- How and where is the expansion tank placed

- open system

- closed system

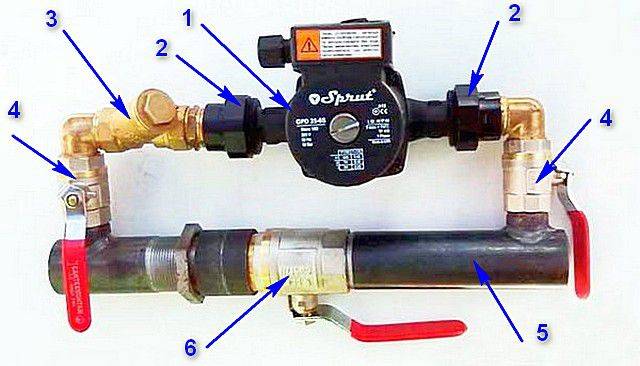

- Installation of the membrane device

- Correct container position

- Features of choosing an installation site

- Setting up the instrument before use

- Tank as additional capacity

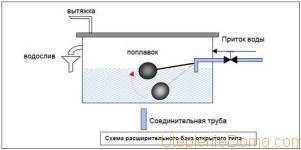

- Do-it-yourself open tank

- How to correctly calculate the volume of the tank for heating systems?

- Calculation formula

- Tank designs

- open type

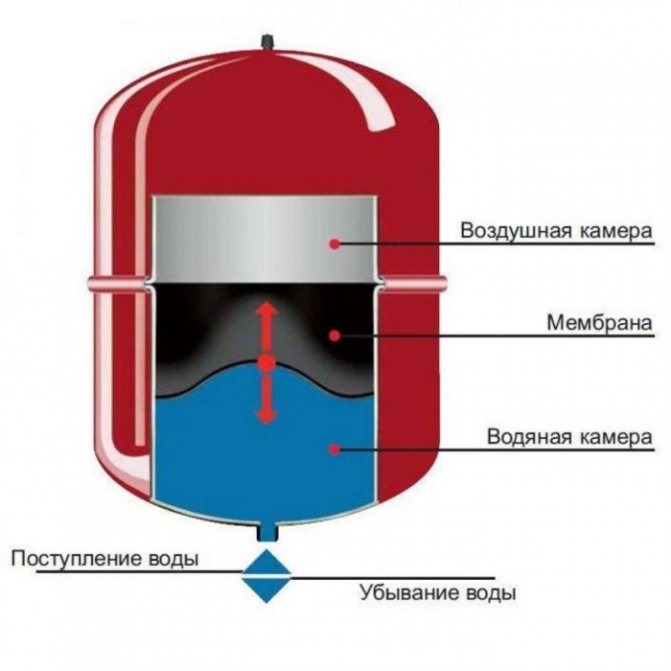

- Closed membrane tank

- Tank power calculation

- Kinds

- open type

- closed tank

- Capacity Recommendations

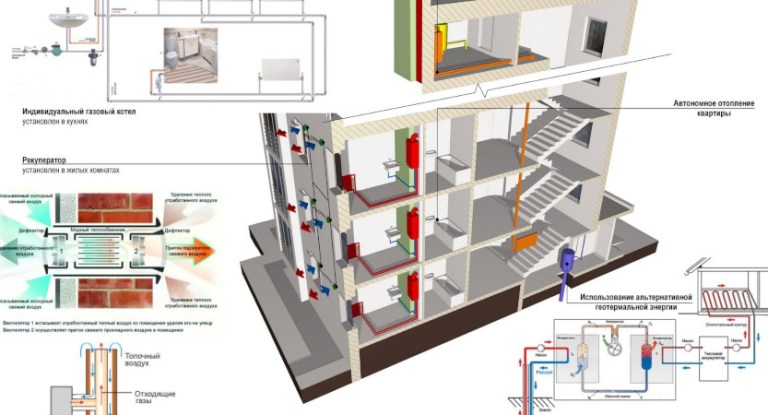

How and where is the expansion tank placed

So, we are going to design and assemble a heating system with our own hands. If she also earns - our joy will not be the limit. Are there any instructions for installing the expansion tank?

open system

In this case, simple common sense will prompt the answer.

An open heating system is, in essence, one large vessel of complex shape with specific convection currents in it.

The installation of the boiler and heating appliances in it, as well as the installation of pipelines, must ensure two things:

- Rapid rise of the water heated by the boiler to the upper point of the heating system and its discharge through the heating devices by gravity;

- The unimpeded movement of air bubbles to wherever they rush in any vessel with any liquid. Up.

- The installation of a heating expansion tank in an open system is always carried out at its highest point. Most often - at the top of the accelerating manifold of a single-pipe system. In the case of top filling houses (although you hardly have to design them), at the top filling point in the attic.

- The tank itself for an open system does not need shutoff valves, a rubber membrane, and even a lid (except to protect it from debris). This is a simple water tank open on top, into which you can always add a bucket of water to replace the evaporated one. The price of such a product is equal to the cost of several welding electrodes and a square meter of steel sheet 3-4 mm thick.

