- Installing an expansion tank in the heating system

- Self installation

- How to choose an expansion tank for heating - the best tips

- Which expansion tank for heating to choose?

- How to choose the volume of the expansion tank?

- Types of heating systems

- Which design is better?

- Pros and cons of an open tank

- Pros and cons of a closed tank

- Capacity Recommendations

- Expansion tank from a gas cylinder

- Advantages of a closed heating system

- Equipment selection

- How is the volume of tanks calculated

Installing an expansion tank in the heating system

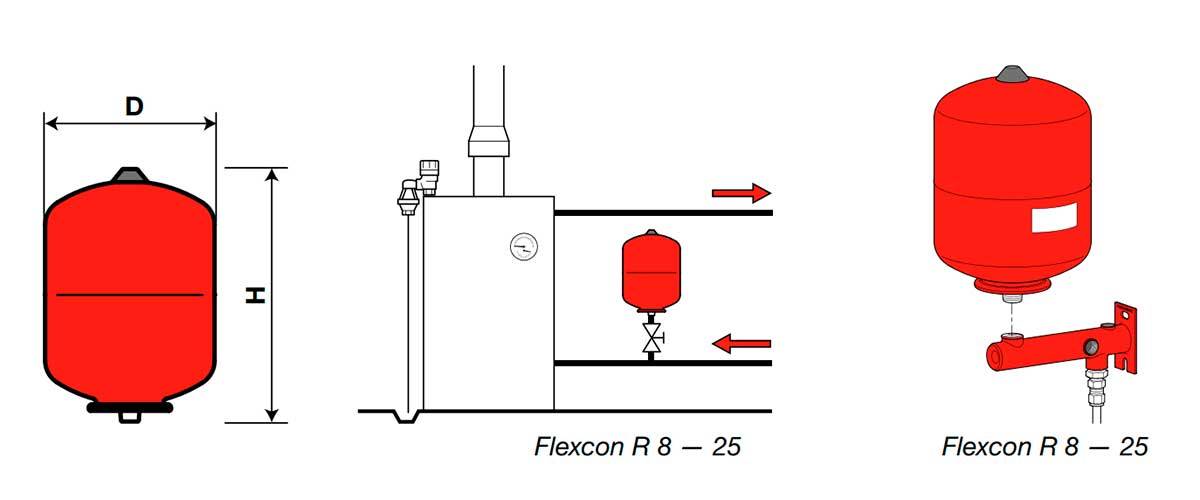

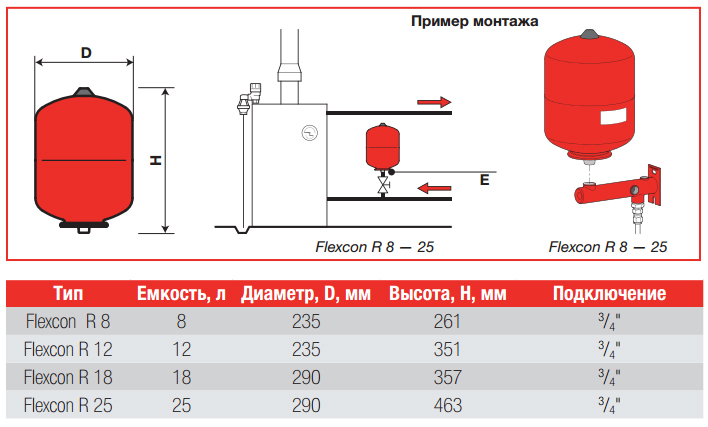

Installation of the expansion tank of the heating system is carried out in accordance with the selected type of the tank itself. We have already said that in closed circuits it is installed near a gas boiler (or any other), and in an open one - at the very top, at the highest vertical point. For connection, metal and plastic pipes of ½ or ¾ inch are used. Fastening is carried out using a special wall mount. As for homemade tanks, they are attached in an arbitrary way.

The most convenient to use are flat expansion tanks - they do not seem as bulky as their barrel-shaped counterparts.

