- The nuances of homemade work

- Disadvantages of a heating system with a collector

- Homemade collector

- Manufacturing process

- Modifications of distribution manifolds

- Most wanted models

- Equipment connection and types of accessories

- Functional purpose

- Collector device

- What is it needed for

- Collector group for heating system assy

- Comb - manifold assembly

- Types of heating systems and their difference

- Conclusions and useful video on the topic

The nuances of homemade work

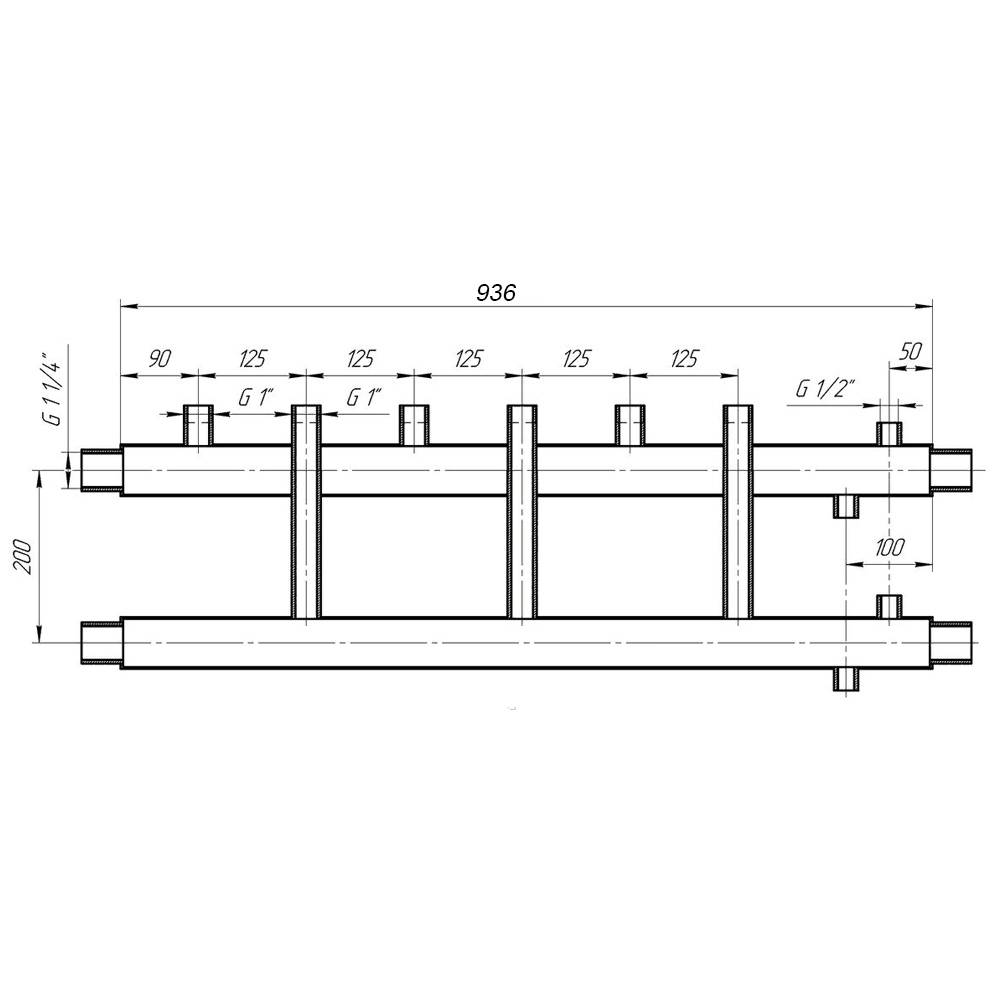

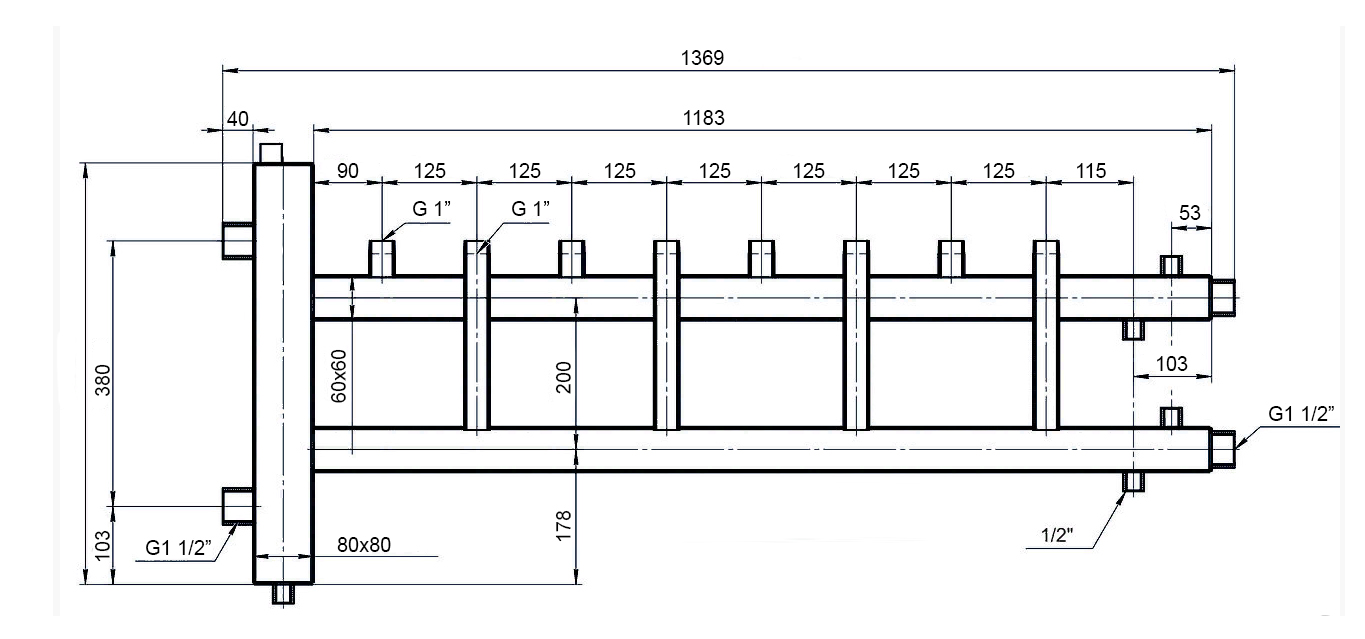

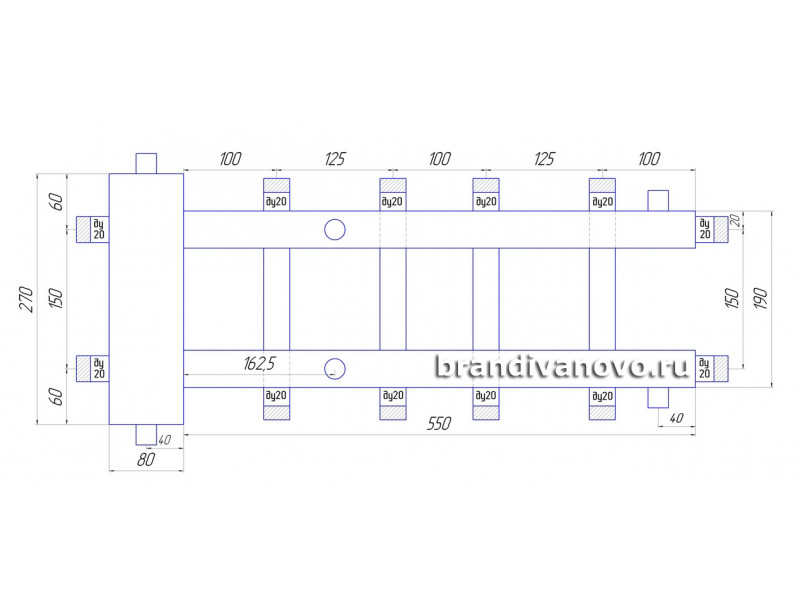

The main condition for the correct operation of heating is the creation of a hydraulic balance in the system. The ring collector for heating must have the same capacity of the inlet pipe (section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 + D3 + D4

Manufacture of the manifold do-it-yourself heating, remember that the distance between the supply and return sections of the pipe must be at least six times the diameter of the comb.

At when installing the device, take into account the following nuances:

- an electric boiler or a gas boiler is connected to the upper or lower nozzles

- the circulation pump cuts only from the end side of the comb

- heating circuits lead to the upper or lower part of the collector.

For heating a house with a large area, circulation pumps installed for each circuit. In addition, to select the optimal volume of the coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and valves for adjustment. These devices limit the flow of hot liquid to a single nozzle.

In order for the boiler wiring collector to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible to additionally (but not necessarily) equip a mixing unit in the manufacture of heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, a two or three-way valve is mounted. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

All this design allows you to adjust the heating temperature of a room or a separate circuit. If too hot water enters the collector in the boiler room, then the flow of cold liquid into the system increases.

