- 6 Main disadvantages

- What is a comb

- Purpose of the heating collector

- The design of various types of combs

- Mounting

- Comb installation rules

- Comb installation rules

- Choosing a comb for underfloor heating

- Both distributor and regulator

- Accessories and rules for soldering polypropylene pipes

- Self-brazing polypropylene pipes

- Sequence of work

- Types of water heating systems in a private house

- Radiator

- Warm floor

- Skirting

- Finally, about homemade collectors

6 Main disadvantages

After the main advantages of using combs in heating systems are understood, certain disadvantages must also be considered. As a rule, the following are distinguished:

- 1. Pipeline consumption in collector heating systems is much higher in contrast to traditional wiring, since a separate circuit must be connected to each device. All this complicates the installation work.

- 2. Collector heating works only with the help of a pump. Accordingly, it is necessary to be prepared for additional electricity costs.

- 3. High cost. Collectors are made of high-quality and durable metal alloy, the price of which is above average. High-precision locking components are also expensive.The greater the number of circuits served by the comb, the greater the cost of equipment.

The collector system, according to experts, as well as those people who already use it, is the most efficient, practical and modern. But at the same time, its device and operation is expensive.

The distribution manifold plays a rather important role in the entire heating system of any private house. This device allows you to distribute the hot coolant in various circuits. This is one of the main nodes in the water distribution scheme. Due to the wide use in country cottages, many owners were able to appreciate the advantage of this equipment and are already making water distribution combs with their own hands.

What is a comb

They call a collector or distribution comb a unit of a special design, designed to accumulate the coolant used in the heating system and its subsequent distribution through pipelines with the same pressure force.

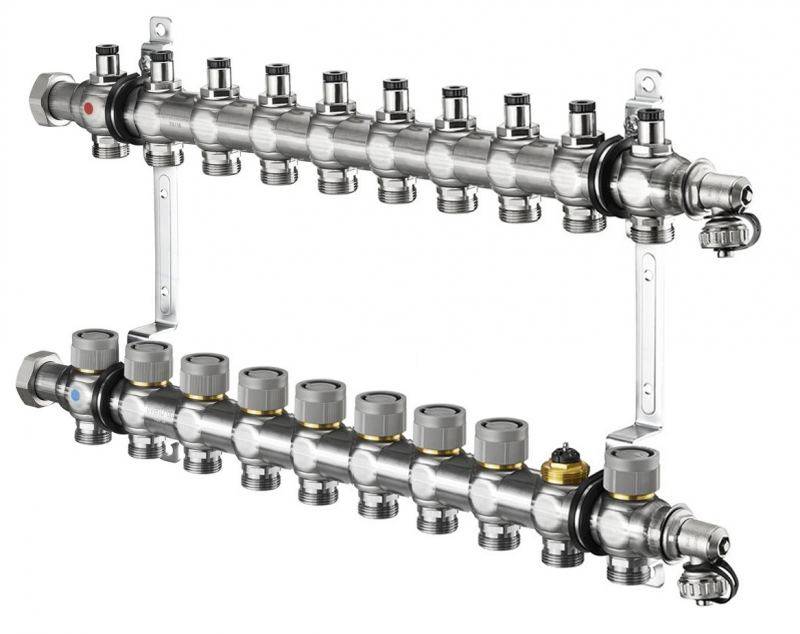

The simplest device of this type is two pieces of pipe with a pump and outlets to which the supply and discharge pipes are connected. Collectors of a more complex design are additionally equipped with control or shut-off valves. The most expensive combs are assembled using mechanical or electrical sensors.

On sale today, collectors with 3-4 outlets are most often found. It is these combs in most cases that it is advisable to use in cottages and large country houses. If there is a need for additional outlets, two or more collector nodes usually crash into the system.

Purpose of the heating collector

In any heating system, one important rule must be observed - the diameter of the pipe leaving the boiler must match or be slightly less than the total diameter of all circuits connected to this boiler. Failure to comply with this rule consistently leads to uneven distribution of the coolant. For example, consider a system to which three separate circuits are connected:

For example, consider a system to which three separate circuits are connected:

- Radiator heating;

- Warm floor;

- Indirect heating boiler providing hot water supply.

Outlet pipe diameters boiler and inlet each of these consumers can coincide, only the total value of the latter will be an order of magnitude larger. As a result, a very simple phenomenon arises - the boiler, even if it operates at full capacity, is simply not able to simultaneously ensure the operation of all the circuits connected to it. Because of this, the temperature in the house decreases.

Of course, you can try to use all the circuits in turn so that they do not load the boiler at the same time. In theory, such measures seem possible, but in practice they turn out to be nothing more than half-measures - after all, the constant “juggling” of contours cannot be called an attribute of comfortable living in a house.

To get rid of such problems, a distribution manifold must be installed in the system. Typically, stainless steel pipes are used to make such collectors, but other options can be used - for example, polypropylene collectors for heating are often found.

The design itself is a device with a set of nozzles for the inlet and outlet of the coolant, as well as its separation into separate circuits. Adjustment of all operating parameters is carried out using shut-off valves, which are equipped with any collector.