Tanks for closed systems are fixed in the same way, using a suitable wall mount. If you are going to put just such a tank, place it next to the heating boiler and the security group - it is more convenient to test and regulate the pressure in the heating expansion tank (we talked about how this is done in the previous section of the review).

Self installation

For a person who has even little experience in plumbing work, installing and connecting a membrane tank will not be difficult. For complete beginners in this area, it is necessary to use the expansion tank connection diagram in the heating system. This will avoid installation errors.

First you need to make a cut into which the tee will be packed. As a rule, this is done on the circulation pipe, but it can also be done on the return pipe as close to the boiler as possible. The type of installation and fastening can be different and depends on the material from which the pipes are made: metal, polypropylene, plastic and others.

The expansion tank can be placed anywhere. It must necessarily be equipped with a tap on the nozzle, which is necessary to turn off the structure during maintenance and repair work. To do this, it is also necessary to install a connecting nut (American type) between the tank and the tap. If the structure is working, the valve must be in the open position.

On the reverse side, a connecting pipe is fixed to the faucet, the other end of which is mounted to the tee. Its length and other design features do not matter, but, as a rule, they are made along the shortest path to the tee and the return system.

After installation, the tank is filled with coolant.If no leaks or fluid leaks are found, the installation of the vacuum tank can be considered complete. You also need to check all connections.

The connection scheme for the expansion tank of the tank in the heating system is not very complicated, but it must be recalled that the sealed type system must necessarily have a reliable security system, including a pressure gauge and thermometer, as well as various valves. For convenience, it is better to install a pressure gauge near the tank.

How to choose an expansion tank for heating - the best tips

In the structure of the heating system, it is necessary to provide for the presence of all structural elements. To exclude even one of them would be unjustified for two reasons. Firstly, it can negatively affect the functionality and efficiency of the entire system. And secondly, such imperfect projects can be dangerous in relation to possible fires or breaks in pipeline communication.

One of such important structural elements of heating systems is an expansion tank for heating. During the heating of the coolant in the line, there is an increase in pressure and an increase in the volume of the coolant itself, which is due to the clear action of physical forces. At this time, critical parameters are created in the supply line of the pipeline, which, in the absence of an expansion tank, can provoke the exit of the coolant from the pipe. Typically, such incidents are accompanied by a pipeline rupture at the weakest point of the junction of individual elements.

To exclude the likelihood of such a development of events, the installation of an expansion tank for heating is provided for in the structure of the heating system.In the absence of an expansion tank, excess water will have to be drained each time the system is heated. In this case, air pockets may occur, which are formed when the coolant cools in the pipeline.

Which expansion tank for heating to choose?

The classification of these structural elements of the heating circuit provides for two categories of devices:

- Tanks of open type;

- Tanks of the closed type.

The first category includes outdated models for use in systems with natural circulation of the coolant in the system. These are containers with an open top and a nozzle for detecting and removing excess water in the system.

The second category includes the use of fully sealed containers equipped with a vent valve to remove air and excess coolant. Exhaust valves in such expansion tanks for heating can be mechanical with manual removal and automatic - equipped with pressure gauges and appropriate automation. This category of expansion tanks is used when installing a heating system with natural or forced circulation of the coolant.