This is what the extension looks like tank for open heating system. If desired, a water tap from the water supply can be brought into the hatch in it. But much more often, as the water evaporates, it is topped up with an ordinary bucket.

closed system

Here, both the choice of the tank and its installation will have to be taken quite seriously.

Let's collect and systematize the basic information available on thematic resources.

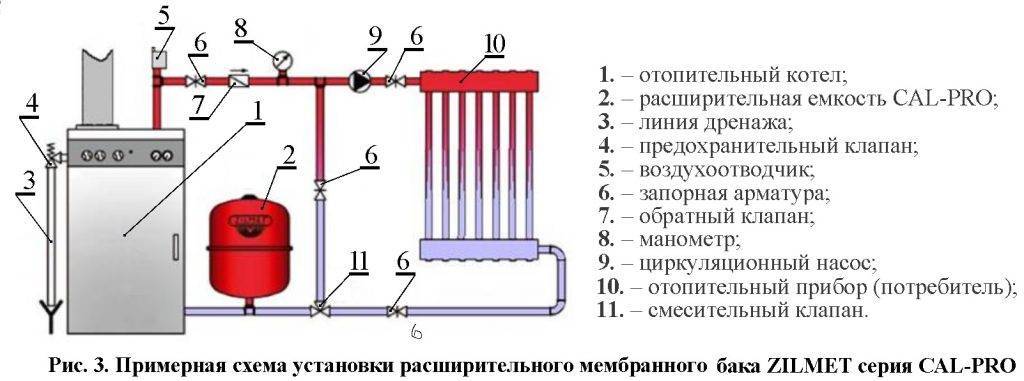

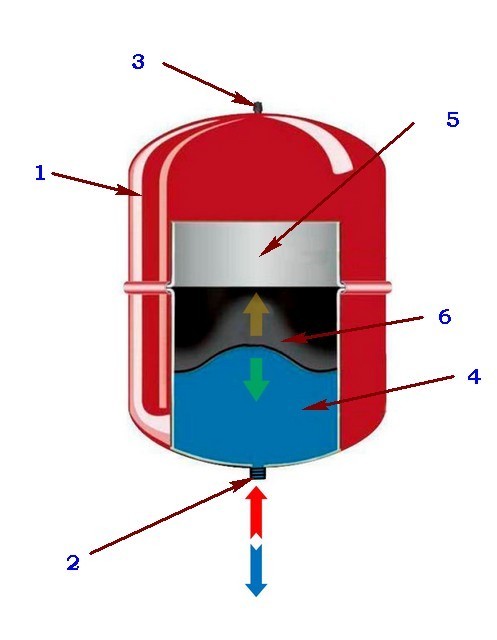

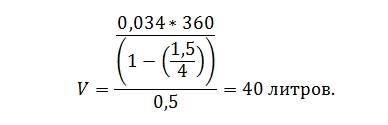

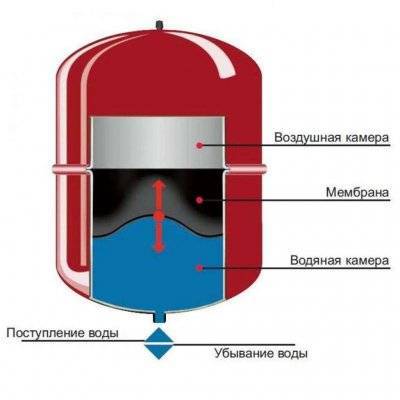

The installation of the expansion tank of the heating system is optimal in the place where the water flow is closest to laminar, where there is a minimum of turbulence in the heating system. The most obvious solution is to place it in a straight filling area in front of the circulation pump. At the same time, the height relative to the floor or the boiler does not matter: the purpose of the tank is to compensate for thermal expansion and dampen water hammer, and we perfectly bleed air through air valves.

A typical tank setup. Its location in a single-pipe system will be the same - in front of the pump along the water course.

- Tanks in the factory are sometimes supplied with a safety valve that relieves excess pressure. However, it is better to play it safe and make sure that your product has it. If not, buy and mount next to the tank.

- Electric and gas boilers with electronic thermostats are often supplied with a built-in circulation pump and a heating expansion tank. Before you go shopping, make sure you need them.

- The fundamental difference between membrane expansion tanks and those used in open systems is their orientation in space. Ideally, the coolant should enter the tank from above. This subtlety of installation is designed to completely remove air from the compartment of the tank that is intended for liquid.

