membrane;

it is not recommended to place the vessel on the outlet pipe immediately after the boiler.

Performing expansion tank installation

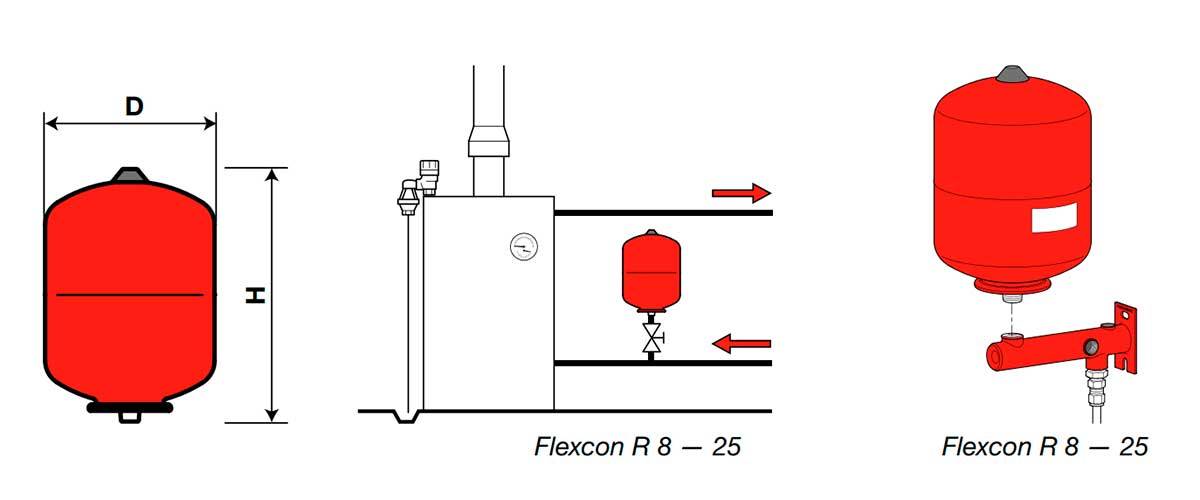

The unit is installed in a room with a temperature of at least 0°C.The minimum distance from walls and floor slabs is no more than 60 cm. It is necessary to provide a passage around the installed equipment for access to the air cock, drain valve, shutoff valves. Do not allow the weight of the connected equipment and piping to affect the body of the instrument.

Before installing the hydraulic tank in the chamber, it is necessary to measure the air density with a manometer; it must correspond to the technical characteristics of the mechanism. Fine adjustment can be made through the nipple at the top of the tank. Installation of the device (vertically or horizontally) depends on the volume of the tank and is indicated in the manufacturer's recommendations when purchasing the equipment.

Installation of a heat accumulator

Improving the operation of heating with additional devices with your own hands will make it necessary to carry out the following work:

Make a detailed diagram

When developing a drawing, you need to take into account where the heating accumulator is located, the insulating layer, the height of the accumulator capacity, the presence of drainage for drainage - factors to reduce heat loss;

Build a manifold-distributor into the system, making sure that the various systems are connected correctly;

Having connected the parts of the pipeline, check the tightness of the connections;

Connect the storage tank;

Connect the circulation pump;

After completing the assembly work with your own hands, conduct a test control of the tightness and correctness of the connections.