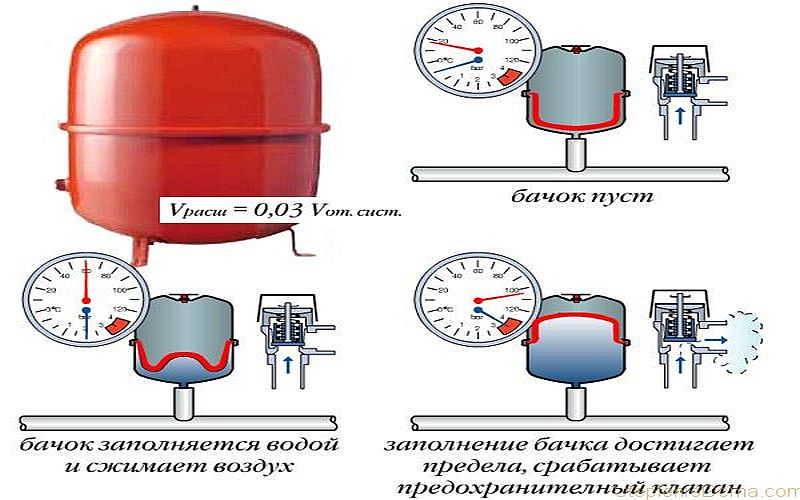

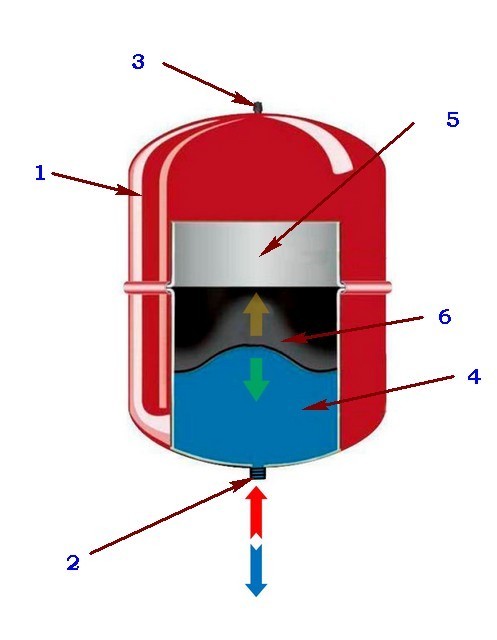

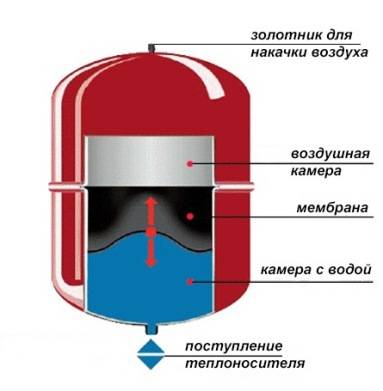

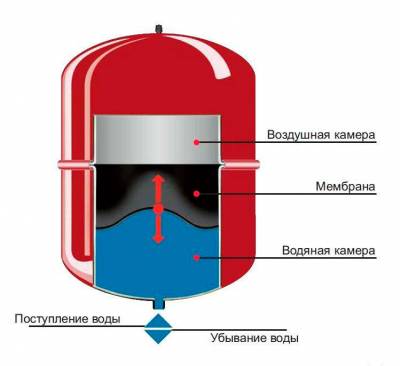

The third option is a membrane tank for heating. This model is more perfect, has more practicality and aesthetic appearance. Its device assumes the presence of two compartments in the design of the tank. One of them contains air under pressure, and the other receives the coolant that has expanded as a result of heating.

Both compartments are separated by a strong and plastic membrane. When the coolant fills the capacity of its compartment, it creates increased pressure in another compartment.When the water cools, the excess pressure in the other compartment forces it back into the heating system pipeline. Thus, a constant volume of coolant and pressure in the system are maintained.

How to choose the volume of the expansion tank?

When the type and location of the tank has been determined, now it is necessary to select the calculation of the volume of the vessel. You can calculate the volume of the expansion tank for heating in different ways.

Professional calculation - done by engineers - designers who use special equipment. Specialists and engineers take into account all the factors that can somehow affect the stability of the heating system. Many people use only this method, as it is the most reliable, accurate, but also expensive.

Special calculator for calculation - various Internet sites make it possible to calculate the volume of expansion tanks. The calculator makes it possible to obtain information on the minimum required capacity of the containers in question. This method can only be applied to individual heating systems.

Calculation by formulas - usually performed independently. A person must be very careful not to make a number of mistakes. On various portals you can find the necessary formulas that will help you decide the volume of the expansion tank.

Types of heating systems

There are two main types of heating systems - open (open) and closed (closed). The first ones are the simplest, the coolant in them flows by gravity through the pipes, without the help of pumps, obeying the laws of physics.The expansion tank for open heating is located at the very top of the circuit - higher than the top line of the batteries installed in the building. The pressure in such a heating circuit is quite small, close to atmospheric.