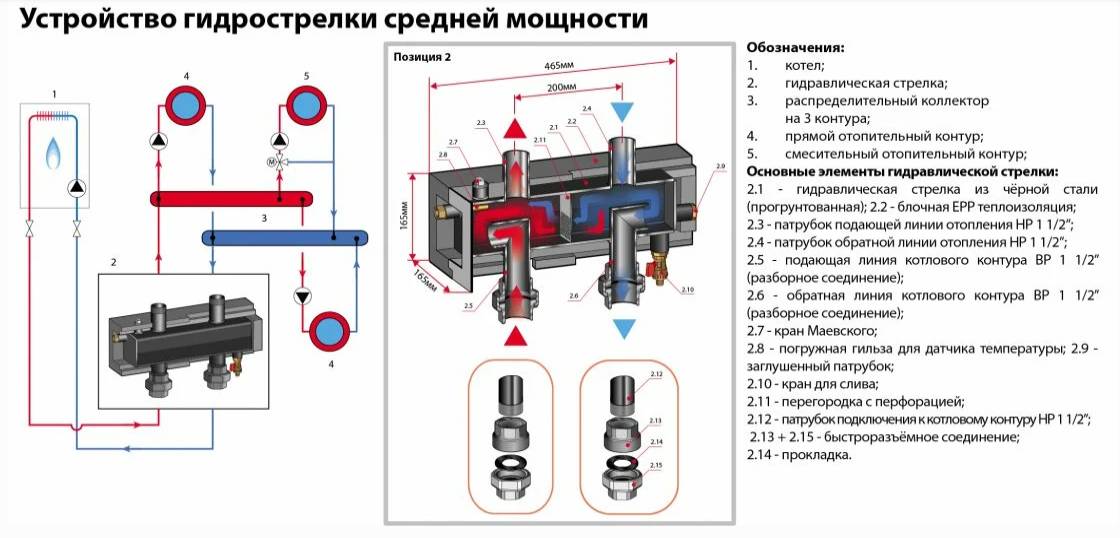

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of the distribution combs.

The collector for the boiler room, which you make yourself, will ensure the normal functioning of the heating only if the parameters of the system stroke are accurately selected.Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that the comfortable temperature in the house depends on many factors. Only a fully balanced system will ensure correct heating operation.

Disadvantages of a heating system with a collector

- The collector heating system has one very significant drawback - this is its high cost. The option of contour underfloor heating with a collector is considered one of the most expensive. In order for the collector of underfloor heating to work with your own hands, it is necessary to purchase and install a circulation pump. Since there is a separate branch of pipes from the boiler to each device, the cost of the pipes significantly adds to the increase in the price of the entire system as a whole.

- Collecting collector heating for underfloor heating is a rather difficult and troublesome business, you need to take into account many nuances and features of technological assembly.

But the collector system in our time is considered the best in terms of reliability. Despite the rather high costs of installing all the links of this system, it is effective and widespread. All private developers understand that with limited funds for construction, it is better to give the palm to a reliable heating system, and expensive finishes can be changed to a cheaper option.

Homemade collector

It is important to follow the direction

Making a homemade distribution manifold must begin with planning. You need to determine for yourself some components of the heating network at home.

The number of circuits where the coolant will be directed. Number of heating equipment.Do not forget to decide on its power, water temperature and so on. That is, you will need its technical characteristics. If in the future you plan to integrate additional heating elements into the heating system, for example, a heat pump or solar panels, then it is best to take them into account in advance. Number of additional equipment (pumps, valves, fittings, storage tanks, thermometers, pressure gauges, etc.).

Now the design of the device is being determined, it is especially necessary to take into account how each circuit will fit and from which side (bottom, top, side)

We draw your attention to some of the nuances of connection

gas or electric boilers are connected to the collector either from below or from above. If a circulation pump is installed in the heating system, then the connection is made only from the end of the comb. Boilers of indirect heating and solid fuel units crash into the collector only from the end. The supply circuits of heating systems cut either from above or from below.

It is good if a small drawing of the collector design is transferred to paper. This will give a visual picture, according to which it will be easier to manufacture the device. In addition, it can accurately indicate the dimensional characteristics that will have to be maintained during the manufacturing process. For example, the distance between the nozzles of the supply and return circuits should be within 10-20 cm. You should not do more or less, it will simply be inconvenient in terms of maintenance. The distance between the two compartments (supply and return) should be in the same range.