The main function of the distribution manifold is displayed in its name - it distributes the coolant over separate circuits, and the intensity of its supply can be adjusted on each branch pipe. The result is several circuits that are completely independent of each other, each of which operates in its own temperature regime.

Of course, there is always the opportunity to simplify your work and purchase a ready-made collector, but such a solution has drawbacks.

So, the production of heating collectors at the factory simply cannot take into account the features of each heating system, so you will have to compensate for the characteristics of the collector with additional elements - and these are extra costs. Homemade devices may lose to factory ones in versatility, but they are much better suited for arranging individual projects.

The design of various types of combs

The budget distribution comb with valves has one significant drawback - water can drip from under the handle. Leakage occurs due to wear of rubber seals.

The budget distribution comb with valves has one significant drawback - water can drip from under the handle. Leakage occurs due to wear of rubber seals.

The threads at the ends are needed for connecting shut-off valves and central hot water supply / removal. In general, such a comb will cope with its function, but the period of its impeccable service is not very long.

If disassembling the valves and replacing worn seals does not lead to initial tightness, you will have to buy a new manifold.

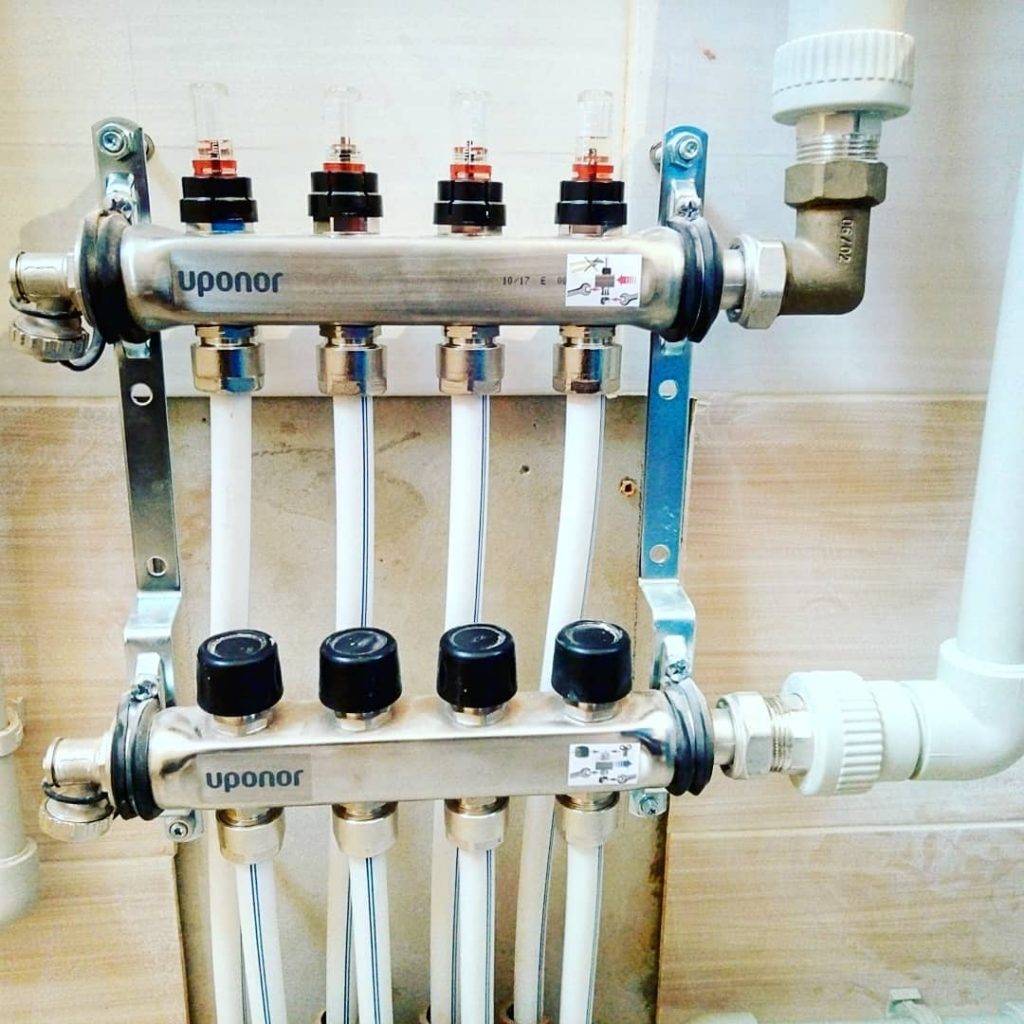

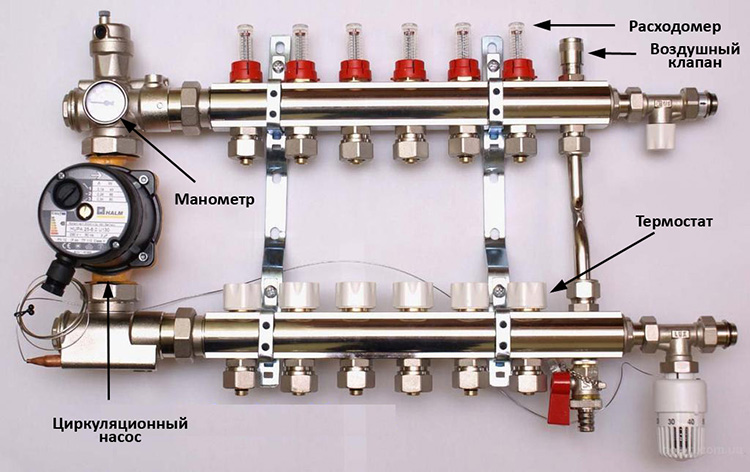

More complex in design will be a comb with plugs on the return manifold (and on the direct one too). Instead of them, in the future, you can install flow meters and thermal heads. The forward and reverse combs in these models are already connected by a bracket for wall mounting.