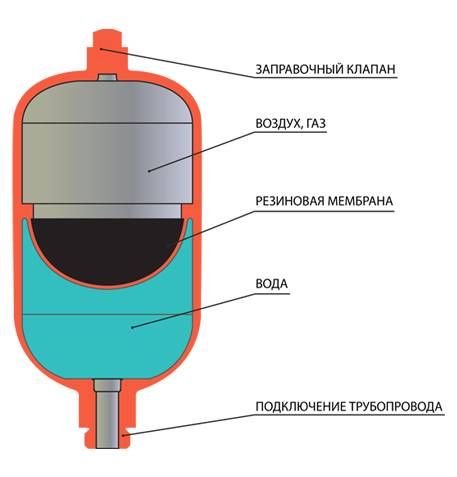

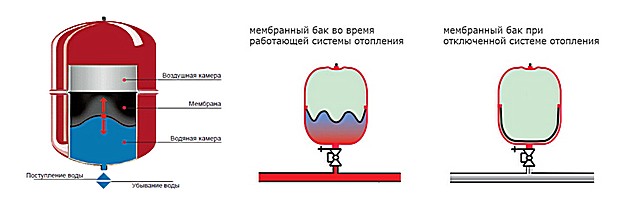

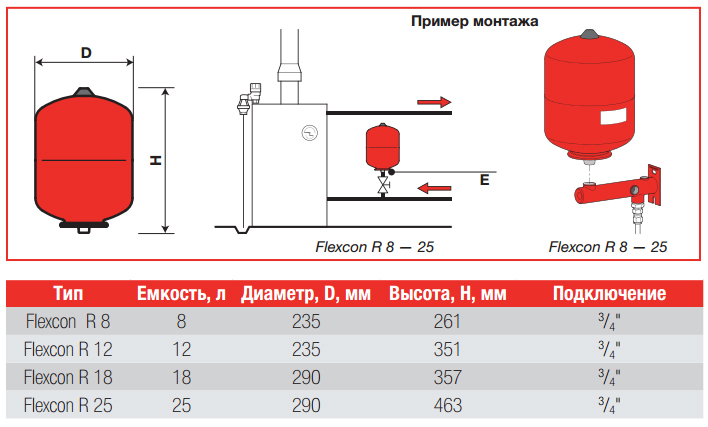

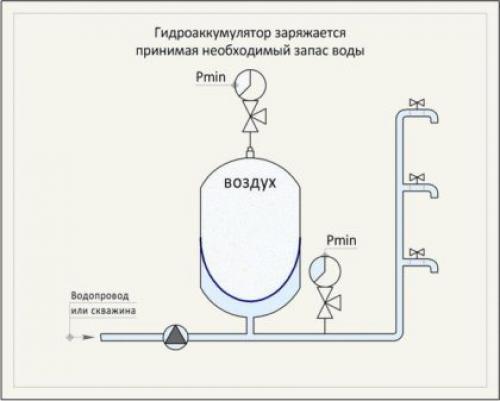

Expansion tank device

Inside the expansion tank there is a rubber membrane that divides the tank into two chambers: air is pumped into one chamber, and the other chamber remains empty. In an empty chamber after installation and start of heating, the flow of coolant will begin.In another chamber, where air is pumped, the required volume will be restored. When the liquid cools, it is forced back into the water supply system. Thus, a constant, necessary pressure is kept in the pipes, which is why the system always works stably, there are no overloads and pressure surges.

Figure 2: Expansion tank dimensions

The fight against water hammer

A water hammer is a short-term pressure surge that occurs in a closed circuit due to the inertia of a moving water flow when it stops instantly. Water hammer often takes pressure beyond the strength of pipes and flexible pipes; the consequences are very predictable - the owner gets breaks in the water supply at the seams and fittings.

The combination of high temperature and pressure surge led to the rupture of a polypropylene pipe

If expansion tanks are connected to the water supply, the water supply is made absolutely safe: the air tank in this case also plays the role of a damper. A small volume tank is mounted on the water supply inlet or (with collector water distribution) on the collector.

Membrane hydraulic shock absorber on the manifold

Kinds

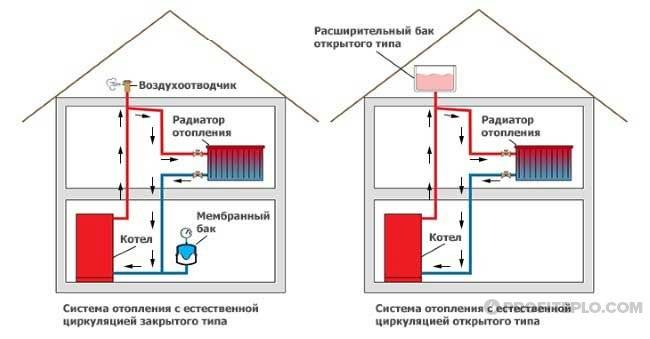

Heating systems are performed with natural and forced circulation of the coolant.