Make the device compact and beautiful.We recommend that you mark all threaded connections in the figure, indicating the dimensions of the thread, do not forget to sign all the necessary contours. This will ensure that you do not make a mistake when connecting. Now it becomes clear from the sketch how much and what materials you will need to make a homemade distribution manifold.

Manufacturing process

Please note that the supply and return compartments can be made from round or square pipes. Many masters prefer the latter option. They claim it's easier to work with

They claim that it is easier to work with him.

So, here is the production sequence:

For all dimensions that were indicated on the sketch, it is necessary to prepare the appropriate materials. It's almost all pipes. They are connected according to the design of the drawing in accordance with the purpose of each. The connection is made using a welding machine. Welding points must be cleaned with an iron brush, if necessary, degreased. The finished device must be tested for leaks. Therefore, all pipes will have to be closed tightly, leaving only one. Hot water is poured into it. If none of the joints drip, then the work was carried out at a high level. The collector must be painted and dried. It is possible to carry out installation and connection of all pipe systems with the installation of stop valves.

An easier option

Now to the question, isn't it better to buy a ready-made version? There is one "BUT" here.The finished distribution manifold may not exactly fit your heating system; you will have to align the thermal performance in other ways. For example, installing an additional comb. And this is an extra cost and an extra amount of installation work. And a home-made comb, in which you took into account all the design features of the heating of your home, will definitely fit it and will work efficiently and rationally.

So it’s worth thinking about the question that was posed at the beginning of the article, how to make a distribution manifold with your own hands? Let's just say that this is a simple process that you will spend one day on. But you simply must have the skills to work with a welding machine and other plumbing tools. Without this, it will be impossible to guarantee the quality of the device.

Modifications of distribution manifolds

Today, there are many varieties of collectors for heating systems on the equipment market.

Manufacturers offer both connecting links of the simplest design, the design of which does not provide for the presence of auxiliary fittings for regulating equipment, and manifold blocks with a full set of built-in elements.

Collector block, which includes all the necessary functional elements to create conditions for uninterrupted and high-performance operation of the heating system

Simple devices are brass models with an inch passage of branches, equipped with two connecting holes on the sides.

On the return manifold, such devices have plugs, instead of which, in the case of "building up" the system, you can always install additional devices.

More complex in terms of design intermediate prefabricated units are equipped with ball valves. Under each outlet, they provide for the installation of shut-off control valves. Fancy expensive models can be equipped with:

- flow meters, the main purpose of which is to regulate the flow of the coolant in each loop;

- temperature sensors designed to control the temperature of each heater;

- automatic air vent valves for draining water;

- electronic valves and mixers aimed at maintaining the programmed temperature.

The number of circuits, depending on the connected consumers, can vary from 2 to 10 pieces.

Regardless of the complexity and versatility of the equipment, materials that are resistant to external factors are used in the manufacture of collector block combs.

If we take the material of manufacture as a basis, then intermediate prefabricated collectors are:

- Brass - differ in high operational parameters at an affordable price.

- Stainless steel structures are extremely durable. They can easily withstand a lot of pressure.

- Polypropylene - models made of polymeric materials, although they are distinguished by a low price, are inferior to metal "brothers" in all characteristics.

Models made of metal are treated with anti-corrosion compounds and covered with thermal insulation to extend the service life and increase operational parameters.

Dividing structures made of polymers are used in the arrangement of systems heated boilers with power from 13 to 35 kW

The details of the device can be cast or equipped with collet clamps, allowing connection with plastic pipes.

But experts do not advise choosing combs with collet clamps, since they often “sin” with coolant leakage at the valve junctions. This is due to the rapid failure of the seal. And it is not always possible to replace it.

Collectors are used in schemes of one - and two-pipe heating. In single-pipe systems, one comb supplies the heated coolant and receives the cooled

Most wanted models

1. Oventrop Multidis SF.

Inch comb heating is intended for organization of heating with a water-heated floor. Manufactured from high wear resistant tool steel. Main characteristics:

- allowable pressure in the circuit - 6 bar;

- coolant temperature - +70 °С.

The series is produced with M30x1.5 valve inserts, and can also be equipped with a flow meter for connecting circuits located in different rooms. Bonus from the manufacturer - soundproof mounting clamps. The number of simultaneously serviced branches is from 2 to 12. The price, respectively, is 5650-18800 rubles.

To work with high-temperature appliances, Oventrop suggests using the distribution manifold of the Multidis SH stainless steel heating system with a Mayevsky tap. The design already withstands 10 bar at + 95-100 ° C, the throughput of the comb is 1-4 l / min. However, for products with 2 circuits, the indicators are slightly weaker. The cost of Oventrop SH hydrodistributors fluctuates in the range of 2780-9980 rubles.

Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

- HKV - brass manifold for underfloor heating. Holds a pressure of 6 bar in the range of + 80-95 ° С. Rehau version D is additionally equipped with a rotameter and a tap for filling the system.

- HLV is a heating distribution manifold designed for radiators, although its characteristics are identical to those of HKV. The only difference is in the configuration: there is already a Eurocone and the possibility of a threaded connection with pipes.

Also, the manufacturer Rehau offers to buy separate Rautitan combs with three exits for pipeline installation using compression sleeves.

Distribution collector of heating from steel with an anticorrosive covering. It works in systems with temperatures up to +110 °C at a pressure of 6 bar and hides in a special heat-insulating casing. The capacity of the comb channels is 3 m3/h. Here, the choice of designs is not too rich: only 3 to 7 circuits can be connected. The cost of such hydraulic distributors will be from 15,340 to 252,650 rubles.

Stainless steel manifolds are produced in an even more modest assortment - for 2 or 3 circuits. With the same characteristics, they can be purchased for 19670-24940 rubles. The most functional Meibes line is the RW series, which already comes with various connecting elements, thermostats and manual valves.

- F - a flow meter is built into the supply;

- BV - has quarter taps;

- C - provides for building a comb through a nipple connection.

Each Danfoss heating manifold allows system pressure 10 atm at optimum temperature (+90 °С). The design of the brackets is interesting - they fix the paired combs with a slight offset relative to each other for more convenient maintenance.At the same time, all valves are equipped with plastic heads with printed markings, which allows you to set their position manually without the use of tools. The price of Danfoss models, depending on the number of connected circuits and additional options, varies between 5170 - 31,390.

The heating manifold can be selected for a euro cone with 1/2″ or 3/4″ outlets or with a metric threaded connection. Far combs withstand pressure up to 10 atm at temperature not higher than +100 °С. But the number of outlet pipes is small: from 2 to 4, but the price is the lowest of all the products considered in our review (730-1700 rubles for an unpaired distributor).

Selection Tips

Despite the seeming simplicity of the combs, they need to be selected based on several technical parameters at once:

1. Head in the system - this value determines what material the distribution manifold can be made of.

2. The throughput must be sufficient so that the connected heating circuits do not “starve” from a lack of coolant.

3. Energy consumption of the mixing unit - as a rule, it is determined by the total power of the circulation pumps.

4

The ability to add contours - this parameter should be paid attention only when it is planned to build additional objects in the future that need heating

The number of nozzles on the hydraulic distributor must correspond to the number of connected branches (heaters). In some cases, it is better to install several collectors, for example, in a two-story house - one block at each level.It is also allowed to install unpaired combs at different points: one on the supply, the other on the return.

Finally, experts and experienced installers in their reviews advise not to save on buying a good collector. In order for it to serve for a long time and not cause any special problems, the name on the box must be known.

Equipment connection and types of accessories

Connecting the pump to the boiler through the collector begins with the fact that you need to choose the best options for filters and check valves. They must be of high quality, it is best to buy Italian or German mechanisms. They are durable and will serve you for a long time. It is worth dwelling separately on why these elements are needed and what role they play. In addition to the main working mechanisms, you will also need consumables, sealing elements and much more. Together, you can create the best conditions for the implementation of the task.

The coarse filter is a set of meshes with different cells that trap chips, pieces of rust, fragments of Teflon and other mechanical contaminants. This segment is installed at the inlet to the pump immediately after the manifold and the tap. In this case, by installing this mechanism, you will be sure that your pump connected to the boiler will be protected from these contaminants, which can instantly damage the internal working elements of the equipment. As for cleaning, the filter is equipped with a special cover that can be turned out and removed accumulated plaque.

The check valve is used to eliminate various hydraulic shocks and pressure drops in the system.It is installed already at the outlet of the pump and also guarantees additional sealing. In the event that the second valve fails and needs to be replaced, the check valve will allow you to carry out all the required maintenance work. If you have correctly selected all the components, you can safely proceed with the installation. Preliminary preparation for the implementation of a particular set of works should be carried out in strict accordance with the plan. The heating system is a complex engineering system that must provide heat to the house. If something breaks in the winter, the house will instantly start to cool down, and the sub-zero temperature will lead to freezing of the entire pipeline. It will no longer be possible to fix this problem.

