- What is a comb for?

- How to build a collector yourself?

- Planning stage

- Define the block design

- Sequence of work

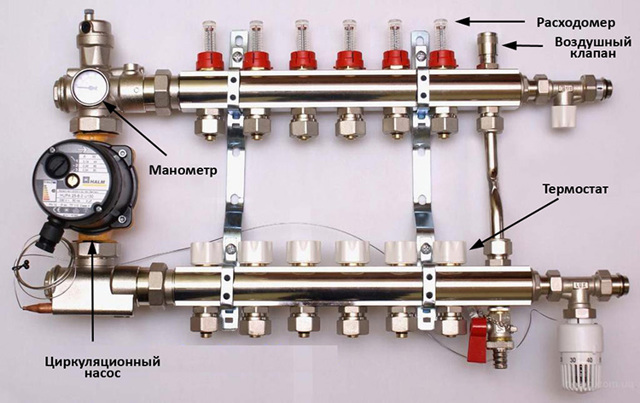

- Heating distribution manifold device

- Advantages and disadvantages

- Winter option

- How is the underfloor heating system

- The nuances of homemade work

- What is a hydraulic gun

- 6 Main disadvantages

- Comb for water floor heating principle of operation

- Areas of application for heating combs

- Price

- Peculiarities

- Scope of application

- Advantages and disadvantages

- Self-assembly of the manifold

- What do you need to know about cons?

What is a comb for?

What makes up the functionality and efficiency of the heating system? It should provide a comfortable temperature in all areas of the house and the necessary heating of water. In addition, it must be safe during operation and as maintainable as possible.

One of the functions of the comb is the ability to turn off the supply of coolant to a separate circuit of the heating system. This allows you to carry out repairs without turning off the heating as a whole.

All these conditions of normal operation help to solve the functional element of the collector (beam) heating wiring diagram, which is called a collector or comb.Suppose, in a house, suddenly, as it most often happens, a radiator or pipe joints leaked. If there is a comb, this local problem can be solved without turning off all heating. It is enough, simply by closing the desired valve, to turn off only the area that needs to be repaired.

In addition, one collector, which is installed on the entire heating system of the cottage, will perfectly cope with the function of controlling the heating process. He will be able to adjust the temperature in every room of the house. Using this device allows you to control the heating system quite efficiently and simply. At the same time, the cost of manpower and resources is reduced to a minimum.

How to build a collector yourself?

You can buy a ready-made uze, choosing one that roughly meets the needs of your home. But to achieve an exact match is quite difficult. Therefore, it is better to make a heating comb with your own hands. Let's figure out what is needed for this.

Planning stage

There are a number of parameters of the heating system at home that you should know when building a unit.

- The number of circuits through which the heated water will pass.

- The number and technical characteristics of the heating equipment included in the scheme.

- Additional equipment involved in the installation. This refers to pressure gauges, thermometers, taps, storage tanks, valves, pumps, etc.

It is also necessary to provide for the possibility of increasing the load, if over time it is necessary to build in elements that are not taken into account in advance. These can be, for example, solar panels or a heat pump.

It is necessary to foresee in advance not only the number of circuits operating in the heating system, but also additional equipment that will be included in the overall scheme

Define the block design

The design of the future node depends on the connection point of each of the circuits. After all, there are some nuances of connection, which cannot be ignored.

- Boilers (electric and gas) must be connected to the comb from above or below.

- The circulation pump should be connected from the end of the structure.

- Solid fuel units and indirect heating boilers also need to be embedded from the end.

- The supply circuits of the heating system are connected from below or from above.

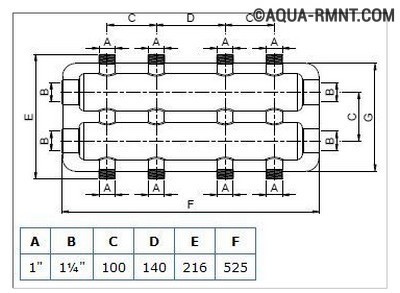

For clarity, it is necessary to make a drawing of the future compact and neat assembly. This will help determine the amount and types of materials that we will need. All necessary dimensions, threaded connections with a thread pitch are also applied to the drawing. All circuits should be marked in order to be guided by the drawing when connecting.

This drawing shows a four-way manifold. You can not make a drawing and limit yourself to a sketch, but do not forget to put on it all the dimensions necessary for work

The distance between the nozzles of both combs should be from 10 to 20 cm. These are the optimal parameters for maintenance. The distance between the supply and return combs themselves should also be within the same limits.

Sequence of work

For the manufacture of both combs, not only round, but also square pipes can be used. The sequence of work performed is as follows:

- In full accordance with the parameters indicated on the drawing, we purchase all the necessary materials.

- According to the drawing, we make a connection by welding pipes, taking into account their subsequent functions. Welding points should be cleaned with a metal brush and degreased.

- Testing a homemade node is a necessary stage of work.To do this, all pipes are hermetically closed except for one, through which hot water is poured into the system. We carefully examine all the joints: they should not leak.

- Now the collector can be painted and dried well.

- Next, pipes, locking mechanisms and control equipment should be connected to it.

After that, the device is ready for use.

This one will compare favorably with purchased products in that it was built taking into account the needs of a particular house, and this is very important for its further operation. Of course, a high-quality and functional device can only be obtained if the master knows how to handle the welding machine and metalwork tools.