Expanding under the influence of thermal energy, the coolant needs to be partially removed from the heating circuit. This is precisely what the simplest expansion tank for open-type heating serves for, mounted above all radiators installed in the house (often placed in the attic). The surplus coming from the pipes is sent to it. If there are too many of them, some of them are removed by gravity from the heating through a pipe welded to the expansion tank.

Despite their size and apparent ease of operation, expansion tanks play an important role in the reliability of the entire heating system.

The coolant in open (non-closed) heating systems is in direct contact with atmospheric air, since the expansion tanks are not hermetic here. And if air bubbles form in the pipes and radiators, they are removed through the tank itself, without the use of special valves. In addition to the expansion tank for an open heating system, circulation pumps are often installed here - in most cases they are mounted immediately after the boiler, along with a bypass.

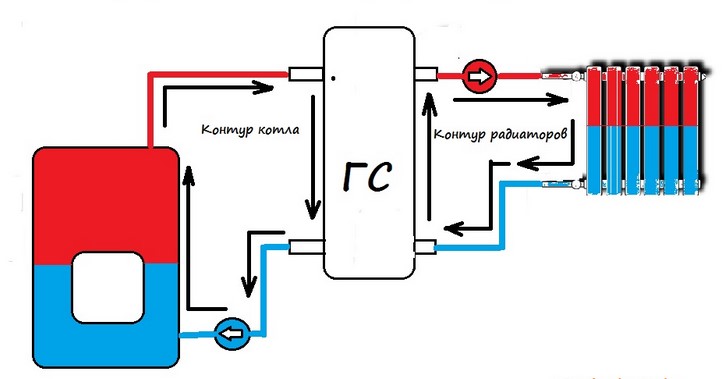

Closed (closed) heating systems are hermetic - in them the coolant does not come into contact with atmospheric air. Features of the installation of such systems:

- Mandatory use of circulation pumps - to ensure proper circulation of the coolant;

- Mandatory use of a safety group - it is responsible for relieving pressure;

- Mandatory use of automatic air vents - no need to explain what they are responsible for.

The coolant flows here under pressure created by the circulation pump

And if in open systems special attention is paid to the slope of the pipes, then this slope is not needed here. The main advantage of closed heating is the rapid and much more uniform distribution of heat throughout the heated rooms.

You can mount an expansion tank for closed-type heating at any arbitrary point in the house - near the heating boiler, at the height of the second floor and in any other place. But most often, expansion tanks of closed-type heating systems are placed near heating boilers, along with security groups.

Which design is better?

Systems, depending on the device and material of the expansion tank, differ in a list of pros and cons. But, according to experts and experienced users, the advantages in functionality are on the side of closed options.

Pros and cons of an open tank

A self-flowing system requires larger diameter pipes, which in turn directly increases costs. The budget for the arrangement of an open heating system with a leaky expander is slightly increased, although it remains relatively small.

The main advantages of this option are simplicity, plus low cost of components and installation work. Another positive feature is the absence of the need to control the pressure level.

An open-type expander for small systems can be assembled from improvised means, and its installation will also be simple

However, there are many more cons:

- the use of antifreeze is dangerous due to toxic fumes;

- installation possibilities are limited only by the top point of the system;

- constant contact with the atmosphere increases the risk of air pockets and corrosion;

- slow heating;

- temperature changes accompanying convection circulation accelerate equipment wear;

- used in heating low-rise buildings, a maximum of two floors;

- large heat losses and energy consumption for heating.

Another disadvantage of an open system is evaporation and overflow losses. Therefore, when installing the tank, care should be taken to ensure the accessibility of the filling hole.

Pros and cons of a closed tank

If open expanders win in terms of prices and ease of installation work, then functionality is the strength of a closed tank, which is also called an expansion tank. They are used in the construction of closed heating systems that do not have direct contact with the atmosphere.