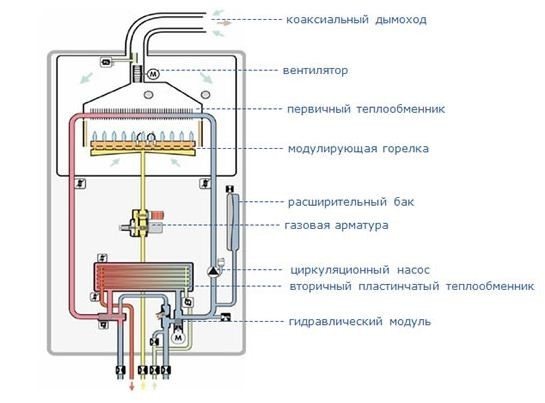

Functional purpose

Let's start with the fact that there is one very important rule, and if you do not strictly adhere to it, then the heating system at home will not work well. This rule states that the diameter of the outlet pipe of the heating boiler must always be equal to or slightly less than the total diameter of all circuits consuming the coolant. The best option if it is more

The best option if it is more.

For comparison, here is an example of a wall-mounted unit in which the diameter of the outlet pipe is ¾ inch. Imagine that three separate circuits will be heated due to this boiler:

- The main heating is a radiator system.

- Warm floor.

- Indirect heating boiler, which will use water intended for household needs.

Now imagine that the diameter of each circuit is at least ¾ inch, like the boiler. But the total figure will be three times higher.That is, no matter how you want, it will be simply impossible to give out the required amount of coolant through the diameter of the heating boiler nozzle so that it is enough for all three circuits. Here you have a decrease in heat transfer over the entire area of \u200b\u200bthe house.

Of course, individually, all circuits will work fine. For example, the main circuit (radiator) without the inclusion of underfloor heating will completely overpower the heated space. But as soon as you turn on the underfloor heating system, everything, neither here nor there, will not be enough coolant. The coolant has enough temperature, but its volume is not enough.

This rather serious problem is solved by installing a distribution manifold in the heating system. In fact, this is a structure made of stainless metal pipes, in the device of which devices are installed for the input and output of the coolant distributed along the circuits. To control the temperature, pressure, flow volume and speed, shut-off valves are installed along the outlets, which performs all the necessary functions.

Most importantly, with the help of a distribution manifold, you can control the temperature in a single room. And it will not affect the neighboring rooms and the temperature of the house as a whole.

Collector device

The collector consists of two pipes:

- Connects the supply pipeline from the boiler to the supply circuits of heating systems. This compartment helps the distribution of hot water. His device is especially helpful when there is a question of repairing one or another branch. At the same time, on a certain circuit, where it is necessary to carry out repair work, the shut-off valve closes. It simply shuts off the coolant supply.

- The return compartment regulates the pressure inside each circuit, which is how the quality of the coolant movement is achieved. And, therefore, the quality of heat transfer of heating systems.

Anyone who does not understand what the essence of the installation of a distribution manifold is, begins to build various additional installations into the heating system: a circulation pump, valves for various purposes, and so on. Let's face it, this will not help, with their help it is impossible to increase the volume of the coolant. You will simply make extra expenses that will turn out to be in vain.

Attention! If you are the owner of a large multi-storey building, it is recommended to install a separate distribution manifold for each floor

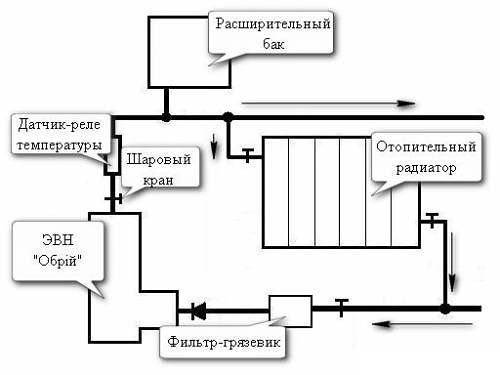

What is it needed for

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small house heated only with radiators, such a system will work effectively.

In fact, there are more heating circuits in a private house or cottage: warm floors. heating of several floors, utility rooms, garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed by collectors, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may be deformed. With the help of a collector and a shut-off temperature, this problem can also be solved.

Video: using a collector system for heating a house.

Collector groups for heating systems are sold ready-made, while they may have a different configuration and number of taps. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are universal and do not always fit the needs of a particular home. Their alteration or refinement can significantly increase costs. Therefore, in most cases it is easier to assemble it from separate blocks with your own hands, taking into account the features of a particular heating system.