In order for a home-made manifold block to work more efficiently than a purchased one, the master needs to be able to handle both welding equipment and locksmith tools

You can learn how to make a polypropylene collector by watching this video:

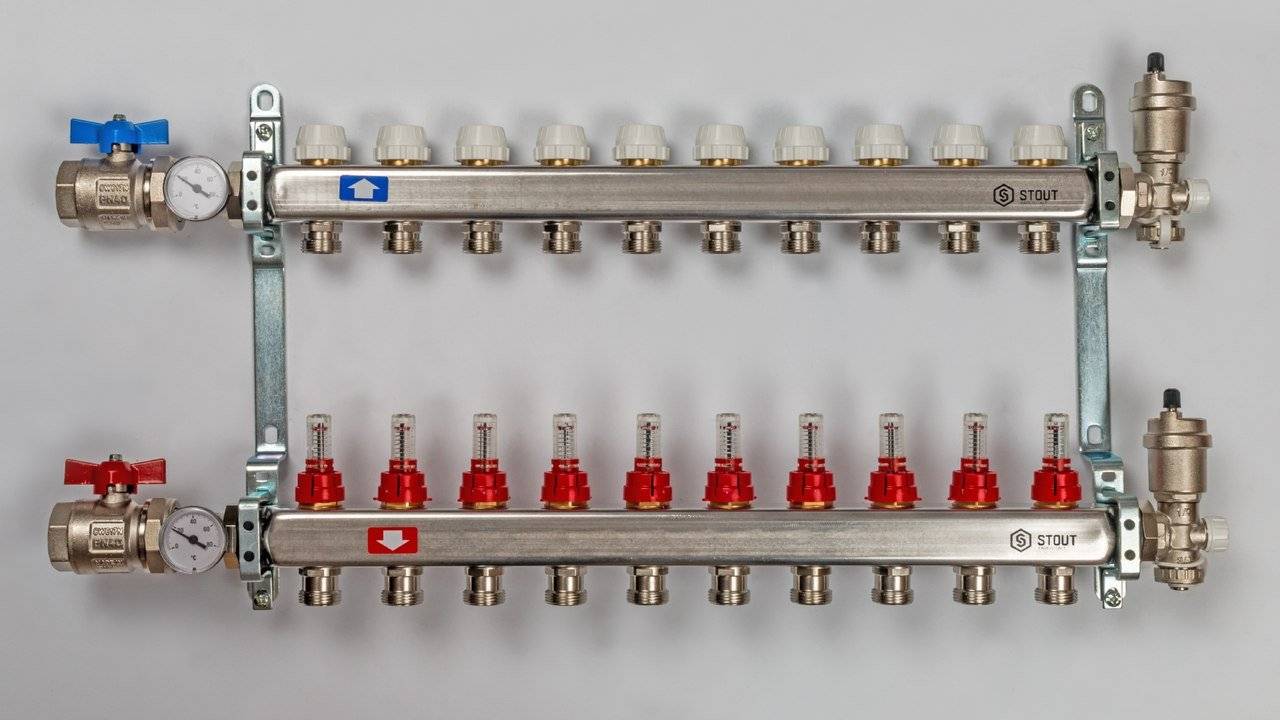

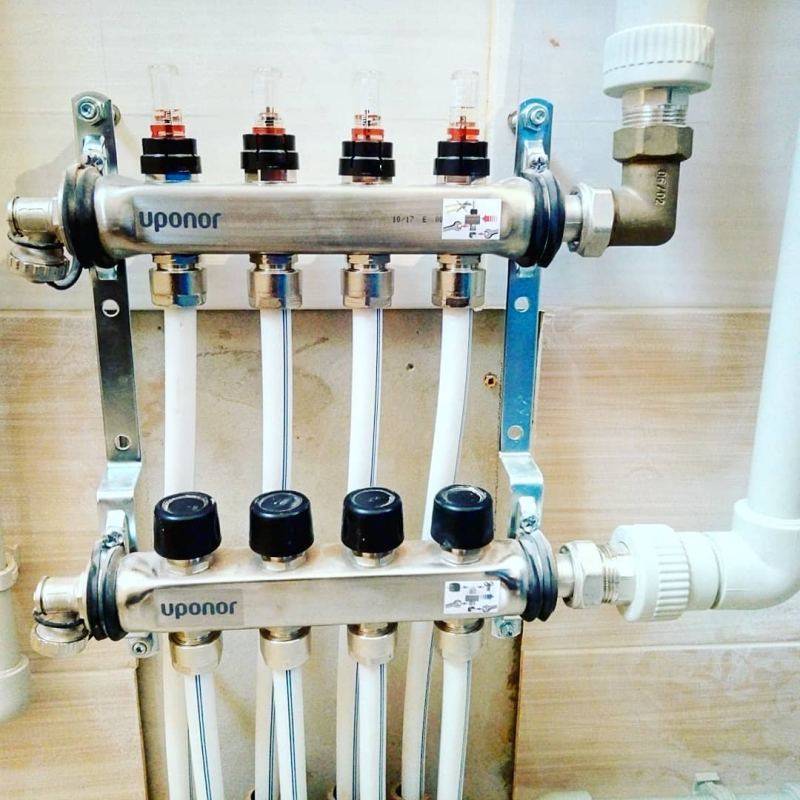

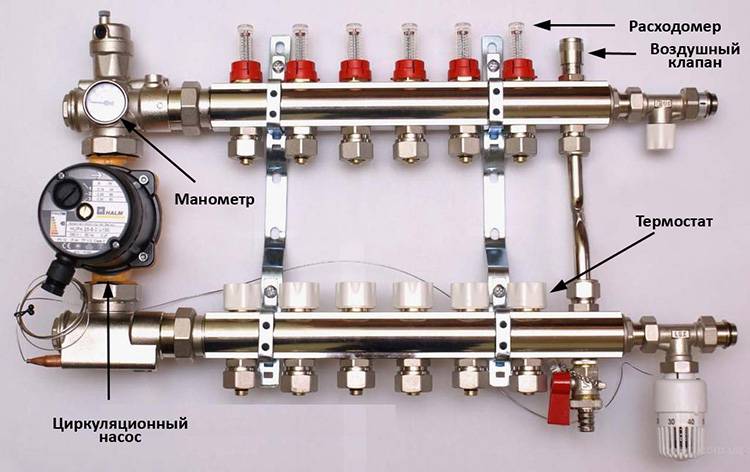

Heating distribution manifold device

Distribution combs for heating, depending on the connected devices, can have from 2 to 20 circuits, and the design allows this number to be increased if necessary. In the production of comb elements, materials with a high degree of resistance to water impurities and external factors are used. Usually the bodies are made of stainless steel or brass.

Such elements are usually quite expensive, but their service life reaches tens of years. Simple and cheap counterparts made of polypropylene are inferior to metal products in all respects.

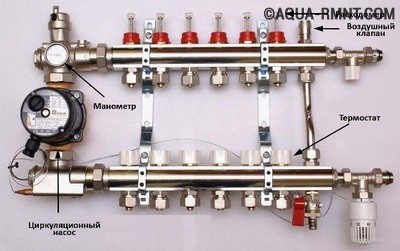

When choosing a manifold, it is necessary to pay attention to the maximum possible pressure, flow capacity, number of connection points and the acceptability of mounting accessories.

