How to carry out the installation?

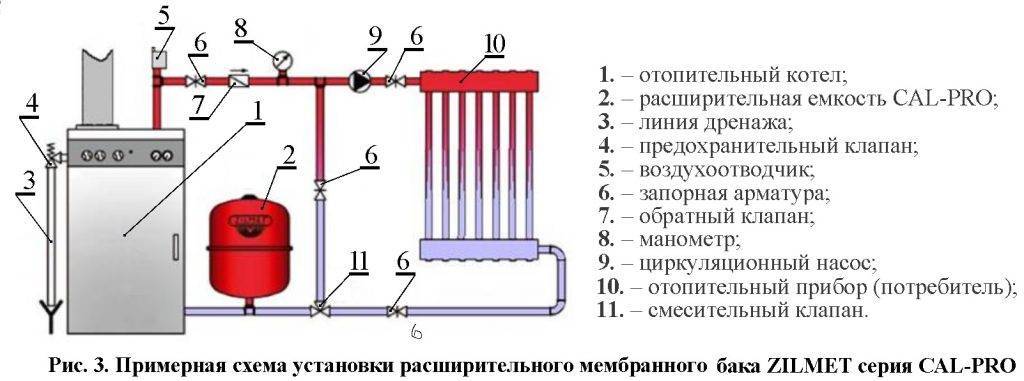

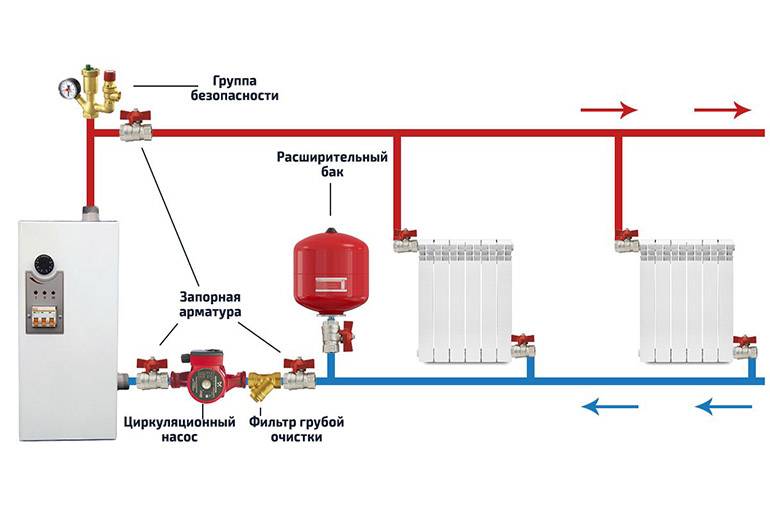

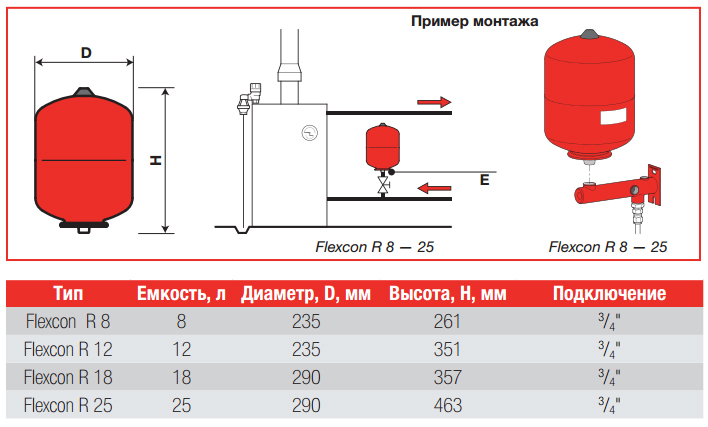

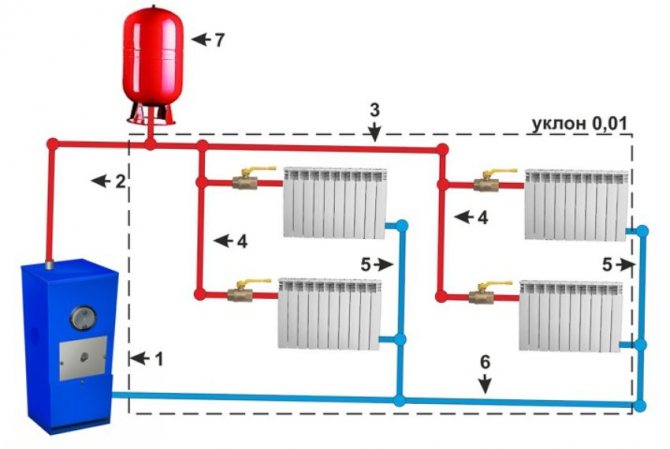

There are no significant restrictions affecting the installation location of the expansion tank in the system. Nevertheless, it is advisable to install it at any convenient point in the return line of the existing heating system.