The presence of plugs makes it possible, if necessary, to improve the heating distribution manifold. In order to avoid problems with the installation of thermostats and other components in the future, it is necessary to provide convenient access to the comb at the stage of its installation.

The presence of plugs makes it possible, if necessary, to improve the heating distribution manifold. In order to avoid problems with the installation of thermostats and other components in the future, it is necessary to provide convenient access to the comb at the stage of its installation.

And, finally, a complex and expensive, but the most efficient distribution manifold with factory-installed flow meters and thermal heads.

Flow meters regulate the uniform delivery of the coolant to its destination, and with thermal heads you can set the temperature for each outlet separately, just like for a heating radiator. More types of thermal heads, how they work and installation features are discussed in our other article.

Flowmeter caps allow you to visually track the flow of coolant along the circuits. Thermal heads regulate the amount of coolant entering each of them

Flowmeter caps allow you to visually track the flow of coolant along the circuits. Thermal heads regulate the amount of coolant entering each of them

Even in the design process, it is necessary to make a choice between different types of combs, but in any case, the collector system is the preferred choice compared to conventional wiring in terms of such criteria as ease of use, durability.

Mounting

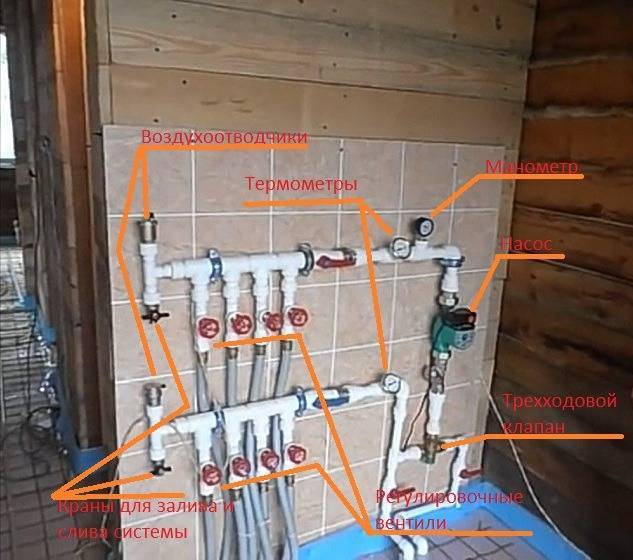

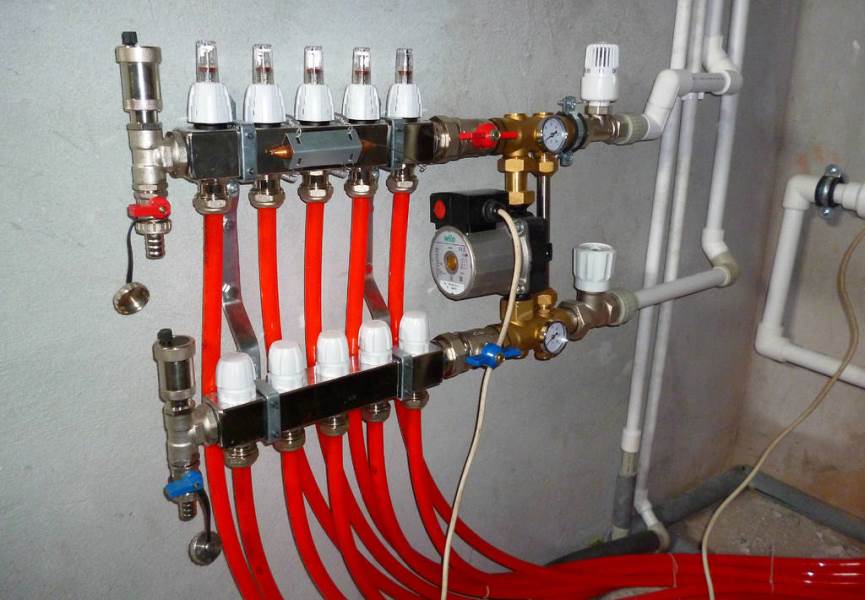

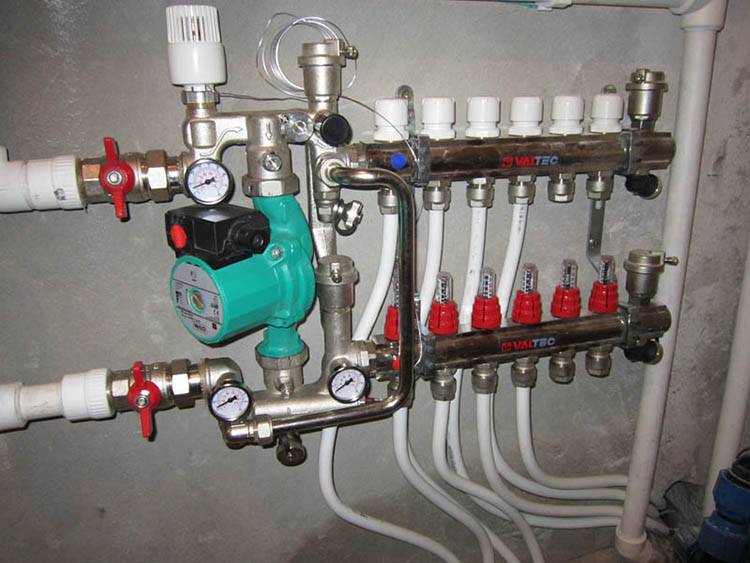

Consider the installation of one of the heating circuit diagrams.

Starting from the heating boiler, the following is installed:

- A simple tee. One of its outlets is directed to the underfloor heating, the other to the radiator heating.

- The manifold cabinet is installed. It is advisable to choose the installation location so that the cabinet is closest to the center of the house.

- Three-way valve (the direction of flow is checked by the arrow).

- Circulation pump. It is installed at the outlet of the three-way so that the flow is sucked out of the valve.

- The supply and return manifolds (assembled from tees, or purchased) are mounted in the cabinet on mounting brackets. The combs are connected by a bypass.

- A temperature sensor from a three-way valve is fixed not far from the pump. The place where it is located can be insulated with penofol or a similar heat insulator to take more accurate readings.

- At the highest point of the comb, an air vent (Maevsky's tap) is placed.

- On the comb - the return line, thermostats are placed for each branch.

- Floor pipes are installed, wiring and laying in rooms is done. The connection is made to the fittings using union nuts. It is not necessary to cut the length of the pipe from the bay until all the turns are laid. Having brought the pipe to the manifold cabinet, it is cut to length and fixed to the return comb.