Expanzomats have the following advantages:

- complete tightness allows the use of antifreeze;

- the location of the expander does not affect the performance of the system;

- isolation of the internal space of the tank minimizes the likelihood of air locks and corrosion;

- after starting, the system warms up faster, is more sensitive to adjusting temperature conditions;

- less difference between the operating conditions of the supply and return lines, which as a result increases the operational resource;

- does not require the installation of pipes of large diameter, which saves on construction;

- does not require constant attention to the level and condition of the liquid;

- the possibility of using in systems designed for several floors;

- low heat losses, reducing the cost of equipment operation.

When choosing expanders of this type, there may be sealed cylinders with a non-separable design. If the diaphragm fails, the balloon will have to be replaced with a new one.

To control the level of working pressure, a pressure gauge is mounted on the cylinder; an automatic or mechanical air vent is installed to remove excess air

Of the minuses, it is important to note the complexity of the design, special requirements for materials that increase the cost of equipment. To this can be added the need for constant monitoring of pressure and its restoration if necessary.

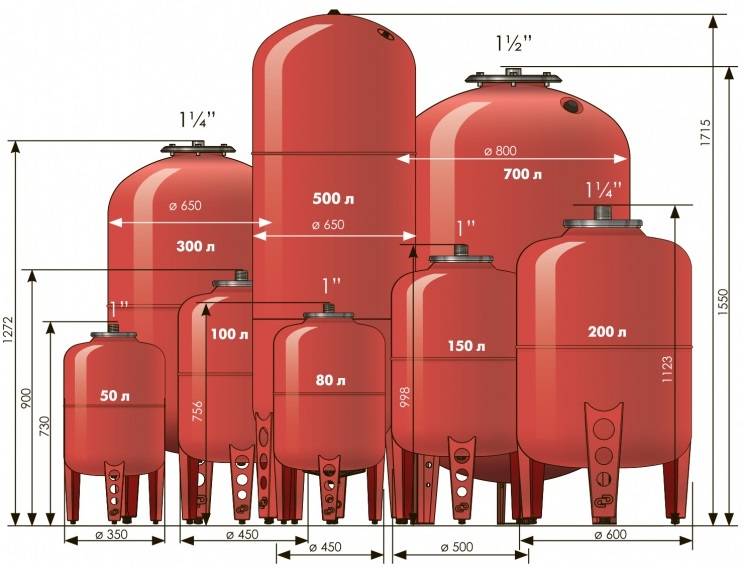

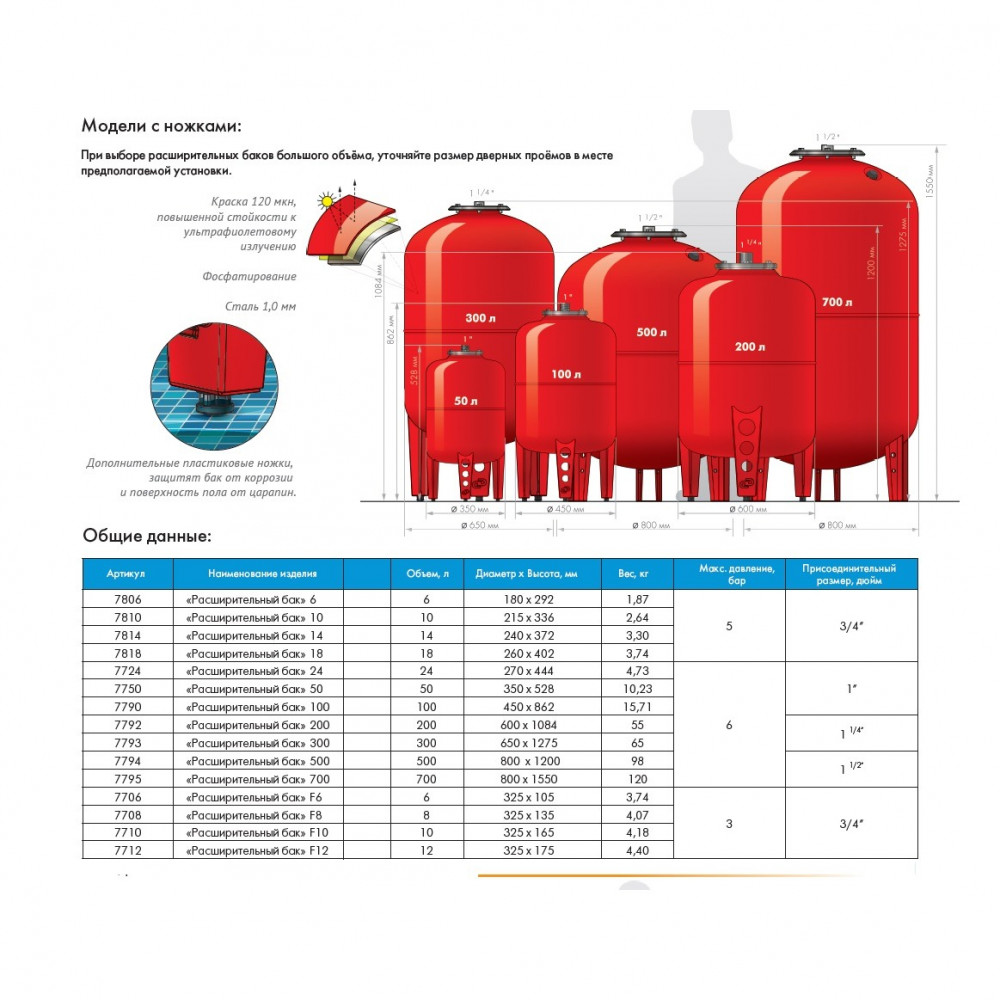

Capacity Recommendations

The most important feature that you should pay attention to when choosing a model of an expansion tank is the volume of its tank. For closed systems with a small circuit, the volume of the coolant in which does not exceed 150 liters, it is easy to calculate the capacity

So, it should be:

- when used as a coolant water - 10% of the volume of the entire heating system (for example, if this figure is 100 liters, then the expansion tank must hold at least 10 liters);

- when using glycolic liquid as a coolant - 15% of the volume of the heating system.

In the latter case, the capacity should be more impressive due to the higher expansion coefficient of the specified antifreeze.

The advantage of modern expansion tanks is the reaction of their membrane to any change in the temperature of the coolant. Which guarantees the safety of use. But it should be remembered that tanks are designed to work in certain conditions, so they must be chosen correctly.