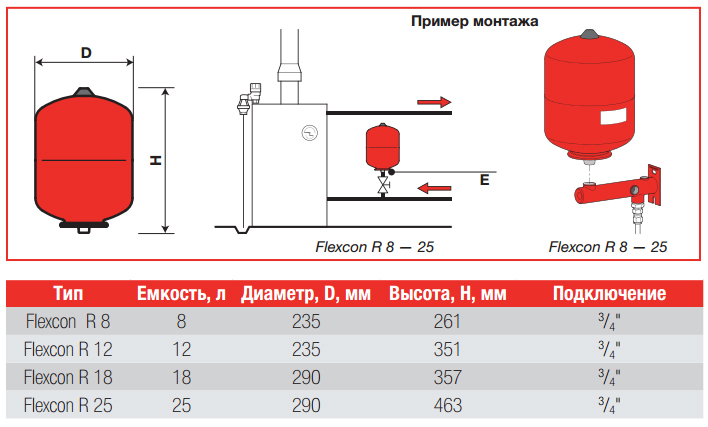

- The minimum volume of the expansion tank for a water heating system is taken approximately equal to 1/10 of the volume of the coolant in the system. More is acceptable. Less is dangerous. The volume of water in the heating system can be roughly calculated based on the heat output of the boiler: as a rule, 15 liters of coolant per kilowatt are taken.

- A pressure gauge mounted next to the expansion tank and the make-up valve (connecting the heating to the water supply) can provide you with an invaluable service. The situation with a stuck spool of the safety valve, alas, is not so rare.

- If the valve relieves pressure too often, this is a clear sign that you miscalculated with the volume of the expansion tank. It is not necessary to change it at all. It is enough to purchase another one and connect it in parallel.

- Water has a relatively low coefficient of thermal expansion.If you switch from it to a non-freezing coolant (for example, ethylene glycol), you will again need to increase the volume of the expansion tank or install an additional one.

The expansion tank in the photo is mounted in accordance with all the rules: the coolant is supplied from above, the tank is equipped with pressure gauge and safety valve.

Installation of the membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for the normal circulation of the water flow along the circuit.

Correct container position

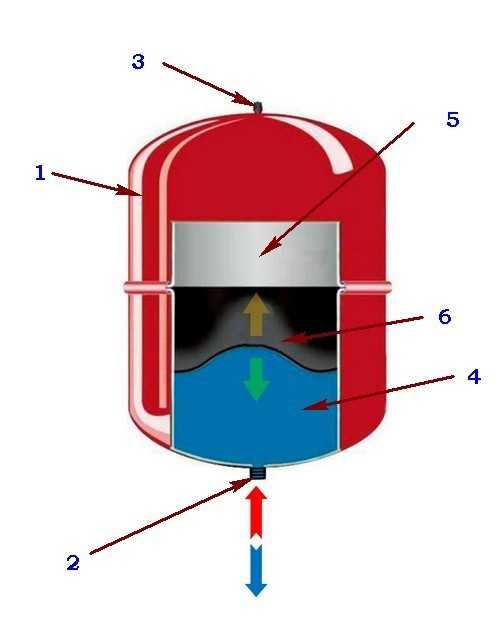

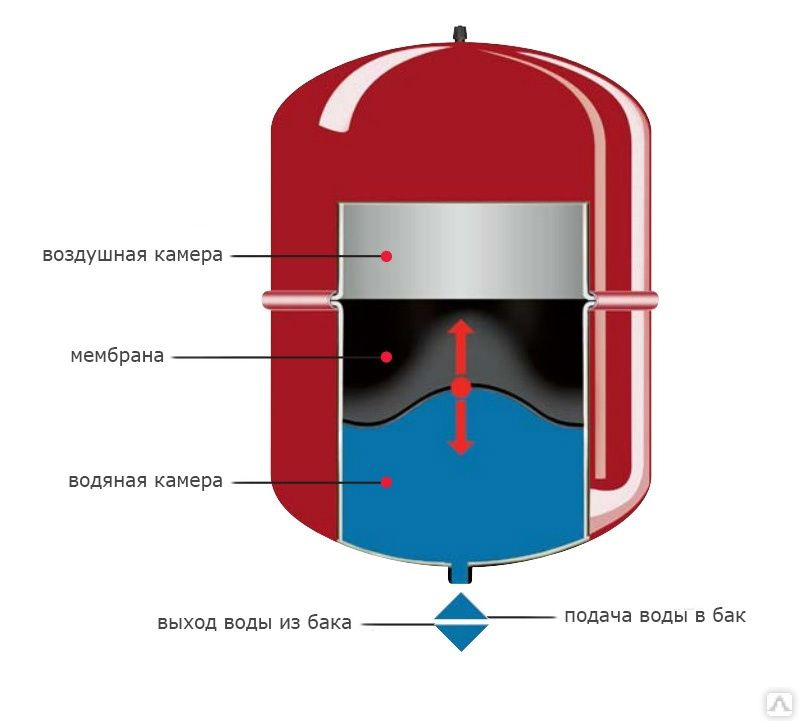

When connected expansion tank to closed the heating system must take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After that, the membrane has to be replaced with a new one.

If the air chamber of such a tank remains at the bottom during installation, then the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster, repairs will be needed sooner.