In traditional heating designs, open-type expansion tanks are used.

In cases where the coolant is induced to move with the help of special circulation pumps, expansion devices of a closed type are more often used.

open type

An open-type expansion tank is an ordinary metal box connected to a pipe from a heating main. It is placed in the highest accessible place of the building (house).

During the heating season, the presence of water in the tank is regularly inspected. If necessary, add liquid to the expansion tank.

Some experts install a float level control system in the expansion tank. When the level drops, the float drops, which leads to the opening of the feed valve.

Water is automatically added to the desired level. Automatic systems are mounted only where there is a water supply system in which pressure is maintained in excess of the hydrostatic value Hst.

- Extremely simple device, easy to make with your own hands.

- It can function for years without causing any complaints from users.

- Corrosion damages the expansion tank first.

- It is necessary to regularly check the presence of fluid and top up if necessary. Often, in private houses, when installing a heating system, the capacity for expanding the coolant is remembered last. I place it near the ceiling, which creates inconvenience when topping up. Forced to use flat bottles to refill water.

- It is necessary to lay an additional pipe that will heat only the space near the ceiling.

Important! The coolant tends to evaporate. It must be periodically topped up so that air pockets do not form inside the heating system.

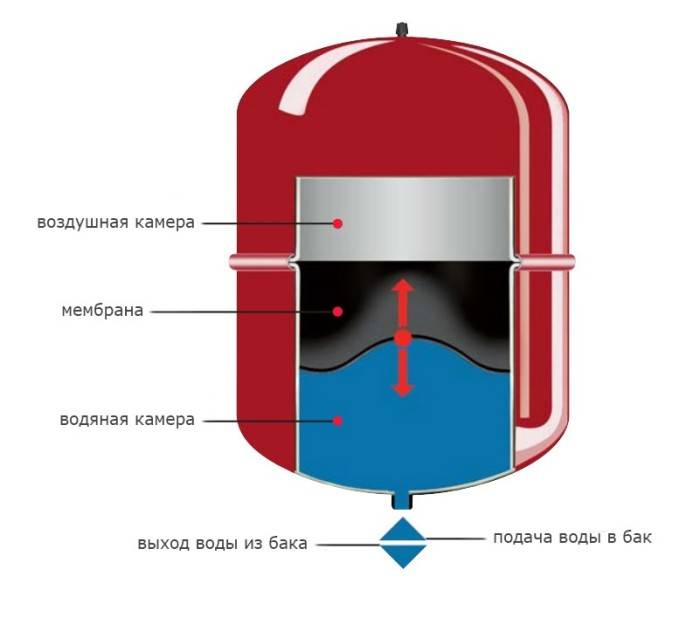

closed tank

In such tanks there are two volumes separated by a movable membrane. In the lower space there is a coolant, and in the upper space there is ordinary air.

To create a preliminary pressure in the system, a valve and a fitting are provided on the air part of the tank. By connecting the pump, you can increase the pressure inside the air chamber.

With the help of a manometer, the set pressure in the heating system is controlled and set Hst.

Installation of such a device is carried out in different parts of the heating, more often it is traditionally installed near the boiler on the supply line.

Some users mount additional taps and pressure gauges in order to know the pressure value during operation.

You do not need to constantly monitor the level of coolant in the system, filling it once, for several years you can not worry about fullness

Non-freezing liquids (high-boiling alcohols) are added to the coolant, which are not afraid of temperatures dropping below 0 ° C, which is important for country houses that are visited only by periodic arrivals. There is no corrosion of the metal, since air does not enter inside. minus conditional

It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

minus conditional. It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

Attention! A sharp increase in pressure in the coolant is possible only if its circulation stops. This can happen if the circulation pump is damaged or turned off. There is another drawback that manufacturers of closed tanks do not want to talk about.