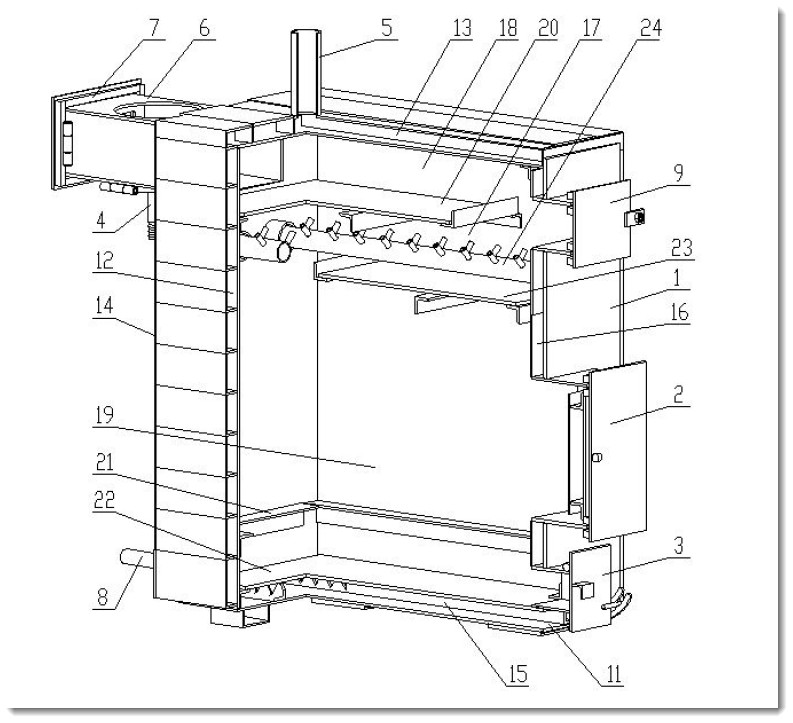

Collector group for heating system assy

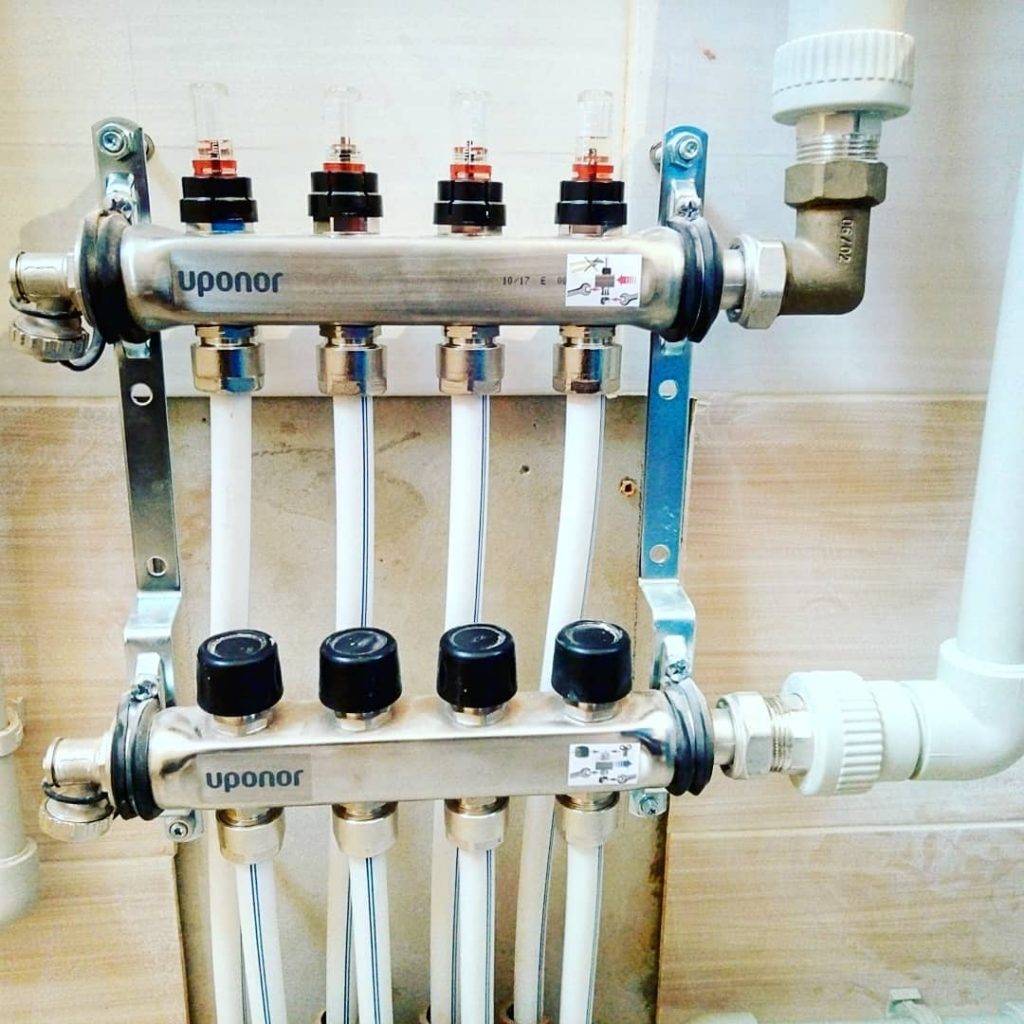

The design of the universal manifold group is shown in the figure. It consists of two blocks for direct and reverse flow of the coolant, equipped with the required number of taps. Flowmeters are installed on the supply (direct) manifold, and thermal heads are located on the return manifold to control the temperature of the return water in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles. and if some of the taps are not involved, installing it will be clearly inappropriate.

The rules for mounting the finished block are shown in the video.

Comb - manifold assembly

The most expensive elements in the manifold distribution block are flow meters and thermal heads. To avoid overpaying for extra elements, you can buy a collector assembly, the so-called "comb", and install the necessary control devices with your own hands only where necessary.

The comb is a brass tube with a diameter of 1 or ¾ inches with a certain number of branches with a diameter for heating pipes ½ inch. They are also connected to each other by a bracket. The outlets on the return manifold are equipped with plugs that allow install thermal heads all or part of the contours.

In order to save money, the collector for heating systems can be assembled from individual elements on your own or completely done by yourself.

Types of heating systems and their difference

Heating systems are based on the principle of hot water circulation. Based on this, they distinguish:

- heating system with circulation based on natural pressure;

- heating system with circulation by means of a pump;

It is not worth dwelling on the description of the first system, since this installation has long been considered obsolete and is practically not used in the construction of new housing due to its low efficiency.Such heating is used in small private houses and some municipal institutions. We will only point out that its functioning is based on the principle of the physical difference in the density of warm and cold water, which leads to its circulation.

The forced circulation heating system provides for the presence of special pumps that provide circulation. This method makes it possible to heat more rooms than the first one. Accordingly, this system is considered the most effective. There is a huge selection of pumps for the circulation of coolant in the system, which makes it possible to vary with their power and other quality characteristics based on the size of the premises and their number.

The heating system with circulation by means of a pump is divided into:

- two-pipe (connecting radiators and pipes in a parallel way, which affects the speed and uniformity of heating);