Each connection point can be equipped with drain valves or shut-off or control valves. With their help, it is possible to block the necessary branch during maintenance or repair without blocking the main flow of the heat-carrying fluid.

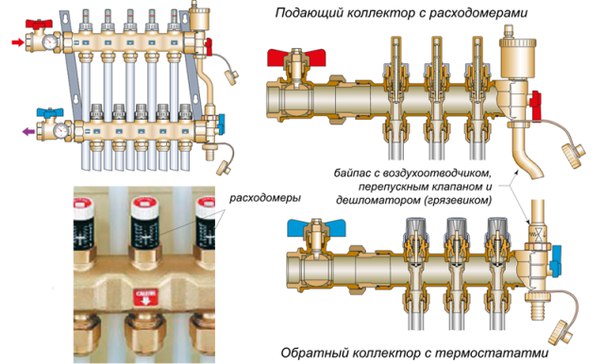

To control thermal processes in separate rooms, air outlet and drain valves, heat meters and flow meters can be mounted on the comb body.

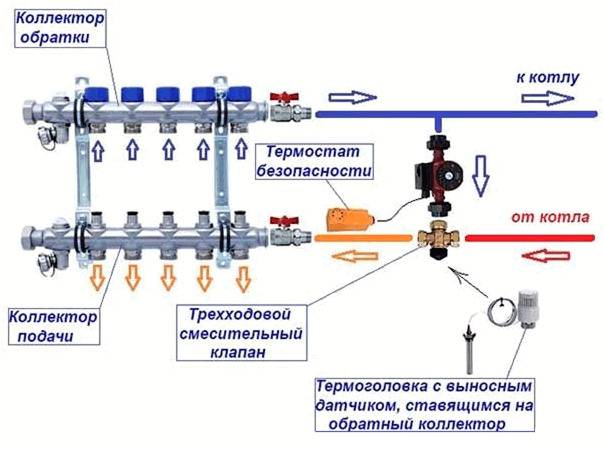

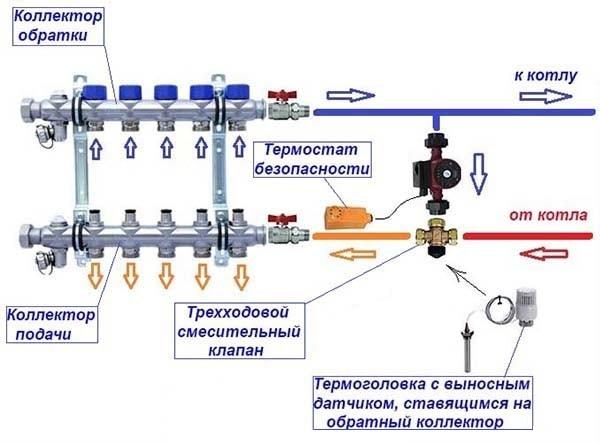

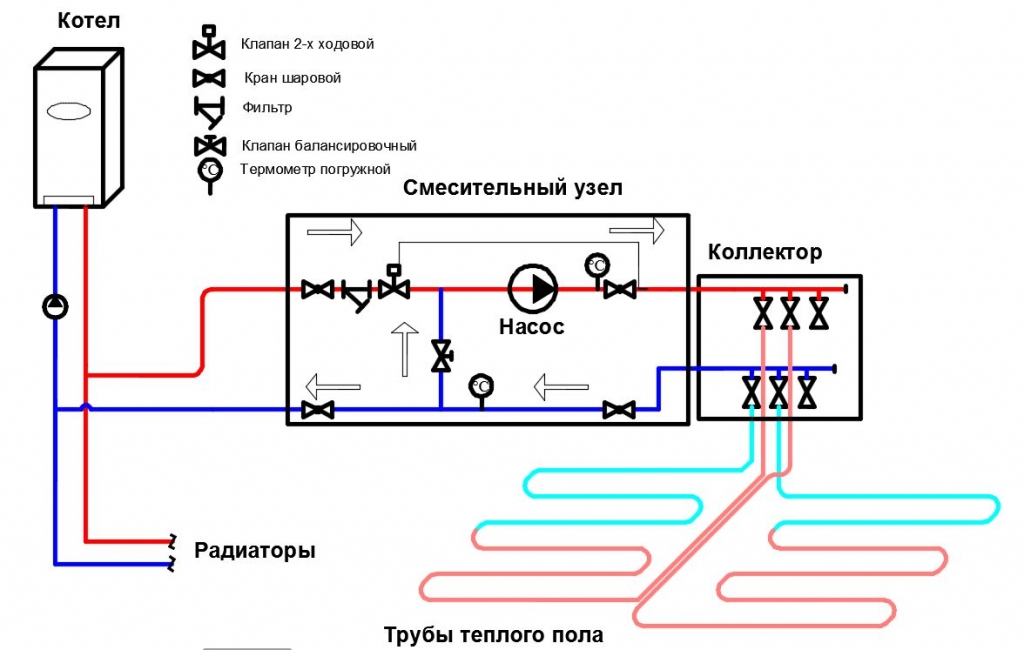

The collector system has a fairly simple principle of operation. After the heating boiler, the heated coolant flows into the supply comb. In the inner part of the collector, it slows down the movement. This is ensured by the increased (in relation to the main) diameter of the inner part of the device. Then the coolant is evenly distributed between the individual connection branches. Entering the connection pipes, having a diameter smaller than the collector, the coolant continues to move to the devices that directly heat the room.

All elements, whether it is a floor heating grid, a radiator or a water convector, receive a coolant of equal temperature, this is achieved by setting special flow meters that control the amount of coolant supplied to each branch.For example, in order to achieve the same temperature of the warm floor in the near and far room, it is necessary to set the corresponding flow meters so that the coolant moves more slowly through the pipes in the branch of the near room, and faster in the branch of the far room.

After heat transfer, the liquid moves through the pipeline towards the return manifold, followed by direction to the heating boiler.