The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale.It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

There is one more disadvantage that manufacturers of closed tanks do not want to talk about. The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale. It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

Required water flow

The total volume of the hydraulic tank and the maximum volume of water are not equivalent parameters. After all, water occupies only part of the internal spaces. An approximate calculation of water is determined taking into account the work of all plumbing: faucets in the kitchen and bathroom, shower, toilet, washing machine and dishwasher. On average, this is 150 liters per minute. But in reality, all devices and equipment are not used at the same time. Therefore, the flow rate is about 70-75 liters per minute. So that the pump does not turn on more than 30 times per hour, you need a double supply, that is, 140-150 liters. For small country houses, where there are few water consumers, these figures are lower.

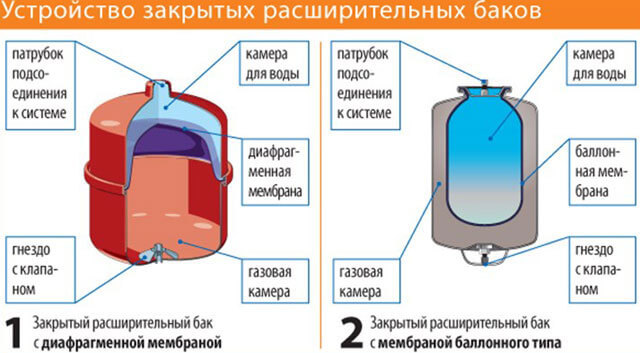

Expansion tank with diaphragm

A feature of such a device is the division of the tank into two separate tanks using a rigidly fixed diaphragm. Therefore, in the event of its failure, you will have to change the entire product as a whole. In such a container, in the part with liquid, there is direct contact of water with the metal case of the device, which leads to the formation of corrosion.

To solve this problem, the internal walls of the device are opened with special dyes.However, such protection is short-lived and after a while rust still appears on the case. As well as expansion tanks with a removable membrane model with a diaphragm, they are vertical or horizontal.

Installation of the membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for the normal circulation of the water flow along the circuit.

Correct container position

When connecting an expansion tank to a closed heating system, it is imperative to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After that, the membrane has to be replaced with a new one.

If the air chamber of such a tank remains at the bottom during installation, then the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster, repairs will be needed sooner.

It makes more sense to install the expansion tank so that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation site

There are a number of requirements to consider when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- Ensure free access to the device for its regular maintenance and necessary repairs.

- The tank hung on the wall should not be too high.

- A stopcock should be placed between the tank and the heating pipes, which will allow the device to be removed without completely draining the coolant from the system.

- The pipes connected to the expansion tank, when wall-mounted, must also be attached to the wall in order to remove possible additional load from the tank nozzle.

For a membrane device, the return section of the line between the circulation pump and the boiler is considered the most suitable connection point. Theoretically, you can put an expansion tank on the supply pipe, but the high temperature of the water will adversely affect the integrity of the membrane and its service life.

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the stopcock and the “American”, it is recommended to install an additional tee and a tap when connecting, which will allow you to empty the expansion tank before turning it off.

Setting up the instrument before use

Before installation or immediately after it, it is necessary to correctly adjust the expansion tank, otherwise called the expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable indicator is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less than about 0.2-0.3 bar. Measurements are carried out with a manometer with a suitable graduation through a nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or its excess is bled off.

The technical documentation usually indicates the working pressure, which is set by the manufacturer at the factory.But practice shows that this is not always true. During storage and transportation, part of the air could escape from the compartment. Be sure to take your own measurements.

If the pressure in the tank is set incorrectly, this can lead to air leakage through the device for removing it. This phenomenon causes a gradual cooling of the coolant in the tank. It is not necessary to pre-fill the membrane tank with coolant, just fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a particular heating system. If the built-in tank is too small, an additional tank must be installed.