The tank volume for larger systems with more than 150 liters circulating around the circuit is most conveniently calculated using the total system volume parameter and the tank selection table.

To calculate the total volume of the system, you can use the following methods:

- Measure the volume of coolant circulating in all individual elements of the system (boiler, radiators, pipelines) with subsequent summation of the results. This method is highly labor-intensive, but at the same time it is the most accurate.

- Multiply each kilowatt of boiler power by 15, assuming that on average there are about 15 liters of coolant per 1 kW. This method is simple, but it should be remembered that the result can be trusted only when there is confidence in the correct selection of the heating element for the system.

- Drain all water from the system and refill it, calculating the required displacement.

Also, to calculate the required volume of the tank, you can use formulas or an online calculator. Why you need to know the volume of the coolant, its temperature and pressure in the system.

The method with formulas is more complex and the resulting volume will not differ significantly from the rough calculation above. Moreover, the found value will be rounded up.

Many manufacturers of expansion tanks offer the consumer assistance in selecting the right tank. To do this, provide tables to facilitate the selection. True, they must indicate that the information provided is advisory in nature and the responsibility in any case lies with the buyer.

The most practical solution when choosing will be an expansion tank designed for closed-type heating systems, equipped with a safety valve.

The reason is that when the pressure rises to critical norms, the device will start working and bleed it. That is, the specified valve is able to significantly increase the safety of the entire heating system.

When buying a container, it should be borne in mind that red paint is most often used to indicate expansion tanks used for heating.

This feature will help to distinguish the desired product from other similar ones, for example, tanks for water supply that are similar in size and shape - hydraulic accumulators, which are mainly covered with blue enamel.

But if necessary, you can find tanks of various colors, which will help to place the right one in any room without compromising its aesthetic qualities.