It makes more sense to install the expansion tank so that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation site

There are a number of requirements to consider when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- Ensure free access to the device for its regular maintenance and necessary repairs.

- The tank hung on the wall should not be too high.

- A stopcock should be placed between the tank and the heating pipes, which will allow the device to be removed without completely draining the coolant from the system.

- The pipes connected to the expansion tank, when wall-mounted, must also be attached to the wall in order to remove possible additional load from the tank nozzle.

For a membrane device, the return section of the line between the circulation pump and the boiler is considered the most suitable connection point. Theoretically, you can put an expansion tank on the supply pipe, but the high temperature of the water will adversely affect the integrity of the membrane and its service life.

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the stopcock and the “American”, it is recommended to install an additional tee and a tap when connecting, which will allow you to empty the expansion tank before turning it off.

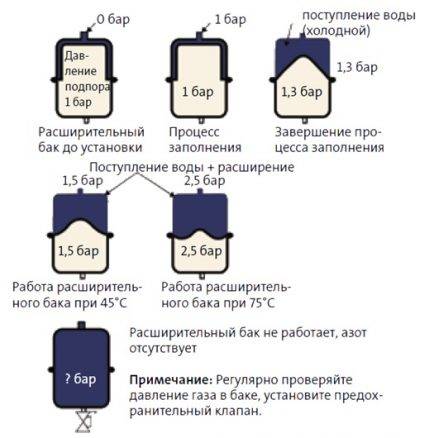

Setting up the instrument before use

Before installation or immediately after it, it is necessary to correctly adjust the expansion tank, otherwise called the expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable indicator is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less than about 0.2-0.3 bar. Measurements are carried out with a manometer with a suitable graduation through a nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or its excess is bled off.

The technical documentation usually indicates the working pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, part of the air could escape from the compartment. Be sure to take your own measurements.

If the pressure in the tank is set incorrectly, this can lead to air leakage through the device for removing it. This phenomenon causes a gradual cooling of the coolant in the tank. It is not necessary to pre-fill the membrane tank with coolant, just fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a particular heating system. If the built-in tank is too small, an additional tank must be installed.

It will ensure the normal pressure of the coolant in the system. Such an addition will also be relevant in case of a change in the configuration of the heating circuit. For example, when a gravity system is converted into a circulation pump and old pipes are left.

This is true for any systems with a significant amount of coolant, for example, in a two-three-story cottage or where, in addition to radiators, there is a warm floor. If used boiler with integrated membrane tank of a small size, the installation of another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here, an expansion valve is an adequate way out.

Do-it-yourself open tank

open tank

Another thing expansion tank for heating of an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store. Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits. And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a step-by-step look at how to make a tank with your own hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them.A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design. Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter. The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands. The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad. Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

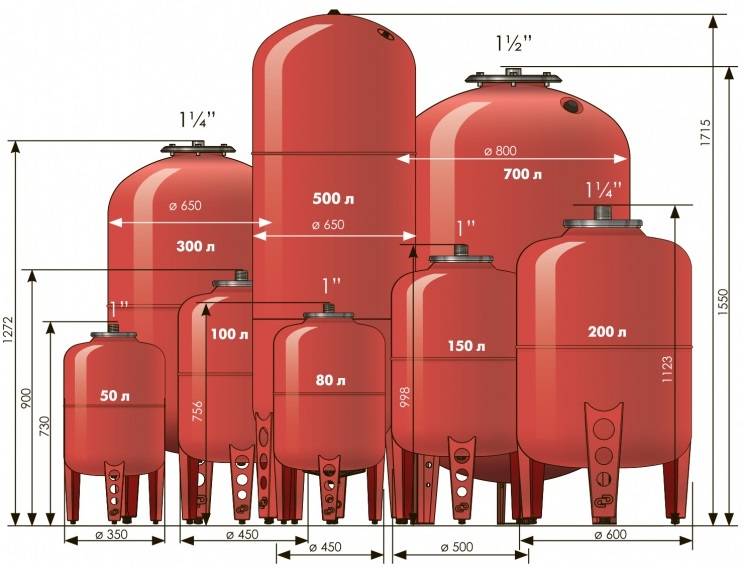

How to correctly calculate the volume of the tank for heating systems?

To correctly calculate the volume of the expansion tank, several factors are taken into account, that influence this:

- The capacity of the expandomat directly depends on the amount of water in the heating system.

- The higher the allowable pressure in the system, the smaller the tank size you will need.

- The higher the temperature to which the coolant is heated, the larger the volume of the device should be.

Reference. If you choose an expansion tank that is too large, it will not provide the necessary pressure in the system. A small tank will not be able to accommodate all the excess coolant.

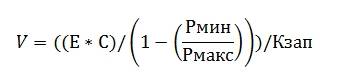

Calculation formula

Vb \u003d (Vc * Z) / N, in which:

Vc- volume of water in the heating system. To calculate this indicator, multiply the boiler power by 15. For example, if the boiler power is 30 kW, then the amount of coolant will be 12 * 15 \u003d 450 liters. For systems where heat accumulators are used, the capacity of each of them in liters must be added to the figure obtained.