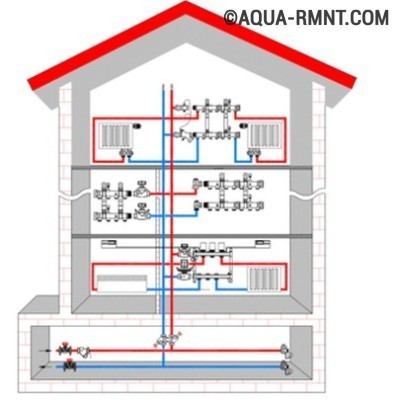

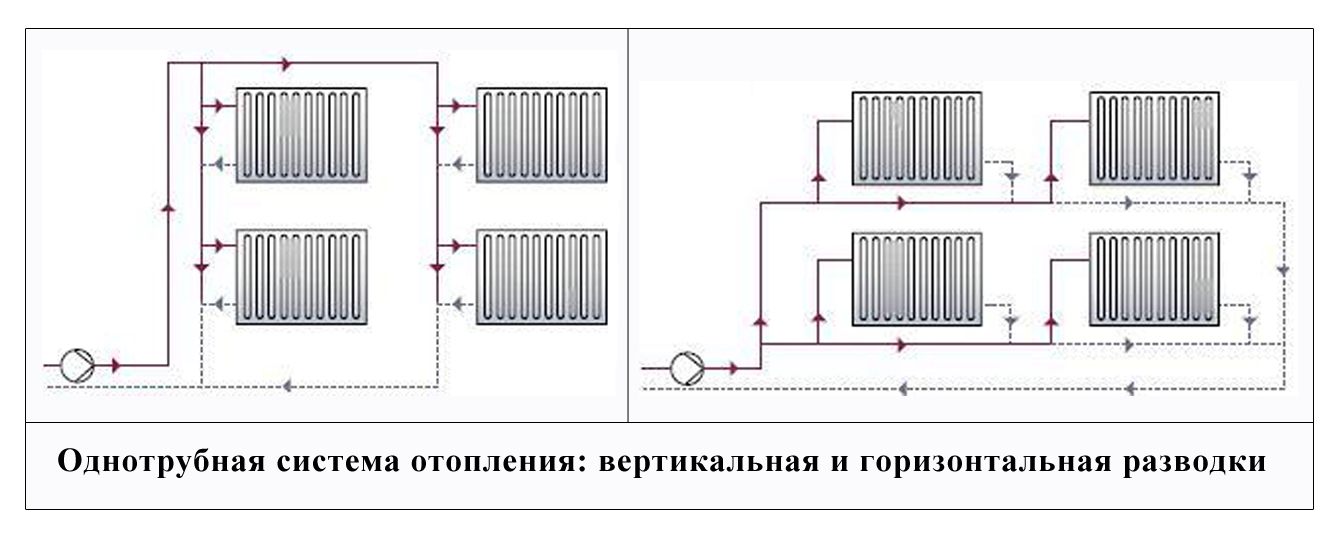

Whatever type the heating system of any house would have, it almost always contains heating radiators. The most popular and popular type of collectors are devices that distribute heat flows to radiators.

The radiator distributor assembly usually consists of two distributor combs connected to each other. The first directs the liquid to the radiators, the second returns to the boiler. Such collectors, as a rule, do not supply additional equipment and devices, in order to save money.

According to the type of connection, the collectors can be divided into devices with top, bottom, side or diagonal connection. More often than others, the lower connection method is used. In this case, it is possible to hide the contours under the decorative details of the floor, and to maximize the advantages of individual heating.