The reason is that the coolant is cooler there. And this allows you to significantly extend the life of the expansion tank, its membrane.

In addition, if you install a tank near a solid fuel boiler, then in certain situations steam can enter the coolant chamber. As a result, the container will lose the ability to compensate for the expansion of the coolant.

The tank can be installed in two ways. These include installation:

- on the wall;

- on the floor.

But it should be understood that the first option is intended only for cases where the expansion tank has a moderate volume.

Tanks should be installed as far as possible from the boilers. And the best solution would be to find it in the return line.Since the temperature of the coolant there is significantly lower, which eliminates the early failure of the membrane

Tanks should be installed as far as possible from the boilers. And the best solution would be to find it in the return line.Since the temperature of the coolant there is significantly lower, which eliminates the early failure of the membrane

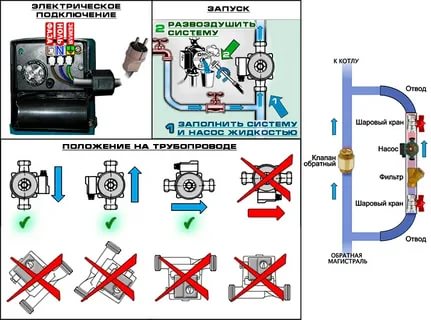

You should not save on connecting the tank to the heating system.

So this procedure should be carried out using:

- a shut-off valve with the so-called "American" - this structural element will allow you to quickly decommission the tank, and, if necessary, replace it, and without waiting for the coolant to cool;

- a tee with a drain tap, which will allow you to quickly empty it before replacing the tank;

- manometer for measuring pressure;

- safety valve or nipple to regulate the pressure inside the equipment.

After installing the tank, it will have to be properly configured, taking into account the manufacturer's recommendations given in the instructions for the purchased equipment. In order for the pressure in the tank to be appropriate, i.e. smaller than in the system, which will allow the membrane to deform when the coolant is heated.

If the calculations were not performed correctly and a tank of a smaller volume than necessary is placed in the heating system, then it will not cope with its duties, but the error can be corrected.

Why you need to purchase and install a second container in the system. The capacity of which is the difference between the required volume and the available tank working in the system. This method will reduce financial losses.

Tank setup and repair

In this section, we will talk more about repairing hermetic heating expansion tanks, since everything is quite simple with an iron open tank. If there is a leak, you need to weld a patch, if it rotted, and they often rot - a replacement. To adjust, you need to fill it by a third. Everything, the tank is ready to work.

Repair of an expansion tank for heating is possible only if it is collapsible, if not, then only setting. To cover both of these aspects, let's figure out how to replace a torn membrane. To repair and adjust the membrane tank you need:

- remove it by first closing the stopcock;

- drain the water from it and release the air from the air chamber through the nipple. If you have a properly installed tank and an American at the tap, a small tank for drained water will suffice. If mistakes were made in the sequence of valves and fittings, then get ready for the fact that there will be a lot of water;

- unscrew the bolts on the flange, in which there is a hole for the coolant;

- remove the flange and take out the torn rubber pear (membrane);

- replace the membrane and screw the flange back;

- one and a half atmospheres are pumped through the nipple on the back of the tank with a conventional pump;

- put the tank in place and check.

If everything is done correctly, the pressure in the heating system will be stable, without drops. Summing up, it can be noted that in a closed system, the tank cannot be placed immediately after the pump. The nipple of the sealed tank should look down and it is better to install the tank on the return line.