Z is the expansion index of the coolant. This coefficient for water is 4%, respectively, when calculating, we take the number 0.04.

Attention! If another substance is used as a coolant, then the expansion coefficient corresponding to it is taken. For example, for 10% ethylene glycol, it is 4.4%

N is an indicator of the efficiency of tank expansion. Since the walls of the device are made of metal, it can slightly increase or decrease in volume under the influence of pressure. To calculate N, you need the following formula:

N= (Nmax—N)/(Nmax+1), where:

Nmax is the maximum pressure in the system. This number is from 2.5 to 3 atmospheres, to find out the exact figure, look at what threshold value the safety valve in the safety group is set to.

N is the initial pressure in the expansion tank. This value is 0.5 atm. for every 5 m height of the heating system.

Continuing the example with a 30 kW boiler, let's assume that Nmax is 3 atm., the height of the system does not exceed 5 m. Then:

N=(3-0.5)/(3+1)=0.625;

Vb \u003d (450 * 0.04) / 0.625 \u003d 28.8 l.

Important! The volumes of commercially available expansion tanks meet certain standards. Therefore, it is not always possible to buy a tank with a capacity that exactly matches the calculated value.

In such a situation, purchase a device with rounding up, because if the volume is slightly less than necessary, it may harm the system.

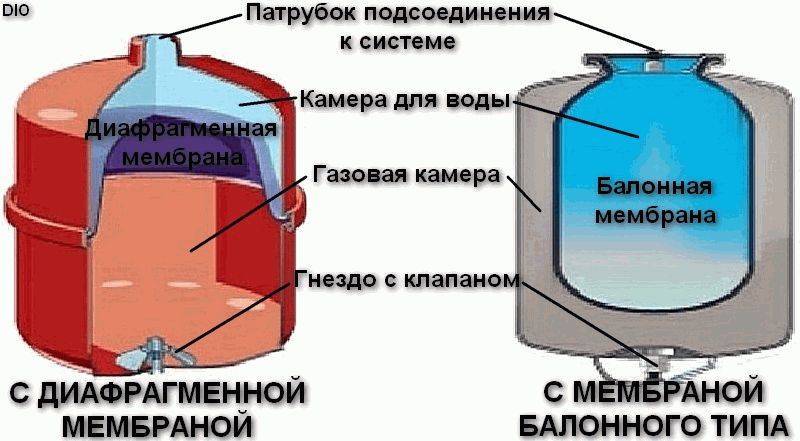

Tank designs

To solve the issue of compensation, you can simply install a separate outlet pipe at the very top of the pipeline. But it will not perform all the functions of an expansion tank to the fullest. To understand why, consider the different types design and installation features this compensator.

open type

This design, for the most part, is made in a handicraft way. Typical open tank diagram shown in the figure:

Open tank design

It is a steel container, which is mounted at the highest point of the pipeline of the heating system. The tank is connected to the system through an expansion pipe, and a circulation pipe is provided to ensure the movement of water.

As the system fills with water, it reaches the signal pipe, on which a tap is installed. An overflow pipe is provided to control water expansion. It provides free movement of air inside the tank.

To calculate the volume of an open tank, you need to know the volume of water in the system. If there is no such information, you can start from boiler power – for 1 kW approximately corresponds to 15 liters of water. That is, for a 24 kW boiler, the maximum volume of coolant will be 360 liters.When the temperature rises to 70 ° C, water at this volume will expand by 9 liters. And at a maximum of 95 ° C - 15 liters. The volume of the tank to the level of the overflow pipe must be at least 15 liters.