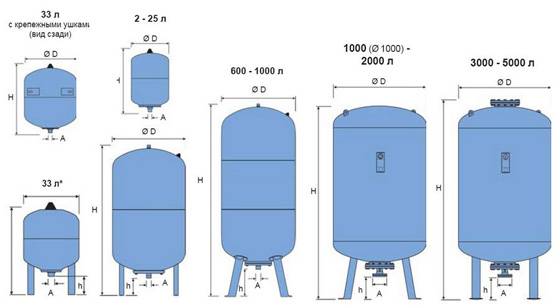

Tanks are horizontal or vertical, and manufacturers make it possible to mount them in different places. This product comes with a variety of accessories.

And when buying, you should pay attention to this, determining the best option in advance.

When choosing, you should also pay attention to the quality of the materials used in the manufacture of the tank body and membrane. And the availability of a guarantee for the purchased equipment and manuals for installation and connecting it to the system

Expansion tank from a gas cylinder

For the manufacture of an expander, you can spend both a 50-liter and a 27-liter gas cylinder. In the first case, a segment with a height of 250 - 300 mm is taken from it. The second option means using the entire cylinder.

Therefore, in order to save material, it is more expedient to use containers with a volume of 27 or even 12 liters. Such a homemade tank from a 12-liter cylinder can be installed in systems with a capacity of up to 240 liters.

The transformation of the cylinder into an expansion tank is carried out as follows.

Before starting work, the entire remaining gas with a fragrance, which gives it such a specific smell, should be completely bled from the cylinder by completely unscrewing the valve from it. After that, through the hole of the unscrewed valve, the cylinder is completely filled with water to its entire volume. This water is drained after 5-10 hours. Bleeding and draining of water should always be carried out away from human habitation.

When the cylinder is prepared in this way, the conical part of its valve is cut off. Then it is welded with a fitting of the required diameter to form an entrance to the expansion tank. If it is not possible to use welding, then you can use the valve as an inlet, joining it to the system by means of a bellows connection. It is usually screwed to the outer fitting of the valve.

Then the legs are welded to the surface of the cylinder body, and the container itself is installed for this operation downwards with a valve. In the absence of welding, the legs are made from corners and fixed to the cylinder with screws, having drilled holes in it and threaded them, or with self-tapping screws for metal with sealed silicone washers.

At the final stage of work, a window 50 × 50 mm is cut in the cylinder. It is made from the side of the balloon bottom. It now becomes the top point of the entire tank. Through such a small hatch, you can fill the coolant into the system, bleed steam from it or excess air from the system.

Advantages of a closed heating system

A conventional open expansion tank is a simpler option if it fully copes with its task. It is much cheaper than the expansion tank of a closed type heating system. In addition, an open design can be done independently. Sometimes a sheet of metal or even plastic canisters are used for this.

Therefore, many may wonder if it makes sense to install a closed structure. It turns out that there is, as it has a number of significant advantages:

- A closed (hermetic) heating system eliminates the possibility of water evaporation. In addition, you can fill in other coolants (antifreeze). This is necessary if the house does not live permanently, but from time to time.

- In an open system, the tank should be located in the attic or at another highest point relative to the entire structure. This requires additional work to insulate the expansion tank so that the coolant does not freeze in winter. The question of where the tank is placed also does not arise, since it can be installed anywhere in the room. The ideal option is a return system before entering the boiler. Thus, the tank is less exposed to temperature effects from the heated coolant. But at the same time, the location of the structure should not create an imbalance in the interior of the room if, for example, the tank is located in the corridor.

- Pipes and radiators of the system with an open type are subject to corrosion and increased gas formation. This happens due to the constant contact of the coolant with air.

- A closed system warms up the coolant much faster. The temperature controls are very precise and sensitive.There is no heat loss in the area of the expansion tank at all, in contrast to an open system.

- The temperature difference between the coolant at the exit from the boiler and at the entrance from the return is much less than in open systems. This significantly affects the life of the system.

- To create a closed structure, it is necessary to purchase pipes of a smaller diameter, which entails lower financial and labor costs. Perhaps this is when installing a structure with forced circulation.

- In an open type tank, it is necessary to constantly monitor the level of the coolant. It is necessary to regulate the level so that there is no overflow when filling, and also so that the liquid does not fall below the critical point. Such problems can be solved by installing additional elements, such as overflow pipes, float chambers, and so on. In a closed design, these problems do not exist.

