- Where to put?

- Device and principle of operation

- Using the tank in a closed system

- Features of installing a membrane-type expansion tank

- Design features and principle of operation

- Kinds

- How to put the tank

- Expansion tank for closed heating system

- Volume calculation

- Place for installation of expansion tank of membrane type

- Do-it-yourself open tank

- Conclusion

Where to put?

If there is forced circulation in the system, then the pressure at the connection site of the device will be equal to the static pressure at this point and at a given temperature regime (note that this rule only works if there is one membrane element). If we assume that it will change, then as a result it will turn out that in a closed system a liquid that has come from nowhere is formed, which is fundamentally wrong.

An open heating system is a container of complex configuration with special convection currents. Absolutely all nodes must guarantee the fastest possible rise of the hot heat carrier to the top point. In addition, they must ensure gravity discharge into the boiler with the involvement of radiators. Also, the design of such a system should not interfere with the passage of air bubbles to the top point.

Device and principle of operation

The body of the tank has a round, oval or rectangular shape. Made from alloy or stainless steel. Painted red to prevent corrosion. Blue-painted cisterns are used for water supply.

Sectional tank

Important. Colored expanders are not interchangeable

Blue containers are used at pressures up to 10 bar and temperatures up to +70 degrees. Red tanks are designed for pressure up to 4 bar and temperatures up to +120 degrees.

According to the design features, the tanks are produced:

- using a replaceable pear;

- with membrane;

- without separation of liquid and gas.

Models assembled according to the first variant have a body, inside of which there is a rubber pear. Its mouth is fixed on the body with the help of a coupling and bolts. If necessary, the pear can be changed. The coupling is equipped with a threaded connection, this allows you to install the tank on the pipeline fitting. Between the pear and the body, air is pumped under low pressure. At the opposite end of the tank there is a bypass valve with a nipple, through which gas can be pumped in or, if necessary, released.

This device works as follows. After installing all the necessary fittings, water is pumped into the pipeline. The filling valve is installed on the return pipe at its lowest point. This is done so that the air in the system can freely rise and exit through the outlet valve, which, on the contrary, is installed at the highest point of the supply pipe.

In the expander, the bulb under air pressure is in a compressed state. As water enters, it fills, straightens and compresses the air in the housing.The tank is filled until the water pressure is equal to the air pressure. If the pumping of the system continues, the pressure will exceed the maximum, and the emergency valve will operate.

After the boiler starts to work, the water heats up and begins to expand. The pressure in the system increases, the liquid begins to flow into the expander pear, compressing the air even more. After the pressure of water and air in the tank comes into equilibrium, the flow of fluid will stop.

When the boiler stops working, the water begins to cool, its volume decreases, and the pressure also decreases. The gas in the tank pushes the excess water back into the system, squeezing the bulb until the pressure equalizes again. If the pressure in the system exceeds the maximum allowable, an emergency valve on the tank will open and release excess water, due to which the pressure will decrease.

In the second version, the membrane divides the container into two halves, air is pumped in on one side, and water is supplied on the other. Works in the same way as the first option. The case is non-separable, the membrane cannot be changed.

Pressure equalization

In the third variant, there is no separation between gas and liquid, so air is partially mixed with water. During operation, gas is periodically pumped up. This design is more reliable, since there are no rubber parts that break through over time.