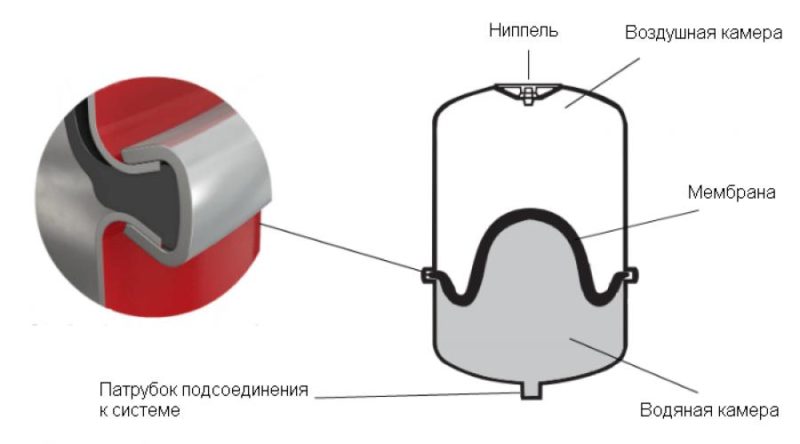

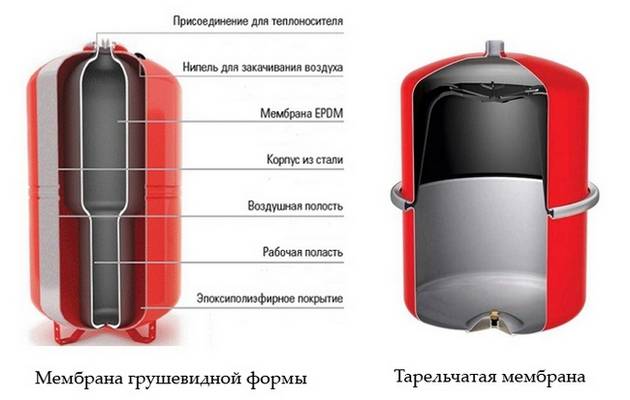

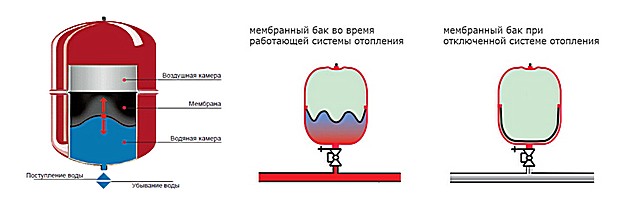

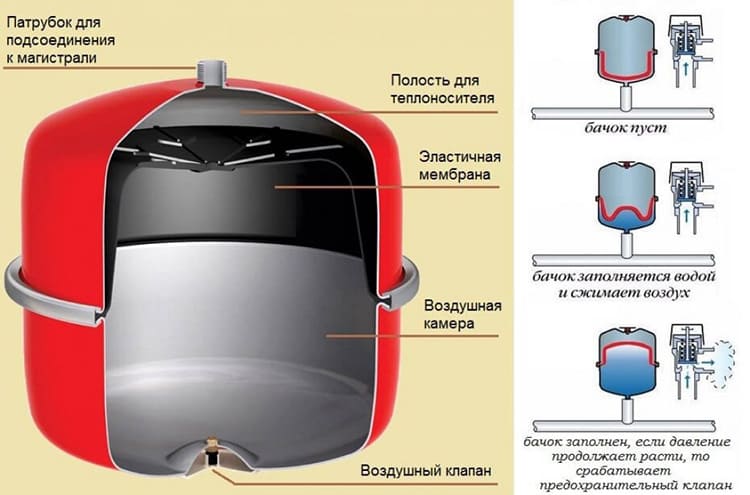

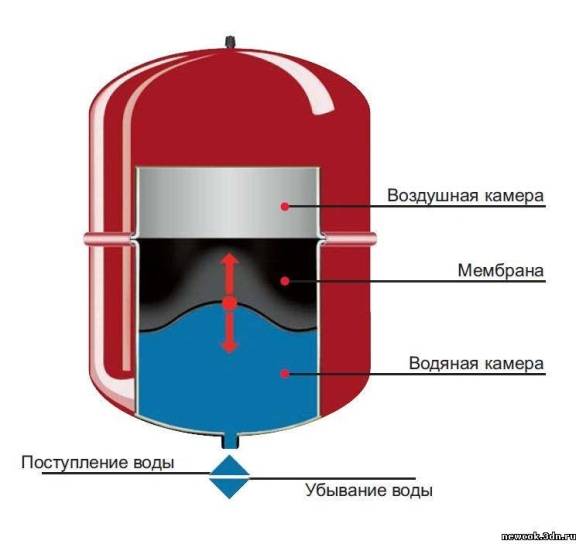

Closed membrane tank

There is also a more advanced pressure compensation system in the system - a membrane tank. Its design is a closed steel tank.

Expansion membrane tank

The insulated housing is divided into 2 parts, one of which has a connection to the heating system. The second is filled with an inert gas - nitrogen. To set the pressure level inside it, a nipple is provided, with which you can reduce (bleed) or increase (pumping) the pressure inside.

When connected to the heating pipes and activating the system, water, after heating, enters the tank chamber. When a certain pressure value is reached, the movable membrane increases the volume of the water chamber. This type of construction is more convenient both in operation and during installation work. The main advantages of a membrane type tank are:

- No contact of water with air, which significantly reduces the likelihood of corrosion.

- The tank can be mounted anywhere in the heating main.

- Since the system is completely sealed, the loss of coolant is minimal.

- Reduced heat loss compared to an open tank.

But for this system there is one obligatory factor - the calculation of the optimal volume of the tank. This is an important stage in the design of the heating system as a whole.

Tank power calculation

When calculating the volume of a membrane-type expansion tank, the following parameters must be taken into account:

Heat carrier type. The coefficient of thermal expansion (E) for different liquids is different

Therefore, it is important to know this value.

The total volume of the coolant in the system is C. An approximate calculation was indicated above.

Initial pressure in the system Rmin.

The maximum allowable pressure value Pmax.

The filling factor of the tank at various pressures (Kzap). It can be calculated from the table:

It can be calculated from the table:

The expansion volume of the coolant can be calculated using the following formula:

- The expansion coefficient for water E is 0.034 (at 85°C).

- The volume of the heating system C- 360 l

- Initial pressure Rmin - 1.5 atm

- The maximum value of pressure Рmax - 4 atm

- According to the table, the filling factor of the tank Kzap is 0.5

This is the standard tank size for a small house.

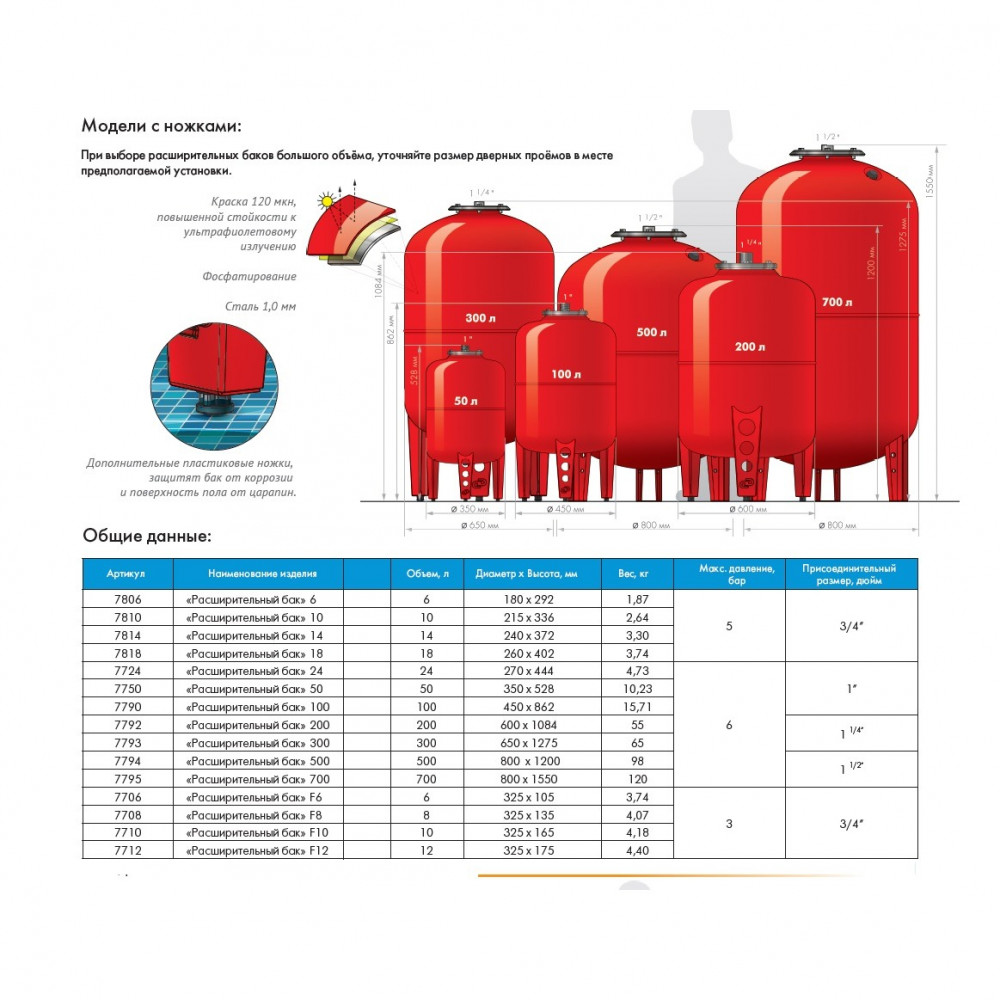

When choosing an expansion tank, you need to pay attention to the quality of workmanship. It is best to consult with specialists, since there are a large number of manufacturers of these structures, and it is very difficult to determine the quality for a particular model without experience and practice.

Kinds

Heating systems perform with natural and forced circulation of the coolant.

In traditional heating designs, open-type expansion tanks are used.

In cases where the coolant is induced to move with the help of special circulation pumps, expansion devices of a closed type are more often used.

open type

An open-type expansion tank is an ordinary metal box connected to a pipe from a heating main. It is placed in the highest accessible place of the building (house).

During the heating season, the presence of water in the tank is regularly inspected. If necessary, add liquid to the expansion tank.

Some experts install a float level control system in the expansion tank. When the level drops, the float drops, which leads to the opening of the feed valve.

Water is automatically added to the desired level. Automatic systems are mounted only where there is a water supply system in which pressure is maintained in excess of the hydrostatic value Hst.

- Extremely simple device, easy to make with your own hands.

- It can function for years without causing any complaints from users.

- Corrosion damages the expansion tank first.