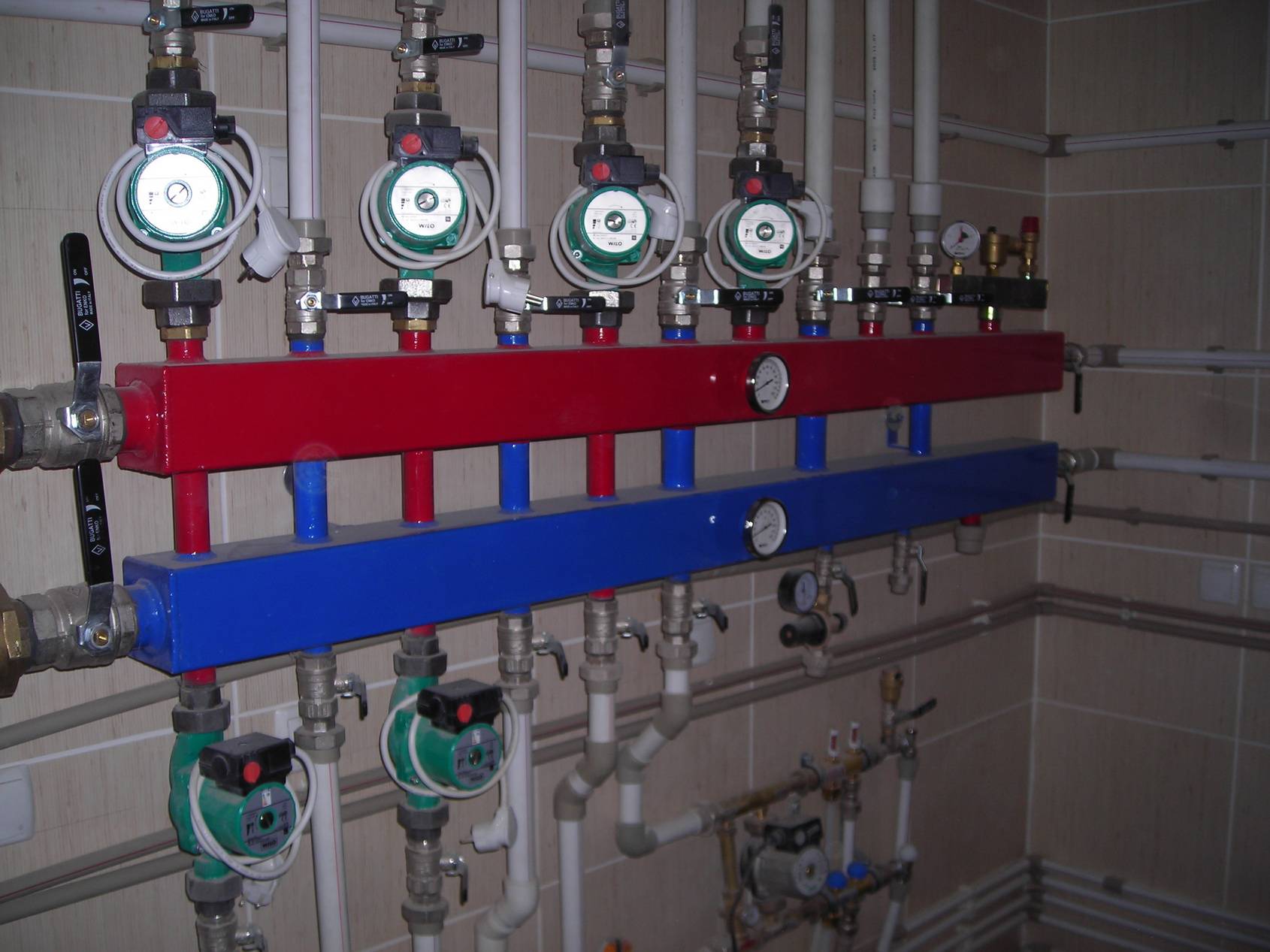

If the house has several floors, a collector assembly for radiators is installed at each level. The installation site can be a special technological recess or a shield that provides free access to the comb.

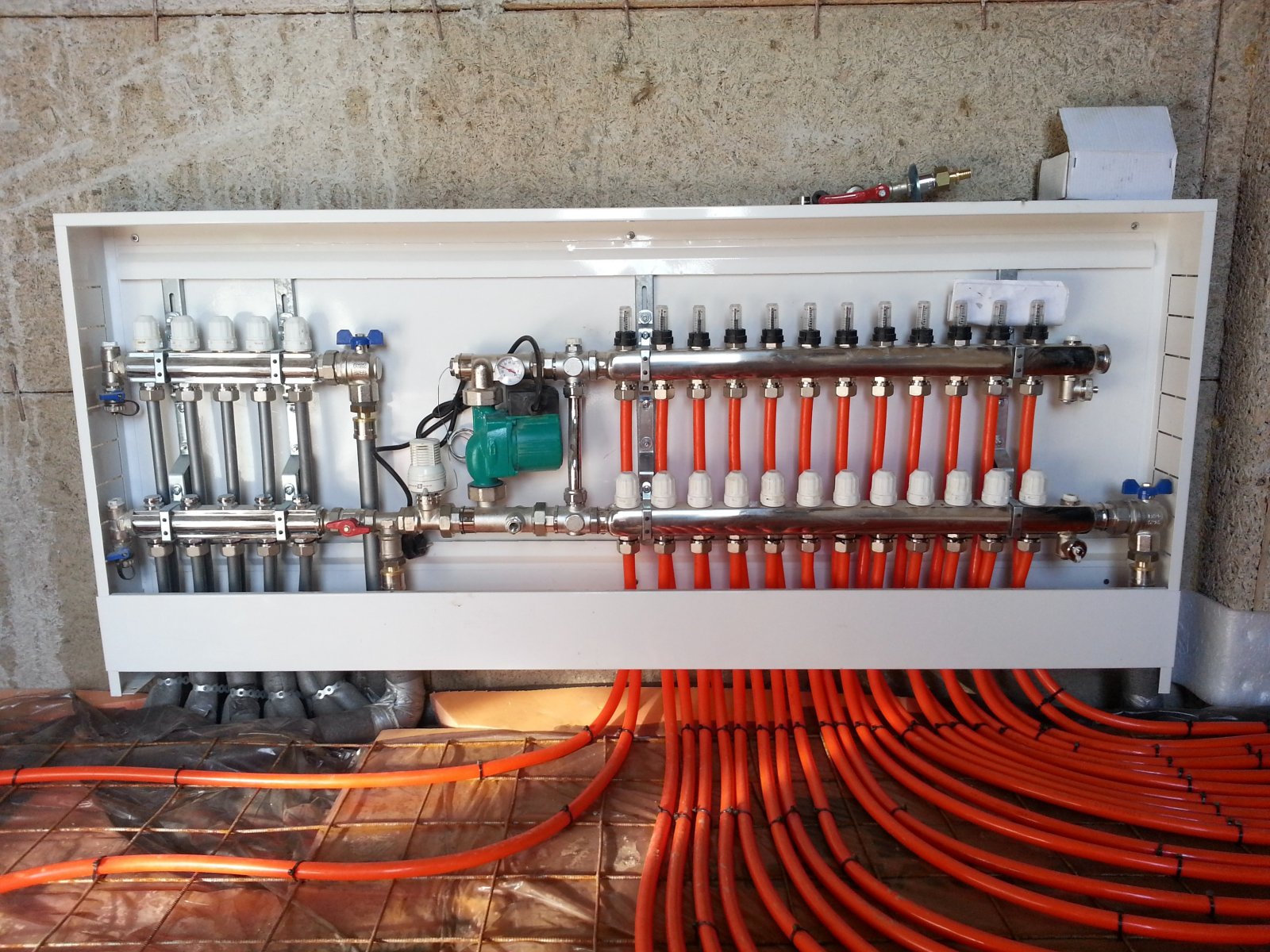

Ideally, all connection branches should have the same length. If it is impossible to maintain a single length of the circuits, then an individual pump can be installed on each of them, which maintains the circulation of the coolant.According to this scheme, warm water floors are usually equipped, each branch of which is equipped not only with its own pump, but also with automation.

Advantages and disadvantages

The water distribution comb, like any other similar design, has a number of advantages. As a result, she quickly won the sympathy of customers. The main advantages of the product are:

- Absence of temperature differences during synchronous connection of a number of heating batteries in different rooms;

- stable pressure in the supply and return pipelines;

- reliable blocking of the flow of heating coolant into a single heater, while ensuring the functionality of the entire system;

- practicality and simplicity of operational adjustment;

- ease of implementation of repair and preventive procedures;

- the admissibility of the use of pipelines hidden in the floor;

- the ability to control various technological characteristics of the system.

Despite the huge number of positive qualities, combs also have a number of disadvantages. Users should certainly reckon with them on the eve of their purchase and before use, otherwise they will face many problems that will complicate the performance of the heating system.

Among the negative reasons for using a collector, professionals note:

- The high price of the product, due to the introduction of innovative materials and technologies in the product;

- inadmissibility of installation in heating heating systems, with natural circulation without a centrifugal pump;

- the need to use a large number of expensive pipelines that need to be extended to all existing radiators.

