- Technical advice

- 3 Extender Maintenance

- What you need to know when making calculations

- Tank pressure

- Open and closed models

- Open expander type

- Closed expansion unit

- Do-it-yourself open tank

- Expansion tank of open type for heating systems

- Operating principle

- Design

- Volume

- Appearance

- Kinds

- open type

- closed tank

- How to calculate tank volume

- materials

- How to fill a closed heating system

Technical advice

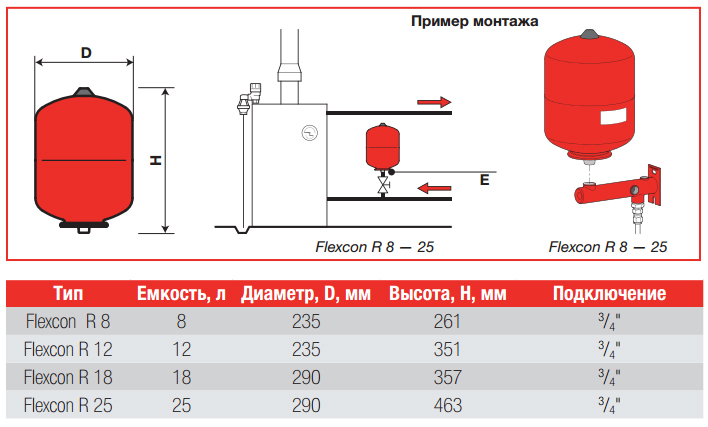

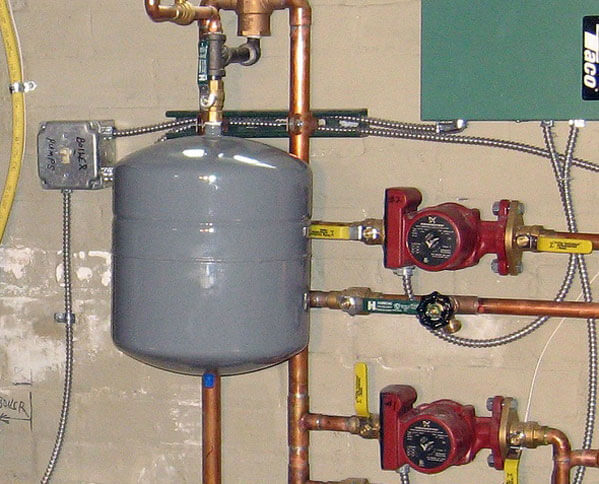

membrane tank installations

Before you start connecting the accumulator to the water supply system, you should:

- Carefully study the instructions supplied with the equipment.

- Carry out technical pressure calculations and compare with those indicated in the regulatory manual for operation.

- In order to carry out the installation with high quality, you need a wrench for detachable connections and plastic pipes, a wrench of the right size.

- Special brackets will be needed to mount large volume equipment.

Note! Measurements and calculations of the operated equipment should be carried out by a highly qualified specialist. The quality of the water supply system depends on the accuracy of the calculations and measurements performed.Many years of experience in using membrane tanks for water supply has shown that horizontal models are the best option.

If you have a submersible pump connected, purchase and install vertical accumulators

Many years of experience in using membrane tanks for water supply has shown that horizontal models are the best option. If you have a submersible pump connected, purchase and install vertical accumulators.

3 Extender Maintenance

In order for the product to work properly for a long period, it is necessary to properly care for it.

Among them are the following:

- 1. Twice a year it is necessary to inspect the system for mechanical damage and corrosion.

- 2. Check the pressure in the system every six months.

- 3. When performing any repair or maintenance work, check the condition of the separating diaphragm.

- 4. If the device is idle for a long time, it is necessary to drain the liquid from the expansion tank and dry it thoroughly.

- 5. Monitor the pressure and temperature readings, and avoid large drops.

- 6. When replacing one of the structural elements, only branded parts must be used.

What you need to know when making calculations

When installing a heating system, it is not always possible to save usable space, which is so important in small rooms. But at the same time, you can find out the exact volume of the desired device. When calculating, the following formula is used:

When calculating, the following formula is used:

Vb (tank volume) = Vt (heat transfer fluid volume) * Kt ( heat expansion factor) / F (membrane tank performance factor)

To determine the volume of the coolant, the following methods are used:

- the time of trial filling of the entire structure is recorded. This can be done with a water meter;

- add up all the volumes of the mechanisms present - pipes, batteries and heat sources;

- a correspondence of 15 liters of coolant fluid per kilowatt of equipment power is applied.

Calculation of volume on a separate example

The coefficient that takes into account the thermal expansion of the coolant used depends on the presence of antifreeze additives. It varies depending on the percentage of these additives, and can also change under the influence of temperature. There are special tables where you can see the data from the calculation of the heating of the coolant. This information is entered into the calculator. If water is used, then this is necessarily displayed in the program.

Antifreeze liquids as a heat carrier are especially relevant if it is necessary to turn off the heating in the cold season.

Be sure to take into account the efficiency factor of the membrane expansion tank. It can be determined by the following formula:

F= (Pm-Pb)/(P1+1)

In this case, Pm stands for the maximum pressure that can lead to emergency activation of a special safety valve. This value must be indicated in the passport data of the product.

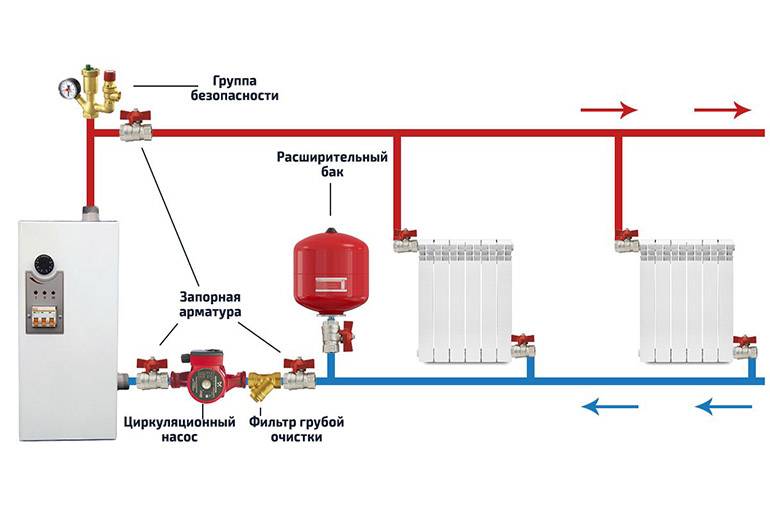

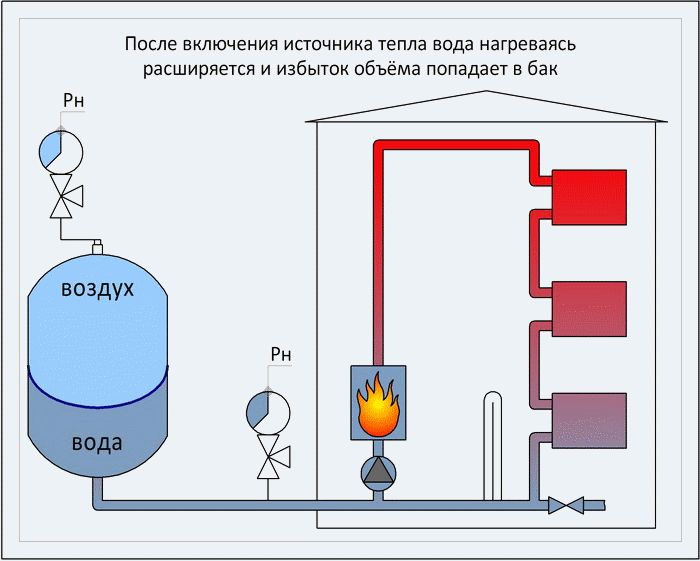

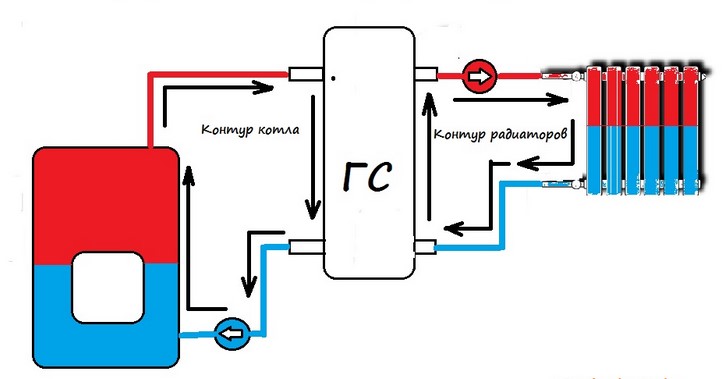

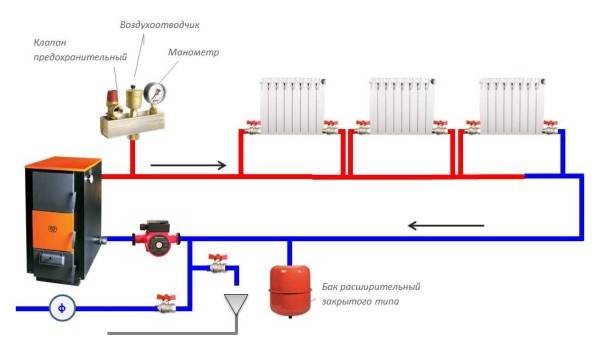

The diagram shows the installation option of the device

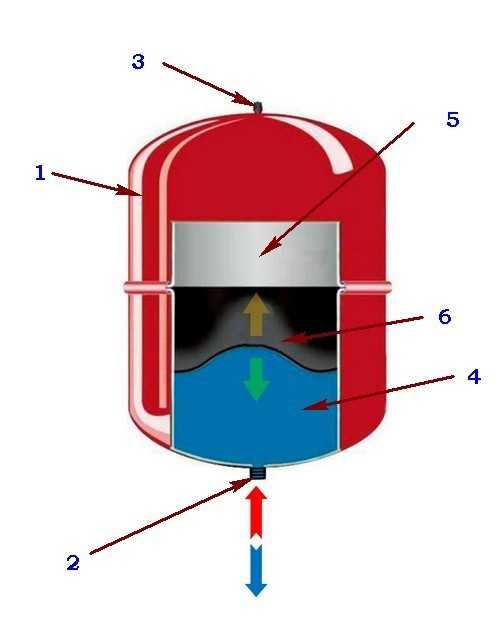

Pb is the pressure for pumping the air chamber of the device. If the design has already been pumped up, then the parameter is indicated in the technical specifications. This value can be changed independently. For example, to resume pumping with a car pump or to remove excess air using a built-in nipple. For autonomous systems, the recommended indicator is 1-1.5 atmospheres.

Related article:

Tank pressure

In some boilers (usually gas boilers), the passport indicates what pressure must be set on the expander. If there is no such record, for normal operation of the system, the pressure in the tank must be 0.2-0.3 atm lower than the working one.

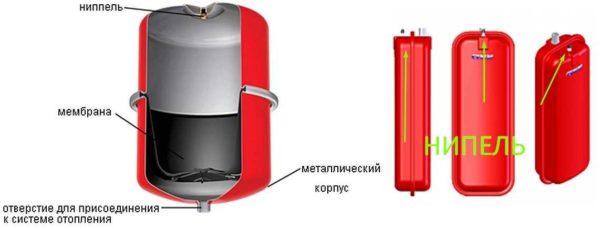

The heating system of a low private house usually operates at 1.5-1.8 atm. Accordingly, the tank should be 1.2-1.6 atm. The pressure is measured with a conventional pressure gauge, which is connected to the nipple, which is located at the top of the tank. The nipple is hidden under a plastic cover, you unscrew it, you get access to the spool. Excess pressure can also be released through it. The principle of operation is the same as that of an automobile spool - bend the plate with something thin, bleed air to the required levels.

Where is the nipple for pumping

You can also increase the pressure in the expansion tank. To do this, you will need a car pump with a pressure gauge. You connect it to the nipple, pump it up to the required readings.

All the above procedures are carried out on the tank disconnected from the system. If it is already installed, you do not need to remove it. You can check the pressure in the expansion tank of the heating system on site. Just be careful! It is necessary to check and correct the pressure in the expansion tank for heating when the system is not working and the coolant is drained from the boiler

For the accuracy of measurements and tank settings, it is important that the pressure on the boiler is zero. Therefore, we lower the water carefully

Then we connect the pump with a pressure gauge and adjust the parameters.

Open and closed models

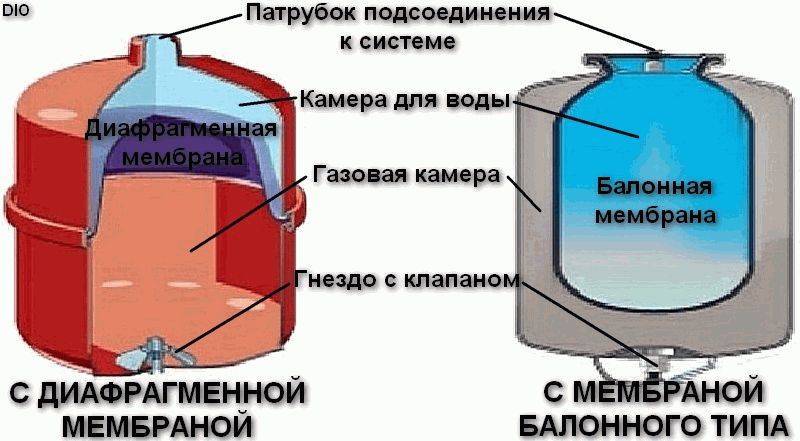

In total, there are three types of expanders: open, closed membrane, closed membraneless.The latter are already difficult to find: there is practically no demand and very few devices are produced. This is due to the fact that the absence of a membrane layer inside a closed expansion tank means the need to install additional equipment - a compressor. The unit will regulate the operation of the tank, will not allow mixing inside the apparatus of special gas and incoming moisture.

Open expander type

The open type provides for the possibility of quick access to the internal cavity, for which a special hatch is installed at the top.

Such a unit must be installed at the highest point of the house, above all heating networks, most often it is to be installed in the attic, roof, sometimes it is displayed on the landing. It looks like an iron box, as it is made of metal sheets.

To drain the liquid from the side there is a special outlet tube. As an open model is used, the moisture removed will partially evaporate, which will require periodic refueling. This is not always convenient, but otherwise there will be a shortage of water and the heating supply will stop.

Closed heating expander

Closed heating expander

There must be a certain amount of liquid inside the heating network for the system to work properly. If this is not enough, the main boiler will not have enough energy to maintain the minimum allowable pressure, and it will turn off. Therefore, it is necessary to regularly check the moisture level, fill the tank in a timely manner.

Closed expansion unit

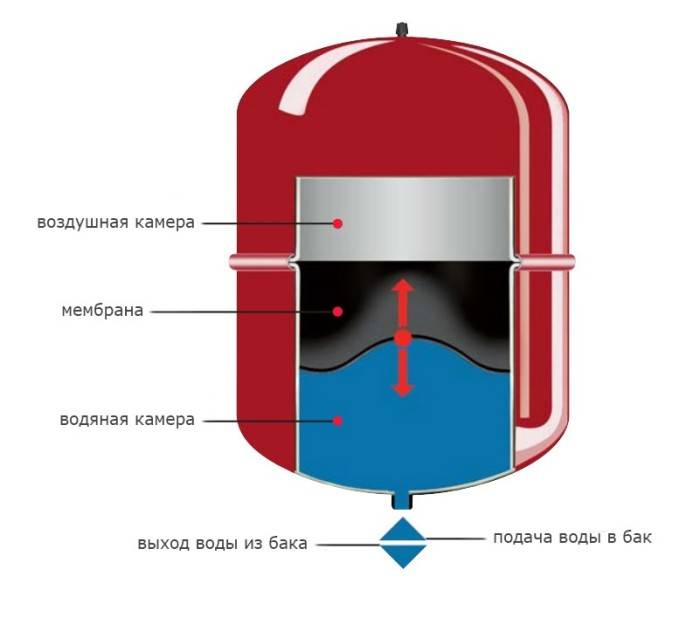

The closed dilator is more convenient to use, as it is completely sealed and does not require refilling with water.It looks like a sealed cylinder with a seam in the middle, which divides the unit into two parts: air space, a place for excess water. Inside it, along the seam line, there is a rigid rubber membrane, which rises when the pressure in the pipes rises, drawing water into the tank. After stabilization of the load level, it produces a return action, pushing the liquid back into the heating network.

Connection to a closed heating system is the most convenient option, since the equipment does not require a special location: you can install a tank anywhere in the house, the placement height does not affect the operational properties of the equipment.

The absence of open areas prevents the evaporation of water, which frees the owner from constant refueling: the heating system will work properly.

closed dilator

In the event that an overload of networks suddenly occurs, it is better to periodically check the performance of the device. With increased pressure, the absence of the owners of the house to adjust the load, the safety valve will work: excess liquid will be discharged from the heating system. It is not recommended to allow this, because now you have to disassemble the installation, add water and collect everything back.

Do-it-yourself open tank

open tank

Another thing is the expansion tank for heating an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store.Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits. And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a step-by-step look at how to make a tank with your own hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open.To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design. Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter. The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands. The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad.Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

Expansion tank of open type for heating systems

Large heating structures use expensive closed tanks.

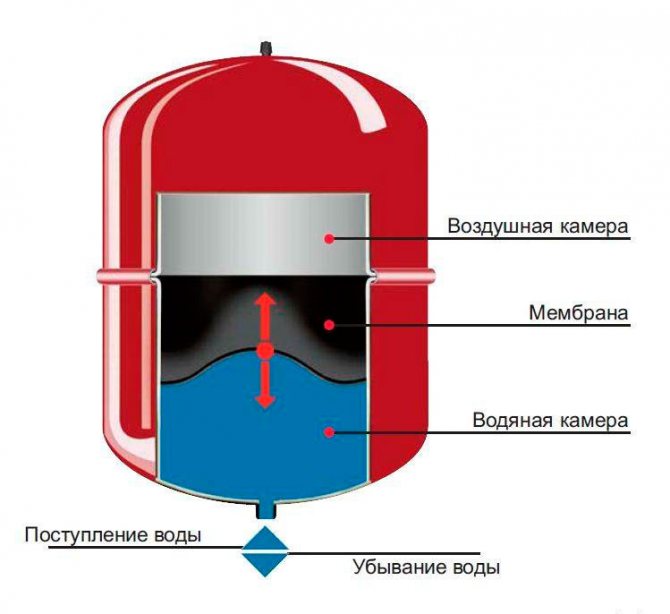

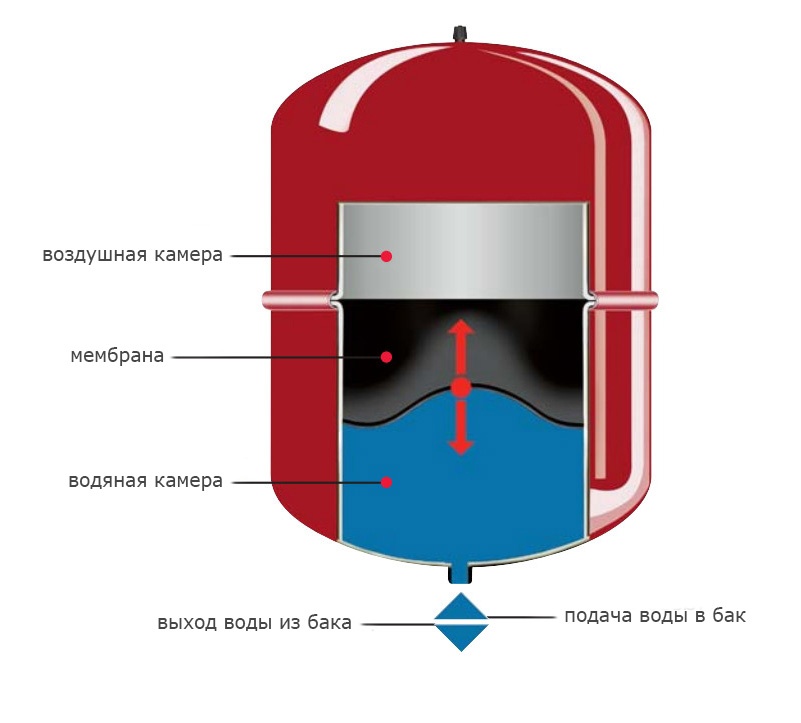

They are characterized by the tightness of the body with an internal rubber partition (membrane) due to which the pressure is adjusted when the coolant expands.

For the full operation of home systems, an open-type expansion tank is a suitable alternative that does not require special knowledge or professional training for the operation and further repair of equipment.

An open tank performs some functions for the smooth operation of the heating mechanism:

- “takes” excess heated coolant and “returns” the cooled liquid back to the system to adjust the pressure;

- removes air, which, due to the slope of the pipes with a couple of degrees, rises to the expansion open tank, located at the top of the heating system;

- The open design feature allows the vaporized volume of liquid to be added directly through the top cap of the reservoir.

Operating principle

The workflow is divided into four simple steps:

- fullness of the tank by two-thirds in normal condition;

- an increase in the incoming liquid into the tank and an increase in the filling level when the coolant is heated;

- liquid leaving the tank when the temperature drops;

- stabilization of the coolant level in the tank to its original position.

Design

The shape of the expansion tank exists in three versions: cylindrical, round or rectangular. An inspection cover is located on the top of the case.

Photo 1. The device of an expansion tank of an open type for heating systems. Components are listed.

The body itself is made of sheet steel, but with a home-made version, other materials are possible, for example, plastic or stainless steel.

Reference. The tank is covered with an anti-corrosion layer to prevent premature destruction (first of all, this applies to iron containers).

The open tank system includes several different nozzles:

- to connect an expansion pipe through which water fills the tank;

- at the junction of the overflow, for pouring out excess;

- when connecting a circulation pipe through which the coolant enters the heating system;

- for connecting a control pipe designed to eliminate air and adjust the fullness of the pipes;

- spare, necessary during repairs to discharge the coolant (water).

Volume

Correctly calculated volume of the tank affects the duration of operation of the joint system and the smooth functioning of individual elements.

A small tank will lead to a breakdown of the safety valve due to frequent operation, and a too large one will require additional finances when buying and heating an excess volume of water.

The presence of free space will also be an influential factor.

Appearance

An open tank is a metal tank in which the upper part is simply closed with a lid, with an additional hole for adding water. The body of the tank is round or rectangular. The latter option is more practical and reliable during installation and fastening, but the round one has the advantage of sealed seamless walls.

Important! A rectangular tank requires additional reinforcement of the walls with an impressive volume of water (home-made version). This makes the entire expansion mechanism heavier, which must be lifted to the highest point of the heating system, for example, to the attic.

Advantages:

- Standard form. In most cases, it is a rectangle that you can install and connect to the general mechanism yourself.

- Simple design without excessive control elements, which makes it easy to control the smooth operation of the tank.

- The minimum number of connecting elements, which gives the body strength and reliability in the process.

- Average market price, thanks to the above facts.

Flaws:

- Unattractive appearance, without the ability to hide thick-walled bulky pipes behind decorative panels.

- Low efficiency.

- The use of water as a heat carrier. With other antifreezes, evaporation occurs faster.

- The tank is not sealed.

- The need to constantly add water (once a week or once a month) due to evaporation, which, in turn, affects airing and the normal functioning of the heating system.

- The presence of air bubbles leads to internal corrosion of the system elements and a decrease in the service life and heat transfer, as well as the appearance of noise.

Kinds

Heating systems are performed with natural and forced circulation of the coolant.

In traditional heating designs, open-type expansion tanks are used.

In cases where the coolant is induced to move with the help of special circulation pumps, expansion devices of a closed type are more often used.

open type

An open-type expansion tank is an ordinary metal box connected to a pipe from a heating main. It is placed in the highest accessible place of the building (house).

During the heating season, the presence of water in the tank is regularly inspected. If necessary, add liquid to the expansion tank.

Some experts install a float level control system in the expansion tank. When the level drops, the float drops, which leads to the opening of the feed valve.

Water is automatically added to the desired level. Automatic systems are mounted only where there is a water supply system in which pressure is maintained in excess of the hydrostatic value Hst.

- Extremely simple device, easy to make with your own hands.

- It can function for years without causing any complaints from users.

- Corrosion damages the expansion tank first.

- It is necessary to regularly check the presence of fluid and top up if necessary.Often, in private houses, when installing a heating system, the capacity for expanding the coolant is remembered last. I place it near the ceiling, which creates inconvenience when topping up. Forced to use flat bottles to refill water.

- It is necessary to lay an additional pipe that will heat only the space near the ceiling.

Important! The coolant tends to evaporate. It must be periodically topped up so that air pockets do not form inside the heating system.

closed tank

In such tanks there are two volumes separated by a movable membrane. In the lower space there is a coolant, and in the upper space there is ordinary air.

To create a preliminary pressure in the system, a valve and a fitting are provided on the air part of the tank. By connecting the pump, you can increase the pressure inside the air chamber.

With the help of a manometer, the set pressure in the heating system is controlled and set Hst.

Installation of such a device is carried out in different parts of the heating, more often it is traditionally installed near the boiler on the supply line.

Some users mount additional taps and pressure gauges in order to know the pressure value during operation.

You do not need to constantly monitor the level of coolant in the system, filling it once, for several years you can not worry about fullness

Non-freezing liquids (high-boiling alcohols) are added to the coolant, which are not afraid of temperatures dropping below 0 ° C, which is important for country houses that are visited only by periodic arrivals.There is no corrosion of the metal, since air does not enter inside. minus conditional

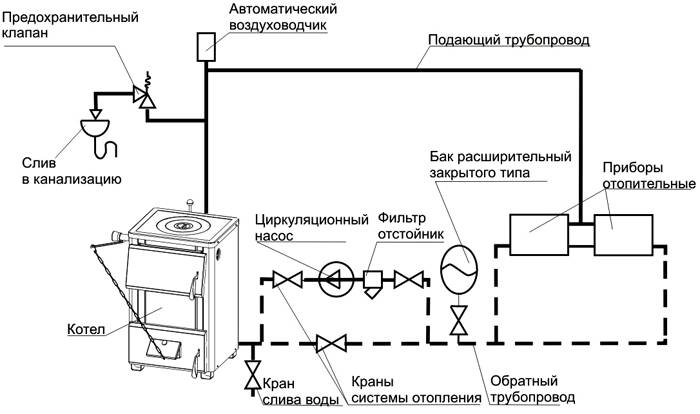

It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

minus conditional. It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

Attention! A sharp increase in pressure in the coolant is possible only if its circulation stops. This can happen if the circulation pump is damaged or turned off. There is another drawback that manufacturers of closed tanks do not want to talk about.

The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale. It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

There is one more disadvantage that manufacturers of closed tanks do not want to talk about. The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale. It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

How to calculate tank volume

When calculating the volume of the expansion tank, several factors must be taken into account:

- capacity and power of the heating system;

- type of heating system;

- expansion tank type.

To calculate the capacity of the tank, the formula is used:

Vb \u003d (Vs * K) / D, where:

Vb - reservoir capacity;

Vc is the volume of coolant in the system;

K is the expansion coefficient of the liquid. For water, this figure is 4%, so 1.04 is used in the formula;

D - expansion coefficient of the tank itself, depends on the material of manufacture and the temperature difference during heating. To accurately establish "D", you can use the formula:

D \u003d (Pmax - Pini) / (Pmax + 1), where:

Pmax is the value of the maximum pressure inside pipes and radiators;

Pnach is the pressure inside the tank, planned by the manufacturers (usually 1.5 atm.).

Thus, the volume of the reservoir depends largely on its own characteristics.

Attention! All indicators and characteristics should not exceed the established standards. When calculating the volume of the device, the data should be equal to or slightly larger than the results obtained. Many sites offer online calculations for expansion tanks

Many sites offer online calculations for expansion tanks.

materials

In the manufacture of expansion tanks, various materials are used, however, models with a steel case are considered the most common.

Currently, many people, in an effort to save money, design such units on their own. To do this, they often use sheet materials, which are subsequently assembled into a single structure by welding. Also, for the manufacture of an expansion tank, you can use the most unexpected items, for example, plastic barrels and canisters, or old gas cylinders. The use of such materials significantly reduces the cost of creating an expansion tank. Despite such a large selection of suitable raw materials, experts still recommend turning to stainless steel if you plan to assemble the tank yourself.

As for the baffle in such units, here most manufacturers use high quality rubber, synthetic rubber, natural butyl rubber raw materials or EPDM. Membrane elements for such units are made from various materials, which, in the course of use, seamlessly tolerate a wide variety of temperature ranges.

If we consider specific cases, then:

- for tanks up to 2 thousand liters, EPDM DIN 4807 marking membranes are most often used;

- tanks with a volume exceeding the above mark are equipped with BUTYL brand membrane elements.

How to fill a closed heating system

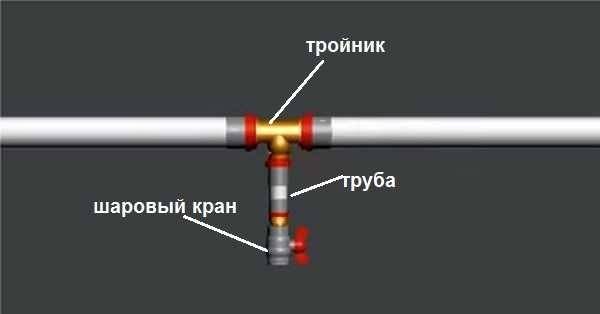

At the lowest point of the system, as a rule, on the return pipeline, an additional tap is installed to supply / drain the system. In the simplest case, this is a tee installed in the pipeline, to which a ball valve is connected through a small section of the pipe.

The simplest unit for draining or filling the coolant into the system

In this case, when draining the system, it will be necessary to substitute some kind of container or connect a hose. When filling the coolant, a hand pump hose is connected to the ball valve. This simple device can be rented at plumbing stores.

There is a second option - when the coolant is just tap water. In this case, the water supply is connected either to a special boiler inlet (in wall-mounted gas boilers), or to a ball valve similarly installed on the return. But in this case, another point is needed to drain the system. In a two-pipe system, this may be one of the last in the radiator branch, to the lower free entrance of which a drain ball valve is installed.Another option is shown in the following diagram. It shows a single-pipe closed-type heating system.

Scheme of a closed single-pipe heating system with a system power supply unit