- The usual tee is to connect the floor return to the three-way valve (to its side outlet, which mixes the cold coolant), the other part of the tee is the return of the entire system, which will go to the boiler.

- Heating connection - test run and adjustment of servomotors separately for each circuit.

Comb with servo

Only after making sure that there is no leakage, you can fill the screed.

Comb installation rules

It is best to install the comb in such a way that all connected devices are approximately at an equal distance from it.However, even with a very uneven length of the "beams", the system will be fully operational if only the nozzles of the supply manifold are equipped with control valves, through which balancing can be performed.

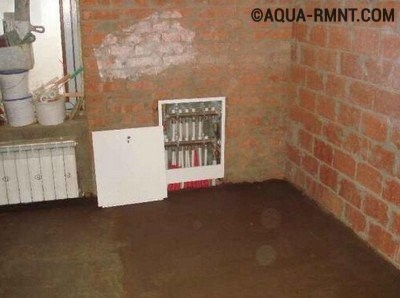

The collector can be mounted on the wall, but since it is a rather bulky element with many protruding parts, it will be much more convenient to place it in a niche.

Installation of a comb for heating

The best option is to place the distribution unit in a special metal cabinet for the heating comb, which you can buy in a store or make yourself. Among the factory-made models, you can find both built-in and overhead.

It is not necessary to install the collector in the boiler room. If there is no free space in the room, the comb can be “settled” in the neighborhood, where it will not interfere with anyone, for example, in the pantry.

It is only important that the relative humidity in the room chosen is within normal limits - up to 60%.

Comb installation rules

The location for the collector block must be determined at the design stage of the house. As mentioned above, if it is a multi-storey cottage, then such nodes should be provided on each of the floors. It is best to prepare special niches for them that have above floor level.

However, if it was not possible to find a place for the node in advance, you can install this block in any room where it will not interfere with anyone: in the pantry, in the corridor or in the boiler room. If only there was no excess moisture in this place.

To prevent the node from being visible, you can place it in a special cabinet, which is offered to its customers by manufacturers of locking mechanisms. The body of this cabinet is made of metal. It is equipped with a door, and in its side walls there are holes for heating pipes. Sometimes the collector group is simply placed in a niche or on a wall, fixing the combs with special clamps.

This comb is placed in a place specially equipped for it. As you can see, it looks quite aesthetically pleasing, and most importantly, access to this node will not be difficult.

The pipes that depart from this switchgear are located in the walls or in the floor, and then connected to the radiators. If the pipes are in the floor screed, the heaters should be equipped with an air vent or an air cock.