Winter option

If it is planned to operate the solar collector for heating water all year round, an antifreeze liquid (antifreeze) is poured into the working circuit. This will prevent the water from freezing and possibly bursting fittings or pipes. An indirect heating boiler is included in the circuit so that the hot refrigerant passes through the heat exchanger coil, heating the water in the tank.

An expansion tank and a safety unit must be installed in the "winter" system. It is an automatic air vent, a pressure gauge and a safety valve adjusted to the operating pressure. Continuous circulation of the coolant is provided by a special pump.

View gallery

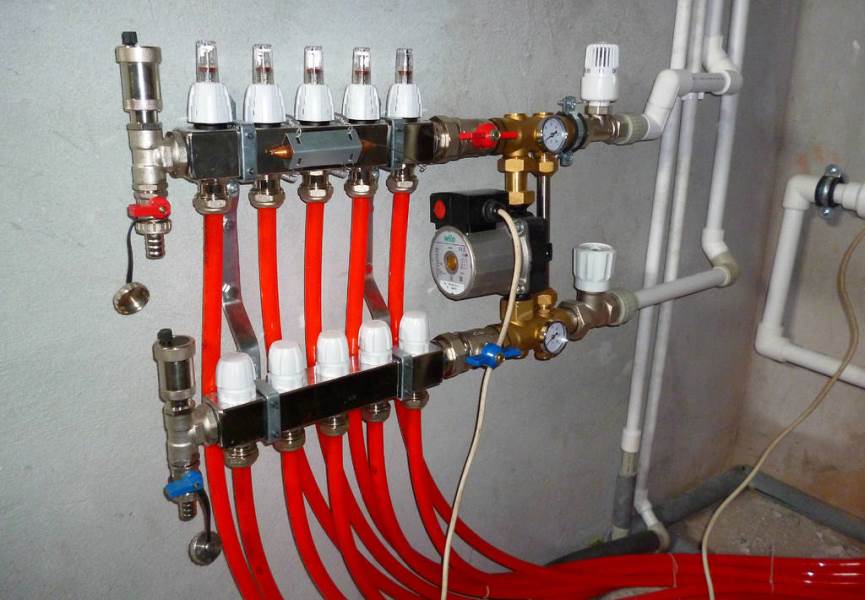

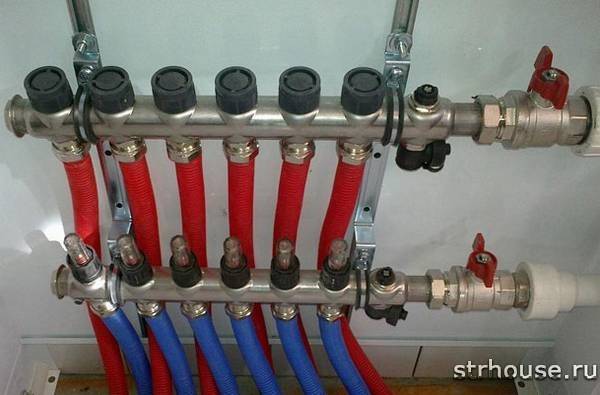

How is the underfloor heating system

Familiar radiators, which in recent times are the only possible installations for heat transfer in the house, are gradually being replaced by warm floors and ceilings. They can run on electricity and hot water. The second option is considered more practical and, if desired, a water-heated floor can be constructed with your own hands. There is nothing complicated in the heating system. Its scheme includes several elements:

Water heating boiler. It should heat the water well enough, distributed through all pipes and still have some power reserve. If this is expressed in numbers, then the additional performance should be equal to 15-20% of the total capacity of underfloor heating.

Water heated floor

- Pipes, which can be polypropylene, or can be made of special cross-linked polyethylene, for distributing water and pipes for laying out the floor surface. The diameter of these pipes must be at least 16-20 mm, and they must also withstand temperatures up to 95 ° C and a pressure of 10 bar.

- The collector is a splitter with taps. This is a necessary element to which several circuits are connected from the central supply line for warm and return intake of already chilled water.

The nuances of homemade work

The main condition for the correct operation of heating is the creation of a hydraulic balance in the system. The ring collector for heating must have the same capacity of the inlet pipe (section of the main pipe connected to the supply line) as the sum of the same indicators in all circuits. For example, for a system with 4 circuits, it looks like this:

D = D1 + D2 + D3 + D4

When making a heating manifold with your own hands, remember that the distance between the supply and return sections of the pipe must be at least six comb diameters.

When installing the device, the following nuances are taken into account:

- an electric boiler or a gas boiler is connected to the upper or lower nozzles

- the circulation pump cuts only from the end side of the comb

- heating circuits lead to the upper or lower part of the collector.

For heating a house with a large area, circulation pumps are installed on each circuit. In addition, to select the optimal volume of the coolant, additional equipment is installed on each inlet and outlet pipe - balancing flow meters and valves for adjustment. These devices limit the flow of hot liquid to a single nozzle.

In order for the boiler wiring collector to perform its functions in full, it is necessary that the length of all circuits connected to it be approximately the same length.

It is possible to additionally (but not necessarily) equip a mixing unit in the manufacture of heating collectors. It consists of pipes that connect the inlet and return combs. In this case, to regulate the amount of cold and hot water as a percentage, a two or three-way valve is mounted. It is controlled by a closed-type servo drive, which receives a signal from a temperature sensor installed in the heating circuit.

All this design allows you to adjust the heating temperature of a room or a separate circuit. If too hot water enters the collector in the boiler room, then the flow of cold liquid into the system increases.