Installation of expansion tanks of open and closed type

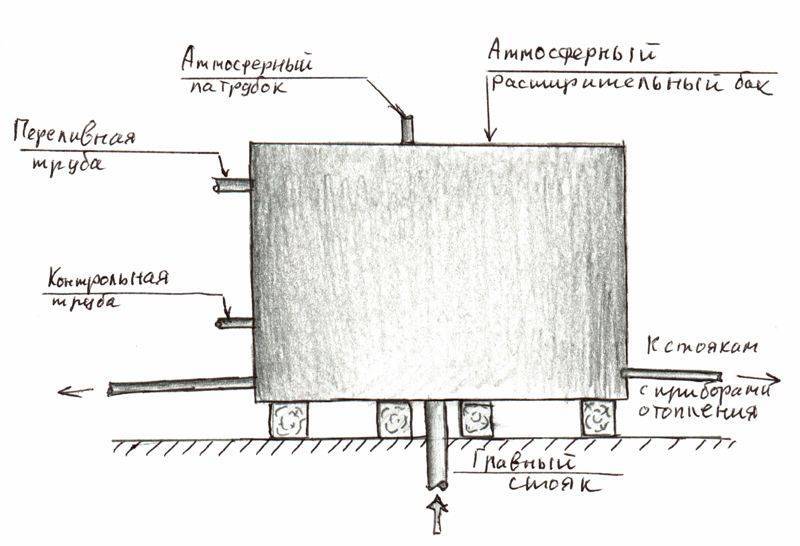

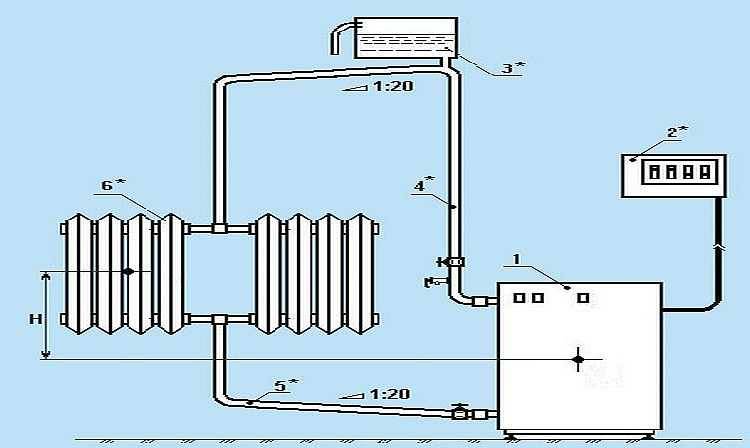

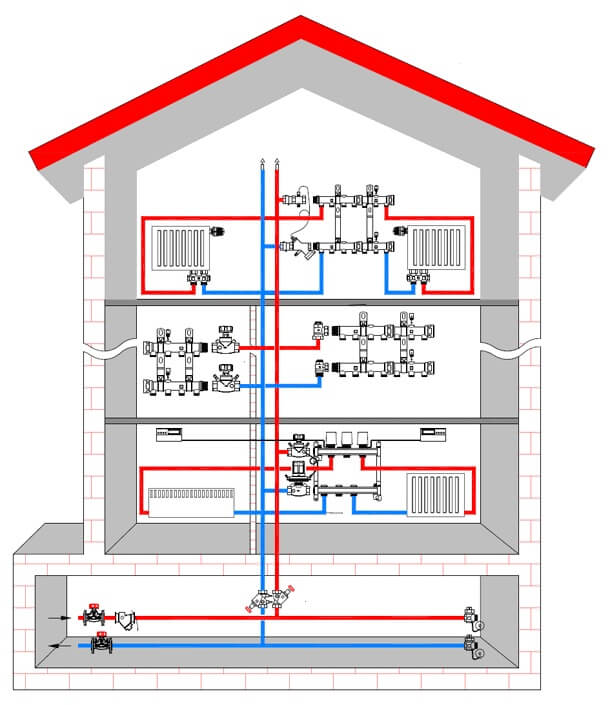

Unlike the installation of expansion tanks in an open heating system, membrane tanks do not need to be mounted on top of the heating system. An open tank is structurally simple and acts as an air exhaust device, the device for an expansion tank of a closed-type heating system is more technologically advanced, and the installation is carried out according to other principles.

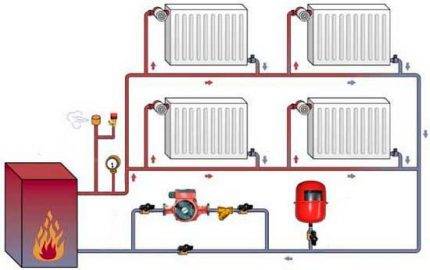

The connection diagram of the RB in the heating system may differ depending on the project, but in any case, with a closed circuit, the tank must not be installed immediately after the circulation pump.