- The main advantage of a closed-type heating expansion tank is the ability to connect various batteries, convectors, underfloor heating, and a boiler.

Of the minuses, we can consider the need to install security systems: a pressure gauge, a thermometer, a safety system and automatic air vents. Although this can hardly be called a disadvantage, since these elements provide security and are necessary according to government regulations.

Equipment selection

Summing up, we can say the following: for an open heating system, take the appropriate type of expansion tank; for a closed one, this rule also applies. In general, you can even make an open tank with your own hands, there is nothing complicated there.The most important thing is to follow the placement rule, which was written above.

Regarding the purchase of closed-type tanks, you should immediately warn: outwardly they are very similar to hydraulic accumulators for a water supply system. But these are different types of equipment, they are not interchangeable. Focus on the markings affixed to the product, they indicate the permissible temperature and pressure indicators. For the expansion tank, this is 120 degrees and 3 Bar, and for the accumulator - 70 degrees and 10 Bar.

Another criterion for choosing an expansion tank is its required volume.

After all, it is important that the right amount of coolant fits into it. The calculation of this indicator is not so simple, although, in principle, there are various online services for this operation.

But any program can fail, so the calculations are still better done manually. To do this, you need to calculate how much water enters the entire heating system during the operation of the latter. That is, you need to consider the following:

- the amount of liquid in the boiler tank. This indicator is taken from the technical passport of the equipment,

- the amount of coolant in all lines. To do this, you need to find the cross-sectional area of \u200b\u200beach section of the pipeline (using the circle area formula), and then multiply the resulting number by the length of the same section,

- the amount of liquid in each radiator connected to the heating system. This indicator is also taken from the technical passport of the product.

After all the calculations made, the resulting numbers are added up, and then 10% of the amount is calculated. This will be the required capacity of the expansion tank.

How is the volume of tanks calculated

Now you know how to install an expansion tank in the heating system. This requires pipes of suitable diameter and suitable fasteners. Some rounded models are mounted with metal clamps - this is more reliable. We have come to the most important section - now we will tell you how the expansion tank for heating is calculated.

You can place the expansion barrel in any, even the most inconspicuous corner - since it does not take up much space.

The easiest and most obvious way is to use one of the online calculators. But this technique has one drawback - we do not know how and by what formula these calculators, written by no one knows who, carry out calculations. We will tell you how to calculate the volume of a heating expansion tank using a special formula. It takes into account:

- The volume of the total coolant poured into the heating;

- The coefficient of thermal expansion of the coolant (depends on its type);

- Membrane tank efficiency.

First, we need to calculate the volume of coolant in the entire heating circuit. It consists of the following indicators - the volume of pipes + the volume of boiler water + the volume of batteries. Everything is simple with the boiler, the indicator of its internal volume is indicated in the passport data. With batteries, everything is about the same - we take the volume of one section and multiply by their number (do not forget to take into account the number of batteries).

Next, the most difficult stage - we will consider the volume of all laid pipes. To do this, we need their diameter and length. We arm ourselves with a tape measure and go to the measurements. Write down the length of pipes of the same diameter, then move on to thicker pipes. Now we begin to count - we multiply the cross-sectional area of \u200b\u200bthe pipe by its length.As for the efficiency indicator, we take this parameter from the passport for the expansion tank itself.

The last calculations - multiply the volume of the system by the coefficient of thermal expansion, divide all this by efficiency. We get the required volume in liters. For water, the expansion coefficient is about 4%, for ethylene glycol - from 4.5 to 5%.

There is another universal way to select an expansion tank by pressure - it uses only the amount of coolant. For example, if the total volume of the circuit is only 80 liters, then the volume of the tank should be 8 liters. But remember that a too capacious tank will not be able to maintain the desired pressure in the system. And its purchase will be associated with clearly unnecessary and high costs.

If the volume of the expansion tank for heating in the circuit you have created is too small, this will cause an increase in pressure in the heating circuit and force the safety valve to operate.