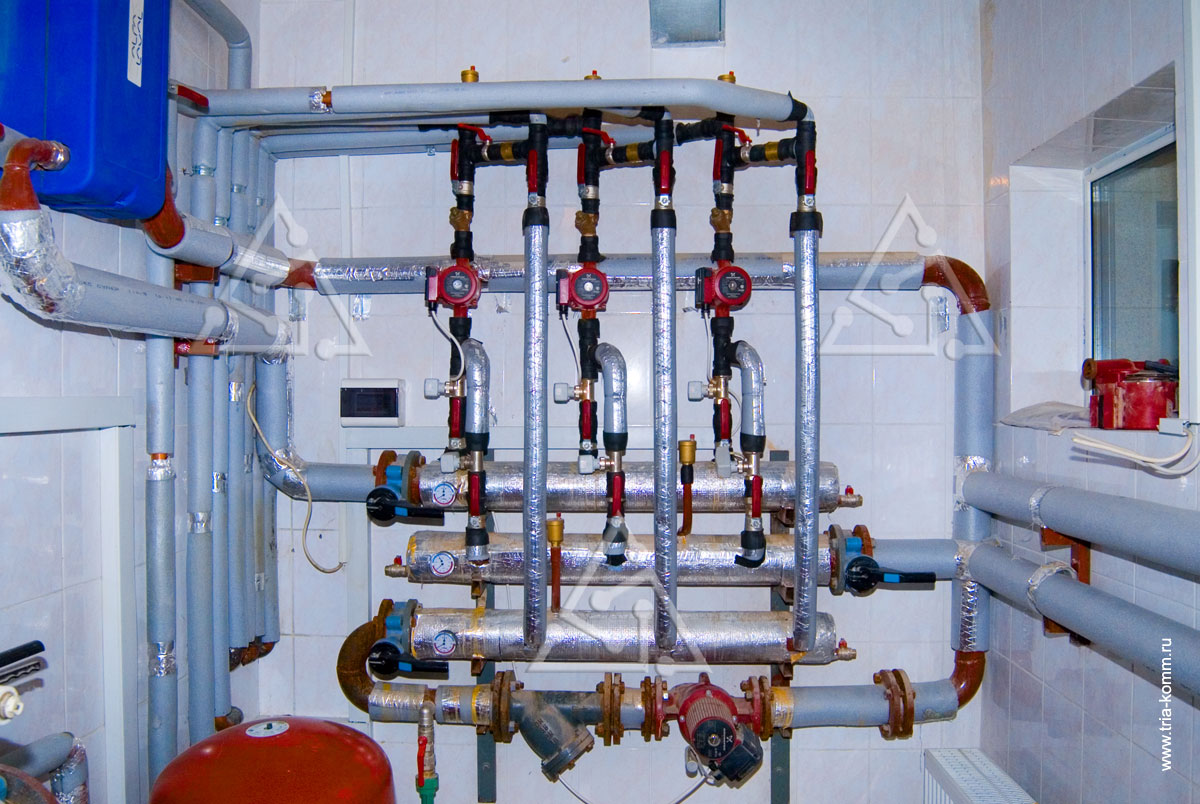

For a complex heating system in which several collectors are installed, a hydraulic arrow is installed. It improves the performance of the distribution combs.

The collector for the boiler room, which you make yourself, will ensure the normal functioning of the heating only if the parameters of the system stroke are accurately selected. Therefore, you first need to entrust the calculations to a professional, and then get to work.

Remember that the comfortable temperature in the house depends on many factors. Only a fully balanced system will ensure correct heating operation.

What is a hydraulic gun

If pumping equipment of considerable power is installed in a multi-circuit complex heating system, then even it will not be able to cope with different conditions and parameters of the network. Such inconsistencies in the operation of different circuits will adversely affect the operation of the heating boiler and reduce the life of expensive equipment.

Branched heating networks cannot work smoothly due to the fact that each circuit has its own performance and pressure. But even if each circuit is equipped with its own circulation pump, taking into account the parameters of the line, the problem of the fragmentation of the system will only worsen. This will lead to an imbalance in the networks, because each heating circuit will have its own parameters.

To solve the problem, one common boiler must heat the required amount of coolant, but each circuit must receive from the collector the required amount of heated liquid. In this case, the functions of the separator of the hydraulic system are performed by the collector. A hydraulic separator is needed to separate the boiler flow from the general circuit. Another name for a hydraulic separator is a hydraulic arrow or GS (hydraulic arrow).

This name of the device comes from an analogy with a railway arrow. Just as the railway switch separates the trains in the right direction, so the hydraulic switch distributes the coolant flows in separate circuits. Externally, the device resembles a piece of pipe with a round or rectangular cross section with end caps. The device is connected by means of a pipeline to the collector and the boiler and has several branch pipes in the side part.

6 Main disadvantages

After the main advantages of using combs in heating systems are understood, certain disadvantages must also be considered. As a rule, the following are distinguished:

- 1. Pipeline consumption in collector heating systems is much higher in contrast to traditional wiring, since a separate circuit must be connected to each device. All this complicates the installation work.

- 2.Collector heating works only with the help of a pump. Accordingly, it is necessary to be prepared for additional electricity costs.

- 3. High cost. Collectors are made of high-quality and durable metal alloy, the price of which is above average. High-precision locking components are also expensive. The greater the number of circuits served by the comb, the greater the cost of equipment.

The collector system, according to experts, as well as those people who already use it, is the most efficient, practical and modern. But at the same time, its device and operation is expensive.

The distribution manifold plays a rather important role in the entire heating system of any private house. This device allows you to distribute the hot coolant in various circuits. This is one of the main nodes in the water distribution scheme. Due to the wide use in country cottages, many owners were able to appreciate the advantage of this equipment and are already making water distribution combs with their own hands.

Comb for water floor heating principle of operation

- normalize the water temperature;

- distribute liquid along the contours.

In heating boilers, the liquid is heated to 60 - 90 ° C and hot diverges along the contour.

For obvious reasons, it is impossible to let such a hot coolant into the warm floor.

Lowering the temperature is one of the main tasks implemented in the collector unit. Temperature reduction can occur in two ways:

Mixing a cooled coolant with a hot one is the most popular method. Mixing takes place in a three-way valve. After the liquid is driven through the circuit by the circulation pump, it cools down.It is this cooled return pipe that is added to the hot coolant. The proportions of both streams are adjusted by the thermal head. Its working part is installed on the valve itself, and the sensor - on the supply.

Instead of a thermal head, there can be a servo drive. And for stable heating systems, when the boiler produces a relatively uniform temperature, you can set the three-way valve to one position, attach a thermometer to it and control the degrees manually.

The main elements of the collector assembly

Without a circulation pump, the water floor circuit will not work. Also, if you place the pump up to the three-way valve, the coolant will not enter the floor coil, but will go in a small circle, where the resistance is less.