For ease of maintenance, closed RBs are often placed next to the heating boiler. Fasteners can be fixed both on the wall and on the floor and ceiling. Manufacturers also offer brackets with installed devices belonging to the safety group, which determine the exact position and secure fastening of the tank in the system.

Tank connections to the system must be made using heat-resistant hermetic materials and run at positive temperatures. The pressure in the gas section is adjusted to the set values using a conventional car pump.

More than one video has been shot about the correct connection of the expansion tank, we suggest watching one of them:

Having understood the principle of operation and the differences between one type of tanks from another, you can easily choose an expansion tank exactly for your needs and for your heating system.

The principle of operation of the device

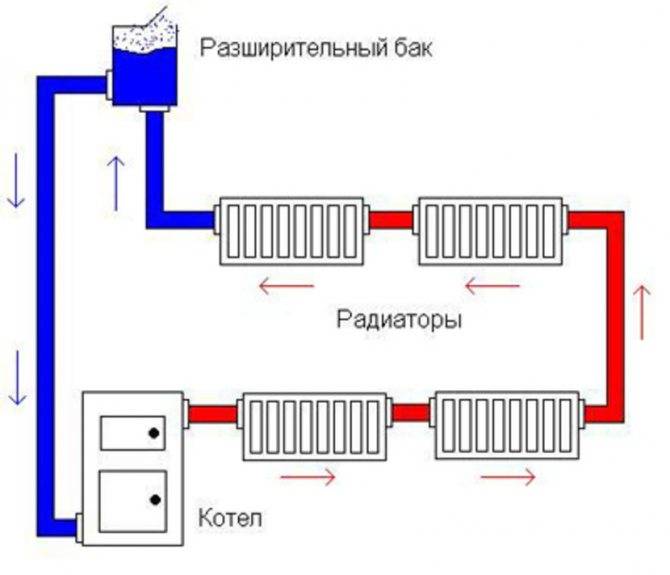

The expansion tank is part of the simplest heating systems that work according to the laws of physics. When the movement of fluid through pipes, radiators is carried out by gravity, the energy for this is provided by a pressure drop.

Otherwise, the presence of a tank will not give the desired effect. That will not protect against pressure increase, water hammer and subsequent breakdowns.

An important advantage of open expansion tanks is their accessibility.For example, a tank can be made even from improvised materials, which are enough in summer cottages, in the back rooms of private houses. Any metal or plastic container of the right size can become an expansion tank, as evidenced by the photo

An important advantage of open expansion tanks is their accessibility.For example, a tank can be made even from improvised materials, which are enough in summer cottages, in the back rooms of private houses. Any metal or plastic container of the right size can become an expansion tank, as evidenced by the photo

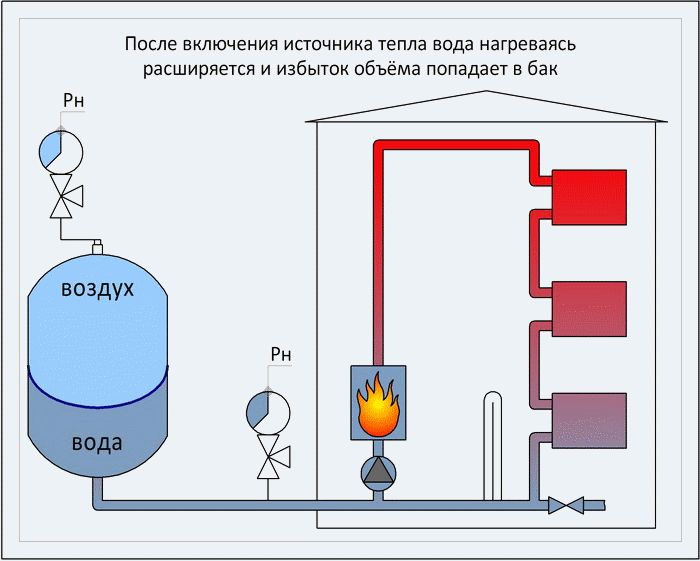

The reservoir itself, with a cold coolant, does not take any part in the operation of the heating system.