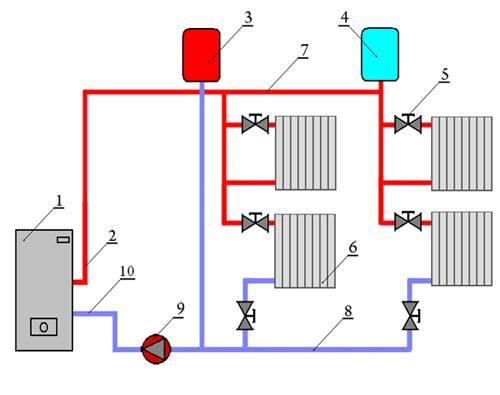

Using the tank in a closed system

Expansion tank

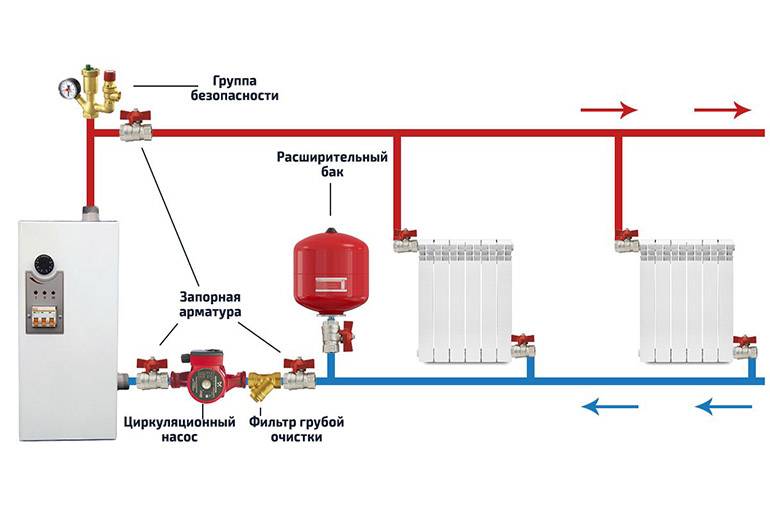

A practical place is suitable for mounting a closed tank. The only important point is that the tank cannot be installed immediately after the circulation pump, because. such placement will cause excessive pressure drops in the heating system.

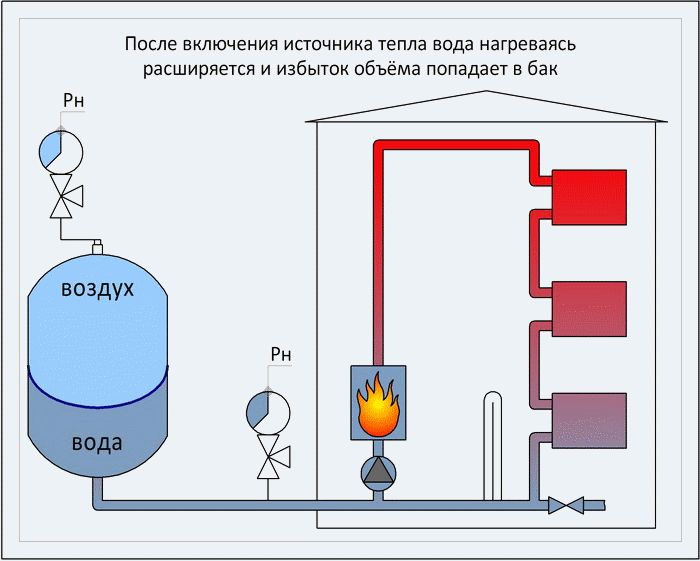

The expansion tanks under consideration operate according to an extremely simple scheme: the coolant is heated, as a result of which its volume increases, then the excess coolant fills the space in the installed membrane tank. This prevents the pressure in the system from rising above an acceptable level.

To make the functions and procedure for using the tank more understandable, these points should be considered using the example of the most popular unit - a double-circuit gas-fired boiler. Closed systems are equipped with additional tanks in situations where the usual capacity of a gas heating boiler is not enough to normalize the pressure.

Expansion tank

The physical properties of water are such that as its temperature increases, it increases in size. To compensate for the surplus formed during the heating process, gas units are equipped with stationary tanks. In the event that the expansion of water begins to lead to an increase in the pressure level in the heating pipes, a special valve opens and a certain amount of coolant enters the tank you installed. When the temperature drops, the liquid leaves the tank and goes into the batteries. That is, in heating radiators, the same amount of water is maintained all the time, which is required for uniform and high-quality heating.

Visual wiring diagram for heating

The standard volume of a stationary expansion tank, which is part of a double-circuit gas boiler, is about 8 liters. For normal operating conditions, this capacity is more than enough.But if it is necessary to provide heating for rooms with a large area, it is necessary to install an appropriate number of batteries, which leads to an increase in the volume of the coolant, i.e. water. And in such situations, the volume of a stationary expansion tank may be too small.

Tank volume calculation

If the volume of the tank is insufficient, it is highly likely that an emergency release of liquid from the heating boiler will occur, which is absolutely unacceptable. As a result of an emergency release, the pressure level in the system may decrease so much that the unit simply cannot start working in automatic mode. And if the owner does not add the missing fluid in a timely manner, the system may defrost or even completely fail.