- single-pipe (serial connection of radiators, which determines the simplicity and cheapness in laying the heating system).

The collector heating system is highly energy efficient compared to the above due to the fact that each radiator is connected personally to one supply and one return pipeline, the water supply through which is carried out using collectors.

Features of the collector system and its differences are as follows:

Collector heating system wiring provides that each radiator is regulated independently and does not depend on the operation of others. In addition, other heating devices are often used in the collector system, which also work autonomously from the collectors.Radiators are mounted in parallel to the collectors, which, according to the principle of operation, makes the collector system similar to a two-pipe system.

Installation of collectors is carried out in a separate utility room, or in a specially designated cabinet-stand, hidden in the wall. The place for the collectors must be planned in advance, as they can be quite impressive in size. The dimensions of the distribution manifolds depend on the power of the radiators, which depend on the size of the rooms.

The collector wiring of the heating system significantly outperforms the other heating systems listed above by the ability to dismantle and replace the radiator without having to stop the entire system. Also, collector wiring requires more pipeline for its operation than a two-pipe system. Despite the significant one-time costs during the construction phase, these measures have a positive effect on the further energy efficiency of the system. That is why the collector heating system has the greatest effect and quickly pays for itself in the construction of housing with a large area.

Conclusions and useful video on the topic

Detailed technical process of assembly of the manifold group:

Finished combs for arranging warm floors, equipped with not always necessary functionality, due to their high cost, are inaccessible to the general public. Let's see how to assemble a budget version of the design with your own hands:

The implementation of the distribution group can also be performed using polypropylene pipes. How to do this, you can learn from the video:

Proper selection of components and installation of the collector assembly is the key to efficient and reliable operation of the heating main.Due to the minimum number of connections, the risk of leakage is minimized. An important plus is the ability to control and configure each heating circuit.

Share with readers your experience in assembling and connecting a distribution manifold. Please leave comments on the article, ask your questions and participate in discussions. The feedback form is located below.