Choosing a comb for underfloor heating

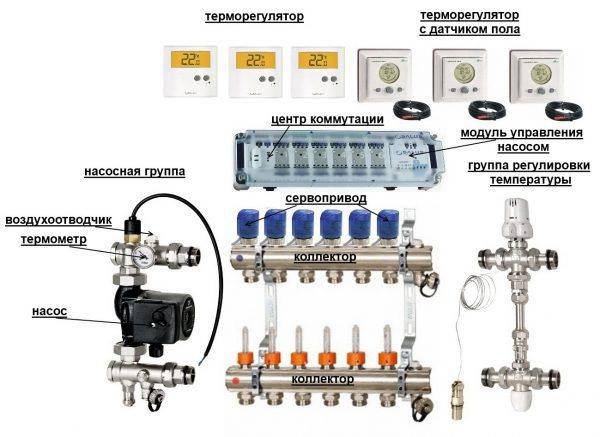

Separately, it is worth mentioning how to choose the right comb for a warm floor

In doing so, attention should be paid to the following criteria:

- the material from which the supply and return manifolds are made;

- the number of circuits on the collectors in the comb, the permissible level of pressure and water flow;

- the degree of automation of the product - what sensors are presented in the comb, are there thermostats and other electronics for finer temperature settings in the underfloor heating circuits;

- manufacturer of combs for underfloor heating.

Choosing a comb for underfloor heating

Now let's expand on each of the points in more detail. Let's start with the material from which the comb is made.

Table. Materials used in the production of combs for underfloor heating.

Material

Description

Brass

Combs for underfloor heating from this material are made by casting.The result is a fairly strong and durable part, but at the same time expensive.

If the price of a comb is not a problem for you, then you should pay attention to brass products.

Stainless steel

It is made by welding (with subsequent careful sealing of the seam). In terms of strength, it is similar to brass products, but at the same time, a stainless steel comb may be subject to electrochemical corrosion.

Plastic

Cheap combs made of high quality plastic resistant to high temperatures and pressures

In terms of their qualities, they are almost not inferior to metal products.

comb for underfloor heating

Having decided on the material, proceed to consider other parameters of the comb. And the most important of them is the number of taps on the collectors. Ideally, it should be equal to the number of circuits in the underfloor heating system. But combs with a large number of taps are also allowed - in this case, you need to use plugs. Even before buying, it is advisable to make the simplest calculations and determine what pressure and fluid flow will be in your system. The comb must be suitable for the conditions in which it will work. At the same time, it is desirable to have a certain “margin of safety” in case sudden increase in pressure or coolant flow in the system.

Next, you need to decide what degree of automation and control of temperature and flow you need. Today, there are technically advanced combs on the plumbing market that can be connected to thermostats and a programmable controller. With their help, you can constantly adjust the temperature and flow on the circuits in accordance with the weather outside and the needs of the residents.At the same time, the high price of the product pays off with additional savings on the coolant.

A set of combs for underfloor heating with automatic regulation using a set of temperature sensors placed directly in those rooms that are heated

And finally, always pay attention to the country and the manufacturer. As a rule, combs for underfloor heating made by European companies are of the best quality, but at the same time they are also expensive.

As an alternative, they can be domestic and Chinese devices, which are inferior in their durability and reliability, but at the same time much more affordable for a simple buyer.

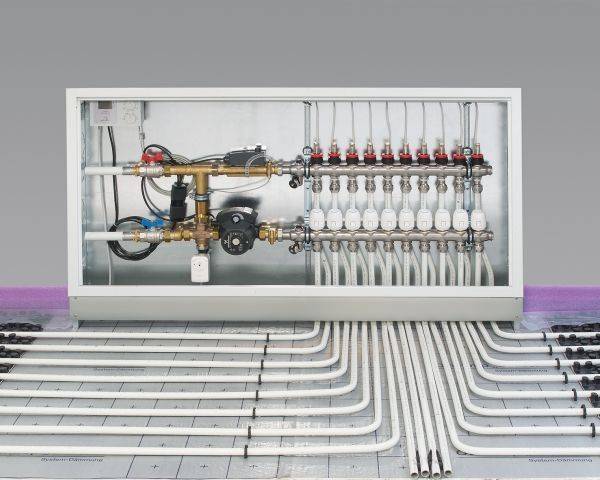

The comb or collector of the underfloor heating is located in a special cabinet (mounting box)