Temperature limitation is implemented by installing a special thermal head in the system, which measures the temperature of the coolant. Outwardly, it is similar to a radiator thermostat, but fundamentally different from the latter, which measures the air temperature in the room.

A person sets an indicator that is comfortable for himself, and the device, fixing the excess of the threshold, limits the clearance inside the device, reducing the flow of coolant.

Russian-made warm floors are in increasing demand. Underfloor heating national comfort - reviews and cost.

What you should pay attention to when choosing a collector for underfloor heating, we will tell here

Areas of application for heating combs

The main purpose of the heating comb is the optimization and rational distribution of the coolant. Without a correctly calculated and installed distribution manifold, the heating may not work properly.The comb allows you to use the entire useful power of the boiler, while obtaining the maximum efficiency of the entire system.

Also, collectors allow you to include several consumer points in the system and be sure that the temperature of the coolant in all sections of the main line will be the same. If you do not use a distribution comb, it often turns out that the radiator near the boiler is very hot, and the radiator, for example, on the second floor, is slightly warm.

This is due to the fact that the coolant cools down until it reaches the last battery. This effect can be avoided and the path of the coolant to the end consumer can be reduced by dividing it into certain circuits.

Price

General Fittings Cold Water Manifold - The manifold is designed for use in cold water systems only. The material from which the device is made - nickel-plated brass, does not enter into chemical interactions with impurities in the water, thereby allowing the device to be operated for at least 10 years.

The comb is equipped with valves that are located on the main pipe of the distributor. The number of outputs of this device is 4 pieces, but if necessary, a block of an unlimited number of outputs can be assembled from separate sections.

The price of the comb is 1400 rubles.

Distribution collector DM, Gidruss is a universal device that can be used for the distribution of water supply and heating systems. The material from which the distributor is made is structural steel, capable of withstanding coolant temperatures up to + 120 degrees.The pressure in the water supply system when installing this device must not exceed 6 bar.

Peculiarities

Modern residential buildings are distinguished by a multi-profile water supply system. The distribution manifold is a large diameter pipe with several outlets. It is mounted in the system for supplying cold and hot liquids. Such a unit has shut-off valves at each outlet: these can be ball valves (they open and close the valve) or control structures (adjustment of the fluid supply is allowed). The second option is more comfortable and practical.

The comb is equipped with taps, with their help they shut off the water supply separately to each of the units available in the house. With the sequential construction of the pipeline, it is necessary to completely close a special valve, usually located near the entrance to the dwelling or in the basement.

Scope of application

A similar distribution unit is used in heating and ventilation structures, with a "warm floor" system, it is involved in heating the liquid for the domestic needs of residents, heating pools.

Advantages and disadvantages

In addition to the fact that the collector allows you to evenly distribute liquid in the plumbing system, it also has other features that are useful for residents:

- makes it possible for all equipment in the house to work independently of each other, while the pressure of the liquid is not lost;

- water is supplied to all appliances in the building;

- the problem of a sharp drop in liquid temperature when another device is turned on disappears;

- reduces the unevenness of the water supply (installed on risers with hot and cold water, which distribute flows through separate pipelines to each device);

- contributes to uniform heating of the premises;

- allows for hidden laying of plumbing or heating systems (thanks to this, it will be possible not to spoil the pre-designed interior of the room);

- no additional connections are required between the distribution manifold and the sanitary appliance;

- provides access to the pipelines of any equipment, which facilitates the maintenance of the wiring system (all communications are located in one place);

- not afraid of corrosion, so it will last more than a dozen years;

- has high hydraulic properties;

- equipped with special fasteners.

The distribution manifold is safe to operate. Residents of the house are not threatened with a pipeline break, since such a device stabilizes the flow of fluid.

For multi-storey buildings, floor-by-floor piping is chosen. In this case, pipes are directed from the risers to the combs, and then to the consumer devices. The distance from each collector to the equipment should be approximately the same.

The water collector is an efficient and easy-to-use device. A central heating meter can be connected to it.

The disadvantages of a system with a comb for heating and water include high cost (pipes alone will be needed several times more than for serial wiring) and complex installation (it is very difficult to make such a design with your own hands).

Self-assembly of the manifold

Having become acquainted with the principle of operation and the device of the collector comb, we can conclude that you can mount such a heater yourself. Here are some tips and rules to follow when installing:

- it is best to choose and install a comb at the stage of designing a heating system, since the introduction of this unit into an already operating system is very difficult and almost unrealistic;

- a niche for a drawer or a collector comb should be located at a small distance above the floor, so that this comb is convenient to maintain, and the cabinet doors, if any, open completely;

The location of the niche under the collector comb

The location of the niche under the collector comb

- you will need to install an expansion tank, if you do not have one, with a volume of at least 10% of the volume of all circulating fluid in the system. It is recommended to install the tank in front of the main circulation pump, so the tank will be protected from water hammer;

- the presence of a circulation pump for each circuit is necessary if the length of the circuit is very large, and the power of the pump installed on the boiler is small;

- when mounting the collector comb, it is best to use special metal clamps that will be attached to the wall and firmly hold the entire structure. Plastic clamps can be used to fasten pipes.

More detailed tips and the process of assembling the distribution manifold itself can be found in the video block. Also there you can watch the work of a professional and take some tricks into service.

We recommend that you do not spare money and time and contact a specialist who will help you choose the right distribution comb.However, if you still decide to figure out this problem yourself, then you should remember that the distribution comb is a small part of the entire heating system that needs to be debugged and adjusted to specific needs. And for this you need a little more knowledge and information in this area.

What do you need to know about cons?

After the advantages of using distribution combs in heating systems have become clear, it makes sense to dwell on some of the disadvantages:

- High price. Collectors are made of durable high-quality metal, the cost of which is above average. High-precision locking equipment is also expensive. The more circuits a comb serves, the higher the cost of equipping it.

- Energy dependence. Collector heating without a circulation pump does not work. Therefore, it is necessary to prepare for additional payment for electricity.

- High pipe consumption. The consumption of pipes in collector heating systems is several times higher than in conventional ones, since a separate loop must be pulled to each device. All this complicates and increases the cost of installation work.

The collector system, according to experts and those who already use it, is the most modern, reliable and efficient.

But at the same time, both its arrangement and operation are expensive.