Everything changes when the liquid is heated to significant temperatures and creates excess pressure in pipes, radiators, since in such situations its excess is actively created and squeezed out into the expansion tank. Where is it located until the coolant cools down, after which it again falls into the pipes and radiators, the boiler by gravity.

The described procedure is performed cyclically, that is, throughout the entire period of operation of the tank.

Due to the fact that the heating system is open, like the tank itself, compensation for the consequences of expansion cannot be carried out without human intervention.

The reason is that the coolant, being in direct contact with air, evaporates, and the more it heats up, the more actively this procedure takes place.

As a result, the user has to regularly monitor the available water level. And top up as needed.

The specified operation is performed using a bucket or other container with water. This is unpleasant, so the system can be automated by organizing the supply of water from the water supply system, and from any: local or centralized.

You should be aware that the geometric shapes and precise calculations in the case of an open expansion tank are absolutely not important.The main condition for efficient operation is placement at the highest point of the system and the presence of a sufficient volume of the tank up to the overflow pipe

You should be aware that the geometric shapes and precise calculations in the case of an open expansion tank are absolutely not important.The main condition for efficient operation is placement at the highest point of the system and the presence of a sufficient volume of the tank up to the overflow pipe

In addition, using additional equipment, the described procedure can be made completely autonomous.

But in this case, the most important advantages of all open tanks and heating systems are lost:

- cheapness;

- complete autonomy, that is, independence from the operability, serviceability and availability of any engineering systems in the room.

All processes in an open tank occur according to the natural cycle, without the help of pumps and other equipment.

As a result, in order for the expansion tank to be guaranteed to be useful, the dimensions of the system itself must be moderate, that is, it should not be used to heat cottages and buildings whose area exceeds 100 m².

The optimal location for expansion tanks are warm attics. Since there is guaranteed to be the highest point of the system, and this solution also allows you to hide the structure with low aesthetic properties away from the eyes

The optimal location for expansion tanks are warm attics. Since there is guaranteed to be the highest point of the system, and this solution also allows you to hide the structure with low aesthetic properties away from the eyes

If this rule is ignored, then this can lead to significant financial losses, since a number of alterations will have to be performed to ensure the efficiency of the tank and the entire system as a whole.

In addition, altitude must be limited. Since it is very problematic to achieve the expected result when trying to heat more than a two-story building in this way.

Hydraulic tank connection diagrams

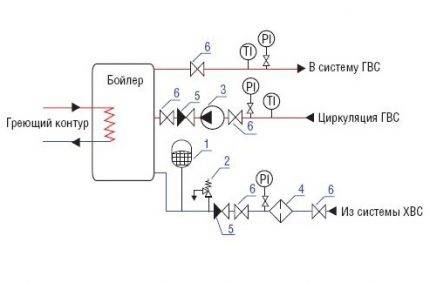

For a hot water supply system, the installation of an expansion tank is carried out in the section of the circulation line, the suction line of the pump, closer to the water heater.

The tank is equipped with:

- pressure gauge, safety valve, air vent - safety group;

- shut-off valve with a device that prevents accidental shutdown.

In the plumbing system, where there is water heating equipment, the device takes on the functions of an expansion tank.

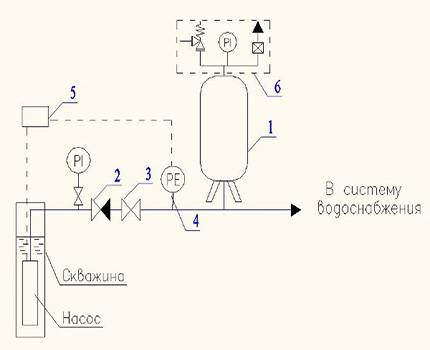

Scheme of installation in the HW system: 1 - hydraulic tank; 2 - safety valve; 3 - pumping equipment; 4 – filtration element; 5 - check valve; 6 - shut-off valve

In the cold water system, the main rule when installing a hydraulic accumulator is installation at the beginning of the piping, closer to the pump.

The connection diagram must include:

- check and shutoff valve;

- security group.

Connection schemes can be very different. A connected hydraulic tank normalizes the operation of the equipment, reducing the number of pump starts per unit of time and thereby extending its service life.