It will ensure the normal pressure of the coolant in the system. Such an addition will also be relevant in case of a change in the configuration of the heating circuit. For example, when a gravity system is converted into a circulation pump and old pipes are left.

This is true for any systems with a significant amount of coolant, for example, in a two-three-story cottage or where, in addition to radiators, there is a warm floor. If a boiler with a small built-in membrane tank is used, the installation of another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here, an expansion valve is an adequate way out.

Advantages and disadvantages of various types of expansion tanks for heating

Before finally deciding which tank design is best for your house or apartment, you need to weigh the pros and cons. This is what we will now do by comparing the strengths and weaknesses of the previously reviewed equipment samples.

| Open expansion tank | |

| Advantages | Flaws |

| Ease of self-manufacturing and installation | Whirlwinds may occur, leading to mechanical damage to the device. |

| Affordable prices for existing factory products | High probability of freezing of the coolant in case of non-compliance with the temperature regime |

| Does not require the installation of safety elements, tk. has contact with the air in the room | The need to periodically add liquid to the tank with its extensive evaporation |

| It has the ability to remove not only excess water, but also excess air | Low, in comparison with competitors, efficiency |

| Easy maintenance and low risk of breakdowns | Inability to use antifreeze and other specialized fluids |

As a material for the manufacture of the unit, you can use an old cylinder or even a muffler from a car - as long as tightness is maintained

As a material for the manufacture of the unit, you can use an old cylinder or even a muffler from a car - as long as tightness is maintained

| Closed expansion tank | |

| Advantages | Flaws |

| Possibility to regulate the pressure level | The need for a constant supply of electricity to operate the pump |

| Due to the absence of evaporation, there is no need to control the water level in the heating system | When installed in houses with old pipes and radiators, there is a high risk of leakage |

| Longer useful life compared to open view | Requires the addition of a large number of elements responsible for security |

| Works effectively with any type of heat carriers | Demanding on the tightness of butt joints, if not observed, it quickly fills with air |

| Most models have a collapsible body, which allows you to replace a worn membrane | Higher cost, because it is almost impossible to make such a product on your own |

The membrane tank has a pleasant design that can be easily used in the interior of any house or apartment.

The membrane tank has a pleasant design that can be easily used in the interior of any house or apartment.

Do-it-yourself open tank

open tank

Another thing is the expansion tank for heating an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store. Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits. And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose.Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a step-by-step look at how to make a tank with your own hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design. Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter. The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands.The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad. Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

Installation and connection

The connection diagram for the expansion tank is simple. To do this, the tank has an inlet and outlet pipe, to which the water supply system must be connected. The installation point of the tank depends on the laying of communications and the availability of free space. It is also recommended to connect the membrane tank to an additional storage tank, which should have a larger volume.

At the same time, during installation, it must be remembered that the storage tank must be installed in the system before connecting the membrane tank (i.e., the storage tank is filled first, then the membrane tank). It is recommended to install a storage tank above the membrane tank. This will significantly increase the supply of water and supply it for a longer time.

Expansion tank pressure?

Refer to the instructions for the device - as a rule, we are talking about a level of 1-3 bar.

Make pressure adjustments based on the location of the expansion tank in relation to the entire system. It is believed that in the tank it is necessary to maintain a pressure 0.4 atmospheres lower than in the pipeline - this is enough for normal, uninterrupted operation of the system. The statement is true if the tank and pipeline are at the same level. Otherwise, the difference should be increased.

You can find out what pressure is in the tank by the pressure gauge. You can check the operation of the device as follows: close the valves to isolate the tank, pump up after a few minutes, and then bleed the air. If during the manipulations the arrow moves - smoothly, predictably, then everything is fine - the device can be trusted. The second way: use a manual pressure gauge. The same connectors for the device and the outlet valve of the tank will allow you to easily make a measurement.