- It is necessary to regularly check the presence of fluid and top up if necessary. Often, in private houses, when installing a heating system, the capacity for expanding the coolant is remembered last. I place it near the ceiling, which creates inconvenience when topping up. Forced to use flat bottles to refill water.

- It is necessary to lay an additional pipe that will heat only the space near the ceiling.

Important! The coolant tends to evaporate. It must be periodically topped up so that air pockets do not form inside the heating system.

closed tank

In such tanks there are two volumes separated by a movable membrane. In the lower space there is a coolant, and in the upper space there is ordinary air.

To create a preliminary pressure in the system, a valve and a fitting are provided on the air part of the tank. By connecting the pump, you can increase the pressure inside the air chamber.

With the help of a manometer, the set pressure in the heating system is controlled and set Hst.

Installation of such a device is carried out in different parts of the heating, more often it is traditionally installed near the boiler on the supply line.

Some users mount additional taps and pressure gauges to know pressure value during operation.

You do not need to constantly monitor the level of coolant in the system, filling it once, for several years you can not worry about fullness

Non-freezing liquids (high-boiling alcohols) are added to the coolant, which are not afraid of temperatures dropping below 0 ° C, which is important for country houses that are visited only by periodic arrivals. There is no corrosion of the metal, since air does not enter inside. minus conditional

It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

minus conditional. It is necessary to equip a closed heating system with control devices, as well as a safety valve that will open in the event of a sharp increase in pressure.

Attention! A sharp increase in pressure in the coolant is possible only if its circulation stops. This may be when damage or disconnection of the circulation pump. There is another drawback that manufacturers of closed tanks do not want to talk about.

The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale. It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

There is one more disadvantage that manufacturers of closed tanks do not want to talk about.The membrane loses elasticity over time. If the pressure changes inside, damage will occur. Therefore, collapsible tanks are on sale. It is easy to replace the membrane in them after a certain time. Usually such maintenance is done in the summer, preparing for the new heating season.

Capacity Recommendations

The most important feature that you should pay attention to when choosing a model of an expansion tank is the volume of its tank. For closed systems with a small circuit, the volume of the coolant in which does not exceed 150 liters, it is easy to calculate the capacity

So, it should be:

- when used as a coolant water - 10% of the volume of the entire heating system (for example, if this figure is 100 liters, then the expansion tank must hold at least 10 liters);

- when using glycolic liquid as a coolant - 15% of the volume of the heating system.

In the latter case, the capacity should be more impressive due to the higher expansion coefficient of the specified antifreeze.

The advantage of modern expansion tanks is the reaction of their membrane to any change in the temperature of the coolant. Which guarantees the safety of use. But it should be remembered that tanks are designed to work in certain conditions, so they must be chosen correctly.

The advantage of modern expansion tanks is the reaction of their membrane to any change in the temperature of the coolant. Which guarantees the safety of use. But it should be remembered that tanks are designed to work in certain conditions, so they must be chosen correctly.

The tank volume for larger systems with more than 150 liters circulating around the circuit is most conveniently calculated using the total system volume parameter and the tank selection table.

To calculate the total volume of the system, you can use the following methods:

- Measure the volume of coolant circulating in all individual elements of the system (boiler, radiators, pipelines) with subsequent summation of the results. This method is highly labor-intensive, but at the same time it is the most accurate.

- Multiply each kilowatt of boiler power by 15, assuming that on average there are about 15 liters of coolant per 1 kW. This method is simple, but it should be remembered that the result can be trusted only when there is confidence in the correct selection of the heating element for the system.

- Drain all water from the system and refill it, calculating the required displacement.

Also, to calculate the required volume of the tank, you can use formulas or an online calculator. Why you need to know the volume of the coolant, its temperature and pressure in the system.

The method with formulas is more complex and the resulting volume will not differ significantly from the rough calculation above. Moreover, the found value will be rounded up.

Many manufacturers of expansion tanks offer the consumer assistance in selecting the right tank. To do this, provide tables to facilitate the selection. True, they must indicate that the information provided is advisory in nature and the responsibility in any case lies with the buyer.

The most practical solution when choosing will be an expansion tank designed for closed-type heating systems, equipped with a safety valve.

The reason is that when the pressure rises to critical norms, the device will start working and bleed it. That is, the specified valve is able to significantly increase the safety of the entire heating system.

When buying a container, it should be borne in mind that red paint is most often used to indicate expansion tanks used for heating.

This feature will help to distinguish the desired product from other similar ones, for example, similar in size and shape of tanks. for water supply - hydraulic accumulators, which are predominantly covered with blue enamel.

But if necessary, you can find tanks of various colors, which will help to place the right one in any room without compromising its aesthetic qualities.

Tanks are horizontal or vertical, and manufacturers make it possible to mount them in different places. This product comes with a variety of accessories.

And when buying, you should pay attention to this, determining the best option in advance.

When choosing, you should also pay attention to the quality of the materials used in the manufacture of the tank body and membrane. And the availability of a guarantee for the purchased equipment and installation and connection manuals it into the system