An additional tank can be installed in any part of the circuit

To avoid such adverse consequences, the system must be equipped with an additional expansion tank. When the main tank is completely filled, the coolant will begin to pass into an additionally installed container, which will prevent an emergency release of water from the boiler. Volume coolant and pressure in the heating system will be maintained at a constant level.

Before installation, the tank must be configured. The whole setup comes down to the fact that it is turned upside down and the plastic plug is removed from it. There is a nipple under the plug. An ordinary pump is connected to this nipple and air is bled from the tank. Next, the container must be pumped with air until the pressure level in it rises to 1.1 kPa.In the heating system, the pressure should be 0.1-0.2 kPa higher than that for the installed expansion tank. Only after such a setting can the container be placed in the place allotted for it.

Features of installing a membrane-type expansion tank

Installing and connecting an expansion tank to a heating system is fraught with some difficulties. Moreover, making mistakes at work, you can face a huge number of problems. Therefore, at the slightest doubt in your abilities, you should not take up the job yourself.

Installation of an expansion membrane unit involves the use of the following tools and materials:

- gas key;

- wrench;

- stepped key;

- plastic pipes.

Indicators of instruments during operation of the expansion tank.

When installing heating a country house using an expansion tank, the tightness of the connections is very important. In this case, in no case should low-quality seals be used, which, as a rule, cannot withstand high temperatures.

The installation of a membrane-type tank must be carried out in accordance with the general rules and regulations to ensure the safe operation of the heating system.

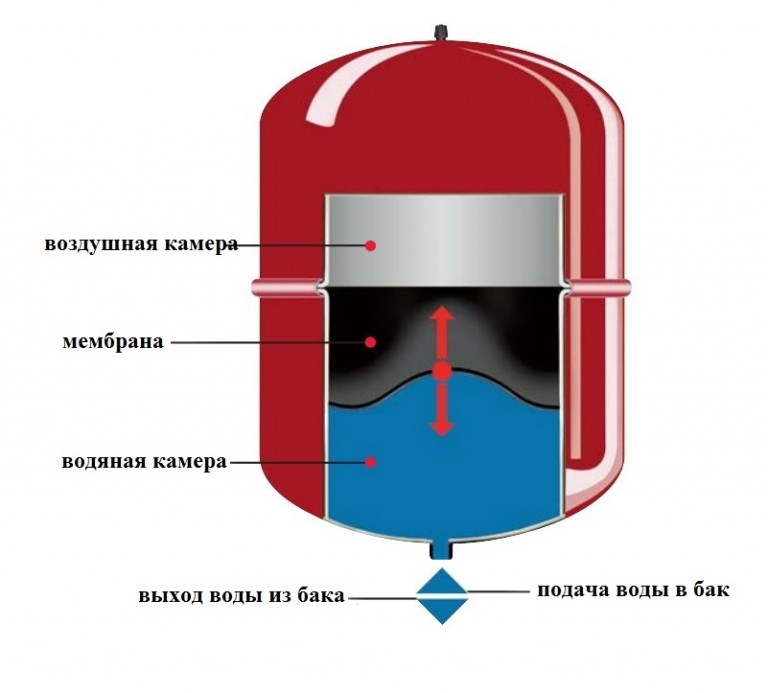

The membrane tank body is divided into two parts by means of a flexible membrane. In one of them water accumulates, and in the second air or gas, which is compressed to a predetermined pressure. From the heating systems, the coolant passes into one part, and the second part, which is under high pressure, at this time is filled with air supported by the nipple.

Such installation requires correct calculations to determine the exact technical parameters.The tank must be connected to a pipeline that runs in the immediate vicinity of the boiler. At the same time, a safety device is installed on the pipeline without fail, which prevents excess pressure.

The membrane tank must not be dismantled and dismantled during operation. In addition, it cannot be opened and drilled with force.

In order to prevent corrosion and increase the life of the heating system and pipes, water must circulate without oxygen impurities and other aggressive gases.