Both distributor and regulator

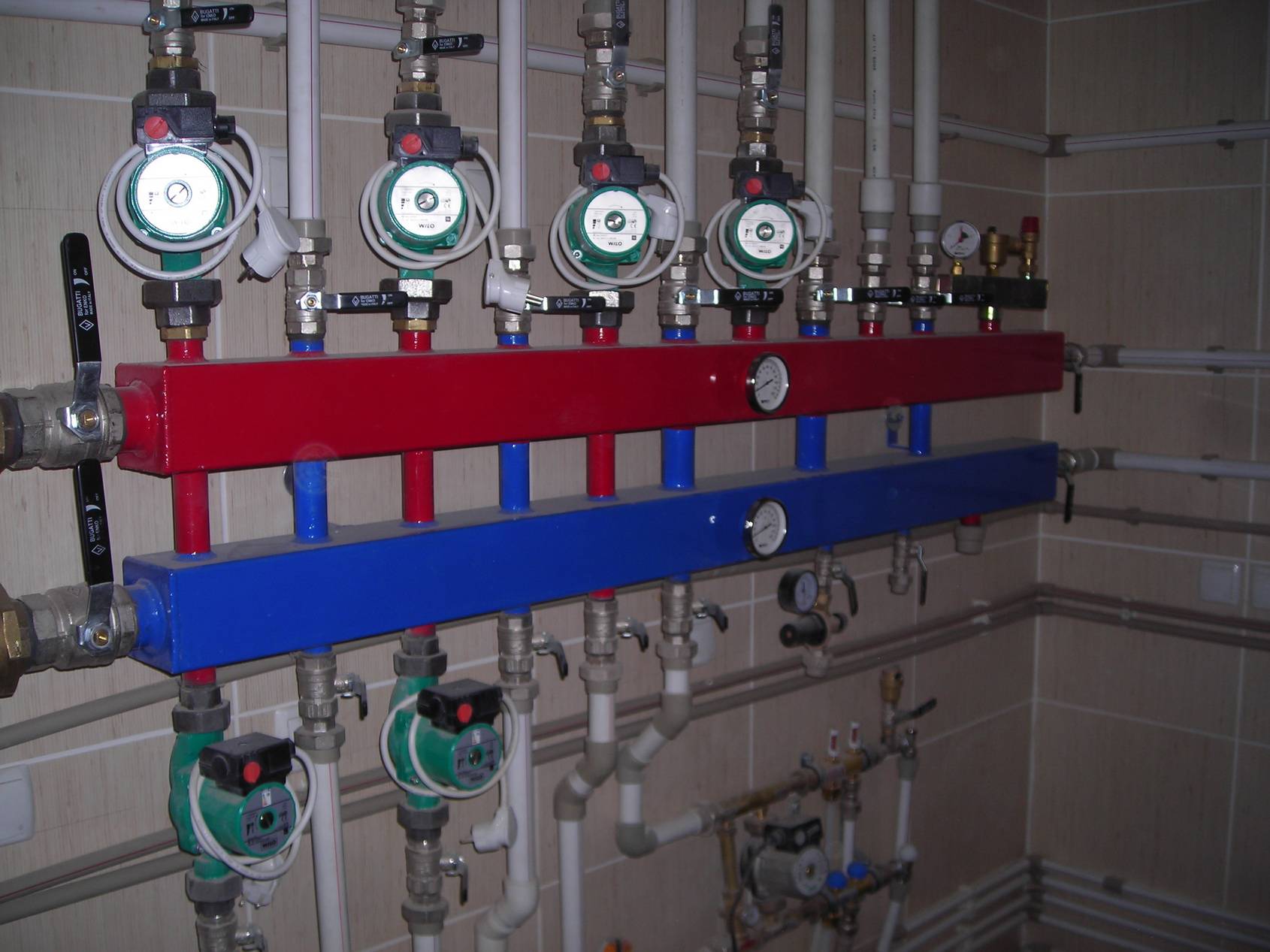

At its core, a distribution comb is a centralized unit that allows the coolant to be distributed to destinations. In the heating system, it performs an equally important function as a circulation pump or the same boiler. It distributes heated water along the lines and regulates the temperature.

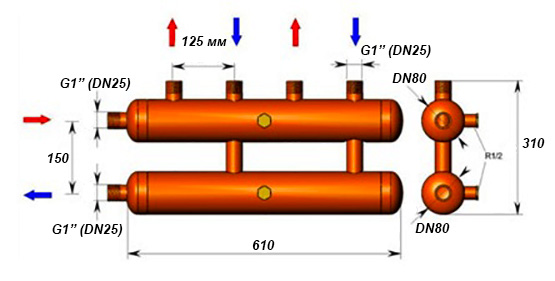

This diagram shows the general principle of operation of the collector unit, which consists of two combs: through one the coolant is supplied to the system, and through the second it is returned

This node can be called a temporary coolant storage. It can be compared to a barrel filled with water, from which the liquid flows out not through one hole, but through several. In this case, the pressure of water flowing out of all holes is the same.This ability to simultaneously provide a uniform distribution of the heated liquid is the basic principle of operation of the device.

Externally, the collector looks like a two-comb assembly, most often made of stainless steel or ferrous metal. The conclusions available in it are intended for connecting heating devices with it. The number of such conclusions should correspond to the number of serviced heating devices. If the number of these devices increases, the node can be increased, so the device can be considered dimensionless.

In addition to the conclusions, each comb is equipped with locking mechanisms. These can be two types of cranes installed at the outlet:

- Cut-offs. Such valves allow you to completely stop the supply of coolant from the common system to its individual circuits.

- Adjusting. With the help of these taps, the volume of water supplied to the circuits can be reduced or increased.

The collector includes water drain valves and air release. It is also most convenient to place measuring equipment in the form of heat control meters here. In this case, everything that is necessary for the efficient operation of this site will be in one place.

Why are there two combs in the manifold block? One serves to supply the coolant to the circuits, and the second is responsible for collecting already cooled water (return) from the same circuits. All the elements necessary for effective functioning should be on each of the combs.

Accessories and rules for soldering polypropylene pipes

Types of fittings for polypropylene pipes

The connection of polymer pipes can be performed in several ways - soldering, detachable or one-piece fittings, gluing. For installation water heating with polypropylene hands, diffusion welding is best suited. The main connecting element in this case are the fittings.