Installation scheme in the cold water system with a well: 1 - tank; 2 - check valve; 3 - shut-off valve; 4 - relay for pressure control; 5 - control device for pumping equipment; 6 - security group

In a scheme with a booster pumping station, one of the pumps is constantly running. Such a system is installed for houses or buildings with high water consumption. The hydraulic tank here serves to neutralize pressure surges, and a container of the largest possible volume is installed to accumulate water.

Device and principle of operation

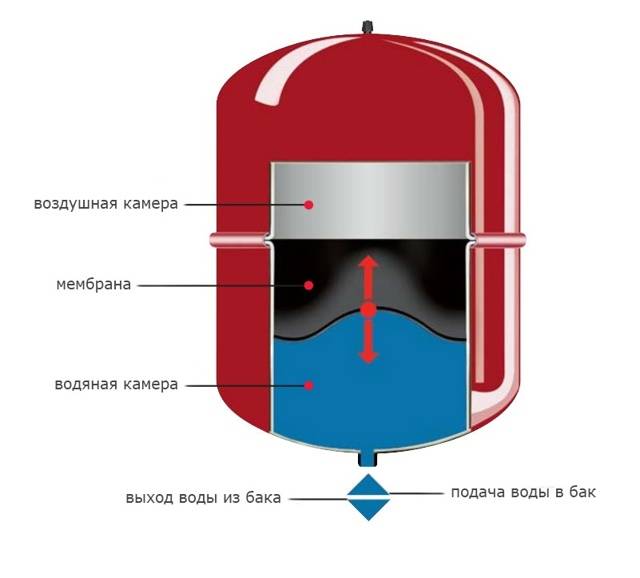

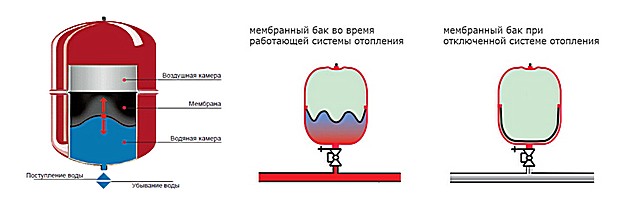

A membrane tank is a hermetically sealed metal container divided into two compartments (chambers) by an elastic membrane. One of these chambers is the pneumatic chamber, which contains pressurized gas or air.The coolant enters the second chamber - the hydro-chamber.

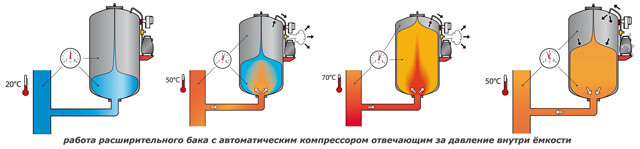

The device works as follows:

- the air pressure, which is in a state of equilibrium, in the pneumatic chamber compensates for the fluid pressure in the heating system, the volume of the coolant and the hydrochamber are minimized;

- when the liquid pressure rises in the system, including during heating, there is an increase in pressure in the hydrochamber, where the excess coolant enters;

- due to the elasticity of the membrane, the volume of the pneumatic chamber decreases, which is accompanied by an increase in gas pressure;

- when the pressure in the pneumatic chamber increases, the increase in pressure in the hydrochamber is compensated, and the system returns to a state of equilibrium.

With a decrease in the pressure of the coolant in the system, opposite actions occur. The gas (air) compressed in the pneumatic chamber expands and displaces the liquid from the hydraulic chamber into the system until the pressure difference is restored. The design eliminates the possibility of contact between the coolant and air, reducing the likelihood of rust not only in the tank, but also in other parts of the heating system - pipelines, boilers. Sealed expansion tanks are equipped with safety valves to limit the maximum pressure in the heating system to an acceptable level. This also characterizes the tank as a protection device for the heating system.

2 Product design

In rooms, heating networks can have open and closed circuits. The first type is used in centralized networks, so that you can directly take water for hot water needs. Devices are placed in the upper part of the circuit.Expansion tanks will not only allow you to control the process of pressure drops, but will also perform the function of separating air from the system. If it is of a closed type, then a design with a membrane inside is used.

If the membrane belongs to the first type, then the coolant is located inside the rubber cylinder, and nitrogen or air is outside. If necessary, such a part can be replaced, which will save on repairs and not change the entire device.

It has a small capacity and compensates for minor pressure drops. If it fails, it is impossible to replace it, so you will have to change the tank completely. But compared to a balloon membrane, it is cheaper.