Design features and principle of operation

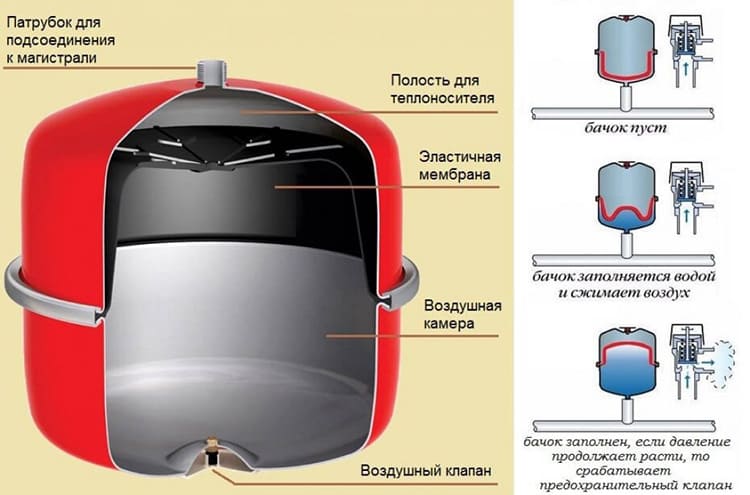

All tanks are similar in design. They have a metal case, divided from the inside into two rolled compartments. The tank has a nipple on one side, and a neck on the other, designed for connection with pipes.

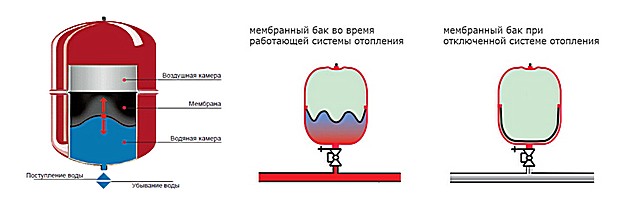

The diaphragm is located inside the body. When the container is empty, it fills most of it, and the remaining space is occupied by air. During the operation of the network, the coolant heats up, its volume increases, and the excess penetrates into the cavity between the diaphragm and the housing.

After the temperature drops, the working medium decreases in volume, and the previously pumped air squeezes it back into the system.

Kinds

Do not think that all expansion tanks have identical designs and performance characteristics. In fact, there are several varieties of such units. Each of them has certain distinctive features and structural features. Let's get to know them better.

Depending on the specific mode of operation, tanks are divided into:

- heating tanks of open type;

- closed expansion vessels.

Not the most popular are open options for expansion tanks. These units are installed in systems in which fluid circulation is not carried out in forced mode (that is, without using a pump)

The main disadvantage of such a unit is that in it the coolant is associated with oxygen, and this provokes the appearance of corrosion in the heating system. If there is not sufficient tightness in the open tank, then the water evaporates many times faster, so it has to be constantly topped up. According to experts, it is necessary to mount such a unit at the highest section of the heating system. It should be noted that such work is not always available.

A closed (or membrane) expander is fixed in a system where the movement of the heat carrier occurs forcibly - using a pump. A closed vessel is usually made in the form of a steel tank (it does not have a lid). It is equipped with a partition inside in the form of a rubber membrane. One half in such a model is needed to fill it with a heat carrier, and the second is a place for air and nitrogen.

One of the sides of the tank itself is attached directly to the system using a fitting or flange. The opposite side is designed to pump air. The pressure indicator in the closed type model makes it possible to automatically change the supply of heat carrier to the system and the tank itself.

Closed tanks are divided into:

- interchangeable;

- non-replaceable.

So, tanks of a replaceable type have a higher cost, but they have significant advantages, which include:

- the ability to change the membrane if it has been damaged or torn;

- the ability to save on pipes, since there is no need to mount a closed tank in the upper part of the heating system;

- replaceable options are responsible for minimal heat loss;

- since the coolant does not “come into contact” with oxygen in any way, the pipes and the entire system as a whole are not subject to corrosion;

- the membrane can be located both vertically and horizontally;

- in this case, there is no connection with the wall inside the metal tank;

- membranes can be replaced very easily and quickly (this is done through the flange).

Non-replaceable varieties of containers are cheaper, but they cannot change the membrane if necessary. This element in the expander is installed as tightly as possible and is firmly pressed against the inner walls of the tank. Damage or rupture of the membrane in this case can only occur if the system was started incorrectly (the pressure rises too quickly and goes beyond the normal range).