It is important that the quality of the purchased components is not inferior to the pipes. All pipe fittings made of polypropylene for heating do not have reinforcement. This is offset by a thicker wall

They differ in appearance and scope:

This is compensated by a thicker wall. They differ in appearance and scope:

- Couplings. Designed to connect individual pipes into a single line. They can be both of the same diameter, and transitional for joining pipelines with a spill section;

- corners. Scope - production of corner sections of highways;

- Tees and crosses. Necessary for dividing the highway into several separate circuits. With their help, a collector for heating is made of polypropylene;

- Compensators. Hot water provokes thermal expansion of pipelines. Therefore, before soldering heating from polypropylene, compensation loops should be installed that prevent surface tension from appearing in the line.

Before starting the soldering process, it is recommended to calculate the amount of all consumables: pipes, fittings and valves. For this, a heat supply scheme is drawn up indicating the configuration of each node.

During the installation of polypropylene heating, it is necessary to use a special type of shut-off valves designed for soldering.

Self-brazing polypropylene pipes

A set of tools for soldering polypropylene pipes

In order to make heating from polypropylene, you should purchase a minimum set of tools.It includes a soldering iron for pipes, special scissors and a trimmer. The latter is necessary for stripping the pipes from the reinforcing layer in the soldering area.

Before soldering heating from polypropylene, the required pipe size should be cut off. For this, special scissors with a base for the nozzle are designed. They will provide an even cut without distortion.

For self-installation of heating from polypropylene, you will need to perform the following steps:

- Degrease the soldering point on the nozzles.

- Using a trimmer, remove the reinforcing layer from the heating zone.

- Turn on the soldering iron and set it to a certain temperature.

- After heating the mirror, install the nozzle and the coupling into the nozzles. It is impossible to make axial rotations during heating of polypropylene.

- After a certain period of time, dock the branch pipe and the coupling with each other.

- Wait for the final cooling.

The procedure for soldering polypropylene pipes

Using this technology, you can make a reliable heating system from polypropylene with your own hands. The advantage of this method lies in the possibility of soldering on already mounted sections of the trunk. In this way, you can quickly repair the heating of a private house with your own hands from polypropylene.

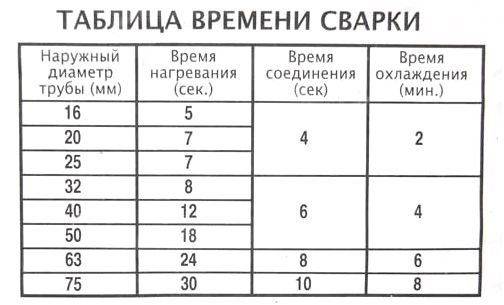

An important point during the self-soldering of water heating from polypropylene is the heating time of the workpieces. It depends on the pipe diameter and wall thickness. With insufficient melting of the material, the diffusion process will be low, which will eventually lead to delamination of the joint. If the pipe and the coupling are overheated, a part of the material will evaporate, and as a result, a strong decrease in the external dimensions will occur.Therefore, for the installation of heating from polypropylene, one should adhere to the recommended heating time for plastic, depending on its diameter and wall thickness.

Table for soldering polypropylene pipes

During self-installation of polypropylene with your own hands, good ventilation in the room is necessary. When plastic evaporates, its volatile components can enter the respiratory system.

For a small amount of work, you can purchase a non-professional soldering iron worth up to 600 rubles. With it, you can solder a polypropylene heating system for a small house or apartment.

Sequence of work

The process of making a comb looks quite simple:

- It is necessary to purchase materials in accordance with the decisions made during the design phase of the distributor.

- Holes for taps are cut in the blank for the body. If a round pipe is used as this, then first you need to draw a hole scan on paper (in everyday life it is called a “fish”). Next, the scan is cut out, applied to the pipe and outlined with a pencil or marker. After that, a hole is cut out - with preliminary drilling along the contour or with a gas cutter.

- We weld the bends to the comb body using electric welding. Plugs are welded to the ends, which, if necessary, are also equipped with nozzles.

- The resulting product must be checked for leaks. We leave one branch open, all the rest are tightly closed. After that, we fill the collector with hot water and observe whether the welds will leak. It does not hurt to get a hand pump for crimping and check the reliability of the seams under pressure.

It is not necessary to use a round pipe as a collector housing; a square one will do just fine.

If the tests were successful, you can paint the comb and, after the paint has dried, proceed with its installation.

Even if the underfloor heating is installed in one room, collector for warm gender is still needed. An overview of collector models and their prices is presented on the website.

Read about the features of making an air solar collector with your own hands in this article.