It is impossible to allow a situation of pumping the pressure of the expansion tank - then it will squeeze out all the water, as a result - water hammer during excessive heating. Lack of pressure will lead to failures of the safety valves - increase the pressure. For example, using a pump from a bicycle or car through a special spool. A compressed air bottle will also work.

By adhering to these rules, you can choose to install an expansion tank, which for a long time without any problems will help maintain the high quality of hot water supply in the house.

Read also:

Tank device

If the heating system does not include an additional device into which an excess volume of liquid can pass, then it may fail. The role of a spare tank is just performed by a membrane tank, which is necessary for uninterrupted operation.

As long as the boiler was not insulated, the energy demand for water was reduced. Another twisty problem. If the use of typical glycols can be poisoned if the boiler is not running. With potassium permanganate, the second is to look for the kazko "eaten", maybe perfume with water?

Meet colleagues in the food industry. As always, most of the time the simplest jobs are done. The days have already passed with us. And the roof is wet - you don't want to come down. Drive a few meters to the ladder in the attic of Belize. It may not be worth it, but it will increase the resistance to sunlight. In addition, it is perfectly sealed from dirt.

Membrane

The tank body has an elastic membrane that divides its inner chamber into two parts. One part contains the coolant, and the second is filled with air. Nitrogen can be used instead.

Depending on the model, the device may include a replaceable or non-replaceable membrane. In the first case, the coolant is placed in an elastic cavity and does not come into contact with metal inner surfaces.

Unfortunately, you weren't able to take a picture - he's dying, but you still have to get up to tighten the pipes. As long as there is no liquid in the system - it should not be used - there is a danger of well-cooled collectors. However, this should not be the starting point if you want to set up such a system.

The Internet is full of good information. But one of my most disturbing sites. The work is slowly moving forward. It remains to fill the system and insulate the pipes in the attic. After a long search, a propylene glycol company in Lithuania was found. Whoever wants it will find more information.

Mounting (or removal) of the membrane is carried out through the flange, for which bolts are used. Such manipulations are performed when current equipment repairs are carried out.

If the device has a non-replaceable membrane, then it is equipped with an internal cavity of two sections. Dismantling in this case is not provided.

Ethylene glycol should not be used in any way. System leakage management is still required. Another reason is that the route to the collector is quite long. The right candidate is the hyperphoretic relay. Both are cheap and have two min. pressure and maximum pressure. Both values can be adjusted. If the heat rises, the expansion tank collapses or the glycol flows into the plumbing. If the pressure drops, it means trenches.

Last word or bandaged hand.A system with a circulation pump that has accumulated so much and has been idle for almost a month. Although the pump was luxurious - even with power control. So, the new pump is built. Tested tightness of the system. Decorated on the roof - ventilation chamber installed. The result of the first day - I worked for about three hours - with a 14-degree boiler, we have 24 degrees. As in three hours, very good results. Even though the pipeline is still not insulated throughout.

To protect the system from overpressure, membrane tanks are equipped with safety valves.

Types of expansion tanks

Used expansion tanks are the main component of water supply devices, heating systems and fire extinguishing devices. There are only a few varieties:

- Membrane tank (closed type). It is a metal capsule-capacity, which has the shape of a ball or capsule. Inside it, the space is divided by a membrane, for the production of which thermal rubber is used. As a result, two chambers are formed - air and liquid. The air valve should be installed in the air chamber. It will allow you to remove some air at a time when the pressure level will be significantly increased. So the liquid fills the entire tank.

- Tank of open type. It looks like a container, at the bottom of which there is a special device that is directly connected to the heating device (its pipe). The characteristic features include the ratio of the total volume of fluid in the heating system and that which is in the expansion tank. The volume will directly depend on the temperature regime inside the system.It is recommended to install the tank at the top of the heating device (attic space). To reduce heat losses, it is possible to use a heat insulator. An open-type tank cannot be called airtight, which makes it not very attractive, rather bulky, which does not allow installation in residential areas.