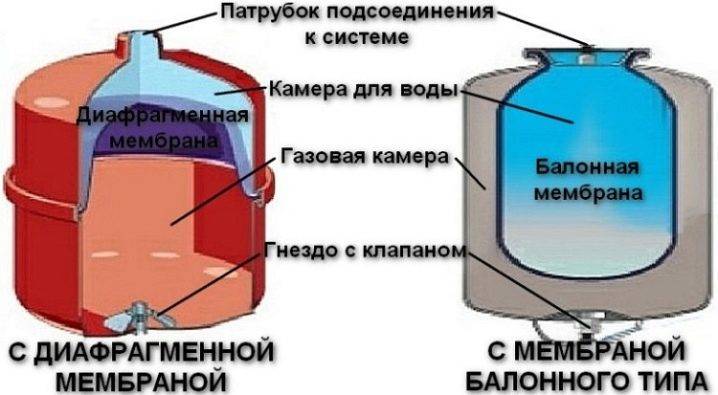

Depending on the type of membrane part, expansion tanks are divided into models with:

- balloon membrane;

- diaphragmatic membrane.

Thus, a dilator with a balloon membrane is very durable and reliable. In addition, it has an impressive volume. At the same time, the heat carrier does not come into contact with the walls of the tank in any way, so the appearance of rust on such products is excluded.

The flat expansion heating tank is equipped with a dividing wall made in the form of a diaphragm.

How to put the tank

When installing an open tank in the attic, a number of rules should be observed:

- The container must stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the vessel must be carefully insulated so as not to waste heat on heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to bring 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

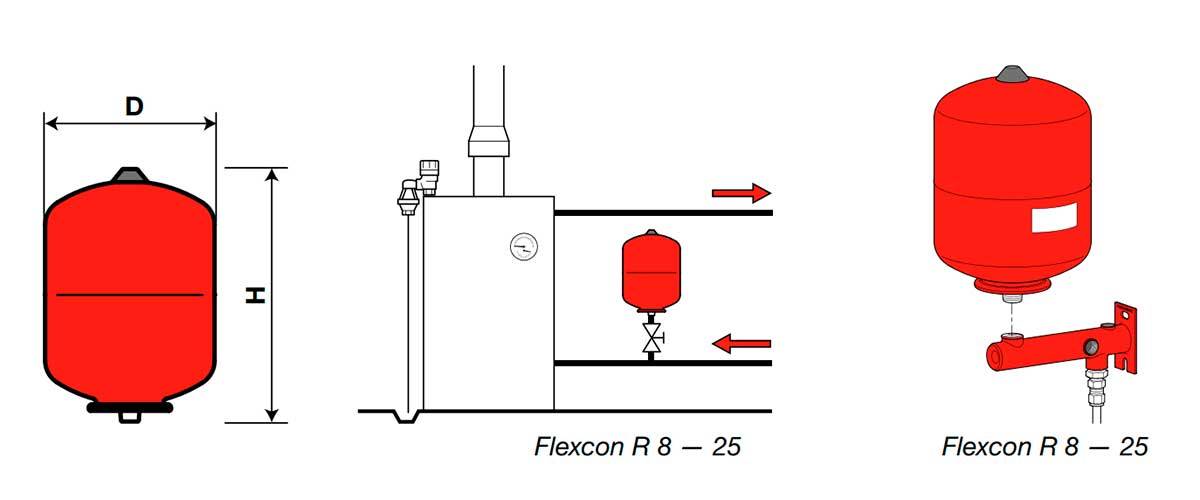

Installation of a membrane-type expansion tank is carried out vertically or horizontally in any position. It is customary to fasten small containers to the wall with a clamp or hang them from a special bracket, while large ones are simply placed on the floor. There is one point: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about the service life.

A vessel with a closed type will last longer if it is mounted vertically with the air chamber up. Sooner or later, the membrane will exhaust its resource, cracks will appear. With a horizontal location of the tank, air from the chamber will quickly penetrate into the coolant, and that one will take its place. You will have to urgently install a new expansion tank for heating. If the container hangs upside down on the bracket, the effect will appear faster.

In a normal vertical position, air from the upper chamber will slowly penetrate through the cracks into the lower one, as well as the coolant will reluctantly go up. Until the size and number of cracks increase to a critical level, the heating will work properly. The process takes a long time, you will not notice the problem immediately.

But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be placed in the boiler room in such a way that it is convenient to service it.Do not install floor-standing units close to a wall.

- When wall-mounting the expansion tank of the heating system, do not place it too high, so that when servicing it is not necessary to reach the shut-off valve or air spool.

- The load from the supply pipelines and shut-off valves should not fall on the tank branch pipe. Fasten the pipes together with the taps separately, this will facilitate the replacement of the tank in case of breakage.

- It is not allowed to lay the supply pipe on the floor through the passage or hang it at head height.

Option for placing equipment in the boiler room - a large tank is placed directly on the floor

Expansion tank for closed heating system

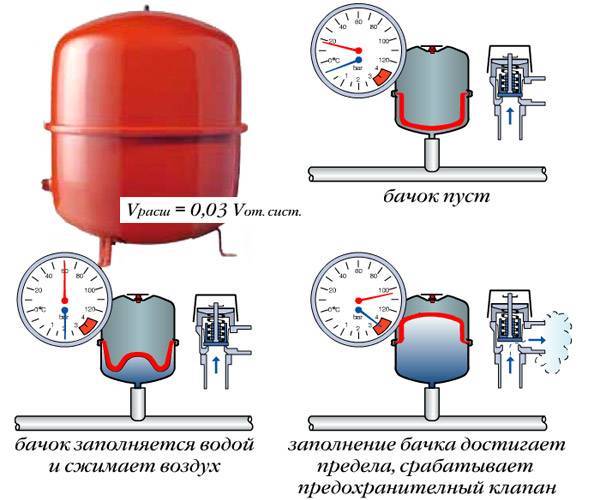

The expansion tank for is designed to compensate for changes in the volume of the coolant depending on temperature. In closed heating systems, this is a sealed container, divided by an elastic membrane into two parts. In the upper part there is air or an inert gas (in expensive models). While the coolant temperature is low, the tank remains empty, the membrane is straightened (picture on the right in the figure).

The principle of operation of the membrane expansion tank

When heated, the coolant increases in volume, its excess rises into the tank, pushing the membrane and compressing the gas pumped into the upper part (in the picture on the left). On the pressure gauge, this is displayed as an increase in pressure and can serve as a signal to reduce the intensity of combustion. Some models have a safety valve that releases excess air/gas when a pressure threshold is reached.

As the coolant cools, the pressure in the upper part of the tank squeezes the coolant out of the tank into the system, the pressure gauge returns to normal.That's the whole principle of operation of the expansion tank of the membrane type. By the way, there are two types of membranes - dish-shaped and pear-shaped. The shape of the membrane does not affect the principle of operation.

Types of membranes for expansion tanks in closed systems

Volume calculation

According to generally accepted standards, the volume of the expansion tank should be 10% of the total volume of the coolant. This means that you have to calculate how much water will fit in the pipes and radiators of your system (it is in the technical data of the radiators, but the volume of pipes can be calculated). 1/10 of this figure will be the volume of the required expansion tank. But this figure is valid only if the coolant is water. If an antifreeze liquid is used, the tank size is increased by 50% of the calculated volume.

Here is an example of calculating the volume of a membrane tank for a closed heating system:

- the volume of the heating system is 28 liters;

- expansion tank size for a system filled with water 2.8 liters;

- the size of the membrane tank for a system with antifreeze liquid is 2.8 + 0.5 * 2.8 = 4.2 liters.

When buying, choose the nearest larger volume. Do not take less - it is better to have a small supply.

What to look for when buying

The stores have red and blue tanks. Red tanks are suitable for heating. Blue ones are structurally the same, only they are designed for cold water and do not tolerate high temperatures.

What else to pay attention to? There are two types of tanks - with a replaceable membrane (they are also called flanged) and with an irreplaceable one. The second option is cheaper, and significantly, but if the membrane is damaged, you will have to buy the whole thing

In flanged models, only the membrane is bought.

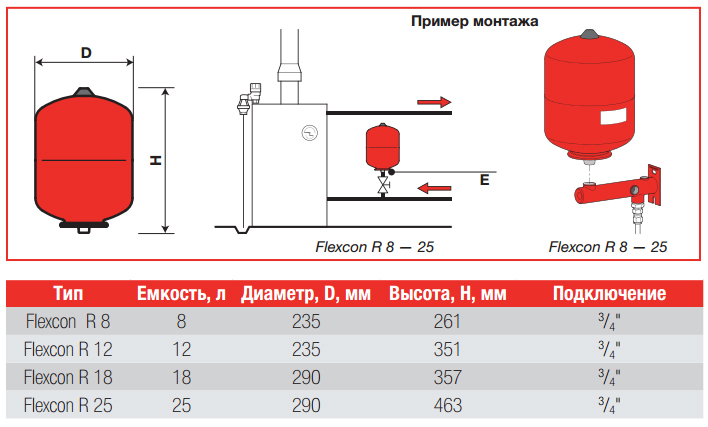

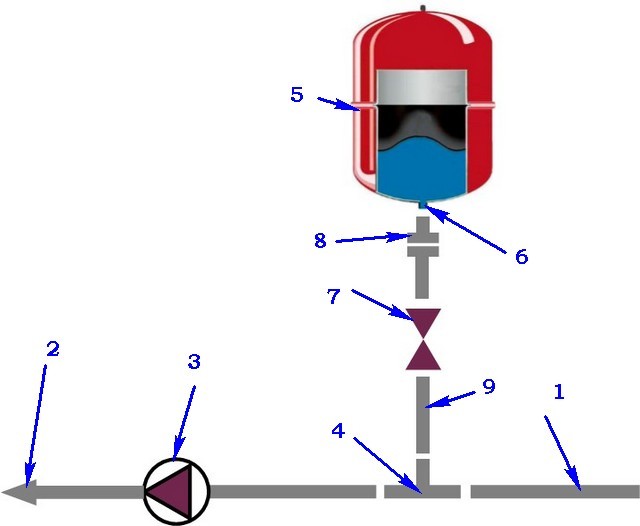

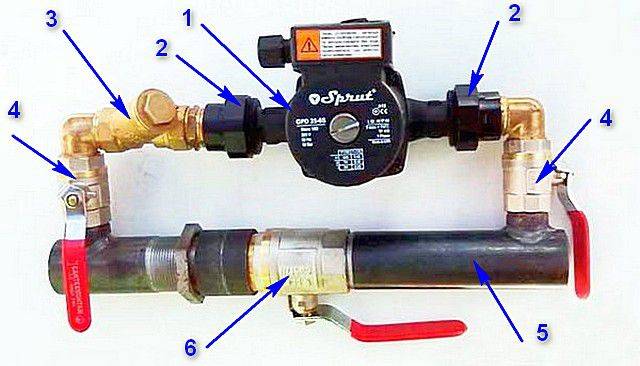

Place for installation of expansion tank of membrane type

Usually they put an expansion tank on the return pipe in front of the circulation pump (when viewed in the direction of the coolant). A tee is installed in the pipeline, a small piece of pipe is connected to one of its parts, and an expander is connected to it, through fittings. It is better to place it at some distance from the pump so that pressure drops are not created. An important point is that the piping section of the membrane tank must be straight.

Scheme of installation of an expansion tank for membrane type heating

After the tee put a ball valve. It is necessary to be able to remove the tank without draining the heat carrier. It is more convenient to connect the container itself with the help of an American (flare nut). This again facilitates assembly/dismantling.

Empty device weighs not so much, but filled with water has a solid mass. Therefore, it is necessary to provide a method of fixing on the wall or additional supports.

Do-it-yourself open tank

open tank

Another thing is the expansion tank for heating an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store. Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits.And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a step-by-step look at how to make a tank with your own hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design.Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter. The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands. The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad. Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

Conclusion

The expansion tank is the most important additional element in any heating system. If for open systems with gravitational circulation it is enough to install a simple open tank at the top point, then for complex closed systems installation of industrial models is required.

These containers are hermetically sealed. During the production process, air is pumped into the housing to maintain the pressure necessary for the normal functioning of forced circulation systems. You can set the desired pressure indicators yourself using a pressure gauge and a conventional automobile compressor.