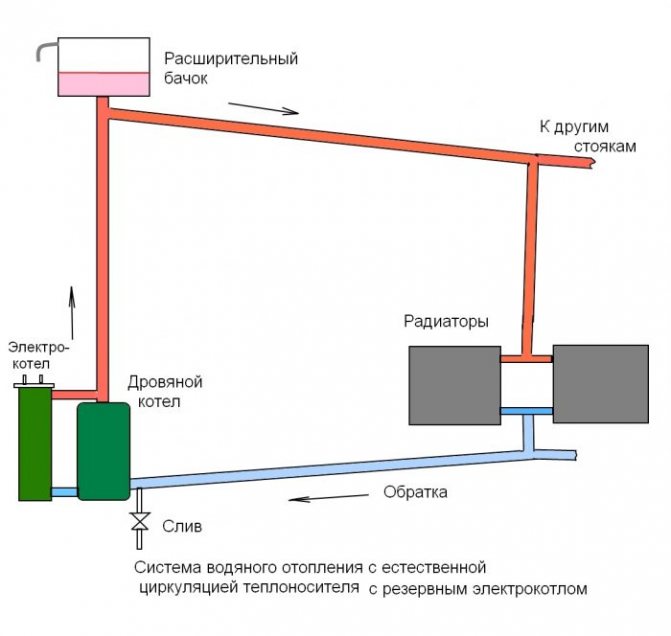

Types of water heating systems in a private house

There are several types of water heating for private houses. Here we mean standard heating systems with radiators, underfloor heating and baseboard heating. Individual types can be combined with each other, which allows you to achieve effective heating. For example, ordinary radiators are mounted in bedrooms and living rooms, and heated floors are often laid in bathrooms and toilets - an excellent solution for those who cannot stand the cold and do not like cold tiles. Let's look at the individual types of heating and their benefits.

Radiator

Radiator heating systems are timeless classics. The principle of their operation is to transfer heat from the coolant through radiators installed in the premises. Such heating systems are installed in the vast majority of buildings for various purposes - in residential, industrial, administrative, utility and many others. They are relatively easy to install - just stretch the pipes and connect radiators to them.

Previously, water heating in a private house involved the installation of bulky cast-iron radiators.Over time, they were replaced by lighter and thinner steel radiators made of corrosion-resistant steel. Later, aluminum batteries were born - they are light, cheap and durable. For a private home, this is the most ideal battery option.

The main advantage of radiator systems is that for their laying it is not necessary to pour concrete screeds. All installation is reduced to the installation of the boiler and radiators with their subsequent connection. Radiators provide effective heating of the premises and do not violate the interior design, especially if they are modern multi-section aluminum batteries.

Warm floor

Water floor heating in a private house can work both in independent mode and in auxiliary mode. In independent mode, there is no need to lay pipes with radiators, and all floors emit heat. Thanks to this, children can play on such floors without fear, they will not blow through or through. Are your feet constantly cold? Then you will definitely like always underfloor heating. In auxiliary mode, they work as an addition to radiator systems.

Underfloor heating systems are good for kitchens, bathrooms and toilets. where on the floor most often lies eternally cold tiles. Heating pad will help make floors warm and comfortable. For example, in the bathroom you no longer have to stand barefoot on cold tiles. The same applies to the toilet. If you have a tiled floor in your kitchen, feel free to install underfloor heating systems here as well. Another place where a warm floor will become an attribute of comfort is a bedroom - you see, it’s not pleasant to get out from under a warm blanket and become heels on cold floors.

Warm floors are characterized by a low coolant temperature, not exceeding +55 degrees, which allows you to create economical heating systems. But the need to make concrete screeds and pass through walls and door frames is a significant disadvantage. It is best to consider the need to install the system at the stage of building a house.

Skirting

Modern heating systems built based on classic aluminum radiators, differ in that the heat from them spreads only upwards - due to natural convection. As a result, all warm air rises, and cold air enters in its place. There is nothing surprising in the fact that the legs of the household begin to freeze. The only plus is the lack of cold from the windows, as it is carried away by convection to the ceiling. But what about heating? Do not lower the radiators to the very floor?

The way out of the situation is skirting heating systems. It uses small-sized radiators made of brass or aluminum. The coolant is supplied through plastic pipes of small diameter. The system is complemented by taps, air vents and other necessary accessories.

All this is placed in a special plastic plinth - the air that enters here heats up and heats the walls on top. Further, the room is warmed by infrared radiation from heated walls and floors. There are no drafts blowing on the floor in heated rooms. Here, not only the walls are heated, but also the floors themselves, making the rooms warm and comfortable.

The advantage of baseboard heating is that it can be laid at any stage, even after construction is completed.Disadvantages - the high cost of installation and a lot of requirements for the placement of skirting boards and other elements. Simultaneous installation of all types of the described systems is also allowed.

Finally, about homemade collectors

Above in the text, we mentioned budget options for combs - plumbing, polypropylene and home-made. Such distributors are used without problems in radiator beam circuits. To balance and regulate the flow, a balance valve and a valve with a thermal head are installed on each battery. We supply the collector with “air vents” + drain taps.

If you put the specified combs on the TP, then you will encounter such nuances:

- the distributor cannot be equipped with rotameters;

- without flowmeters, it is difficult to balance circuits of different lengths;

- there are stopcocks on the factory plastic collectors, which means there is nothing to regulate the flow;

- combs assembled from polypropylene or brass tees have many joints;

- it is worth noting that homemade distributors do not look too good.

A self-made underfloor heating collector can still be brought to mind. We assemble the distributor from tees, and on the return pipes we mount thermostatic radiator valves with RTL thermal heads, as shown in the photo.

A skilled owner will calmly manufacture a coplanar common house collector - weld it from a round or shaped pipe. But here there is a snag in the calculations: you need to know the cross section of the chambers and pipes for a particular heating system. If a specialist calculates these parameters, use the experience of the wizard from the video: